Robust Autoland Design by Multi-Model ℋ∞ Synthesis with a Focus on the Flare Phase

Abstract

:1. Introduction

2. ILS-Based Automatic Landing

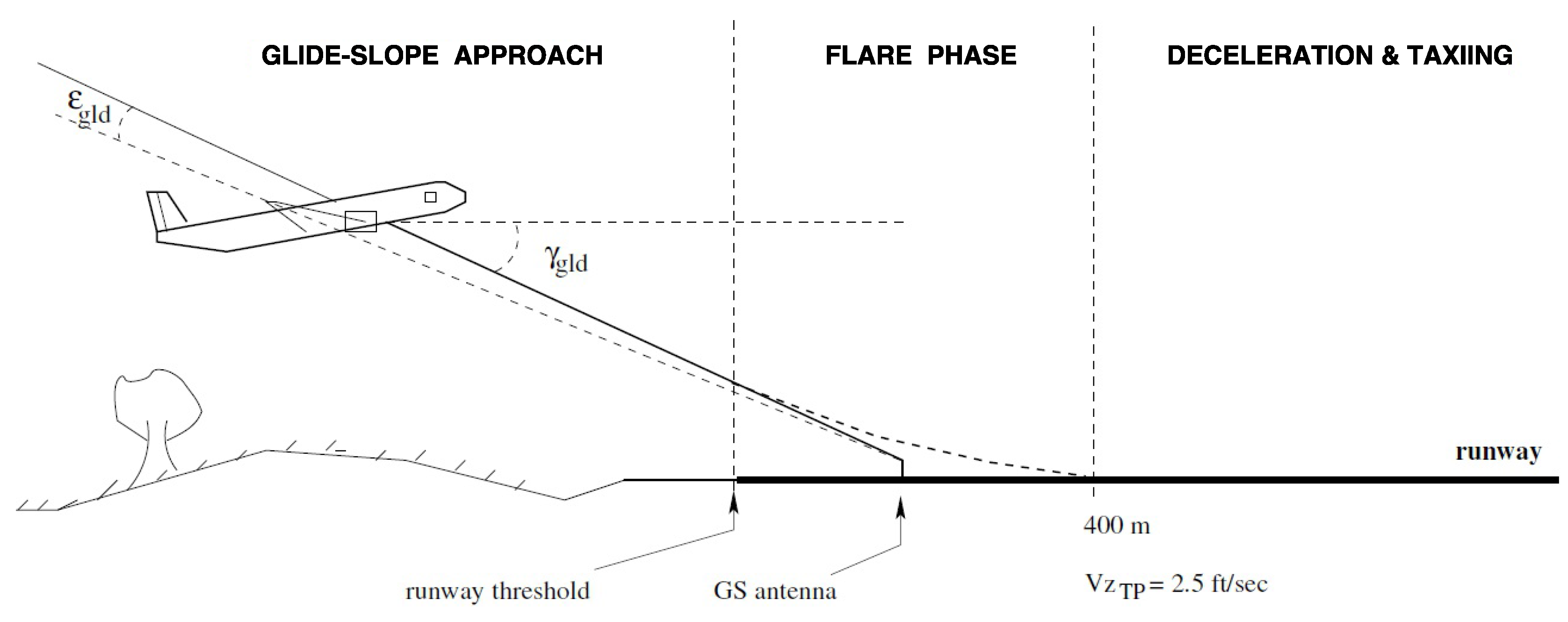

2.1. Final Approach

2.2. Flare and Align Phases

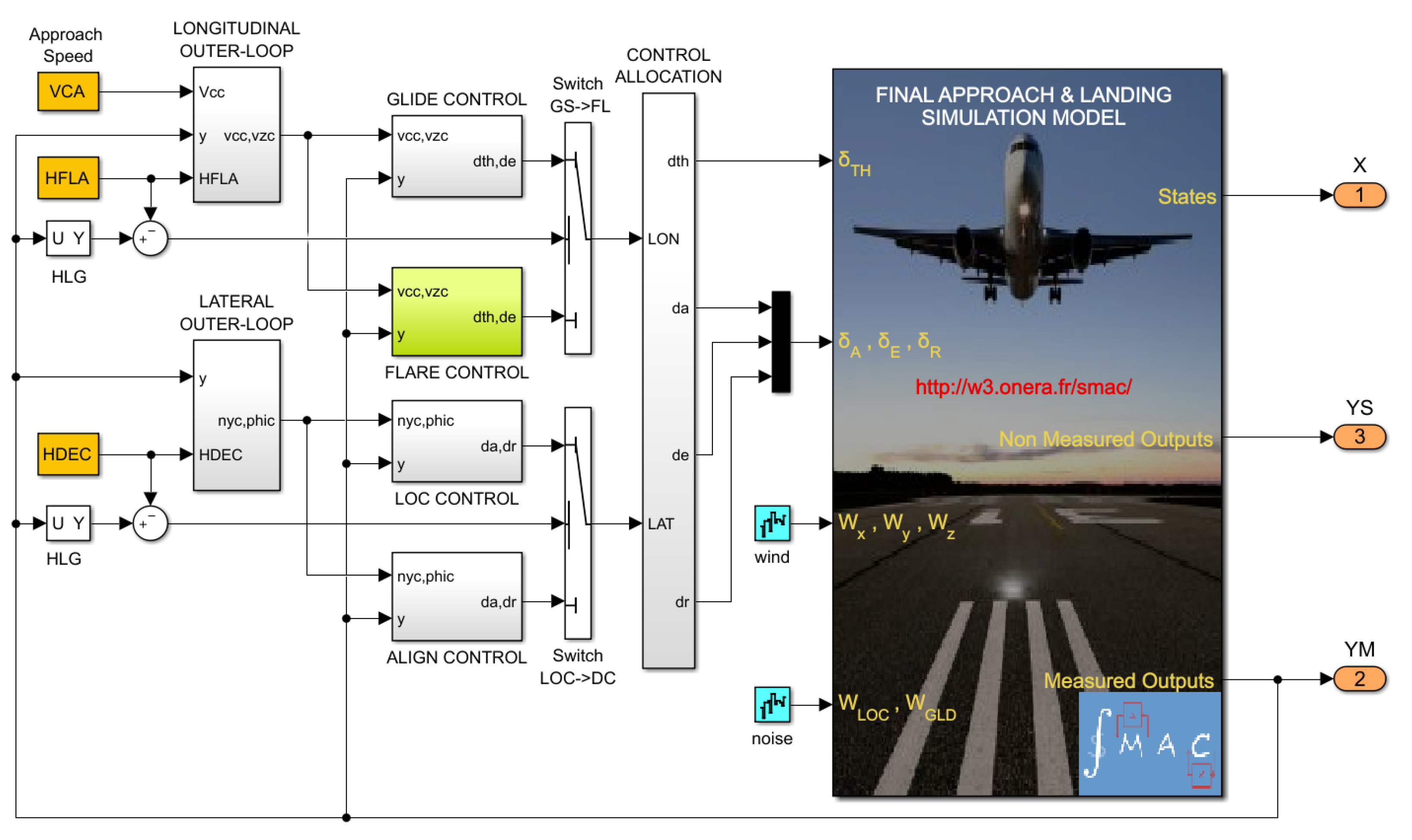

2.3. Overview of the Autoland Architecture

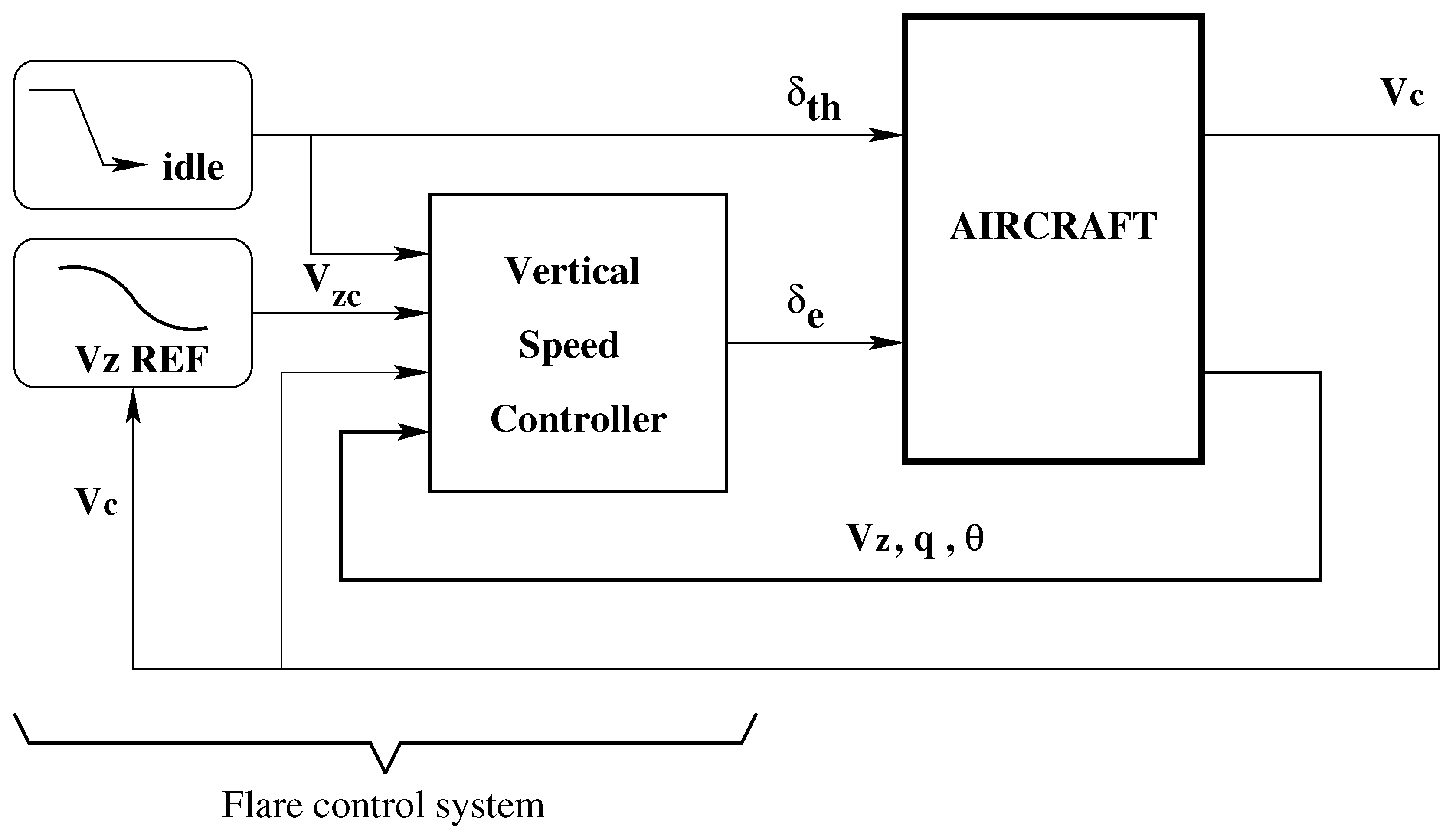

