The Complementary Perspective of System of Systems in Collaboration, Integration, and Logistics: A Value-Chain Based Paradigm of Supply Chain Management

Abstract

:1. Introduction

- Introduce the SoS as it relates to B2B process systems. It is argued that introducing SoS to the SCM field provides a supplement to the current SCM literature for better design, analysis and management of supply chains as complex SoS. While individual theories already in existence could explain aspects of supply chain phenomena, a SoS view could expand the lens used to examine B2B relationship processes. As coordinating activities lies at the heart of both SCM and SoS formulations, this paper will focus on collaboration and integration theories/concepts and discuss the influence and hierarchy of SoS into SCM, and thus enhance the current state of knowledge.

- Discuss the main attributes of complex systems from a SoS perspective. These attributes are characteristic of supply chain management and therefore create conditions that can cause failures and potential disastrous consequences for the system. There is some convergence regarding the attributes of SoS and SCM existing principles and concepts in the conventional supply chain management literature. However, there is still a list of SoS principles, and concepts that can be applied in SCM field.

- Detail the holistic systems based approach—that considers the spectrum of technology, organizational, managerial, human, social, policy, and political dimensions of the system domain—as well as illustrate how this approach parallels and supplements broader views of SCM. These elements of both SCM and SoS are particularly important as they capture the non-technical, relational factors contributing to B2B process failures. Thus, this conceptual research introduces the concept of SoS to the supply chain management domain to achieve four primary objectives:

- Consistent with the holistic paradigm that exists in SCM, the introduction of SoS—Systems theory, principles and concepts, can provide SCM scholars sources to stimulate more holistic decision making based on understating supply chains on a global level (holism).

- Identify cases where SCM and SoS have obscured commonalities and differences through jingle-jangle.

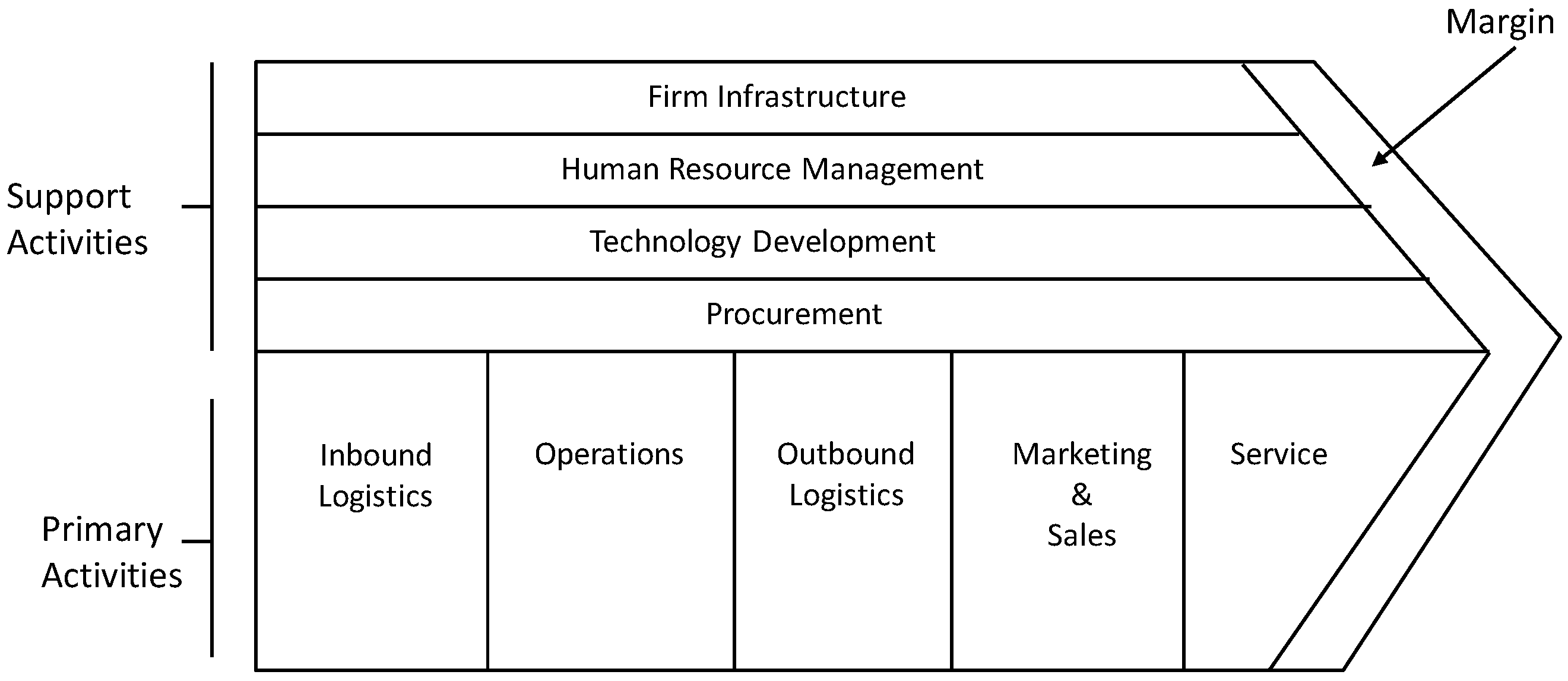

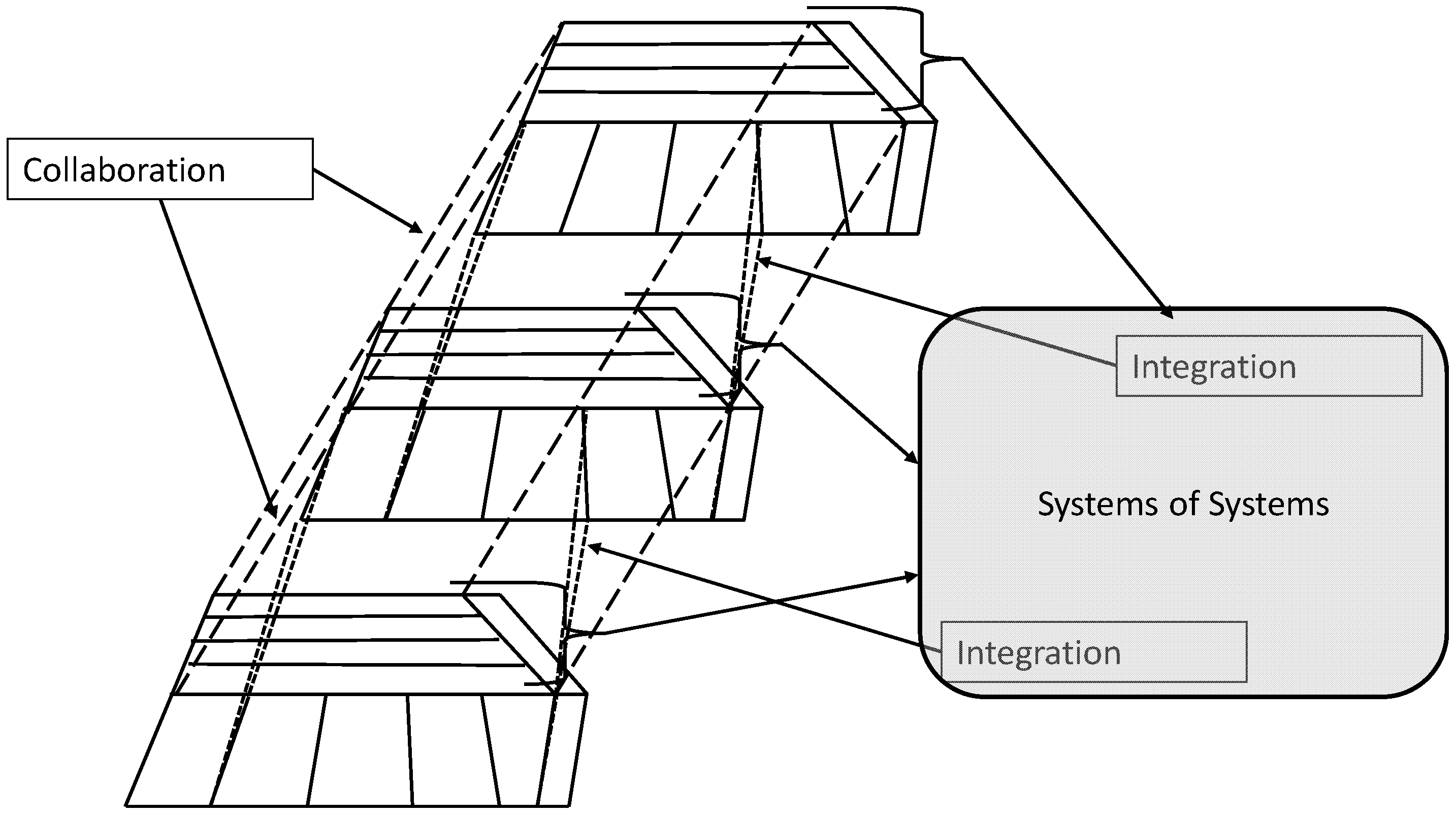

- Employ Porter’s Value Chain to link the domain of SoS with SCM conceptualizations related to collaboration and integration.

