1. Introduction

Membrane filtration is one of the widely used techniques in food industry (fruits juices clarification, protein standardization in dairy industry, fractionation of milk fat, beer filtration, and stabilization…). Cross flow filtration (also known as tangential flow filtration) is a filtration technique in which the starting solution passes tangentially along the surface of the filter. The application of crossflow ultrafiltration in clarification or concentration fruit juice has been studied on kiwi, orange, melon, cantaloupe, and umbu juice [

1,

2,

3,

4,

5]. To our knowledge, this has not been studied and applied on processing of fruit juice in Vietnam.

Cashew apple (

Anacardium occidentale Line), a pseudo fruit, is a by-product of the cashew nut industry. Viet Nam produces more than 600.000–700.000 tons of cashew apple per year [

6]. Although highly nutritious and full of vitamin C [

7], most of Vietnam’s cashew apples are disposed at harvest and not utilized in the country. This study will highlight the opportunities for a processing of the cashew apple juice by ultrafiltration.

Dragon fruit (

Hylecereus polyhizus) is well known for its rich nutritional contents and is commercially available worldwide for improving many health problems. Its origin is from Central America and then it was introduced in Vietnam in the early twentieth century by the French. Dragon fruit is rich in nutritional values such as fibers, vitamin C, potassium, protein, fiber, sodium, calcium, and minerals [

8]. It has relatively high antioxidant activity when compared to that of the other subtropical fruits. Mostly fleshed varieties are used for fresh consumption. Processed dragon fruit products are rarely available in local markets and very little work has been done on processing of dragon fruit in Vietnam.

Pineapple (

Ananas comosus (L.) Merr), is the edible member of the

Bromeliaceae family. Pineapple is known for its good aroma, flavor, juiciness, sweetness, and its various nutritional and health benefits, as it contains a considerable amount of calcium, potassium, fiber, vitamin C, phenolic, fiber, and minerals [

9]. Moreover, pineapple is the best-known source of endopeptidase bromelain [

10]. Pineapples can be consumed fresh or processed as condiments, sweets, savories, cakes, pastries, yoghurt, and punches. Clarification of pineapple juice by cross-flow filtration has not been done in Vietnam.

Pomelo (

Citrus grandis L.) is a subtropical citrus tree and also a very cultivated fruit in Vietnam. The total amount of pomelo production is 50.000 tons per year [

11]. Pomelo has a high nutritional value to human health as it is rich in vitamin C and other mineral elements [

12].

Gac (

Momordica cochinchinensis Spreng.) fruit, a traditional fruit in Vietnam is extremely good for health. Oil extracted from gac aril has high content in carotenoids, mainly

β-carotene and lycopene [

13]. Carotenoids concentration and purification by cross-flow filtration has been simple than the conventional chemical process because of their advantages, such as low energy consumption, operation at mild temperatures, and the absence of addition of chemical products [

14].

Membrane blockage (fouling) is major difficulty of the filtration process that needs to be controlled. This phenomenon is caused by different contributions, including polarization concentration, gel formation, particle adsorption, and pore blockage [

