Recent Advances and Applications of Pulsed Electric Fields (PEF) to Improve Polyphenol Extraction and Color Release during Red Winemaking

Abstract

:1. Introduction

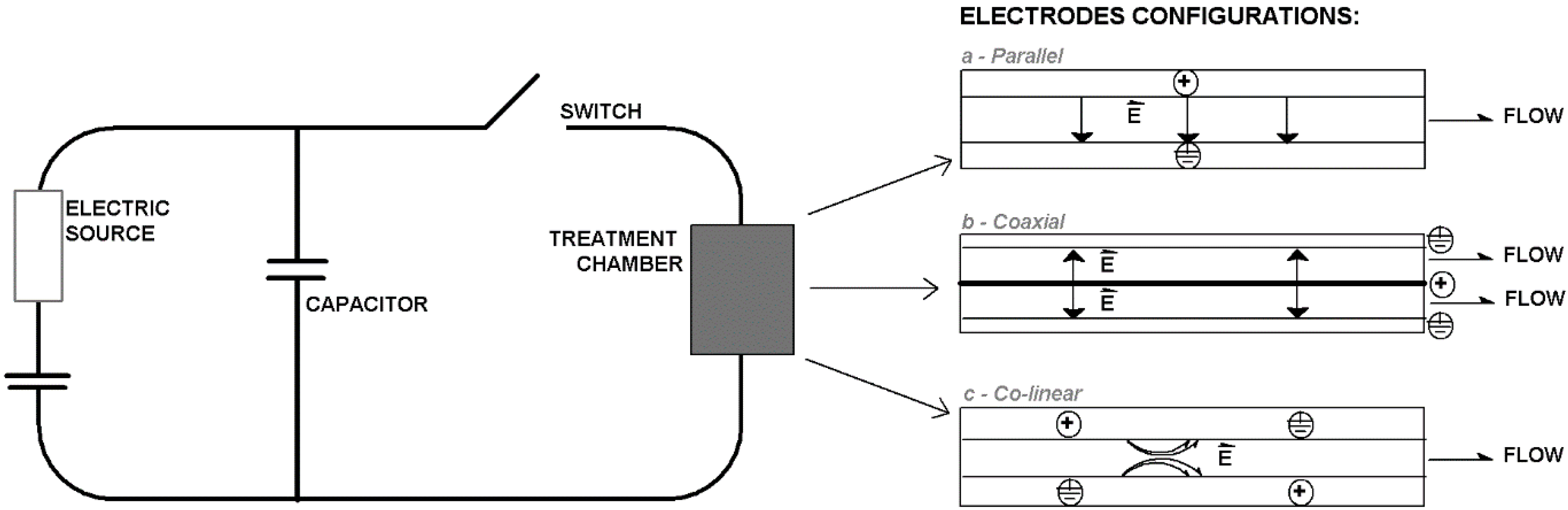

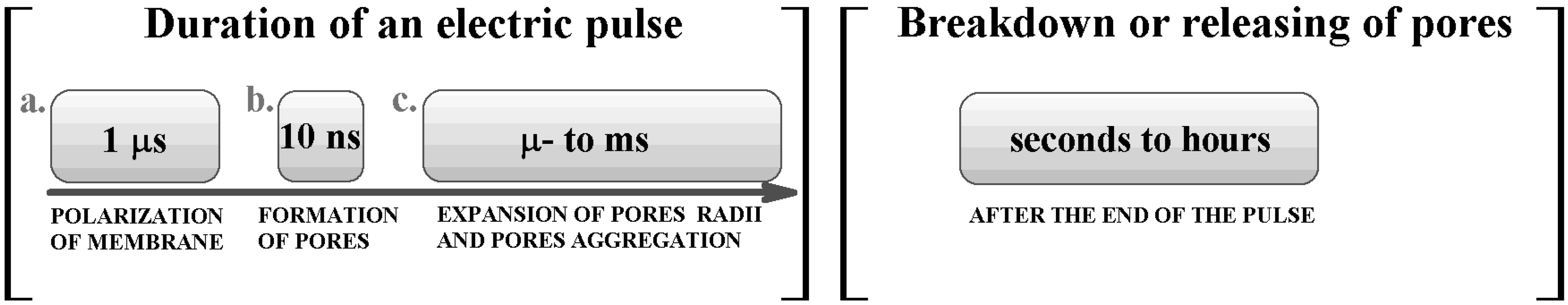

2. An Overview on PEF Technology: Equipment and Processes

3. Enhancement of Mass Transfer from Vegetable Tissues by PEF

4. PEF Technology in Red Winemaking (Decade 2007–2017)

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vilkhu, K.; Mawson, R.; Simons, L.; Bates, D. Applications and opportunities for ultrasound assisted extraction in the food industry—A review. Innov. Food Sci. Emerg. Technol. 2008, 9, 161–169. [Google Scholar] [CrossRef]

- Costa, A.I.A.; Dekker, M.; Jongen, W.M.F. Quality function deployment in the food industry: A review. Trends Food Sci. Technol. 2000, 11, 306–314. [Google Scholar] [CrossRef]

- Cardello, A.V.; Schutz, H.G.; Lesher, L.L. Consumer perceptions of foods processed by innovative and emerging technologies: A conjoint analytic study. Innov. Food Sci. Emerg. Technol. 2007, 8, 73–83. [Google Scholar] [CrossRef]

- Jay, J.M. Microbiological food safety. Crit. Rev. Food Sci. Nutr. 1992, 31, 177–190. [Google Scholar] [CrossRef] [PubMed]

- Alwazeer, D.; Delbeau, C.; Divies, C.; Cachon, R. Use of redox potential modification by gas improves microbial quality, color retention, and ascorbic acid stability of pasteurized orange juice. Int. J. Food Microbiol. 2003, 89, 21–29. [Google Scholar] [CrossRef]

