The Proportion of Fermented Milk in Dehydrated Fermented Milk–Parboiled Wheat Composites Significantly Affects Their Composition, Pasting Behaviour, and Flow Properties on Reconstitution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Ingredients Used

2.2. Preparation of Fermented Milk

2.3. Preparation of Parboiled Wheat

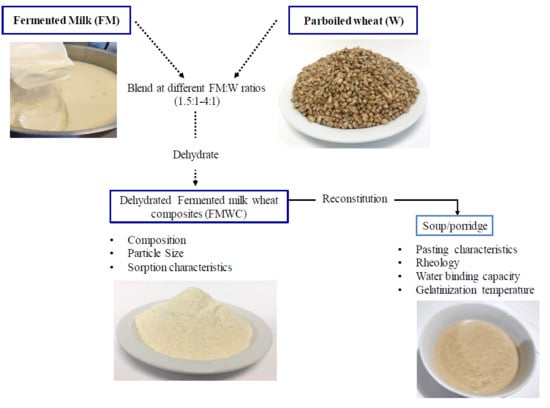

2.4. Preparation of Dehydrated Fermented Milk–Wheat Composite

2.5. Analysis of Dehydrated Fermented Milk–Wheat Composites

2.5.1. Composition

2.5.2. Particle Size

2.5.3. Water Sorption

2.6. Analysis of Reconstituted Fermented Milk-Wheat Composites

2.6.1. Water Holding Capacity

2.6.2. Gelatinization Temperature

2.6.3. Pasting Behaviour

2.6.4. Rheological Properties

2.7. Statistical Analysis

3. Results

3.1. Properties of Dehydrated Fermented Milk–Wheat Composite

3.1.1. Composition

3.1.2. Particle Size

3.1.3. Water Sorption Behaviour of Dehydrated Fermented Milk–Wheat Composites

3.2. Properties of Reconstituted Fermented Milk–Wheat Composites

3.2.1. Gelatinization Temperature

3.2.2. Water Holding Capacity

3.2.3. Pasting Behaviour

3.2.4. Rheological Properties.

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Auestad, N.; Hurley, J.S.; Fulgoni, V.L.; Schweitzer, C.M. Contribution of food groups to energy and nutrient intakes in five developed countries. Nutrients 2015, 7, 4593–4618. [Google Scholar] [CrossRef] [PubMed]

- Simsek, S.; Martinez, M.O.; Daglioglu, O.; Guner, K.G.; Gecgel, U. Physicochemical properties of starch from a cereal-based fermented food (tarhana). J. Nutr. Food Sci. 2014, 4, 263. [Google Scholar]

- Akissoé, N.H.; Sacca, C.; Declemy, A.L.; Bechoff, A.; Anihouvi, V.B.; Dalodé, G.; Pallet, D.; Fliedel, G.; Mestres, C.; Hounhouigan, J.D; et al. Cross-cultural acceptance of a traditional yoghurt-like product made from fermented cereal. J. Sci. Food Agric. 2015, 95, 1876–1884. [Google Scholar] [CrossRef] [PubMed]

- Koca, A.F.; Koca, I.; Hasbay, I.; Yilmaz, V.A. Physical, rheological and sensory properties of tarhana prepared with two wild edible plants (Trachystemon orientalis (L.) G. Don) and (Portulaca oleracea L.). J. Food Process Technol. 2015, 6, 443. [Google Scholar]

- World Food Programme. Specialised Nutritious Foods. Available online: http://www.wfp.org/nutrition/special-nutritional-products (accessed on 25 May 2018).

- World Food Programme. Technical specifications for the Manufacture of: SUPER CEREAL Plus—Wheat Soya Blend. Version 15.1. Available online: https://documents.wfp.org/stellent/groups/public/documents/manual_guide_proced/wfp281208.pdf (accessed on 25 May 2018).

