Impact of Fecal Sludge and Municipal Solid Waste Co-Compost on Crop Growth of Raphanus Sativus L. and Capsicum Anuum L. under Stress Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Co-Compost Production

2.2. Fertilizer Treatments

2.3. Trial Setup

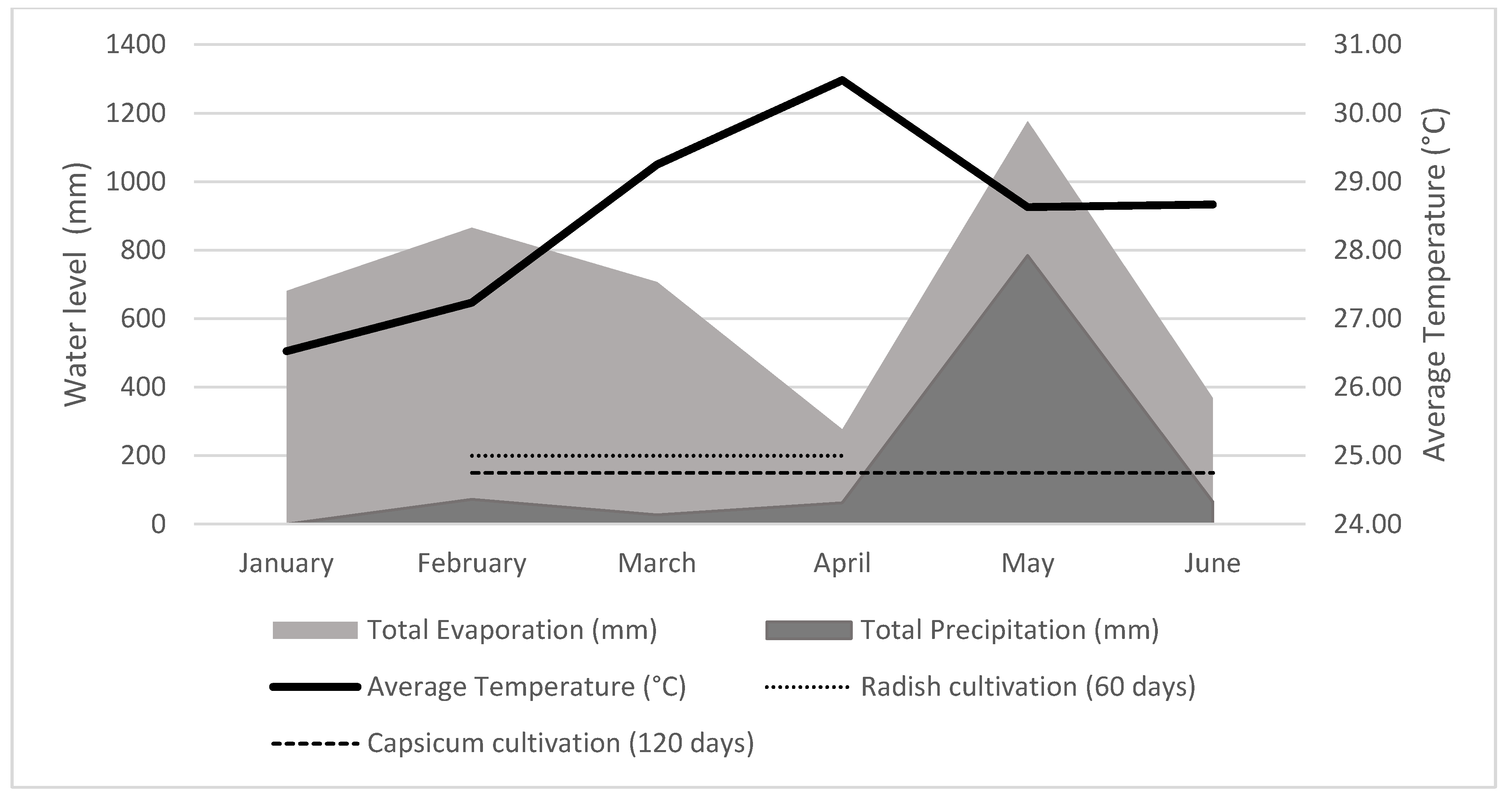

2.4. Trial Site

2.5. Parameters

2.6. Fertilizer Cost-Benefit-Analysis

2.7. Statistical Analysis

3. Results

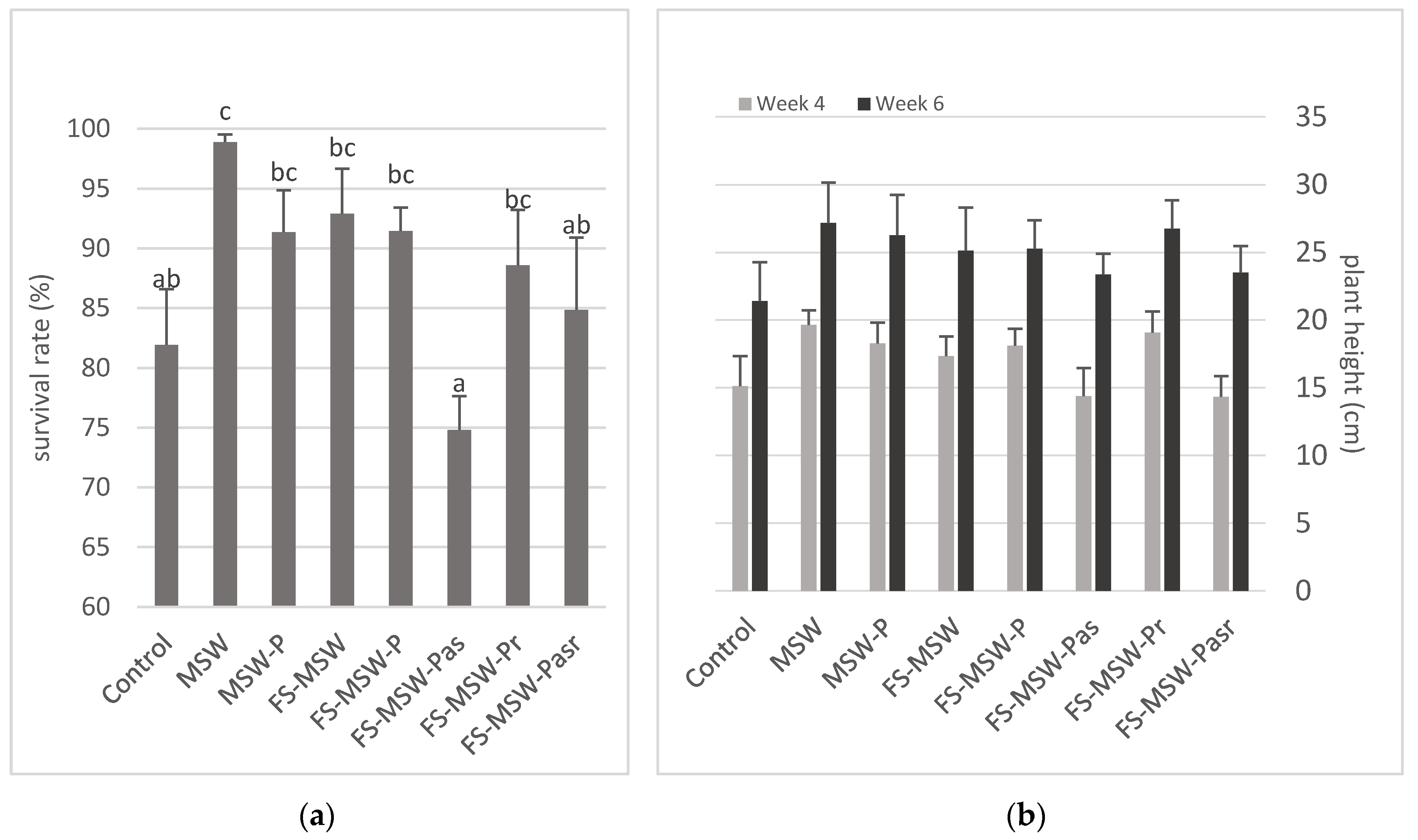

