1. Introduction

Thermal treatment is a common and important strategy in the dairy industry for inactivating microorganisms and enzymes and, thus, guaranteeing safe products throughout the predicted shelf-life. However, traditional thermal treatments rely on heat transfer by conduction and convection, resulting in relatively long heating-up times, depending on the respective food matrix. These limitations can lead to strong physicochemical changes within the product, resulting in sensorial and textural modifications, as well as potentially decreasing the nutritive value. Hence, the dairy industry is always searching for new technologies. Over the last few decades, new technologies have been described in scientific publications, but many have not been broadly transferred to manufacturing processes in the food industry. One of these techniques is the radio frequency (RF) heating of foods with common frequencies of 13.56 MHz and 27.12 MHz. RF heating was first described in the middle of the last century in the context of thawing and curing meat [

1,

2,

3]. The advantage of electromagnetic heating is its ability to generate heat inside the food material by orientation polarization of dipoles, such as water, or the forced movement of ions [

4]. In this way, the limitations of conventional heat transfer and heat diffusion are overcome and very rapid heating becomes possible, at least in principle. However, RF heating installations in most cases use very high voltages and are prone to electric flashovers. More recently, RF heating was applied to bottled or packaged food in a water bath equipped with electrodes, as described by Bach [

5] and Felke

et al. [

6]. By using water, with its high relative permittivity or so-called relative dielectric constant (ε

r), instead of air as the dielectric field transfer medium between electrodes and food packages, the electrode voltage can be much reduced without reducing the heating rate. This fact minimizes the risk of electric flashovers. Moreover, the ε

r of water is closer to that of food materials than the ε

r of air. Exposing food to the electric field in a dielectric environment with similar ε

r, field concentrations at the edges and corners of packages, which cause local overheating, can be avoided and heating is more uniform. In addition, the preheated water acts as a thermal buffer and provides additional temperature uniformity to the surface of the food package. In order to avoid the absorption of RF energy by the water, de-ionized water is used.

Microwave heating has also been used to heat milk products, and this has resulted in improved sensorial characteristics compared to conventional heating on a laboratory scale [

7]. However, microwave fields with the commonly used frequency of 2.45 GHz have a limited ability to penetrate larger food volumes. The limited penetration is described by the penetration depth parameter. This is the distance from the food surface into the food volume at which 63% of the electromagnetic power has already been absorbed. The penetration depth of microwave fields of 2.45 GHz into milk or yoghurt is in the order of 1 cm, while, according to Felke

et al. [

6], in the case of 27.12 MHz RF fields, the penetration depths into food materials is about 20 cm and, thus, leads to the more uniform heating of products of a larger diameter. A further disadvantage of microwave fields compared to 27.12 MHz RF fields is the presence of patterns of constructive and destructive wave interference inside the food, which leads to patterns of hot and cold spots. In the case of RF fields, the waves are so long, that interference is not relevant on the scale of a food item or a food package.

Due to the demand of consumers for minimally processed, but safe foods, fuelling the need for constant technological progress, heating using radio frequencies was chosen as a promising technological approach for the present study. The aim was to perform a feasibility study on the technological applicability of RF heating on stirred yoghurt gels after culturing.

Generally, yoghurt is consumed not only because of its high nutritive value and appealing organoleptic properties, but also due to its health-promoting effects. Especially, the living microflora of lactic acid bacteria has a positive influence on human digestion (probiotic effect). Moreover, bioactive peptides that are released, e.g., during fermentation as a result of the enzymatic cleavage of milk proteins, are known to have various effects on human health (biogenic effect) [

8]. According to the Code of Federal Regulations [

9], yoghurt may be heat-treated to destroy viable microorganisms to extend shelf-life. Nevertheless, if dairy ingredients are heat-treated after culturing, then the name of the food must be followed by the parenthetical phrase “heat treated after culturing”. To increase the shelf-life of yoghurt products beyond three to four weeks at refrigeration temperatures, Kessler [

