Finite Element Analysis of Self-Healing and Damage Processes in Alumina/SiC Composite Ceramics

Abstract

:1. Introduction

2. Damage-Healing Constitutive Model

2.1. Stress–Strain Relation

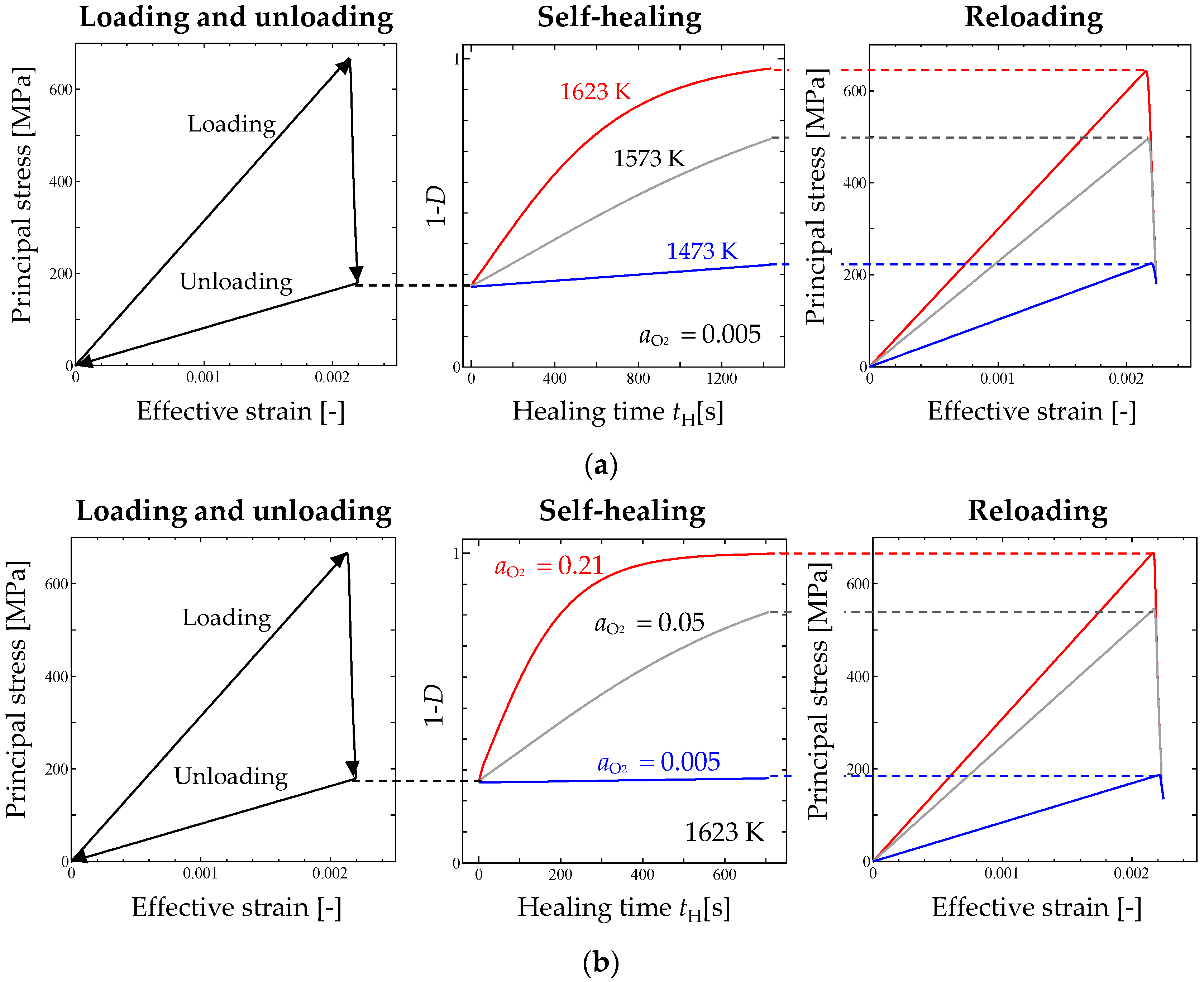