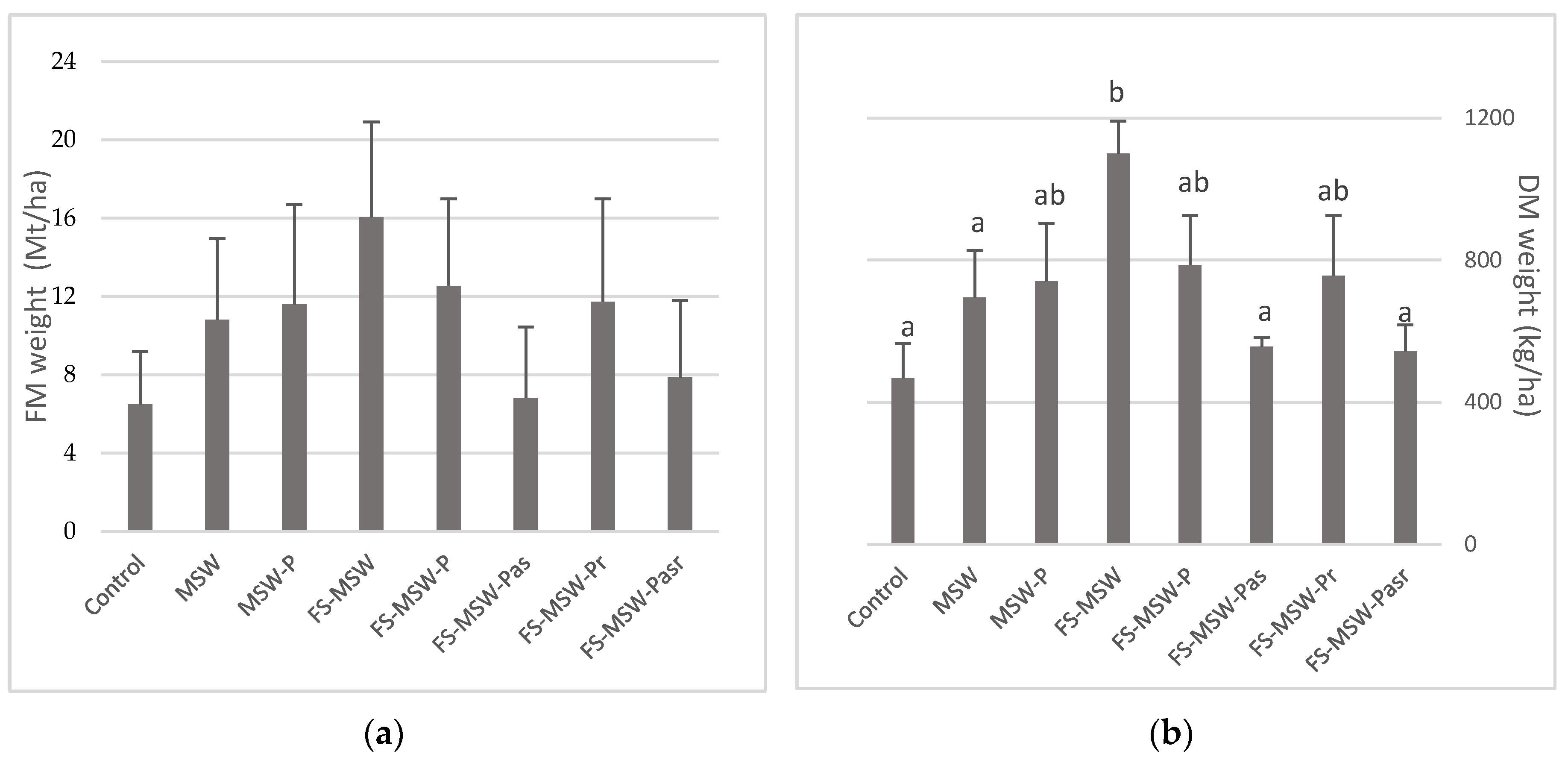

3.1. Raphanus sativus

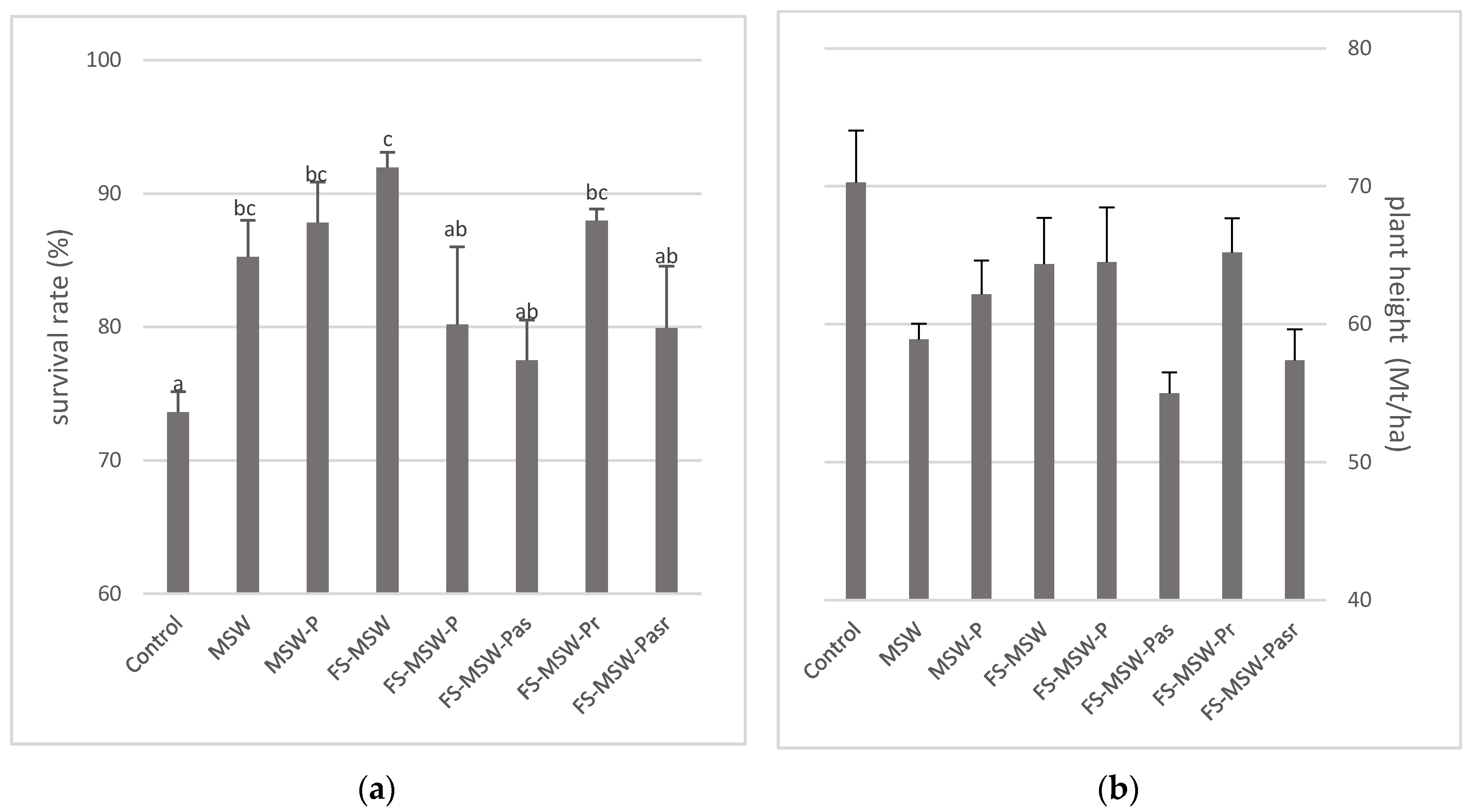

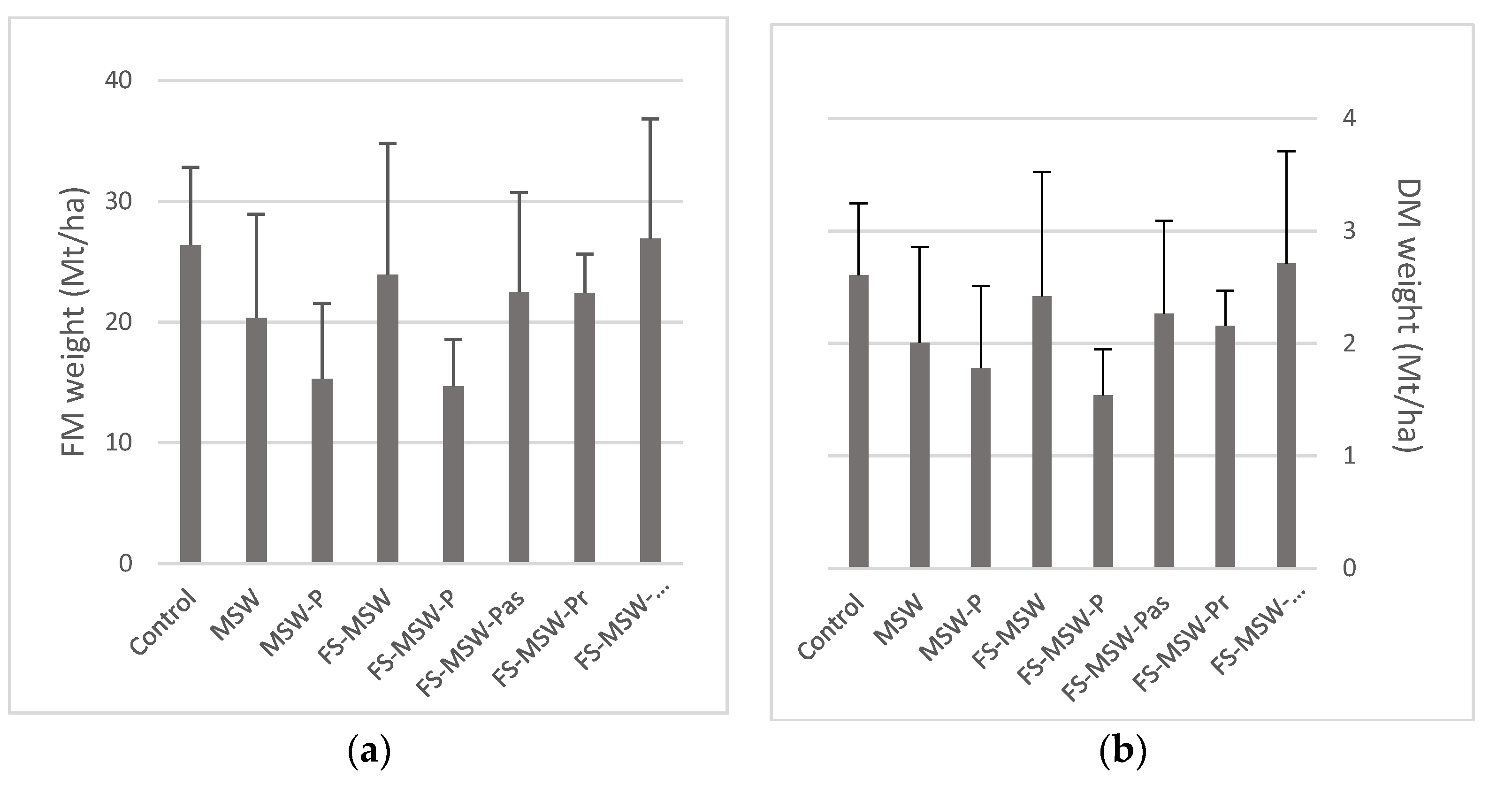

3.2. Capsicum anuum

3.3. Cost-Benefit Analysis

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Eheliyagoda, D.; Prematilake, N. Assessment of a planned Municipal Waste Management System in Sri Lanka. J. Appl. Sci. Envrion. Manag. 2016, 20, 58061. [Google Scholar] [CrossRef]

