1. Introduction

The spiral-wound membrane (SWM) module is the dominant element of the reverse osmosis (RO) and nanofiltration (NF) water-treatment plants, which are comprised of pressure vessels, each containing several SWM modules in series. Therefore, significant research and development (R&D) efforts have been invested aiming to optimize SWM-module design (for various applications) and improve its overall performance (e.g., [

1,

2]). The operation at steady state of a desalination SWM module, and of the entire RO plant, is characterized by an inherent spatial variability of all process parameters [

3,

4] due to the passage/filtration of purified water from the feed-side channels to the permeate side. However, in RO and NF plants there is also temporal variability due to fouling [

5,

6], usually caused by rejected organic and/or inorganic impurities depositing on the membrane surfaces, which leads to deterioration in plant performance; this undesirable variability (manifested in feed-pressure increase, for constant recovery, and in reduced salt rejection) is extremely difficult to predict, although it is necessary for developing optimal plant design and operation strategies. A direct attack of the full 3D dynamic problem, enabling simulation and prediction of the SWM and pressure-vessel performance from first principles, is impossible at present due to its complexity and considering the lack of understanding of some key physico-chemical interactions affecting fouling (e.g., [

7,

8,

9]). Nevertheless, some efforts in that direction have been reported (e.g., [

5,

10]), in which significant simplifying assumptions have been made.

To address this complicated problem in a systematic manner, researchers have numerically analyzed, first, the flow field and mass transfer in restricted spatial domains of the spacer-filled membrane channels, as summarized in [

11]. Significant work along these lines has been reported (focusing on small or intermediate spatial scales) aiming to understand the effect of spacer characteristics on flow and mass transfer (e.g., [

12,

13,

14]) in order to optimize the feed-spacer geometry (e.g., [

15,

16,

17]) and to study fouling, including bio-fouling (e.g., [

18,

19]) phenomena. These detailed studies of the flow field in the spacer-filled channels, focusing on a “unit cell” formed by the net-type spacers (also considering periodicity), have proven to be quite fruitful; in addition to improved basic understanding, they have yielded correlations of pressure drop and mass transfer applicable at “unit cell” scale [

20,

21]. Comprehensive modeling of flow and mass transfer throughout a membrane sheet (or a SWM module) can rely on such correlations in order to develop a reliable simulator of SWM performance at steady state [

3,

4,

22,

23] and to further a dynamic model and respective simulator accounting for a developing fouling layer [

6,

24]; the dynamic simulator, as a general-purpose tool, would enable reliable projections of the performance of a pressure vessel and of an entire desalination plant.

In practically all the aforementioned studies, a fairly idealized feed-side channel geometry is considered, with the membrane-channel gap characterized by the nominal thickness of the net-type spacer which is assumed to be in line- or point-contact with the bounding flat membranes. However, there are two main effects in practice that cause the real membrane channel gap to be smaller than the “reference gap”, with significant negative impact on the process; i.e., the pressure applied on the spacer-filled membrane envelopes during winding in SWM-module fabrication [

1] and the foulants depositing on the membranes [

8,

25]. The former leads to the deformation of the membrane and/or the spacer, thereby effectively reducing the channel gap [

1]; the latter effect manifests itself as deposit/fouling layers gradually developing on the active membrane surfaces. In general, the fouling layers considered here (in addition to the added resistance to permeation) tend to modify the detailed geometrical characteristics of the spacer-filled flow-channels, impacting on the transport phenomena therein. Therefore, this effect of channel-gap reduction merits particular attention for the improved understanding and comprehensive process modeling outlined above.

The scope of this work is to study in detail the effect of thickness h of a fouling layer (assumed to develop uniformly on the membranes) on hydrodynamics and mass transfer in the spacer-filled channels, under conditions representative of those prevailing in RO desalination plants. For this purpose, 3D-flow simulations were performed in “unit cells”, with geometry representative of typical commercial spacers, by employing advanced numerical techniques described in previous publications [

20,

21]. In the analysis and the reported results and correlations (for pressure drop and mass transfer), an additional parameter (

h/

D) is introduced, involving the fouling-layer thickness

h made dimensionless with the diameter

D of spacer filaments, the latter considered to be cylindrical.

