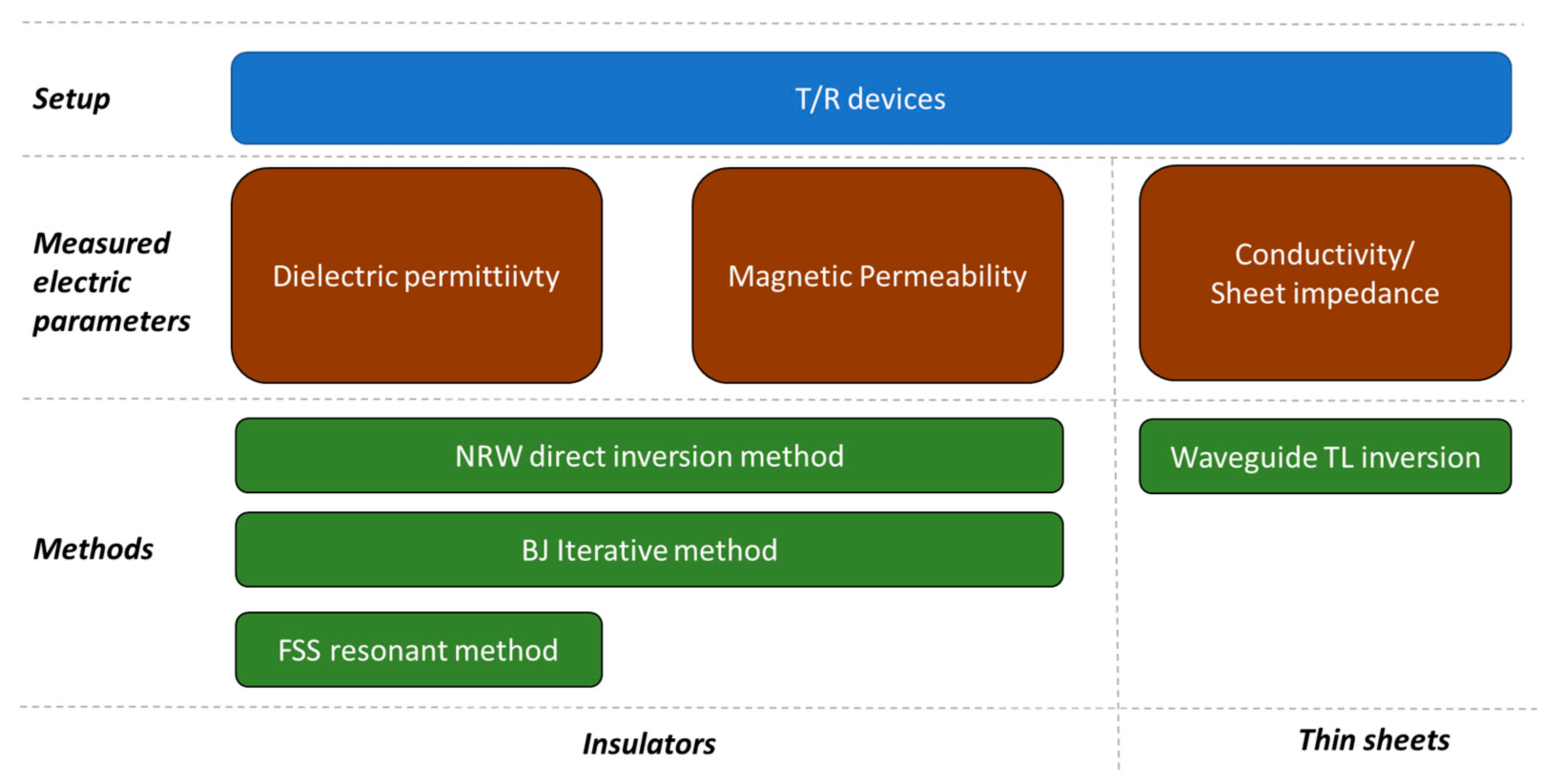

Electromagnetic Characterisation of Materials by Using Transmission/Reflection (T/R) Devices