10] describes several temperature ranges that are sufficient for the pasteurization of the yoghurt curds: 65 to 75 °C and holding times of 30 to 60 s. Based on this, a comparable approach was chosen in the present study for post-heating stirred yoghurt filled in glass jars. Three temperature regimes were tested: 58, 65 and 72 °C. In detail, we aimed to prolong the shelf-life by mild heat treatment using an adapted heating technology, reducing the microbial numbers, while, at the same time, maintaining the yoghurt’s sensorial and textural profiles as close as possible to those of the stirred yoghurt reference. RF heating was expected to result in shorter heating-up times compared to convectional (CV) heating and, thus, to impart less damage or deterioration with respect to favorable aspects, such as the sensory properties of the products. A further goal of our study was to determine whether RF heating can achieve the same required homogeneous temperature distribution in the yoghurt curd, as expected from CV heating. Accordingly, for comparison, the yoghurts were also heated via CV treatment using steam as the heat carrier medium. The properties of the treated products (changes in pH, color and sensory properties) were then compared to the stirred yoghurt reference without any additional heat treatment. Additionally, in view of the microbial aspects and the related effects on yoghurt shelf-life, potential changes in microbial numbers (lactic acid bacteria (LAB), yeasts and molds) were investigated.

A second, separate part of this feasibility study will focus on the changes in microstructure and texture caused by a post-fermentative heat treatment [

11].

2. Experimental Section

2.1. Yoghurt

Commercially available plain stirred yoghurt (4.4% protein, 5.4% carbohydrates, 3.8% fat) was purchased from a local supermarket. The yoghurt was filled in 500 mL glass jars, which were closed with a metal screw cap (twist-off, 70 mm) and were filled up to about 100 mm. The jars had a diameter of 87 mm. All yoghurts were purchased at the same time and had the same best-before date, which was four weeks after purchase. According to the manufacturer disclosure, the yoghurts had a shelf-life of four weeks and, thus, were delivered immediately after manufacturing.

For further investigations, a set-style yoghurt reference (3.8% fat, 3.4% protein, 4.4% carbohydrates), matured in a cup (150 mL), was purchased from a local supermarket and stored with the other yoghurt samples.

2.2. Heat Treatment

Post-fermentative heat-treatments were performed within three days after the samples were purchased. Prior to heating, the yoghurt samples were pre-tempered to a controlled starting temperature of 40 ± 1 °C. The following target temperatures were applied: 58, 65 and 72 °C. Immediately after heating, the glass jars were placed in an ice water bath for rapid cooling. Before and after heat treatment (Week 0), the samples were placed into a cooling chamber at refrigeration temperatures of 8 ± 1 °C up to a storage period of five weeks. Thus, the storage period exceeded the yoghurt best-before date by one week. In weekly cycles, various quality parameters were investigated, as explained in the respective sections (

Section 2.3,

Section 2.4,

Section 2.5 and

Section 2.6). Samples without any additional heating step were held as references for comparative investigations.

