The Effect of Soundwaves on Foamability Properties and Sensory of Beers with a Machine Learning Modeling Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Beer Samples Description and Processing

2.2. Color and Foam-Related Parameters

2.3. Sensory Descriptive Analysis

2.4. Statistical Analysis

3. Results

3.1. Color and Foam-Related Parameters

3.2. Descriptive Sensory Evaluation

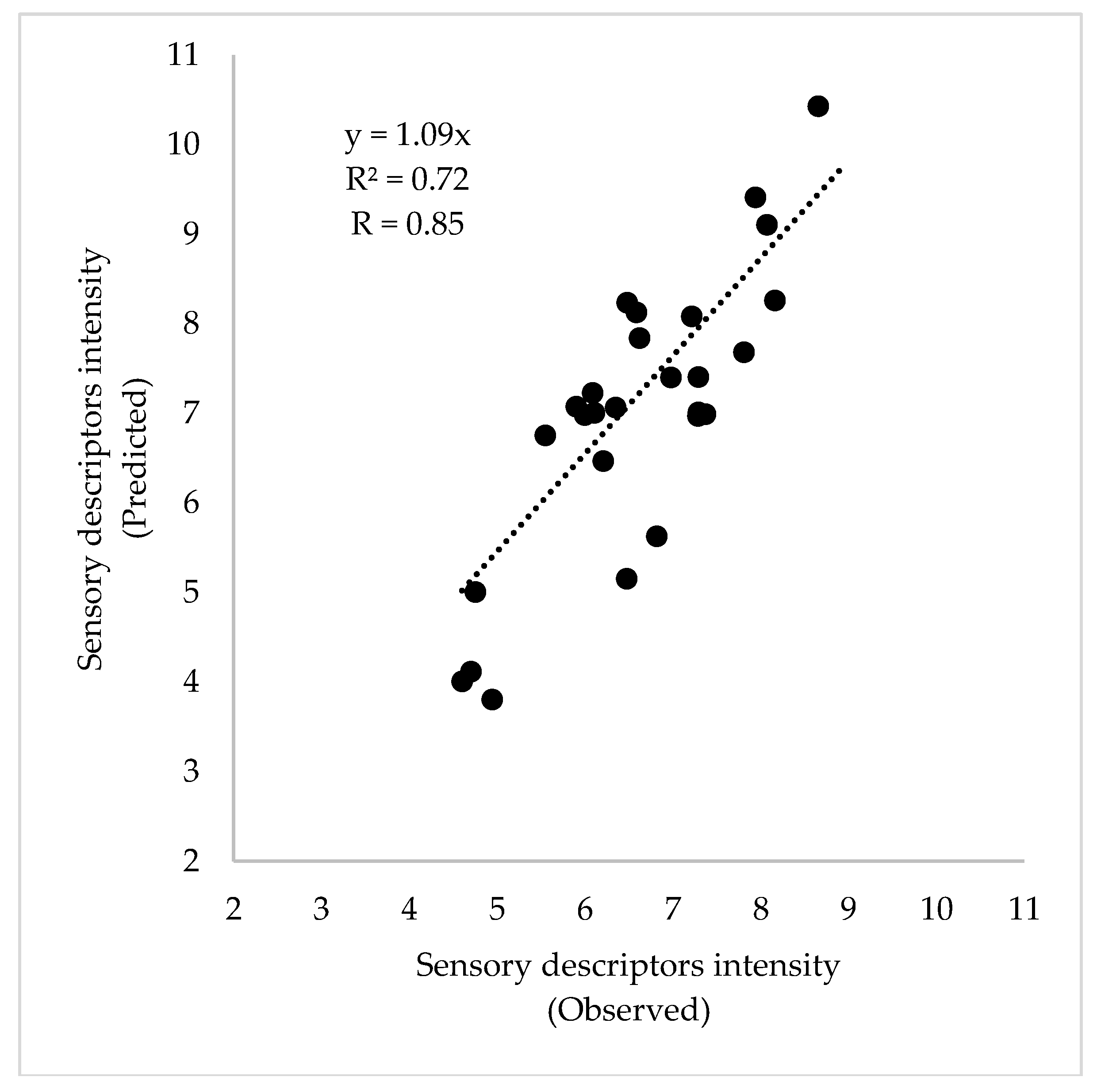

3.3. Validation of Machine Learning Models

4. Discussion

4.1. Color and Foam-Related Parameters

4.2. Descriptive Sensory Evaluation

4.3. Validation and Testing of Machine Learning Models

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cromer, A.H.; Vázquez, J.C. Física Para Las Ciencias de la Vida; Reverté: Barcelona, Spain, 1981. [Google Scholar]