2. Mathematical Formulation and Numerical Simulations

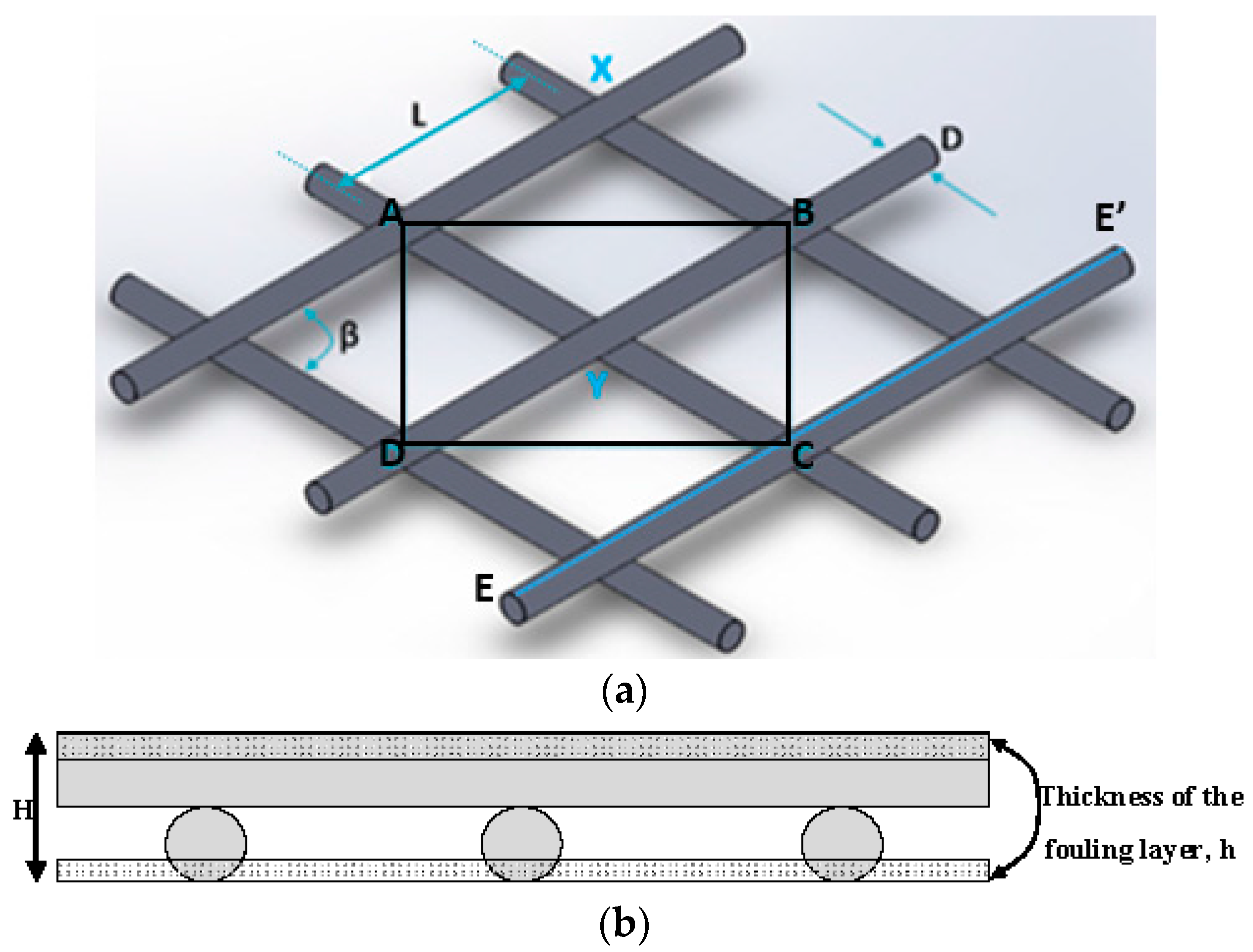

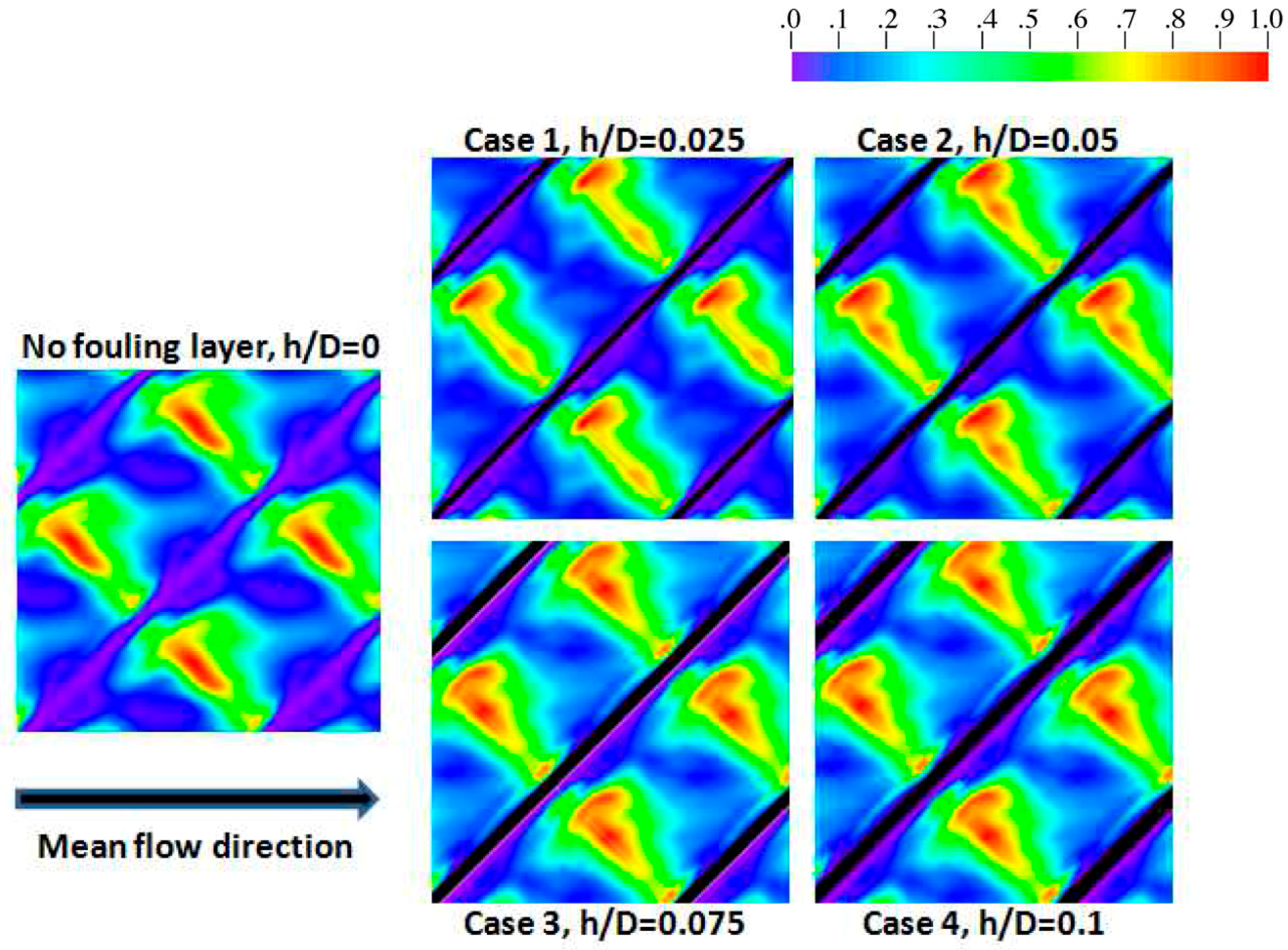

The base case of the problem at hand is the flow field within flat narrow channels (bounded by membranes) whose gap/height is determined by the nominal feed-spacer thickness. This geometry is commonly considered a satisfactory approximation of spacer-filled channels in spiral-wound elements, when no fouling or other channel deformation exists [

20]. In the basic (or initial) geometry, shown in

Figure 1a, a flat narrow channel is formed by the membrane-bounding surfaces, in contact with two layers of straight cylindrical filaments (comprising the spacer). The filaments of each layer are parallel and equidistant, while the two superposed layers have different orientation and “intersect” at a certain angle β. All cylindrical filaments have the same diameter (

D), so that the channel gap or height (

H) is twice the filament diameter (i.e.,

H = 2

D). Another parameter of interest is the ratio (

L/

D) of distance L between the axes of symmetry of parallel filaments over the filament diameter

D. It will be noted that recent studies (e.g., [

26]) take into consideration the irregularities of the filament cylindrical shape, developing during filament extrusion and spacer fabrication. These irregularities, and their impact on the flow field, have to be taken into account in future studies, particularly in the context of fouling-layer development. The particular problem studied here involves fouling layers developing on both bounding membrane surfaces, but not on the spacer surfaces (

Figure 1b). The thickness h of these fouling layers is considered to develop uniformly on both membrane surfaces, resulting in a flow channel with reduced gap, and reduced spacer-filament surfaces exposed to the flow, compared to the initial configuration, as indicated in

Figure 1b.

As in previous similar studies [

20,

21] it is considered that the flow exhibits periodicity in each unit cell AXBY formed by four neighboring filaments (shown in

Figure 1a); therefore, the detailed flow-field study is restricted to a computational domain indicated as ABCD in

Figure 1a. The rationale and usefulness of adopting periodic boundary conditions to describe the flow field in the present case, as well as other types of transport phenomena in geometries with a periodic character, is discussed elsewhere [

20,

21].

Flow development and mass transport are governed by the Navier–Stokes, continuity and mass-transfer equations, considering that the fluid is Newtonian and incompressible:

The channel walls are assumed to be impermeable, which may be justified considering that the RO permeation velocities are much smaller than the feed-flow velocities. Consequently, no-slip and no penetration boundary conditions are considered on the channel walls and on the cylindrical filament surfaces. Additionally, for the mass-transfer simulations, uniform membrane wall/surface concentration, Cw, is assumed.

It is emphasized that the results of this study are obtained through a direct numerical simulation (DNS) involving Equation 1a–c, without the introduction of any approximation regarding flow development or turbulence modeling. A commercial CFD code (FLUENT, v.6.2.16, ANSYS, Canonsburg, PA, USA) is used, which employs the finite-volume method. In each simulation the governing equations are integrated in time by imposing a constant mean-pressure gradient until the flow and the concentration reach a statistically steady state. More details regarding the fluid flow and mass transfer simulations are provided elsewhere [

20,

21].

The physical parameters of the fluid flow and mass transport in the retentate spacer-filled channels are the dimensionless Reynolds, Schmidt and Sherwood numbers defined here as follows:

where

D′: D−h;

D: Spacer filament diameter (m);

h: Fouling layer thickness (m);

U: Superficial axial velocity in the retentate channel of gap (H−2h) (m/s);

ν: Water kinematic viscosity (m2/s);

Dc: Species/salt diffusivity (m2/s);

k: Mass-transfer coefficient (m/s).

