The Electrical Properties of Plasma-Deposited Thin Films Derived from Pelargonium graveolens

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yim, J.H.; Joe, S.-Y.; Pang, C.; Lee, K.M.; Jeong, H.; Park, J.-Y.; Ahn, Y.H.; de Mello, J.C.; Lee, S. Fully solution-processed semitransparent organic solar cells with a silver nanowire cathode and a conducting polymer anode. ACS Nano 2014, 8, 2857–2863. [Google Scholar] [CrossRef] [PubMed]

- Tseng, H.R.; Phan, H.; Luo, C.; Wang, M.; Perez, L.A.; Patel, S.N.; Ying, L.; Kramer, E.J.; Nguyen, T.Q.; Bazan, G.C.; et al. High-Mobility Field-Effect Transistors Fabricated with Macroscopic Aligned Semiconducting Polymers. Adv. Mater. 2014, 26, 2993–2998. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Xiao, B.; Liu, F.; Wu, H.; Yang, Y.; Xiao, S.; Wang, C.; Russell, T.P.; Cao, Y. Single-junction polymer solar cells with high efficiency and photovoltage. Nat. Photonics 2015, 9, 174–179. [Google Scholar] [CrossRef]

- Moon, H.; Seong, H.; Shin, W.C.; Park, W.-T.; Kim, M.; Lee, S.; Bong, J.H.; Noh, Y.-Y.; Cho, B.J.; Yoo, S.; et al. Synthesis of ultrathin polymer insulating layers by initiated chemical vapour deposition for low-power soft electronics. Nat. Mater. 2015, 14, 628–635. [Google Scholar] [CrossRef] [PubMed]

- Ortiz, R.P.; Facchetti, A.; Marks, T.J. High-k organic, inorganic, and hybrid dielectrics for low-voltage organic field-effect transistors. Chem. Rev. 2009, 110, 205–239. [Google Scholar] [CrossRef] [PubMed]

- Kumar, B.; Kaushik, B.K.; Negi, Y. Perspectives and challenges for organic thin film transistors: Materials, devices, processes and applications. J. Mater. Sci. Mater. Electron. 2014, 25, 1–30. [Google Scholar] [CrossRef]

- Liu, X.; Guo, Y.; Ma, Y.; Chen, H.; Mao, Z.; Wang, H.; Yu, G.; Liu, Y. Flexible, Low-Voltage and High-Performance Polymer Thin-Film Transistors and Their Application in Photo/Thermal Detectors. Adv. Mater. 2014, 26, 3631–3636. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Joo, M.; Seong, H.; Pak, K.; Park, H.; Park, C.W.; Im, S.G. Flexible, Low-Power Thin-Film Transistors (TFTs) Made of Vapor-Phase Synthesized High-k, Ultrathin Polymer Gate Dielectrics. ACS Appl. Mater. Interfaces 2017, 9, 20808–20817. [Google Scholar] [CrossRef] [PubMed]

- Facchetti, A.; Yoon, M.H.; Marks, T.J. Gate Dielectrics for Organic Field-Effect Transistors: New Opportunities for Organic Electronics. Adv. Mater. 2005, 17, 1705–1725. [Google Scholar] [CrossRef]

- Cheng, X.; Caironi, M.; Noh, Y.-Y.; Wang, J.; Newman, C.; Yan, H.; Facchetti, A.; Sirringhaus, H. Air stable cross-linked Cytop ultrathin gate dielectric for high yield low-voltage top-gate organic field-effect transistors. Chem. Mater. 2010, 22, 1559–1566. [Google Scholar] [CrossRef]

- Eslamian, M. Inorganic and organic solution-processed thin film devices. Nano-Micro Lett. 2017, 9, 3. [Google Scholar] [CrossRef]

- Friedrich, J. Mechanisms of Plasma Polymerization—Reviewed from a Chemical Point of View. Plasma Process. Polym. 2011, 8, 783–802. [Google Scholar] [CrossRef]

- Boscher, N.D.; Hilt, F.; Duday, D.; Frache, G.; Fouquet, T.; Choquet, P. Atmospheric Pressure Plasma Initiated Chemical Vapor Deposition Using Ultra-Short Square Pulse Dielectric Barrier Discharge. Plasma Process. Polym. 2015, 12, 66–74. [Google Scholar] [CrossRef]

- Hilt, F.; Duday, D.; Gherardi, N.; Frache, G.; Didierjean, J.; Choquet, P. Plasma polymerisation of an allyl organophosphate monomer by atmospheric pressure pulsed-PECVD: Insights into the growth mechanisms. RSC Adv. 2015, 5, 4277–4285. [Google Scholar] [CrossRef]