- Serrano Vida, M.; Gil Corral, J. Musica. Volumen III. Profesores de Educacion Secundaria. Temario Para la Preparacion de Oposiciones; Ebook; MAD-Eduforma: Sevilla, Spain, 2003. [Google Scholar]

- Figura, L.O.; Teixeira, A.A. Acoustical properties. In Food Physics: Physical Properties—Measurement and Applications; Springer: Berlin, Germany, 2007. [Google Scholar]

- Glasscock, M.E.; Gulya, A.J.; Shambaugh, G.E. Glasscock-Shambaugh Surgery of the Ear; BC Decker: Hamilton, ON, Canada, 2003. [Google Scholar]

- Vining, W.; Day, R.; Botch, B. General Chemistry: Atoms First; Cengage Learning: Boston, MA, USA, 2017. [Google Scholar]

- Hassani, S.N.; Bard, R.L. Real Time Opthalmic Ultrasonography; Springer: New York, NY, USA, 2012. [Google Scholar]

- Malik, H.K.; Singh, A.K. Engineering Physics; Tata McGraw Hill Education Private Ltd.: New Delhi, India, 2010. [Google Scholar]

- Ferrer, J.F.; Carrera, M.P. Iniciación a la Física; Reverté: Barcelona, Spain, 1981. [Google Scholar]

- Hassanien, R.H.; Hou, T.-Z.; Li, Y.-F.; Li, B.-M. Advances in effects of sound waves on plants. J. Integr. Agric. 2014, 13, 335–348. [Google Scholar] [CrossRef]

- Czekaj, P.; López, F.; Güell, C. Membrane fouling by turbidity constituents of beer and wine: Characterization and prevention by means of infrasonic pulsing. J. Food Eng. 2001, 49, 25–36. [Google Scholar] [CrossRef]

- Ying, J.C.L.; Dayou, J.; Phin, C.K. Experimental investigation on the effects of audible sound to the growth of Escherichia coli. Mod. Appl. Sci. 2009, 3. [Google Scholar] [CrossRef]

- Jasmine, K.R.; Manohar Das, S.S. Studies on the changes induced by audible sound waves in the total body protein profile of corcyra cephalonica (stainton). J. Scott Res. Forum 2008, 2–4, 32–39. [Google Scholar]

- Aggio, R.B.M.; Obolonkin, V.; Villas-Bôas, S.G. Sonic vibration affects the metabolism of yeast cells growing in liquid culture: A metabolomic study. Metabolomics 2012, 8, 670–678. [Google Scholar] [CrossRef]

- Morales-de la Peña, M.; Welti-Chanes, J.; Martín-Belloso, O. Application of novel processing methods for greater retention of functional compounds in fruit-based beverages. Beverages 2016, 2, 14. [Google Scholar] [CrossRef]

- Abdullah, N.; Chin, N.L. Application of thermosonication treatment in processing and production of high quality and safe-to-drink fruit juices. Agric. Agric. Sci. Procedia 2014, 2, 320–327. [Google Scholar] [CrossRef]

- de Sousa, D.P. Application of Ultrasounds for Transformation Processes of Agroalimentary Products; Université d’Avignon: Avignon, France, 2012. [Google Scholar]

- Viejo, C.G.; Fuentes, S.; Howell, K.; Torrico, D.; Dunshea, F.R. Robotics and computer vision techniques combined with non-invasive consumer biometrics to assess quality traits from beer foamability using machine learning: A potential for artificial intelligence applications. Food Control 2018, 92, 72–79. [Google Scholar] [CrossRef]

- Viejo, C.G.; Fuentes, S.; Howell, K.; Torrico, D.D.; Dunshea, F.R. Integration of non-invasive biometrics with sensory analysis techniques to assess acceptability of beer by consumers. Physiol. Behav. 2018. [Google Scholar] [CrossRef]

- Bamforth, C. Perceptions of beer foam. J. Inst. Brew. 2000, 106, 229–238. [Google Scholar] [CrossRef]

- Donadini, G.; Fumi, M.D.; Faveri, M. How foam appearance influences the Italian consumer’s beer perception and preference. J. Inst. Brew. 2011, 117, 523–533. [Google Scholar] [CrossRef]

- Smythe, J.E.; Bamforth, C.W. The path analysis method of eliminating preferred stimuli (PAMEPS) as a means to determine foam preferences for lagers in European judges based upon image assessment. Food Qual. Preference 2003, 14, 567–572. [Google Scholar] [CrossRef]

- Becker, T.; Mitzscherling, M.; Delgado, A. Ultrasonic velocity—A noninvasive method for the determination of density during beer fermentation. Eng. Life Sci. 2001, 1, 61–67. [Google Scholar] [CrossRef]