- Establish an emerging SCM paradigm based on a holistic approach. This paper looks at collaboration and integration concepts from a new perspective, and a theory originating from systems engineering domain, that is SoS engineering.

2. The Concept of System of Systems

3. Building a Context: SoS Attributes

3.1. Interconnectivity

3.2. Integration

3.3. Evolutionary Development

3.4. Emergence

3.5. Complexity

3.6. Ambiguity and High Level of Uncertainty

- Explicit articulation of the system (of systems)—this would have identified directly the issues related to capacity, interrelationships, boundaries, and resources.

- Environmental scanning and knowledge processing—this would provide a ‘systemic’ design for early identification, assessment, and response to environmental perturbations. The result would be increased time for mounting more effective responses to supply chain issues stemming from environmental shifts.

- Integration of multiple systems—this would have provided an emphasis and focus on purposeful integration of multiple, potentially disparate, systems to perform as a unity (integrated supply chain).

- Tension between integration and autonomy—Balance must be achieved between the desires for autonomy by member systems with the integration necessary for performance of the larger system.

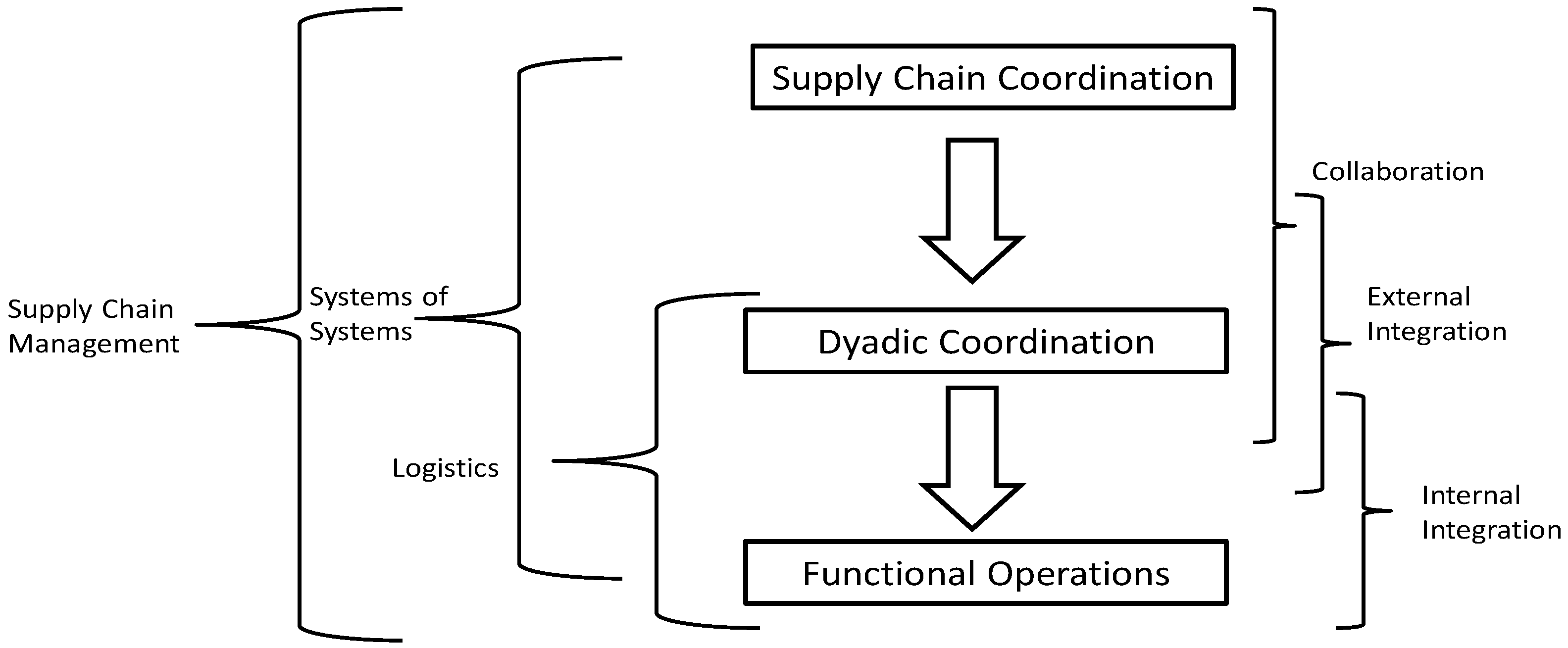

4. Collaboration and Integration Theories as the Coordinating Features of Supply Chains

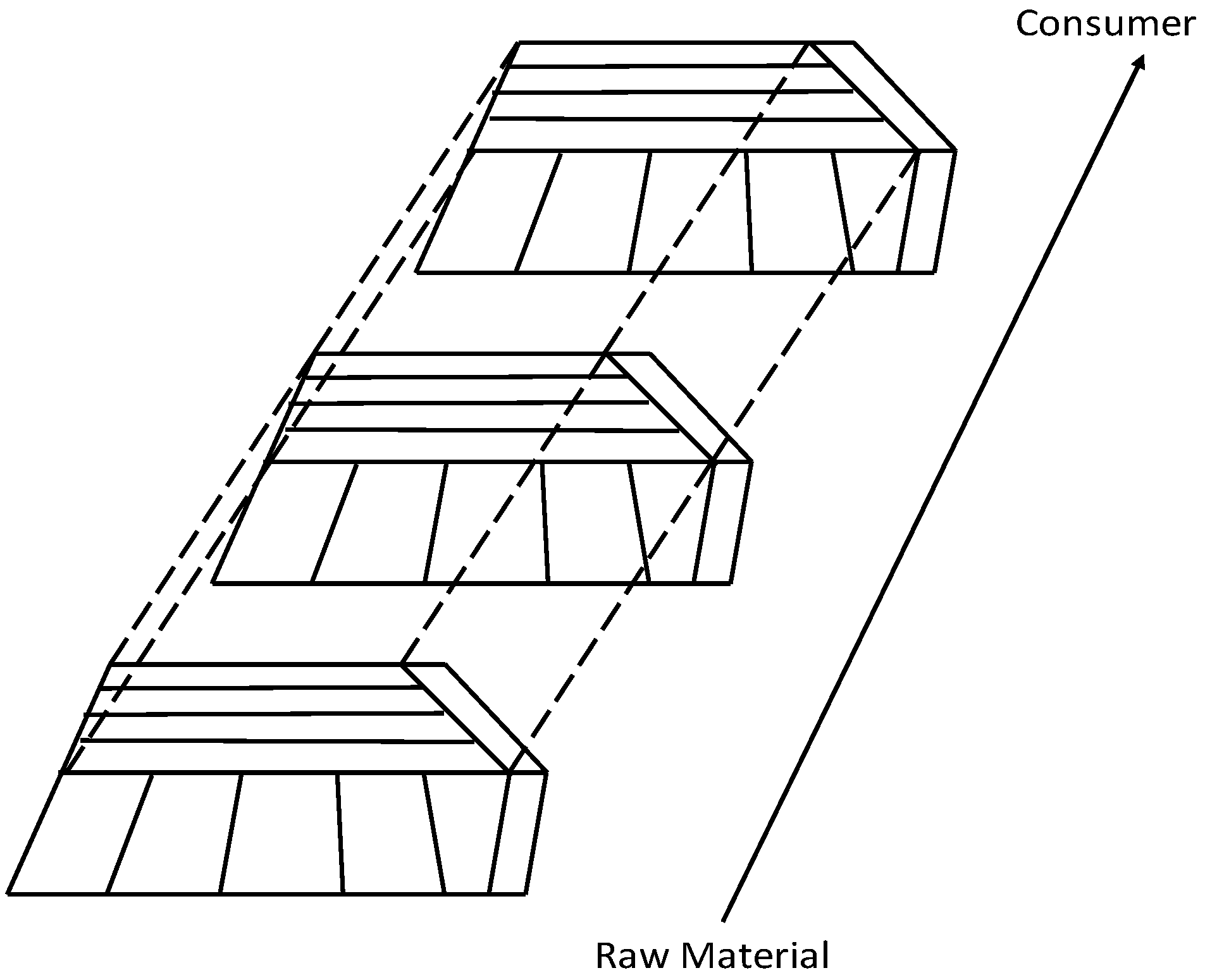

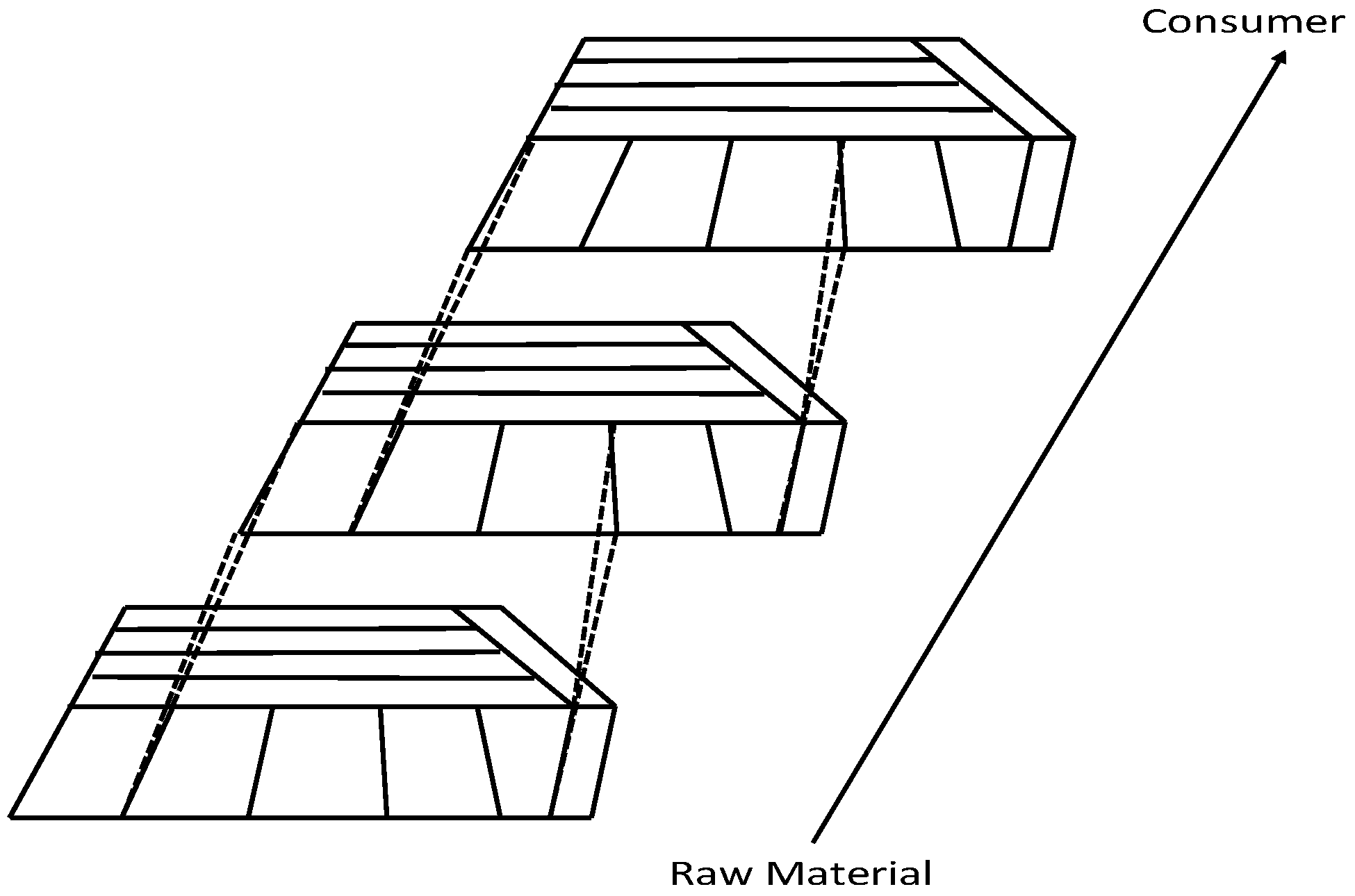

5. A Value-Chain View of Collaboration and Integration in Supply Chains

6. The Complementary Perspective of SoS in SCM

- I.

- SoS provides a sound theoretical basis for further development of supply chain management study. By supplementing supply chain management thought and practice with the underlying Systems Theory upon which SoS is based, a broader set of language, thinking, and corresponding methods can be introduced in SCM, perhaps more fully capturing and addressing the problem. Therefore, the exposure of supply chain management to a new and wider array of systems theory based concepts may prove insightful for consideration related to supply chain management. For example, concepts and principles such as holism, eighty-twenty principle, homeostasis principle, basin of stability system principle self-organization, requisite saliency, requisite parsimony, and emergence certainly offer an expansion of the language and corresponding conceptualization of supply chain management problems faced by practitioners (See Table 6). The