Application of Nanofibrillated Cellulose on BOPP/LDPE Film as Oxygen Barrier and Antimicrobial Coating Based on Cold Plasma Treatment

Abstract

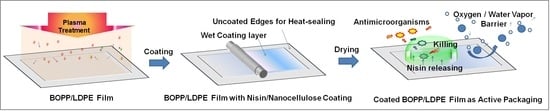

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Plasma Treatment

2.3. Preparation of NC/Nisin Coating Solution

2.4. Surface Coating of BOPP/LDPE Film

2.5. Surface Wettability of the Films

2.6. Microscope Observations of the Films

2.7. Optical Properties of the Films

2.8. Mechanical Properties of the Films

2.9. Gas Barrier Properties of the Films

2.10. Antimicrobial Activity of the Films Against L. monocytogenes

2.11. Statistical Analysis

3. Results and Discussions

3.1. Hydrophilic Analysis of the Films

3.2. Mechanical Properties

3.3. Optical Properties

3.4. Barrier Properties

3.5. Antimicrobial Activity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- López-Rubio, A.; Lagaron, J.M.; Ankerfors, M.; Lindstrőm, T.; Nordqvist, D.; Mattozzi, A.; Hedenqvist, M.S. Enhanced film forming and film properties of amylopectin using micro-fibrillated cellulose. Carbohyr. Polym. 2007, 68, 718–727. [Google Scholar] [CrossRef]

- Rodionova, G.; Lenes, M.; Eriksen, Ø.; Gregerse, Ø. Surface chemical modification of microfibrillated cellulose: Improvement of barrier propertiesfor packaging applications. Cellulose 2011, 18, 127–134. [Google Scholar] [CrossRef]

- Herrera, M.A.; Mathew, A.P.; Oksman, K. Barrier and mechanical properties of plasticized and cross-linked nanocellulose coatings for paper packaging applications. Cellulose 2017, 24, 3969–3980. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Sillard, C.; Bras, J. Controlled release and long-term antibacterial activity of chlorhexidine digluconate through the nanoporous network of microfibrillated cellulose. Cellulose 2014, 21, 4429–4442. [Google Scholar] [CrossRef]

- Ferrer, A.; Pal, L.; Hubbe, M. Nanocellulose in packaging: Advances in barrier layer technologies. Ind. Crops Prod. 2017, 95, 574–582. [Google Scholar] [CrossRef]

- Fang, Z.; Zhao, Y.; Warner, R.D.; Johnson, S.K. Active and intelligent packaging in meat industry. Trends Food Sci. Technol. 2017, 61, 60–71. [Google Scholar] [CrossRef]

- Syverud, K.; Stenius, P. Strength and barrier properties of MFC films. Cellulose 2009, 16, 75–85. [Google Scholar] [CrossRef]

- Lange, J.; Wyser, Y. Recent innovations in barrier technologies for plastic packaging—A review. Packag. Technol. Sci. 2003, 16, 149–158. [Google Scholar] [CrossRef]

- Hong, S.-I.; Krochta, J.M. Oxygen barrier properties of whey protein isolate coatings on polypropylene films. J. Food Sci. 2010, 68, 224–228. [Google Scholar] [CrossRef]

- Tihminlioglu, F.; Atik, İ.D.; Őzen, B. Water vapor and oxygen-barrier performance of corn-zein coated polypropylene films. J. Food Eng. 2010, 96, 342–347. [Google Scholar] [CrossRef]

- Herrera, M.A.; Sirviö, J.; Mathew, A.P.; Oksman, K. Environmental friendly and sustainable gas barrier on porous materials: Nanocellulose coatings prepared using spin- and dip-coating. Mater. Design. 2016, 93, 19–25. [Google Scholar] [CrossRef]

- Pandiyaraj, K.N.; Kumar, A.A.; Ramkumar, M.C.; Deshmukh, R.R.; Bendavid, A.; Su, P.-G.; Kumar, U.; Packirisamy, G. Effect of cold atmospheric pressure plasma gas composition on the surface and cyto-compatible properties of low density polyethylene (LDPE) films. Curr. Appl. Phys. 2016, 16, 784–792. [Google Scholar] [CrossRef]

- Misra, N.N.; Jo, C. Applications of cold plasma technology for microbiological safety in meat industry. Trends Food Sci. Technol. 2017, 64, 74–86. [Google Scholar] [CrossRef]