3. Flare Control Design

3.1. Overall Controller Structure

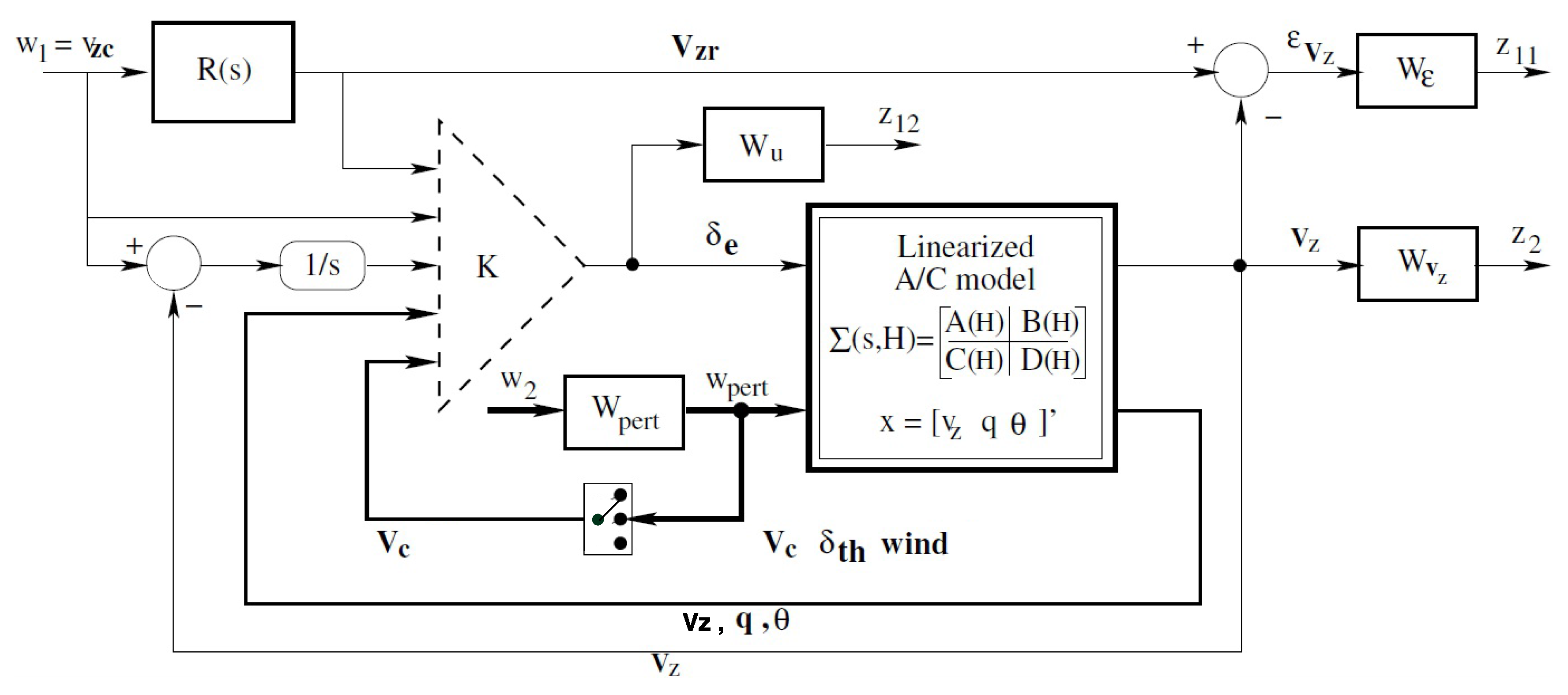

3.2. Vertical Speed Control via Multi-Channel Structured Optimization

- the norm of the error is minimized,

- the control activity is such that magnitude and rate saturations are avoided, and

- the perturbations have a negligible effect on the vertical speed variations.

3.3. Robustness Against Parametric Uncertainties and Modeling Errors

3.4. Weight Selection & Resolution Aspects

- two values of the landing gear height:

- four models (indexed by j) at the vertices of the (mass × centering) hypercube, and

- two separate optimization channels (indexed by i).