2.2.1. Radio Frequency (RF) Treatment

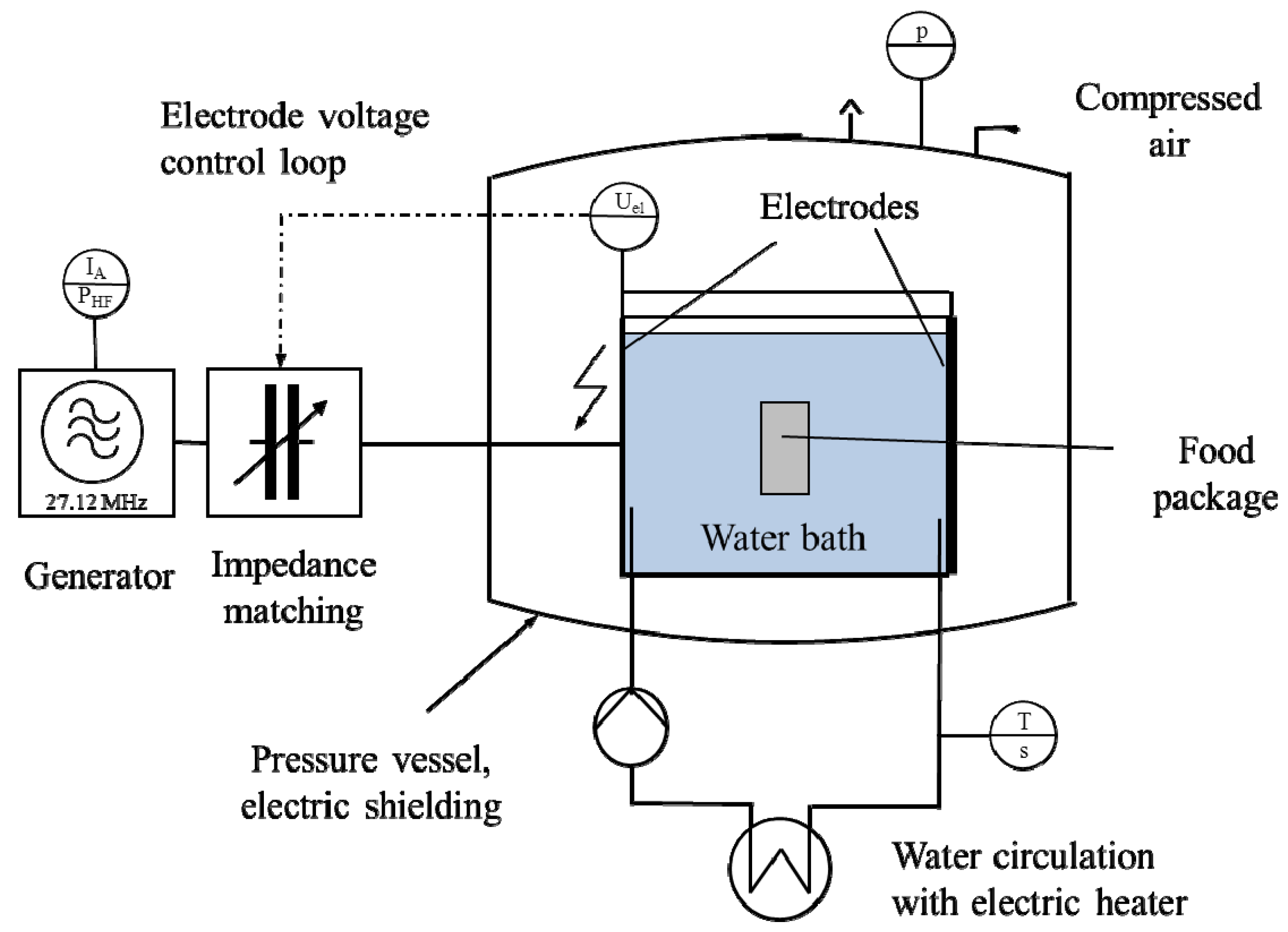

RF heating of yoghurt was performed in an RF water bath on pilot scale, as displayed in

Figure 1. RF power was provided by a tube generator with 27.12 MHz operating frequency and 16 kW rated power (Type 16000 K, Kiefel AG, Freilassing, Germany) together with an impedance matching network by the same manufacturer. The power flow to the products was controlled by automatically adjusting the electrode voltage, which was measured directly at the electrodes. Applied electrode voltages during the yoghurt heating trials were between 2.2 and 2.4 kV; with resulting field intensities in the water bath between 17.8 kV·m

−1 and 19.2 kV·m

−1. By the additional control of exposure time, the average temperature in the product at the end of RF heating could be determined with a tolerance of ±2 °C.

Figure 1.

Schematic set-up of the RF water bath, modified from Felke

et al. [

6].

Figure 1.

Schematic set-up of the RF water bath, modified from Felke

et al. [

6].

