1. Introduction

Semiconductor and, in particular, titania, photocatalysis has been field of very high interest during the past decade, with over 3300 publications regarding the subject between 2005 and 2016. Its many uses, such as the photodegradation of volatile and non-volatile organics and (to a lesser extent) UV-induced superhydrophilicity and photo-sterilization, guarantee a wide range of possible applications [

1,

2,

3,

4] because of the material’s high robustness, both chemically and photochemically [

5,

6,

7]. Self-cleaning surfaces are very beneficial from an economical and an environmental point of view and are, nowadays, readily available to the consumer public. Their broad area of application range from indoor applications in fabrics, furnishing materials, and window glasses to exterior applications in construction materials, roof tiles, car mirrors, and solar panels. These materials can easily be cleaned by a stream of water, which significantly reduces routine maintenance costs, illustrating the great economic relevance of crystalline titania coatings. Such coatings are already commercialized on glass by companies such as Pilkington, PPG Industries, and Saint-Gobain Vitrage [

8]. However, all of these companies employ deposition techniques such as chemical vapor deposition and magnetron sputtering—techniques that all require a powerful vacuum, which make them more expensive than wet chemistry deposition methods such as chemical solution deposition (CSD) [

9,

10]. Furthermore, chemical solution deposition methods offer an easy route for upscaling purposes and straightforward processing, making it a desired candidate for an industrial production process [

11,

12].

In this research, the main focus is twofold: first, to extend the use of these titania coatings on polymer substrates through an innovative and sustainable deposition process. Scalable techniques, such as dip-coating, are applied for depositing photocatalytically active, transparent titania thin films, leading to the production of these coatings at competitive prices. If deposition on polymers is made possible, this would open a large market of photo-active coatings for applications on thermo-sensitive materials.

By using a suspension of crystalline titania nanoparticles as a coating solution, one can convert deposited wet coatings into a functional, thin film, by using only a minor heat treatment [

3,

8]. This research thus puts focus on the synthesis and characterization of titania nanocrystal suspensions through microwave synthesis. These coating suspensions are well-suited for subsequent deposition on polymers.

The second main focus of this study is to incorporate an amorphous, silica buffer layer architecture during the deposition of the titania coatings on the polymer substrates. This is envisioned to improve the compatibility between the organic substrate and the functional ceramic coating. Thus, it was aimed to achieve titania coatings on polymers through a CSD method that yields photocatalytic activities that are at least as good as those obtained in literature on glass substrates [

2,

3].

It can be predicted that the use of polymers as a substrate for inorganic, self-cleaning coatings will exhibit some problems concerning wetting behavior. Furthermore, the production of an inorganic-organic hybrid material (TiO

2-polymer) will not be beneficial for its compatibility and/or durability because of possible degradation of the polymer substrate by the photocatalytic titania coating. Therefore, efforts must be made to increase the durability of the final composite material. A predictable risk lies in the fact that the photocatalytic titania coating will corrode the interface with the polymer substrate when exposed to UV-light. Although some studies have raised this problem [

8,

13], no concrete research has been carried out on this topic to this date.

Separating the photocatalytically active titania coating from the organic substrate by a silica buffer layer can be an elegant solution to this problem, because this intermediate silica can act as a protective layer for the polymeric substrate against photocatalytic degradation [

8,

14]. Moreover, this intermediate silica layer also enhances the compatibility between the inorganic titania top coating and the organic substrate [

14]. In this work, a buffer layer structure in the form of an amorphous silica thin layer will be used to circumvent the deterioration of the polymer by the titania coating [

4]. The choice of polymeric substrates has been limited to polymethylmethacrylate (PMMA) and polyphenylsulphone (PPSU). PPSU is known for its applications in (high-temperature) visors, because it can withstand temperatures of more than 400 °C and thus is very suitable for the envisioned low-temperature deposition. PMMA, however, only has a glass transition temperature of 105 °C and will be the most challenging polymer upon which to deposit an inorganic self-cleaning coating. PMMA is widely known as Plexiglas

®, being a transparent (in the visible area of the electromagnetic spectrum) glass substitute for use in light domes and displays, and therefore is a very interesting substrate given the commercial relevance of this research.