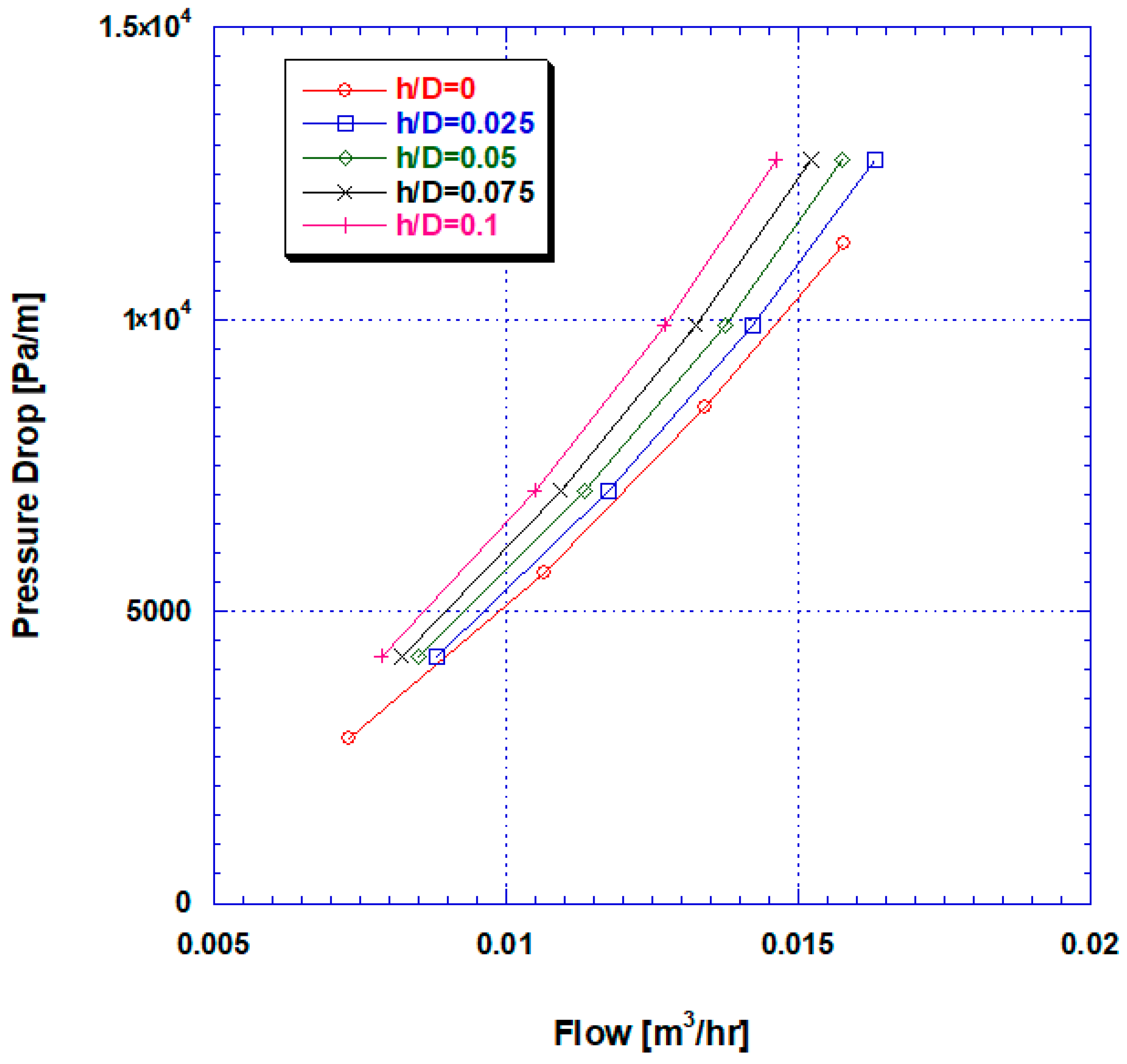

It should be noted that in the geometry studied (i.e., channel of width w and gap 2D′), the superficial velocity and Re number are given as U = Q/[w·2D′] and Re = [D′·U]/ν = [Q/2wν]. The latter expression shows that, for constant flow rate Q, the Reynolds number remains constant for different gaps, because the reduction of channel gap (2D′) is compensated by an increase of velocity U. Consequently, one can conveniently present and compare results on pressure drop and other quantities (for various gaps 2D′) as a function of either Re number or flow rate Q.

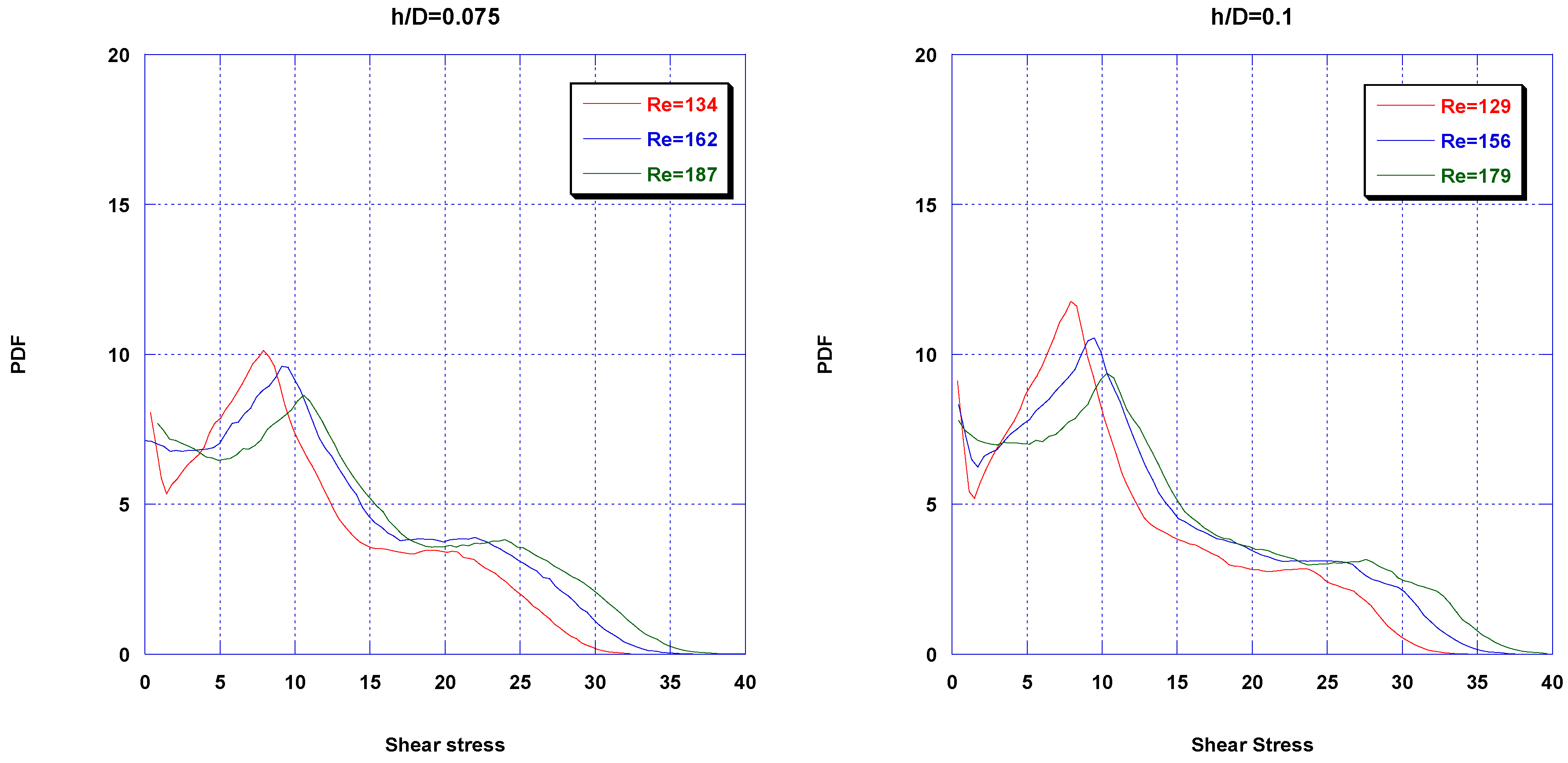

Under typical conditions prevailing in spiral-wound membrane elements, the velocity in the retentate channels created by two adjacent membrane leaves (separated by the spacer) does not exceed ~0.35 m/s whereas the allowable pressure drop, recommended by manufacturers, should not exceed 0.6 bar/m [

27]. Therefore, the Reynolds number, defined on the basis of the superficial velocity and the spacer filament diameter

D′, is commonly less than 200. Typical Schmidt numbers for brackish and sea water are of the order 103. In the series of mass transfer simulations reported herein, the Schmidt number values varied from 1 to 100; calculations at higher

Sc were not performed due to limitations associated with available computer power.