- Torregrosa, F.; Cortés, C.; Esteve, M.J.; Frígola, A. Effect of high-intensity pulsed electric fields processing and conventional heat treatment on orange−carrot juice carotenoids. J. Agric. Food Chem. 2005, 53, 9519–9525. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.S.; Park, S.J.; Cho, Y.H.; Park, J. Effects of combined treatment of high hydrostatic pressure and mild heat on the quality of carrot juice. J. Food Sci. 2001, 66, 1355–1360. [Google Scholar] [CrossRef]

- Loginova, K.V.; Vorobiev, E.; Bals, O.; Lebovka, N.I. Pilot study of countercurrent cold and mild heat extraction of sugar from sugar beets, assisted by pulsed electric fields. J. Food Eng. 2011, 102, 340–347. [Google Scholar] [CrossRef]

- Lebovka, N.I.; Praporscic, I.; Vorobiev, E. Effect of moderate thermal and pulsed electric field treatments on textural properties of carrots, potatoes and apples. Innov. Food Sci. Emerg. Technol. 2004, 5, 9–16. [Google Scholar] [CrossRef]

- Butz, P.; Tauscher, B. Emerging technologies: Chemical aspects. Food Res. Int. 2002, 35, 279–284. [Google Scholar] [CrossRef]

- Morris, C.; Brody, A.L.; Wicker, L. Non-thermal food processing/preservation technologies: A review with packaging implications. Packag. Technol. Sci. 2007, 20, 275–286. [Google Scholar] [CrossRef]

- Barbosa-Canovas, G.V.; Pierson, M.D.; Zhang, Q.H.; Schaffner, D.W. Pulsed Electric Fields. J. Food Sci. 2000, 65, 65–79. [Google Scholar] [CrossRef]

- Góngora-Nieto, M.M.; Sepúlveda, D.R.; Pedrow, P.; Barbosa-Cánovas, G.V.; Swanson, B.G. Food processing by pulsed electric fields: Treatment delivery, inactivation level, and regulatory aspects. Food Sci. Technol. 2002, 35, 375–388. [Google Scholar] [CrossRef]

- Zhao, W.; Yu, Z.; Liu, J.; Yu, Y.; Yin, Y.; Lin, S.; Chen, F. Optimized extraction of polysaccharides from corn silk by pulsed electric field and response surface quadratic design. J. Sci. Food Agric. 2011, 91, 2201–2209. [Google Scholar] [CrossRef] [PubMed]