- Flamm, D.L.; Auciello, O. Plasma Deposition, Treatment, and Etching of Polymers: The Treatment and Etching of Polymers; d’Agostino, R., Ed.; Academic Press: San Diego, CA, USA, 2012. [Google Scholar]

- Bhattacharyya, D.; Yoon, W.-J.; Berger, P.R.; Timmons, R.B. Plasma-Polymerized Multistacked Organic Bipolar Films: A New Approach to Flexible High-κ Dielectrics. Adv. Mater. 2008, 20, 2383–2388. [Google Scholar] [CrossRef]

- Xu, Y.; Berger, P.R. Pulsed plasma polymerized dichlorotetramethyldisiloxane high-k gate dielectrics for polymer field-effect transistors. J. Appl. Phys. 2006, 99, 014104. [Google Scholar] [CrossRef]

- Lim, J.-S.; Shin, P.-K.; Lee, B.-J. Organic Thin Film Transistors with Gate Dielectrics of Plasma Polymerized Styrene and Vinyl Acetate Thin Films. Trans. Electric. Electron. Mater. 2015, 16, 95–98. [Google Scholar] [CrossRef]

- Feng, L.; Anguita, J.V.; Tang, W.; Zhao, J.; Guo, X.; Silva, S.R.P. Room Temperature Grown High-Quality Polymer-Like Carbon Gate Dielectric for Organic Thin-Film Transistors. Adv. Electron. Mater. 2016, 2, 1500374. [Google Scholar] [CrossRef]

- Tsai, C.H.; Li, Y.-S.; Cheng, I.-C.; Chen, J.-Z. O2/HMDSO-Plasma-Deposited Organic–Inorganic Hybrid Film for Gate Dielectric of MgZnO Thin-Film Transistor. Plasma Process. Polym. 2014, 11, 89–95. [Google Scholar] [CrossRef]

- Lim, J.-S.; Shin, P.-K.; Lee, B.-J.; Lee, S. Plasma polymerized methyl methacrylate gate dielectric for organic thin-film transistors. Org. Electron. 2010, 11, 951–954. [Google Scholar] [CrossRef]

- Yoon, W.-J.; Bhattacharyya, D.; Timmons, R.B.; Berger, P.R. Plasma-polymerized multistacked bipolar gate dielectric for organic thin-film transistors. Org. Electron. 2010, 11, 1767–1771. [Google Scholar] [CrossRef]

- Jacob, M.V.; Bazaka, K.; Weis, M.; Taguchi, D.; Manaka, T.; Iwamoto, M. Fabrication and characterization of polyterpenol as an insulating layer and incorporated organic field effect transistor. Thin Solid Films 2010, 518, 6123–6129. [Google Scholar] [CrossRef]

- Kwok, H.S.; Wong, M.; Peng, H.; Sun, J. Metallic Anode Treated by Carbon Tetrafluoride Plasma for Organic Light Emitting Device. U.S. Patent 9,166,197 B2, 20 October 2015. [Google Scholar]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-derived materials for green electronics, biological devices, and energy applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef] [PubMed]

- Irimia-Vladu, M. “Green” electronics: Biodegradable and biocompatible materials and devices for sustainable future. Chem. Soc. Rev. 2014, 43, 588–610. [Google Scholar] [CrossRef] [PubMed]

- Irimia-Vladu, M.; Głowacki, E.; Voss, G.; Bauer, S.; Sariciftci, N.S. Green and biodegradable electronics. Mater. Today 2012, 15, 340–346. [Google Scholar] [CrossRef]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef] [PubMed]

- Bazaka, K.; Jacob, M. Synthesis of radio frequency plasma polymerized non-synthetic Terpinen-4-ol thin films. Mater. Lett. 2009, 63, 1594–1597. [Google Scholar] [CrossRef]

- Jacob, M.V.; Rawat, R.S.; Ouyang, B.; Bazaka, K.; Kumar, D.S.; Taguchi, D.; Iwamoto, M.; Neupane, R.; Varghese, O.K. Catalyst-free plasma enhanced growth of graphene from sustainable sources. Nano Lett. 2015, 15, 5702–5708. [Google Scholar] [CrossRef] [PubMed]

- Bazaka, K.; Jacob, M.V.; Ostrikov, K. Sustainable Life Cycles of Natural-Precursor-Derived Nanocarbons. Chem. Rev. 2016, 116, 163–214. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Jumaili, A.; Alancherry, S.; Bazaka, K.; Jacob, M.V. Review on the antimicrobial properties of carbon nanostructures. Materials 2017, 10, 1066. [Google Scholar] [CrossRef] [PubMed]