- Meinzinger, F. Resource Efficiency of Urban Sanitation Systems: A Comparative Assessment Using Material and Energy Flow Analysis. Ph.D. Thesis, University of Hamburg, Hamburg, Germany, 2010. [Google Scholar]

- Lal, R. Soils and world food security. Soil Tillage Res. 2009, 102, 1–4. [Google Scholar] [CrossRef]

- Horn, R.; Blume, H.-P.; Brümmer, G.W.; Fleige, H.; Horn, R.; Kandeler, E.; Kögel-Knabner, I.; Kretzschmar, R.; Stahr, K.; Wilke, B.-M. Scheffer/Schachtschabel Soil Science; Springer: Berlin Heidelberg, Germany, 2015. [Google Scholar]

- Wimalawansa, S.A.; Wimalawansa, S.J. Impact of changing agricultural practices on human health: Chronic kidney disease of multi-factorial origin in Sri Lanka. Wudpecker J. Agric. Res. 2014, 3, 110–124. [Google Scholar]

- Cofie, O.; Nikiema, J.; Impraim, R.; Adamtey, N.; Paul, J.; Koné, D. Co-composting of Solid Waste and Fecal Sludge for Nutrient and Organic Matter Recovery; Resource Recovery and Reuse Series 3; IWMI: Colombo, Sri Lanka, 2016. [Google Scholar]

- Grau, F.; Drechsel, N.; Trautz, D.; Weerakody, J.; Ranaweera, B. Fertiliser Derived from Fecal Sludge in Sri Lanka: Analysis of Plant Nutritional Value and Heavy Metal Contamination. In Proceedings of the Tropentag, Vienna, Austria, 19–21 September 2016. [Google Scholar]