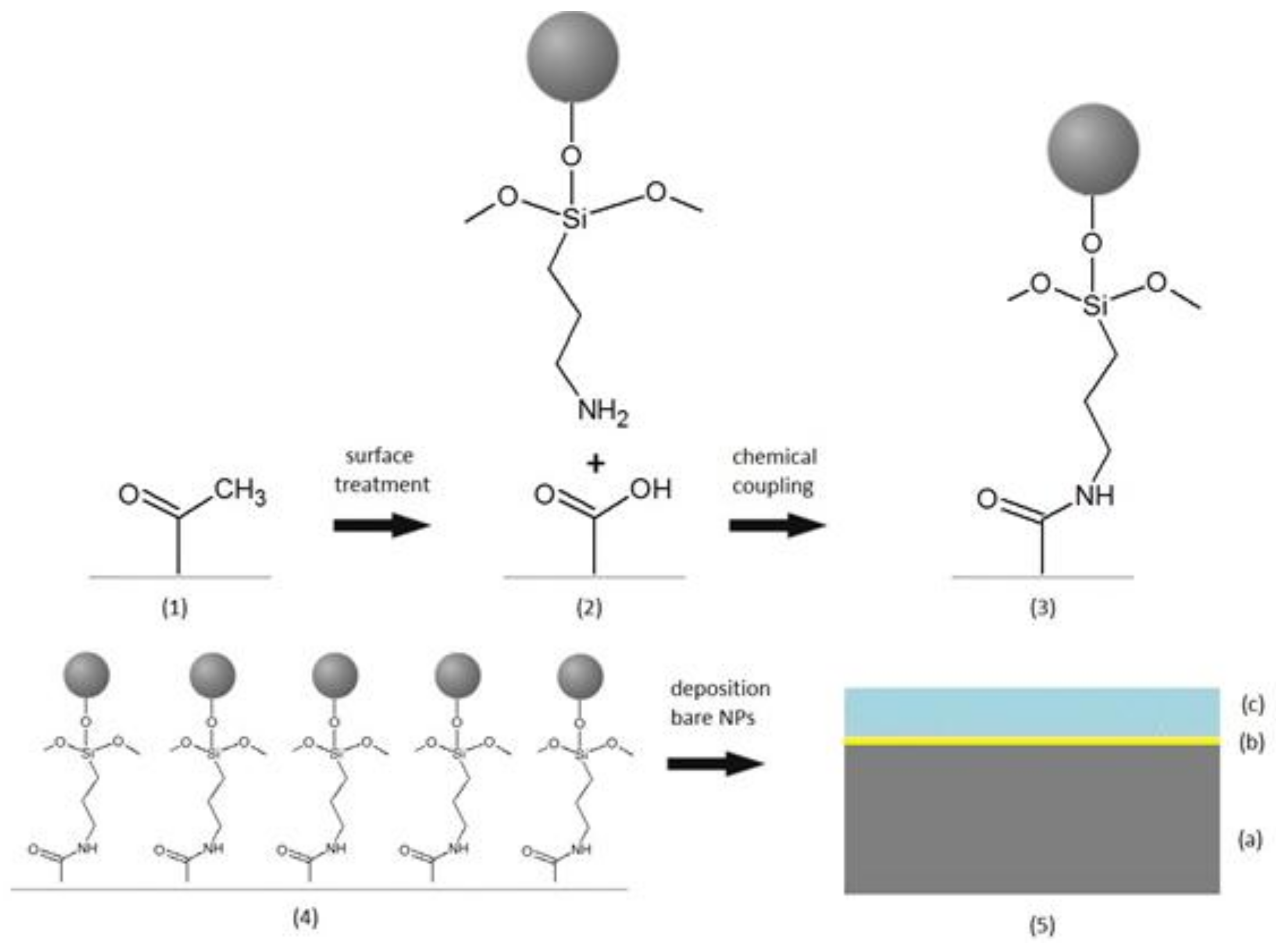

In our parallel research [

15], silane-functionalized titania nanocrystals have been prepared to chemically link these functional titania nanocrystals to selected polymer substrates. To our knowledge, the use of ligands on anatase nanocrystals to act as chemical links between these nanocrystals and the surface of a polymer substrate has not been described in the literature. The formation of covalent bonds between the nanocrystals and the surface of the polymer is envisioned to enhance the durability of the titania coating on the substrate. For this (earlier) research [

15], PMMA was chosen as a substrate because it is transparent, and its functional groups can be induced due to UV etching [

16], such that nanoparticles functionalized with ligands that possess an amine functionality can be coupled to the surface via the formation of an amide bond. The first step to obtain a titania thin film on a polymer substrate is the surface treatment of the polymer substrate. This surface treatment should activate the polymer surface (i.e., induce the presence of carboxylic acids with which the primary amine group of (3-aminopropyl)triethoxysilane (APTES) can react), as well as improve the wettability of the substrate. Next, the surface concentration of these groups needs to be determined to select the amount of coupling reagents (1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) and

n-hydroxysuccinimide (NHS)) to be used. The next step is the coupling of the nanoparticles to the activated surface of the polymer. Once a layer of covalently coupled nanoparticles is obtained, a second (thicker) layer of titania nanoparticles can be coated on top of the first layer (which therefore serves as a kind of buffer layer next to the coupling layer). Schematically, these steps are illustrated in

Figure 1.

2. Materials and Methods

2.1. TiO2 Nanoparticle Suspension Synthesis