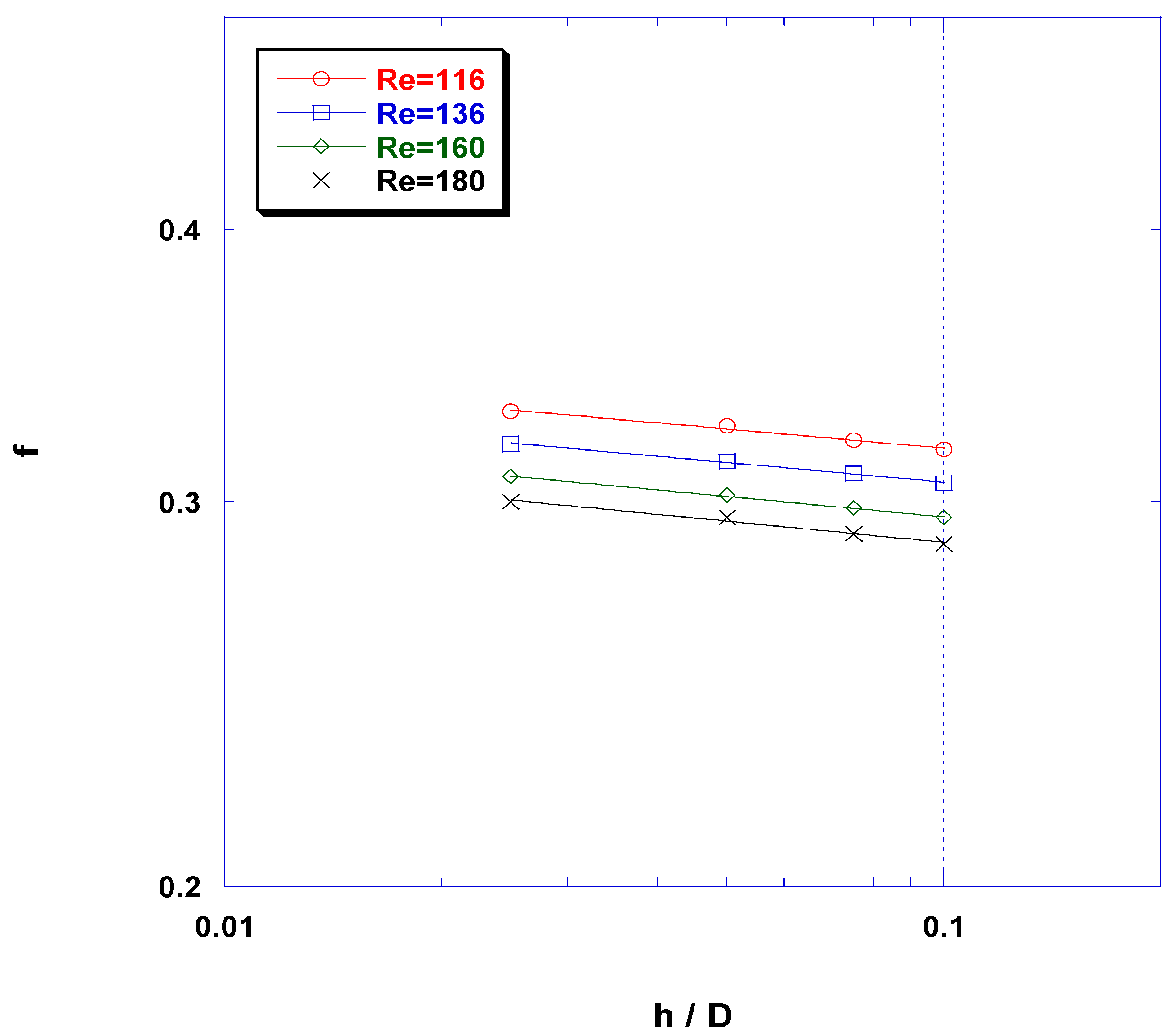

Table 1 summarizes the conditions of performed simulations.

To select a realistic range of fouling-layer thickness

h for these computations, the results of fairly extensive RO membrane fouling studies, performed in this laboratory (e.g., [

8,

28,

29,

30]) have been used for guidance. In particular, the results of fouling studies with alginates [

30,

31,

32], which are representative of a major class of common RO foulants [

8,

30,

33], suggest that the developing fouling layers are quite coherent gels that tend to deposit fairly evenly on the RO membranes [

32]. Moreover, these layers exhibit viscoelastic properties and a significant yield stress that (at least in the cases studied [

32]) appears to be greater than typical mean shear stresses prevailing in the spacer-filled channels [

20]; this implies that, once formed, such layers would not be detached by the flow. Measured alginate fouling-layer thickness

h on a RO membrane, of magnitude order ~10% of the channel gap ([

32],

Table 1) was associated with a substantial trans-membrane pressure (TMP) increase (e.g., >20%), which is considered excessive in practice, requiring membrane cleaning [

27]. Therefore, the range of h values selected for this work was 0–10% of filament diameter; specifically, numerical simulations were performed for four values of fouling-layer thickness (

h/

D = 0.025, 0.05, 0.075, 0.1) for the typical spacer geometry with characteristics:

L/

D = 8 and β = 90° (

Table 1,

Figure 1). The main flow was directed along the diagonal of the spacer unit cell; i.e., along the line AB (

Figure 1).

4. Discussion

Prediction from first principles of the spatial-temporal flow-field evolution, under simultaneous development of fouling layers, throughout the desalination membrane sheets (in spacer-filled narrow channels), is a formidable task, considered impossible at present. Aiming to develop a sound approximate method to tackle this problem, by un-coupling fouling-layer evolution from the fluid mechanical problem, this study considers the effect of uniformly developing fouling layers on fluid dynamics and mass transfer in spacer-filled channel walls. The assumption is made of fouling-layer uniformity at the “unit cell” spatial scale, realizing that it may be realistic only for some types of foulants but not for all of them. Indeed, as outlined in the Introduction, common foulants such as polysaccharides (including extracellular polymeric substances (EPS) in biofilms) seem to develop fairly coherent gels on membranes [

8,

32], impossible to detach by fluid-shear forces prevailing during desalination [

32], thus prone to be fairly uniform. However, for other foulant types such as humic acids alone, the fouling-layer thickness in spacer-filled channels appears to be non-uniform [

21]. Similarly, it is reported that there is non-uniform layer thickness in biofouling experiments [

34]. However, the simplifying assumption of thickness uniformity made here for rather thin layers is considered realistic in efforts to model and quantify channel-gap reduction effects on flow and convective mass transfer at a large spatial scale; this assumption is also made in other, similar studies [

5]. Obviously, the topic of fouling-layer development at small as well as large spatial scales merits further attention.

The results obtained here, including the correlations for pressure drop and mass-transfer coefficient, are readily applicable to the case of gap reduction of spacer-filled narrow channels (by causes other than fouling) in order to obtain reliable estimates of the respective quantities. Such gap reduction, attributed to feed-channel deformation in the SWM-module fabrication, is reported by membrane manufacturers [

1], but no means to accurately determine key parameters such as pressure drop are available for such cases to the authors’ best knowledge.

The spacer geometric parameters employed in this study (L/D = 8, β = 90°), closely correspond to the commercial “28 mil” spacer, where L/D ≈ 8.5. However, the similarity of the flow field and the dimensionless quantities employed, in the simulations and in the developed correlations, permit the use of the new results and correlations to the others frequently encountered in practice-spacer types, i.e., “26 mil” and “34 mil”, where L/D ≈ 8.9 and ~8.0, respectively.