3.4.1. Reference Model on the Vertical Speed

3.4.2. Performance & Robustness Oriented Weighting Filters

3.4.3. Optimization Results

4. Nonlinear Implementation & Simulation Results

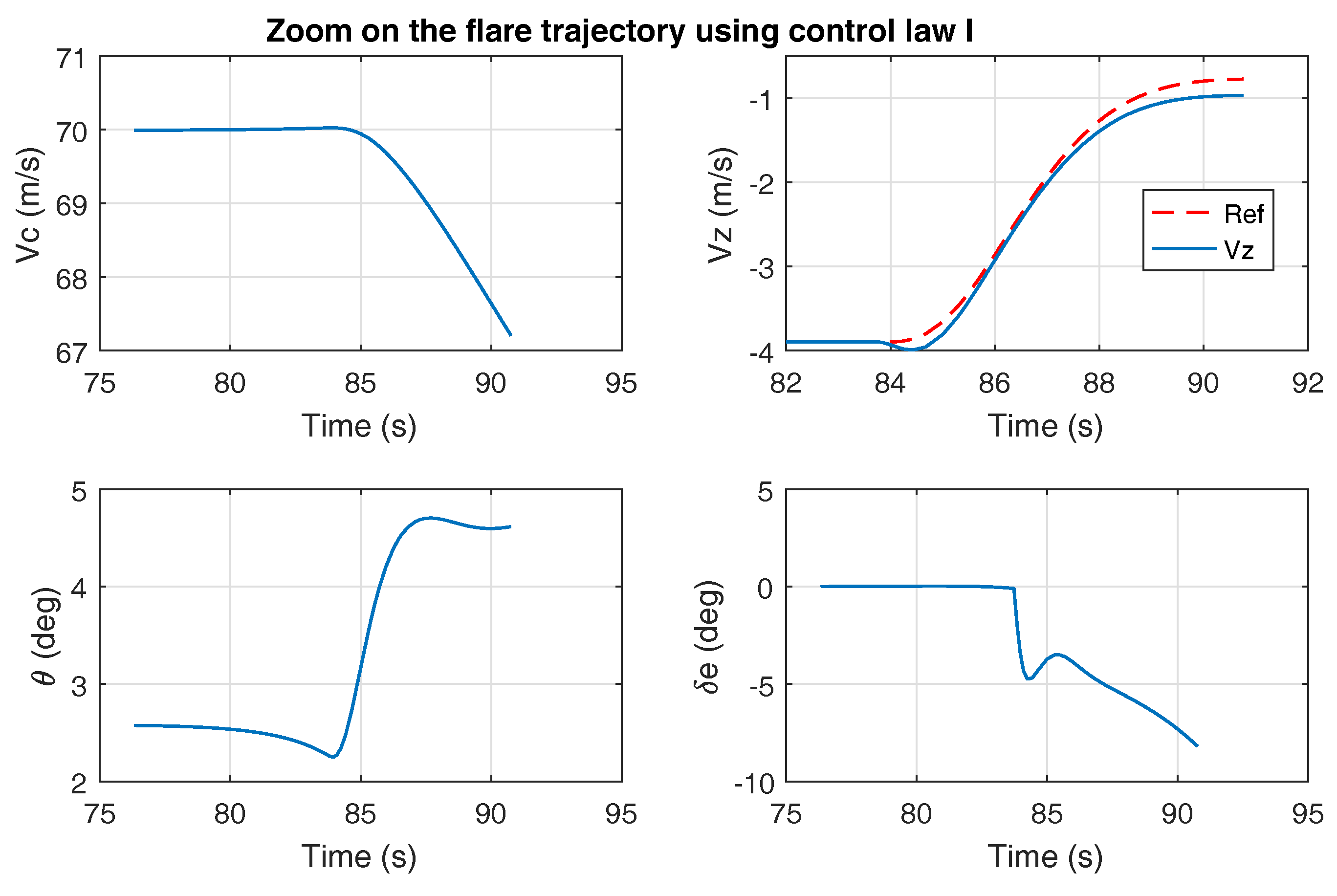

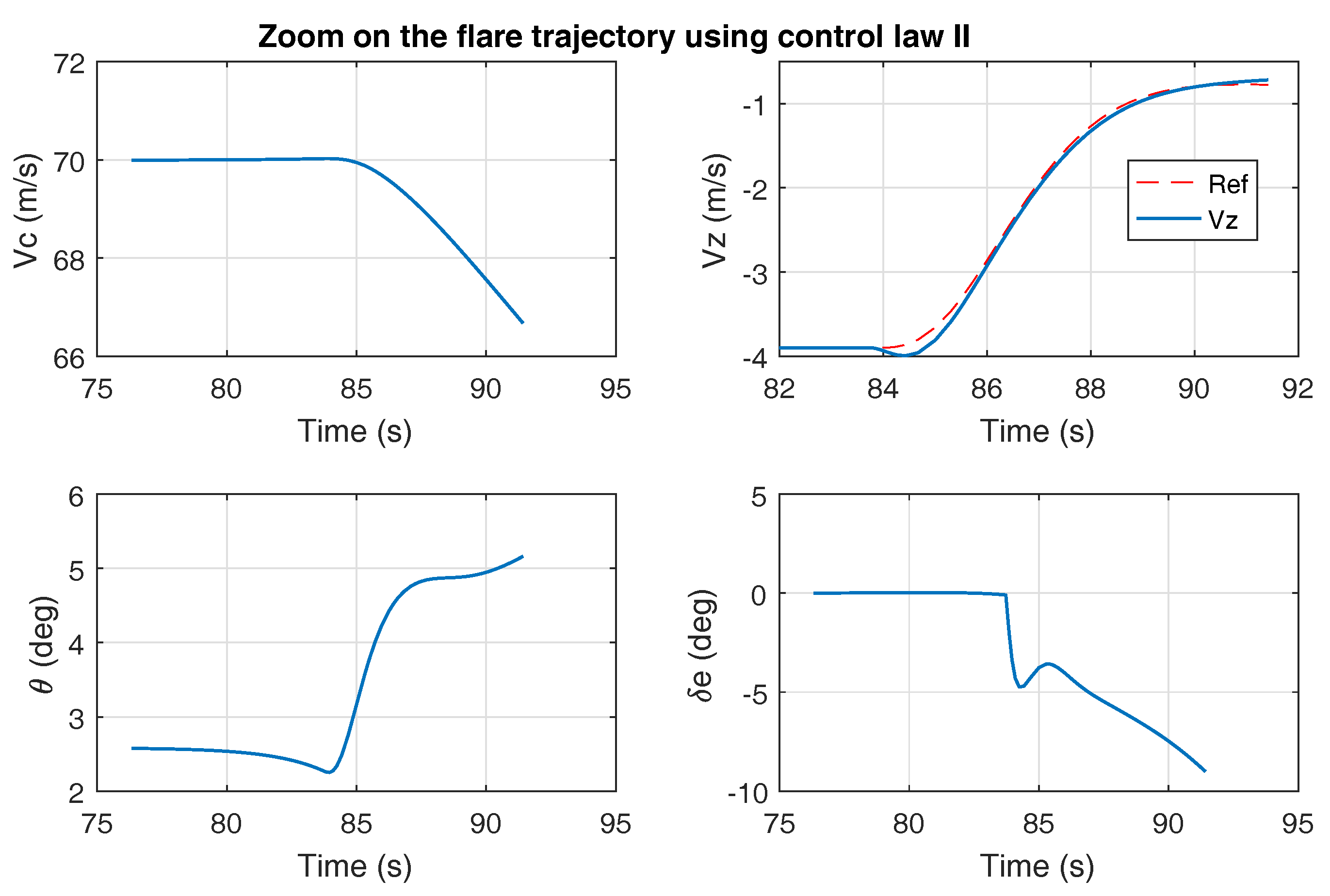

4.1. On the Interest of Using the Airspeed During Flare: Comparison of Laws I & II

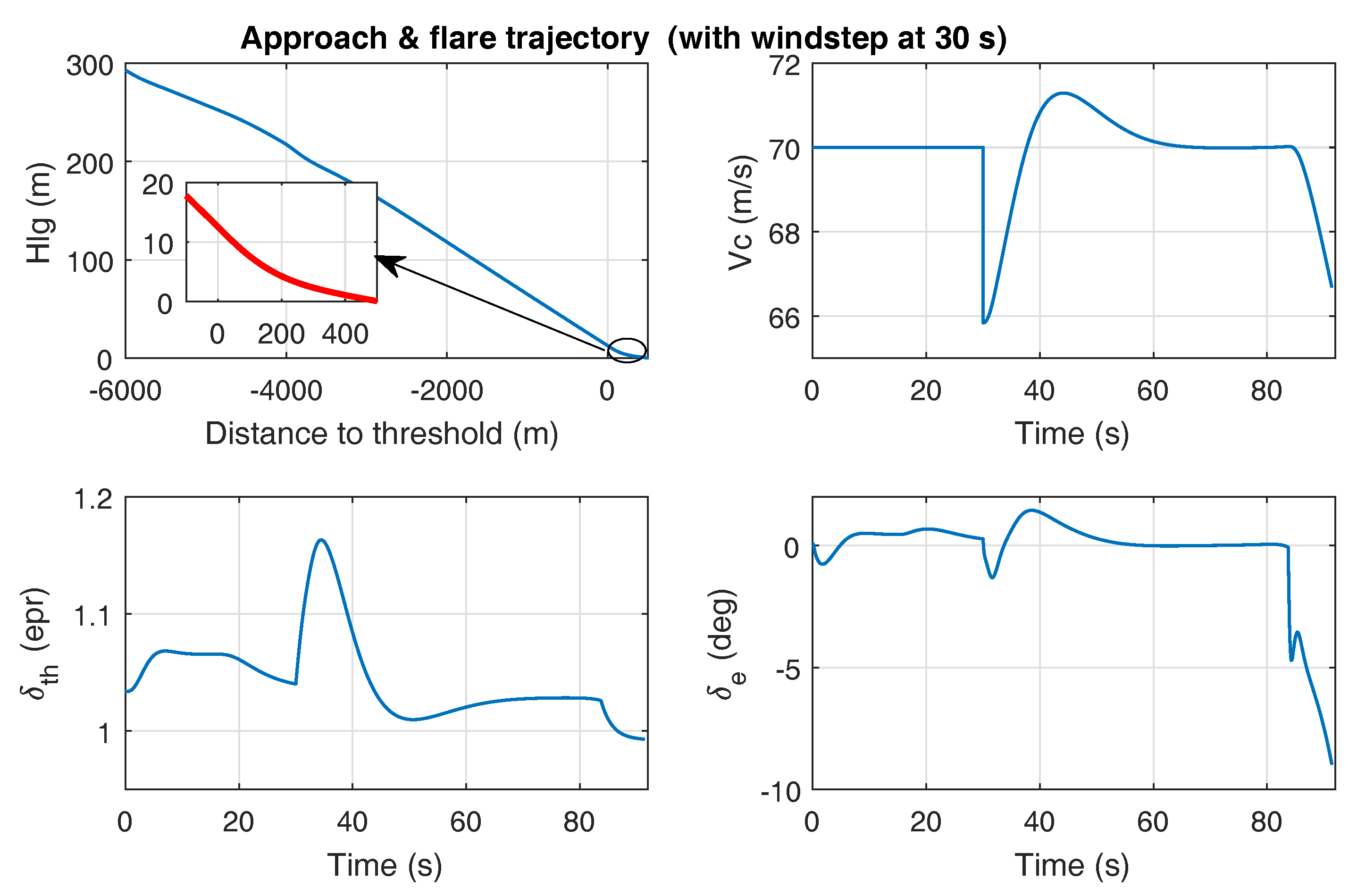