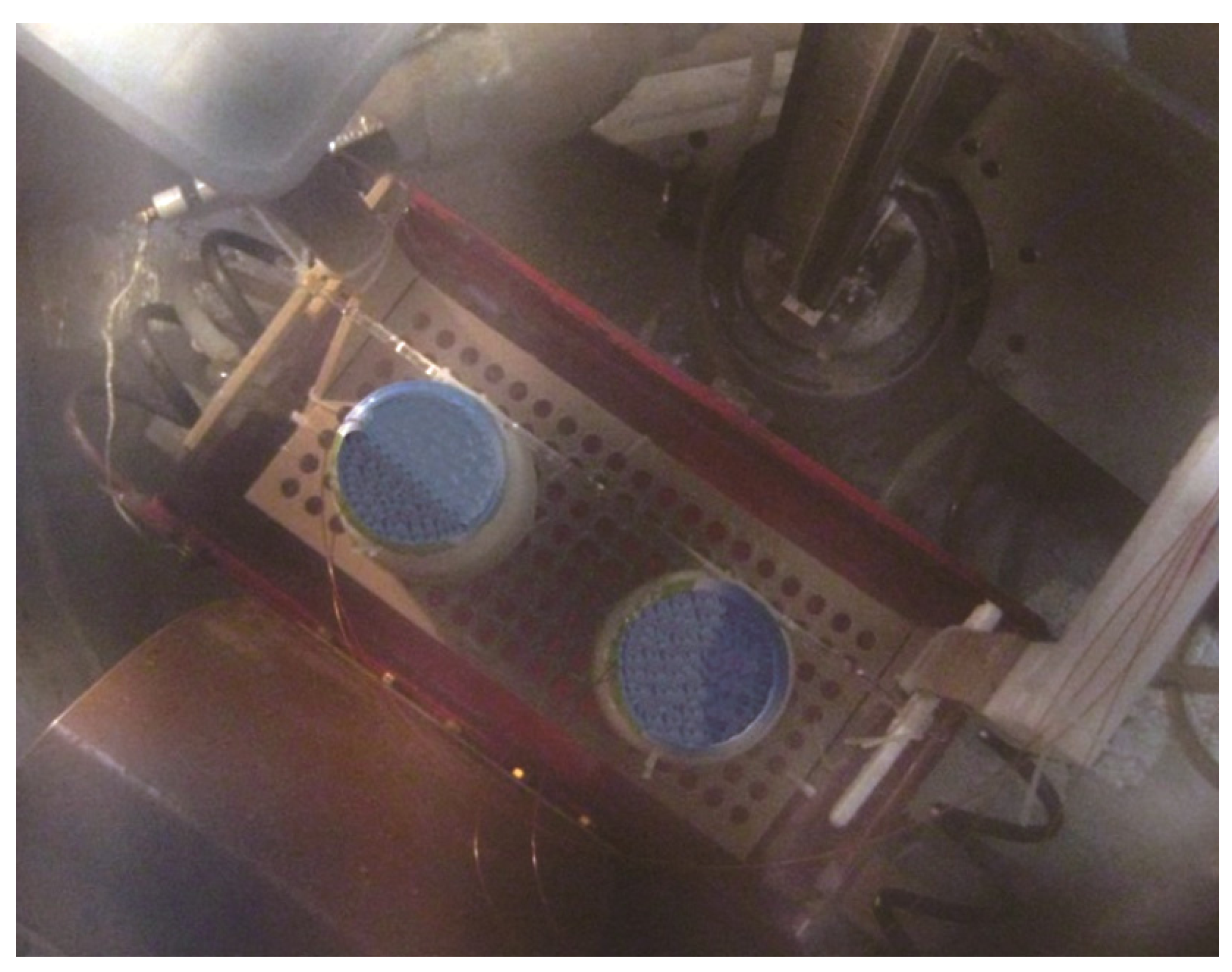

Heating procedure: Two glass jars with tightly closed screw caps placed on a support were immersed in the water bath under atmospheric pressure (

Figure 2). The water bath was preheated to a temperature slightly above the process target temperature. RF exposure started immediately after immersion and continued for a preset time. The electrode voltages and the exposure times had been determined in previous heating experiments according to the respective target temperatures. Samples for further microbiological, structural, textural and sensory evaluation were exposed to an additional temperature holding time and were not subjected to inline-temperature measurements. However, to guarantee temperature control, three to four spare samples were opened for supervisory purposes during a sample heating series. All details on the specific heating parameters used to produce the product samples are compiled in

Table 1.

Figure 2.

Experimental set-up: Yoghurt jars on a support immersed between the electrodes of the RF water bath (here: inline-temperature measurement with fiber-optic temperature sensors).

Figure 2.

Experimental set-up: Yoghurt jars on a support immersed between the electrodes of the RF water bath (here: inline-temperature measurement with fiber-optic temperature sensors).