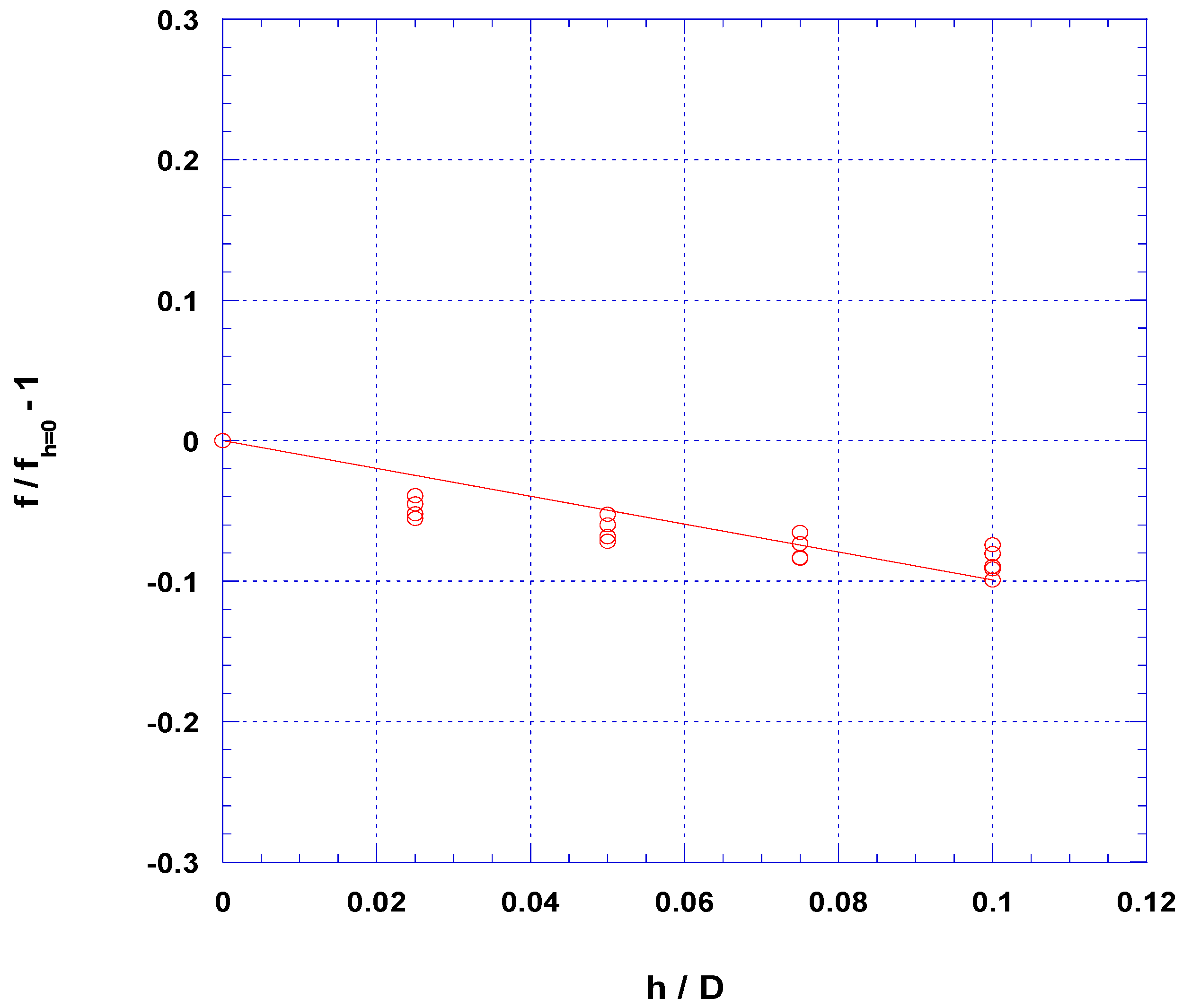

The correlations obtained in this work can find practical use in parametric studies and in various benchmarking exercises. However, the usefulness of the new results and correlations on developing and/or improving comprehensive dynamic simulators of RO desalination plant performance, which is pursued by the present authors [

4,

6,

24], is of particular interest and will be briefly assessed. The effect of even a modest reduction of channel gap on the pressure drop Δ

P/Δ

x appears to be quite important, as discussed in the foregoing section; therefore, the Δ

P/Δ

x correlation, including the channel-gap correction, can be properly adapted to SWM performance models and simulators (e.g., [

22,

24]). Regarding the mass-transfer correlation, Equations (6) or (7) show that the channel-gap reduction is also significantly affecting the mass-transfer coefficient

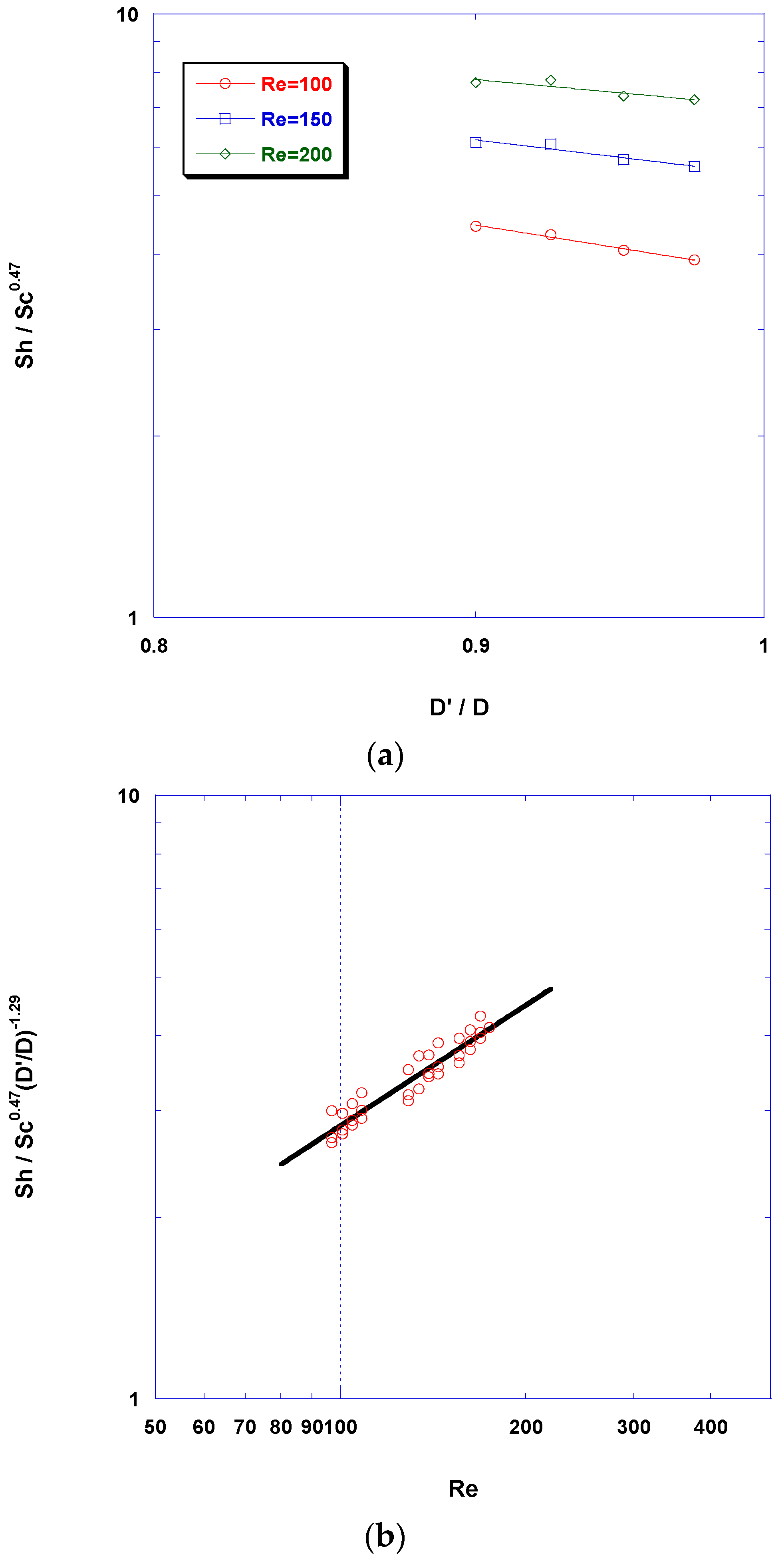

k, even though there is some scatter (

Figure 11b) in numerical-data correlation due to the fact that the exponent on

D′/

D is weakly dependent on

Re number whereas a constant average value is chosen (−1.29). However, it is shown below that even a rough estimate of dissolved species mass-transfer coefficient due to fluid convection at the membrane surface (

k) is sufficient in modeling species mass transfer in the presence of a fouling layer, because

k during the desalination process tends to contribute insignificantly to the overall mass transfer