systems based language and concepts may provide a different framing of familiar supply chain management issues for practitioners. The basis of this underlying systems language and practical utility can be found in the work of ([58,67,74,75,76,77,83,93,94]) and others. Therefore, with application of complementary systemic thinking/language alternative decisions, action, and interpretations can invoke different ‘system-based’ paths forward to previously intractable supply chain management problems.

- II.

- SoS provides access to a host of systems-based approaches for dealing with modern complex systems and their problems. Such exposure to this wider array of possible systems-based approaches (e.g., viable system model, complex system governance, soft systems methodology) can add to the (systems-based) approaches available to practitioners of supply chain management. A primary entry point for SoS application to supply chain management can be found in the SoS engineering methodology [95]. This methodology provides a strong initial framing of the problem domain for a system of interest. This opens an entirely new set of methodologies and corresponding methods, tools, and techniques that can be embedded with current SCM tools, for supply chain management professionals. Based on the conceptual hierarchy of SCM Domains and SoS, we present some implications for supply chain management from a SoS perspective. (See Table 8).

7. Case Example

8. Conclusions and Limitations

- Increasing complexity of supply chains demands new thinking, methods, and tools—approaches to supply chains based in reductionist analysis are not likely to have the success they have had in the past. Reductionist analysis proceeds from the assumption that the understanding of a system is not lost from the successive breaking of the system to smaller constituent elements. For supply chains an example would be to assume that a complex supply chain can ‘reduced’ to the point that optimization techniques could be applied. While this assumption may be appropriate for some supply chains, for truly complex supply chains is may be incapable of addressing complexities in supply chains dominated by irreducible factors (e.g., power, politics, divisive relationships) that cannot be analyzed our understood (i.e., reduced) by traditional means (e.g., supply chain optimization). The new environment for supply chains is dominated by conditions of emergence, uncertainty, and ambiguity. These conditions are no longer the exception, but are now the dominant characterization of modern supply chains.