Table 1.

Heating procedure of RF heating in an RF water bath.

Table 1.

Heating procedure of RF heating in an RF water bath.

| Process target | Electrode | RF exposure | Holding time 1 | Water bath |

|---|

| temperature | voltage | time | (RF switched off) | temperature |

|---|

| 58 °C | 2.3 ± 0.1 kV | 60 s | 60 s | 63 ± 1 °C |

| 65 °C | 2.3 ± 0.1 kV | 90 s | 60 s | 70 ± 1 °C |

| 72 °C | 2.3 ± 0.1 kV | 120 s | 60 s | 77 ± 2 °C |

Temperature measurements: In previous heating experiments, inline-measurements with fiber-optic temperature sensors (Fotemp 4 fiber-optical thermometer with TS5 0.5-mm diameter sensors, Optocon AG, Dresden, Germany) were performed to adjust the electrode voltage and the exposure times according to the respective target temperatures. The fibers were introduced through septa glued onto holes, which were drilled into the metal screw caps of the jars. Temperatures were measured in the center of the jars, as well as near the walls, at mid-height of the filled yoghurt mass.

During the main series of the heating experiments, manual temperature measurements were performed directly after heating with a fast response thermocouple (0.5 mm diameter, type K, Thermocoax GmbH, Stapelfeld, Germany) connected to an electronic thermometer (Ebro TFN 520-SMP, Ebro GmbH, Ingolstadt, Germany). Temperatures were measured at different height levels within the yoghurt mass in the jars. In addition, the average temperature of the yoghurt filling was measured after mixing with a plastic spoon, because of its low thermal capacity.