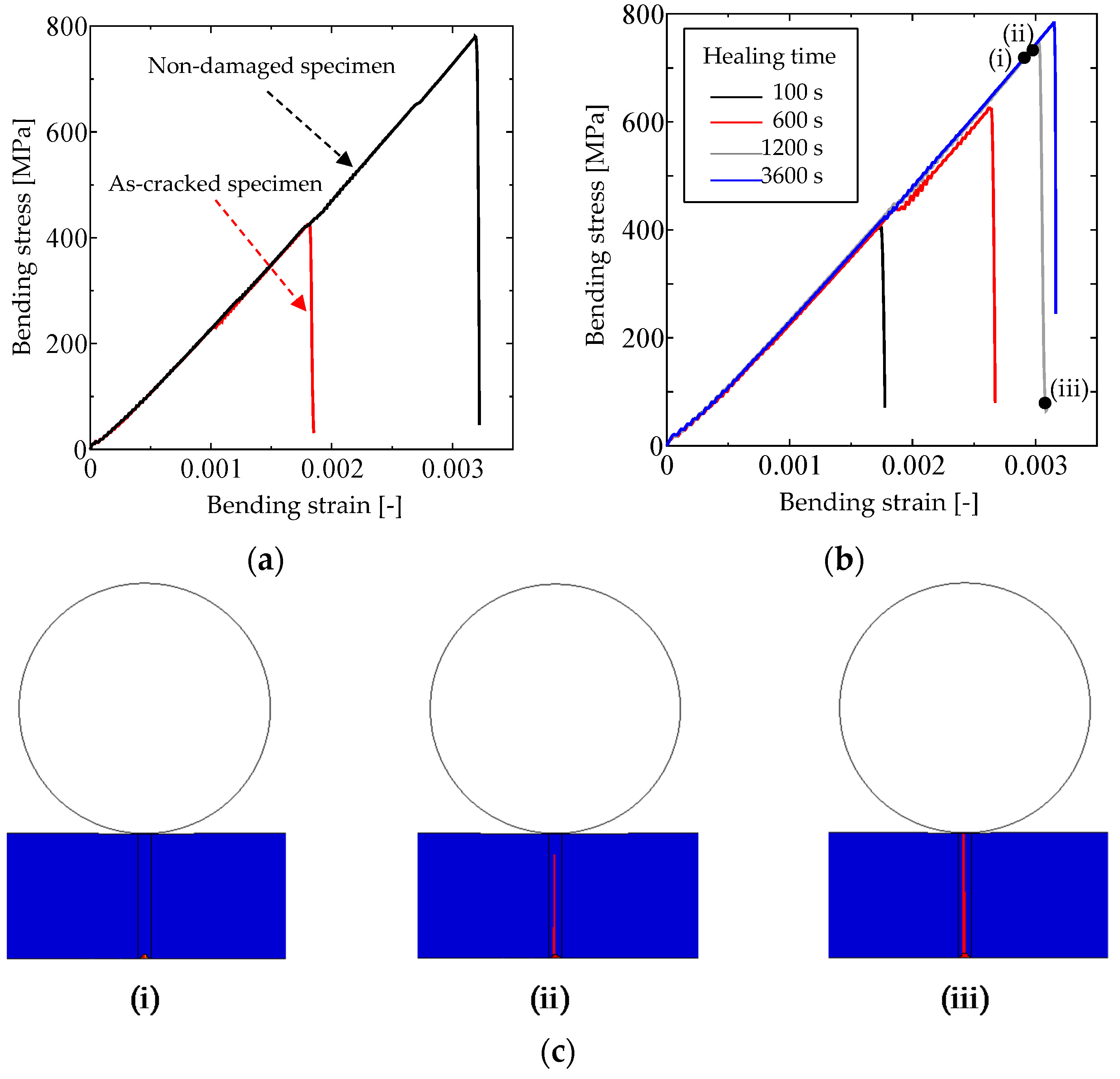

2.2. Typical Response of the Damage-Healing Constitutive Model

3. Results and Discussion

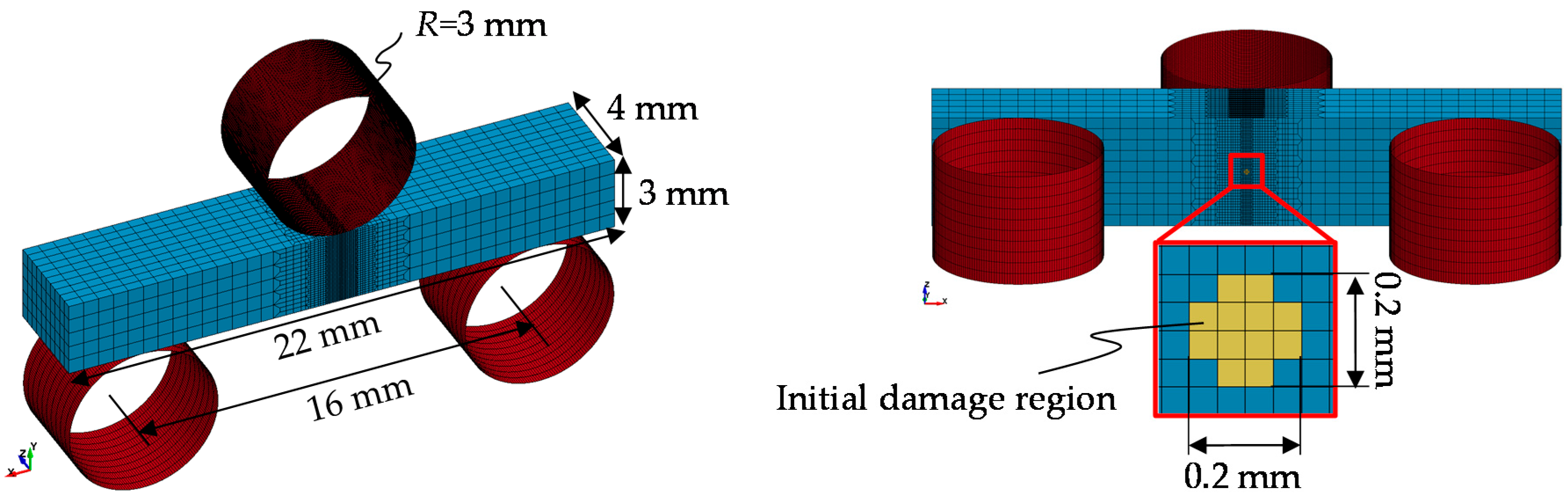

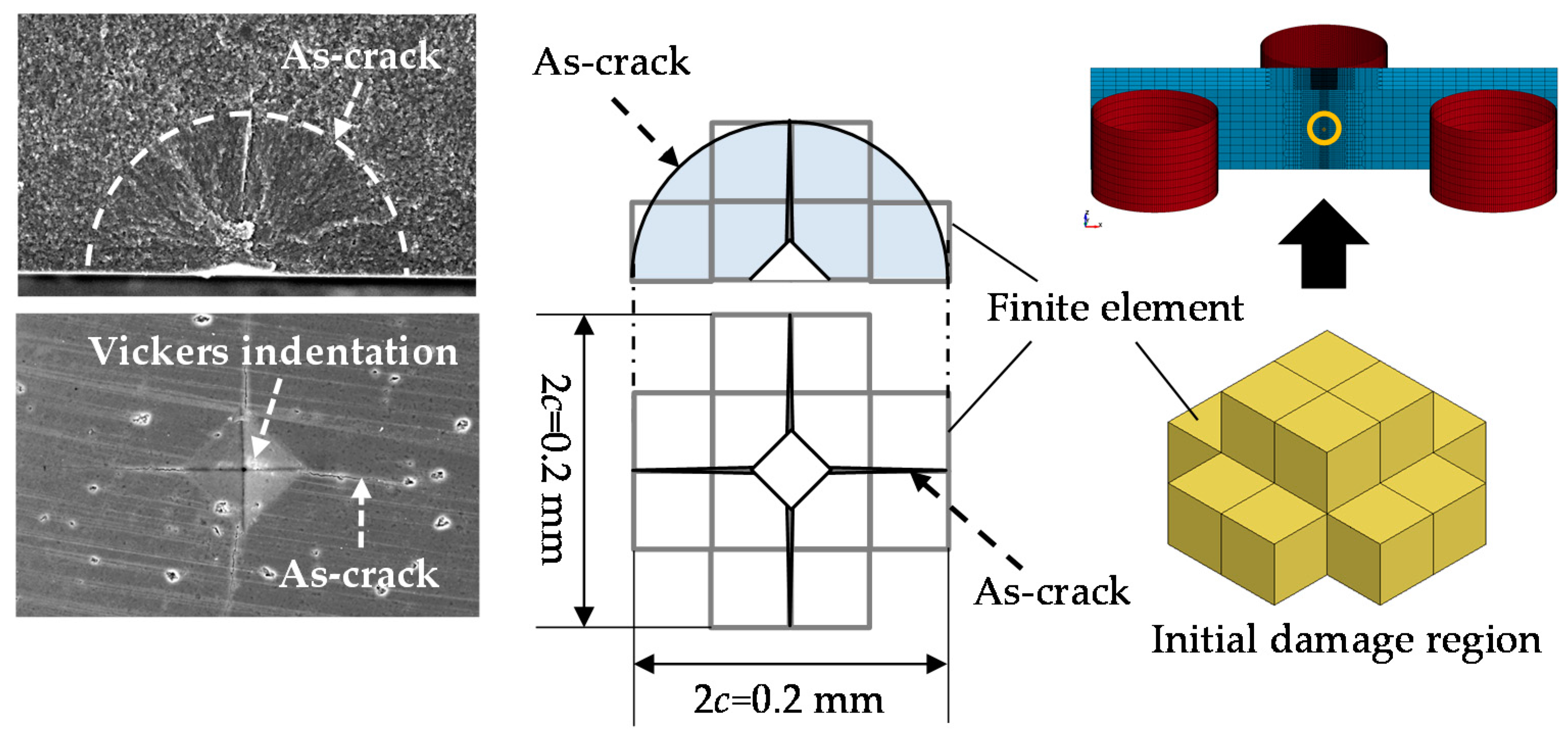

3.1. FE Model and Analysis

- Introduction of a prescribed pre-crack by the Vickers indentation method

- Self-healing under prescribed temperature and oxygen partial pressure conditions

- Strength evaluation by the three-point bending test after a specified self-healing time