The synthesis route to obtain highly crystalline titania nanoparticles containing suspensions has been published in previous work by our group [

8]. In this method, 8.4 mL titanium-isopropoxide (Sigma-Aldrich, Overijse, Belgium, ≥97.0%) was hydrolyzed to Ti(OH)

4 in 100 mL H

2O. After filtering and washing with an excess of deionized H

2O, this wet precipitate was transferred to a beaker in which 2 mol equivalents of both iminodiacetic acid powder (IDA, Alfa Aesar, Karlsruhe, Germany, >98%) and H

2O

2 (Sigma-Aldrich, 35 wt % in H

2O) were added. To complete the reaction mixture, a base was added, (ethanolamine (EA), Carl Roth, 99.5% or tetraethyl ammoniumhydroxide (TEAOH), Sigma-Aldrich, 40 wt % in H

2O) according to the molar ratios represented in

Table 1. The addition of the base caused an exothermic reaction, heating the reaction solution to 85 °C. Then, the mixture was left stirring for 30 min at 60 °C.

A stable, deep, red solution was finally obtained with a Ti concentration of 0.7 mol/L.

Table 1 gives an overview of the composition of the aforementioned synthesized titanium ion precursors by using two different bases and molar ratios. All precursor solutions have a minimum shelf stability of 6 months (i.e., no occurrence of any precipitation inside the precursors).

To synthesize highly crystalline titania nanosuspensions, the titanium precursors were transferred to a laboratory microwave furnace (CEM Discover) used at a frequency of 2450 MHz. In each reaction vessel, 3 mL of an aqueous Ti-precursor was pipetted and then placed inside the microwave reactor. For both precursors, the reaction temperature was set to 140 °C, and the residence time was set at 30 min, resulting in titania nanoparticle suspensions without any precipitation. The power output was set at 300 W, and pressures generated inside the reaction vials ranged from 0.3 to 4 bars. After microwave synthesis, each suspension was filtered with a 0.20 µm PET (polyethylene terphtalate) filter in order to remove the presence of any agglomerations.