- Strauss, M. Human Waste (Excreta and Wastewater) Reuse; EAWAG/SANDEC: Duebendorf, Switzerland, 2000. [Google Scholar]

- Nikiema, J.; Cofie, O.; Impraim, R. Technological Options for Safe Resource Recovery from Fecal Sludge; Resource Recovery and Reuse Series 2; IWMI: Colombo, Sri Lanka, 2014. [Google Scholar]

- Hargreaves, J.C.; Adl, M.S.; Warman, P.R. A review of the use of composted municipal solid waste in agriculture. Agric. Ecosyst. Environ. 2008, 123, 1–14. [Google Scholar] [CrossRef]

- Soumare, M.; Tack, F.M.G.; Verloo, M.G. Characteristics of Malian and Belgian solid waste composts with respect to fertility and suitability for lan application. Waste Manag. 2003, 23, 517–522. [Google Scholar] [CrossRef]

- García-Gil, J.C.; Plaza, C.; Soler-Rovira, P.; Polo, A. Long-term effects of municipal solid waste compost application on soil enzyme activities and microbial biomass. Soil Biol. Biochem. 2000, 32, 1907–1913. [Google Scholar]

- Montemurro, F.; Maiorana, M.; Convertini, G.; Ferri, D. Compost organic amendments in fodder crops: Effects on yield, nitrogen utilization and soil characteristics. Compost Sci. Utili. 2006, 14, 114–123. [Google Scholar] [CrossRef]

- Agassi, M.; Levy, G.J.; Hadas, A.; Benyamini, Y.; Zhevelev, H.; Fizik, E.; Gotessman, M.; Sasson, N. Mulching with composted municipal solid wastes in Central Negev, Israel: I. Effects on minimizing rainwater losses and on hazards to the environment. Soil Tillage Res. 2004, 78, 103–113. [Google Scholar] [CrossRef]

- Celik, I.; Ortas, I.; Kilic, S. Effects of compost, mycorrhiza, manure and fertilizer on some physical properties of a Chromoxerert soil. Soil Tillage Res. 2004, 78, 59–67. [Google Scholar] [CrossRef]

- Department of Agriculture. Available online: http://www.doa.gov.lk/index.php/en/croptechnology (accessed on 29 April 2017).

- Mapa, R. Soils of the Intermediate Zone of Sri Lanka: Morphology, Characterization and Classification, Special Publication Soil Science Society; Soil Science Society of Sri Lanka: Colombo, Sri Lanka, 2005. [Google Scholar]

- Eriyagama, N.; Smakhtin, V.; Chandrapala, L.; Fernando, K. Impacts of Climate Change on Water Resources and Agriculture in Sri Lanka: A Review and Preliminary Vulnerability Mapping; IWMI: Colombo, Sri Lanka, 2010. [Google Scholar]

- Adamtey, N.; Cofie, O.; Ofosu-Budu, K.G.; Ofosu-Anim, J.; Laryea, K.B.; Forster, D. Effect of N-enriched co-compost on transpiration efficiency and water-use efficiency of maize (Zea mays L.) under controlled irrigation. Agric. Water Manag. 2010, 7, 995–1005. [Google Scholar] [CrossRef]

- Smith, S.R. A critical review of the bioavailability and impacts of heavy metals in municipal solid waste composts compared to sewage sludge. Environ. Int. 2009, 35, 142–156. [Google Scholar] [CrossRef] [PubMed]

- Amoah, P.; Keraita, B.; Akple, M.; Drechsel, P.; Abaidoo, R.C.; Konradsen, F. Low-Cost Options for Reducing Consumer Health Risks from Farm to Fork Where Crops Are Irrigated with Polluted Water in West Africa; Research report 141; IWMI: Colombo, Sri Lanka, 2011. [Google Scholar]