Kt, compared to cake-induced mass-transfer reduction. To demonstrate the significance of the latter effect, one should consider the total mass-transfer coefficient, which is given as:

where

De is the species effective diffusion coefficient in the fouling layer. Multiplying both sides of Equation (9) by

D/

Dc and substituting the correlation (Equation (7)) for k in the form

kD/

Dc =

Sho(1 +

az) where

z =

h/

D and

a = 1.65 one obtains:

Here E = De/Dc is the ratio of the effective diffusivity in the fouling layer over the species diffusivity in the liquid phase. A comparison of the terms at the right-hand side of Equation (10) clearly shows that (as the fouling layer grows) the increase of mass transfer due to convection (k) contributes very little to the total mass-transfer variation. In particular, using the ratio αE/Sho, one can show, for typical values of the parameters involved, that only 1–2% of the total mass-transfer variation is due to an increase of coefficient k, because of channel-gap reduction; therefore, the accuracy in the computation of k does not affect the estimates for total mass-transfer coefficient Kt, needed in comprehensive desalination-process modeling.

It is evident from this study that the reliable prediction of increasing fouling-layer thickness

h and of transport phenomena related to fouling-layer properties (as a function of desalination-system parameters and foulants) is critical in the development of a sound dynamic process simulator [

24]. Therefore, future work should be focused on measuring, understanding and modeling fouling-layer development. Significant efforts to understand, monitor and predict developing fouling-layer properties, including

h, have already been reported (e.g., [

8,

9,

35,

36,

37,

38]) under idealized conditions. Furthermore, in the context of hydrodynamics and fouling evolution in spacer-filled channels, investigating the effect of the detailed geometry and filament shape of the spacer is of high priority. The present results with the common spacer type, comprised of unwoven filaments of cylindrical shape, for which there is extensive literature and experimental data, provide a kind of base case.