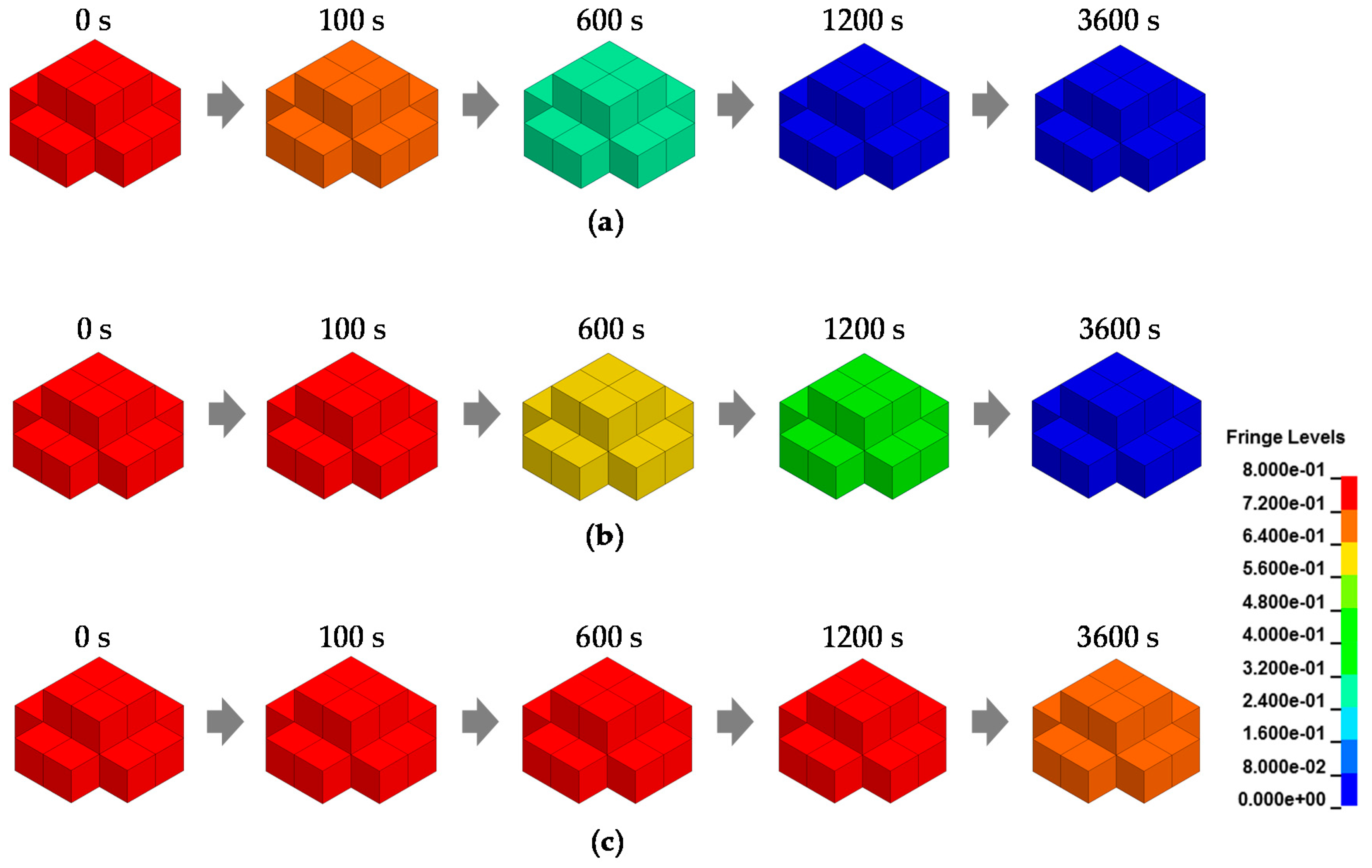

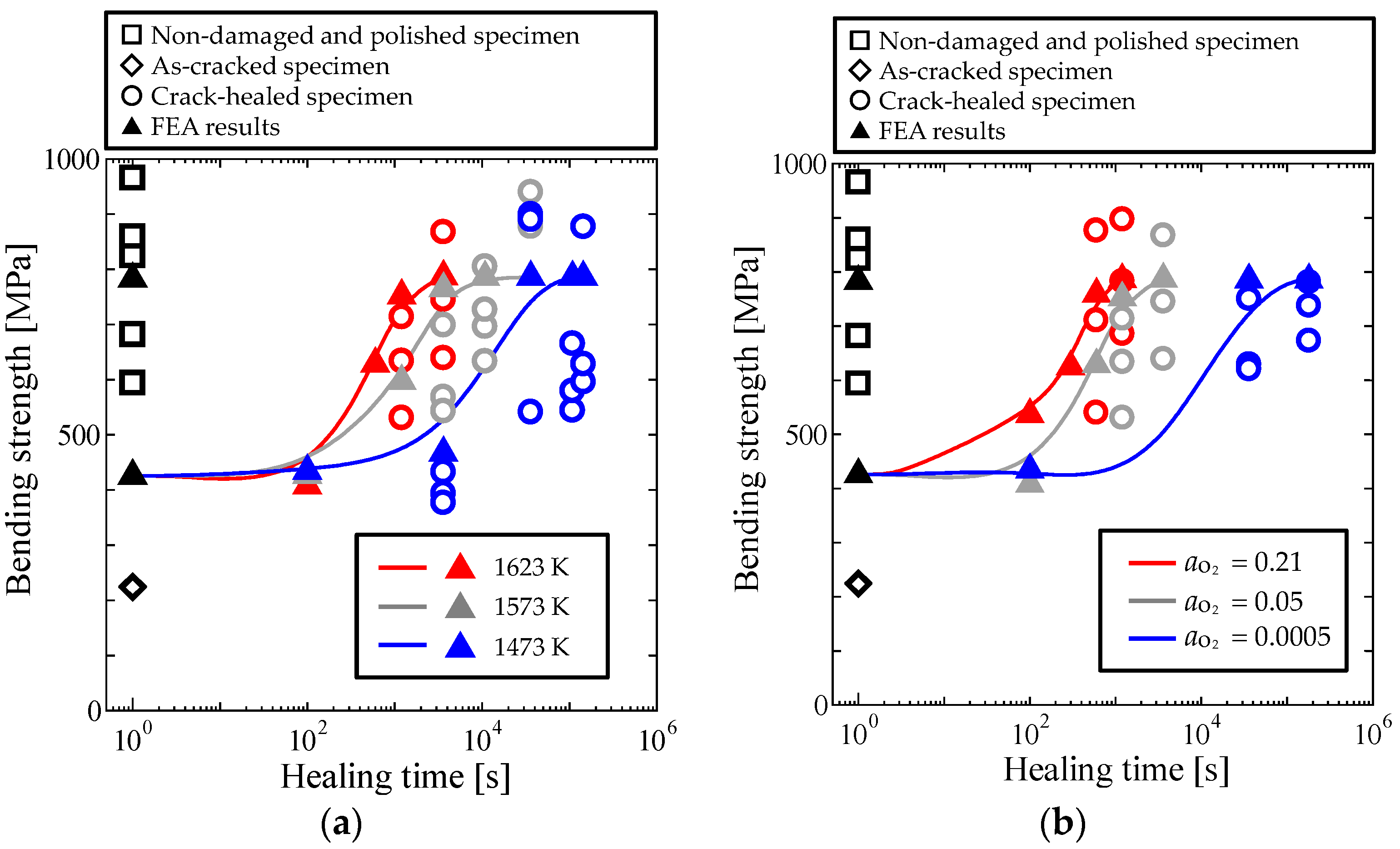

3.2. Comparison with the Experimental Result of the Self-Healing Behavior

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Halbig, M.C.; Jaskowiak, M.; Kiser, J.D.; Zhu, D. Evaluation of ceramic matrix composite technology for aircraft turbine engine applications. In Proceedings of the 51st AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013; pp. 1–11. [Google Scholar]