2.2. SiO2 Buffer Layer Synthesis

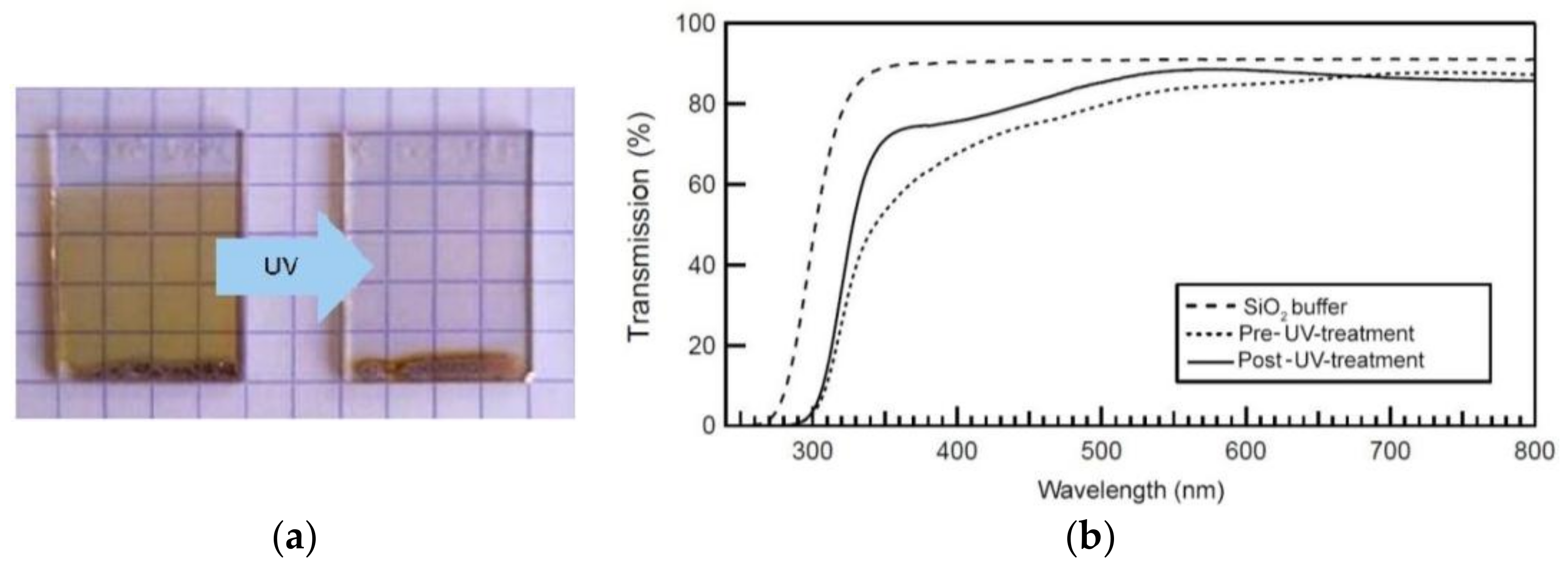

The synthesis of the amorphous silica buffer layer is done as follows: 4.91 mL tetraorthosilicate (TEOS, Carl Roth, Karlsruhe, Germany, >98%) was pipetted in a mixture of 10.27 mL ethanol (Fiers, Kuurne, Belgium, 99.8%) and 4.76 mL water. This precursor solution was then stirred at room temperature for 10 min. Subsequently, 0.03 mL formic acid (Sigma-Aldrich, ≥95% in H2O) was pipetted to catalyze the condensation reaction, after which the mixture was refluxed at 60 °C for 3 h. After that, 33.33 mL of ethanol was added as a quenching step, yielding a 3 wt % of SiO2 in a 53.33 mL precursor solution. During the entire synthesis process, the solution remained transparent and colorless. This SiO2 precursor was used to deposit buffer layers on the PMMA and PPSU substrates.