- Vögeli, Y.; Lohri, C.R.; Gallardo, A.; Diener, S.; Zurbrügg, C. Anaerobic Digestion of Biowaste in Developing Countries: Practical Information and Case Studies; Swiss Federal Institute of Aquatic Science and Technology: Dübendorf, Switzerland, 2014. [Google Scholar]

| Treatment | Fertiliser Type | N | P | K | Corg |

|---|---|---|---|---|---|

| (% FM) | |||||

| Control | Control (Mineral) | 45.00 (Urea) | 7.84 (TSP) | 49.80 (MoP) | - |

| MSW | Organic | 1.37 | 0.09 | 2.43 | 12.48 |

| MSW-P | 1.37 | 0.09 | 2.43 | 12.48 | |

| FS-MSW | 2.22 | 0.63 | 1.11 | 15.5 | |

| FS-MSW-P | 2.22 | 0.63 | 1.11 | 15.5 | |

| FS-MSW-Pas | Mineral-Organic | 5.00 | 0.54 | 0.94 | 7.62 |

| FS-MSW-Pr | Organic | 2.15 | 0.62 | 1.07 | 10.73 |

| FS-MSW-Pasr | Mineral-Organic | 5.00 | 0.52 | 0.91 | 9.26 |

| Capsicum | Application Rate and Timing (kg/ha) | |||

|---|---|---|---|---|

| Initial | 1 MAP | 2 MAP | 3 MAP | |

| Control (Urea, TSP, MoP) | 100 | 100 | 100 | 100 |

| 215 | 0 | 0 | 0 | |

| 65 | 65 | 65 | 65 | |

| MSW | 3357 | 3357.66 | 3357 | 3357 |

| MSW-P | 3357 | 3357.66 | 3357 | 3357 |

| FS-MSW | 2071 | 2071.26 | 2071 | 2071 |

| FS-MSW-P | 2071 | 2071.26 | 2071 | 2071 |

| FS-MSW-Pas | 920 | 920.00 | 920 | 920 |

| FS-MSW-Pr | 2135 | 2135.32 | 2135 | 2135 |

| FS-MSW-Pasr | 920 | 920.00 | 920 | 920 |

| Radish | Initial | 3 WAP | ||

| Control (Urea, TSP, MoP) | 85 | 85 | ||

| 110 | 0 | |||

| 65 | 65 | |||

| MSW | 2854 | 2854 | ||

| MSW-P | 2854 | 2854 | ||

| FS-MSW | 1760 | 1760 | ||

| FS-MSW-P | 1760 | 1760 | ||

| FS-MSW-Pas | 782 | 782 | ||

| FS-MSW-Pr | 1815 | 1815 | ||

| FS-MSW-Pasr | 782 | 782 | ||

| Treatments | Components | Amount (kg/ha) | Cost (USD/kg) | Cost (USD/ha) |

|---|---|---|---|---|

| Capsicum | ||||

| Control | Urea | 400.00 | 0.33 | 132.89 |

| TSP | 215.00 | 0.33 | 71.43 | |

| MoP | 260.00 | 0.33 | 86.38 | |

| MSW | 13,430.64 | 0.06 | 805.84 | |

| MSW-P | pelletized | 13,430.64 | 0.13 | 1745.98 |

| FS-MSW | 8285.04 | 0.12 | 994.20 | |

| FS-MSW-P | pelletized | 8285.04 | 0.19 | 1574.16 |

| FS-MSW-Pas | Pelletized | 3135.36 | 0.19 | 595.72 |

| AS | 544.64 | 0.29 | 157.95 | |

| FS-MSW-Pr | pelletized | 8285.04 | 0.19 | 1574.16 |

| rice flour | 256.24 | 1.05 | 269.05 | |

| FS-MSW-Pasr | pelletized | 3030.76 | 0.19 | 575.84 |

| rice flour | 93.56 | 1.05 | 98.24 | |

| AS | 555.68 | 0.29 | 161.15 | |

| Radish | ||||

| Control | Urea | 170.00 | 0.33 | 56.48 |

| TSP | 110.00 | 0.33 | 36.54 | |

| MoP | 130.00 | 0.33 | 43.19 | |

| MSW | 5708.02 | 0.06 | 342.48 | |

| MSW-P | pelletized | 5708.02 | 0.13 | 742.04 |

| FS-MSW | 3521.14 | 0.12 | 422.54 | |

| FS-MSW-P | pelletized | 3521.14 | 0.19 | 669.02 |

| FS-MSW-Pas | Pelletized | 1332.53 | 0.19 | 253.18 |

| AS | 231.47 | 0.29 | 67.13 | |

| FS-MSW-Pr | pelletized | 3521.14 | 0.19 | 669.02 |

| rice flour | 108.90 | 1.05 | 114.35 | |

| FS-MSW-Pasr | pelletized | 1288.00 | 0.18 | 231.84 |