Abstract

:1. Introduction

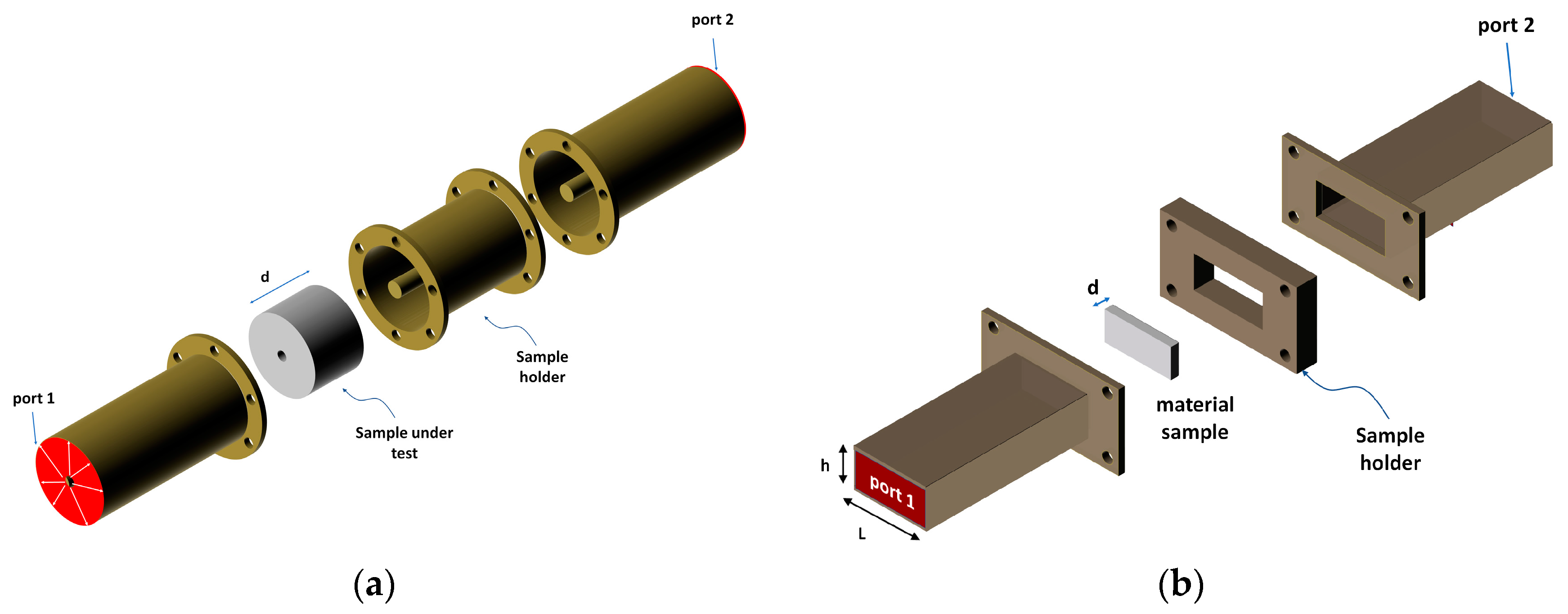

2. Measuring Properties of Dielectric Materials

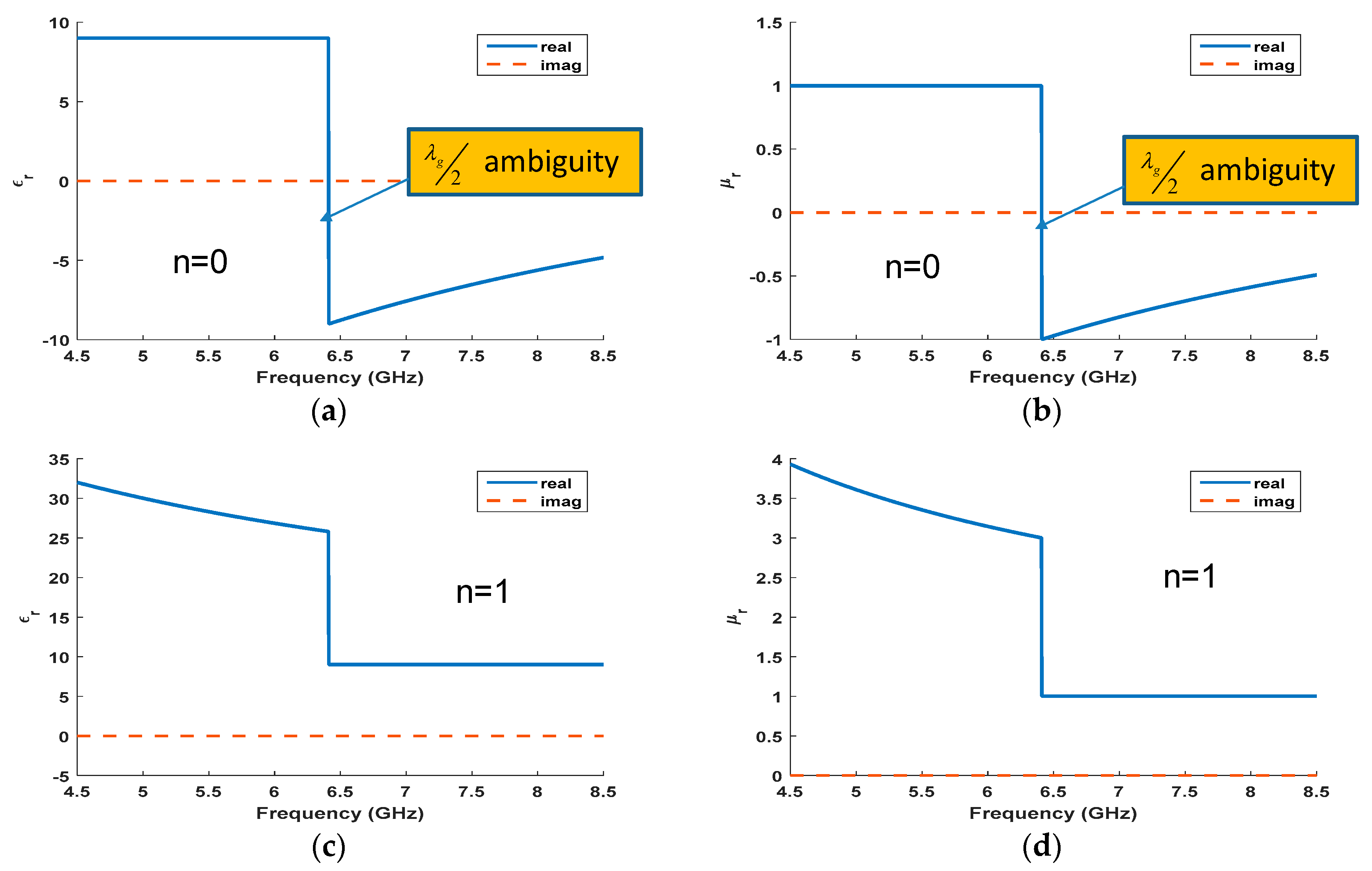

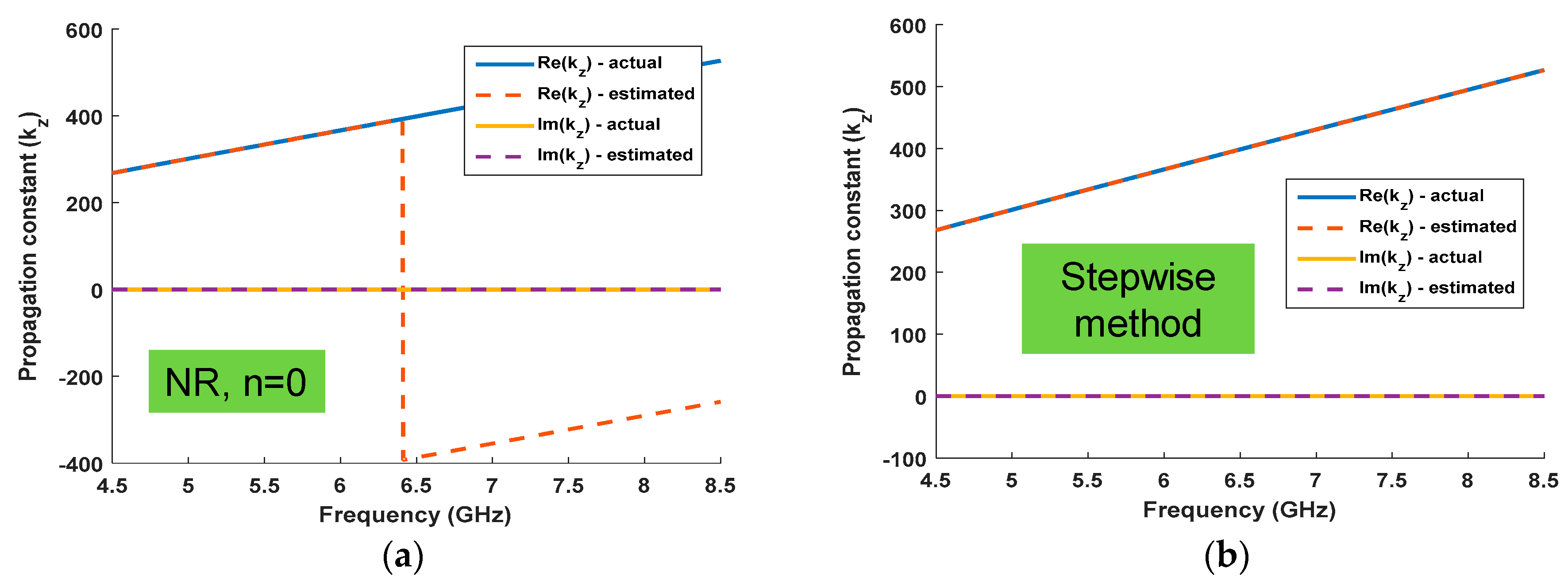

2.1. Nicolson–Ross–Weir Procedure

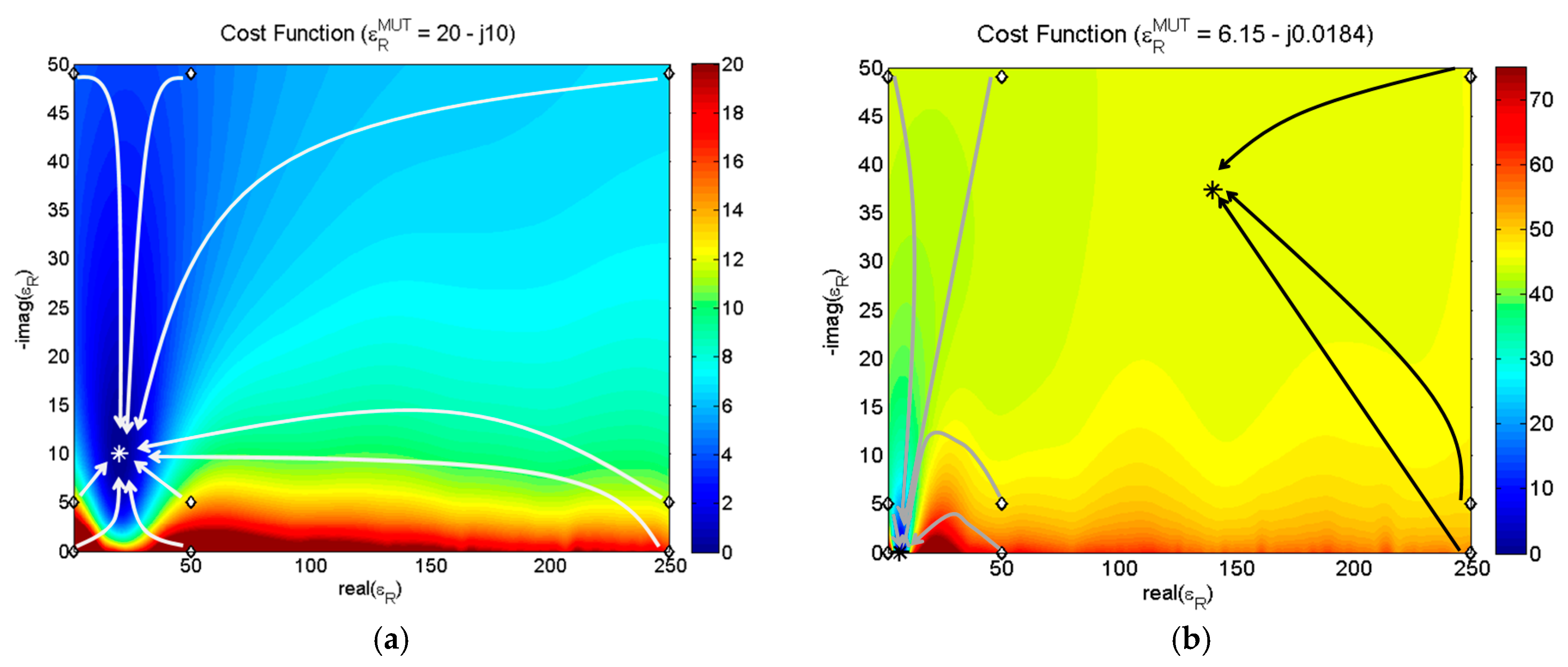

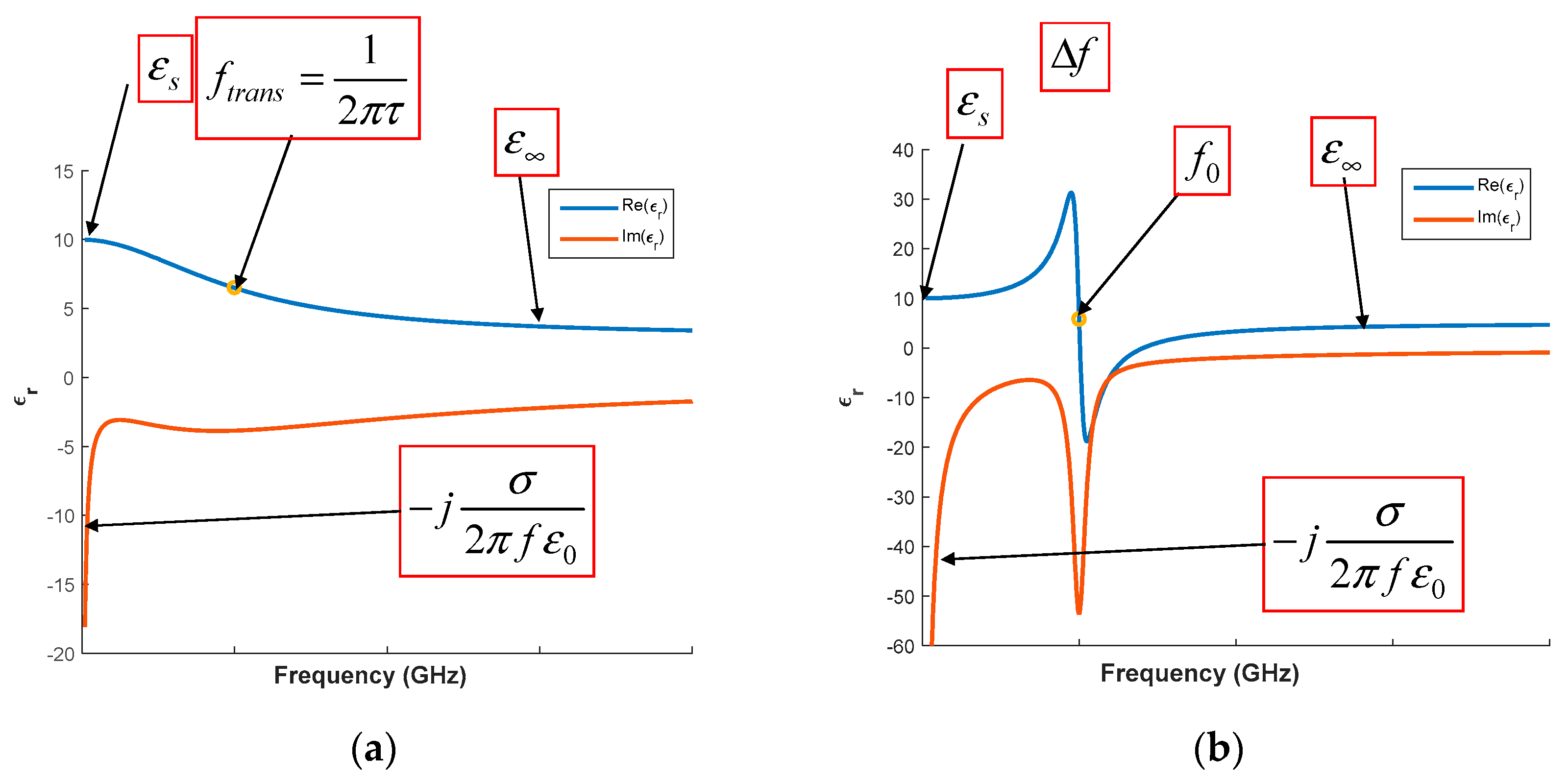

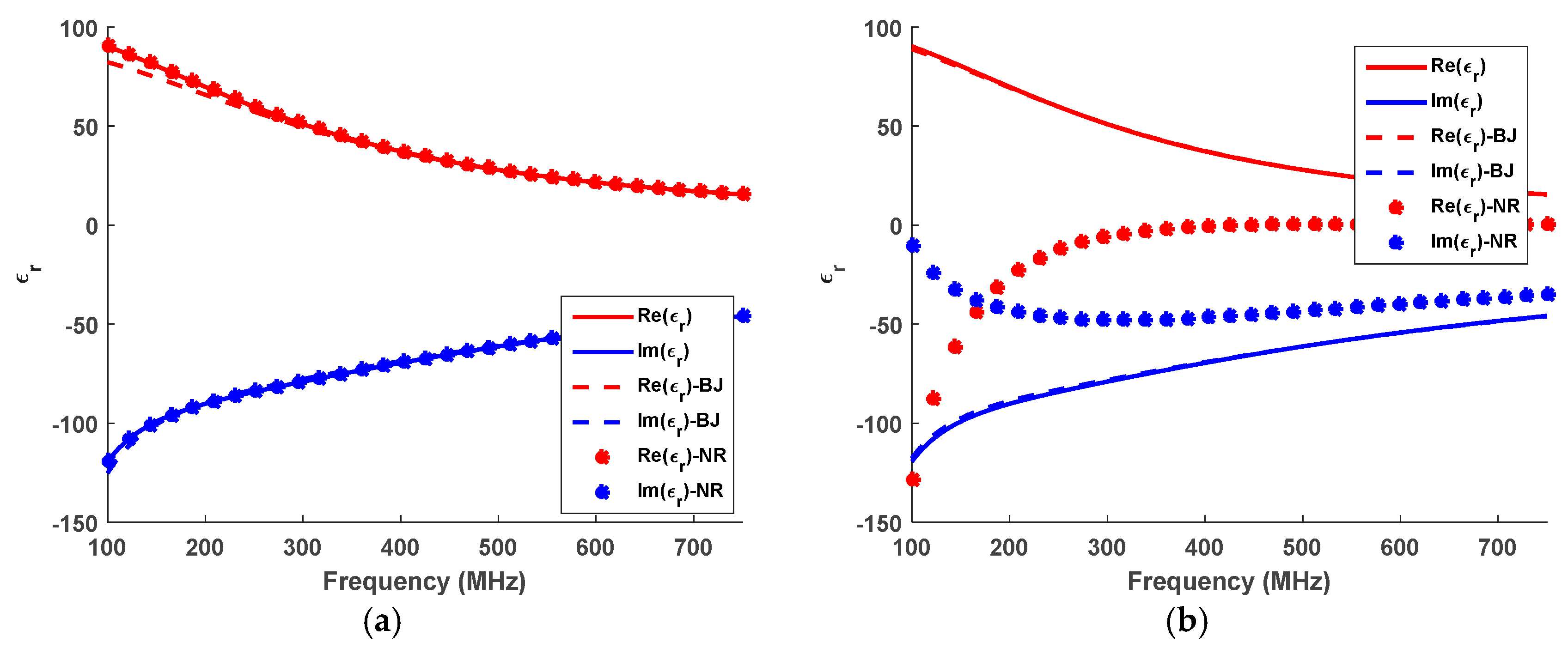