- Tendero, C.; Tixier, C.; Tristant, P.; Desmaison, J.; Leprince, P. Atmospheric pressure plasmas: A review. Spectrochim. Acta Part B At. Spectrosc. 2006, 61, 2–30. [Google Scholar] [CrossRef]

- Pandiyaraj, K.N.; Deshmukh, R.R.; Ruzybayev, I.; Shah, S.I.; Su, P.-G.; Halleluyah, J.M.; Halim, A.S. Influence of non-thermal plasma forming gases on improvement of surface properties of low density polyethylene (LDPE). Appl. Surf. Sci. 2014, 307, 109–119. [Google Scholar] [CrossRef]

- Clarke, D.; Tyuftin, A.A.; Cruzromero, M.C.; Bolton, D.; Fanning, S.; Pankaj, S.K.; Bueno-Ferrer, C.; Cullen, P.J.; Kerry, J.P. Surface attachment of active antimicrobial coatings onto conventional plastic-based laminates and performance assessment of these materials on the storage life of vacuum packaged beef sub-primals. Food Microbiol. 2017, 62, 196–201. [Google Scholar] [CrossRef] [PubMed]

- Ozen, B.F.; Floros, J.D. Effects of emerging food processing techniques on the packaging materials. Trends Food Sci. Technol. 2001, 12, 60–67. [Google Scholar] [CrossRef]

- Hong, S.-I.; Krochta, J.M. Whey protein isolate coating on LDPE film as a novel oxygen barrier in the composite structure. Packag. Technol. Sci. 2004, 17, 13–21. [Google Scholar] [CrossRef]

- Shukri, N.A.; Ghazali, Z.; Fatimah, N.A.; Mohamad, S.F.; Wahit, M.U. Physical, mechanical and oxygen barrier properties of antimicrobial active packaging based on ldpe film incorporated with sorbic acid. Adv. Environ. Biol. 2014, 8, 2748–2752. [Google Scholar]

- Störmer, A.; Bott, J.; Kemmer, D.; Franz, R. Critical review of the migration potential of nanoparticles in food contact plastics. Trends Food Sci. Technol. 2017, 63, 39–50. [Google Scholar] [CrossRef]

- Ribeiro-Santos, R.; Andrade, M.; Melo, N.R.D.; Sanches-Silva, A. Use of essential oils in active food packaging: Recent advances and future trends. Trends Food Sci. Technol. 2017, 61, 132–140. [Google Scholar] [CrossRef]

- Limjaroen, P.; Ryser, E.T.; Lockhart, H.; Harte, B. Development of a food packaging coating material with antimicrobial properties. J. Plast. Film Sheet. 2003, 19, 95–109. [Google Scholar] [CrossRef]

- Lopes, N.A.; Pinilla, C.M.B.; Brandelli, A. Pectin and polygalacturonic acid-coated liposomes as novel delivery system for nisin: Preparation, characterization and release behavior. Food Hydrocoll. 2017, 70, 1–7. [Google Scholar] [CrossRef]

- Benech, R.O.; Kheadr, E.E.; Laridi, R.; Lacroix, C.; Fliss, I. Inhibition of Listeria innocua in cheddar cheese by addition of nisin Z in liposomes or by in situ production in mixed culture. Appl. Environ. Microb. 2002, 68, 3683–3690. [Google Scholar] [CrossRef]

- Janes, M.E.; Kooshesh, S.; Johnson, M.G. Control of Listeria monocytogenes on the surface of refrigerated, ready-to-eat chicken coated with edible zein film coatings containing nisin and/or calcium propionate. J. Food Sci. 2002, 67, 2754–2757. [Google Scholar] [CrossRef]

- Cui, H.; Wu, J.; Li, C.; Lin, L. Improving anti-Listeria activity of cheese packaging via nanofiber containing nisin-loaded nanoparticles. LWT-Food Sci. Technol. 2017, 81, 233–242. [Google Scholar] [CrossRef]

- Cutter, C.N.; Willett, J.L.; Siragusa, G.R. Improved antimicrobial activity of nisin-incorporated polymer films by formulation change and addition of food grade chelator. Lett. Appl. Microbiol. 2001, 33, 325–328. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Loh, X.J. Layer-by-layer assemblies for antibacterial applications. Biomater. Sci. 2015, 3, 1505–1518. [Google Scholar] [CrossRef] [PubMed]