- Corrales, M.; Toepfl, S.; Butz, P.; Knorr, D.; Tauscher, B. Extraction of anthocyanins from grape by-products assisted by ultrasonics, high hydrostatic pressure or pulsed electric fields: A comparison. Innov. Food Sci. Emerg. Technol. 2008, 9, 85–91. [Google Scholar] [CrossRef]

- Tylewicz, U.; Tappi, S.; Mannozzi, C.; Romani, S.; Dellarosa, N.; Laghi, L.; Ragni, L.; Rocculi, P.; Dalla Rosa, M. Effect of pulsed electric field (PEF) pre-treatment coupled with osmotic dehydration on physico-chemical characteristics of organic strawberries. J. Food Eng. 2017, 213, 2–9. [Google Scholar] [CrossRef]

- Dellarosa, N.; Tappi, S.; Ragni, L.; Laghi, L.; Rocculi, P.; Dalla Rosa, M. Metabolic response of fresh-cut apples induced by pulsed electric fields. Innov. Food Sci. Emerg. Technol. 2016, 38, 356–364. [Google Scholar] [CrossRef]

- Traffano-Schiffo, M.V.; Laghi, L.; Castro-Giraldez, M.; Tylewicz, U.; Rocculi, P.; Ragni, L.; Dalla Rosa, M.; Fito, P.J. Osmotic dehydration of organic kiwifruit pre-treated by pulsed electric fields and monitored by NMR. Food Chem. 2017, 236, 87–93. [Google Scholar] [CrossRef] [PubMed]

- Sacchi, K.L.; Bisson, L.F.; Adams, D.O. A review of the effect of winemaking techniques on phenolic extraction in red wines. Am. J. Enol. Vitic. 2005, 56, 197–206. [Google Scholar]

- Pinelo, M.; Arnous, A.; Meyer, A.S. Upgrading of grape skins: Significance of plant cell-wall structural components and extraction techniques for phenol release. Trends Food Sci. Technol. 2006, 17, 579–590. [Google Scholar] [CrossRef]

- Aguilar, T.; Loyola, C.; de Bruijn, J.; Bustamante, L.; Vergara, C.; von Baer, D.; Mardones, C.; Serra, I. Effect of thermomaceration and enzymatic maceration on phenolic compounds of grape must enriched by grape pomace, vine leaves and canes. Eur. Food Res. Technol. 2016, 242, 1149–1158. [Google Scholar] [CrossRef]

- Bautista-Ortín, A.B.; Martínez-Cutillas, A.; Ros-García, J.M.; López-Roca, J.M.; Gómez-Plaza, E. Improving colour extraction and stability in red wines: The use of maceration enzymes and enological tannins. Int. J. Food Sci. Technol. 2005, 40, 867–878. [Google Scholar] [CrossRef]

- Hüfner, E.; Haßelbeck, G. Application of Microbial Enzymes During Winemaking. In Biology of Microorganisms on Grapes, in Must and in Wine; König, H., Unden, G., Fröhlich, J., Eds.; Springer: Cham, Germany, 2017; pp. 635–658. [Google Scholar]

- Geffroy, O.; Siebert, T.; Silvano, A.; Herderich, M. Impact of winemaking techniques on classical enological parameters and rotundone in red wine at the laboratory scale. Am. J. Enol. Vitic. 2017, 68, 141–146. [Google Scholar] [CrossRef]

- Puértolas, E.; López, N.; Condón, S.; Álvarez, I.; Raso, J. Potential applications of PEF to improve red wine quality. Trends Food Sci. Technol. 2010, 21, 247–255. [Google Scholar] [CrossRef]

- Asavasanti, S.; Ersus, S.; Ristenpart, W.; Stroeve, P.; Barrett, D.M. Critical electric field strengths of onion tissues treated by pulsed electric fields. J. Food Sci. 2010, 75, E433–E443. [Google Scholar] [CrossRef] [PubMed]

- Puértolas, E.; Luengo, E.; Álvarez, I.; Raso, J. Improving mass transfer to soften tissues by pulsed electric fields: Fundamentals and applications. Annu. Rev. Food Sci. Technol. 2012, 3, 263–282. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Wang, J. Designs of pulsed electric fields treatment chambers for liquid foods pasteurization process: A review. J. Food Eng. 2009, 95, 227–239. [Google Scholar] [CrossRef]