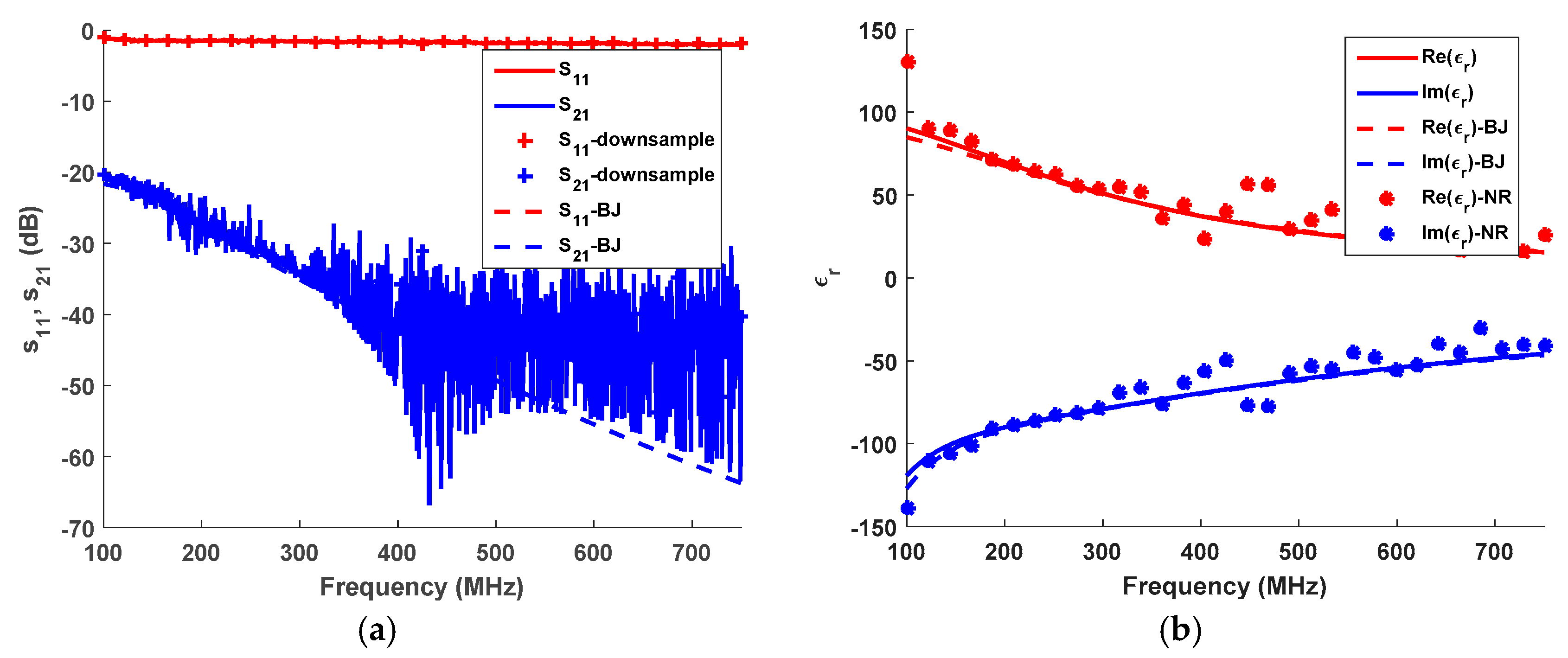

2.2. Iterative Non-Ambiguous Estimation of Dielectric Permittivity from Broadband Transmission/Reflection Measurements

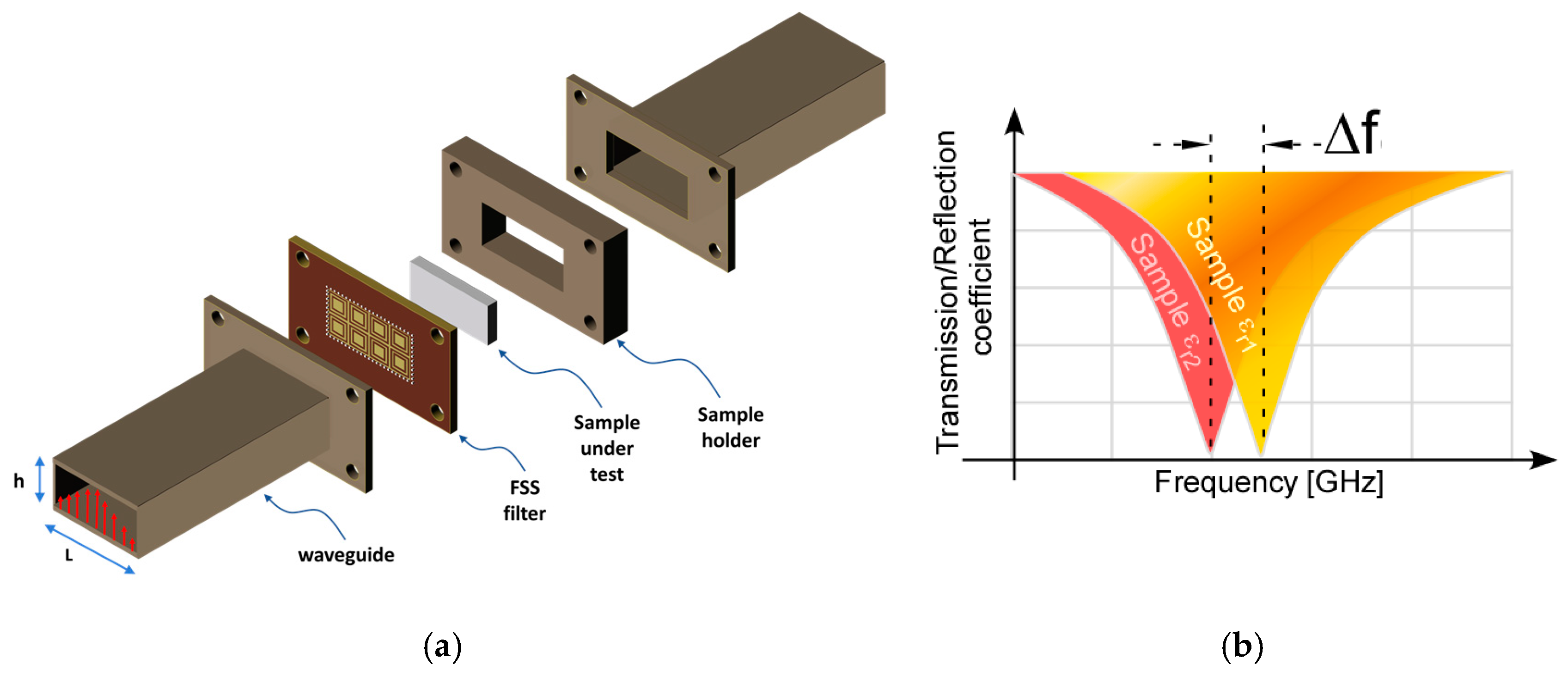

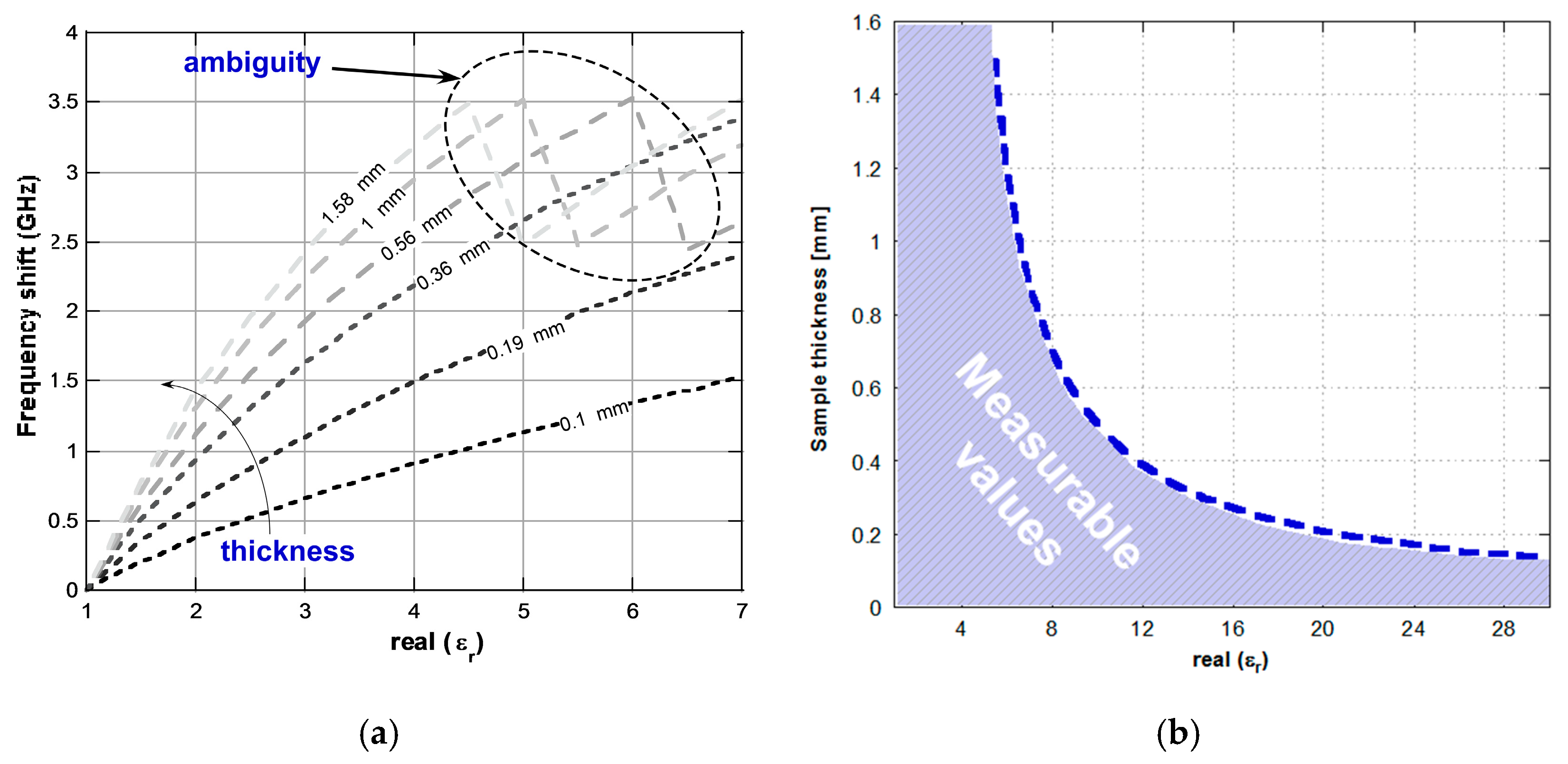

2.3. FSS-Based Waveguide Resonant Method

- The transmission/reflection response of the unloaded filter is initially measured, thus identifying the resonant peak;

- The additional dielectric is placed close to the FSS, measuring the new response and hence the frequency shift of the resonant peak;

- The frequency shift is mapped into the unknown permittivity through a shift–permittivity map that is pre-defined through an iterative Periodic Method of Moments (PMM) simulation [65].