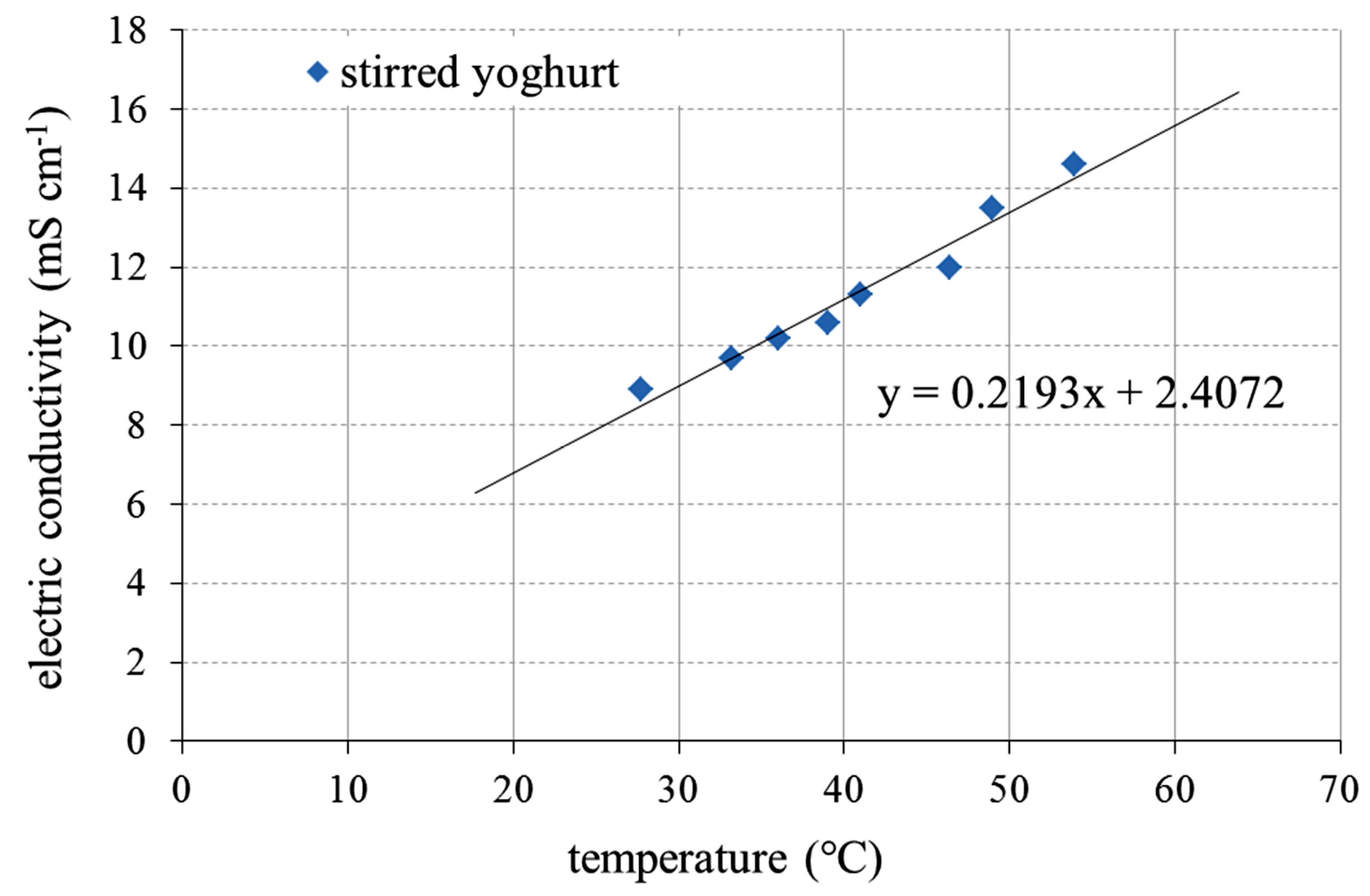

The electric conductivity (mS·cm−1) of the stirred reference yoghurt was measured with a laboratory conductometer (Innolab Cond level 2, WTW GmbH, Weilheim, Germany) within a temperature range of 25 to 55 °C.

2.2.2. Convectional (CV) Treatment

CV heating of yoghurts was performed in a convection oven (Rational white efficiency SCC WE61, Rational AG, Landsberg am Lech, Germany) in steam mode with 100% saturated steam.

Heating procedure: Five glass jars with tightly closed screw caps were placed on a fence that was positioned in the center of the convection oven. The oven temperature was set to slightly above the process target temperatures. An inline-thermocouple was used to control the products temperature, with its tip placed in the core of one additional yoghurt jar. Therefore, the lid of the jar was perforated to yield a center hole; this temperature control sample was discarded afterwards. The samples were exposed to CV heating until the process target temperature was reached and an additional temperature holding time was maintained. All details on the respective CV heating parameters used to produce the product samples are compiled in

Table 2.

Temperature measurements: In addition to the inline-thermocouple, the entire temperature profile was recorded once by the use of a fast response thermocouple (0.5 mm diameter, type K, Thermocoax GmbH, Stapelfeld, Germany), placed in the core of the product and connected to a data logging instrument (ALMEMO 2890-9, Ahlborn Mess- und Regelungstechnik GmbH, Holzkirchen, Germany).

Table 2.

Heating procedure of convectional (CV) heating in a convection oven (100% saturated steam).

Table 2.

Heating procedure of convectional (CV) heating in a convection oven (100% saturated steam).