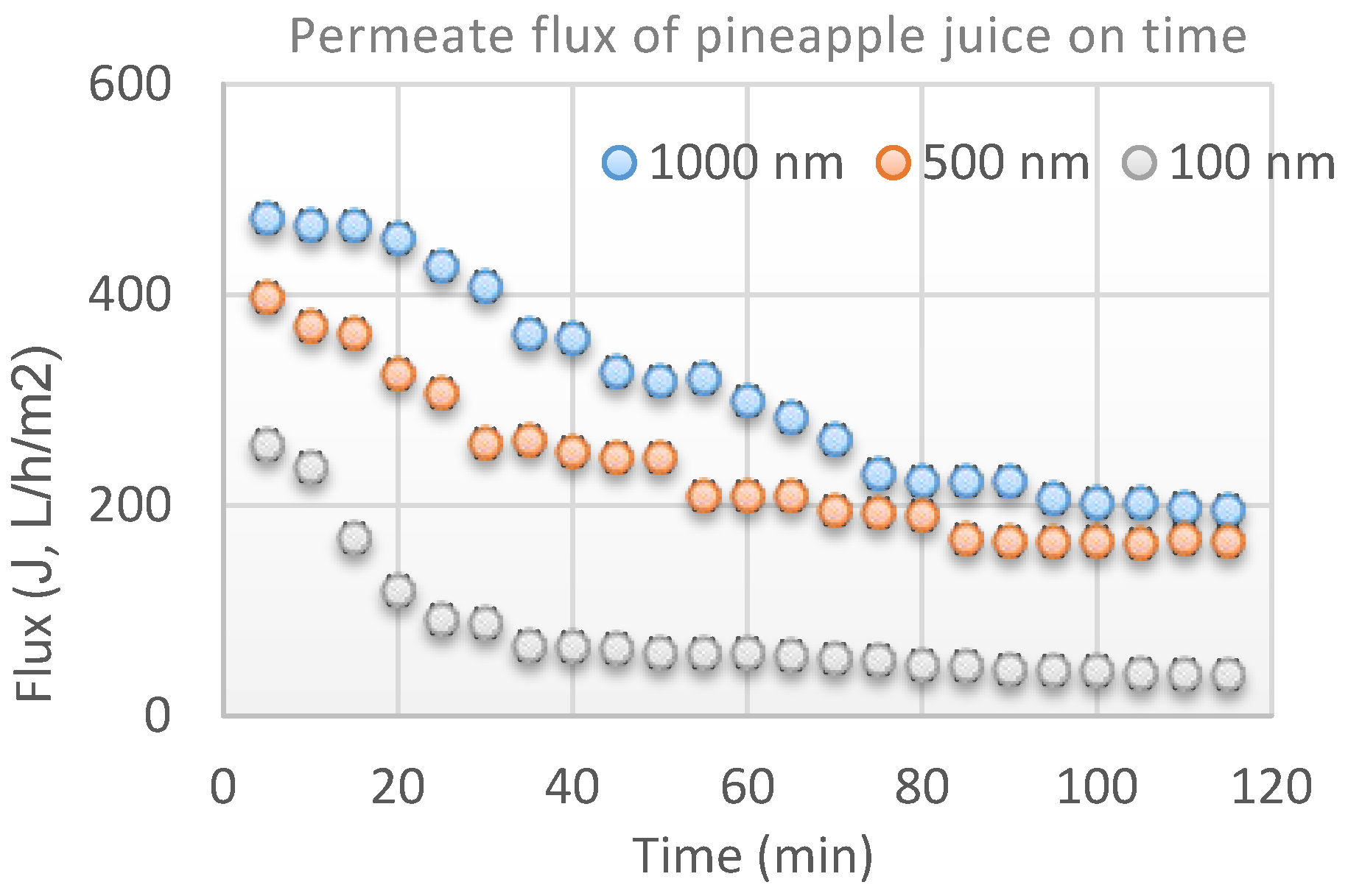

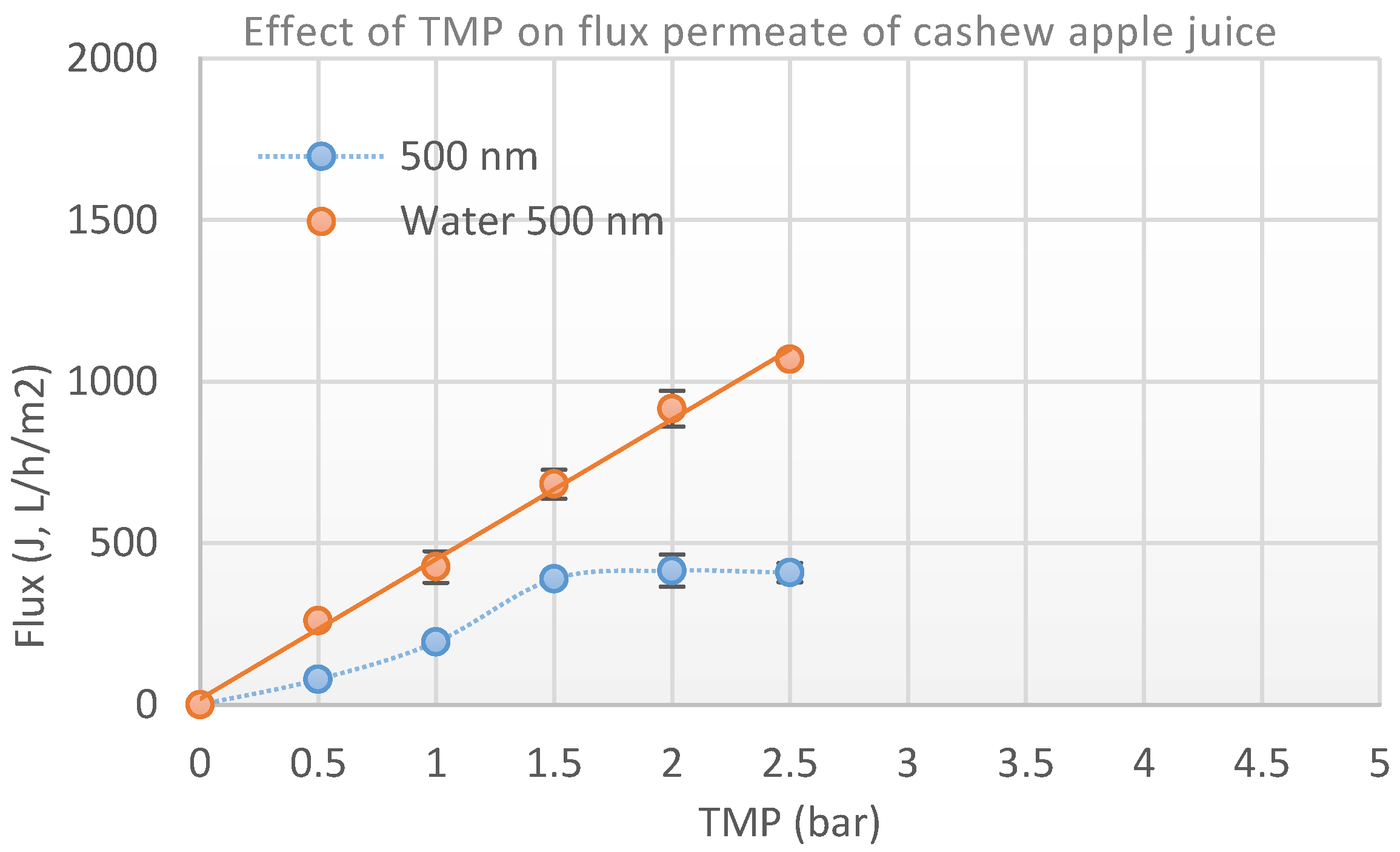

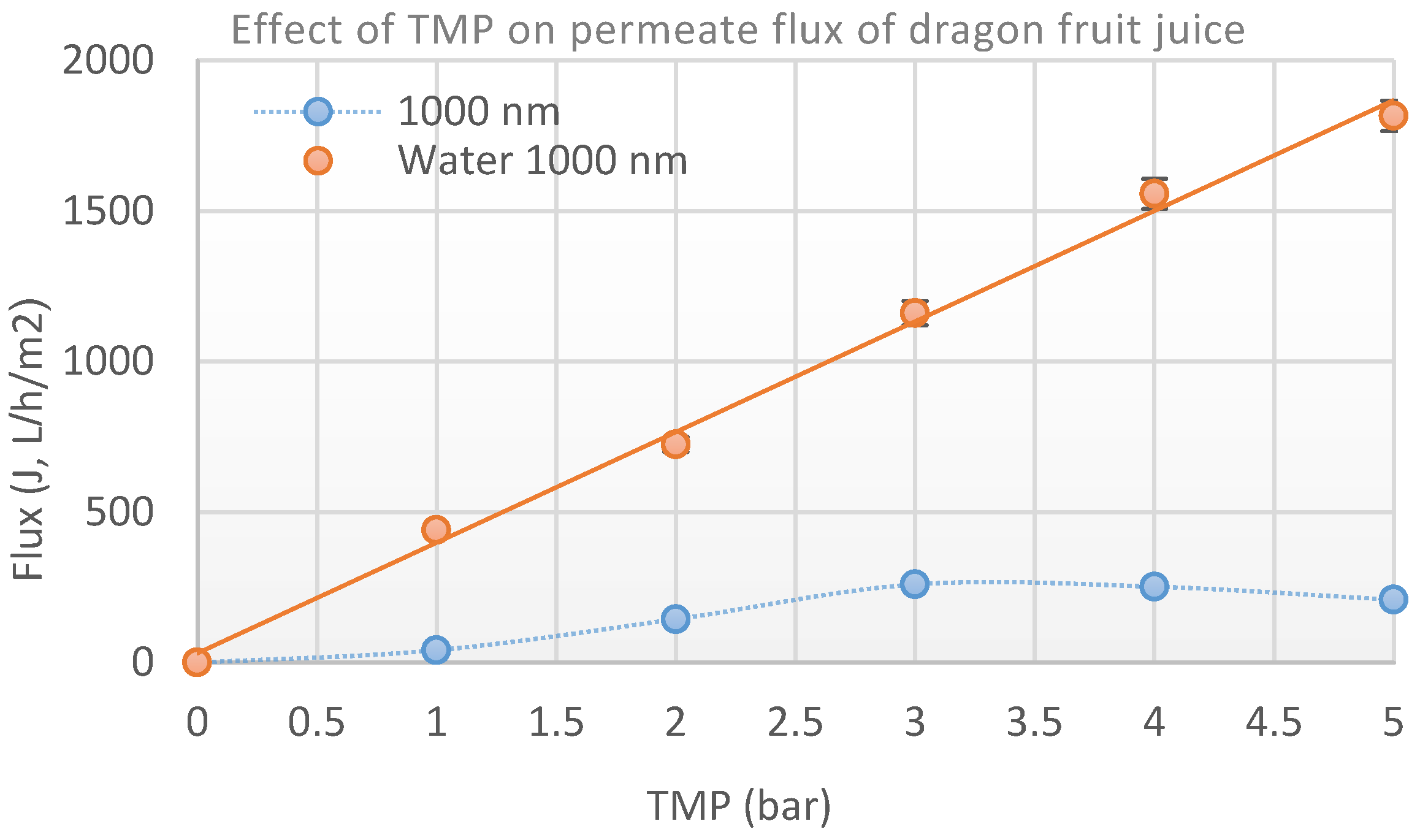

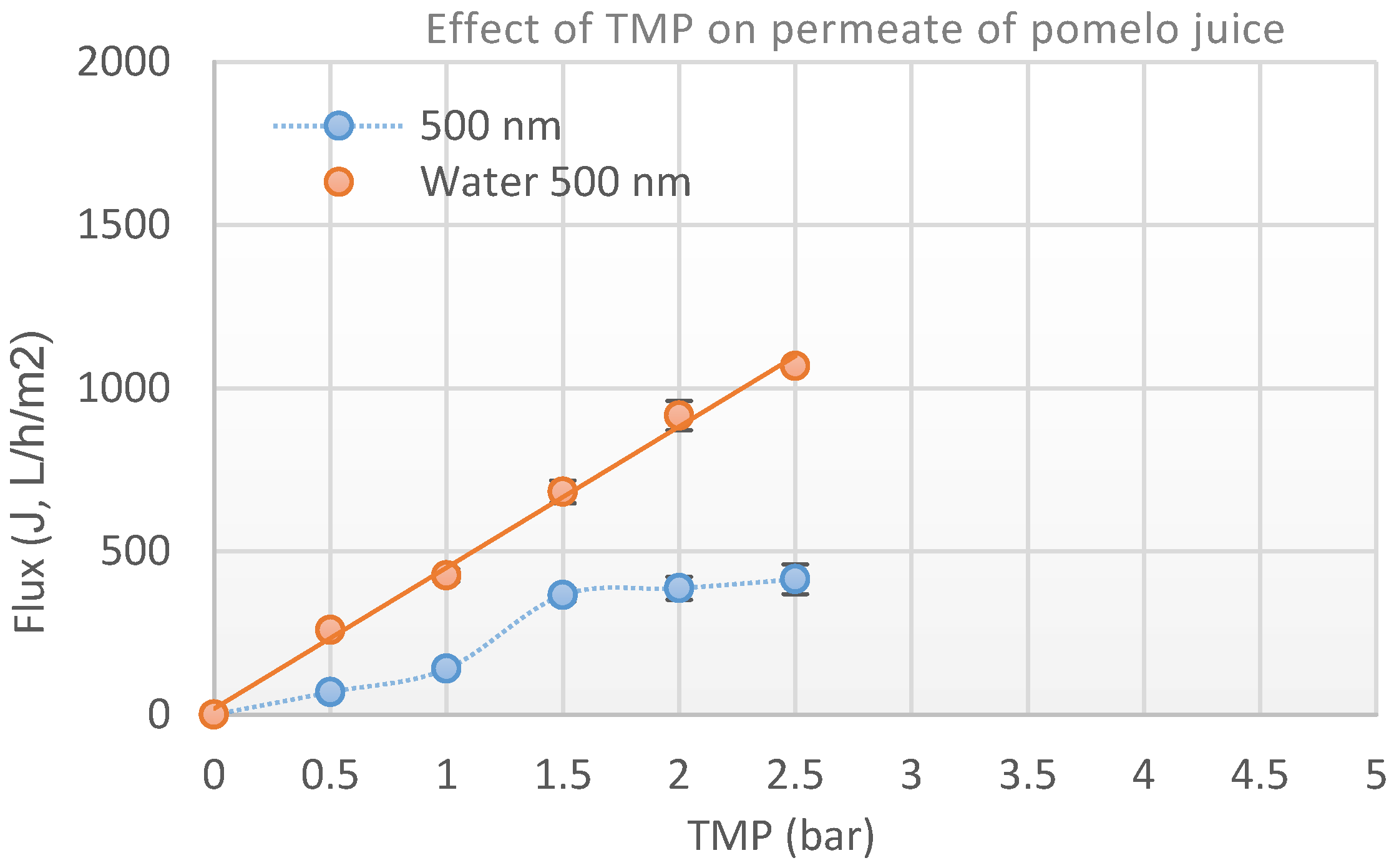

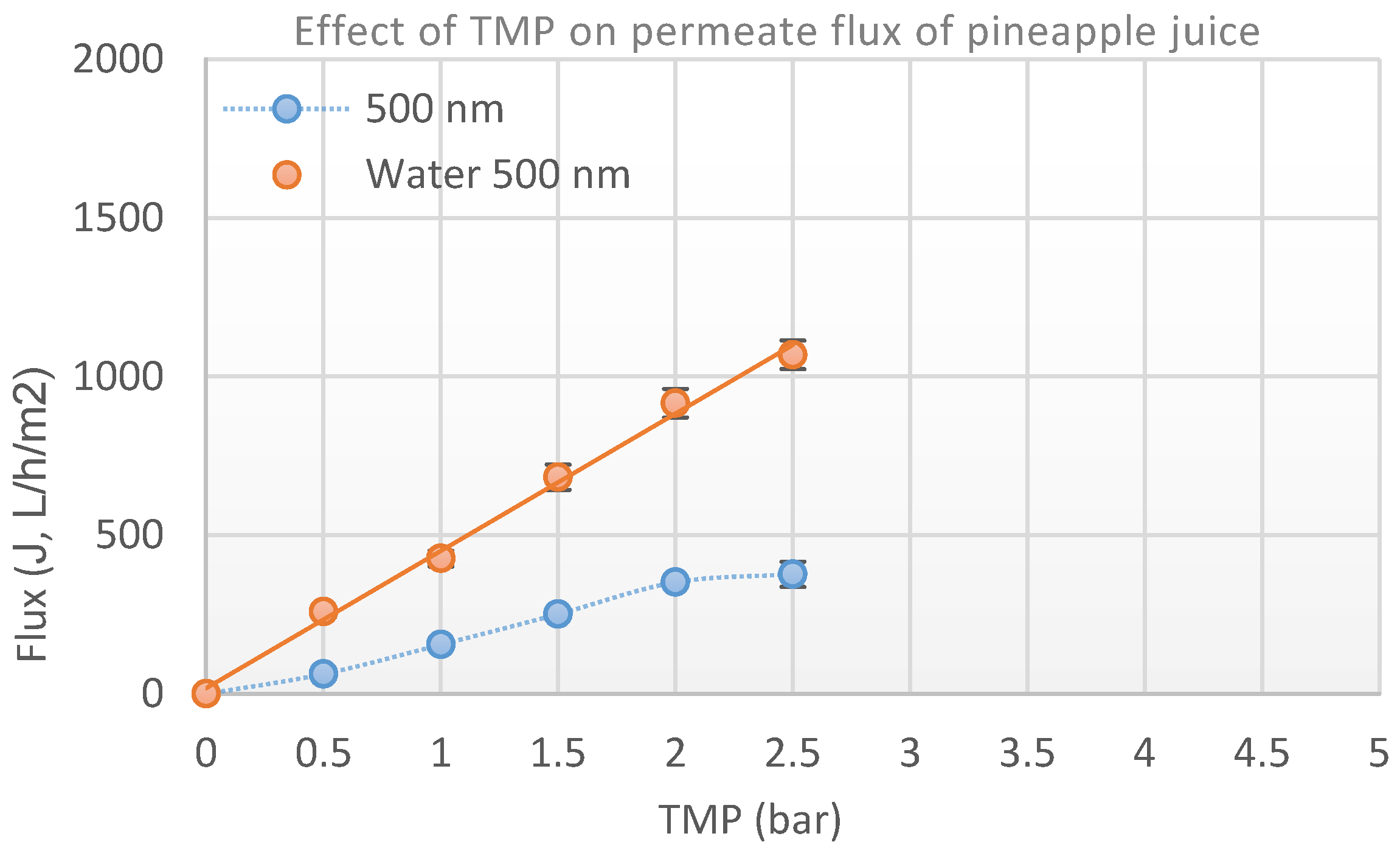

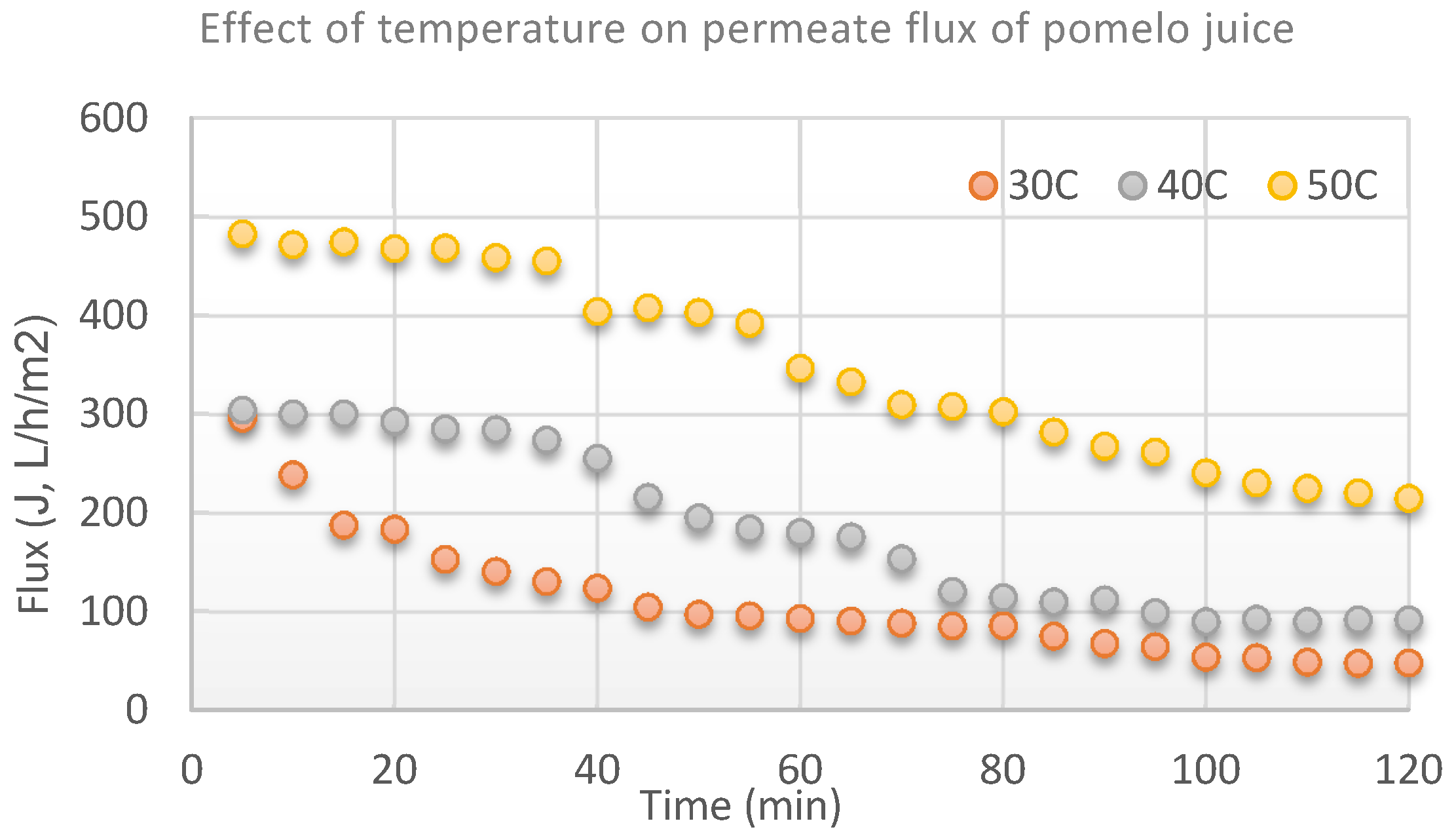

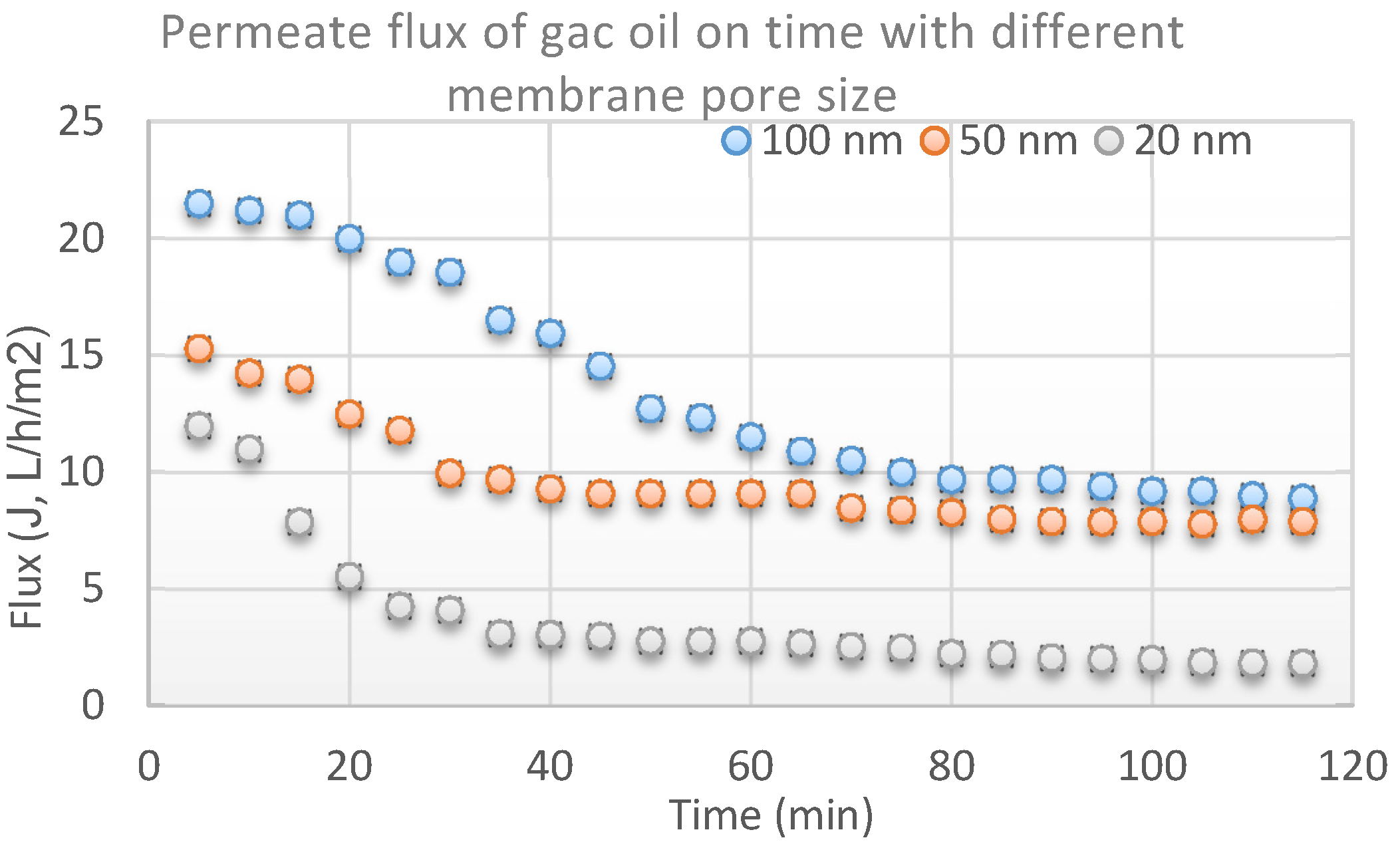

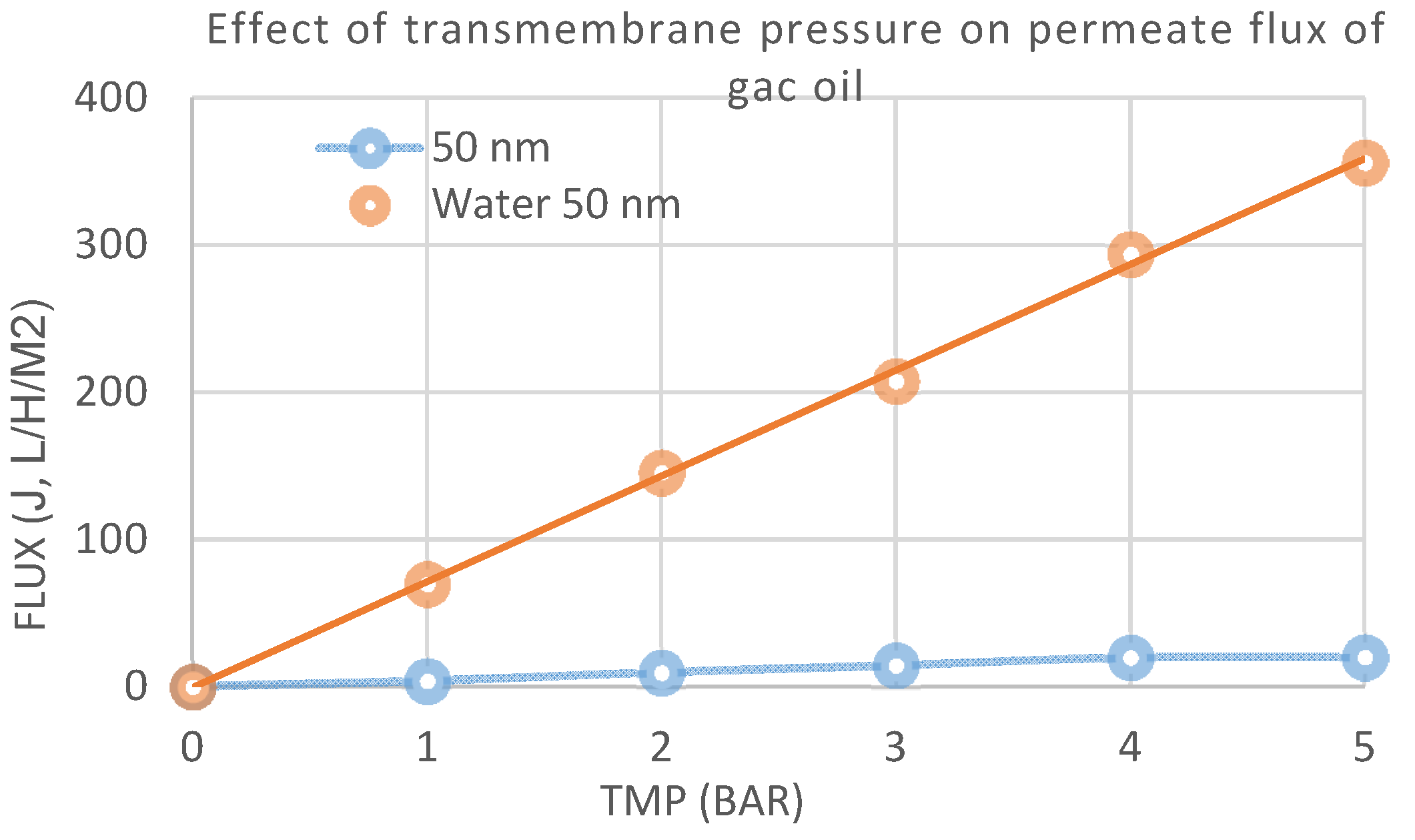

15]. In the filtration process, the membrane pore size, temperature, and transmembrane pressure are important factors that need to be optimized in order to increase the filtration yield [

16].

The application of membranes technology for tropical fruits processing in Vietnam has not been reported in literature. Using this technology to concentrate and purify the juice can improve the quality of products and increase economic value of Vietnamese fruits. The purpose of this study is to offer the 1st highlight of application of crossflow ultrafiltration on Vietnamese