| rice flour | 39.84 | 1.05 | 41.83 | |

| AS | 236.16 | 0.29 | 68.49 |

| Groups of Treatments | Treatment Code | Plant Height (cm) | |

|---|---|---|---|

| 4 WAP | 6 WAP | ||

| Control | Control | 15.11 ab | 21.23 a |

| Mineral-Organic | FS-MSW-Pas, FS-MSW-Pasr | 14.35 a | 23.14 ab |

| Organic | MSW, MSW-P, FS-MSW, FS-MSW-P, FS-MSW-Pr | 18.49 b | 26.01 b |

| Duncan | 0.019 | 0.029 | |

| Treatments | Price | Yield FM | Revenue | Benefit | Benefit Marg. |

|---|---|---|---|---|---|

| USD/ha | Mt/ha | 000 USD/ha | 000 USD/ha | % | |

| Capsicum | |||||

| Control | 290.70 | 26.37 (±6.45) | 20.87 (±7.22) | 20.58 | - |

| MSW | 805.84 | 20.34 (±8.61) | 16.10 (±9.64) | 15.29 | 74.32 |

| MSW-P | 1745.98 | 15.29 (±6.27) | 12.10 (±7.01) | 10.35 | 50.30 |

| FS-MSW | 994.20 | 23.91 (±10.89) | 18.93 (±12.19) | 17.93 | 87.14 |

| FS-MSW-P | 1574.16 | 14.68 (±3.88) | 11.62 (±4.34) | 10.04 | 48.81 |

| FS-MSW-Pas | 753.66 | 22.49 (±8.22) | 17.80 (±9.20) | 17.04 | 82.81 |

| FS-MSW-Pr | 1843.21 | 22.39 (±3.25) | 17.72 (±3.64) | 15.88 | 77.15 |

| FS-MSW-Pasr | 835.23 | 26.93 (±9.90) | 21.31(±11.08) | 20.47 | 99.49 |

| Radish | |||||

| Control | 136.21 | 6.48 (±2.72) | 1.07 (±0.63) | 0.93 | - |

| MSW | 342.48 | 10.82 (±4.14) | 1.78 (±0.96) | 1.44 | 154.59 |

| MSW-P | 742.04 | 11.59 (±5.10) | 1.91 (±1.19) | 1.17 | 125.40 |

| FS-MSW | 422.54 | 16.04 (±4.86) | 2.65 (±1.13) | 2.22 | 238.46 |

| FS-MSW-P | 669.02 | 12.53 (±4.46) | 2.07 (±1.04) | 1.40 | 149.80 |

| FS-MSW-Pas | 320.31 | 6.81 (±3.62) | 1.12 (±0.84) | 0.80 | 86.12 |

| FS-MSW-Pr | 783.36 | 11.73 (±5.25) | 1.93 (±1.22) | 1.15 | 123.54 |

| FS-MSW-Pasr | 342.15 | 7.86 (±3.92) | 1.30 (±0.92) | 0.95 | 102.28 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grau, F.; Drechsel, N.; Haering, V.; Trautz, D.; Weerakkody, W.J.S.K.; Drechsel, P.; Marschner, B.; Dissanayake, D.M.P.S.; Sinnathamby, V. Impact of Fecal Sludge and Municipal Solid Waste Co-Compost on Crop Growth of Raphanus Sativus L. and Capsicum Anuum L. under Stress Conditions. Resources 2017, 6, 26. https://doi.org/10.3390/resources6030026

Grau F, Drechsel N, Haering V, Trautz D, Weerakkody WJSK, Drechsel P, Marschner B, Dissanayake DMPS, Sinnathamby V. Impact of Fecal Sludge and Municipal Solid Waste Co-Compost on Crop Growth of Raphanus Sativus L. and Capsicum Anuum L. under Stress Conditions. Resources. 2017; 6(3):26. https://doi.org/10.3390/resources6030026

Chicago/Turabian StyleGrau, Felix, Nikita Drechsel, Volker Haering, Dieter Trautz, Weerakkodige Jayantha Sisira Kumara Weerakkody, Pay Drechsel, Bernd Marschner, Dissanayake Mudiyanselage Priyanga Sashikanjali Dissanayake, and Vijayapala Sinnathamby. 2017. "Impact of Fecal Sludge and Municipal Solid Waste Co-Compost on Crop Growth of Raphanus Sativus L. and Capsicum Anuum L. under Stress Conditions" Resources 6, no. 3: 26. https://doi.org/10.3390/resources6030026