Process target

temperature | CV exposure

time | Holding time 1 | Oven/ steam

Temperature |

|---|

| 58 °C | 60.0 ± 0.5 min | 60 s | 63 °C |

| 65 °C | 61.5 ± 4.5 min | 60 s | 70 °C |

| 72 °C | 58.0 ± 0.5 min | 60 s | 77 °C |

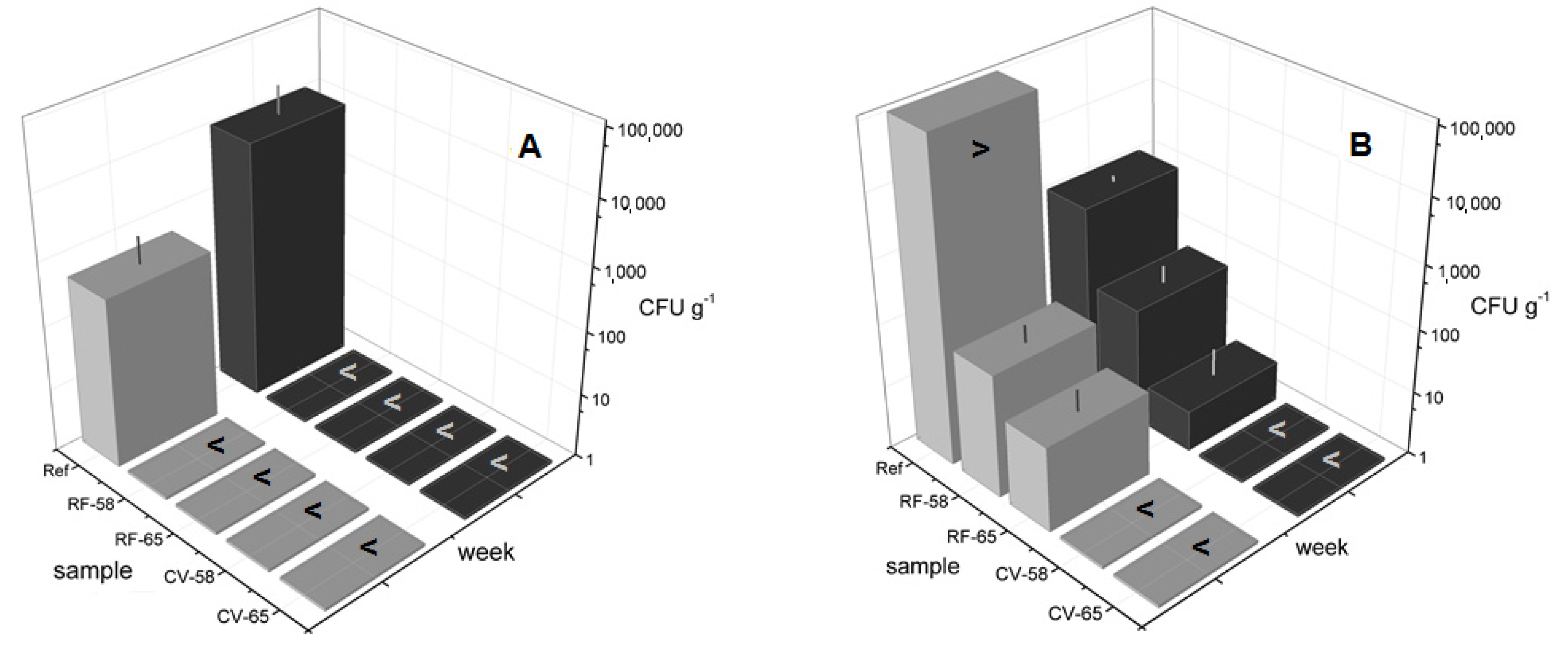

2.3. Microbiological Investigations

The microbial numbers of yeasts and molds, as well as lactic acid bacteria (LAB) were investigated directly after (post-)manufacturing of the different yoghurt samples (Week 0) and after a storage period of five weeks. No further inoculation of the samples with LAB or other microorganisms was performed, and the jars were opened just immediately before the samples were taken for further microbial investigations. For the preparation of sample dilutions, 10 g of yoghurt were dissolved in 90 mL of Ringer’s solution (25%, OXOID LTD., Hampshire, U.K.). Ringer’s solution was also used for any further dilution steps. In detail, for each treatment and temperature regime, three independent yoghurt jars were randomly selected and three dilution steps were prepared in threefold repetition to analyze microbial numbers.

Yeasts and molds: yeast extract glucose chloramphenicol (YGC) agar (Merck KGaA) was selected as the medium for the viability investigation. The incubation was performed at 25 °C aerobically for three to five days. LAB: de Man, Rogosa and Sharpe (MRS) agar (Merck KGaA) was used for enumeration, and aerobic incubation was performed at 37 °C for 72 h. Microbial numbers were expressed as colony forming units (CFU) g−1.

