Preparation of Yttria-Stabilized Zirconia Hollow Sphere with Reduced Shell Thickness by Controlling Ambient Temperature during Plasma Process

Abstract

:1. Introduction

2. Materials and Methods

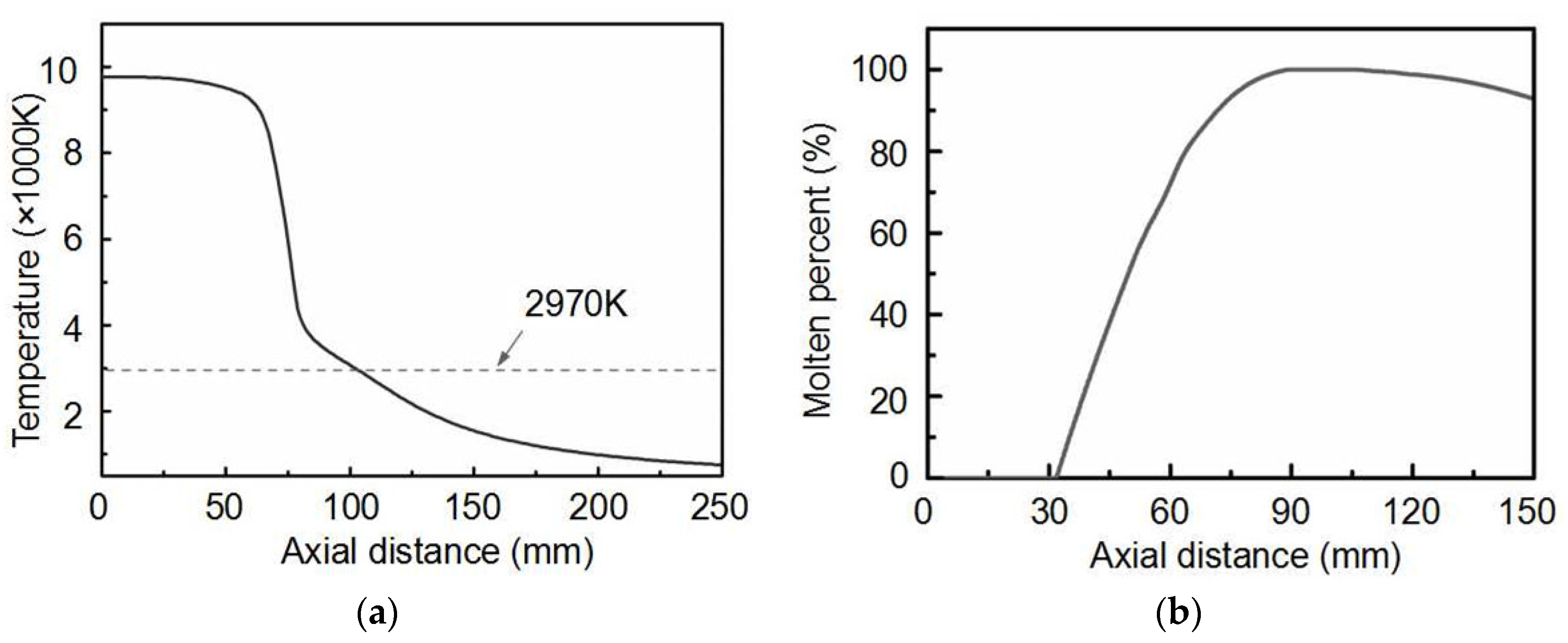

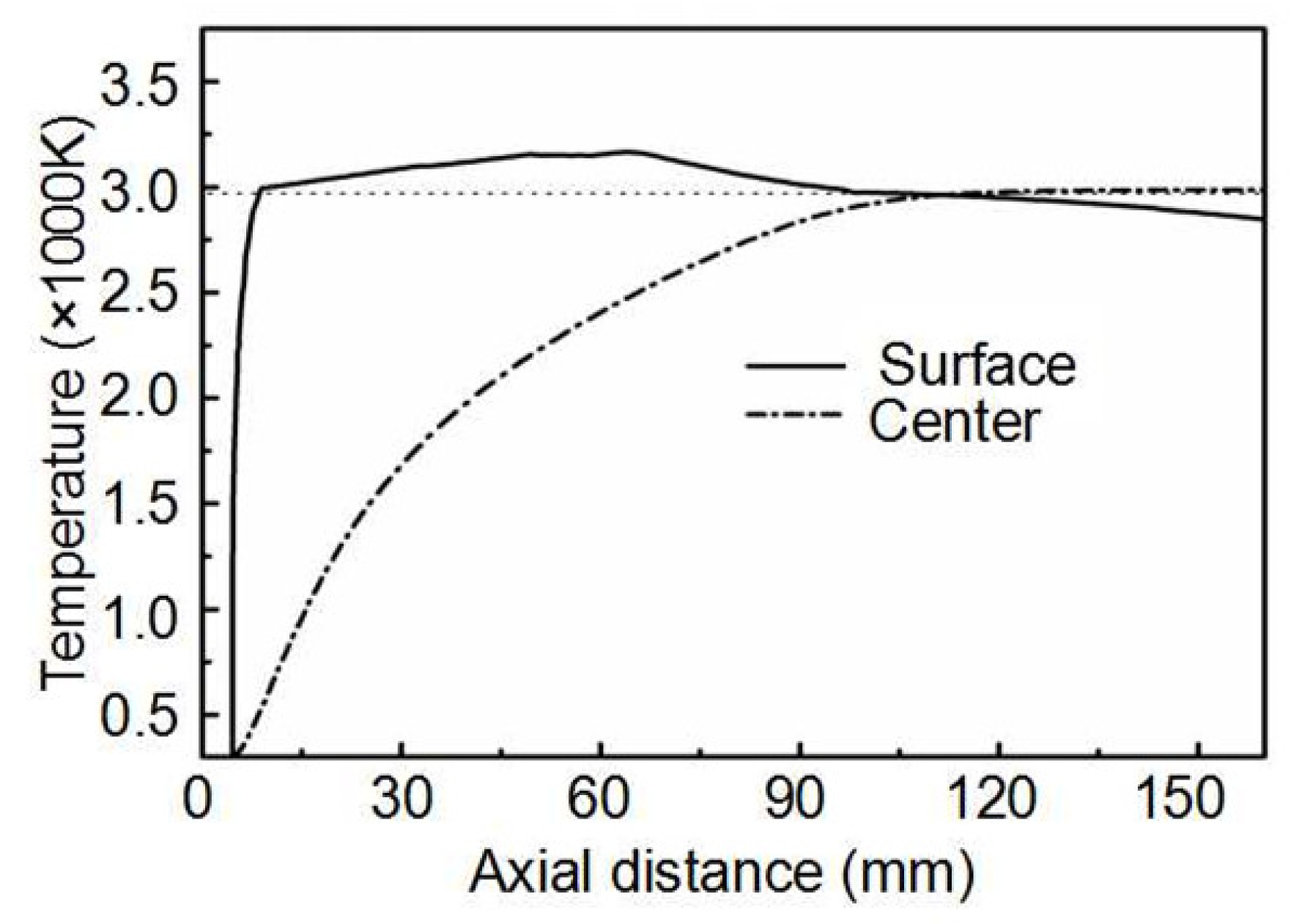

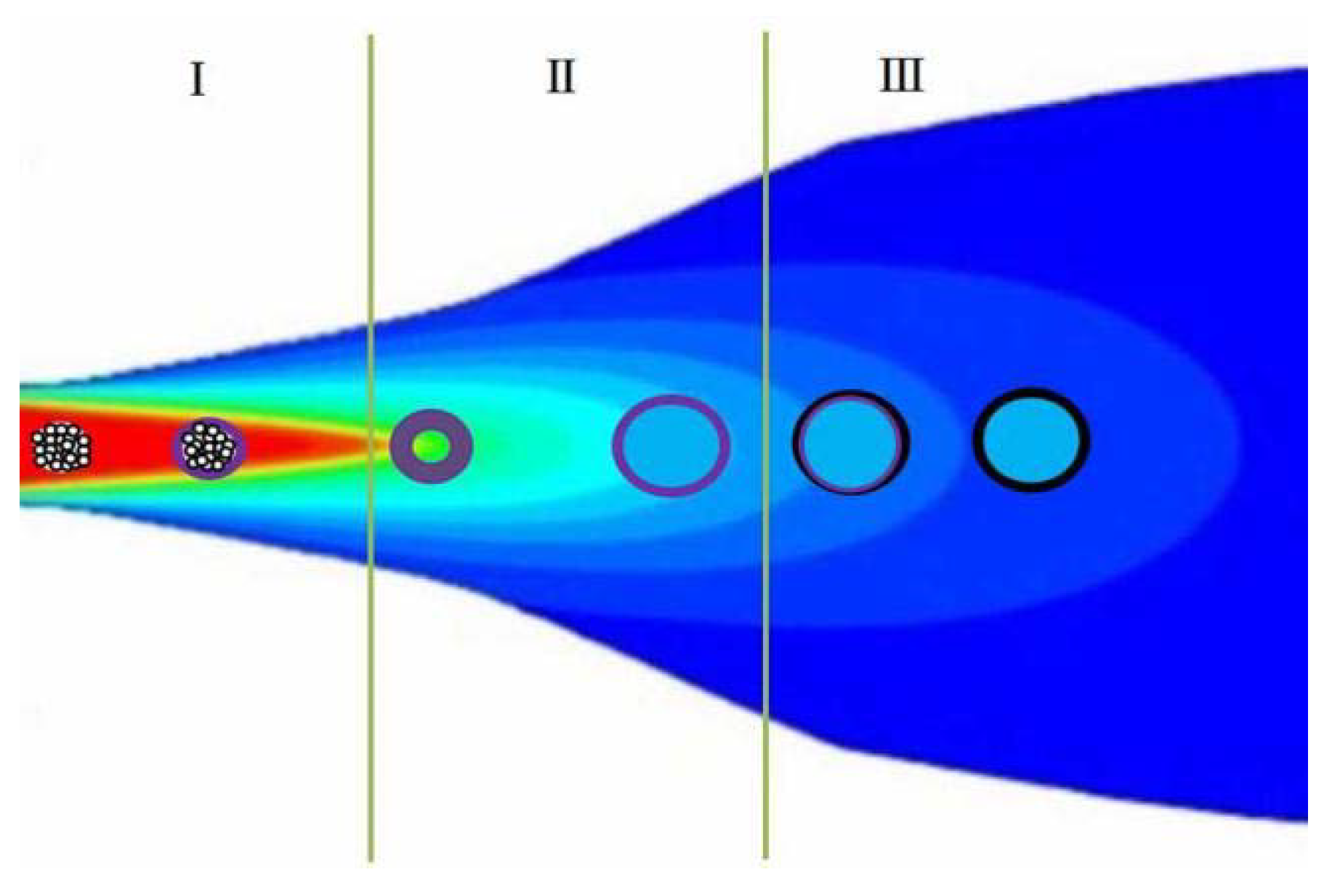

3. Results and Discussion

4. Conclusions

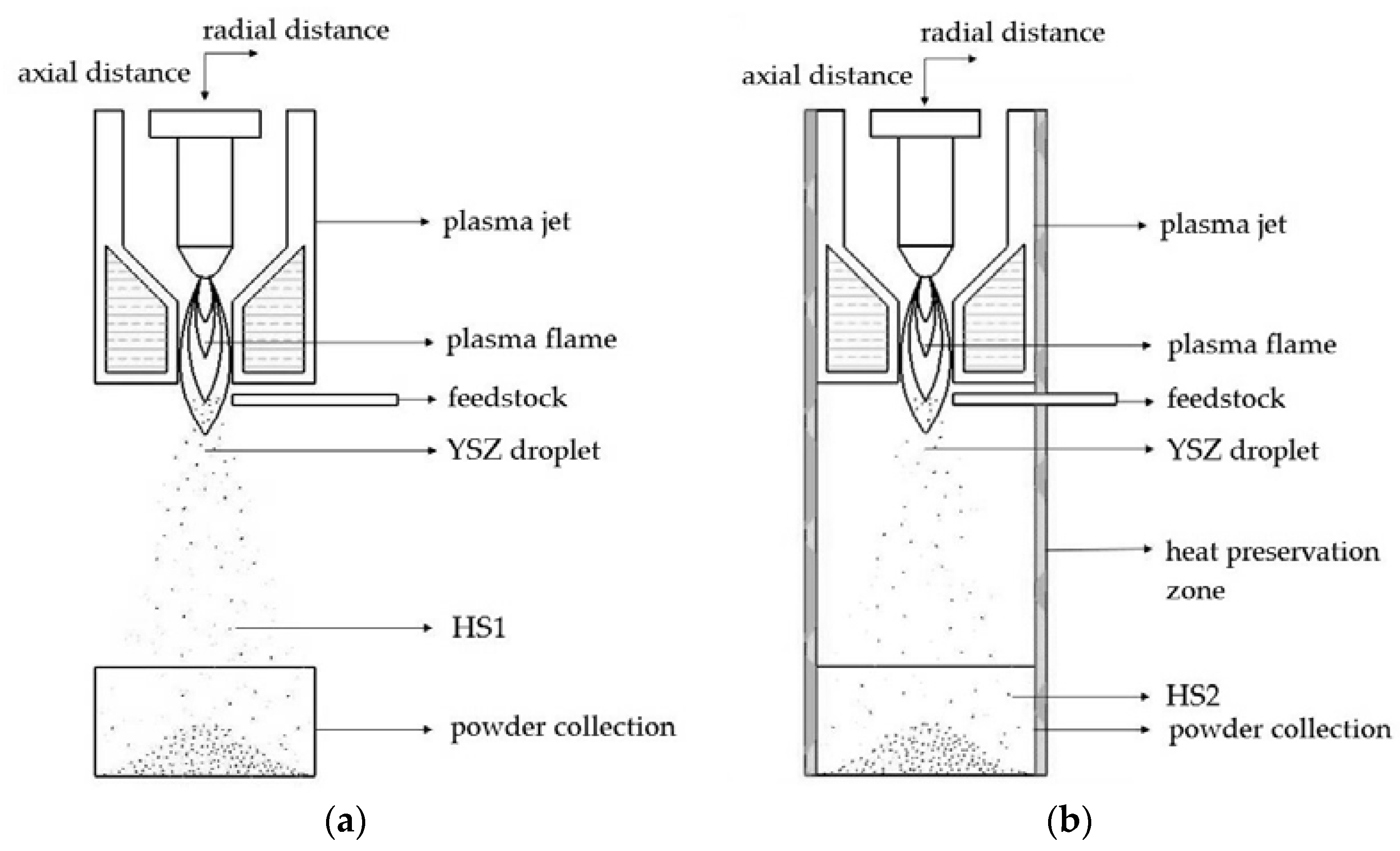

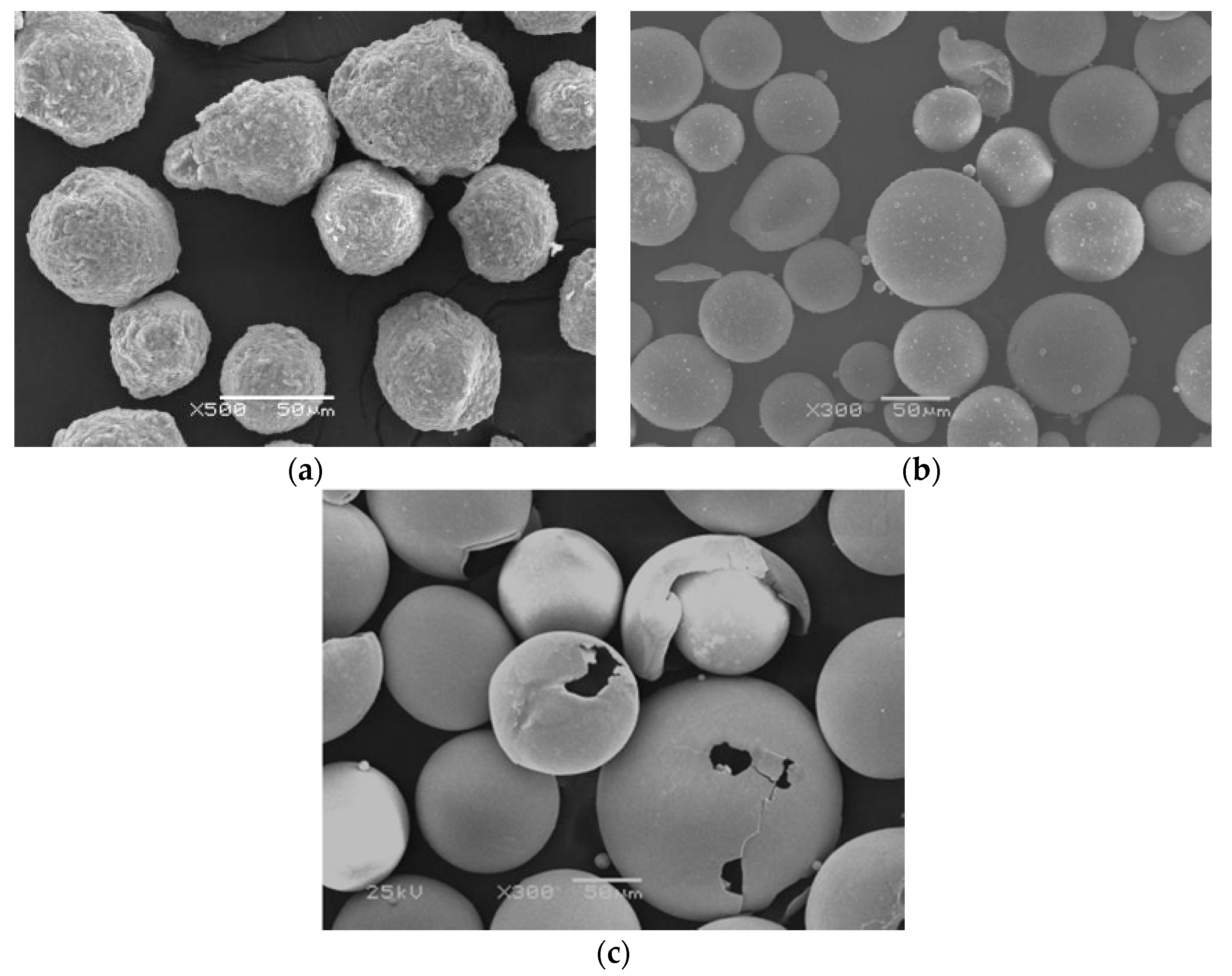

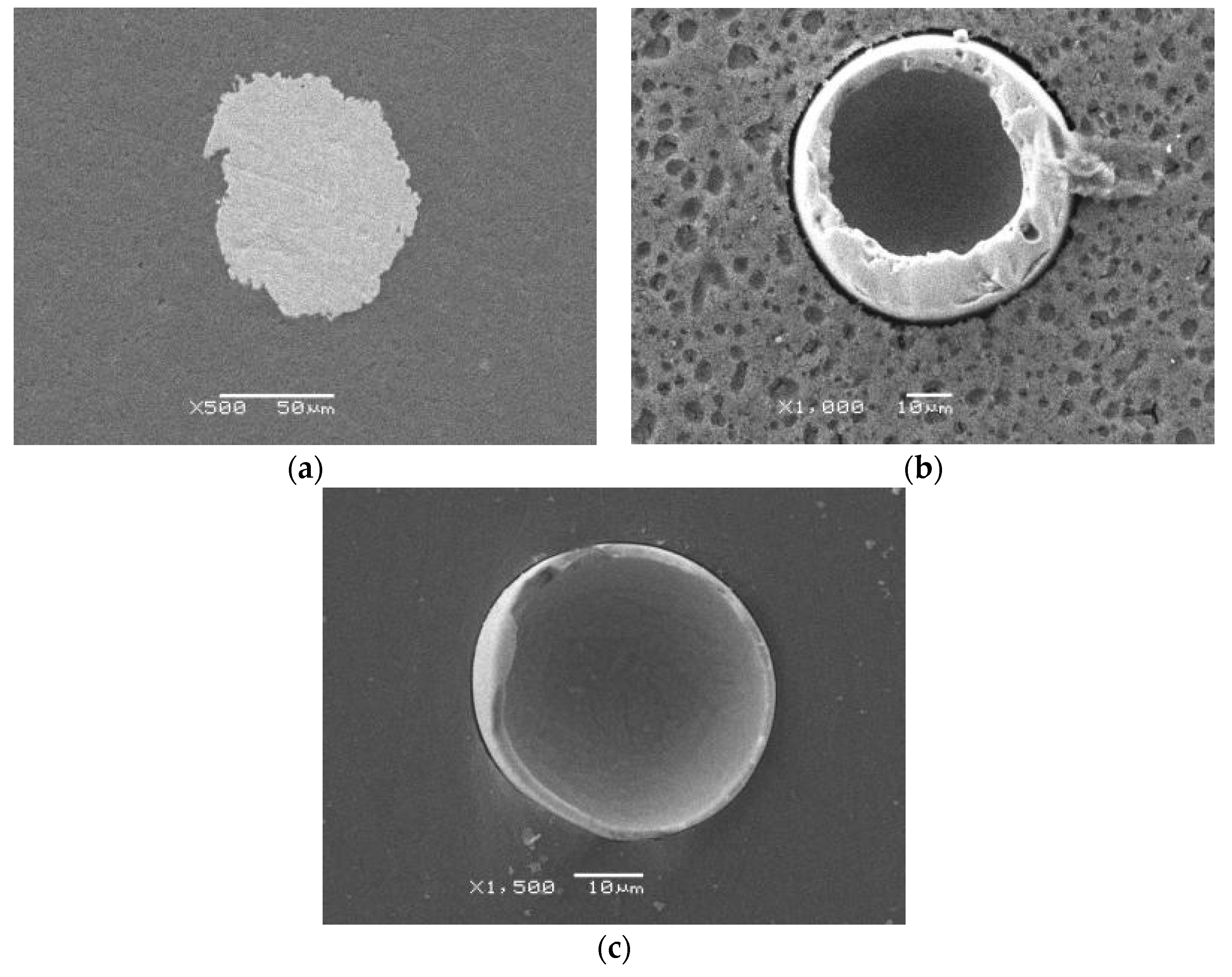

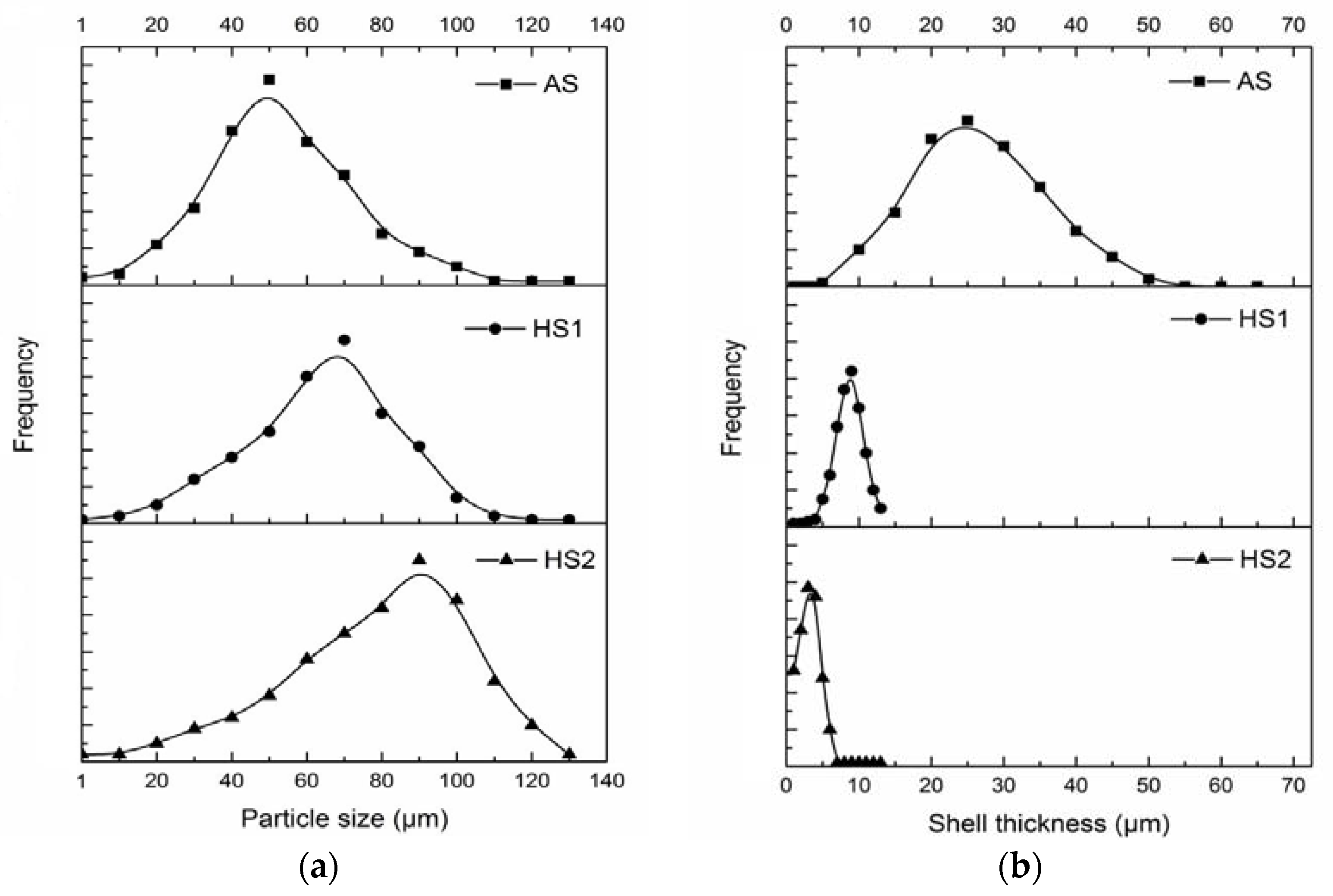