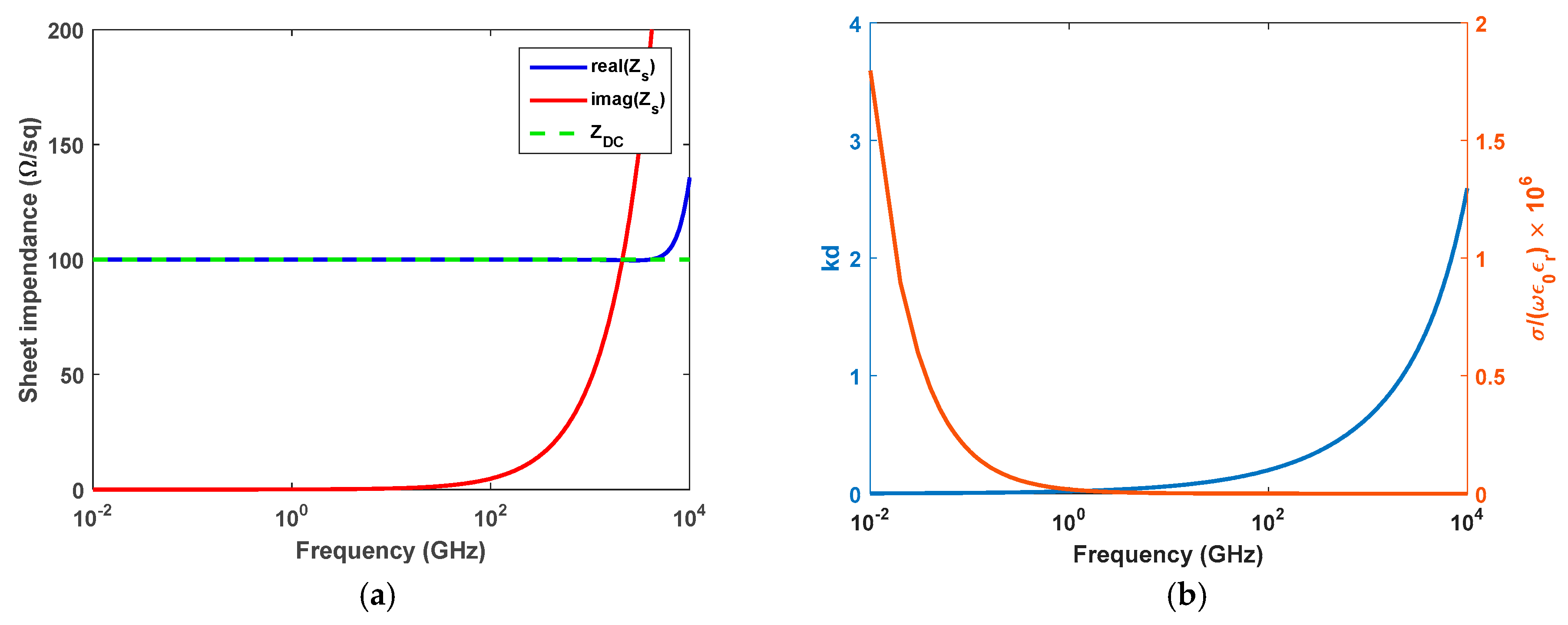

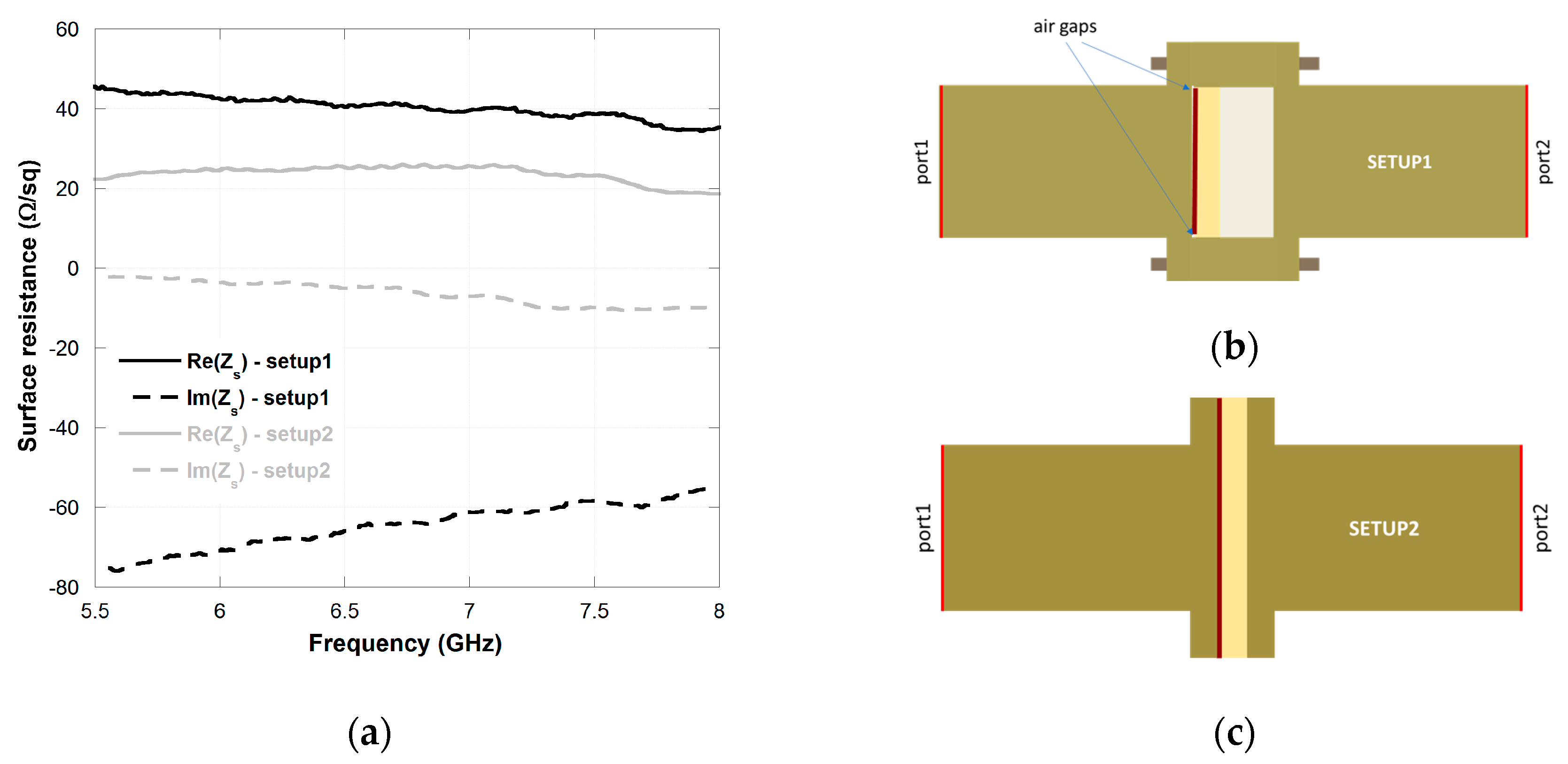

3. Measuring the Surface Impedance of Thin Sheets

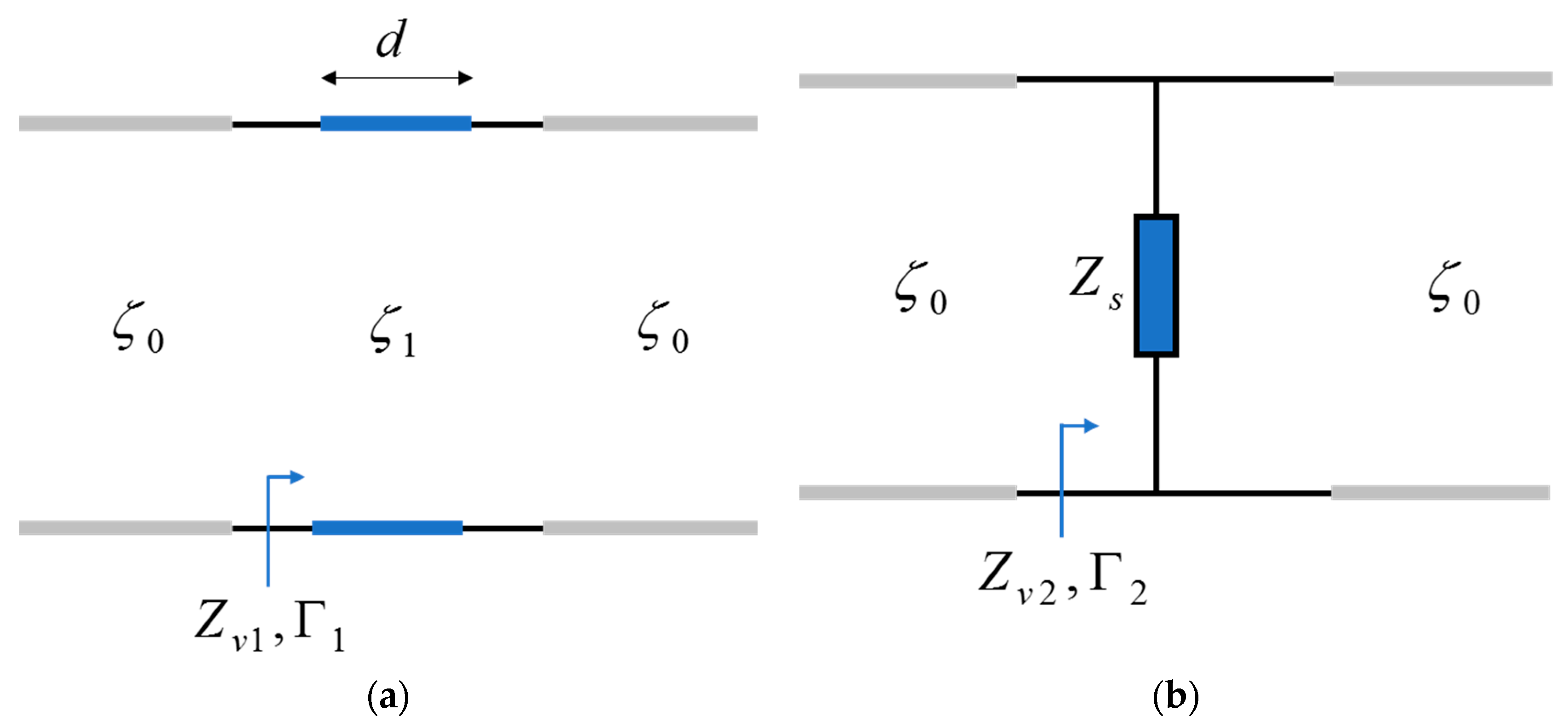

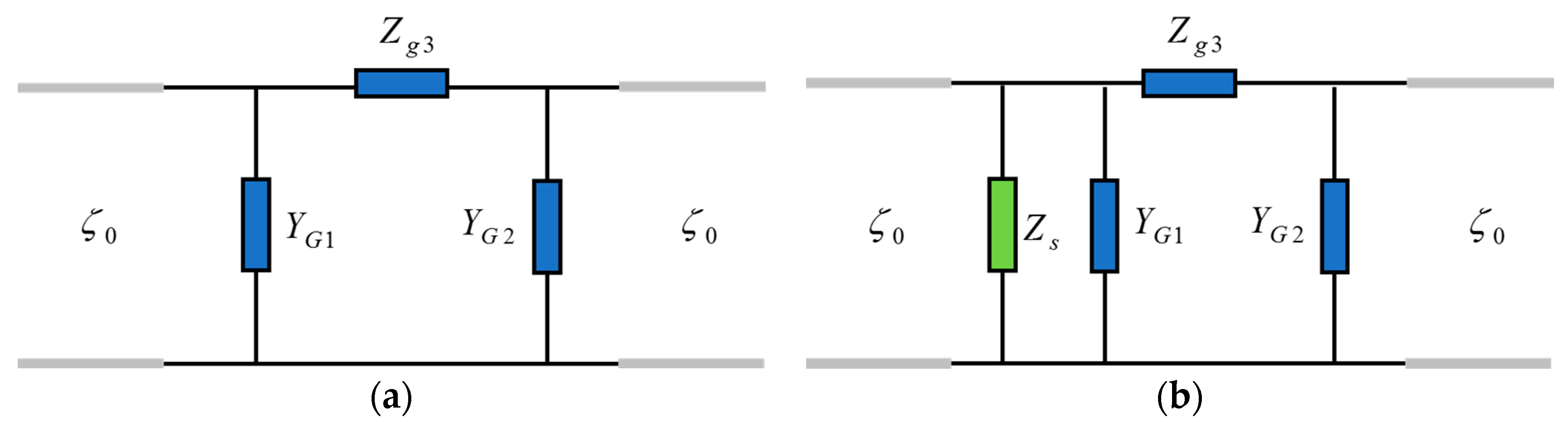

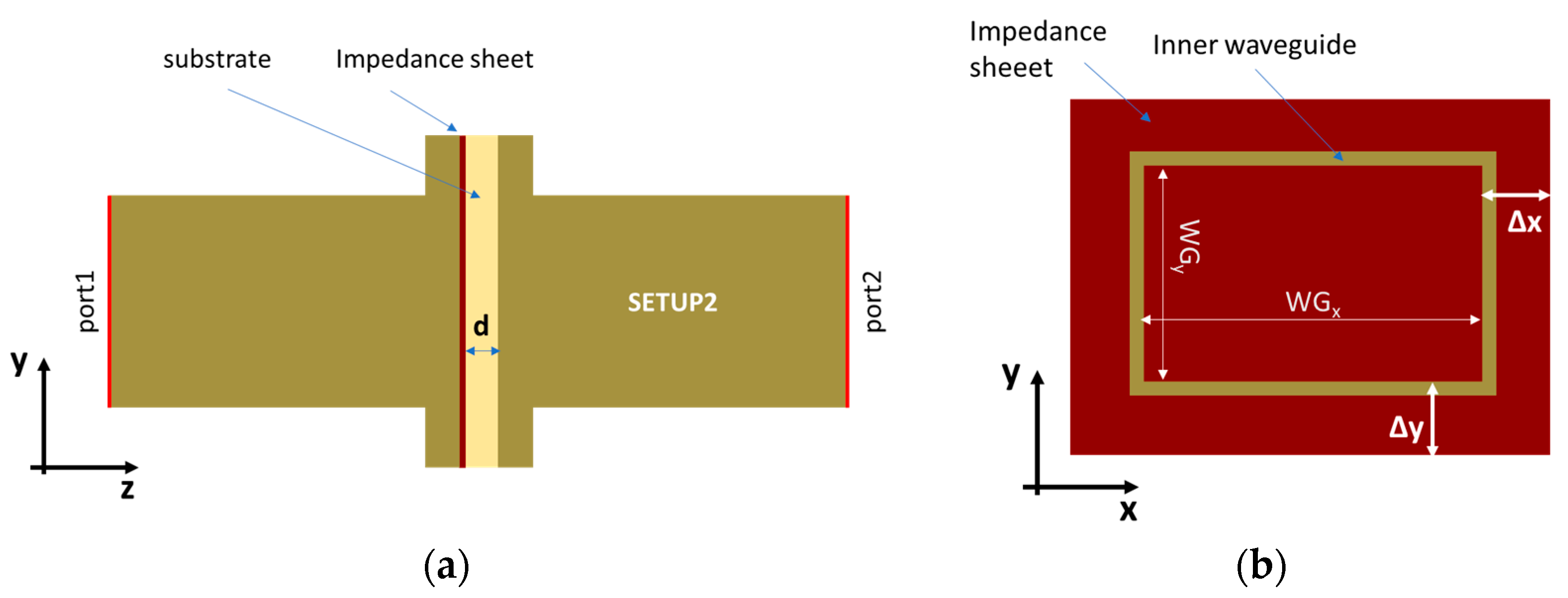

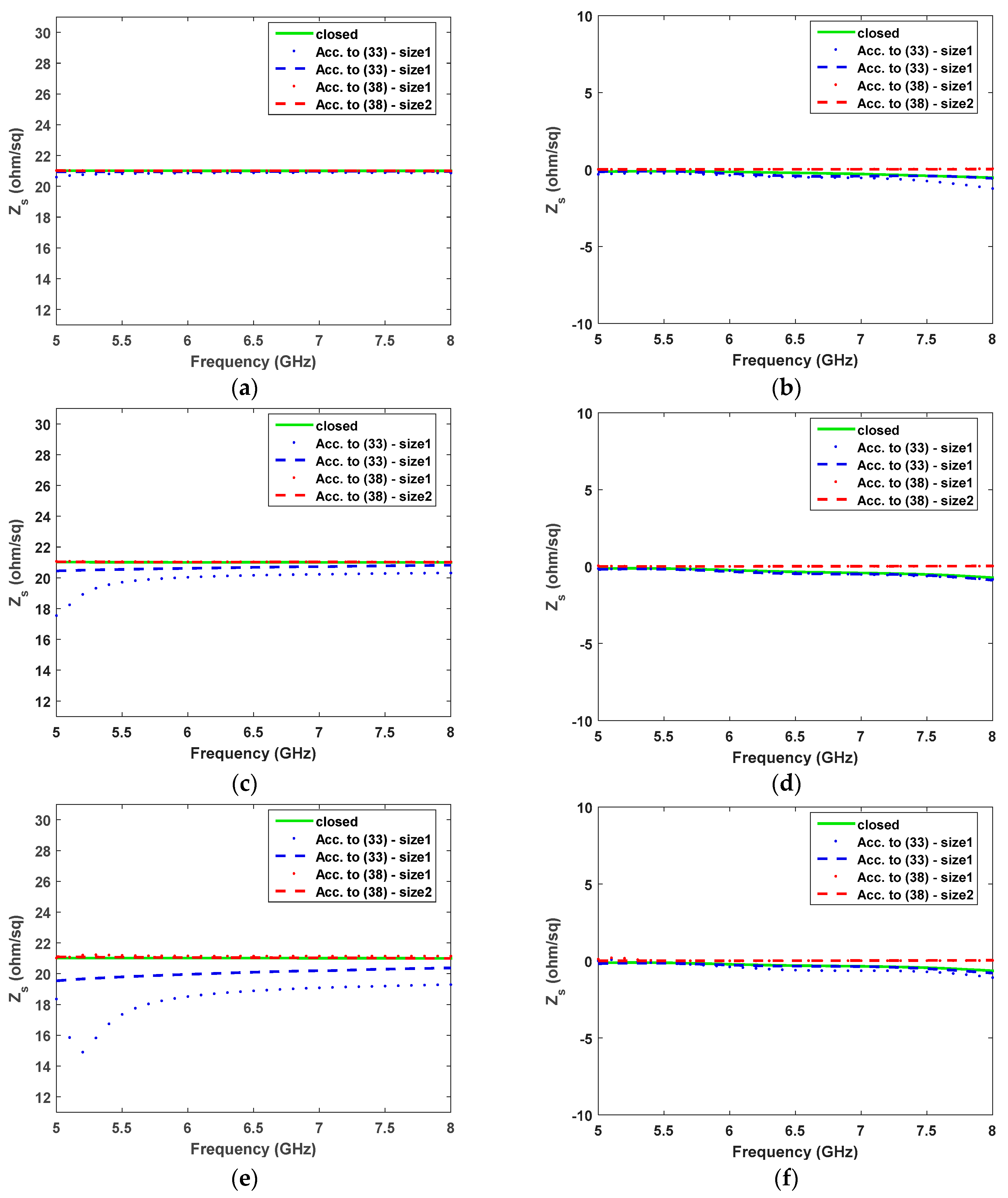

3.1. Inversion Procedure in a Closed Waveguide

3.2. Sample Positioning

3.3. Calibration Procedure of the Open Junction to Improve Estimation

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Schwierz, F.; Pezoldt, J.; Granzner, R. Two-dimensional materials and their prospects in transistor electronics. Nanoscale 2015, 7, 8261–8283. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Zhang, R.; Staiculescu, D.; Wong, C.P.; Tentzeris, M.M. A Novel Conformal RFID-Enabled Module Utilizing Inkjet-Printed Antennas and Carbon Nanotubes for Gas-Detection Applications. IEEE Antennas Wirel. Propag. Lett. 2009, 8, 653–656. [Google Scholar] [CrossRef]

- Genovesi, S.; Costa, F.; Fanciulli, F.; Monorchio, A. Wearable Inkjet-Printed Wideband Antenna by Using Miniaturized AMC for Sub-GHz Applications. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1927–1930. [Google Scholar] [CrossRef]

- Kim, S.; Cook, B.; Le, T.; Cooper, J.; Lee, H.; Lakafosis, V.; Vyas, R.; Moro, R.; Bozzi, M.; Georgiadis, A.; Collado, A.; Tentzeris, M.M. Inkjet-printed antennas, sensors and circuits on paper substrate. Antennas Propag. IET Microw. 2013, 7, 858–868. [Google Scholar] [CrossRef]