- Tamime, A.; O’Connor, T. Kishk—A dried fermented milk/cereal mixture. Int. Dairy J. 1995, 5, 109–128. [Google Scholar] [CrossRef]

- Tamime, A.; Muir, D.; Khaskheli, M.; Barclay, M. Effect of processing conditions and raw materials on the properties of kishk 1. Compositional and microbiological qualities. LWT-Food Sci. Technol. 2000, 33, 444–451. [Google Scholar] [CrossRef]

- Georgala, A. The nutritional value of two fermented milk/cereal foods named ‘Greek Trahanas’ and ‘Turkish Tarhana’: A review. J. Nutr. Disorder Ther. 2013, S11, 2. [Google Scholar] [CrossRef]

- Michaelsen, K.F.; Hoppe, C.; Roos, N.; Kaestel, P.; Stougaard, M.; Lauritzen, L.; Mølgaard, C.; Girma, T.; Friis, H. Choice of foods and ingredients for moderately malnourished children 6 months to 5 years of age. Food Nutr. Bull. 2009, 30, S343–S404. [Google Scholar] [CrossRef] [PubMed]

- Marciani, L.; Gowland, P.A.; Spiller, R.C.; Manoj, P.; Moore, R.J.; Young, P.; Fillery-Travis, A.J. Effect of meal viscosity and nutrients on satiety, intragastric dilution, and emptying assessed by MRI. Am. J. Physiol. Gastrointest. Liver Physiol. 2001, 280, 1227–1233. [Google Scholar] [CrossRef] [PubMed]

- Campbell, C.L.; Wagoner, T.B.; Foegeding, E.A. Designing foods for satiety: The roles of food structure and oral processing in satiation and satiety. Food Struct. 2017, 13, 1–12. [Google Scholar] [CrossRef]

- Zhu, Y.; Hsu, W.H.; Hollis, J.H. The impact of food viscosity on eating rate, subjective appetite, glycemic response and gastric emptying rate. PLoS ONE 2013, 8, e67482. [Google Scholar] [CrossRef] [PubMed]

- Rahmawati, I.S.; Suntornsuk, W. Effects of fermentation and storage on bioactive activities in milks and yoghurts. Procedia Chem. 2016, 18, 53–62. [Google Scholar] [CrossRef]

- Poutanen, K.; Flander, L.; Katina, K. Sourdough and cereal fermentation in a nutritional perspective. Food Microbiol. 2009, 26, 693–699. [Google Scholar] [CrossRef] [PubMed]

- Ertaş, N.; Sert, D.; Demir, M.K.; Elgüen, A. Effect of whey concentrate addition on the chemical, nutritional and sensory properties of tarhana (a Turkish fermented cereal-based food). Food Sci. Technol. Res. 2009, 15, 51–58. [Google Scholar] [CrossRef]

- Gaucheron, F. Milk Minerals, Trace Elements, and Macroelements. In Milk and Dairy Products in Human Nutrition: Production, Composition and Health; Park, Y.W., Haenlein, G.F.W., Eds.; Wiley-Blackwell, John Wiley and Sons Ltd.: West Sussex, UK, 2013; pp. 172–199. [Google Scholar]

- Tamime, A.Y.; Barclay, M.N.; Amarowicz, R.; McNulty, D. Kishk—A dried fermented milk/cereal mixture. 1 composition of gross components, carbohydrates, organic acids and fatty acids. Le Lait 1999, 79, 317–330. [Google Scholar] [CrossRef]

- Tamime, A.; Muir, D.; Barclay, M.; Khaskheli, M.; McNulty, D. Laboratory-made kishk from wheat, oat and barley: 2. Compositional quality and sensory properties. Food Res. Int. 1997, 30, 319–326. [Google Scholar] [CrossRef]