- Jacob, M.V.; Easton, C.D.; Woods, G.S.; Berndt, C.C. Fabrication of a novel organic polymer thin film. Thin Solid Films 2008, 516, 3884–3887. [Google Scholar] [CrossRef]

- Anderson, L.; Jacob, M. Effect of RF power on the optical and morphological properties of RF plasma polymerised linalyl acetate thin films. Appl. Surf. Sci. 2010, 256, 3293–3298. [Google Scholar] [CrossRef]

- Anderson, L.; Jacob, M. Electrical characterisations of plasma polyermised linalyl acetate. Mater. Sci. Eng. B 2012, 177, 311–315. [Google Scholar] [CrossRef]

- Ahmad, J.; Bazaka, K.; Vasilev, K.; Jacob, M.V. Electrical conduction in plasma polymerized thin films of γ-terpinene. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef] [Green Version]

- Bazaka, K.; Jacob, M.V.; Crawford, R.J.; Ivanova, E.P. Plasma-assisted surface modification of organic biopolymers to prevent bacterial attachment. Acta Biomater. 2011, 7, 2015–2028. [Google Scholar] [CrossRef] [PubMed]

- Bazaka, K.; Jacob, M.V.; Bowden, B.F. Optical and chemical properties of polyterpenol thin films deposited via plasma-enhanced chemical vapor deposition. J. Mater. Res. 2011, 26, 1018–1025. [Google Scholar] [CrossRef] [Green Version]

- Jacob, M.V.; Bazaka, K.; Taguchi, D.; Manaka, T.; Iwamoto, M. Electron-blocking hole-transport polyterpenol thin films. Chem. Phys. Lett. 2012, 528, 26–28. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, J.; Bazaka, K.; Jacob, M.V. Optical and surface characterization of radio frequency plasma polymerized 1-isopropyl-4-methyl-1, 4-cyclohexadiene thin films. Electronics 2014, 3, 266–281. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, J.; Bazaka, K.; Whittle, J.D.; Michelmore, A.; Jacob, M.V. Structural Characterization of γ-Terpinene Thin Films Using Mass Spectroscopy and X-ray Photoelectron Spectroscopy. Plasma Process. Polym. 2015, 12, 1085–1094. [Google Scholar] [CrossRef]

- Vassallo, E.; Cremona, A.; Ghezzi, F.; Laguardia, L.; Ambrosone, G.; Coscia, U. Structural and optical properties of amorphous hydrogenated silicon carbonitride films produced by PECVD. Appl. Surf. Sci. 2006, 252, 7993–8000. [Google Scholar] [CrossRef]