5. Conclusions

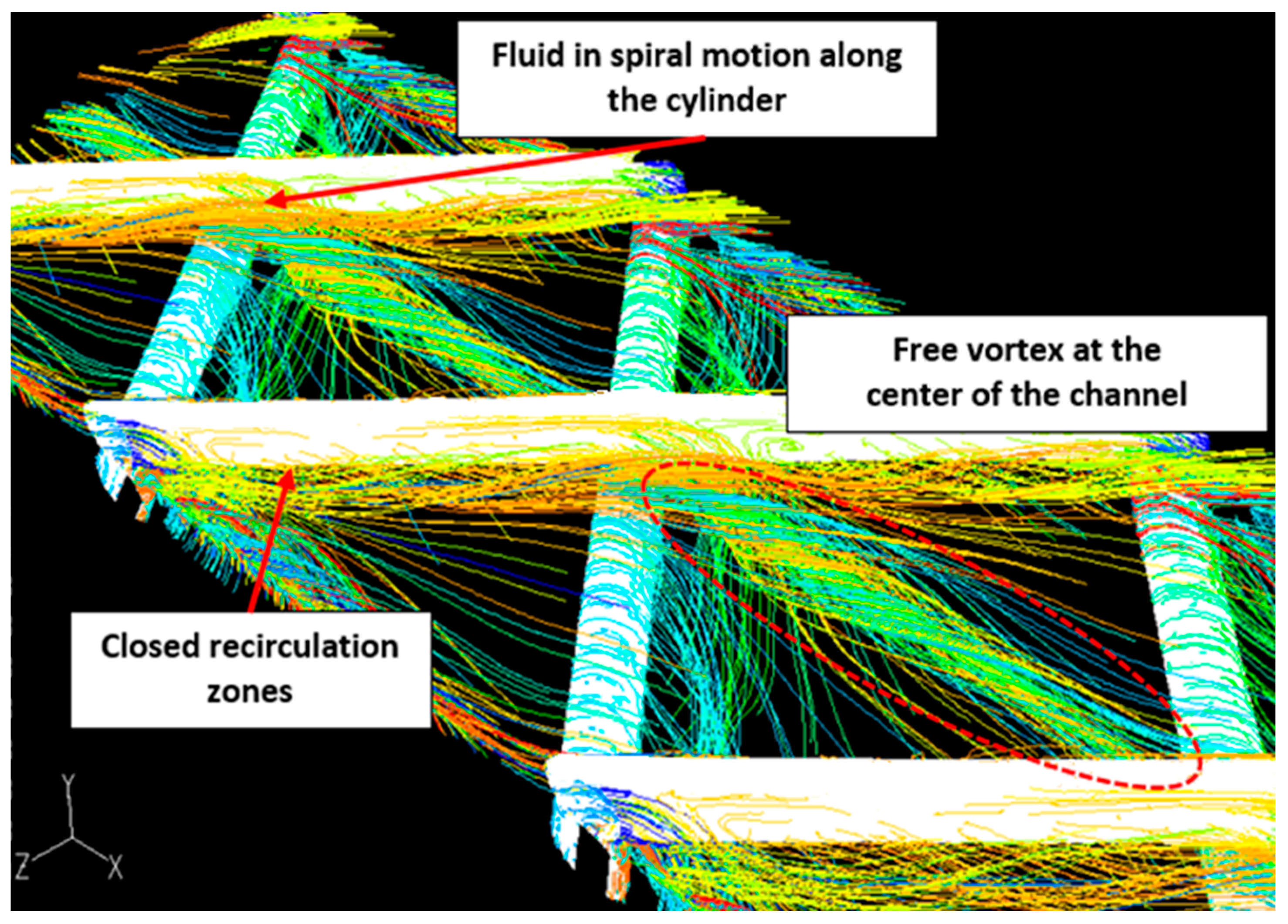

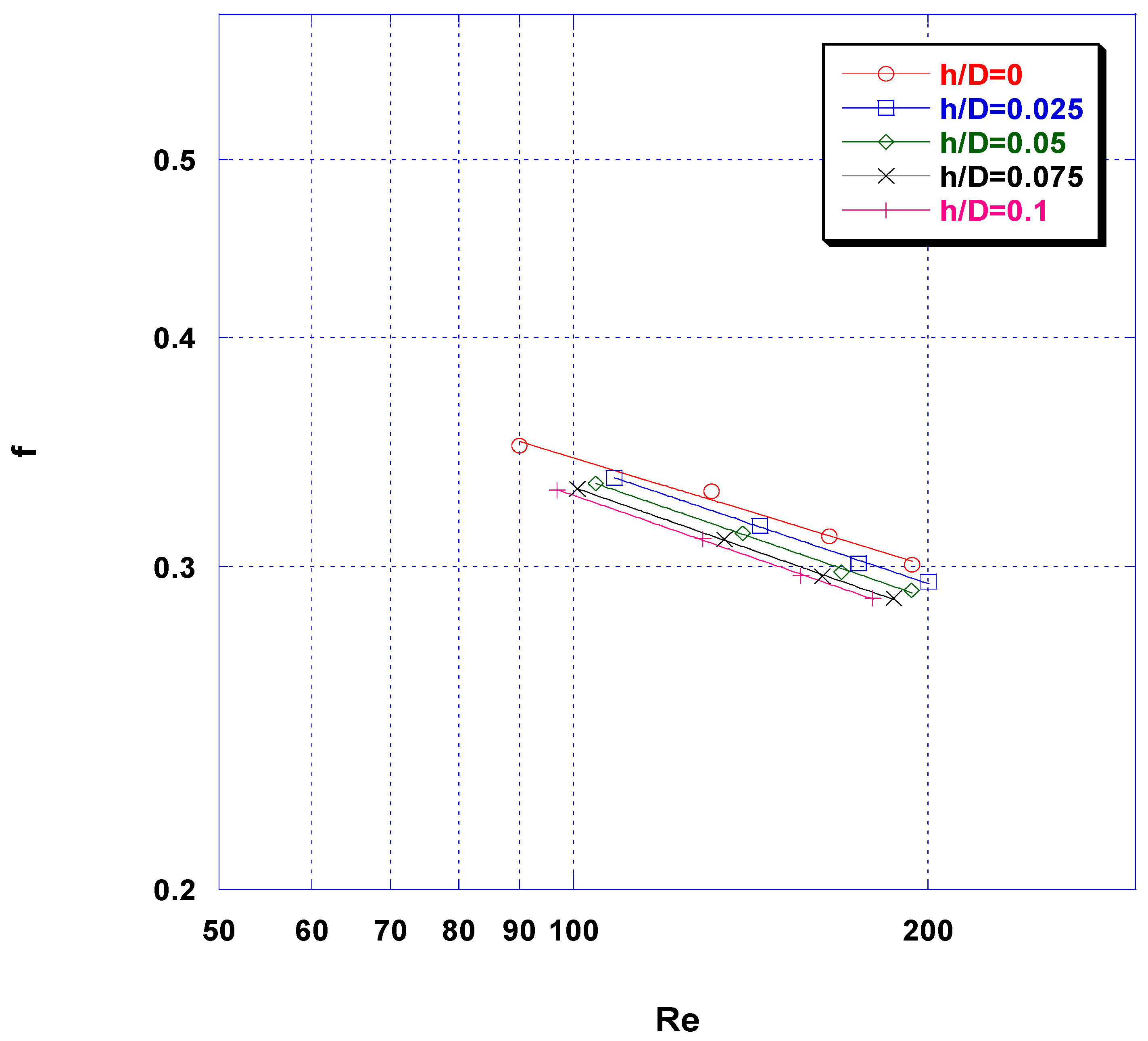

This study is mainly motivated by the need to simulate the time-varying flow field in spacer-filled desalination membrane channels, caused by the development of fouling layers on the membranes that modify the flow-field geometry and affect the transport phenomena at the membrane surface. As the complete dynamic problem of flow and mass transfer, under the simultaneous growth of fouling layers, cannot be tackled at present due its complexity, a simplified approach is pursued whereby at a small spatial scale the fluid dynamics and mass transfer are uncoupled from the fouling-layer growth process. Therefore, fluid dynamics and mass transfer are studied herein in detail for a spacer-filled narrow channel whose geometry is altered by a developed uniform fouling layer of thickness h on the membranes. For this purpose, 3D direct numerical simulations are performed (in a restricted spatial domain) employing the “unit cell” approach where periodic boundary conditions are applied. The specific thickness values considered are in the range 2.5–10% of the cylindrical spacer filament diameter D, which covers conditions of practical significance. The geometric parameters of the spacer employed in the simulations correspond to those of commonly encountered commercial spacers.