2.3. Silica Layer Deposition and Thermal Processing

To obtain homogeneous and defect-free silica buffer layers, it is imperative to treat the (polymer) substrates before coating. Every substrate was cleaned with isopropanol and subsequently sonicated in isopropanol. Afterwards, the residual isopropanol on the substrates was removed by using pressurized air in order to be free of any drying effects. The silica precursor was dip-coated (KSV Instruments, Trumbull, CT, USA) on PMMA or PPSU with dimensions of 20 mm × 20 mm, at a speed of 60 mm/s in a clean room (class 100,000/1000). The subsequent thermal processing was performed in a Carbolite tube furnace (CARBOLITE GERO, Derbyshire, UK) at 200 °C for 1 h for the coatings on the PPSU substrates, with a heating rate of 2 °C/min and under a 0.5 L/min nitrogen flow. The thermal treatment on the coated PMMA substrates was carried out under the same circumstances, but at 120 °C. After thermal treatment, the samples were air-cooled by removing the coated substrates immediately from the furnace.

2.4. TiO2 Layer Deposition and Thermal Processing

The Ti-EA and Ti-TEAOH suspensions were sonicated to remove any bubbles related to an excess presence of hydrogen peroxide. Subsequently, the suspensions were coated onto the SiO2-polymer buffer layer system with a dip-coating speed of 100 mm/s. The thermal processing of these wet films was performed in a Carbolite tube furnace at 120 °C for the coated PMMA substrates and at 200 °C for the coated PPSU substrates for 1 h, with a heating rate of 2 °C/min and under a 0.5 L/min air flow. After thermal treatment, the samples are again air-cooled by removing the coated substrates immediately from the furnace.