- System of systems ‘holistic’ systems theoretic based paradigm offers SCM a fruitful path forward to accelerate development—incorporation of SoS and the underlying complex systems paradigm offers the emerging SCM field a chance to accelerate development in new and novel ways. The inclusion of both ‘hard’ and ‘soft’ systems thinking are more indicative of the realities faced by practitioners in SCM. The SoS field brings a strong heritage of effectively including holistic appreciation of complexities that are the hallmarks of modern supply chains.

- Supply Chain Management can be enhanced for practitioners by inclusion of existing models, methodologies, and techniques from SoS and related systems based fields—there is a rich theoretical, methodological, and practice basis that demark the SoS field and associated systems based approaches. Inclusion of these perspectives and approaches can amplify the effectiveness of practitioners that must contend with increasingly complex supply chains. This does not preclude the inclusion and appreciation of the prior knowledge generated and successfully applied to SCM. On the contrary, this inclusion only serves to extend SCM capabilities, thinking, and maturation of the field by incorporation of SoS.

Author Contributions

Conflicts of Interest

References

- Jaradat, R.; Keating, C. Fragility of oil as a complex critical infrastructure problem. Int. J. Crit. Infrastruct. Prot. 2014, 7, 86–99. [Google Scholar] [CrossRef]

- Jaradat, R.M.; Pinto, A.C. Development of a framework to evaluate human risk in a complex problem domain. Int. J. Crit. Infrastruct. 2015, 11, 1–19. [Google Scholar] [CrossRef]

- Kuhns, T.S. The Structure of Scientific Revolutions, 3rd ed.; University of Chicago Press: Chicago, IL, USA, 1996. [Google Scholar]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.W.; Zacharia, Z.G. Defining supply chain management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Cooper, M.C.; Lambert, D.M.; Pagh, J.D. Supply chain management: More than a new name for logistics. Int. J. Logist. Manag. 1997, 8, 1–14. [Google Scholar] [CrossRef]

- Carter, C.R.; Easton, P.L. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Esper, T.L.; Ellinger, A.E.; Stank, T.P.; Flint, D.J.; Moon, M. Demand and supply integration: A conceptual framework of value creation through knowledge management. J. Acad. Market. Sci. 2010, 38, 5–18. [Google Scholar] [CrossRef]

- Christopher, M. Logistics and Supply Chain Management; Pitman Publishing: London, UK, 1992. [Google Scholar]

- Cox, A. Business Success; Earlsgate Press: Bath, UK, 1997. [Google Scholar]

- Drucker, P.F. Management’s New Paradigms. Forbes Mag. 1998, 5, 152–177. [Google Scholar]

- Jaradat, R.M.; Keating, C.B.; Bradley, J.M. A histogram analysis for system of systems. Int. J. Syst. Syst. Eng. 2014, 5, 193–227. [Google Scholar] [CrossRef]

- Smuts, J. Holism and Evaluation; Macmillan: London, UK, 1926. [Google Scholar]

- Ackoff, R. Towards a system of systems concepts. Manag. Sci. 1971, 17, 661–672. [Google Scholar] [CrossRef]

- Beer, S. The Heart of Enterprise; John Wiley and Sons: New York, NY, USA, 1979. [Google Scholar]

- Northrop, L.; Feiler, P.; Gabriel, R.P.; Goodenough, J.; Linger, R.; Longstaff, T.; Wallnau, K. Ultra-Large-Scale Systems; The Software Challenge of the Future: Pittsburgh, PA, USA, 2006. [Google Scholar]

- Shenhar, A.; Bonen, Z. The new taxonomy of systems: Toward an adaptive systems engineering framework. IEEE Trans. Syst. Man Cybern Part A 1997, 27, 137–145. [Google Scholar] [CrossRef]

- Eisner, H. RCASSE: Rapid computer-aided systems of systems (S2) Engineering. In Proceedings of the 3rd INCOSE International Symposium Council Systems Engineering, Arlington, VA, USA, 26–28 July 1993; pp. 267–273. [Google Scholar]

- Keating, C.; Rogers, R.; Unal, R.; Dryer, D.; Sousa-Poza, A.; Safford, R.; Peterson, W.; Rabadi, G. System of systems engineering. Eng. Manag. J. 2003, 15, 36–45. [Google Scholar] [CrossRef]

- Keating, C.B.; Katina, P.F. Systems of systems engineering: Prospects and challenges for the emerging field. Int. J. Syst. Syst. Eng. 2011, 2, 234–256. [Google Scholar] [CrossRef]

- Jaradat, R. Complex system governance requires systems thinking—How to find systems thinkers. Int. J. Syst. Syst. Eng. 2015, 6, 53–70. [Google Scholar] [CrossRef]

- Jaradat, R.; Keating, C.; Bradley, J. Individual Capacity and Organizational Competency for Systems Thinking. IEEE Syst. J. 2017. [Google Scholar] [CrossRef]

- Strauss, A.; Corbin, J. Basics of Qualitative Research: Grounded Theory Procedures and Techniques; Sage: Newbury Park, CA, USA, 1990. [Google Scholar]

- Krygiel, A.J. Behind the Wizard’s Curtain. An Integration Environment for a System of Systems; Office of the Assistant Secretary of Defense Washington DC Command and Control Research Program (CCRP): Washingtong, DC, USA, 1999. [Google Scholar]

- Frohlich, M.T.; Westbrook, R. Arcs of integration: An international study of supply chain strategies. J. Oper. Manag. 2001, 19, 185–200. [Google Scholar] [CrossRef]

- Whitten, S.M.; Hertzler, G.; Strunz, S. How real options and ecological resilience thinking can assist in environmental risk management. J. Risk Res. 2012, 15, 331–346. [Google Scholar] [CrossRef]

- Germain, R.; Claycomb, C.; Dröge, C. Supply chain variability, organizational structure, and performance: The moderating effect of demand unpredictability. J. Oper. Manag. 2008, 26, 557–570. [Google Scholar] [CrossRef]

- Barratt, M.; Oke, A. Antecedents of supply chain visibility in retail supply chains: A resource-based theory perspective. J. Oper. Manag. 2007, 25, 1217–1233. [Google Scholar] [CrossRef]

- Mastrocinque, E.; Yuce, B.; Lambiase, A.; Packianather, M.S. A System of Systems Approach to Supply Chain Design. Appl. Mech. Mater. 2014, 496, 2807–2814. [Google Scholar] [CrossRef]

- Baker, S.W.; Ivanov, G. In the Crossfire: Critical Infrastructure in the Age of Cyber War; McAfee Report; McAfee: Santa Clara, CA, USA, 2009. [Google Scholar]

- Reschly, A.L.; Christenson, S.L. Jingle, Jangle, and Conceptual Haziness: Evolution and Future Directions of the Engagement Construct; Springer: New York, NY, USA, 2012. [Google Scholar]

- Bowersox, D.J.; Smykay, E.W.; LaLonde, B.J. Physical Distribution Management: Logistics Problems of the Firm; Macmillan: New York, NY, USA, 1968. [Google Scholar]

- Lambert, D.M.; Burduroglu, R. Measuring and selling the value of logistics. Int. J. Logist. Manag. 2000, 11, 1–17. [Google Scholar] [CrossRef]

- Spekman, R.; Kamauff, J.; Myhr, N. An empirical investigation into supply chain management: A perspective on partnerships. Supply Chain. Manag. Int. J. 1998, 3, 53–67. [Google Scholar] [CrossRef]

- Ellinger, A. Improving marketing/logistics cross-functional collaboration in the supply chain. Ind. Market. Manag. 2000, 29, 85–96. [Google Scholar] [CrossRef]

- Barratt, M. Unveiling enablers and inhibitors of collaborative planning. Int. J. Logist. Manag. 2004, 15, 73–90. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Magnan, G.; McCarter, M. A three-stage implementation model for supply chain collaboration. J. Bus. Logist. 2008, 29, 93–112. [Google Scholar] [CrossRef]

- Ellinger, A.; Keller, S.; Hansen, J. Bridging the divide between logistics and marketing: Facilitating collaborative behavior. J. Bus. Logist. 2006, 27, 1–27. [Google Scholar] [CrossRef]