- Tamime, A.; Muir, D.; Barclay, M.; Khaskheli, M.; McNulty, D. Laboratory-made kishk from wheat, oat and barley: 1. Production and comparison of chemical and nutritional composition of burghol. Food Res. Int. 1997, 30, 311–317. [Google Scholar] [CrossRef]

- Toufeili, I.; Melki, C.; Shadarevian, S.; Robinson, R.K. Some nutritional and sensory properties of bulgur and whole wheatmeal kishk (a fermented milk-wheat mixture). Food Qual. Prefer. 1998, 10, 9–15. [Google Scholar] [CrossRef]

- Nassar, K.; Shamsia, S.; Attia, I. Improvement of the nutritional value of cereal fermented milk: 1. Soft kishk like. J. Food Process Technol. 2016, 7, 619. [Google Scholar]

- Gadallah, M.G.; Hassan, M.F. Quality properties of kishk (a dried fermented cereal-milk mixture) prepared from different raw materials. J. Saudi Soc. Agric. Sci. 2017, in press. [Google Scholar] [CrossRef]

- Demirci, A.S.; Palabiyik, I.; Ozalp, S.; Tirpanci Sivri, G. Effect of using kefir in the formulation of traditional tarhana. Food Sci. Technol. 2018. [Google Scholar] [CrossRef]

- İbanoğlu, Ş.; İbanoğlu, E. Rheological properties of cooked tarhana, a cereal-based soup. Food Res. Int. 1999, 32, 29–33. [Google Scholar] [CrossRef]

- Bilgiçli, N. Effect of buckwheat flour on chemical and functional properties of tarhana. LWT-Food Sci. Technol. 2009, 42, 514–518. [Google Scholar] [CrossRef]

- Yilmaz, M.T.; Sert, D.; Demir, M.K. Rheological properties of tarhana soup enriched with whey concentrate as a function of concentration and temperature. J. Texture Stud. 2010, 41, 863–879. [Google Scholar] [CrossRef]

- DAFM, Department of Agriculture, Food and the Marine, Agriculture House, Kildare St. Dublin 2. D02 WK12, Ireland. Available online: https://www.agriculture.gov.ie/research/fundedprojects/food/functionalfoodshealth/developmentoffortifiedblendedfoodsusingfermentedbuttermilkcereal/ (accessed on 13 July 2018).

- Lin, Y.; Kelly, A.L.; O'Mahony, J.A.; Guinee, T.P. Fortification of milk protein content with different dairy protein powders alters its compositional, rennet gelation, heat stability and ethanol stability characteristics. Int. Dairy J. 2016, 61, 220–227. [Google Scholar] [CrossRef]

- Lin, Y.; Kelly, A.L.; O’Mahony, J.A.; Guinee, T.P. Effects of milk heat treatment and solvent composition on physicochemical and selected functional characteristics of milk protein concentrate. J. Dairy Sci. 2018. [Google Scholar] [CrossRef] [PubMed]

- International Dairy Federation (IDF). Cheese and Processed Cheese Products—Determination of Chloride Content (Potentiometer Titration Method). IDF Standard 88A; IDF: Brussels, Belgium, 1981. [Google Scholar]

- Association of analyticial chemists (AOAC). Moisture in dried milk. AOAC Official Methods of Analysis—AOAC International; AOAC: Arlington, VA, USA, 1995. [Google Scholar]

- Silva, J.V.; O’Mahony, J.A. Flowability and wetting behaviour of milk protein ingredients as influenced by powder composition, particle size and microstructure. Int. J. Dairy Technol. 2017, 70, 277–286. [Google Scholar] [CrossRef]

- Hogan, S.; O’Callaghan, D. Influence of milk proteins on the development of lactose-induced stickiness in dairy powders. Int. Dairy J. 2010, 20, 212–221. [Google Scholar] [CrossRef]

- Ramaswamy, H.; Basak, S. Rheology of stirred yogurts. J. Texture Stud. 1991, 22, 231–241. [Google Scholar] [CrossRef]

- SAS Institute. SAS User’s Guide, version 9.3; SAS Institute Inc.: Cary, NC, USA, 2011. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing. R Foundation for Statistical Computing, Vienna, Austria. Available online: http://www.R-project.org/ (accessed on 25 May 2018).