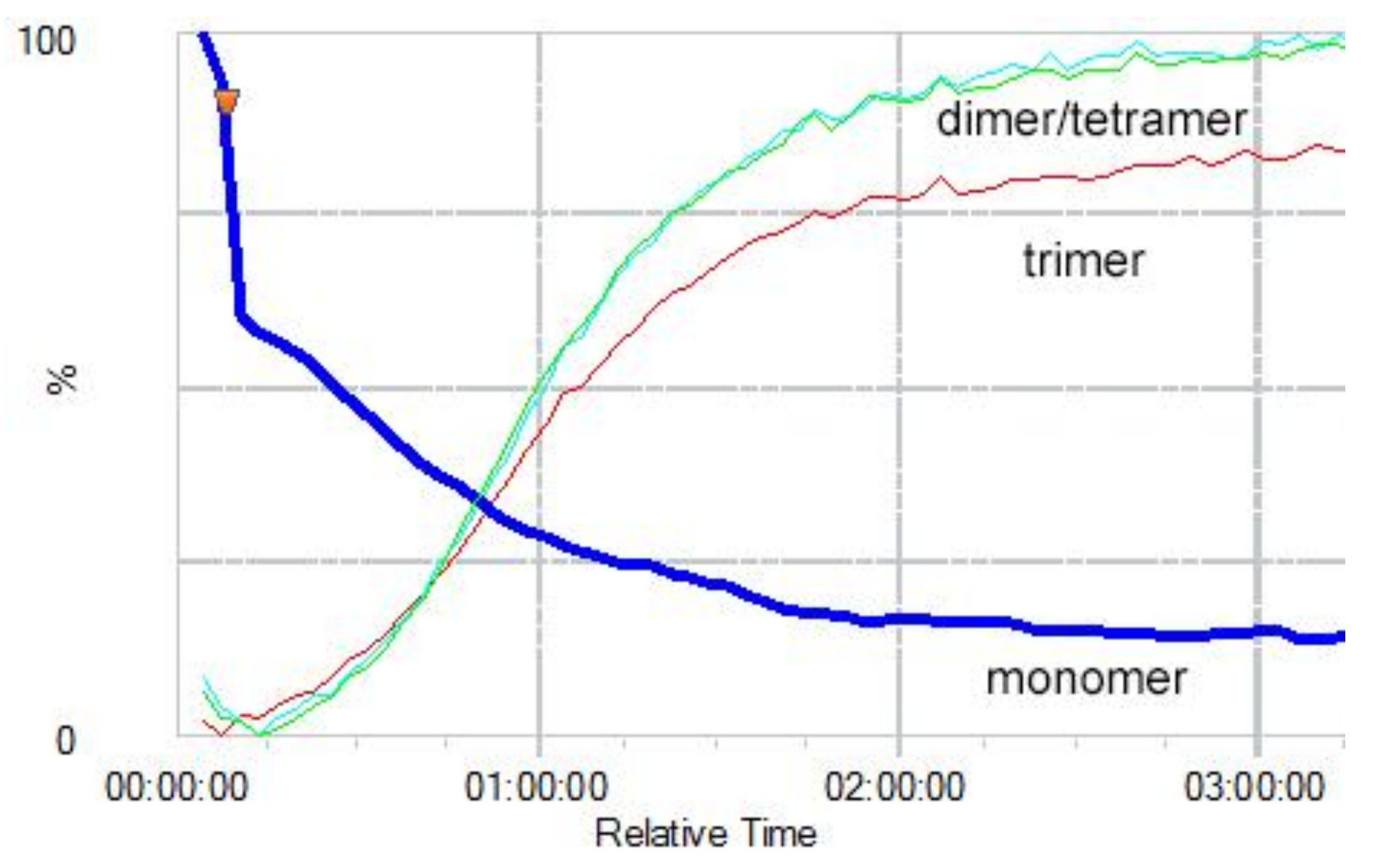

2.5. Spectroscopic Characterization

The kinetics of the pre-condensation step were monitored with a RamanRxn system (model Rxn1-532) from Kaiser optical systems (Ann Arbor, MI, USA). The wavelength of the laser was 532 nm with a maximum power output of 450 mW. A resampling interval of 1 cm−1 was used while recording 13 accumulations with an exposure time of 10 s. The transparency of the deposited films on polymer substrates was determined using a UV-Vis Spectrophotometer (PerkinElmer Lambda 950, PerkinElmer, Zaventem, Belgium).