- Sheffi, Y. Supply chain management under the threat of international terrorism. Int. J. Logist. Manag. 2001, 12, 1–11. [Google Scholar] [CrossRef]

- Stank, T.; Keller, S.; Daugherty, P. Supply chain collaboration and logistical service performance. J. Bus. Logist. 2001, 22, 29–48. [Google Scholar] [CrossRef]

- Shore, B.; Venkatachalam, A. Evaluating the information sharing capabilities of supply chain partners: A fuzzy logic model. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 804–824. [Google Scholar] [CrossRef]

- Simatupang, T.; Sridharan, R. The collaboration index: A measure for supply chain collaboration. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 44–62. [Google Scholar] [CrossRef]

- Stefansson, G. Collaborative logistics management and the role of third-party service providers. Int. J. Phys. Distrib. Logist. Manag. 2006, 36, 76–92. [Google Scholar] [CrossRef]

- Min, S.; Kim, S.; Chen, H. Developing social identity and social capital for supply chain management. J. Bus. Logist. 2008, 29, 283–304. [Google Scholar] [CrossRef]

- Sabet, E.; Yazdani, B.; De Leeuw, S. Supply chain integration strategies in fast evolving industries. Int. J. Logist. Manag. 2017, 28, 29–46. [Google Scholar] [CrossRef] [Green Version]

- Mackelprang, A.W.; Robinson, J.L.; Bernardes, E.; Webb, S.G. The relationship between strategic supply chain integration and performance: A meta-analytic evaluation and implications for supply chain management research. J. Bus. Logist. 2014, 35, 71–96. [Google Scholar] [CrossRef]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Jayaram, J.; Tan, K. Supply chain integration with third-party logistics providers. Int. J. Prod. Econ. 2010, 125, 262–271. [Google Scholar] [CrossRef]

- Huo, B. The impact of supply chain integration on company performance: An organizational capability perspective. Supply Chain Manag. Int. J. 2012, 17, 596–610. [Google Scholar] [CrossRef]

- Huang, M.; Yen, G.; Liu, T. Reexamining supply chain integration and the supplier’s performance relationships under uncertainty. Supply Chain Manag. Int. J. 2014, 19, 64–78. [Google Scholar] [CrossRef]

- Vickery, S.K.; Jayaram, J.; Droge, C.; Calantone, R. The effects of an integrative supply chain strategy on customer service and financial performance: An analysis of direct versus indirect relationships. J. Oper. Manag. 2003, 21, 523–539. [Google Scholar] [CrossRef]

- Wong, C.Y.; Boon-Itt, S.; Yong, C.Y.W. The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. J. Oper. Manag. 2011, 29, 601–615. [Google Scholar] [CrossRef]

- Kannan, V.R.; Tan, K. Supply chain integration: Cluster analysis of the impact of span of integration. Supply Chain Manag. Int. J. 2010, 15, 207–215. [Google Scholar] [CrossRef]

- Chen, H.; Daugherty, P.J.; Landry, T.D. Supply chain process integration: A theoretical framework. J. Bus. Logist. 2009, 30, 27–46. [Google Scholar] [CrossRef]

- Richey, R.; Roath, A.S.; Whipple, J.M.; Fawcett, S.E. Exploring a governance theory of supply chain management: Barriers and facilitators to integration. J. Bus. Logist. 2010, 31, 237–256. [Google Scholar] [CrossRef]

- Wolf, J. Sustainable supply chain management integration: A qualitative analysis of the German manufacturing industry. J. Bus. Ethics 2011, 102, 221–235. [Google Scholar] [CrossRef]

- Zhang, M.; Huo, B. The impact of dependence and trust on supply chain integration. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 544–563. [Google Scholar] [CrossRef]

- Yu, W.; Jackobs, M.A.; Salisbury, W.D.; Enns, H. The effects of supply chain integration on customer satisfaction and financial performance: An organizational learning perspective. Int. J. Product. Econ. 2013, 146, 346–358. [Google Scholar] [CrossRef]

- Adams, F.G.; Richey, R.G.; Autry, C.W.; Morgan, T.R.; Gabler, C.B. Supply chain collaboration, integration, and relational technology: How complex operant resources increase performance outcomes. J. Bus. Logist. 2014, 35, 299–317. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York, NY, USA, 1985. [Google Scholar]

- Porter, M.E.; Millar, V.E. How information gives you competitive advantage. Harv. Bus. Rev. 1985, 63, 149–160. [Google Scholar]

- Narasimhan, R.; Kim, S.W. Information system utilization strategy for supply chain integration. J. Bus. Logist. 2001, 22, 51–75. [Google Scholar] [CrossRef]

- Sanders, N.; Premus, R. Modeling the relationship between firm IT capability, collaboration and performance. J. Bus. Logist. 2005, 26, 1–23. [Google Scholar] [CrossRef]

- Cavinato, J.L. A total cost/value model for supply chain competitiveness. J. Bus. Logist. 1992, 13, 285. [Google Scholar]

- Wisner, J.D. A structural equation model of supply chain management strategies and firm performance. J. Bus. Logist. 2003, 24, 1–26. [Google Scholar] [CrossRef]

- Xu, K.; Dong, Y. Information gaming in demand collaboration and supply chain performance. J. Bus. Logist. 2004, 25, 121–144. [Google Scholar] [CrossRef]

- DiMario, J.; Cloutier, R.; Verma, D. Applying frameworks to manage SoS Architecture. Eng. Manag. J. 2008, 20, 18–23. [Google Scholar] [CrossRef]

- Jamshidi, M. System of Systems Engineering—Principles and Applications; John Wiley & Sons: New York, NY, USA, 2009. [Google Scholar]

- Wojcik, L.A.; Hoffman, K.C. Systems of systems engineering in the enterprise context: A unifying framework for dynamics. In Proceedings of the 2006 IEEE/SMC International Conference on System of Systems Engineering, Los Angeles, CA, USA, 24–26 April 2006; pp. 8–15. [Google Scholar]

- Maier, M.W. Architecting principles for systems-of-systems. INCOSE Int. Symp. 1996, 6, 565–573. [Google Scholar] [CrossRef]

- Sheard, S.; Mostashari, A. Principles of Complex Systems for Systems Engineering. Syst. Eng. 2009, 12, 295–311. [Google Scholar] [CrossRef]

- Maier, M. Architecting principles for systems-of-systems. Syst. Eng. 1998, 1, 267–284. [Google Scholar] [CrossRef]

- Adams, K.M.; Hester, P.T.; Bradley, J.M.; Meyers, T.J.; Keating, C.B. Systems theory as the foundation for understanding systems. Syst. Eng. 2014, 17, 112–123. [Google Scholar] [CrossRef]

- Skyttner, L. General Systems Theory: Ideas and Applications; World Scientific: Singapore, 2001. [Google Scholar]

- Brooks, R.; Sage, A. System of systems integration and test. Inf. Knowl. Syst. Manag. 2006, 5, 261–280. [Google Scholar]

- Bar-Yam, Y.; Allison, M.; Batdorf, R.; Chen, H.; Generazio, H.; Singh, H.; Tucker, S. The characteristics and emerging behaviors system of systems. In NECSI: Complex Physical, Biological and Social Systems Project; New England Complex Systems Institute: Cambridge, MA, USA, 2004. [Google Scholar]

- Blanchard, B.; Fabrycky, W. Systems Engineering and Analysis; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Jackson, M. The system of systems methodologies: A guide to researchers. J. Oper. Res. Soc. 1993, 44, 208–209. [Google Scholar] [CrossRef]

- Bowler, D. General Systems Thinking; North Holland: New York, NY, USA, 1981. [Google Scholar]

- Sauser, B.; Boardman, J.; Gorod, A. System of systems management. In System of Systems Engineering-Innovation for the 21st Century; Jamshidi, M., Ed.; John Wiley & Sons: New York, NY, USA, 2008; pp. 2–25. [Google Scholar]