fruit juice processing. This work will study the impact of the operational conditions (transmembrane pressure, membrane pore size, and temperature) on permeate flux and quality of product. The resistance of process will be also analyzed.

2. Materials and Methods

2.1. Materials

Fresh fruits (dragon fruit, pineapple, pomelo, and gac fruit) were purchased from Co.op Mart supermarket in Ho Chi Minh, Viet Nam. Cashew apple was purchased from Long Khanh, Dong Nai province. The maturity of fruits had to be controlled as these significantly affect the characteristics of juices. A ripe dragon fruit will have a bright and vibrant coloration and a smooth surface. It takes the dragon fruits about 50 days to reach maturity after flowering. The time from flowering to mature fruit is about 60–70 days, 190–210 days, 90–100 days, and 80–90 days for cashew apple, pomelo, pineapple, and gac fruit, respectively. Gac fruit itself becomes a dark orange color upon ripening, and is typically round or oblong, maturing to a size of about 13 cm in length and 10 cm in diameter. Its exterior skin is covered in small spines while its dark red interior consists of clusters of fleshy pulp and seeds.

Fruits were manually washed in water and then peeled, obtaining the flesh of the fruit. Fruit juices were obtained by juice presses, model Panasonic MJ-DJ01S (Osaca, Japan). Gac aril oil was obtained by screw oil presses, model Anyang 6YL-68 (AGICO Co., Anyang, China). The juice and oil were pre-filtered by cloth and cellulose acetate membrane filter before the processing of ultrafiltration (UF). Cellulose acetate membrane was from Sartorious Company, Germany with 5 μm of membrane pore size. The antioxidant agent (Butylated Hydroxytoluene, BHT, 0.1% v/v) was added into the juice and oil before storage. The juice and oil were stored in the fridge (<10 °C) during the experiment. Chemical agents such as BHT, n-hexane, acetone, sodium hydroxide (NaOH), methanol, and other analytic reagents were purchased from Merck Ltd. and India supplied by Bach Khoa Chemical Company, 334 Tô Hien Thanh street, District 10, Ho Chi Minh City, Viet Nam.

2.2. Chemical and Physical Analysis

Physiochemical characterization of juice and oil (both of feeding and final product) was evaluated by measuring their viscosity, pH, and their nutritional compositions (protein, carbohydrates, lipid, total solid content (TSC), total soluble solids (TSS), and total carotenoids content (TCC). The total carotenoid content (TCC) was measured using a Thermo Spectronic model Genesys 20 (Thermo Scientific, Waltham, MA, USA) at a wavelength of 473 nm following the procedure presented by Tran [

17]. Other parameters were measured by using methods as in

Table 1.