- Heinz, V.; Alvarez, I.; Angersbach, A.; Knorr, D. Preservation of liquid foods by high intensity pulsed electric fields—basic concepts for process design. Trends Food Sci. Technol. 2001, 12, 103–111. [Google Scholar] [CrossRef]

- Tsong, T.Y. Electroporation of cell membranes. Biophys. J. 1991, 60, 297–306. [Google Scholar] [CrossRef]

- Knorr, D.; Angersbach, A.; Eshtiaghi, M.N.; Heinz, V.; Lee, D.-U. Processing concepts based on high intensity electric field pulses. Trends Food Sci. Technol. 2001, 12, 129–135. [Google Scholar] [CrossRef]

- Vorobiev, E.; Lebovka, N. Pulsed-electric-fields-induced effects in plant tissues: Fundamental aspects and perspectives of applications. In Electrotechnologies for Extraction from Food Plants and Biomaterials; Springer: New York, NY, USA, 2008; pp. 39–81. [Google Scholar]

- Donsì, F.; Ferrari, G.; Pataro, G. Applications of pulsed electric field treatments for the enhancement of mass transfer from vegetable tissue. Food Eng. Rev. 2010, 2, 109–130. [Google Scholar] [CrossRef]

- Morata, A.; Loira, I.; Vejarano, R.; González, C.; Callejo, M.J.; Suárez-Lepe, J.A. Emerging preservation technologies in grapes for winemaking. Trends Food Sci. Technol. 2017, 67, 36–43. [Google Scholar] [CrossRef]

- Knorr, D. Impact of non-thermal processing on plant metabolites. J. Food Eng. 2003, 56, 131–134. [Google Scholar] [CrossRef]

- Praporscic, I.; Lebovka, N.; Vorobiev, E.; Mietton-Peuchot, M. Pulsed electric field enhanced expression and juice quality of white grapes. Sep. Purif. Technol. 2007, 52, 520–526. [Google Scholar] [CrossRef]

- Grimi, N.; Lebovka, N.I.; Vorobiev, E.; Vaxelaire, J. Effect of a pulsed electric field treatment on expression behavior and juice quality of Chardonnay grape. Food Biophys. 2009, 4, 191–198. [Google Scholar] [CrossRef]

- López, N.; Puértolas, E.; Condón, S.; Álvarez, I.; Raso, J. Effects of pulsed electric fields on the extraction of phenolic compounds during the fermentation of must of Tempranillo grapes. Innov. Food Sci. Emerg. Technol. 2008, 9, 477–482. [Google Scholar] [CrossRef]

- López, N.; Puértolas, E.; Condón, S.; Álvarez, I.; Raso, J. Application of pulsed electric fields for improving the maceration process during vinification of red wine: Influence of grape variety. Eur. Food Res. Technol. 2008, 227, 1099–1107. [Google Scholar] [CrossRef]

- Luengo, E.; Franco, E.; Ballesteros, F.; Álvarez, I.; Raso, J. Winery trial on application of pulsed electric fields for improving vinification of Garnacha grapes. Food Bioprocess Technol. 2014, 7, 1457–1464. [Google Scholar] [CrossRef]

- López-Alfaro, I.; González-Arenzana, L.; López, N.; Santamaría, P.; López, R.; Garde-Cerdán, T. Pulsed electric field treatment enhanced stilbene content in Graciano, Tempranillo and Grenache grape varieties. Food Chem. 2013, 141, 3759–3765. [Google Scholar] [CrossRef] [PubMed]

- López, N.; Puértolas, E.; Hernández-Orte, P.; Álvarez, I.; Raso, J. Effect of a pulsed electric field treatment on the anthocyanins composition and other quality parameters of Cabernet Sauvignon freshly fermented model wines obtained after different maceration times. Food Sci. Technol. 2009, 42, 1225–1231. [Google Scholar] [CrossRef]