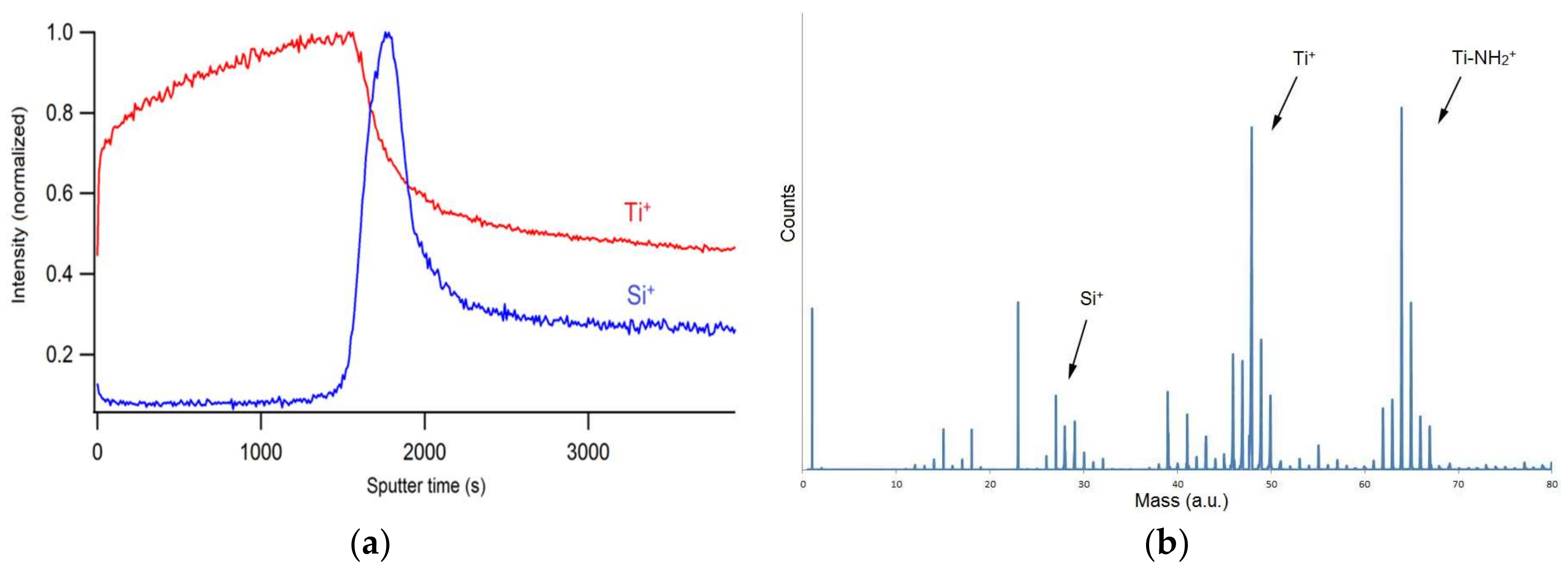

2.6. Structural Characterization

The wettability of the titania nanosuspensions was determined by measuring the contact angle of a 10 µL droplet on both the PMMA and PPSU substrates by using an optical tensiometer (Kruss DSA30, KRÜSS GmbH, Hamburg, Germany). The composition of the silica buffer layer was evaluated by secondary ion mass spectrometry (SIMS). The SIMS set up used was a modified TOF-SIMS IV, equipped with a 25 kV Bi LMIG and 10 kV C60 sputter source, supplied by IONTOF (Münster, Germany). Sputtering was performed by using C60++ clusters, using a sputter current of approximately 1.4 nA. The raster size of the sputter beam was set at 300 µm × 300 µm. Bi+ ions were used as primary ions with a pulsed target current between 0.2 and 0.5 pA. The time of flight analyzer was set in positive mode.