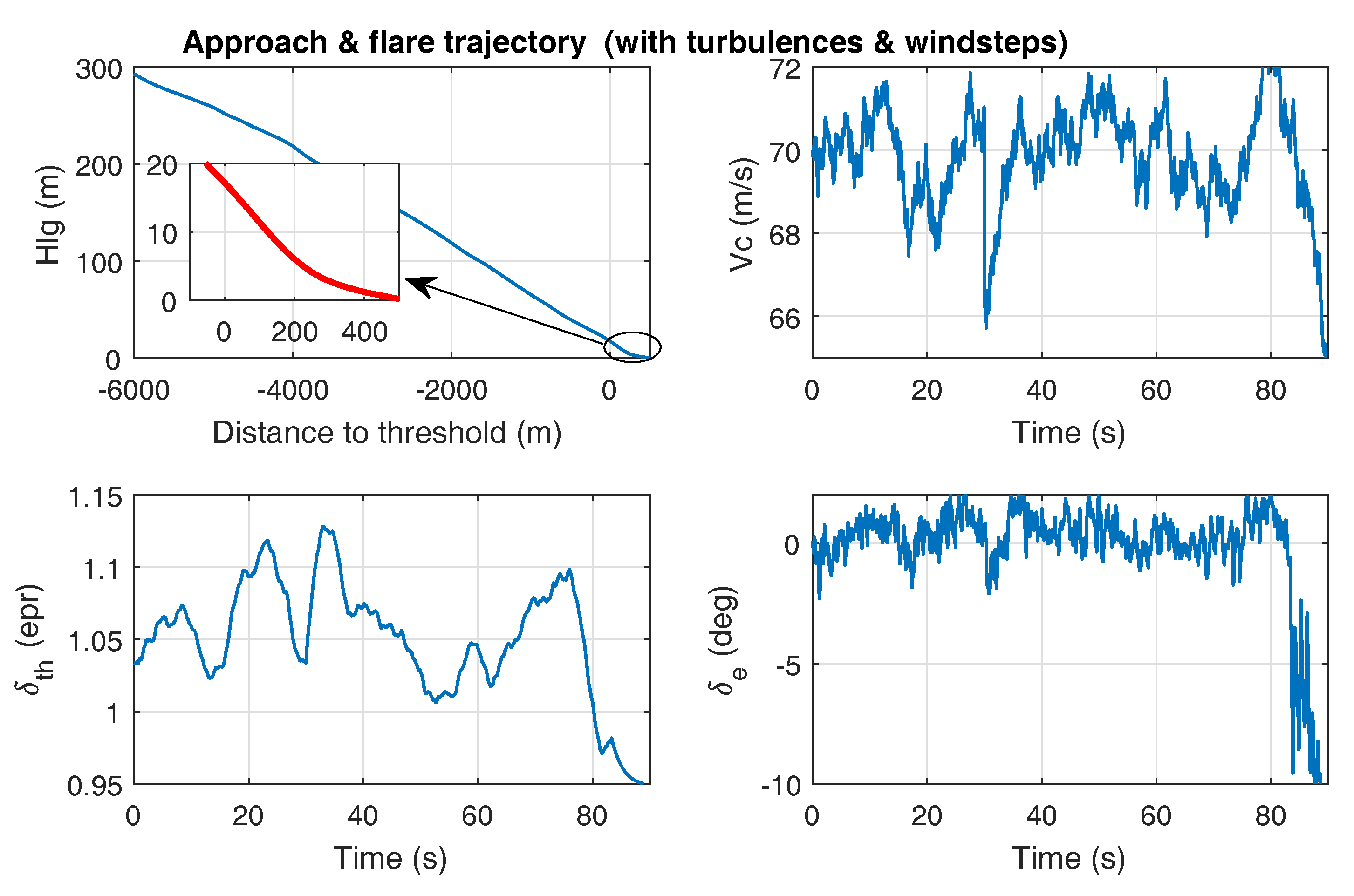

4.2. Wind & Turbulence Effects

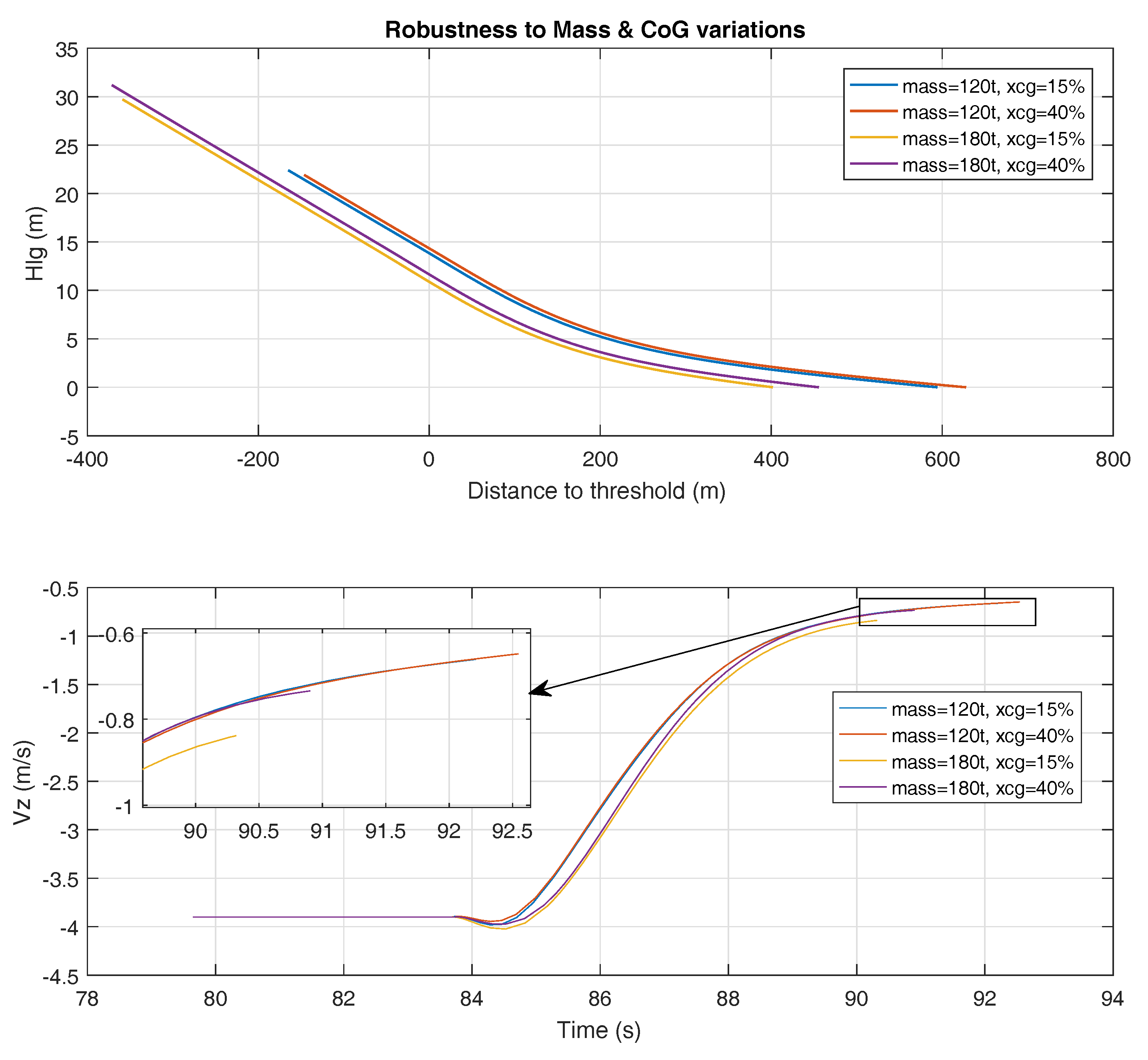

4.3. Illustration of Robustness

5. Conclusions

Author Contributions

Conflicts of Interest

Appendix A. The Aircraft Model

Appendix A.1. General Equations

Appendix A.2. Forces and Moments

Appendix A.3. Wind and Atmosphere Effects

Appendix A.4. Aerodynamic Coefficients

Appendix A.5. Engines and Actuators