- Anbukkarasi, K.; UmaMaheswari, T.; Hemalatha, T.; Nanda, D.K.; Singh, P.; Singh, R. Preparation of low galactose yogurt using cultures of Gal+ Streptococcus thermophilus in combination with Lactobacillus delbrueckii ssp. Bulgaricus. J. Food Sci. Technol. 2014, 51, 2183–2189. [Google Scholar] [CrossRef] [PubMed]

- Salameh, C.; Scher, J.; Petit, J.; Gaiani, C.; Hosri, C.; Banon, S. Physico-chemical and rheological properties of Lebanese kishk powder, a dried fermented milk-cereal mixture. Powder Technol. 2016, 292, 307–313. [Google Scholar] [CrossRef]

- Mathlouthi, M. Water content, water activity, water structure and the stability of foodstuffs. Food Control 2001, 12, 409–417. [Google Scholar] [CrossRef]

- Sandler, N.; Reiche, K.; Heinämäki, J.; Yliruusi, J. Effect of moisture on powder flow properties of theophylline. Pharmaceutics 2010, 2, 275–290. [Google Scholar] [CrossRef] [PubMed]

- Kaya, S.; Ibanoglu, S.; Kaya, A. Moisture sorption characteristics of tarhana, a fermented Turkish cereal food. J. Food Qual. 1999, 22, 95–100. [Google Scholar] [CrossRef]

- Al-Muhtaseb, A.; McMinn, W.; Magee, T. Moisture sorption isotherm characteristics of food products: A review. Food Bioprod. Process 2002, 80, 118–128. [Google Scholar] [CrossRef]

- Majzoobi, M.; Radi, M.; Farahnaky, A.; Jamalian, J.; Tongtang, T.; Mesbahi, G. Physicochemical properties of pre-gelatinized wheat starch produced by a twin drum drier. J. Agric. Sci. Technol. 2010, 13, 193–202. [Google Scholar]

- Sittipod, S.; Shi, Y.-C. Changes of starch during parboiling of rice kernels. J. Cereal Sci. 2016, 69, 238–244. [Google Scholar] [CrossRef]

- Wani, A.A.; Singh, P.; Shah, M.A.; Schweiggert-Weisz, U.; Gul, K.; Wani, I.A. Rice starch diversity: Effects on structural, morphological, thermal, and physicochemical properties—A review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 417–436. [Google Scholar] [CrossRef]

- Alcázar-Alay, S.C.; Meireles, M.A.A. Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci. Technol. Campinas 2015, 35, 215–236. [Google Scholar] [CrossRef] [Green Version]

- Biswas, S.K.; Juliano, B.O. Laboratory parboiling procedures and properties of parboiled rice from varieties differing in starch properties. Cereal Chem. 1988, 65, 417–423. [Google Scholar]

- Himmelsbach, D.; Manful, J.; Coker, R. Changes in rice with variable temperature parboiling: Thermal and spectroscopic assessment. Cereal Chem. 2008, 85, 384–390. [Google Scholar] [CrossRef]

- Mir, S.A.; Bosco, S.J.D. Effect of soaking temperature on physical and functional properties of parboiled rice cultivars grown in temperate region of India. Food Nutr. Sci. 2013, 4, 282–288. [Google Scholar] [CrossRef]

- Sharma, P.; Singh, V.; Subramanian, R. Pasting, swelling, and solubility characteristics of rice batter prepared from different wet grinding systems. Starch/Stärke 2013, 65, 374–381. [Google Scholar] [CrossRef]