- Hoggan, J. Ultrasonic hop extraction. Ultrasonics 1968, 6, 217–219. [Google Scholar] [CrossRef]

- Choi, E.J.; Ahn, H.; Kim, M.; Han, H.; Kim, W.J. Effect of ultrasonication on fermentation kinetics of beer using six-row barley cultivated in Korea. J. Inst. Brew. 2015, 121, 510–517. [Google Scholar] [CrossRef] [Green Version]

- Flint, E.B.; Suslick, K.S. The Temperature of cavitation. Science 1991, 253, 1397–1399. [Google Scholar] [CrossRef] [PubMed]

- Galuszka, J. Universities Receive $1 Million to Study Impact of Sound on Fermenting Beer. Available online: https://www.stuff.co.nz/national/education/97068212/universities-receive-1-million-to-study-impact-of-sound-on-fermenting-beer (accessed on 26 June 2018).

- Fowle, Z. Good Vibrations: Brewers Use Music to Ferment Their Beers. Available online: http://draftmag.com/brewers-ferment-beer-with-music/ (accessed on 26 June 2018).

- Boxall, A. Does Music Affect the Taste of Beer? Try B&O Play’s Beobrew to Find Out. Available online: https://www.digitaltrends.com/home-theater/beoplay-beobrew-music-infused-beer-news/ (accessed on 4 July 2018).

- Gonzalez Viejo, C.; Fuentes, S.; Li, G.; Collmann, R.; Condé, B.; Torrico, D. Development of a robotic pourer constructed with ubiquitous materials, open hardware and sensors to assess beer foam quality using computer vision and pattern recognition algorithms: RoboBEER. Food Res. Int. 2016, 89, 504–513. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez Viejo, C.; Fuentes, S.; Torrico, D.D.; Howell, K.; Dunshea, F.R. Assessment of beer quality based on a robotic pourer, computer vision, and machine learning algorithms using commercial beers. J. Food Sci. 2018, 83, 1381–1388. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.-Y.; Rubinstein, M.; Shih, E.; Guttag, J.; Durand, F.; Freeman, W. Eulerian video magnification for revealing subtle changes in the world. Video Magnif. 2012. [Google Scholar] [CrossRef]

- Torrico, D.D.; Fuentes, S.; Gonzalez Viejo, C.; Ashman, H.; Gunaratne, N.M.; Gunaratne, T.M.; Dunshea, F.R. Images and chocolate stimuli affect physiological and affective responses of consumers: A cross-cultural study. Food Qual. Preference 2018, 65, 60–71. [Google Scholar] [CrossRef]

- Torrico, D.D.; Fuentes, S.; Viejo, C.G.; Ashman, H.; Gurr, P.A.; Dunshea, F.R. Analysis of thermochromic label elements and colour transitions using sensory acceptability and eye tracking techniques. LWT Food Sci. Technol. 2018, 89, 475–481. [Google Scholar] [CrossRef]

- Bamforth, C.; Russell, I.; Stewart, G. Beer: A Quality Perspective; Elsevier Science: Cambridge, MA, USA, 2011. [Google Scholar]

- Badui Dergal, S.; Cejudo Gómez, H.R.T. Química de los Alimentos; Pearson Educación: Naucalpan de Juárez, Estado de Mexico, Mexico, 2006. [Google Scholar]

- Delcour, J.A.; Hoseney, R.C. Principles of Cereal Science and Technology; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Gallego-Juárez, J.; Rodríguez, G.; Riera, E.; Cardoni, A. Ultrasonic defoaming and debubbling in food processing and other applications. In Power Ultrasonics; Elsevier: New York, NY, USA, 2015; pp. 793–814. [Google Scholar] [CrossRef]

- Piggott, J. Alcoholic Beverages: Sensory Evaluation and Consumer Research; Elsevier: Philadelphia, PA, USA, 2011. [Google Scholar]

- Martín, J.F.G.; Guillemet, L.; Feng, C.; Sun, D.-W. Cell viability and proteins release during ultrasound-assisted yeast lysis of light lees in model wine. Food Chem. 2013, 141, 934–939. [Google Scholar] [CrossRef] [PubMed]