- HS2 has a larger particle diameter, thinner shell thickness, and lower apparent density than that of AS and HS1.

- For the main conditions of preparation of HS2 by the plasma process, aside from the amount of gas entrapped, entrapped gas pressure and ambient pressure, ambient temperature should also be taken into consideration, which prevents the surface from premature solidification.

- By adding a heat preservation zone around the particle flying path during the plasma process, HS could be obtained with a larger particle diameter and thinner shell thickness.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bakan, E.; Vaßen, R. Ceramic top coats of plasma-sprayed thermal barrier coatings: Materials, processes, and properties. J. Therm. Spray Technol. 2017, 26, 992–1010. [Google Scholar] [CrossRef]

- Igumenov, I.K.; Aksenov, A.N. Thermal barrier coatings on gas turbine blades: Chemical vapor deposition (Review). Therm. Eng. 2017, 64, 865–873. [Google Scholar] [CrossRef]

- Mishra, R.K. Life enhancement of gas turbine combustor liner through thermal barrier coating. J. Fail. Anal. Prev. 2017, 17, 914–918. [Google Scholar] [CrossRef]

- Donegan, S.P.; Rollett, A.D. Simulation of residual stress and elastic energy density in thermal barrier coatings using fast Fourier transforms. Acta Mater. 2015, 96, 212–228. [Google Scholar] [CrossRef] [Green Version]

- Mauer, G.; Du, L.; Vaßen, R. Atmospheric plasma spraying of single phase lanthanum zirconate thermal barrier coatings with optimized porosity. Coatings 2016, 6, 49. [Google Scholar] [CrossRef]

- Chen, X.G.; Zhang, H.; Zhang, H.S.; Zhao, Y.D.; Gang, L.I. Ce1−xSmxO2−x/2—A novel type of ceramic material for thermal barrier coatings. J. Adv. Ceram. 2016, 5, 244–252. [Google Scholar] [CrossRef]

- Wang, X.F.; Xiang, H.M.; Feng, J.C.; Zhou, Y.C. Mechanical properties and damage tolerance of bulk Yb3Al5O12 ceramic. J. Mater. Sci. Technol. 2015, 31, 369–374. [Google Scholar] [CrossRef]

- Tang, W.Z.; Yang, L.; Zhu, W.; Zhou, Y.C.; Guo, J.W.; Lu, C. Numerical simulation of temperature distribution and thermalstress field in a turbine blade with multilayer-structure TBCs by a fluid–solid coupling method. J. Mater. Sci. Technol. 2016, 32, 452–458. [Google Scholar] [CrossRef]