- Keating, C.B. Emergence in system of systems. In System of Systems Engineering-Innovation for the 21st Century; Jamshidi, M., Ed.; John Wiley &Sons: New York, NY, USA, 2008; pp. 169–190. [Google Scholar]

- Taylor, J.C.; Felten, D.F. Performance by Design: Sociotechnical Systems in North America; Prentice-Hall: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

- Gibson, J.; Scherer, W.; Gibson, J. How to do Systems Analysis; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Clemson, B. Cybernetics: A New Management Tool, 4nd ed.; CRC Press: New York, NY, USA, 1991. [Google Scholar]

- Simon, A.H. The Sciences of the Artificial; MIT Press: Cambridge, MA, USA, 1969. [Google Scholar]

- Watt, K.; Craig, P. Surprise, Ecological Stability Theory in C.S.; Wiley: New York, NY, USA, 1988. [Google Scholar]

- Cook, S.C.; Sproles, N. Synoptic views of defense Systems development. In Proceedings of the SETE 2000, Brisbane, Australia, 15–17 November 2000. [Google Scholar]

- Checkland, P. Systems Thinking, Systems Practice, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Sage, A. Systems Engineering; Wiley: New York, NY, USA, 1992. [Google Scholar]

- Maani, K.; Cavana, R. Systems Thinking and Modelling: Understanding Change and Complexity; Prentice Hall: Auckland, New Zealand, 2000. [Google Scholar]

- Flood, R.; Jackson, M. Creative Problem Solving: Total Systems Intervention; Wiley: London, UK, 1991. [Google Scholar]

- Mason, R.; Mitroff, I. Challenging Strategic Planning Assumptions; Wiley: New York, NY, USA, 1981. [Google Scholar]

- Keating, C.B.; Katina, P.F.; Bradley, J.M. Complex system governance: Concept, challenges, and emerging research. Int. J. Syst. Syst. Eng. 2014, 5, 263–288. [Google Scholar] [CrossRef]

- Bertalanffy, L. General Systems Theory; Brazillier: New York, NY, USA, 1968. [Google Scholar]

- Boardman, J.; Sauser, B. Systems Thinking: Coping with 21st Century Problems; CRC Press: New York, NY, USA, 2008. [Google Scholar]

- Adams, K.; Mac, G.; Keating, C.B. Overview of the systems of systems engineering methodology. Int. J. Syst. Syst. Eng. 2011, 2, 112–119. [Google Scholar] [CrossRef]

- Waller, M.A.; Fawcett, S.E. Data science, predictive analytics, and big data: A revolution that will transform supply chain design and management. J. Bus. Logist. 2013, 34, 77–84. [Google Scholar] [CrossRef]

- Signori, P.; Flint, D.J.; Golici, S. Towards sustainable supply chain orientation (SSCO): Mapping managerial perspectives. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 536–564. [Google Scholar] [CrossRef]

- Mentzer, J.T.; Stank, T.P.; Esper, T.L. Supply chain management and its relationship to logistics, marketing, production, and operations management. J. Bus. Logist. 2008, 29, 31–46. [Google Scholar] [CrossRef]

- Gligor, D.M.; Holcomb, M.C. Antecedents and consequences of supply chain agility: Establishing the link to firm performance. J. Bus. Logist. 2012, 33, 295–308. [Google Scholar] [CrossRef]

- Richey, R.G.; Daugherty, P.J.; Roath, A.S. Firm technological readiness and complementarity: Capabilities impacting logistics service competency and performance. J. Bus. Logist. 2007, 28, 195–228. [Google Scholar] [CrossRef]

- Autry, C.W.; Grawe, S.J.; Daugherty, P.J.; Richey, R.G. The effects of technological turbulence and breadth on supply chain technology acceptance and adoption. J. Oper. Manag. 2010, 28, 522–536. [Google Scholar] [CrossRef]

- Stevenson, M.; Spring, M. Flexibility from a supply chain perspective: Definition and review. Int. J. Oper. Prod. Manag. 2007, 27, 685–713. [Google Scholar] [CrossRef]

- Kim, D.; Lee, R.P. Systems collaboration and strategic collaboration: Their impacts on supply chain responsiveness and market performance. Decis. Sci. 2010, 41, 955–981. [Google Scholar] [CrossRef]

| Attribute of Problem Domain | SoS Perspective | B2B Contribution |

|---|---|---|

| Quantifiable | Not easily | Consideration of complex system aspects of supply chains that are not easily quantifiable to support more holistic formulation of SCM considerations. |

| Structure | Emergent | Added emphasis on understanding and designing supply chains that are resilient across a broad spectrum of perturbations. |

| Analysis Approach | Holistic analysis | Extended consideration of the supply chain from a systemic (holistic) perspective that ranges across organizational, managerial, human, social, policy, and political dimensions. |

| Definition | Pluralism | Taking into account the variety of different, and potentially conflicting, perspectives concerning the supply chain as a system. Accounting for differences in interpretations of what constitutes the supply chain for purposes of systemic design, analysis, and development. |

| Environment | Turbulent | Appreciation of the complex turbulent nature of the environment within which the supply chain must operate. |

| Boundaries | Ambiguous | Understanding of the difficulties of establishing clear boundary conditions for a supply chain. This accounts for the dynamic, permeable, and continual shifting of boundaries for the supply chain. |

| Purpose | Consistent Reference Point | Supply chain continuity maintenance through the shared understanding of identity such that consistency in decisions, actions, and interpretations are supported by a common reference point. |

| Interval | Main Theme | Definition of SoS |

|---|---|---|

| Recognition of Complex System (1920–1969) | The term ‘holon’, which becomes a major tenant in SoS, was introduced. | [12] used the term ‘holon’ to describe SoS which is the whole and the parts of a system. |

| The Exploration of SoS (1970–1989). | Focus on the whole to understand complex systems. | “A set of interrelated or integrated elements.” ([13]). SoS is the integration of systems using a cybernetic perspective ([14], p.662). He used the term ‘metasystem’ to describe SoS. |

| The Revolution of SoS (1990–present) | Significant development of SoS field. Several perspectives, taxonomies, and methodologies have been proposed. | Large scale systems that should be considered as a whole to satisfy a specific mission [15]. |

| A network of interrelated systems working together to achieve a particular purpose. [16]. | ||

| The integration of multiple systems that is beyond the simple aggregation of individual systems [17]. |

| Problem | Description of the Problem | Core Issue | Relevant SoS Attributes | Relevant SCM Attributes |

|---|---|---|---|---|

| General Motors (1980s–1990) | GM suffered from financial loss after buying more than 300 unnecessary and rarely used robots similar to those they already had. This bad investment cost GM millions of dollars with no profit. | Rapid technological changes and evolving need. Shifting and dynamic environment with multiple competitors and unpredictable contextual issues | Evolutionary Development, Complexity, Emergence | Adaptability, Complexity, Variability, Transparency |

| Toys R US.com (1999) | The online retailer accepted large orders to be delivered on Christmas Day as promised. Because the thousands of orders were above the system’s capacity and resources, the company failed to deliver the orders on time and customers were irate | Mismatch of the system’s capabilities with the system’s resources. Unexpected large demand for the toys | Ambiguity and Uncertainty, Complexity, Emergence, Evolutionary Development | Ambiguity, Complexity, Adaptability, Variability, Transparency |

| Oil Industry (SCADA systems) | Attacks from hackers on SCADA systems can cause large-scale power outages and environmental disasters in addition to threatening the privacy of individuals. Based on Baker and Ivanov [29] report, the oil industry supply chain sector was reported to have the highest rate of distributed denial of service (DDoS) attacks, which have severe impacts on other systems and, therefore, cause harm to people. | Connections between the systems and their components in the oil industry are complex and ambiguous. The complex nature of the oil industry and the high level of interconnectivity create unexpected behavior such as the hackers attacks | Uncertainty, Complexity, Interconnectivity, Emergence, Ambiguity, Evolutionary Development, Integration | Ambiguity, Complexity, Integration, Adaptability, Variability, Transparency, Integration |