- Puértolas, E.; Saldaña, G.; Condón, S.; Álvarez, I.; Raso, J. A comparison of the effect of macerating enzymes and pulsed electric fields technology on phenolic content and color of red wine. J. Food Sci. 2009, 74, C647–C652. [Google Scholar] [CrossRef] [PubMed]

- Puértolas, E.; Saldaña, G.; Condón, S.; Álvarez, I.; Raso, J. Evolution of polyphenolic compounds in red wine from Cabernet Sauvignon grapes processed by pulsed electric fields during aging in bottle. Food Chem. 2010, 119, 1063–1070. [Google Scholar] [CrossRef]

- Puértolas, E.; Hernández-Orte, P.; Sladaña, G.; Álvarez, I.; Raso, J. Improvement of winemaking process using pulsed electric fields at pilot-plant scale. Evolution of chromatic parameters and phenolic content of Cabernet Sauvignon red wines. Food Res. Int. 2010, 43, 761–766. [Google Scholar] [CrossRef]

- Delsart, C.; Cholet, C.; Ghidossi, R.; Grimi, N.; Gontier, E.; Gény, L.; Vorobiev, E.; Mietton-Peuchot, M. Effects of pulsed electric fields on Cabernet Sauvignon grape berries and on the characteristics of wines. Food Bioprocess Technol. 2014, 7, 424–436. [Google Scholar] [CrossRef]

- Delsart, C.; Ghidossi, R.; Poupot, C.; Cholet, C.; Grimi, N.; Vorobiev, E.; Milisic, V.; Mietton Peuchot, M. Enhanced extraction of phenolic compounds from Merlot grapes by pulsed electric field treatment. Am. J. Enol. Vitic. 2012, 63, 205–211. [Google Scholar] [CrossRef]

- Puértolas, E.; Saldaña, G.; Álvarez, I.; Raso, J. Experimental design approach for the evaluation of anthocyanin content of rosé wines obtained by pulsed electric fields. Influence of temperature and time of maceration. Food Chem. 2011, 126, 1482–1487. [Google Scholar] [CrossRef]

- El Darra, N.; Grimi, N.; Maroun, R.G.; Louka, N.; Vorobiev, E. Pulsed electric field, ultrasound, and thermal pretreatments for better phenolic extraction during red fermentation. Eur. Food Res. Technol. 2013, 236, 47–56. [Google Scholar] [CrossRef]

- Donsì, F.; Ferrari, G.; Fruilo, M.; Pataro, G. Pulsed electric field-assisted vinification of Aglianico and Piedirosso grapes. J. Agric. Food Chem. 2010, 58, 11606–11615. [Google Scholar] [CrossRef] [PubMed]

- Puértolas, E.; Saldaña, G.; Alvarez, I.; Raso, J. Effect of pulsed electric field processing of red grapes on wine chromatic and phenolic characteristics during aging in oak barrels. J. Agric. Food Chem. 2010, 58, 2351–2357. [Google Scholar] [CrossRef] [PubMed]

- Castro-López, C.; Rojas, R.; Sánchez-Alejo, E.J.; Niño-Medina, G.; Martínez-Ávila, G.C.G. Phenolic compounds recovery from grape fruit and by-products: An overview of extraction methods. In Grape and Wine Biotechnology; Morata, A., Ed.; InTech: London, UK, 2016; pp. 103–123. [Google Scholar]

- Yang, N.; Huang, K.; Lyu, C.; Wang, J. Pulsed electric field technology in the manufacturing processes of wine, beer, and rice wine: A review. Food Control 2016, 61, 28–38. [Google Scholar] [CrossRef]

- Evrendilek, G.A.; Li, S.; Dantzer, W.R.; Zhang, Q.H. Pulsed electric field processing of beer: Microbial, sensory, and quality analyses. J. Food Sci. 2004, 69, M228–M232. [Google Scholar] [CrossRef]