- Sushko, O.; Pigeon, M.; Donnan, R.S.; Kreouzis, T.; Parini, C.G.; Dubrovka, R. Comparative Study of Sub-THz FSS Filters Fabricated by Inkjet Printing, Microprecision Material Printing, and Photolithography. IEEE Trans. Terahertz Sci. Technol. 2017, 7, 184–190. [Google Scholar] [CrossRef]

- Batchelor, J.C.; Parker, E.A.; Miller, J.A.; Sanchez-Romaguera, V.; Yeates, S.G. Inkjet printing of frequency selective surfaces. Electron. Lett. 2009, 45, 7–8. [Google Scholar] [CrossRef] [Green Version]

- Borgese, M.; Dicandia, F.A.; Costa, F.; Genovesi, S.; Manara, G. An Inkjet Printed Chipless RFID Sensor for Wireless Humidity Monitoring. IEEE Sens. J. 2017, 17, 4699–4707. [Google Scholar] [CrossRef]

- Ando, B.; Baglio, S. Inkjet-printed sensors: A useful approach for low cost, rapid prototyping. IEEE Instrum. Meas. Mag. 2011, 14, 36–40. [Google Scholar] [CrossRef]

- Yang, L.; Rida, A.; Vyas, R.; Tentzeris, M.M. RFID Tag and RF Structures on a Paper Substrate Using Inkjet-Printing Technology. IEEE Trans. Microw. Theory Tech. 2007, 55, 2894–2901. [Google Scholar] [CrossRef]

- Munk, B.A. Frequency Selective Surfaces: Theory and Design; John Wiley & Sons: Hoboken, NJ, USA, 2005; ISBN 978-0-471-72376-9. [Google Scholar]

- Costa, F.; Monorchio, A.; Manara, G. Theory, design and perspectives of electromagnetic wave absorbers. IEEE Electromagn. Compat. Mag. 2016, 5, 67–74. [Google Scholar] [CrossRef]