| Stuxnet Virus (2010) | In 2010 several Windows computers were attacked by the most serious cyber various in the world. This virus has a devastating impact on any supply chain in any sector. | Large number of hardware and software components, rich interactions, and unclear boundaries make it difficult to have a complete understanding of the system. This is a challenge to making appropriate decisions. | all the SoS attributes applied | Collaboration |

| Boeing Company (2010) | Using several suppliers from around the world to design the 787 Dreamliner aircraft caused Boeing to suffer a tremendous financial loss (billions of dollars), delays, and challenges to its supply chain system The causes of the problems can be traced to (1) a lack of visibility and management from the Boeing executives, (2) a mismatch between the allocation of resources such as work force, cost, time, expertise and the new system’s requirements (787 aircraft) and, (3) a high level of contextual influence (e.g., different suppliers’ worldviews) | The integration of multiple autonomous systems to design the new aircraft. Integration always produces new behaviors in the system, which in this example was considered a main reason for failure of the system. Lack of communication between the systems and their subsystems is another contributor to the failure | Integration, Emergence, Interconnectivity, Complexity | Integration, Adaptability, Integration, Complexity |

| Apple Power Book Laptops (1995–1997) | With the huge demand for its Mac laptops, Apple failed to fill and deliver all the orders and therefore lost approximately 1 billion dollars. The main reason for that loss was the inflexibility of Apple’s supply chain system. | Dynamic and shifting demand. Insufficient resources to handle the demand because of the lack of knowledge in understanding the system’s behavior and structure | Evolutionary Development, Complexity, Ambiguity and Uncertainty | Variability, Transparency, Complexity, Ambiguity |

| Author | Definition Quote | Page |

|---|---|---|

| Spekman et al. [33] | Collaboration requires high levels of trust, commitment and information sharing among supply chain partners. In addition, partners also share a common vision of the future. | 57 |

| Ellinger, [34] | Collaborative interdepartmental integration involves predominantly informal processes based on trust, mutual respect and information sharing, the joint ownership of decisions, and collective responsibility for outcomes. | 86 |

| Sheffi [38] | Collaboration among enterprises is what integrates the supply chain. | 9 |

| Stank et al. [39] | Collaboration is a process of decision making among interdependent parties. It involves joint ownership of decisions and collective responsibility for outcomes. | 31 |

| Shore and Venkatachalam [40] | Collaboration is defined here as the supplier’s ability to work in a close partnership with headquarters and its willingness to share a range of data from cost structures to scheduling and logistics. It manifests itself in attitudes that relate to a supplier’s integrity, trustworthiness, helpfulness in reducing costs, synergy with headquarters, and support of customer service. | 809 |

| Barratt [35] | … relationship based on information exchange in support of joint strategic, tactical and operational planning, forecasting and demand fulfillment processes. | 74 |

| Simatupang and Sridharan [41] | Supply chain collaboration is often defined as two or more chain members working together to create a competitive advantage through sharing information, making joint decisions, and sharing benefits which result from greater profitability of satisfying end customer needs than acting alone. Collaborative capability is the key ingredient in reaching external integration and cross-enterprise collaboration. | 45, 46 |

| Ellinger et al. [37] | Inter-functional collaboration is an informal, integrative work-management approach that involves departments working together, having a mutual understanding, sharing a common vision, sharing resources, and achieving goals collectively. | 3 |

| Stefansson [42] | Collaboration is a process of decision-making among interdependent parties. | 81 |

| Fawcett et al. [36] | SC Collaboration is defined here as the ability to work across organizational boundaries to build and manage unique value-added processes to better meet customer needs. [Supply chain] collaboration involves the sharing of resources-information, people, and technology-among [supply chain] members to create synergies for competitive advantage. Collaboration goes beyond managing transactions for efficiency to managing relationships for creativity and continuous improvement. | 93 |

| Min et al. [43] | Collaboration refers to a business process in which supply chain partners work together to achieve common goals that benefit them mutually. | 294 |

| Author | Definition Quote | Page |

|---|---|---|

| Kannan and Tan [52] | Supply chain integration (SCI) can be broadly defined as the extent to which supply chain members work cooperatively together to achieve mutually beneficial outcomes. | 207 |

| Chen et al. [53] | While SCM encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities, supply chain integration refers to linking major business functions and business processes within and across companies into a cohesive and high-performing business model. | 27 |

| Jayaram and Tan [47] | Supply chain integration refers to coordination mechanisms in the form of business processes that should be streamlined and interconnected both within and outside company boundaries. | 262 |

| Richey et al. [54] | ... integration is defined as a firm’s objective to attain operational and strategic efficiencies through collaboration among internal functions and with other firms. | 238 |

| Wolf [55] | The concept of supply chain integration asserts that the objectives of different functional areas and partners in a supply chain need to be arranged according to the same set of objectives in order to deliver the highest value to the customer. Poorly managed supply chains are characterized by one or more value creating processes working at cross purposes to other processes. | 222 |

| Wong et al. [51] | SCI [supply chain integration] is defined as the strategic collaboration of both intra-organizational and inter-organizational processes. We have collapsed SCI construct into three dimensions: customer, supplier and internal integration, to reflect its multidimensionality. | 605 |

| Huo [48] | SCI can be defined as the degree to which a firm can strategically collaborate with its SC partners and cooperatively manage intra- and inter-organisational processes to achieve effective and efficient flows of products, services, information, money, and decisions to provide the maximum value to the final customer with low costs and high speed. | 596 |

| Zhang and Huo [56] | SCI includes both economic actions, such as system alignment, information sharing, joint investments, and on-going inter-organizational social relationships among exchange partners. | 545 |

| Huang et al. [49] | SCI is a process of interaction and collaboration across firms that incorporate customers and suppliers into a cohesive supply network. A highly integrated supply chain can be a purposive integrated organisational entity that shapes the attraction, the selection, and the retention of the members of the collective; this type of supply chain can be referred to as a meta-organisation. | 65 |

| Mackelprang et al. [45] | A key aspect of strategic integration described in the literature is that it can confer both operational and strategic benefits, while operational integration can only confer operational benefits. | 72 |

| Systems Principle | Theme |

|---|---|

| Metasystem [80] | Provides the structure of relationships that integrate a system. Relieve the tensions between the autonomy of the subsystems and the integration of the higher level system. |

| Value Free Production | A system accords no value judgments to output or outcomes that it produces. There are no bad systems, just systems that disappoint the interpretation of the products they generate. |

| Equifinality [73] | There are multiple paths, from different initial conditions, that can result in the same output/outcomes for a complex system. |

| Minimum Critical Specification [81] | Determine the essential constrains to achieve the performance level required by a system. Over specification unnecessarily limits the flexibility in the operation of the system to respond to varying conditions. |

| Iteration [82] | The design and transformation of complex systems are interpretative process that continue to evolve with additional information and understanding of the system and context. |

| Self-organization [83] | The majority of the structural and behavioral patterns for a complex system only emerge after operation of the system in its environment (context). Unintended consequences can be mitigated through design for robust feedback, feedforward, and redundancy of critical system functions. |

| Basin of Stability [83] | A system will seek a level of stability (lowest energy state) unless acted on by external forces. The system will move to a new basin of stability (past a threshold) only when sufficient energy (resources) are applied to provide ‘momentum’ necessary to shift to the new basin of stability |

| System Control [14] | System control is best established as close as possible to the point at which decisive decision and action can be taken in response to variances to system performance. This encourages maximum autonomy (freedom and independence of decision, action, and interpretation) for system constituents in the best position to make timely decisions that can reduce variances at the point that they occur. |

| Satisficing Solutions [84] | Solutions to complex system problems should be focused not on achieving ‘optimal’ results (pursuit of a solution that exist above all others, regardless of other considerations, e.g., resources). Instead, pursuit of ‘satisficing’ (good enough) results. |

| Omnivory principle [85] | Stability in a complex system is achieved by having a greater number of different pathways for their flow to the main system components (i.e., modification of internal structures to enable intake of different resources. In other words, ‘don’t put all your eggs in one basket.’) |