- Sun, J.; Bai, W.; Zhang, Y.; Liao, X.; Hu, X. Effects of electrode materials on the degradation, spectral characteristics, visual colour, and antioxidant capacity of cyanidin-3-glucoside and cyanidin-3-sophoroside during pulsed electric field (PEF) treatment. Food Chem. 2011, 128, 742–747. [Google Scholar] [CrossRef]

| Grape Variety | PEF Parameters | Major Achievements (Compared to Control Wine) | Ref. |

|---|---|---|---|

| Mazuelo | (a) 2 kV/cm; 0.4 kJ/kg | TPI + 19.8%; CI + 21.2%; AC + 20.3% (120 h maceration) | [39] |

| (b) 5 kV/cm; 1.8 kJ/kg | TPI + 24.0%; CI + 35.3%; AC + 28.6% (120 h maceration) | ||

| (c) 10 kV/cm; 6.7 kJ/kg | TPI + 31.0%; CI + 49.8%; AC + 41.8% (120 h maceration) | ||

| Tempranillo | (a) 5 kV/cm; 1.8 kJ/kg | TPI + 13.7%; CI + 11.5%; AC + 21.5% (96 h maceration) | [38] |

| (b) 10 kV/cm; 6.7 kJ/kg | TPI + 29.0%; CI + 18.4%; AC + 28.6% (96 h maceration) | ||

| Garnacha | 4.3 kV/cm | TPI + 23.5%; CI + 12.5%; AC + 25% (7 days maceration) | [40] |

| Cabernet sauvignon | 5 kV/cm; 2.1 kJ/kg | TPI + 45.2%; CI + 48.4%; AC + 42.2% (268 h maceration) | [42] |

| Cabernet sauvignon | 5 kV/cm; 3.67 kJ/kg | TPI + 17%; CI + 28% (12 months aging); AC + 17% (end of maceration) | [43] |

| Cabernet sauvignon | 5 kV/cm; 3.67 kJ/kg | TPI + 23%; CI + 29%; AC + 26% (4 months aging) | [44] |

| Cabernet sauvignon | 5 kV/cm; 3.67 kJ/kg | TPI + 23%; AC + 34% (48 h maceration); CI + 38% (4 months aging) | [45] |

| Cabernet sauvignon | 5 kV/cm; 3.67 kJ/kg | Decrease in maceration T from 20 °C to 4 °C to have comparable results with control | [48] |

| Cabernet sauvignon | (a) 0.7 kV/cm; 31 Wh/kg | Tannins extraction + 19% | [46] |

| (b) 4 kV/cm; 4 Wh/kg | Anthocyanins extraction + 19% | ||

| Merlot | (a) 0.7 kV/cm; 40 ms | TPI + 18% (all) | [47] |

| (b) 0.7 kV/cm; 100 ms | CI—no significant differences | ||

| (c) 0.5 kV/cm; 100 ms | Increasing kinetic of extraction with increasing process parameters | ||

| Cabernet franc | (a) 0.8 kV/cm; 42 kJ/kg | TPI + 51%; CI + 20%; AC + 49% | [49] |

| (b) 5 kV/cm; 53 kJ/kg | TPI + 62%; CI + 23%; AC + 60% | ||

| Aglianico | (a) 1 kV/cm; 50 kJ/kg | TPI + 13%; CI + 6%; AC + 9% (following treatment) | [50] |

| (b) 1.5 kV/cm; 10 kJ/kg | TPI + 31%; CI + 12%; AC + 54% (following treatment) | ||

| (c) 1.5 kV/cm; 25 kJ/kg | TPI + 38%; CI + 19%; AC + 76% (following treatment) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ricci, A.; Parpinello, G.P.; Versari, A. Recent Advances and Applications of Pulsed Electric Fields (PEF) to Improve Polyphenol Extraction and Color Release during Red Winemaking. Beverages 2018, 4, 18. https://doi.org/10.3390/beverages4010018

Ricci A, Parpinello GP, Versari A. Recent Advances and Applications of Pulsed Electric Fields (PEF) to Improve Polyphenol Extraction and Color Release during Red Winemaking. Beverages. 2018; 4(1):18. https://doi.org/10.3390/beverages4010018

Chicago/Turabian StyleRicci, Arianna, Giuseppina P. Parpinello, and Andrea Versari. 2018. "Recent Advances and Applications of Pulsed Electric Fields (PEF) to Improve Polyphenol Extraction and Color Release during Red Winemaking" Beverages 4, no. 1: 18. https://doi.org/10.3390/beverages4010018