- Costa, F.; Monorchio, A.; Manara, G. Analysis and Design of Ultra Thin Electromagnetic Absorbers Comprising Resistively Loaded High Impedance Surfaces. IEEE Trans. Antennas Propag. 2010, 58, 1551–1558. [Google Scholar] [CrossRef]

- Maier, T.; Brückl, H. Wavelength-tunable microbolometers with metamaterial absorbers. Opt. Lett. 2009, 34, 3012. [Google Scholar] [CrossRef] [PubMed]

- Okano, Y.; Ogino, S.; Ishikawa, K. Development of Optically Transparent Ultrathin Microwave Absorber for Ultrahigh-Frequency RF Identification System. IEEE Trans. Microw. Theory Tech. 2012, 60, 2456–2464. [Google Scholar] [CrossRef]

- Wu, B.; Tuncer, H.M.; Naeem, M.; Yang, B.; Cole, M.T.; Milne, W.I.; Hao, Y. Experimental demonstration of a transparent graphene millimetre wave absorber with 28% fractional bandwidth at 140 GHz. Sci. Rep. 2014, 4, 4130. [Google Scholar] [CrossRef] [PubMed]

- Knott, E.F.; Schaeffer, J.F.; Tuley, M.T. Radar Cross-Section: Its Prediction, Meauserement and Reduction; Dedham, M.A., Ed.; Artech House: Norwood, MA, USA, 1985. [Google Scholar]

- Fukuda, K.; Yoshimura, Y.; Okamoto, T.; Takeda, Y.; Kumaki, D.; Katayama, Y.; Tokito, S. Reverse-Offset Printing Optimized for Scalable Organic Thin-Film Transistors with Submicrometer Channel Lengths. Adv. Electron. Mater. 2015, 1. [Google Scholar] [CrossRef]

- Räisänen, A.V.; Ala-Laurinaho, J.; Asadchy, V.; Diaz-Rubio, A.; Khanal, S.; Semkin, V.; Tretyakov, S.; Wang, X.; Zheng, J.; Alastalo, A.; et al. Suitability of roll-to-roll reverse offset printing for mass production of millimeter-wave antennas: Progress report. In Proceedings of the 2016 Loughborough Antennas Propagation Conference (LAPC), Loughborough, UK, 14–15 November 2016; pp. 1–5. [Google Scholar]

- Havemann, R.H.; Hutchby, J.A. High-performance interconnects: An integration overview. Proc. IEEE 2001, 89, 586–601. [Google Scholar] [CrossRef]

- Maex, K.; Baklanov, M.R.; Shamiryan, D.; lacopi, F.; Brongersma, S.H.; Yanovitskaya, Z.S. Low dielectric constant materials for microelectronics. J. Appl. Phys. 2003, 93, 8793–8841. [Google Scholar] [CrossRef]

- Rida, A.; Yang, L.; Vyas, R.; Tentzeris, M.M. Conductive Inkjet-Printed Antennas on Flexible Low-Cost Paper-Based Substrates for RFID and WSN Applications. IEEE Antennas Propag. Mag. 2009, 51, 13–23. [Google Scholar] [CrossRef]

- Choi, M.-C.; Kim, Y.; Ha, C.-S. Polymers for flexible displays: From material selection to device applications. Prog. Polym. Sci. 2008, 33, 581–630. [Google Scholar] [CrossRef]

- Hyde IV, M.W.; Havrilla, M.J. A Nondestructive Technique for Determining Complex Permittivity and Permeability of Magnetic Sheet Materials Using Two Flanged Rectangular Waveguides. Prog. Electromagn. Res. 2008, 79, 367–386. [Google Scholar] [CrossRef]

- Zoughi, R. Microwave Non-Destructive Testing and Evaluation Principles; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 978-94-015-1303-6. [Google Scholar]

- Hasar, U.C. Non-destructive testing of hardened cement specimens at microwave frequencies using a simple free-space method. NDT E Int. 2009, 42, 550–557. [Google Scholar] [CrossRef]

- Blitz, J. Electrical and Magnetic Methods of Non-destructive Testing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 978-94-011-5818-3. [Google Scholar]

- Kharkovsky, S.; Zoughi, R. Microwave and millimeter wave nondestructive testing and evaluation—Overview and recent advances. IEEE Instrum. Meas. Mag. 2007, 10, 26–38. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, B.; Tian, G.Y.; Woo, W.L.; Bai, L. Metal defects sizing and detection under thick coating using microwave NDT. NDT E Int. 2013, 60, 52–61. [Google Scholar] [CrossRef]

- Chen, L.-F.; Ong, C.K.; Neo, C.P.; Varadan, V.V.; Varadan, V.K. Microwave Electronics: Measurement and Materials Characterization; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Von Hippel, A.R. Dielectric Materials and Applications; Artech House: Dedham, MA, USA, 1954; Volume 2. [Google Scholar]

- Nicolson, A.M.; Ross, G.F. Measurement of the Intrinsic Properties of Materials by Time-Domain Techniques. IEEE Trans. Instrum. Meas. 1970, 19, 377–382. [Google Scholar] [CrossRef]

- Weir, W.B. Automatic measurement of complex dielectric constant and permeability at microwave frequencies. Proc. IEEE 1974, 62, 33–36. [Google Scholar] [CrossRef]

- Baker-Jarvis, J.; Janezic, M.D.; Grosvenor, J.H., Jr.; Geyer, R.G. Transmission/reflection and short-circuit line methods for measuring permittivity and permeability. NASA STIRecon Tech. Rep. N 1992, 93, 12084. [Google Scholar]

- Baker-Jarvis, J.; Geyer, R.G.; Grosvenor, J.H.; Janezic, M.D.; Jones, C.A.; Riddle, B.; Weil, C.M.; Krupka, J. Dielectric characterization of low-loss materials a comparison of techniques. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 571–577. [Google Scholar] [CrossRef]

- Baker-Jarvis, J.; Vanzura, E.J.; Kissick, W.A. Improved technique for determining complex permittivity with the transmission/reflection method. IEEE Trans. Microw. Theory Tech. 1990, 38, 1096–1103. [Google Scholar] [CrossRef]

- Baker-Jarvis, J.; Geyer, R.G.; Domich, P.D. A nonlinear least-squares solution with causality constraints applied to transmission line permittivity and permeability determination. IEEE Trans. Instrum. Meas. 1992, 41, 646–652. [Google Scholar] [CrossRef]

- Marks, R.B. A multiline method of network analyzer calibration. IEEE Trans. Microw. Theory Tech. 1991, 39, 1205–1215. [Google Scholar] [CrossRef]

- Luukkonen, O.; Maslovski, S.I.; Tretyakov, S.A. A Stepwise Nicolson–Ross–Weir-Based Material Parameter Extraction Method. IEEE Antennas Wirel. Propag. Lett. 2011, 10, 1295–1298. [Google Scholar] [CrossRef]

- Degiorgi, M.; Costa, F.; Fontana, N.; Usai, P.; Monorchio, A. A stepwise transmission/reflection multiline-based algorithm for broadband permittivity measurements of dielectric materials. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, Puerto Rico, 26 June–1 July 2016; pp. 1989–1990. [Google Scholar]

- Arslanagić, S.; Hansen, T.V.; Mortensen, N.A.; Gregersen, A.H.; Sigmund, O.; Ziolkowski, R.W.; Breinbjerg, O. A Review of the Scattering-Parameter Extraction Method with Clarification of Ambiguity Issues in Relation to Metamaterial Homogenization. IEEE Antennas Propag. Mag. 2013, 55, 91–106. [Google Scholar] [CrossRef]

- Alù, A.; Yaghjian, A.D.; Shore, R.A.; Silveirinha, M.G. Causality relations in the homogenization of metamaterials. Phys. Rev. B 2011, 84, 054305. [Google Scholar] [CrossRef]

- Simovski, C.R. Material parameters of metamaterials (a Review). Opt. Spectrosc. 2009, 107, 726. [Google Scholar] [CrossRef]

- Costa, F.; Amabile, C.; Monorchio, A.; Prati, E. Waveguide Dielectric Permittivity Measurement Technique Based on Resonant FSS Filters. IEEE Microw. Wirel. Compon. Lett. 2011, 21, 273–275. [Google Scholar] [CrossRef]

- Costa, F. Surface Impedance Measurement of Resistive Coatings at Microwave Frequencies. IEEE Trans. Instrum. Meas. 2013, 62, 432–437. [Google Scholar] [CrossRef]

- Wang, X.C.; Díaz-Rubio, A.; Tretyakov, S.A. An Accurate Method for Measuring the Sheet Impedance of Thin Conductive Films at Microwave and Millimeter-Wave Frequencies. IEEE Trans. Microw. Theory Tech. 2017, 99, 1–10. [Google Scholar] [CrossRef]

- Gómez-Díaz, J.S.; Perruisseau-Carrier, J.; Sharma, P.; Ionescu, A. Non-contact characterization of graphene surface impedance at micro and millimeter waves. J. Appl. Phys. 2012, 111, 114908. [Google Scholar] [CrossRef]

- Chen, X.; Grzegorczyk, T.M.; Wu, B.-I.; Pacheco, J.; Kong, J.A. Robust method to retrieve the constitutive effective parameters of metamaterials. Phys. Rev. E 2004, 70, 016608. [Google Scholar] [CrossRef] [PubMed]

- Koschny, T.; Markoš, P.; Smith, D.R.; Soukoulis, C.M. Resonant and antiresonant frequency dependence of the effective parameters of metamaterials. Phys. Rev. E 2003, 68, 065602. [Google Scholar] [CrossRef] [PubMed]

- Alù, A. Restoring the physical meaning of metamaterial constitutive parameters. Phys. Rev. B 2011, 83, 081102. [Google Scholar] [CrossRef]

- Sjoberg, D.; Larsson, C. Cramér–Rao Bounds for Determination of Permittivity and Permeability in Slabs. IEEE Trans. Microw. Theory Tech. 2011, 59, 2970–2977. [Google Scholar] [CrossRef]