2.4. pH and Color Measurement

The determination of the pH of the yoghurt samples was performed over the entire storage period (Weeks 0, 2, 4 and 5) using a pH meter (pH 538, WTW GmbH, Weilheim, Germany) together with a pH electrode (BlueLine 11pH, SI Analytics GmbH, Mainz, Germany) and temperature electrode (TFK 325, WTW GmbH). Instrumental color analysis was carried out directly after manufacturing (Week 0) by the use of a Chroma-meter CR-300 (Konika Minolta Inc., Marunouchi, Japan) with a DP-301 data processor. Calibration was performed on a white standard (CR-A43, Konika Minolta Inc.). The stirred samples were filled in Petri dishes, and the surface was sleeked. Each sample was analyzed at ten different points above the surface, and the color was expressed in L*a*b* mode, in which L* represents the lightness value and a* and b* values the chromaticity coordinates. For color and pH measurements, the samples were analyzed in triplicate.

2.5. Aroma and Taste Profile Analysis

Stirred yoghurt samples (20 mL) were filled into sensory glass beakers (140 mL, J. Weck GmbH u. Co. KG, Wehr, Germany) and closed with a lid. Sensory analyses were performed in a sensory panel room at 21 ± 1°C. Trained panelists (n = 12, male/female, age 24 to 45) with normal olfactory and gustatory function participated in the sensory sessions and exhibited no known illness at the time of examination. Prior to this study, the assessors were recruited in weekly training sessions in the recognition of about 100 selected odor-active compounds according to their odor qualities by means of an in-house developed flavor language. The order of the presentation of the different yoghurts was randomized, and no information on the purpose of the experiment or the composition of the samples was given to the panelists. The results were averaged for each attribute. Sensory analyses were performed up to Week 4 of storage (best-before date) in intervals of two weeks (Weeks 0, 2 and 4).

Aroma profile analysis (APA): in the first session, the panelists were asked to evaluate the yoghurt gels (retronasal), and the named odor attributes of the different products were collected. Attributes that were detected by more than 50% of the panelists were selected for subsequent evaluations. In subsequent sessions, the panelists were asked to score the perceived retronasal intensities of the selected attributes on a seven-point-scale from 0 (no perception) to 3 (strong perception) in increments of 0.5.

Taste Profile Analysis: in addition to the APA, the panelists were requested to evaluate the following taste attributes: sweet, sour, salty and bitter. The panelists had to score the attributes’ intensities on a visual analogue scale from 0 (not perceivable) to 10 (strongly perceivable).

2.6. Triangle Test

A triangle test was performed according to DIN EN ISO 4120:2007 [

12]. Two triangles of the following yoghurt gels were tested: reference

vs. RF 65 °C and RF 58 °C

vs. CV 58 °C. During the tests, the panelists had their eyes bandaged to avoid any influence of the possible differences in the yoghurts’ appearance. Twelve panelists evaluated each triad in duplicate, leading to 24 evaluations in total. The test was performed after a storage period of four weeks (best-before date).

2.7. Statistical Analysis

Statistical analyses were performed by the use of the software OriginPro 9G (OriginLab Co., Northampton, MA, USA) and Statistica 10 (StatSoft Europe GmbH, Hamburg, Germany), respectively. For all groups of data, one-way analysis of variances (ANOVA) and Fisher LSD post-hoc testing were carried out to elaborate differences between the differently treated yoghurts and during storage (repeated measures one-way ANOVA). The level of statistical significance was set at 5%.

4. Conclusions

The present study evaluated the effect of additional heat treatment (CV and RF) after the fermentation process in yoghurt production. Such additional heat treatment has been little studied previously. Both heating methods showed promise concerning the homogeneity of the temperature distribution. However, RF appeared to be superior, due to a very fast heating rate of 0.3 K·s−1. This study also focused on the yoghurt shelf-life, pH, color and sensorial quality. Microbial characterization demonstrated the mildness of the RF treatment, because LAB partially survived. Nevertheless, a reduction in LAB highlighted the potential of this method for prolonging the yoghurt shelf-life, not only by inactivating the yeasts and molds, but also by preventing strong post-acidification. Whereas generally, no significant changes in pH and sensorial quality were observed, slight color changes were found to occur after heat treatment, possibly due to the onset of the caramelization processes. Based on these observations, we believe RF heating is a promising technological tool for future applications in the dairy industry (e.g., milk pasteurization, sterilization or post-heating of fermented products). However, further improvements with regard to batch-wise manufacturing are necessary in order to open up this technique to industry, such as the application of radio frequencies in a continuous process.