| System Method(ology) | Major Theme | Potential Utility in SCM |

|---|---|---|

| Viable System Model, Beer [14] | Diagnosis of structural system functions, relationships, and communications channels necessary for any system to maintain existence. | An approach that can identify system structural deficiencies in the supply chain. Traces deficiency to performance of system functions and communication channels from a management cybernetics perspective. |

| Sociotechnical Systems, Taylor and Felten [81] | Work system analysis and redesign based on joint optimization of the social and technical subsystems for performing work. | Provides for examination of technical aspects of SCM issues and deficiencies of the social components of the SCM. Can establish a more comprehensive set of considerations for SCM development, including social as well as technical concerns. |

| Systems Engineering, Sage [88] | Structured formulation, analysis and interpretation of the technical, human, and organizational aspects of complex systems to address needs or resolve problems subject to cost, schedule, and operational performance constraints. | Treatment of supply chain problems from a systems perspective that seeks to understand SCM issues related to deficiencies across cost, schedule, and technical performance requirements. |

| System Dynamics, Maani and Cavana, [89] | Computer modeling and simulation approach to understand the relationships and underlying behavior of complex systems. | Can be influential in understanding the nature of relationships in the SC, particularly impacts across hard and soft variables that can influence system performance over time. Can examine potential SCM modifications for impacts prior to deployment. |

| Soft Systems Methodology, Checkland [87] | A process of inquiry focused on formulation of ill-structured problems appreciative of multiple perspectives. | Provides for a more comprehensive structuring of SCM problems rooted in the underlying system. Can be effective in identification of technically and culturally feasible improvements for problematic SCM issues. |

| Total Systems Intervention, Flood and Jackson [90] | A system problem solving approach based on creative thinking, appropriate method selection, and implementation of method based change proposals to resolve complex issues. | Can contribute to formulation of the SCM problem domain, and suggest appropriate systems based approach(es) that are most appropriate to the situation/system under consideration. |

| Strategic Assumption Surfacing and Testing, Mason and Mitroff [91] | Focuses on the resolution of ill-structured problems by identifying multiple stakeholders, their assumptions, and engaging in dialectical debate over proposed strategies to develop a higher-level course of action. | For SCM problems that involve multiple stakeholders, with potentially divergent or conflicting perspectives, can provide an approach to articulate and examine the problem(s)/situation. Can offer alternative formulations in ways that alternative paths forward might be identified. |

| Gibson’s Systems Analysis Methodology, Gibson, et al. [82] | Provides six iterative phases to study complex systems problems, including System Goals, Ranking Criteria, Alternative Development, Alternative Ranking, Iteration, and Action. | Offers SCM an approach to conduct rigorous systems-based generalization of the SC or problems and objective evaluation of different response alternatives. |

| Complex System Governance, Keating, et al. [92] | Design, execution, and development of nine metasystem functions responsible for achievement of control, communications, integration, and coordination that produces system performance such that viability [existence] is maintained. | Can provide for comprehensive identification and assessment of systems based pathologies (issues) that occur in the SC functions. Emphasis on implications for redesign, execution modification, and SC development can be achieved. |

| Complex System Problem Domain | Description | Implications for Supply Chain Management | Paralleling Research or Research Calls in Supply Chain Management |

|---|---|---|---|

| Information Proliferation | Expansion of information intensive systems and technologies and exponential rise in information. | Criticality of robust design for information as a key artifact that is both consumed and produced throughout a supply chain. | Big Data [96] |

| Divergent Stakeholders | Multiple stakeholders with potentially incompatible worldviews and divergent objectives, often politically driven. | An assumption of unitary perspectives and objectives within the supply chain is naïve. Care must be taken to understand multiple, and potentially conflicting perspectives. | Sustainable Supply Chain Management [97] |

| Unstable Resources | Scarce and dynamically shifting resources that create a source of uncertainty and potential instabilities in operations. | Realities of the supply chain dictate that resources may be unstable and that sufficient redundancy should be built to preclude single points of resource failure. | Risk Management [98] |

| Emergence Domination | Constantly shifting conditions and emergent understanding of problems and context dominate the landscape. Assumptions of stable development of requirements and well understood life cycle driven approaches are unrealistic. | Future supply chains will not be capable of full understanding, explanation, or necessarily stable planning. Focus must be on robust designs that are built to respond to a wide range of unplanned emergent conditions and disruptions. | Agility [99] Adaptability [25] |

| Technology Integration | Technology advancements that outpace the capabilities, and potential compatibility, of infrastructures necessary to support their development, integration, maintenance, and evolution. | Technology is necessary, but not sufficient, to effectiveness in supply chain management. Technology must be considered in relation to the holistic spectrum of organizational, social, policy, and political implications. | Technological Readiness [100]. Technological Turbulence [101]. |

| Demands for Responsive Action | Urgency in demands for responsive action and solution development to alleviate mission shortfalls. | Supply chain decisions, actions, and interpretations initiated out of urgency must take into account deeper and longer range potential impacts on the overall supply chain. | Flexibility [102]. Responsiveness [103]. |

| Sacrifice of the Long View | Abdication of long term thinking in response to immediate perceived operational needs—rendering traditional forms of long range planning virtually innocuous | Balance must be achieved between urgent short term thinking and important long term thinking. Tension between these can help the supply chain to both perform near term and maintain fruitful trajectory. | Supply Chain Orientation [4] |

| Unstable Planning | Increasing complexities and uncertainties question the ability of traditional systematic planning approaches, based in assumptions of stability, to effectively plan for present and future operations. | Planning for supply chains must consider the level of stability for the planning horizon. Increased emphasis on planning designs that are sufficiently robust and reconfigurable to adjust to the rate of change in the supply change. | Adaptability [25]. Responsiveness [103]. |

| 6 SoS Functions | 8 SoS Communications Channels and Responsibility | Implications to B2B Process (Collaboration and Integration) |

|---|---|---|

| Policy and Identity Function: Focuses on overall steering and trajectory for the system. Focuses on the specific context within which the system is embedded (set of factors, circumstances, conditions, or patterns that enable or constrain execution of the system). | Command and dialog Channels:

| External Collaboration and Relational Governance:

|

| Strategic System Monitoring Function: Focuses on oversight of the system performance indicators at a strategic level and identifies performance that exceeds or fails to meet established expectations. | Algedonic Channel:

| Modularity/Flexibility:

|

| System development, learning and transformation Function: Maintains the models of the current and future system, concentrating on the long range development of the system to ensure future viability. | Learning Channel:

| Market Orientation:

|

| Environmental Scanning Function: Designs, deploys, monitors, and communicates sensing of the environment for trends, patters, or events with implications for both present and future system viability. | Scanning Channel:

| Market Orientation:

|

| Systems Operations and performance Function: Focuses on the day-to-day execution to ensure that the overall system maintains established performance level. Identifies and assesses aberrant conditions, exceeded thresholds or anomalies. | Resource bargain/integration Channel:

| Internal Collaboration/ Integration and S&OP:

|

| Information and communications Function: Designs, establishes, and maintains the flow of information and consistent interpretation of exchanges (communication channels) necessary to execute the SoS functions. | Informing Channel:

| Internal Collaboration/ Integration and S&OP:

|

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaradat, R.; Adams, F.; Abutabenjeh, S.; Keating, C. The Complementary Perspective of System of Systems in Collaboration, Integration, and Logistics: A Value-Chain Based Paradigm of Supply Chain Management. Systems 2017, 5, 50. https://doi.org/10.3390/systems5040050

Jaradat R, Adams F, Abutabenjeh S, Keating C. The Complementary Perspective of System of Systems in Collaboration, Integration, and Logistics: A Value-Chain Based Paradigm of Supply Chain Management. Systems. 2017; 5(4):50. https://doi.org/10.3390/systems5040050

Chicago/Turabian StyleJaradat, Raed, Frank Adams, Sawsan Abutabenjeh, and Charles Keating. 2017. "The Complementary Perspective of System of Systems in Collaboration, Integration, and Logistics: A Value-Chain Based Paradigm of Supply Chain Management" Systems 5, no. 4: 50. https://doi.org/10.3390/systems5040050