- Dutta, H.; Mahanta, C.L.; Singh, V. Changes in the properties of rice varieties with different amylose content on dry heat parboiling. J. Cereal Sci. 2015, 65, 227–235. [Google Scholar] [CrossRef]

- Debet, M.R.; Gidley, M.J. Why do gelatinized starch granules not dissolve completely? Roles for amylose, protein, and lipid in granule “ghost” integrity. J. Agric. Food Chem. 2007, 55, 4752–4760. [Google Scholar] [CrossRef] [PubMed]

- Buggenhout, J.; Brijs, K.; Delcour, J.A. Impact of starch gelatinization and kernel fissuring on the milling breakage susceptibility of parboiled brown rice. Cereal Chem. 2013, 90, 490–496. [Google Scholar] [CrossRef]

- Eliasson, A.C. Viscoelastic behaviour during gelatinization of starch I. A comparison of wheat, maize, potato and waxy-barley starches. J. Texture Stud. 1986, 17, 253–265. [Google Scholar] [CrossRef]

- Hirashima, M.; Takahashi, R.; Nishinari, K. Effects of adding acids before and after gelatinization on the viscoelasticity of cornstarch pastes. Food Hydrocoll. 2005, 19, 909–914. [Google Scholar] [CrossRef]

- Ohishi, K.; Kasai, M.; Shimada, A.; Hatae, K. Effects of acetic acid on the rice gelatinization and pasting properties of rice starch during cooking. Food Res. Int. 2007, 40, 224–231. [Google Scholar] [CrossRef]

- Chung, C.; Degner, B.; McClements, D.J. Physicochemical characteristics of mixed colloidal dispersions: Models for foods containing fat and starch. Food Hydrocoll. 2013, 30, 281–291. [Google Scholar] [CrossRef]

- Kett, A.P.; Chaurin, V.; Fitzsimons, S.M.; Morris, E.R.; O’Mahony, J.A.; Fenelon, M.A. Influence of milk proteins on the pasting behaviour and microstructural characteristics of waxy maize starch. Food Hydrocoll. 2013, 30, 661–671. [Google Scholar] [CrossRef]

- Ahmad, F.B.; Williams, P.A. Effect of salts on the gelatinization and rheological properties of sago starch. J. Agric. Food Chem. 1999, 47, 3359–3366. [Google Scholar] [CrossRef] [PubMed]

- Chiotelli, E.; Pilosio, G.; Le Meste, M. Effect of sodium chloride on the gelatinization of starch: A multi-measurement study. Biopolymers 2002, 63, 41–58. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Raymundo, V.G.; Vélez-Ruiz, J.F. Physicochemical and rheological properties of a dairy dessert, enriched with chickpea flour. Foods 2018, 7, 25. [Google Scholar] [CrossRef] [PubMed]

| Ingredient Used (%, w/w) | Unsalted FMWC | Unsalted FMWC | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1.5 | 1.9 | 2.3 | 3.0 | 4.0 | 1.5s | 1.9s | 2.3s | 3.0s | 4.0s | |

| FM | 60 | 65 | 70 | 75 | 80 | 59.4 | 64.4 | 69.3 | 74.3 | 79.2 |

| Parboiled wheat | 40 | 35 | 30 | 25 | 20 | 39.6 | 34.7 | 29.7 | 24.8 | 19.8 |

| Salt | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 |

| Characteristic | Unsalted FMWC | Salted FMWC | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FM:W | FM:W | |||||||||||

| 1.5 | 1.9 | 2.3 | 3.0 | 4.0 | SED 2 | 1.5s | 1.9s | 2.3s | 3.0s | 4.0s | SED 2 | |

| Composition | ||||||||||||

| Total Solids (%, w/w) | 95.9 aA | 96.0 aA | 95.2 bA | 94.6 cA | 92.3 dA | 0.23 | 95.7 aA | 96.0 aA | 95.4 aA | 94.1 aA | 92.0 bA | 0.45 |