- twin engines that both provide the same thrust in the fuselage direction (x-axis),

- a pair of ailerons whose asymmetric deflection generates moments about the x-axis (roll),

- an elevator whose deflection controls the y-axis (pitch), and

- a rudder whose deflection controls the z-axis (yaw).

| Control Input () | Time Constant () | Lower Bound () | Upper Bound () | Rate Limit () |

|---|---|---|---|---|

| Engines () | s | |||

| Ailerons () | s | deg | deg | deg/s |

| Elevators () | s | deg | deg | deg/s |

| Rudder () | s | deg | deg | deg/s |

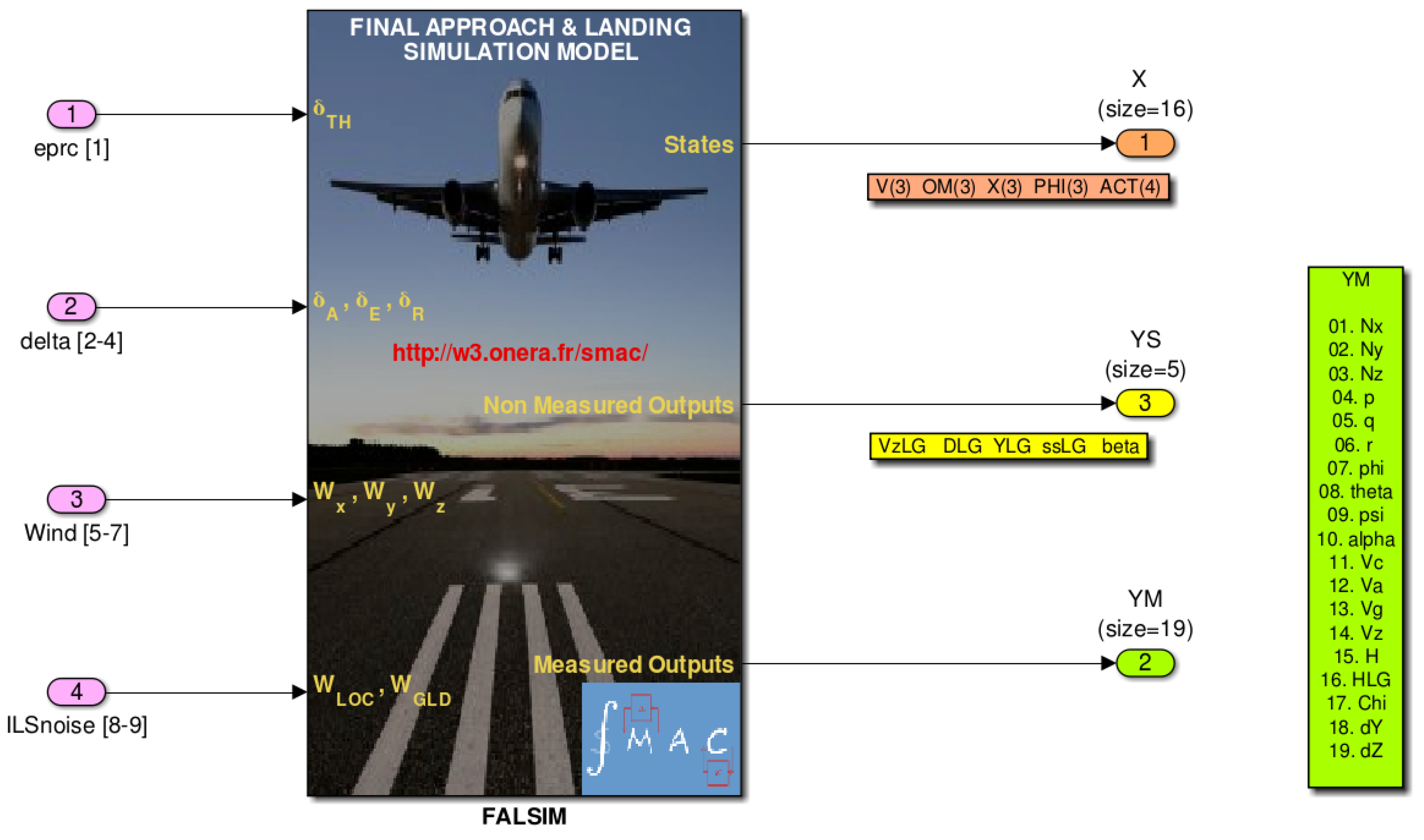

Appendix A.6. SIMULINK® Implementation

References

- Airbus. A Statistical Analysis of Commercial Aviation Accidents 1958–2016; Technical Report; Airbus: Toulouse, France, 2017. [Google Scholar]