- Huang, J.; Wang, W.; Lu, X.; Hu, D.; Feng, Z.; Guo, T. Effect of particle size on the thermal shock resistance of plasma-sprayed YSZ coatings. Coatings 2017, 7, 150. [Google Scholar] [CrossRef]

- Guo, L.; Li, M.Z.; Zhang, Y. Improved toughness and thermal expansion of non-stoichiometry Gd2−xZr2+xO7+X/2 ceramics for thermal barrier coating application. J. Mater. Sci. Technol. 2016, 32, 28–33. [Google Scholar] [CrossRef]

- Kang, Y.X.; Bai, Y.; Yuan, T.; Wang, Y.; Fan, W.; Gao, Y.; Bao, C.G.; Chen, H.Y.; Li, B.Q. Thermal cycling lives of plasma sprayed YSZ based thermal barrier coatings in a burner rig corrosion test. Surf. Coat. Technol. 2017, 324, 307–317. [Google Scholar] [CrossRef]

- Ghasemi, R.; Vakilifard, H. Plasma-sprayed nanostructured YSZ thermal barrier coatings: Thermal insulation capability and adhesion strength. Ceram. Int. 2017, 12, 8556–8563. [Google Scholar] [CrossRef]

- Zhou, D.; Guillon, O.; Vaßen, R. Development of YSZ thermal barrier coatings using axial suspension plasma spraying. Coatings 2017, 7, 120. [Google Scholar] [CrossRef]

- Huang, J.; Wang, W.; Yu, J.; Wu, L.; Feng, Z. Effect of particle size on the micro-cracking of plasma-sprayed YSZ coatings during thermal cycle testing. J. Therm. Spray Technol. 2017, 26, 755–763. [Google Scholar] [CrossRef]

- Cheng, B.; Yang, N.; Zhang, Q.; Zhang, M.; Zhang, Y.M.; Chen, L.; Yang, G.J.; Li, C.X.; Li, C.J. Sintering induced the failure behavior of dense vertically crack and lamellar structured TBCs with equivalent thermal insulation performance. Ceram. Int. 2017, 47, 15459–15465. [Google Scholar] [CrossRef]

- Yang, G.J.; Chen, Z.L.; Li, C.X.; Li, C.J. Microstructural and mechanical property evolutions of plasma-sprayed YSZ coating during high-temperature exposure: Comparison study between 8YSZ and 20YSZ. J. Therm. Spray Technol. 2013, 22, 1294–1302. [Google Scholar] [CrossRef]

- Cheng, B.; Zhang, Y.M.; Yang, N.; Zhang, M.; Chen, L.; Yang, G.J.; Li, C.X.; Li, C.J. Sintering-induced delamination of thermal barrier coatings by gradient thermal cyclic test. J. Am. Ceram. Soc. 2017, 100, 1820–1830. [Google Scholar] [CrossRef]

- Li, G.R.; Li, C.X.; Li, C.J.; Yang, G.J. Sintering characteristics of plasma-sprayed TBCs: Experimental analysis and an overall modelling. Ceram. Int. 2018, 44, 2982–2990. [Google Scholar] [CrossRef]

- Li, G.R.; Yang, G.J.; Li, C.X.; Li, C.J. Force transmission and its effect on structural changes in plasma-sprayed lamellar ceramic coatings. J. Eur. Ceram. Soc. 2017, 37, 2877–2888. [Google Scholar] [CrossRef]

- Johnson, S.L.; Venugopal, G.; Hunt, A.T. Flame-assisted flash sintering: A noncontact method to flash sinter coatings on conductive substrates. J. Am. Ceram. Soc. 2018, 101, 536–541. [Google Scholar] [CrossRef]

- Li, G.; Xie, H.; Yang, G.; Liu, G.; Li, C.; Li, C. A comprehensive sintering mechanism for TBCs-Part I: An overall evolution with two-stage kinetics. J. Am. Ceram. Soc. 2017, 100, 2176–2189. [Google Scholar] [CrossRef]

- Li, G.; Xie, H.; Yang, G.; Liu, G.; Li, C.; Li, C. A comprehensive sintering mechanism for TBCs-Part II: Multiscale multipoint interconnection-enhanced initial kinetics. J. Am. Ceram. Soc. 2017, 100, 4240–4251. [Google Scholar] [CrossRef]

- Shinozaki, M.; Clyne, T.W. A methodology, based on sintering-induced stiffening, for prediction of the spallation lifetime of plasma-sprayed coatings. Acta Mater. 2013, 61, 579–588. [Google Scholar] [CrossRef]

- Li, G.; Yang, G.; Li, C.; Li, C. A comprehensive sintering mechanism for thermal barrier coatings-Part III: Substrate constraint effect on healing of 2D pores. J. Am. Ceram. Soc. 2018, 101, 3636–3648. [Google Scholar] [CrossRef]

- Cocks, A.C.F.; Fleck, N.A. Constrained sintering of an air-plasma-sprayed thermal barrier coating. Acta Mater. 2010, 58, 4233–4244. [Google Scholar] [CrossRef]

- Li, G.R.; Yang, G.J.; Li, C.X.; Li, C.J. Strain-induced multiscale structural changes in lamellar thermal barrier coatings. Ceram. Int. 2016, 43, 2252–2266. [Google Scholar] [CrossRef]

- Li, G.R.; Cheng, B.; Yang, G.J.; Li, C.X. Strain-induced stiffness-dependent structural changes and the associated failure mechanism in TBCs. J. Eur. Ceram. Soc. 2017, 37, 3609–3621. [Google Scholar] [CrossRef]

- Cheng, B.; Yang, G.J.; Zhang, Q.; Yang, N.; Zhang, M.; Zhang, Y.; Li, C.X.; Li, C.J. Gradient thermal cyclic behaviour of La2Zr2O7/YSZ DCL-TBCs with equivalent thermal insulation performance. J. Eur. Ceram. Soc. 2017, 38, 1888–1896. [Google Scholar] [CrossRef]