2.7. Photocatalytic Activity Analysis

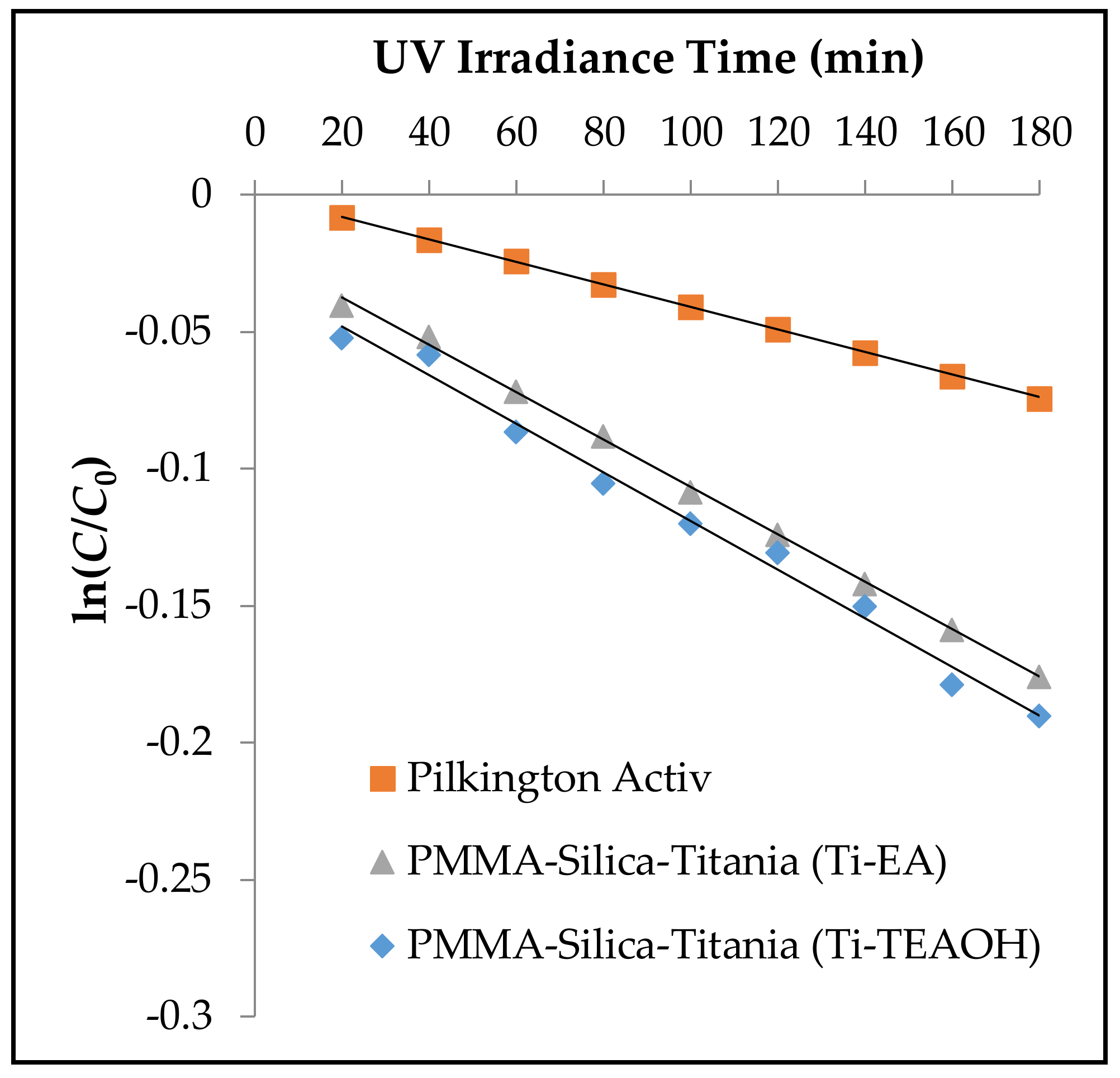

The rate of degradation of organic material by TiO

2 thin layers, coated onto the SiO

2-polymer system, was determined by measuring the decolorization of a 35 mL aqueous solution of methylene blue, which was in direct contact with a TiO

2-SiO

2-polymer coating. This analysis was carried out in confirmation with ISO 10678:2010(E) through UV-Vis spectrophotometer [

17]. The color removal, or more precisely, the reduction of the dye solution follows a pseudo first-order kinetic mechanism (Equation (1)).

where,

C is the concentration of methylene blue at a certain UV irradiation time

t,

C0 is the initial dye concentration (and equals to 10

−5 mol/L), and

k is the reaction rate constant. The UV light source (Vilber Lourmat VL-315BLB blacklight blue fluorescent light tube; 10 W/m

2 at 365 nm, Vilber, Paris, France) used during analysis was assessed for radiation intensity according to ISO 10677:2011 [

17].

4. Conclusions

PMMA and PPSU polymeric sheets were successfully coated with a transparent TiO2 thin film through chemical solution deposition, using highly crystalline titania nanoparticle suspensions in a dip-coating process. The incorporation of a silica intermediate layer is envisioned to prevent the organic substrates from deterioration from the effect of the photocatalytic titania top layer. This silica buffer layer yields the potential to guarantee better compatibility between the inorganic TiO2 coating and the polymer substrate; however, this should be researched further in future work. A transparent titania coating on the polymer substrates was obtained through the incorporation of a buffer layer architecture and the use of a low-temperature procedure compatible with the thermal sensitivity of the PMMA and PPSU substrates. An extensive study on the morphology of the final coatings, albeit the titania coatings or silica buffer layers should be conducted in the future. Future research on layer thicknesses, surface roughness, and porosity can provide an explanation for the observed photocatalytic activities and transparency or homogeneity of the final coatings. Furthermore, the durability of the coatings should be evaluated using more rigorous tests, such as weathering tests in a Weather-O-meter (UVAtlas2000, Atlas Material Testing Technology GmbH, Linsengericht, Germany) to assess the long-term durability of the coatings for outdoor applications. Furthermore, mechanical testing (stretch, adhesion, and scratch testing) should be conducted in future research.