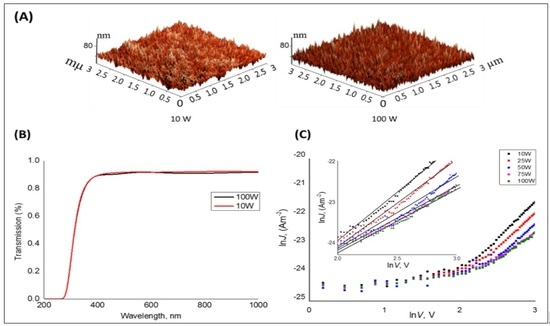

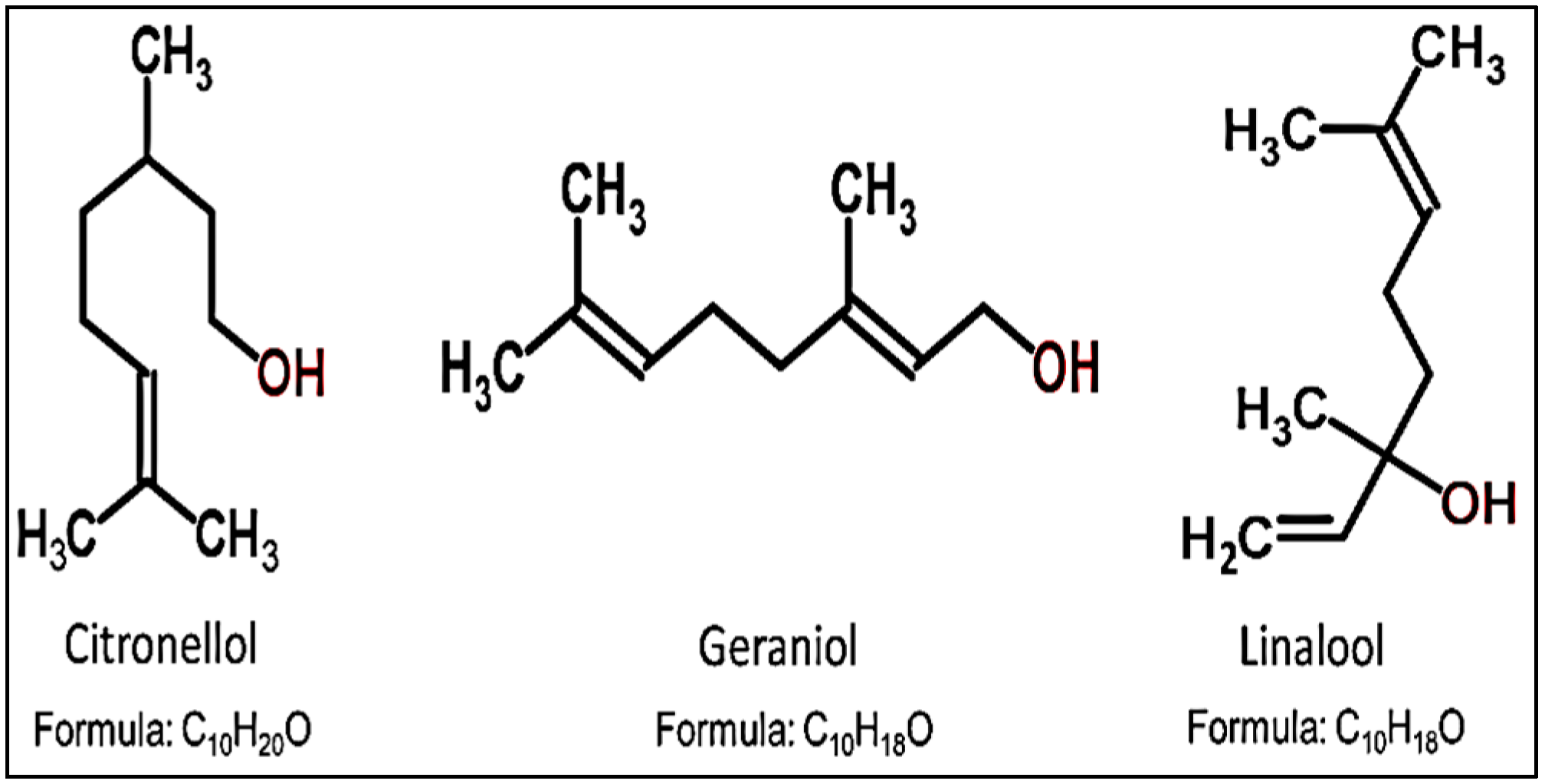

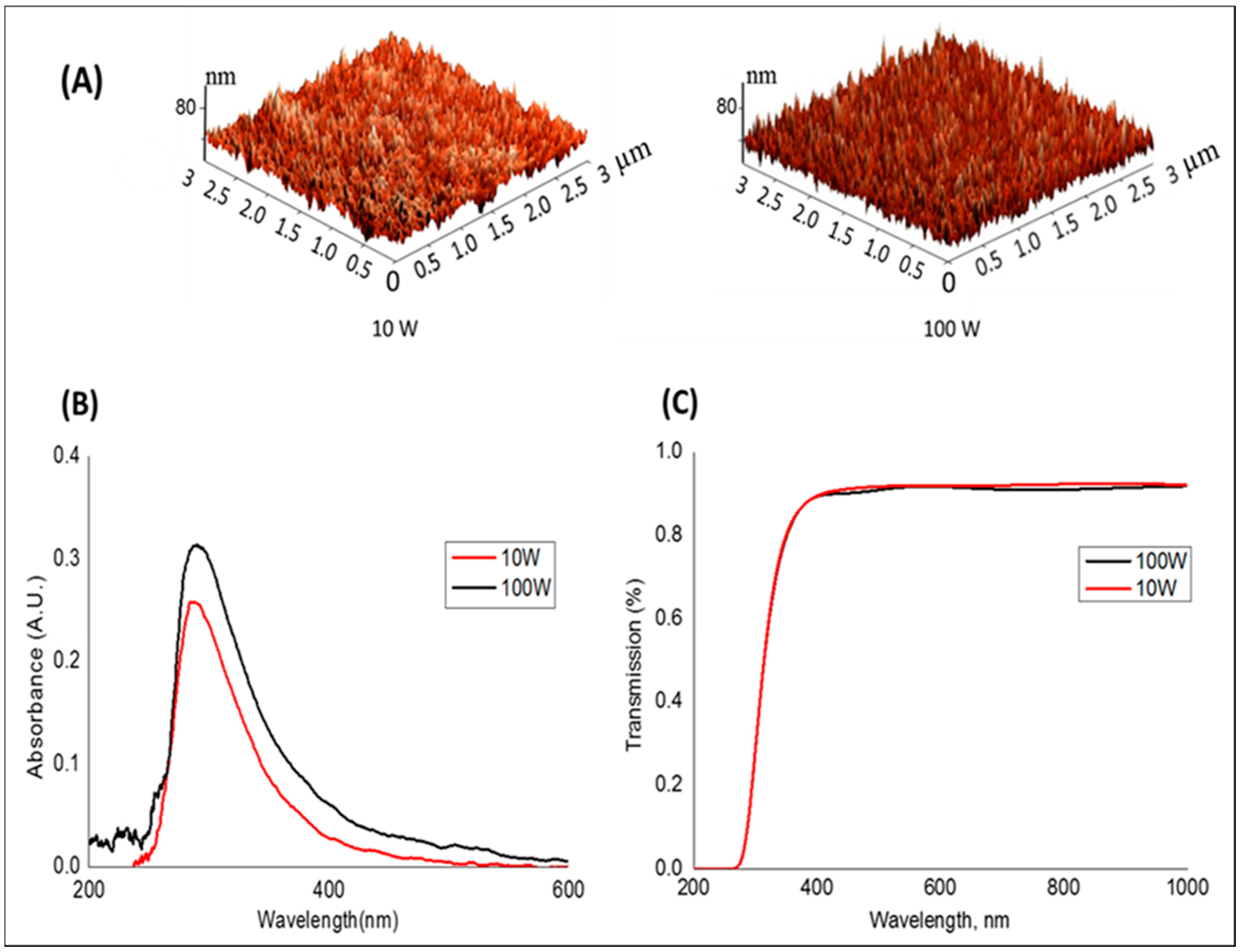

- Al-Jumaili, A.; Bazaka, K.; Jacob, M.V. Retention of Antibacterial Activity in Geranium Plasma Polymer Thin Films. Nanomaterials 2017, 7, 270. [Google Scholar] [CrossRef] [PubMed]

- Bazaka, K.; Destefani, R.; Jacob, M.V. Plant-derived cis-β-ocimene as a precursor for biocompatible, transparent, thermally-stable dielectric and encapsulating layers for organic electronics. Sci. Rep. 2016, 6, 38571. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.S.; Yoshida, Y. Dielectric properties of plasma polymerized pyrrole thin film capacitors. Surf. Coat. Technol. 2003, 169, 600–603. [Google Scholar] [CrossRef]

- Chowdhury, F.-U.-Z.; Bhuiyan, A. Dielectric properties of plasma-polymerized diphenyl thin films. Thin Solid Films 2000, 370, 78–84. [Google Scholar] [CrossRef]

- Mathai, C.J.; Saravanan, S.; Anantharaman, M.R.; Venkitachalam, S.; Jayalekshmi, S. Characterization of low dielectric constant polyaniline thin film synthesized by ac plasma polymerization technique. J. Phys. D Appl. Phys. 2002, 35, 240–245. [Google Scholar] [CrossRef]