2.3. Ultrafiltration Experimental Setup

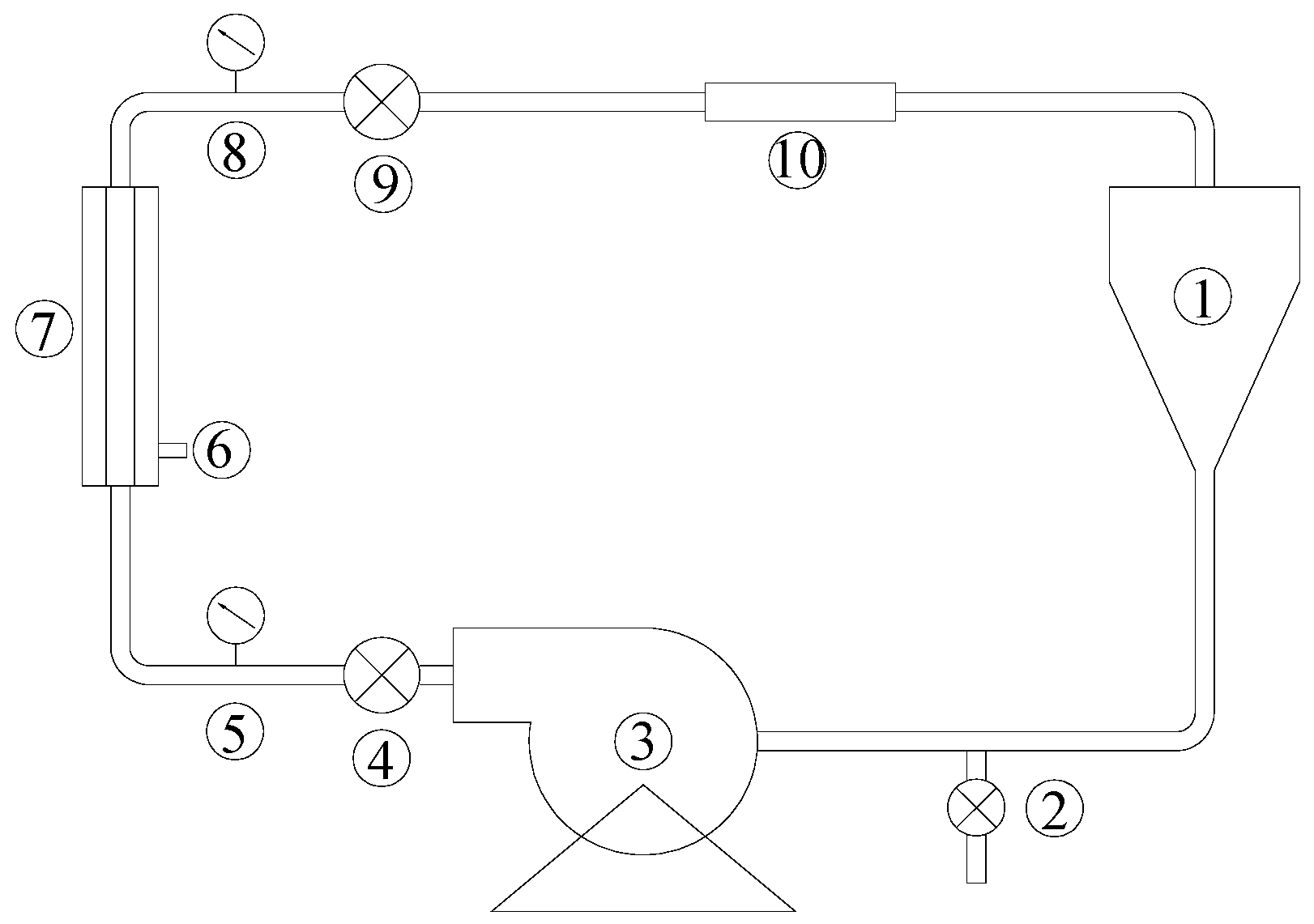

The filtration experiments were carried out in a laboratory pilot unit (

Figure 1), equipped by:

- -

A 10-liter stainless steel feed tank.

- -

A feed pressure pump, motor Lucky Pro MRS/4 water pump (flow range: 16.7 to 100 L/min)

- -

A tube and shell heat exchanger circulated with water, this was used to maintain the constant temperature of the feed oil.

- -

2 pressure gauges (0–10 kgf/cm2, by graduation 0.2) located at the inlet (Pin) and outlet (Pout) of the membrane.

- -

One ceramic membrane (characteristics of these membranes are presented in

Table 2) is set in the filtration module for each experiment.

2.4. Filtration Processing

In the filtration process, the solution that passes along the membrane surface and back to the feed reservoir is the retentate. Solution that passes across the membrane is the permeate. In this study, to clarify juices of cashew, apple, dragon fruit, pineapple, and pomelo, membrane process was used and the desired products were permeate. At the same time, the membrane process was also applied to concentrate the carotenoids and to eliminate the phospholipids and free fatty acid in gac oil, and as the result, the desired product was retentate. Filtration experiments were realized by two modes of operating: total recycle mode and batch concentration mode. In total recycle mode, permeate and retentate were totally recycled in the feed tank. This experiment is to determine optimal operating hydrodynamic condition. In batch mode, only retentate was recycled to feed tank. This process is to determine the filtration yield and product quality. This process is operated at the optimal conditions identified by total recycle model. The following parameters were used in filtration process:

Permeate flux (J, L/h/m2): measures the volume (l) of permeate obtained on function of time (h) per filtration area (m2).

Coefficient of retention (

R, %): measures the retention rate of determined solute by the membrane during filtration:

where

CP and

CF are the concentration of the solute in permeate and feeding, presented in Kg/m

3, respectively.

Transmembrane pressure (TMP, bar): The total hydraulic resistance corresponds , where RM, RP, RF is membrane resistance, concentration polarization resistance and fouling resistance, respectively. These three parameters were evaluated experimentally.

