Fluoropolymer-Wrapped Conductive Threads for Textile Touch Sensors Operating via the Triboelectric Effect

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

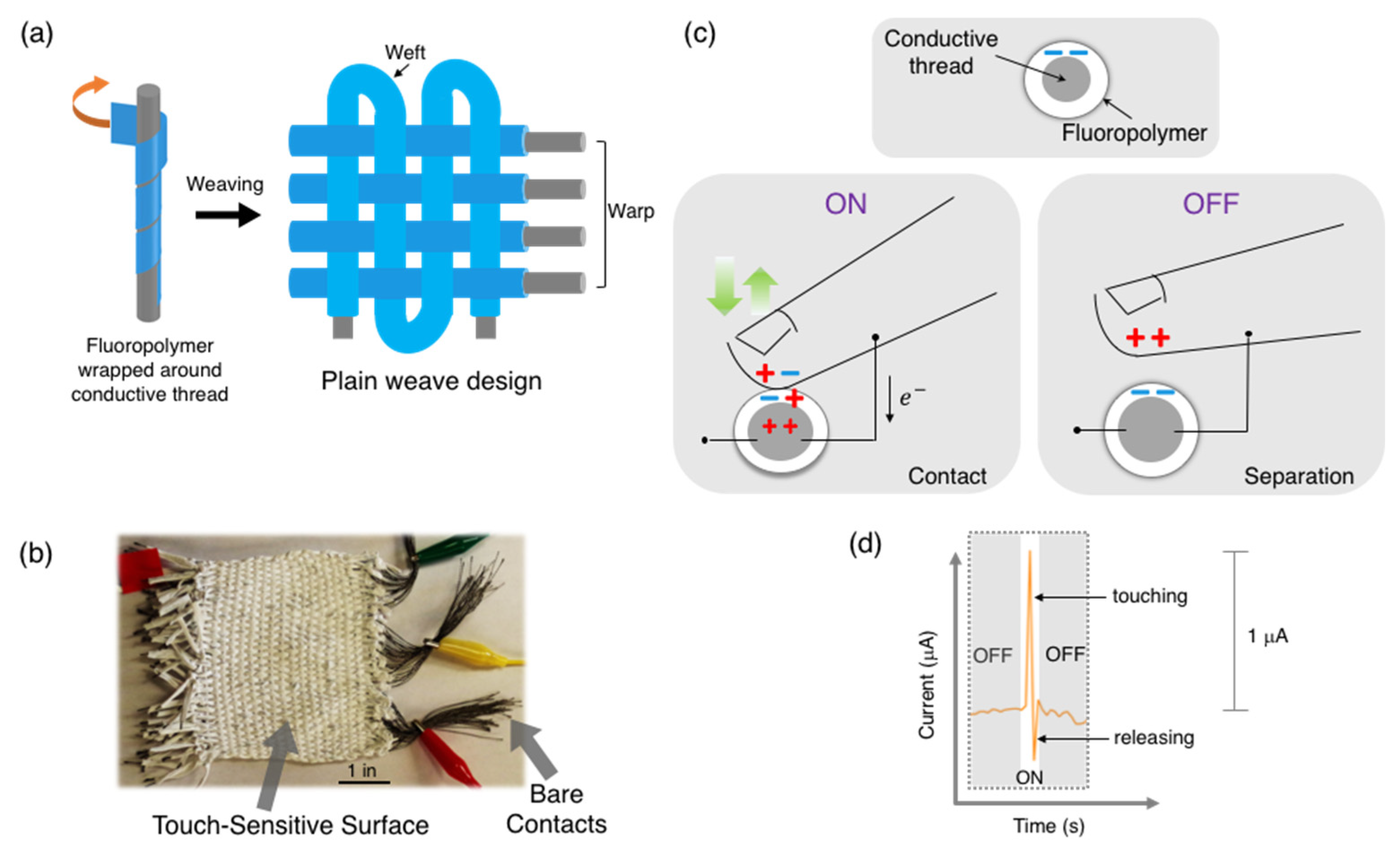

3.1. Fluoropolymer-Wrapped Conductive Threads

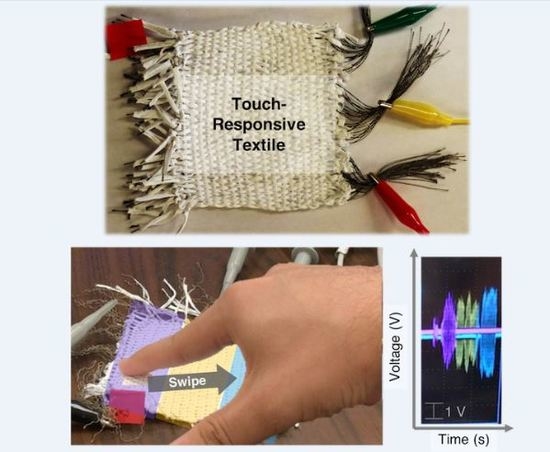

3.2. Plain-Woven Triboelectric Textile Touch Sensors

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Walker, G. A review of technologies for sensing contact location on the surface of a display. J. Soc. Inf. Disp. 2012, 20, 413–440. [Google Scholar] [CrossRef]