- Wang, W.; Wei, J.; Hong, H.; Xuan, F.; Shan, Y. Effect of processing and service conditions on the luminescence intensity of plasma sprayed (Tm3+ + Dy3+) co-doped YSZ coatings. J. Alloys Compd. 2014, 584, 136–141. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, H.; Sun, K.; Dang, X.; Zhang, H.; Ren, B.; Tang, A. Thermal conductivity and expansion coefficient of (Sm1−xYbx)2Ce2O7 ceramics for thermal barrier coatings. J. Mater. Eng. Perform. 2017, 26, 6193–6197. [Google Scholar]

- Li, G.R.; Lei, J.; Yang, G.J.; Li, C.X.; Li, C.J. Substrate-constrained effect on the stiffening behavior of lamellar thermal barrier coatings. J. Eur. Ceram. Soc. 2018, 38, 2579–2587. [Google Scholar] [CrossRef]

- Liu, M.J.; Zhang, M.; Zhang, Q.; Yang, G.J.; Li, C.X.; Li, C.J. The gaseous material capacity of open plasma jet in plasma spray-physical vapor deposition process. Appl. Surf. Sci. 2017, 428, 877–884. [Google Scholar] [CrossRef]

- Schmitt, M.P.; Harder, B.J.; Wolfe, D.E. Process-structure-property relations for the erosion durability of plasma spray-physical vapor deposition (PS-PVD) thermal barrier coatings. Surf. Coat. Technol. 2016, 297, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.Y.; Peng, X.Z.; Yang, G.J.; Li, C.X.; Li, C.J. Characterization of plasma jet in plasma spray-physical vapor deposition of YSZ using a <80 kW shrouded torch based on optical emission spectroscopy. J. Therm. Spray Technol. 2015, 24, 1038–1045. [Google Scholar]

- Li, M.; Guo, L.; Ye, F. Phase structure and thermal conductivities of Er2O3 stabilized ZrO2 toughened Gd2Zr2O7 ceramics for thermal barrier coatings. Ceram. Int. 2016, 42, 16584–16588. [Google Scholar] [CrossRef]

- Liu, M.J.; Zhang, M.; Zhang, Q.; Yang, G.J.; Li, C.X.; Li, C.J. Evaporation of Droplets in Plasma Spray–Physical Vapor Deposition Based on Energy Compensation Between Self-Cooling and Plasma Heat Transfer. J. Therm. Spray Technol. 2017, 26, 1641–1650. [Google Scholar] [CrossRef]

- Keshavarz, M.; Idris, M.H.; Ahmad, N. Mechanical properties of stabilized zirconia nanocrystalline EB-PVD coating evaluated by micro and nano indentation. J. Adv. Ceram. 2013, 2, 333–340. [Google Scholar] [CrossRef] [Green Version]

- Tian, L.; Feng, Z.; Xiong, W. Microstructure, microhardness, and wear resistance of AlCoCrFeNiTi/Ni60 coating by plasma spraying. Coatings 2018, 8, 112. [Google Scholar] [CrossRef]

- Xie, H.; Xie, Y.C.; Yang, G.J.; Li, C.X.; Li, C.J. Modeling thermal conductivity of thermally sprayed coatings with intrasplat cracks. J. Therm. Spray Technol. 2013, 22, 1328–1336. [Google Scholar] [CrossRef]

- Li, G.R.; Lv, B.W.; Yang, G.J.; Zhang, W.X.; Li, C.X.; Li, C.J. Relationship between lamellar structure and elastic modulus of thermally sprayed thermal barrier coatings with intra-splat cracks. J. Therm. Spray Technol. 2015, 24, 1355–1367. [Google Scholar] [CrossRef]

- Yang, G.J.; Li, C.J.; Li, C.X.; Kondoh, K.; Ohmori, A. Improvement of adhesion and cohesion in plasma-sprayed ceramic coatings by heterogeneous modification of nonbonded lamellar interface using high strength adhesive infiltration. J. Therm. Spray Technol. 2013, 22, 36–47. [Google Scholar] [CrossRef]

- Yang, G.J.; Li, C.X.; Li, C.J. Characterization of nonmelted particles and molten splats in plasma-sprayed Al2O3 coatings by a combination of scanning electron microscopy, X-ray diffraction analysis, and confocal raman analysis. J. Therm. Spray Technol. 2013, 22, 131–137. [Google Scholar] [CrossRef]

- Zhang, W.W.; Li, G.R.; Zhang, Q.; Yang, G.J. Comprehensive damage evaluation of localized spallation of thermal barrier coatings. J. Adv. Ceram. 2017, 6, 230–239. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.W.; Li, G.R.; Zhang, Q.; Yang, G.J. Multiscale pores in TBCs for lower thermal conductivity. Chem. Phys. Lett. 2012, 546, 1183–1197. [Google Scholar] [CrossRef]

- Gao, P.H.; Yang, G.J.; Cao, S.T.; Li, J.P.; Yang, Z.; Guo, Y.C. Heredity and variation of hollow structure from powders to coatings through atmospheric plasma spraying. Surf. Coat. Technol. 2016, 305, 76–82. [Google Scholar] [CrossRef]

- Li, G.R.; Yang, G.J.; Li, C.X.; Li, C.J. Stage-sensitive microstructural evolution of nanostructured TBCs during thermal exposure. J. Eur. Ceram. Soc. 2018, 38, 3325–3332. [Google Scholar] [CrossRef]

- Li, G.R.; Yang, G.J.; Li, C.X.; Li, C.J. A comprehensive mechanism for the sintering of plasma-sprayed nanostructured thermal barrier coatings. Ceram. Int. 2017, 43, 9600–9615. [Google Scholar] [CrossRef]