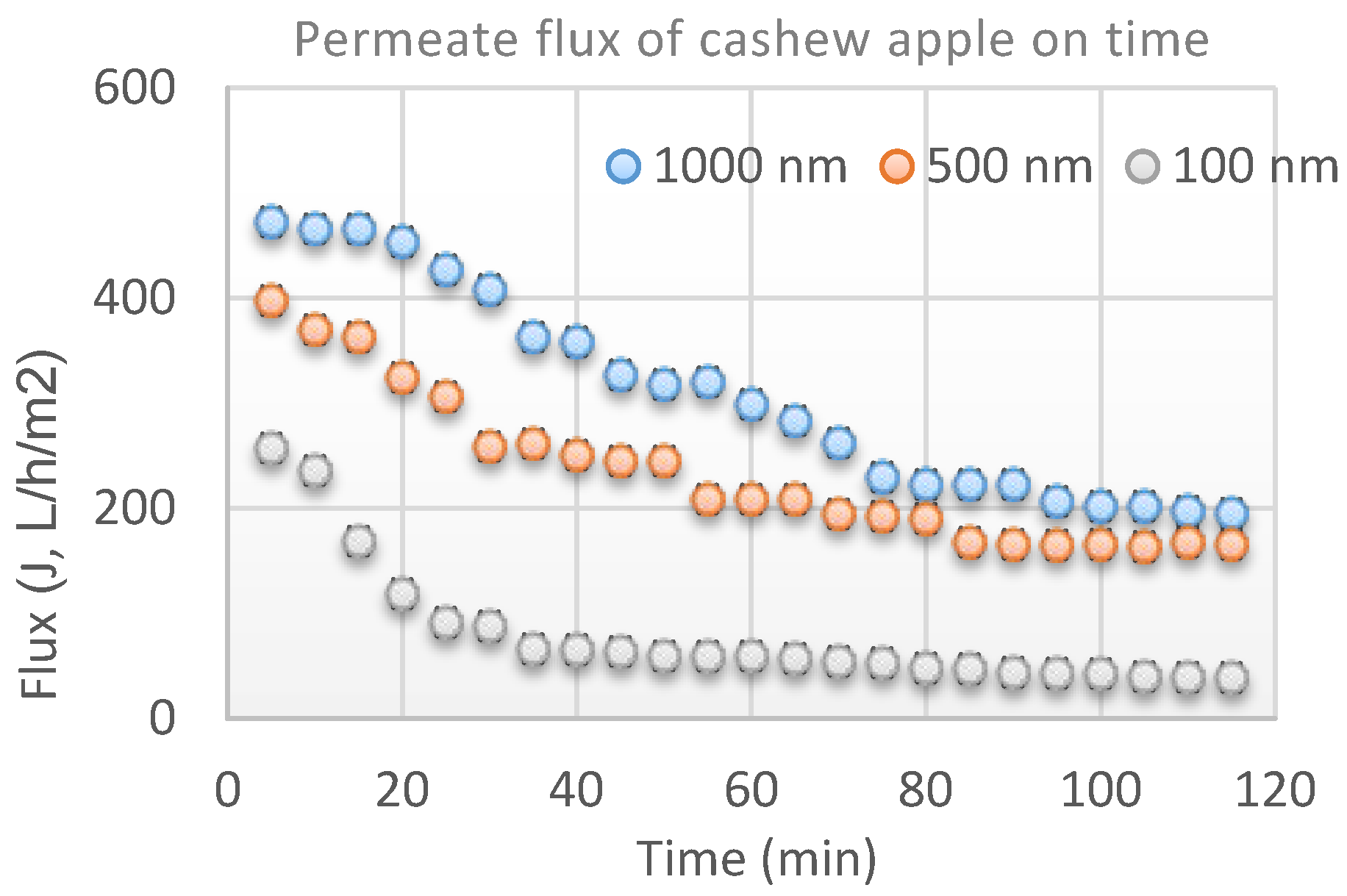

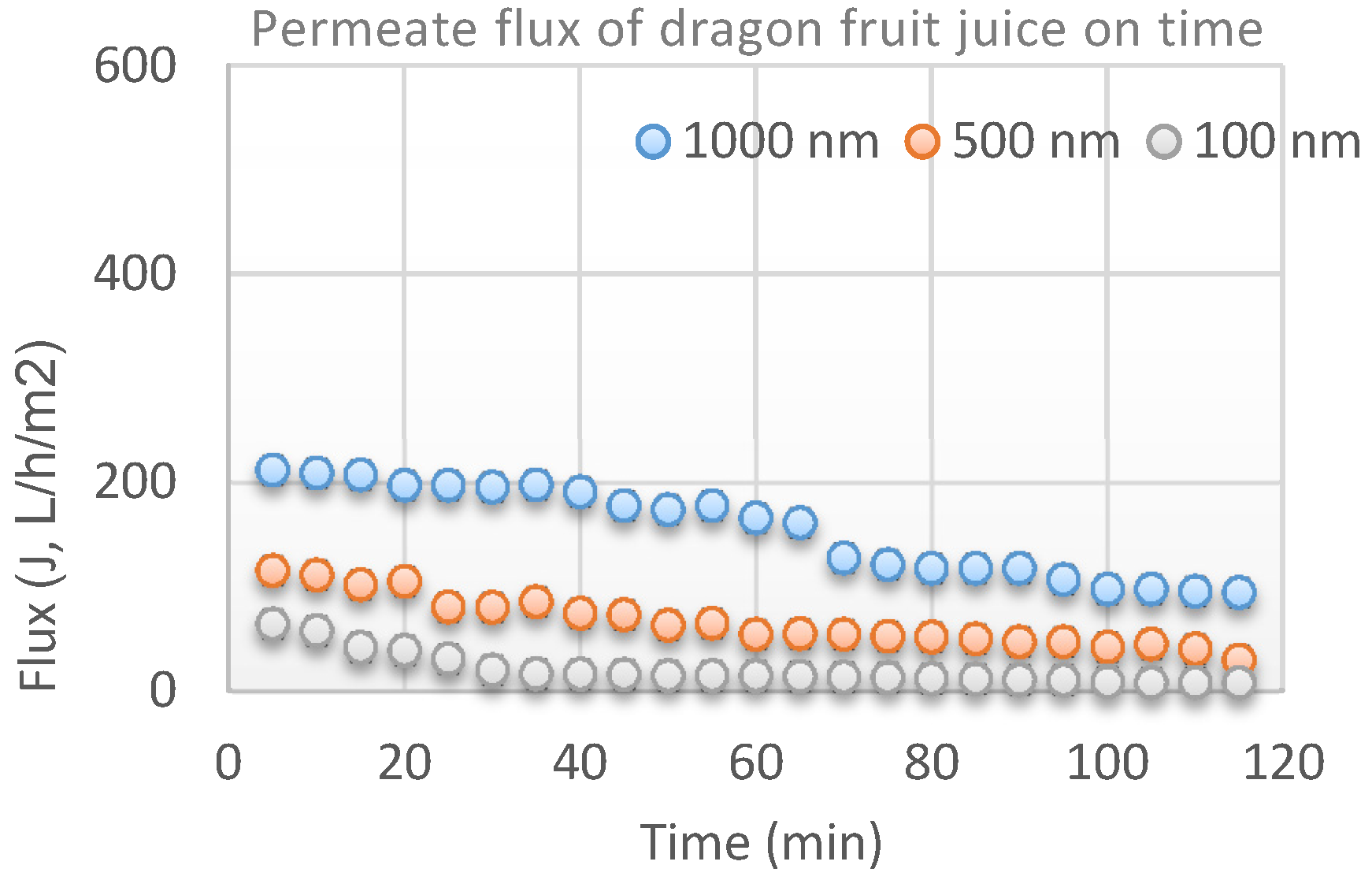

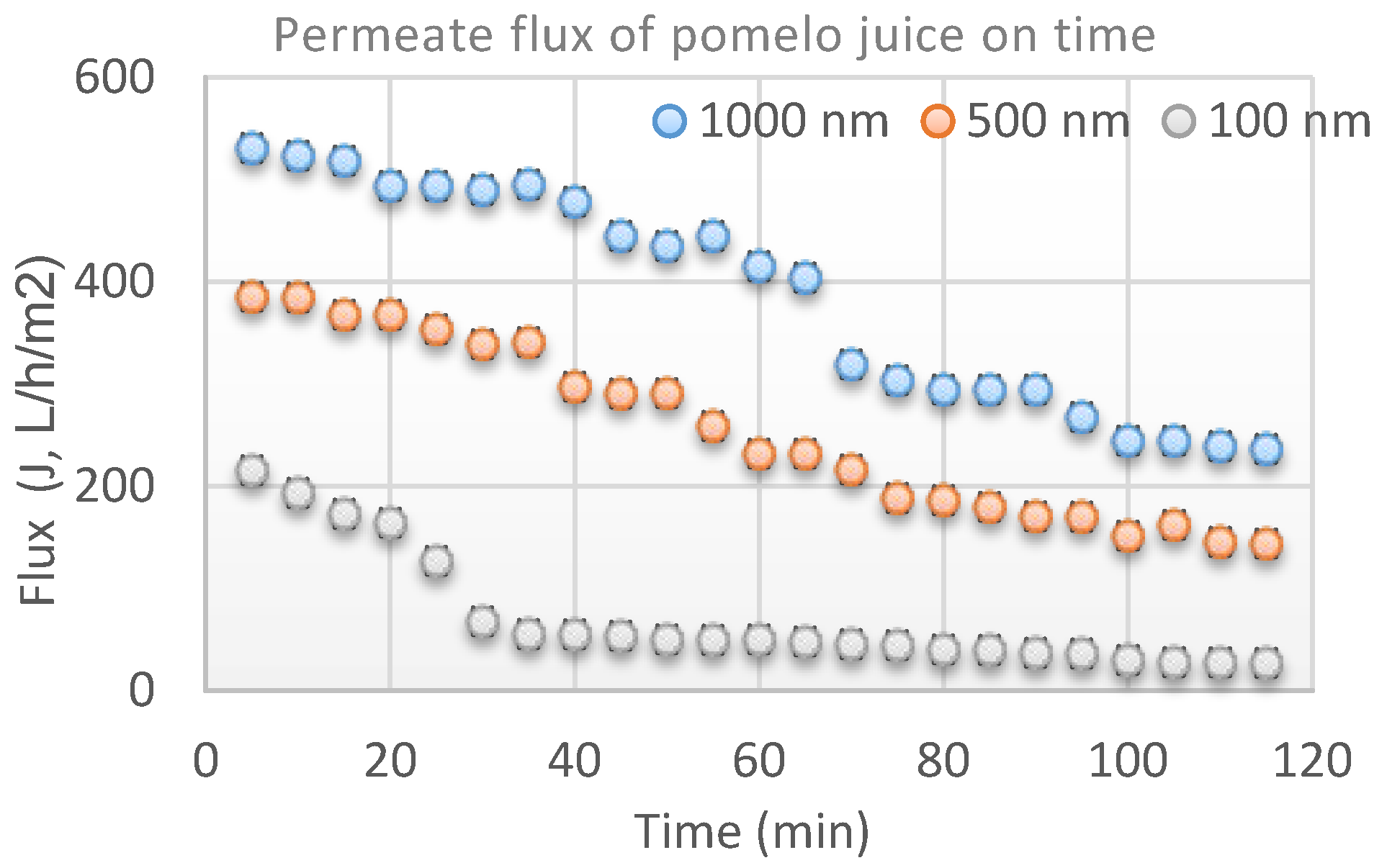

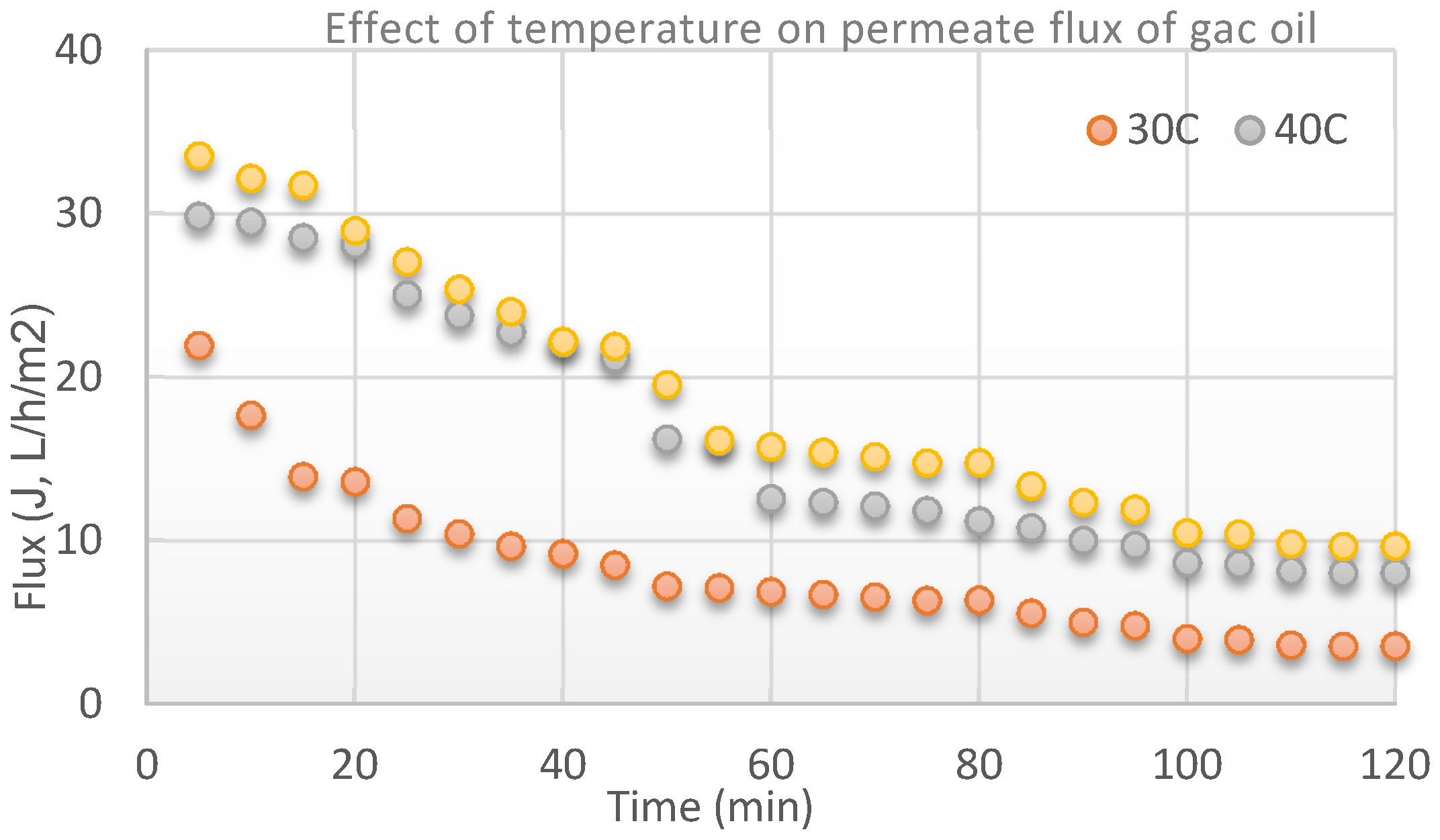

5. Conclusions

Cashew apple, dragon fruit, pomelo, and pineapple juices were clarified by the UF process at different operating conditions. Membrane pore size, TMP, and the temperature of processing have influence on the permeate flux and turbidity. Membrane pore size of 500 nm is highly recommended for juice clarification objectives. The reasonable pressure for UF processing of cashew apple, dragon fruit, pomelo, and pineapple juice is 1.5 bars, 3 bars, 1.5 bars, and 2 bars, respectively. The optimum temperature for UF processing is 50 °C, 40 °C, 50 °C, and 50 °C, respectively. The impact of these factors on other nutritional components should be further exanimated in order to control the quality of the final product. Carotenoids in gac oil can be concentrated by using the ultrafiltration membrane at the operating conditions. Membrane pore size of 50 nm is acceptable because of its high permeate flux and high coefficient of retention of TCC. TMP of 3 bars and temperature of 40 °C are highly recommended for gac oil filtration process because of its high flux permeates and relatively high effective retention of TCC. The total resistance is mainly contributed by RP, followed by RF. Compressibility of fouling cake needs to be determined in further study.