| Fat (%, w/w) | 3.7 eA | 4.2 dA | 4.6 cA | 5.2 bA | 5.9 aA | 0.26 | 3.7 eA | 4.1 dA | 4.5 cA | 5.1 bA | 5.8 aA | 0.30 |

| Protein (%, w/w) | 15.2 cA | 15.9 bcA | 16.7 bcA | 17.9 abA | 18.9 aA | 0.29 | 14.2 cA | 15.4 bcA | 16.9 abA | 17.3 abA | 18.6 aB | 0.47 |

| Starch (%, w/w) | 52.0 aA | 48.8 aA | 47.1 abA | 42.3 bcA | 38.9 cA | 1.06 | 51.1 aA | 49.9 aA | 45.8 abA | 41.2 bcA | 37.6 cA | 0.94 |

| Lactose (%, w/w) | 6.4 aA | 7.4 aA | 8.0 aA | 9.7 aA | 10.9 aA | 3.23 | 6.6 bA | 7.9 abA | 8.7 abA | 9.9 abA | 11.4 aA | 2.86 |

| Galactose (%, w/w) | 2.4 cA | 2.9 bA | 3.3 bA | 3.8 aA | 4.2 aA | 0.06 | 2.2 cA | 2.8 bcA | 3.2 abcA | 3.5 abA | 4.2 aA | 0.19 |

| Lactic acid (%, w/w) | 2.7 cA | 3.0 cA | 3.6 bA | 3.8 abA | 4.2 aA | 0.25 | 2.4 cA | 2.9 bcA | 3.2 bA | 3.5 abA | 4.0 aA | 0.19 |

| Salt (%, w/w) | 0.42 eB | 0.49 dB | 0.55 cB | 0.61 bB | 0.70 aB | 0.005 | 2.50 eA | 2.68 dA | 2.95 cA | 3.50 bA | 3.61 aA | 0.01 |

| pH | 4.1 aA | 4.0 aA | 3.9 bA | 3.9 bA | 3.9 bA | 0.03 | 4.2 aAA | 4.0 bA | 4.0 bcA | 4.0 bcA | 3.9 cA | 0.05 |

| Particle diameter 3 | ||||||||||||

| D10 (µm) | 42 aA | 36 aA | 36 aA | 36 aA | 36 aA | 1.36 | 34 aB | 34 aA | 33 aA | 35 aA | 41 aA | 2.36 |

| D50 (µm) | 208 aA | 195 bA | 186 bcA | 185 bcA | 180 cA | 1.73 | 192 aA | 196 aA | 186 aA | 182 aA | 195 aA | 4.95 |

| D90 (µm) | 501 aA | 493 abA | 477 abA | 482 abA | 475 bA | 4.12 | 472 aA | 496 aA | 482 aA | 475 aA | 491 aA | 7.28 |

| Water sorption (g water/100 g dm) | ||||||||||||

| At 85% RH 4 | 23.9 cB | 25.0 bcA | 26.3 bcB | 28.3 abA | 30.5 aA | 1.35 | 29.01 aA | 29.7 aA | 32.8 aA | 35.4 aA | 34.7 aA | 1.33 |

| At 5% RH | 3.1 bA | 2.8 bA | 2.9 bA | 3.5 bA | 4.7 aA | 0.87 | 2.8 aA | 3.2 aA | 3.2 aA | 3.6 aA | 4.6 aA | 0.62 |

| Characteristic | Unsalted FMWC | Salted FMWC | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FM:W | FM:W | |||||||||||

| 1.5 | 1.9 | 2.3 | 3.0 | 4.0 | SED 1 | 1.5s | 1.9s | 2.3s | 3.0s | 4.0s | SED 1 | |

| WHC (g/100 g) 2 | ||||||||||||

| At 0 min | 50.3 a | 46.3 b | 45.9 b | 45.7 b | 45.9 b | 0.58 | - | - | - | - | - | - |