- Kaminer, I.; Khargonekar, P. Design of the Flare Control Law for Longitudinal Autopilot Using H∞ Synthesis. In Proceedings of the 29th IEEE Conference on Decision and Control, Honolulu, HI, USA, 5–7 December 1990; pp. 2981–2986. [Google Scholar]

- Biannic, J.M.; Apkarian, P. A New Approach to Fixed-order H∞ Synthesis: Application to Autoland Design. In Proceedings of the AIAA Guidance, Navigation, and Control Conference, Monterey, CA, USA, 6–9 August 2001. [Google Scholar]

- Looye, G.; Joos, H. Design of Autoland Controller Functions with Multiobjective Optimization. J. Guid. Control Dyn. 2006, 29, 475–484. [Google Scholar] [CrossRef]

- Sadat-Hoseini, H.; Fazelzadeh, A.; Rasti, A.; Marzocca, P. Final Approach and Flare Control of a Flexible Aircraft in Crosswind Landings. J. Guid. Control Dyn. 2013, 36, 946–957. [Google Scholar] [CrossRef]

- Isidori, A.; Marconi, L.; Serrani, A. Robust Nonlinear Motion Control of a Helicopter. IEEE Trans. Autom. Control 2003, 48, 413–426. [Google Scholar] [CrossRef]

- Peng, K.; Cai, G.; Chen, B.; Dong, M.; Lum, K.; Lee, T. Design and implementation of an autonomous flight control law for a UAV helicopter. Automatica 2009, 45, 2333–2338. [Google Scholar] [CrossRef]

- Magni, J.F. Multimodel Eigenstructure Assignment in Flight-Control Design. Aerosp. Sci. Technol. 1999, 3, 141–151. [Google Scholar] [CrossRef]

- Dorobantu, A.; Murch, A.; Balas, G. Robust Control Design for the NASA AirSTAR Flight Test Vehicle. In Proceedings of the 50th AIAA Aerospace Sciences Meeting, Nashville, TN, USA, 9–12 January 2012. [Google Scholar]

- Apkarian, P.; Noll, D. Nonsmooth H∞ Synthesis. IEEE Trans. Autom. Control 2006, 51, 71–86. [Google Scholar] [CrossRef]

- Burke, J.; Henrion, D.; Lewis, A.; Overton, M. Stabilization via Nonsmooth, Nonconvex Optimization. IEEE Trans. Autom. Control 2006, 51, 1760–1769. [Google Scholar] [CrossRef]

- Apkarian, P.; Gahinet, P.; Buhr, P. Multi-Model, Multi-Objective Tuning of Fixed-Structure Controllers. In Proceedings of the European Control Conference, Strasbourg, France, 24–27 June 2014; pp. 856–861. [Google Scholar]

- Biannic, J.M.; Roos, C. Flare Control Law Design via Multi-Channel H∞ Synthesis: Illustration on a Freely Available Nonlinear Aircraft Benchmark. In Proceedings of the American Control Conference, Chicago, IL, USA, 17–19 June 2015; pp. 1303–1308. [Google Scholar]

- Zhou, K.; Doyle, J. Essential of Robust Control; Prentice-Hall: Upper Saddle River, NJ, USA, 1998. [Google Scholar]

- Biannic, J.M.; Roos, C.; Lesprier, J. Nonlinear Structured H∞ Controllers for Parameter-Dependent Uncertain Systems with Application to Aircraft Landing. AerospaceLab J. 2017, 13. [Google Scholar] [CrossRef]

- The Mathworks Inc. Robust Control Toolbox. Available online: https://mathworks.com/products/robust.html (accessed on 8 February 2016).

- Biannic, J.M.; Boada-Bauxell, J. A Civilian Aircraft Landing Challenge. Online Available from the Aerospace Benchmark Section of the SMAC Toolbox. Available online: http://w3.onera.fr/smac/ (accessed on 8 February 2016).

- Navarro-Tapia, D.; Simplicio, P.; Iannelli, A.; Marcos, A. Flare Control Design Using Structured H∞ Synthesis: A Civilian Aircraft Landing Challenge. In Proceedings of the 20th IFAC World Congress, Toulouse, France, 9–14 July 2017; pp. 4032–4037. [Google Scholar]

- Theis, J.; Ossmann, D.; Pfifer, H. Robust Autopilot Design for Crosswind Landing. In Proceedings of the 20th IFAC World Congress, Toulouse, France, 9–14 July 2017. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biannic, J.-M.; Roos, C. Robust Autoland Design by Multi-Model ℋ∞ Synthesis with a Focus on the Flare Phase. Aerospace 2018, 5, 18. https://doi.org/10.3390/aerospace5010018

Biannic J-M, Roos C. Robust Autoland Design by Multi-Model ℋ∞ Synthesis with a Focus on the Flare Phase. Aerospace. 2018; 5(1):18. https://doi.org/10.3390/aerospace5010018

Chicago/Turabian StyleBiannic, Jean-Marc, and Clément Roos. 2018. "Robust Autoland Design by Multi-Model ℋ∞ Synthesis with a Focus on the Flare Phase" Aerospace 5, no. 1: 18. https://doi.org/10.3390/aerospace5010018