| Descriptor | Abbreviation | Anchors |

|---|---|---|

| Foam Stability | FStab | Short time–Long time |

| Foam Height | FHeight | Short–High |

| Foam Texture (Bubble size) | FText | Small–Large |

| Color Intensity | CInt | Light–Dark |

| Clarity | Clarity | Haze–Clear |

| Aroma–Hops | AHops | Absent–Intense |

| Aroma–Spices | ASpices | Absent–Intense |

| Aroma–Floral | AFloral | Absent–Intense |

| Aroma–Fruity | AFruity | Absent–Intense |

| Aroma–Brown Sugar | ABSugar | Absent–Intense |

| Aroma–Yeast | AYeast | Absent–Intense |

| Aroma–Nuts | ANut | Absent–Intense |

| Aroma–Grains | AGrain | Absent–Intense |

| Viscosity | MVisc | Thin–Thick |

| Astringency | MAstr | Absent–Intense |

| Carbonation Mouthfeel | MCarb | Absent–Intense |

| Warming Mouthfeel | MWarm | Absent–Intense |

| Taste–Bitter | TBitt | Absent–Intense |

| Taste–Sweet | TSweet | Absent–Intense |

| Taste–Sour | TSour | Absent–Intense |

| Flavor–Hops | FHops | Absent–Intense |

| Treatment | MaxVol (mL) | TLTF(s) | LTF (mL s−1) | FDrain (mL s−1) | SmBubb (number) | MedBubb (number) | LgBubb (number) |

|---|---|---|---|---|---|---|---|

| Control | 25.7 a ± 14.0 | 1647.6 a ± 1288.5 | 594.9 a ± 537.7 | 42.4 a ± 16.4 | 597.2 b ± 390.0 | 8.3 a ± 9.9 | 4.0 a ± 4.3 |

| SWC | 43.9 a ± 12.9 | 3243.7 a ± 1468.0 | 1552.3 a ± 1222.3 | 36.2 a ± 9.2 | 2519.5 a ± 1651.5 | 28.2 a ± 49.9 | 5.7 a ± 4.9 |

| SWF | 39.2 a ± 9.4 | 3005.5 a ± 1139.4 | 1100.7 a ± 482.8 | 34.4 a ± 3.1 | 1400.0 ab ± 1030.2 | 7.8 a ± 11.3 | 4.5 a ± 3.3 |

| Treatment | * L | * a | * b | * RI | * GI | * BI | * OH | CO2 (ppm) | Alcohol (%) | * pH | Visc (cP) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 74.7 a ± 1.6 | −3.9 a ± 1.4 | 68.6 a ± 1.2 | 0.6 a ± 0.0 | 0.4 a ± 0.0 | 0.02 b ± 0.0 | 287.0 a ± 16.6 | 12,055.6 a ± 10514.7 | 5.3 b ± 0.2 | 4.25 a ± 0.03 | 11.2 b ± 1.0 |

| SWC | 73.8 a ± 2.9 | −2.0 a ± 1.9 | 63.2 b ± 2.5 | 0.6 a ± 0.0 | 0.4 a ± 0.0 | 0.04 a ± 0.01 | 286.8 a ± 43.6 | 16,020.5 a ± 13469.6 | 5.2 b ± 0.3 | 4.26 a ± 0.03 | 11.5 b ± 0.7 |

| SWF | 73.6 a ± 3.8 | −2.5 a ± 2.8 | 65.5 b ± 2.8 | 0.6 a ± 0.0 | 0.4 a ± 0.0 | 0.03 ab ± 0.01 | 288.3 a ± 37.1 | 16,853.2 a ± 11429.4 | 5.6 a ± 0.1 | 4.28 a ± 0.02 | 12.7 a ± 0.6 |

| Treatment | Top | Bottom | Spontaneous |

|---|---|---|---|

| Control | 0.996 | 0.000 | 0.004 |

| SWF | 0.997 | 0.000 | 0.003 |

| SWC | 0.994 | 0.000 | 0.006 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonzalez Viejo, C.; Fuentes, S.; Torrico, D.D.; Lee, M.H.; Hu, Y.Q.; Chakraborty, S.; Dunshea, F.R. The Effect of Soundwaves on Foamability Properties and Sensory of Beers with a Machine Learning Modeling Approach. Beverages 2018, 4, 53. https://doi.org/10.3390/beverages4030053

Gonzalez Viejo C, Fuentes S, Torrico DD, Lee MH, Hu YQ, Chakraborty S, Dunshea FR. The Effect of Soundwaves on Foamability Properties and Sensory of Beers with a Machine Learning Modeling Approach. Beverages. 2018; 4(3):53. https://doi.org/10.3390/beverages4030053

Chicago/Turabian StyleGonzalez Viejo, Claudia, Sigfredo Fuentes, Damir D. Torrico, Mei Huii Lee, Yue Qin Hu, Sanjit Chakraborty, and Frank R. Dunshea. 2018. "The Effect of Soundwaves on Foamability Properties and Sensory of Beers with a Machine Learning Modeling Approach" Beverages 4, no. 3: 53. https://doi.org/10.3390/beverages4030053