- Chen, L.; Yang, G.J.; Li, C.X.; Li, C.J. Hierarchical formation of intrasplat cracks in thermal spray ceramic coatings. J. Therm. Spray Technol. 2016, 25, 959–970. [Google Scholar] [CrossRef]

- Chen, L.; Yang, G.J.; Li, C.X.; Li, C.J. Edge effect on crack patterns in thermally sprayed ceramic splats. J. Therm. Spray Technol. 2016, 26, 302–314. [Google Scholar] [CrossRef]

- Yang, G.J.; Li, C.X.; Hao, S.; Xing, Y.Z.; Yang, E.J.; Li, C.J. Critical bonding temperature for the splat bonding formation during plasma spraying of ceramic materials. Surf. Coat. Technol. 2013, 235, 841–847. [Google Scholar] [CrossRef]

- Chen, L.; Yang, G.J.; Li, C.X. Formation of lamellar pores for splats via interfacial or sub-interfacial delamination at chemically bonded region. J. Therm. Spray Technol. 2017, 26, 315–326. [Google Scholar] [CrossRef]

- Kulkarni, A.; Herman, H. Microstructure-property correlations in industrial thermal barrier coatings. J. Am. Ceram. Soc. 2010, 87, 1294–1300. [Google Scholar] [CrossRef]

- Chen, L.; Yang, G.J. Anomalous epitaxial growth in thermally sprayed YSZ and LZ splats. J. Therm. Spray Technol. 2017, 26, 1168–1182. [Google Scholar] [CrossRef]

- Chen, L.; Yang, G.J. Epitaxial growth and cracking of highly tough 7YSZ splats by thermal spray technology. J. Adv. Ceram. 2018, 7, 17–29. [Google Scholar] [CrossRef]

- Bakan, E.; Mack, D.E.; Mauer, G.; Mücke, R.; Vaßen, R. Porosity-property relationships of plasma-sprayed Gd2Zr2O7/YSZ thermal barrier coatings. J. Am. Ceram. Soc. 2015, 98, 2647–2654. [Google Scholar] [CrossRef]

- Li, C.J.; Ohmori, A. Relationships between the microstructure and properties of thermally sprayed deposits. J. Therm. Spray Technol. 2003, 12, 365–374. [Google Scholar] [CrossRef]

- Chen, L.; Yang, G.J. Epitaxial growth and cracking mechanisms of thermally sprayed ceramic splats. J. Therm. Spray Technol. 2018, 27, 255–268. [Google Scholar] [CrossRef]

- Chen, L.; Gao, L.L.; Yang, G.J. Imaging slit pores under delaminated splats by white light interference. J. Therm. Spray Technol. 2018, 27, 319–335. [Google Scholar] [CrossRef]

- Herman, H. Powders for thermal spray technology. KONA 1991, 9, 187–199. [Google Scholar] [CrossRef]

- Li, F.; Li, Y.; Xu, K.; Song, Z.; Zhang, Z.; Cui, H.; Li, Z. Research progress of the preparation of zirconia hollow sphere powder and the performance of its coating. Rare Met. Mater. Eng. 2014, 43, 3183–3187. [Google Scholar]

- Tan, Y.; Srinivasan, V.; Nakamura, T.; Sampath, S.; Bertrand, P.; Bertrand, G. Optimizing compliance and thermal conductivity of plasma sprayed thermal barrier coatings via controlled powders and processing strategies. J. Therm. Spray Technol. 2012, 21, 950–962. [Google Scholar] [CrossRef] [Green Version]

- Gulyaev, I.P.; Solonenko, O.P. Hollow droplets impacting onto a solid surface. Exp. Fluids 2013, 54, 1432–1443. [Google Scholar] [CrossRef]

- Solonenko, O.P.; Gulyaev, I.P.; Smirnov, A.V. Plasma processing and deposition of powdered metal oxides consisting of hollow spherical particles. Tech. Phys. Lett. 2008, 34, 1050–1052. [Google Scholar] [CrossRef]

- Solonenko, O.P.; Gulyaev, I.P.; Smirnov, A.V. Thermal plasma processes for production of hollow spherical powders. J. Stat. Mech. 2011, 6, 219–234. [Google Scholar]

- Gulyaev, I.P. Production and modification of hollow powders in plasma under controlled pressure. J. Phys. 2013, 1, 303–311. [Google Scholar] [CrossRef]

- Ettouil, F.B.; Mazhorova, O.; Pateyron, B.; Ageorges, H.; El Ganaoui, M.; Fauchais, P. Predicting dynamic and thermal histories of agglomerated particles injected within a d.c. plasma jet. Surf. Coat. Technol. 2008, 202, 4491–4495. [Google Scholar] [CrossRef]

| Primary Gas Flow Rate N2 (L/min) | Secondary Gas Flow Rate H2 (L/min) | Current (A) | Voltage (V) |

|---|---|---|---|

| 39 | 10 | 500 | 75 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Zhang, Z.; Duan, Y.; Cui, H.; Gao, Y. Preparation of Yttria-Stabilized Zirconia Hollow Sphere with Reduced Shell Thickness by Controlling Ambient Temperature during Plasma Process. Coatings 2018, 8, 245. https://doi.org/10.3390/coatings8070245

Zhao L, Zhang Z, Duan Y, Cui H, Gao Y. Preparation of Yttria-Stabilized Zirconia Hollow Sphere with Reduced Shell Thickness by Controlling Ambient Temperature during Plasma Process. Coatings. 2018; 8(7):245. https://doi.org/10.3390/coatings8070245

Chicago/Turabian StyleZhao, Lina, Zhi Zhang, Yugang Duan, Hong Cui, and Yong Gao. 2018. "Preparation of Yttria-Stabilized Zirconia Hollow Sphere with Reduced Shell Thickness by Controlling Ambient Temperature during Plasma Process" Coatings 8, no. 7: 245. https://doi.org/10.3390/coatings8070245