- Sjöberg, D.; Larsson, C. Opportunities and challenges in the characterization of composite materials in waveguides. Radio Sci. 2011, 46, RS0E19. [Google Scholar] [CrossRef]

- Boughriet, A.-H.; Legrand, C.; Chapoton, A. Noniterative stable transmission/reflection method for low-loss material complex permittivity determination. IEEE Trans. Microw. Theory Tech. 1997, 45, 52–57. [Google Scholar] [CrossRef]

- Williams, T.C.; Stuchly, M.A.; Saville, P. Modified transmission-reflection method for measuring constitutive parameters of thin flexible high-loss materials. IEEE Trans. Microw. Theory Tech. 2003, 51, 1560–1566. [Google Scholar] [CrossRef]

- Hasar, U.C.; Kaya, Y.; Barroso, J.J.; Ertugrul, M. Determination of Reference-Plane Invariant, Thickness-Independent, and Broadband Constitutive Parameters of Thin Materials. IEEE Trans. Microw. Theory Tech. 2015, 63, 2313–2321. [Google Scholar] [CrossRef]

- Hasar, U.C. A New Calibration-Independent Method for Complex Permittivity Extraction of Solid Dielectric Materials. IEEE Microw. Wirel. Compon. Lett. 2008, 18, 788–790. [Google Scholar] [CrossRef]

- Hasar, U.C. A Fast and Accurate Amplitude-Only Transmission-Reflection Method for Complex Permittivity Determination of Lossy Materials. IEEE Trans. Microw. Theory Tech. 2008, 56, 2129–2135. [Google Scholar] [CrossRef]

- Hasar, U.C. Elimination of the multiple-solutions ambiguity in permittivity extraction from transmission-only measurements of lossy materials. Microw. Opt. Technol. Lett. 2009, 51, 337–341. [Google Scholar] [CrossRef]

- Cohen, D.; Shavit, R. Bi-anisotropic Metamaterials Effective Constitutive Parameters Extraction Using Oblique Incidence S-Parameters Method. IEEE Trans. Antennas Propag. 2015, 63, 2071–2078. [Google Scholar] [CrossRef]

- Hasar, U.C.; Muratoglu, A.; Bute, M.; Barroso, J.J.; Ertugrul, M. Effective Constitutive Parameters Retrieval Method for Bianisotropic Metamaterials Using Waveguide Measurements. IEEE Trans. Microw. Theory Tech. 2017, 65, 1488–1497. [Google Scholar] [CrossRef]

- Sozio, V.; Vallecchi, A.; Albani, M.; Capolino, F. Generalized Lorentz-Lorenz homogenization formulas for binary lattice metamaterials. Phys. Rev. B 2015, 91, 205127. [Google Scholar] [CrossRef]

- Baker-Jarvis, J.; Janezic, M.D.; Domich, P.D.; Geyer, R.G. Analysis of an open-ended coaxial probe with lift-off for nondestructive testing. IEEE Trans. Instrum. Meas. 1994, 43, 711–718. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Costa, F.; Monorchio, A.; Manara, G. Efficient Analysis of Frequency-Selective Surfaces by a Simple Equivalent-Circuit Model. IEEE Antennas Propag. Mag. 2012, 54, 35–48. [Google Scholar] [CrossRef]

- Costa, F.; Monorchio, A.; Manara, G. An Overview of Equivalent Circuit Modeling Techniques of Frequency Selective Surfaces and Metasurfaces. Appl. Comput. Electromagn. Soc. J. 2014, 29, 960–976. [Google Scholar]

- Mittra, R.; Chan, C.H.; Cwik, T. Techniques for analyzing frequency selective surfaces-a review. Proc. IEEE 1988, 76, 1593–1615. [Google Scholar] [CrossRef]

- Costa, F.; Monorchio, A.; Amabile, C.; Prati, E. Dielectric permittivity measurement technique based on waveguide FSS filters. In Proceedings of the 2011 41st European Microwave Conference, Manchester, UK, 10–13 October 2011; pp. 945–948. [Google Scholar]

- Street, R.A. Thin-Film Transistors. Adv. Mater. 2009, 21, 2007–2022. [Google Scholar] [CrossRef]

- Krebs, F.C. Roll-to-roll fabrication of monolithic large-area polymer solar cells free from indium-tin-oxide. Sol. Energy Mater. Sol. Cells 2009, 93, 1636–1641. [Google Scholar] [CrossRef]

- Kao, H. Carbon-Conductive Ink Resistor Printed Circuit board and Its Fabrication Method. U.S. Patent 6,713,399, 30 March 2004. [Google Scholar]

- Leyland, N.S.; Evans, J.R.G.; Harrison, D.J. Lithographic printing of force-sensitive resistors. J. Mater. Sci. Mater. Electron. 2002, 13, 387–390. [Google Scholar] [CrossRef]

- Chen, H.C.; Lee, K.C.; Lin, J.H.; Koch, M. Comparison of electromagnetic shielding effectiveness properties of diverse conductive textiles via various measurement techniques. J. Mater. Process. Technol. 2007, 192, 549–554. [Google Scholar] [CrossRef]

- Kulkarni, A.K.; Schulz, K.H.; Lim, T.S.; Khan, M. Dependence of the sheet resistance of indium-tin-oxide thin films on grain size and grain orientation determined from X-ray diffraction techniques. Thin Solid Films 1999, 345, 273–277. [Google Scholar] [CrossRef]

- Bae, S.; Kim, H.; Lee, Y.; Xu, X.; Park, J.-S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Ri Kim, H.; Song, Y.I.; Kim, Y.-J.; Kim, K.S.; Özyilmaz, B.; Ahn, J.-H.; Hong, B.H.; Iijima, S. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578. [Google Scholar] [CrossRef] [PubMed]

- Parashkov, R.; Becker, E.; Riedl, T.; Johannes, H.H.; Kowalsky, W. Large Area Electronics Using Printing Methods. Proc. IEEE 2005, 93, 1321–1329. [Google Scholar] [CrossRef]

- VAN DER PAUW, L.J. A method of measuring specific resistivity and Hall effect of discs of arbitrary shapes. Philips Res. Rep. 1958, 13, 1–9. [Google Scholar]

- Bussey, H.E. Standards and Measurements of Microwave Surface Impedance, Skin Depth, Conductivity and Q. IRE Trans. Instrum. 1960, I-9, 171–175. [Google Scholar] [CrossRef]

- Hernandez, A.; Martin, E.; Margineda, J.; Zamarro, J.M. Resonant cavities for measuring the surface resistance of metals at X-band frequencies. J. Phys. E 1986, 19, 222–225. [Google Scholar] [CrossRef]

- Booth, J.C.; Wu, D.H.; Anlage, S.M. A broadband method for the measurement of the surface impedance of thin films at microwave frequencies. Rev. Sci. Instrum. 1994, 65, 2082–2090. [Google Scholar] [CrossRef]

- Wu, R.; Qian, M. A simplified power transmission method used for measuring the complex conductivity of superconducting thin films. Rev. Sci. Instrum. 1997, 68, 155–158. [Google Scholar] [CrossRef]

- Sarabandi, K.; Ulaby, F.T. Technique for measuring the dielectric constant of thin materials. IEEE Trans. Instrum. Meas. 1988, 37, 631–636. [Google Scholar] [CrossRef]

- Hyde, I.V. Determining the Resistivity of Resistive Sheets Using Transmission Measurements. Master’s Thesis, Air Force Institute of Technology, Wright Patterson AFB, Montgomerie County, OH, USA, 2006. [Google Scholar]

- Hyde, M.W.; Havrilla, M.J.; Crittenden, P.E. A Novel Method for Determining the R-Card Sheet Impedance Using the Transmission Coefficient Measured in Free-Space or Waveguide Systems. IEEE Trans. Instrum. Meas. 2009, 58, 2228–2233. [Google Scholar] [CrossRef]

- Datta, A.N.; Nag, B.R. Techniques for the Measurement of Complex Microwave Conductivity and the Associated Errors. IEEE Trans. Microw. Theory Tech. 1970, 18, 162–166. [Google Scholar] [CrossRef]

| εs | ε | ftrans [MHz] | σ | µ | t [mm] | |

|---|---|---|---|---|---|---|

| Actual values | 100 | 2 | 300 | 0.5 | 1 | 100 |

| Best values (3 runs) | 87 | 1.43 | 305 | 0.64 | 1.01 | 100 |

| Actual values | 100 | 2 | 300 | 0.5 | 1 | 150 |

| Best values (6 runs) | 97.9 | 1.1 | 305 | 0.49 | 1.0 | 150 |

| GA search space (min) | 1 | 1 | 1 | 0 | 1 | |

| GA search space (max) | 200 | 50 | 1000 | 10 | 5 |

| Advantages | Disadvantages | Computation Time | |

|---|---|---|---|

| Nicolson Ross Weir direct inversion |

|

| Immediate |

| Baker-Jarvis iterative search |

|

| ∼1 min |

| Resonant Methods |

|

| Immediate |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, F.; Borgese, M.; Degiorgi, M.; Monorchio, A. Electromagnetic Characterisation of Materials by Using Transmission/Reflection (T/R) Devices. Electronics 2017, 6, 95. https://doi.org/10.3390/electronics6040095

Costa F, Borgese M, Degiorgi M, Monorchio A. Electromagnetic Characterisation of Materials by Using Transmission/Reflection (T/R) Devices. Electronics. 2017; 6(4):95. https://doi.org/10.3390/electronics6040095

Chicago/Turabian StyleCosta, Filippo, Michele Borgese, Marco Degiorgi, and Agostino Monorchio. 2017. "Electromagnetic Characterisation of Materials by Using Transmission/Reflection (T/R) Devices" Electronics 6, no. 4: 95. https://doi.org/10.3390/electronics6040095