- Salmieri, S.; Islam, F.; Khan, R.A.; Hossain, F.M.; Ibrahim, H.M.M.; Miao, C.; Hamad, W.Y.; Lacroix, M. Antimicrobial nanocomposite films made of poly(lactic acid)-cellulose nanocrystals (PLA-CNC) in food applications: Part A—Effect of nisin release on the inactivation of Listeria monocytogenes in ham. Cellulose 2014, 21, 1837–1850. [Google Scholar] [CrossRef]

- Khan, A.; Gallah, H.; Riedl, B.; Bouchard, J.; Safrany, A.; Lacroix, M. Genipin cross-linked antimicrobial nanocomposite films and gamma irradiation to prevent the surface growth of bacteria in fresh meats. Innov. Food Sci. Emerg. 2016, 35, 96–102. [Google Scholar] [CrossRef]

- Aveyard, J.; Bradley, J.W.; Mckay, K.; McBride, F.; Donaghy, D.; Raval, R.; D’Sa, R.A. Linker-free covalent immobilization of nisin using atmospheric pressure plasma induced grafting. J. Mater. Chem. B 2017, 5, 2500–2510. [Google Scholar] [CrossRef]

- Duday, D.; Vreuls, C.; Moreno, M.; Frache, G.; Boscher, N.D.; Zocchi, G.; Archambeau, C.; Weerdt, C.V.D.; Martial, J.; Choquet, P. Atmospheric pressure plasma modified surfaces for immobilization of antimicrobial nisin peptides. Surf. Coat. Technol. 2013, 218, 152–161. [Google Scholar] [CrossRef]

- Khan, A.; Salmieri, S.P.; Fraschini, C.; Bouchard, J.; Riedl, B.; Lacroix, M. Genipin cross-linked nanocomposite films for the immobilization of antimicrobial agent. ACS Appl. Mater. Interfaces 2014, 6, 15232–15242. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Wang, Z.; Liu, H.; Xie, S.; Wu, J.; Jiang, H.; Zhang, J.; Li, L.; Li, J. Laundering durability of photocatalyzed self-cleaning cotton fabricwith TiO2 nanoparticles covalently immobilized. ACS Appl. Mater. Interfaces 2013, 5, 3697–3703. [Google Scholar] [CrossRef] [PubMed]

- ASTM. ASTM D882. In Standard Test Method for Tensile Properties of Thin Plastic Sheeting; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Karam, L.; Jama, C.; Mamede, A.-S.; Fahs, A.; Louarn, G.; Dhulster, P.; Chihib, N.-E. Study of nisin adsorption on plasma-treated polymer surfaces for setting up materials with antibaterial properties. React. Funct. Polym. 2013, 73, 1473–1479. [Google Scholar] [CrossRef]

- Karam, L.; Jama, C.; Nuns, N.; Mamede, A.-S.; Dhulster, P.; Chihib, N.-E. Nisin adsorption on hydrophilic and hydrophobic surfaces: Evidences of its interactions and antibacterial activity. J. Pept. Sci. 2013, 19, 377–385. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Xu, S.; Seetharaman, K. A novel in situ atomic force microscopy imaging technique to probe surface morphological features of starch granules. Carbohyr. Res. 2011, 346, 847–853. [Google Scholar] [CrossRef] [PubMed]

- Lu, P.; Zhang, W.; He, M.; Yan, Y.; Xiao, H. Cellulase-assisted refining of bleached softwood kraft pulp for making water vapor barrier and grease-resistant paper. Cellulose 2016, 23, 891–900. [Google Scholar] [CrossRef]

- Österberg, M.; Vartiainen, J.; Lucenius, J.; Hippi, U.; Seppälä, J.; Serimaa, R.; Laine, J. A fast method to produce strong NFC films as a platform for barrier and functional materials. ACS Appl. Mater. Interface 2013, 5, 4640–4647. [Google Scholar] [CrossRef] [PubMed]

- Henriksson, M.; Berglund, L.A.; Isaksson, P.; Lindstrőm, T.; Nishino, T. Cellulose nanopaper structures of high toughness. Biomacromolecules 2008, 9, 1579–1585. [Google Scholar] [CrossRef] [PubMed]

- Fukuzumi, H.; Saito, T.; Iwata, T.; Kumamoto, Y.; Isogai, A. Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 2009, 10, 162–165. [Google Scholar] [CrossRef] [PubMed]

- Aulin, C.; Gällstedt, M.; Lindström, T. Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 2010, 17, 559–574. [Google Scholar] [CrossRef]