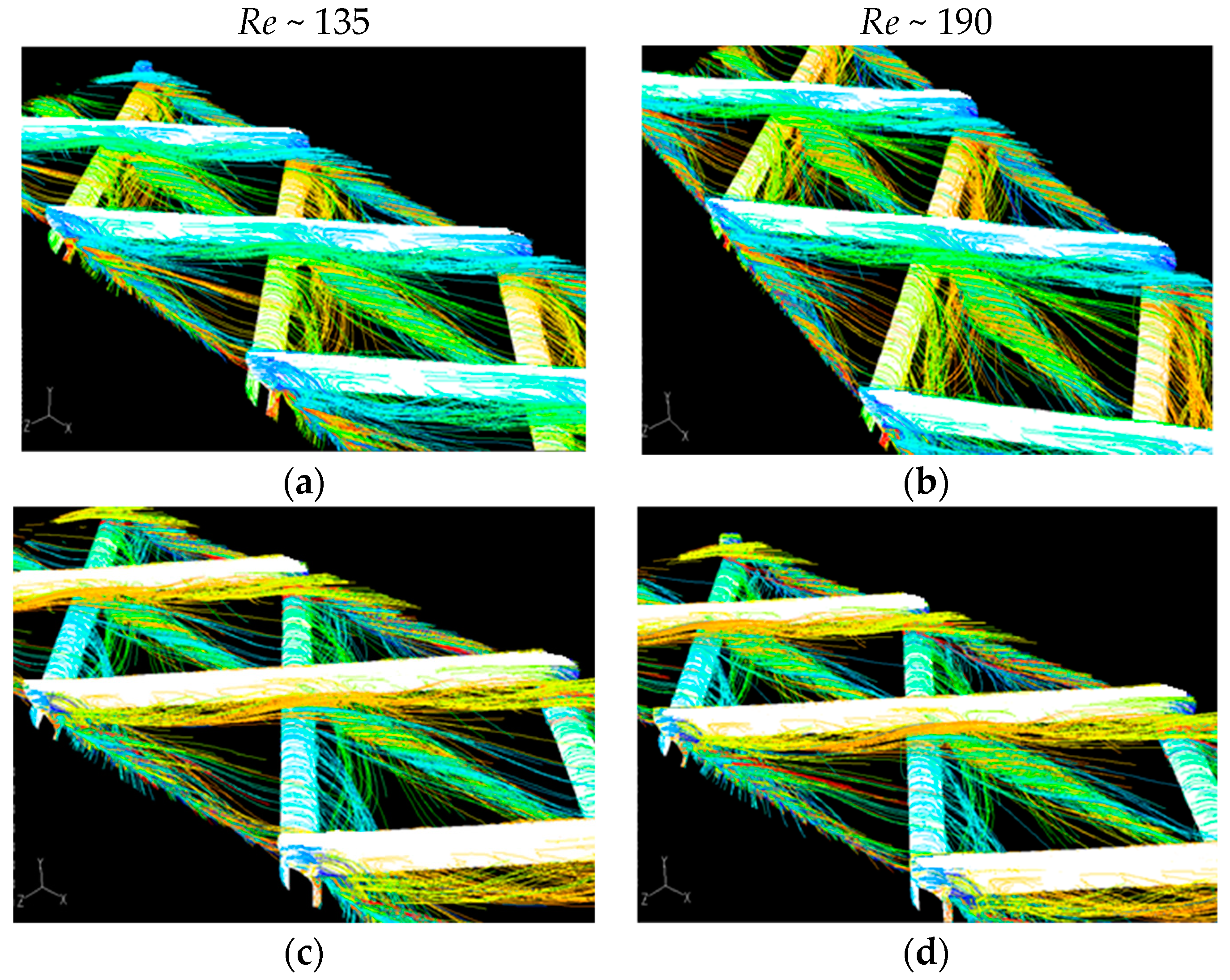

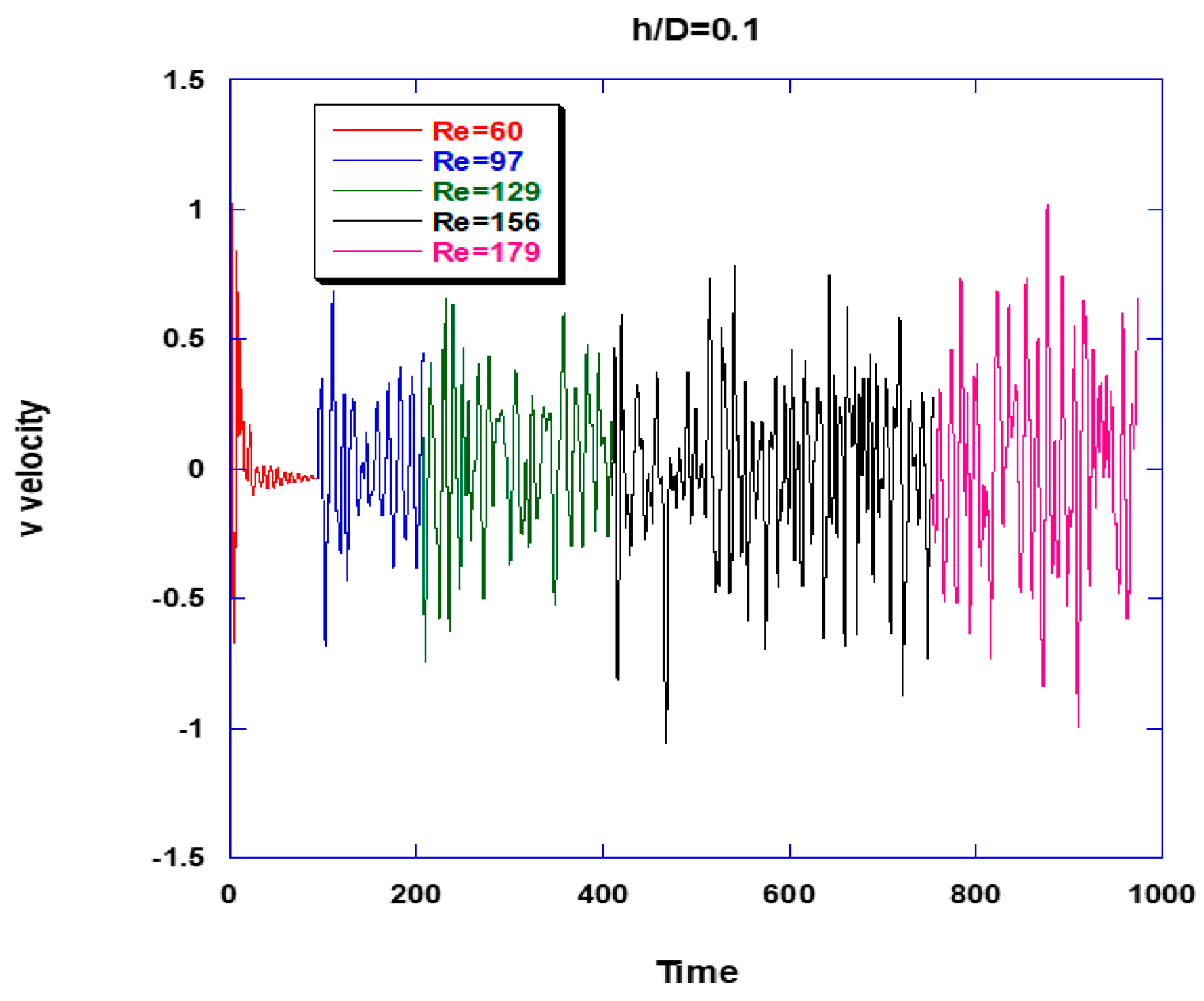

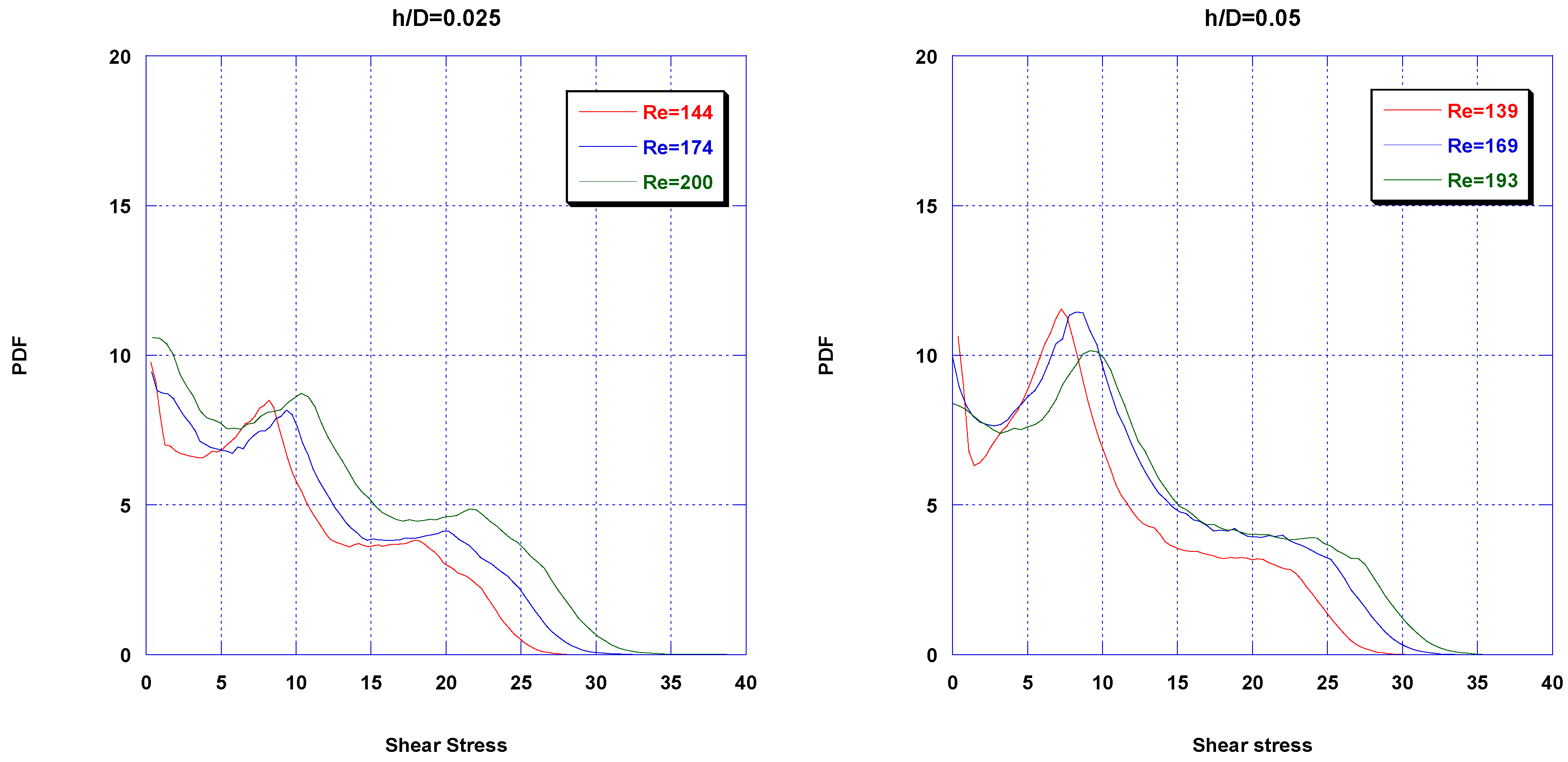

The new results reveal that the qualitative characteristics of the altered flow field in the spacer-filled channel (of reduced gap due to fouling) are very similar to those of the reference geometry, i.e., with no gap reduction. The main flow characteristics include a free vortex along the diagonal of the unit cell (roughly in the main flow direction) as well as spiral vortices and recirculation zones downstream of each spacer filament. It is interesting, however, that the gap reduction apparently tends to stabilize the flow and extend the transition to unsteady flow to somewhat greater Re numbers. As expected, for a given flow rate, pressure drop and time-averaged wall shear stress as well mass-transfer coefficient k tend to significantly increase with increasing fouling-layer thickness h due to the reduced effective channel-gap, leading to increased flow velocities.

Useful correlations are obtained from the numerical data on friction factor f and overall average Sh number, which exhibit similar functional dependence of f and Sh on Re and Sc numbers to the reference case of the unobstructed channel (h = 0). A noteworthy feature of these correlations is the incorporation of the effect of channel-gap reduction, which allows predictions in the range of fouling-layer thickness (h/D) = 0–0.10. The proposed correlations, in addition to other uses, can be employed tο improve steady-state models and develop realistic dynamic models simulating the operation of SWM modules and RO/NF plants.