- Bazaka, K.; Jacob, M.V. Effects of iodine doping on optoelectronic and chemical properties of polyterpenol thin films. Nanomaterials 2017, 7, 11. [Google Scholar] [CrossRef] [PubMed]

- Matin, R.; Bhuiyan, A. Electrical transport mechanism in plasma polymerized 2, 6, diethylaniline thin films. Thin Solid Films 2011, 519, 3462–3467. [Google Scholar] [CrossRef]

- Dakhel, A. Mechanisms of dc-current transfer in tris (acetylacetonato) iron (III) films. J. Non-Cryst. Solids 2007, 353, 1529–1533. [Google Scholar] [CrossRef]

- Capan, R.; Davis, F. Electrical properties of a calix [4] acid/amine Langmuir–Blodgett thin film. Mater. Chem. Phys. 2011, 125, 883–886. [Google Scholar] [CrossRef]

- Bazaka, K.; Jacob, M.V. Complex permittivity measurements of RF plasma polymerized polyterpenol organic thin films employing split post dielectric resonator. J. Polym. Eng. 2011, 31, 73–75. [Google Scholar] [CrossRef]

- Kiesow, A.; Heilmann, A. Deposition and properties of plasma polymer films made from thiophenes. Thin Solid Films 1999, 343, 338–341. [Google Scholar] [CrossRef]