- Soni, B.; Hassan, E.B.; Schilling, M.W.; Mahmoud, B. Transparent bionanocomposite films based on chitosan and TEMPO-oxidized cellulose nanofibers with enhanced mechanical and barrier properties. Carbohyr. Polym. 2016, 151, 779–789. [Google Scholar] [CrossRef] [PubMed]

- Abdellatief, A.; Welt, B.A. Comparison of new dynamic accumulation method for measuring oxygen transmission rate of packaging against the steady-state method described by ASTM D3985. Packag. Technol. Sci. 2013, 26, 281–288. [Google Scholar] [CrossRef]

- Brody, A.L.; Bugusu, B.; Han, J.H.; Sand, C.K.; Mchugh, T.H. Innovative food packaging solutions. J. Food Sci. 2008, 73, R107–R116. [Google Scholar] [CrossRef] [PubMed]

- Belbekhouche, S.; Bras, J.; Siqueira, G.; Chappey, C.; Lebrun, L.; Khelifi, B.; Marais, S.; Dufresne, A. Water sorption behavior and gas barrier properties of cellulose whiskers and microfibrils films. Carbohyr. Polym. 2011, 83, 1740–1748. [Google Scholar] [CrossRef]

- Rastogi, V.K.; Samyn, P. Bio-based coatings for paper applications. Coatings 2015, 5, 887–930. [Google Scholar] [CrossRef]

- Quintavalla, S.; Vicini, L. Antimicrobial food packaging in meat industry. Meat Sci. 2002, 62, 373–380. [Google Scholar] [CrossRef]

- Wu, S.; Yu, P.-L.; Flint, S. Persister cell formation of Listeria monocytogenes in response to natural antimicrobial agent nisin. Food Control 2017, 77, 243–250. [Google Scholar] [CrossRef]

- Luchansky, J.B.; Call, J.E. Evaluation of nisin-coated cellulose casings for the control of Listeria monocytogenes inoculated onto the surface of commercially prepared frankfurters. J. Food Prot. 2004, 67, 1017–1021. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, A.; Lee, D.S.; Chikindas, M.L.; Yam, K.L. Effect of Nisin’s controlled release on microbial growth as modeled for micrococcus luteus. Probiotics Antimicrob. 2011, 3, 113–118. [Google Scholar] [CrossRef] [PubMed]

- Honarvar, Z.; Farhoodi, M.; Khani, M.R.; Mohammadi, A.; Shokri, B.; Ferdowsi, R.; Shojaee-Aliabadi, S. Application of cold plasma to develop carboxymethyl cellulose-coated polypropylene films containing essential oil. Carbohyr. Polym. 2017, 176, 1–10. [Google Scholar] [CrossRef] [PubMed]

| BOPP/LDPE Samples | Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|

| untreated film | 55.84 ± 3.52 | 52.98 ± 2.21 | 1.57 ± 0.14 |

| plasma treated film | 51.62 ± 7.02 | 52.32 ± 3.56 | 1.67 ± 0.11 |

| plasma treated film with NC coating | 51.65 ± 4.16 | 53.95 ± 2.42 | 1.55 ± 0.13 |

| plasma treated film with NC/S1 coating | 51.88 ± 3.33 | 48.62 ± 2.16 | 1.67 ± 0.13 |

| plasma treated film with NC/S3 coating | 50.26 ± 4.03 | 52.18 ± 4.03 | 1.48 ± 0.16 |

| plasma treated film with NC/S5 coating | 43.95 ± 7.20 | 49.23 ± 1.96 | 1.65 ± 0.12 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, P.; Guo, M.; Xu, Z.; Wu, M. Application of Nanofibrillated Cellulose on BOPP/LDPE Film as Oxygen Barrier and Antimicrobial Coating Based on Cold Plasma Treatment. Coatings 2018, 8, 207. https://doi.org/10.3390/coatings8060207

Lu P, Guo M, Xu Z, Wu M. Application of Nanofibrillated Cellulose on BOPP/LDPE Film as Oxygen Barrier and Antimicrobial Coating Based on Cold Plasma Treatment. Coatings. 2018; 8(6):207. https://doi.org/10.3390/coatings8060207

Chicago/Turabian StyleLu, Peng, Mengya Guo, Zhijun Xu, and Min Wu. 2018. "Application of Nanofibrillated Cellulose on BOPP/LDPE Film as Oxygen Barrier and Antimicrobial Coating Based on Cold Plasma Treatment" Coatings 8, no. 6: 207. https://doi.org/10.3390/coatings8060207