| At 10 min | 70.0 a | 69.9 a | 62.5 b | 60.9 b | 54.7 c | 0.64 | - | - | - | - | - | - |

| At 35 min | 99.0 aA | 97.4 aA | 91.5 bA | 90.8 bA | 78.0 cA | 0.58 | 94.7 aA | 98.6 aA | 97.2 aA | 90.5 aA | 72.2 bA | 1.27 |

| Pasting Characteristics 2 | ||||||||||||

| V95 (Pa·s) | 1.17 aA | 1.04 aA | 0.71 bA | 0.50 bA | 0.23 cA | 0.04 | 0.56 bcB | 0.92 aA | 0.68 abA | 0.31 cA | 0.25 cA | 0.06 |

| Vh (Pa·s) | 1.61 aA | 1.36 abA | 1.02 abcA | 0.83 bcA | 0.46 cA | 0.09 | 0.98 abA | 1.40 aA | 1.05 abA | 0.65 bA | 0.47 bA | 0.10 |

| Vc (Pa·s) | 4.42 aA | 4.07 abA | 2.87 bcA | 2.39 cdA | 1.47 dA | 0.20 | 2.95 abA | 4.20 aA | 3.19 abA | 2.07 bA | 1.47 bA | 0.40 |

| SBV (Pa·s) | 2.81 aA | 2.71 aA | 1.85 bA | 1.57 bcA | 1.01 cA | 0.15 | 1.98 abA | 2.80 aA | 2.14 abA | 1.42 abA | 0.99 bA | 0.30 |

| Rheology 2 | ||||||||||||

| o | 67.2 aA | 36.6 bA | 24.0 bcA | 18.0 cA | 6.5 dB | 3.39 | 71.8 aA | 35.2 bA | 24.1 bcA | 14.0 cdA | 8.0 dA | 2.82 |

| k (Pa·sn) | 10.2 aA | 6.3 bA | 6.0 bA | 2.8 cA | 2.7 cA | 0.54 | 6.3 aA | 4.70 bA | 3.7 cB | 3.2 cdA | 2.64 dA | 0.11 |

| n (-) | 0.60 A | 0.59 aA | 0.57 aA | 0.63 aA | 0.53 aA | 0.01 | 0.65 aA | 0.61 aA | 0.61 aA | 0.60 aA | 0.49 aA | 0.05 |

| η at 120 s−1 (Pa·s) | 1.7 aA | 1.21 abA | 0.85 abA | 0.64 abA | 0.34 bA | 0.24 | 1.61 aA | 1.08 bA | 0.85 bcA | 0.51 cdA | 0.36 dA | 0.06 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shevade, A.V.; O’Callaghan, Y.C.; O’Brien, N.M.; O’Connor, T.P.; Guinee, T.P. The Proportion of Fermented Milk in Dehydrated Fermented Milk–Parboiled Wheat Composites Significantly Affects Their Composition, Pasting Behaviour, and Flow Properties on Reconstitution. Foods 2018, 7, 113. https://doi.org/10.3390/foods7070113

Shevade AV, O’Callaghan YC, O’Brien NM, O’Connor TP, Guinee TP. The Proportion of Fermented Milk in Dehydrated Fermented Milk–Parboiled Wheat Composites Significantly Affects Their Composition, Pasting Behaviour, and Flow Properties on Reconstitution. Foods. 2018; 7(7):113. https://doi.org/10.3390/foods7070113

Chicago/Turabian StyleShevade, Ashwini V., Yvonne C. O’Callaghan, Nora M. O’Brien, Tom P. O’Connor, and Timothy P. Guinee. 2018. "The Proportion of Fermented Milk in Dehydrated Fermented Milk–Parboiled Wheat Composites Significantly Affects Their Composition, Pasting Behaviour, and Flow Properties on Reconstitution" Foods 7, no. 7: 113. https://doi.org/10.3390/foods7070113