- Baxter, L.K. Capacitive Sensors: Design and Applications; Wiley: Hoboken, NJ, USA, 1996. [Google Scholar]

- Yuan, Z.; Zhou, T.; Yin, Y.; Cao, R.; Li, C.; Wang, Z.L. Transparent and flexible triboelectric sensing array for touch security applications. ACS Nano 2017, 11, 8364–8369. [Google Scholar] [CrossRef] [PubMed]

- Pu, X.; Liu, M.; Chen, X.; Sun, J.; Du, C.; Zhang, Y.; Zhai, J.; Hu, W.; Wang, Z.L. Ultrastretchable, trasparent triboelectric nanogenerator as electronic skin for biomechanical energy harvesting and tactile sensing. Sci. Adv. 2017, 3, e1700015. [Google Scholar] [CrossRef] [PubMed]

- Wijesiriwardana, R.; Mitcham, K.; Hurley, W.; Dias, T. Capacitive fiber-meshed transducers for touch and proximity-sensing applications. IEEE Sens. J. 2005, 5, 989–994. [Google Scholar] [CrossRef] [Green Version]

- Vallett, R.; Young, R.; Knittel, C.; Kim, Y.; Dion, G. Development of a carbon fiber knitted capacitive touch sensor. MRS Adv. 2016, 1, 2641–2651. [Google Scholar] [CrossRef]

- Roh, J.S. Textile touch sensors for wearable and ubiquitous interfaces. Text. Res. J. 2013, 84, 739–750. [Google Scholar] [CrossRef]

- Ferri, J.; Lidon-Roger, J.V.; Morena, J.; Martinez, G.; Garcia-Breijo, E. A wearable textile 2D touchpad sensor based on screen-printing technology. Materials 2017, 10, 1450. [Google Scholar] [CrossRef] [PubMed]

- Takamatsu, S.; Yamashita, T.; Imai, T.; Itoh, T. Fabric Touch Sensors using Projected Self-Capacitive Touch Technique. Sens. Mater. 2013, 25, 627–634. [Google Scholar]

- Büscher, G.H.; Kõiva, R.; Schürmann, C.; Haschke, R.; Ritter, H.J. Flexible and Stretchable Fabric-Based Tactile Sensor. Robot. Autonom. Syst. 2015, 63, 244–252. [Google Scholar] [CrossRef]

- Suen, M.; Lin, Y.; Chen, R. A Flexible Multifunctional Tactile Sensor using Interlocked ZnO Nanorod Arrays for Artificial Electronic Skin. Proc. Eng. 2016, 168, 1044–1047. [Google Scholar] [CrossRef]

- Tu, H.; Chen, X.; Feng, X.; Xu, Y. A post-CMOS compatible smart yarn technology based on SOI wafers. Sens. Actuators A 2015, 233, 397–404. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Yang, Y. Hybridized nanogenerator for simultaneously scavenging mechanical and thermal energies by electromagnetic-triboelectric-thermoelectric effects. Nano Energy 2016, 26, 164–171. [Google Scholar] [CrossRef]

- Lee, K.; Yoon, H.; Jiang, T.; Wen, X.; Seung, W.; Kim, S.; Wang, Z.L. Fully packages self-powered triboelectric pressure sensor using hemispere-array. Adv. Energy Mater. 2016, 6, 1502566. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Dong, L.; Han, X.; Du, W.; Zhai, J.; Pan, C.; Wang, Z.L. Self-powered high-resolution and pressure-sensitive triboelectric sensor matrix for real-time tactile mapping. Adv. Mater. 2016, 28, 2896–2903. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Yu, Y.; Eyer, G.P.; Suo, G.; Kozik, L.A.; Fairbanks, M.; Wang, X.; Andrew, T.L. All-textile triboelectric generator compatible with traditional textile process. Adv. Mater. Technol. 2016, 1, 1600147. [Google Scholar] [CrossRef]

- Thomas, S.W., III; Vella, S.J.; Dickey, M.D.; Kaufman, G.K.; Whitesides, G.M. Controlling the kinetics of contact electrification with patterned surfaces. J. Am. Chem. Soc. 2009, 131, 8746–8747. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baima, M.; Andrew, T.L. Fluoropolymer-Wrapped Conductive Threads for Textile Touch Sensors Operating via the Triboelectric Effect. Fibers 2018, 6, 41. https://doi.org/10.3390/fib6020041

Baima M, Andrew TL. Fluoropolymer-Wrapped Conductive Threads for Textile Touch Sensors Operating via the Triboelectric Effect. Fibers. 2018; 6(2):41. https://doi.org/10.3390/fib6020041

Chicago/Turabian StyleBaima, Morgan, and Trisha L. Andrew. 2018. "Fluoropolymer-Wrapped Conductive Threads for Textile Touch Sensors Operating via the Triboelectric Effect" Fibers 6, no. 2: 41. https://doi.org/10.3390/fib6020041