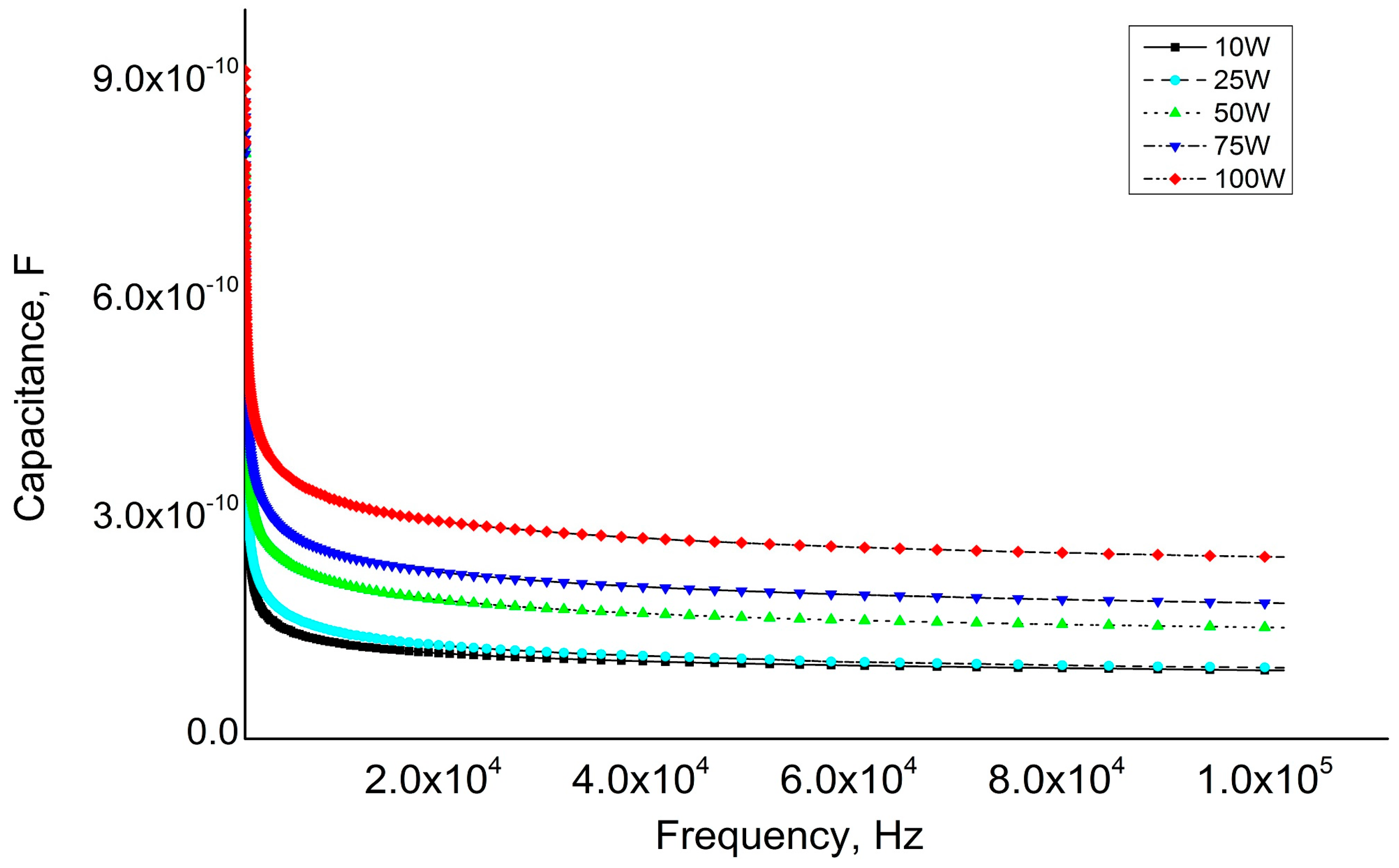

| Frequency (Hz) | Dielectric Constant | ||||

|---|---|---|---|---|---|

| 10 W | 25 W | 50 W | 75 W | 100 W | |

| 10 | 5.75 | 4.92 | 4.74 | 4.62 | 4.29 |

| 100 | 4.73 | 4.10 | 3.38 | 2.97 | 2.56 |

| 500 | 4.48 | 3.88 | 3.03 | 2.62 | 2.20 |

| 1000 | 4.40 | 3.80 | 2.93 | 2.52 | 2.10 |

| 10,000 | 4.17 | 3.59 | 2.66 | 2.26 | 1.85 |

| 50,000 | 3.69 | 3.24 | 2.37 | 1.98 | 1.59 |

| 100,000 | 3.05 | 2.78 | 2.04 | 1.68 | 1.32 |

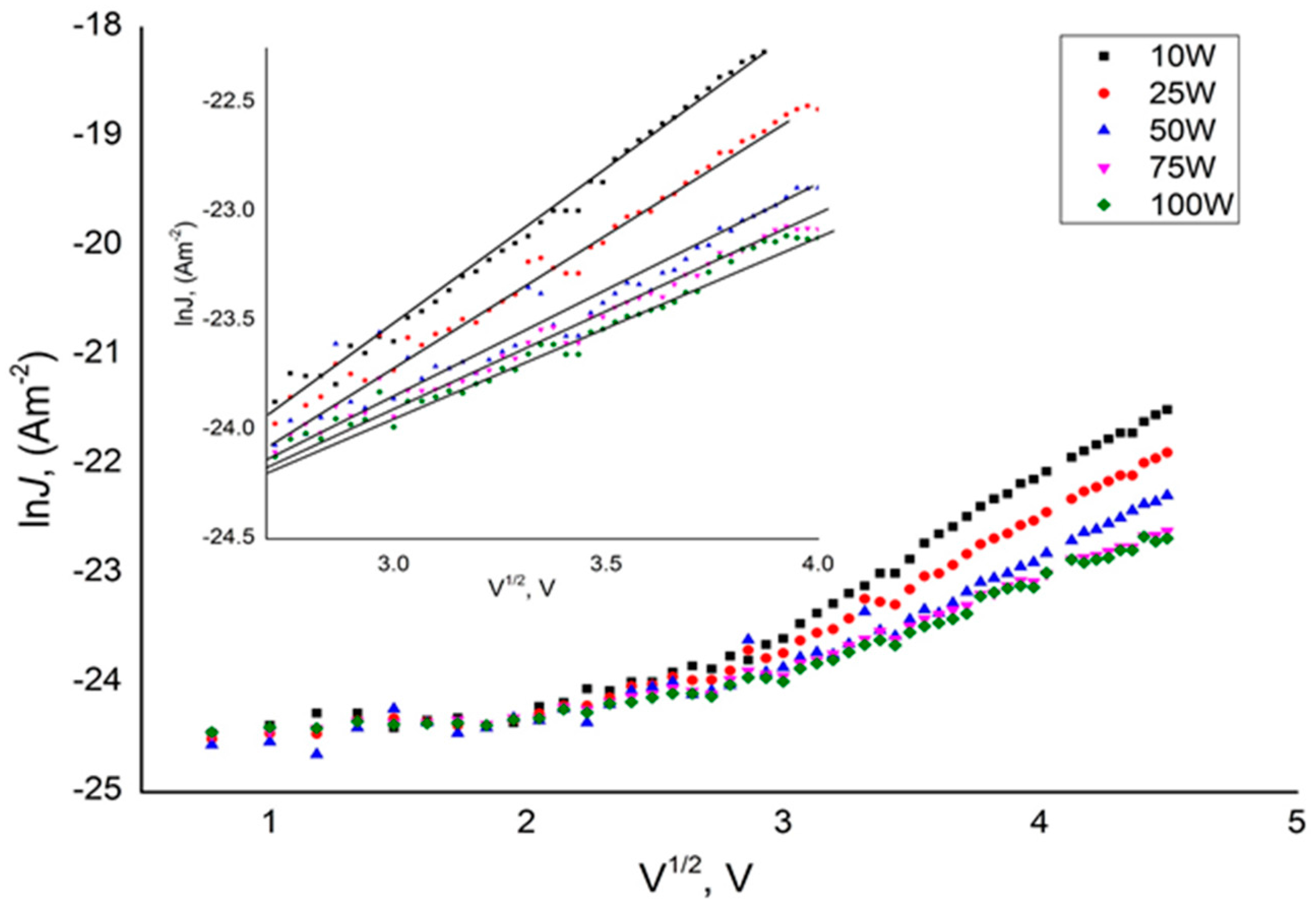

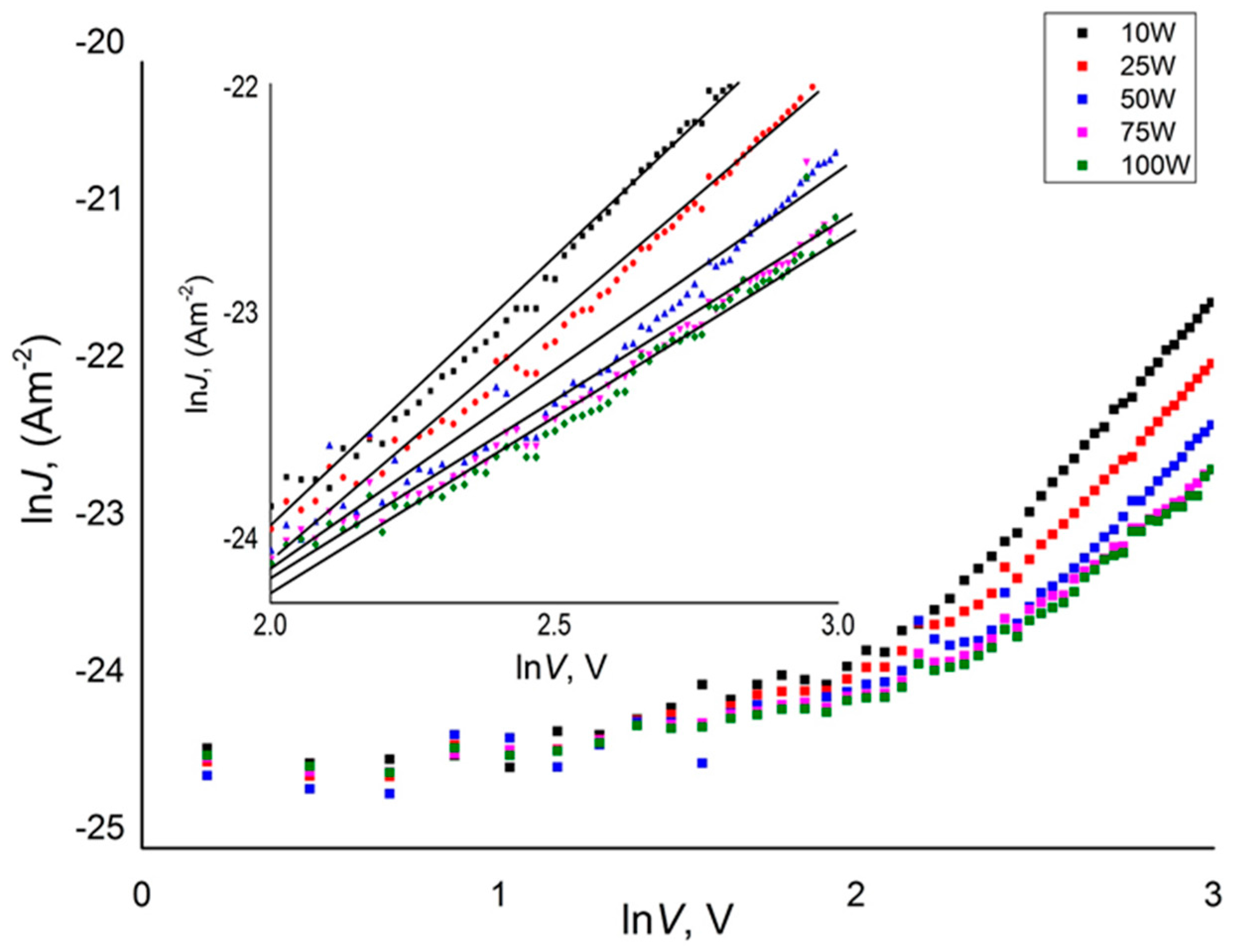