- Nakao, W.; Maruoka, D.; Ozaki, S.; Nanko, M.; Osada, T. Advanced ceramic composite using self-healing fiber-reinforcement. In Mechanical Properties and Performance of Engineering Ceramics and Composites IX, Ceramic Engineering and Science Proceedings; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 187–193. [Google Scholar]

- Ando, K.; Chu, M.C.; Tsuji, K.; Hirasawa, T.; Kobayashi, Y.; Sato, S. Crack healing behaviour and high-temperature strength of mullite/SiC composite ceramics. J. Eur. Ceram. Soc. 2002, 22, 1313–1319. [Google Scholar] [CrossRef]

- Ando, K.; Furusawa, K.; Takahashi, K.; Sato, S. Crack-healing ability of structural ceramics and a new methodology to guarantee the structural integrity using the ability and proof-test. J. Eur. Ceram. Soc. 2005, 25, 549–558. [Google Scholar] [CrossRef]

- Nakao, W.; Mori, S.; Nakamura, J.; Takahashi, K.; Ando, K.; Yokouchi, M. Self-crack-healing behavior of mullite/SiC particle/SiC whisker multi-composites and potential use for ceramic springs. J. Am. Ceram. Soc. 2006, 89, 1352–1357. [Google Scholar] [CrossRef]

- Osada, T.; Nakao, W.; Takahashi, K.; Ando, K.; Saito, S. Strength recovery behavior of machined Al2O3/SiC nano-composite ceramics by crack-healing. J. Eur. Ceram. Soc. 2007, 27, 3261–3267. [Google Scholar] [CrossRef]

- Osada, T.; Nakao, W.; Takahashi, K.; Ando, K. Kinetics of self-crack-healing of alumina/silicon carbide composite including oxygen partial pressure effect. J. Am. Ceram. Soc. 2009, 92, 864–869. [Google Scholar] [CrossRef]

- Ozaki, S.; Osada, T.; Nakao, W. Finite element analysis of the damage and healing behavior of self-healing ceramics material. Int. J. Solids Struct. 2016, 100, 307–318. [Google Scholar] [CrossRef]

- Kurumatani, M.; Terada, K.; Kato, J.; Kyoya, T.; Kashiyama, K. An isotropic damage model based on fracture mechanics for concrete. Eng. Fract. Mech. 2016, 155, 49–66. [Google Scholar] [CrossRef]

- De Vree, J.H.P.; Brekelmans, W.A.M.; van Gils, M.A.J. Comparison of nonlocal approaches in continuum damage mechanics. Comput. Struct. 1995, 55, 581–588. [Google Scholar] [CrossRef]

- Osada, T. Kinetic model for self-crack-healing in ceramics and possibility of turbine blade applications. In Proceedings of the 4th International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; pp. 573–577. [Google Scholar]

- Osada, T.; Nakao, W.; Takahashi, K.; Ando, K. Self crack-healing behavior in ceramic-matrix composites. In Advances in Ceramics Matrix Composites; Woodhead Publishing: Sawston, UK, 2014; pp. 410–441. [Google Scholar]

- LSCT. LS-DYNA User’s Manual; LSCT: Singapore, 2016. [Google Scholar]

| E (MPa) | ν | Gf (MPa/mm) | k | |

|---|---|---|---|---|

| 3.54 × 105 | 0.21 | 3.31 × 10−2 | 2.14 × 10−3 | 10 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakamura, M.; Takeo, K.; Osada, T.; Ozaki, S. Finite Element Analysis of Self-Healing and Damage Processes in Alumina/SiC Composite Ceramics. Technologies 2017, 5, 40. https://doi.org/10.3390/technologies5030040

Nakamura M, Takeo K, Osada T, Ozaki S. Finite Element Analysis of Self-Healing and Damage Processes in Alumina/SiC Composite Ceramics. Technologies. 2017; 5(3):40. https://doi.org/10.3390/technologies5030040

Chicago/Turabian StyleNakamura, Marika, Kyohei Takeo, Toshio Osada, and Shingo Ozaki. 2017. "Finite Element Analysis of Self-Healing and Damage Processes in Alumina/SiC Composite Ceramics" Technologies 5, no. 3: 40. https://doi.org/10.3390/technologies5030040