| Power of Deposition (W) | βexp | βPF | βRS |

|---|---|---|---|

| 10 | 2.53 × 10−5 | 4.32 × 10−5 | 2.16 × 10−5 |

| 25 | 2.55 × 10−5 | 4.40 × 10−5 | 2.20 × 10−5 |

| 50 | 2.58 × 10−5 | 4.42 × 10−5 | 2.21 × 10−5 |

| 75 | 2.59 × 10−5 | 4.45 × 10−5 | 2.22 × 10−5 |

| 100 | 2.61 × 10−5 | 4.46 × 10−5 | 2.23 × 10−5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Jumaili, A.; Alancherry, S.; Bazaka, K.; Jacob, M.V. The Electrical Properties of Plasma-Deposited Thin Films Derived from Pelargonium graveolens. Electronics 2017, 6, 86. https://doi.org/10.3390/electronics6040086

Al-Jumaili A, Alancherry S, Bazaka K, Jacob MV. The Electrical Properties of Plasma-Deposited Thin Films Derived from Pelargonium graveolens. Electronics. 2017; 6(4):86. https://doi.org/10.3390/electronics6040086

Chicago/Turabian StyleAl-Jumaili, Ahmed, Surjith Alancherry, Kateryna Bazaka, and Mohan V. Jacob. 2017. "The Electrical Properties of Plasma-Deposited Thin Films Derived from Pelargonium graveolens" Electronics 6, no. 4: 86. https://doi.org/10.3390/electronics6040086