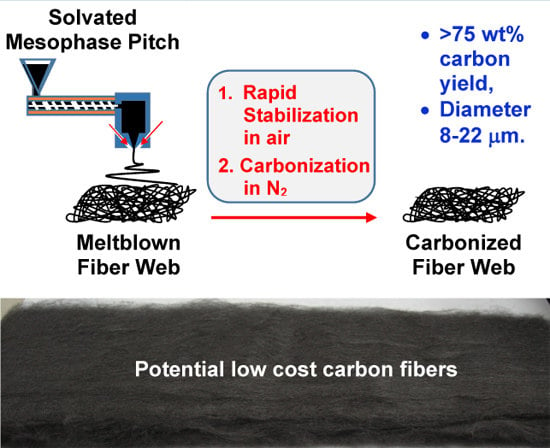

Meltblown Solvated Mesophase Pitch-Based Carbon Fibers: Fiber Evolution and Characteristics

Abstract

:1. Introduction

2. Results and Discussion

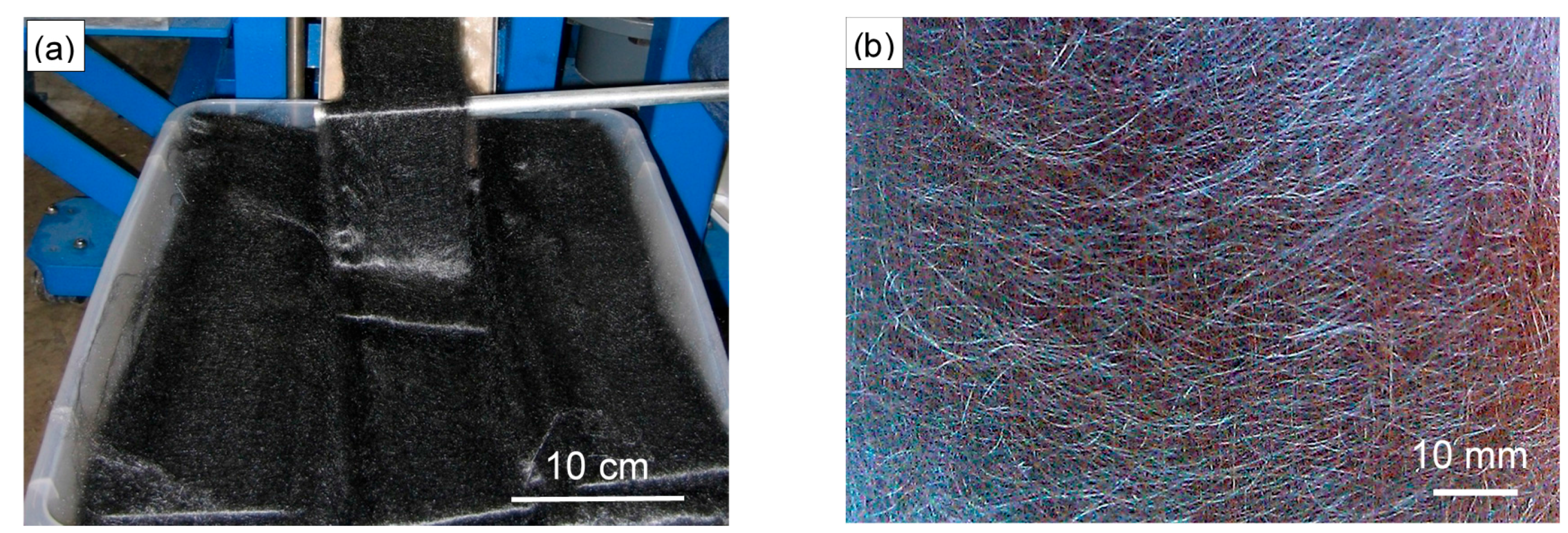

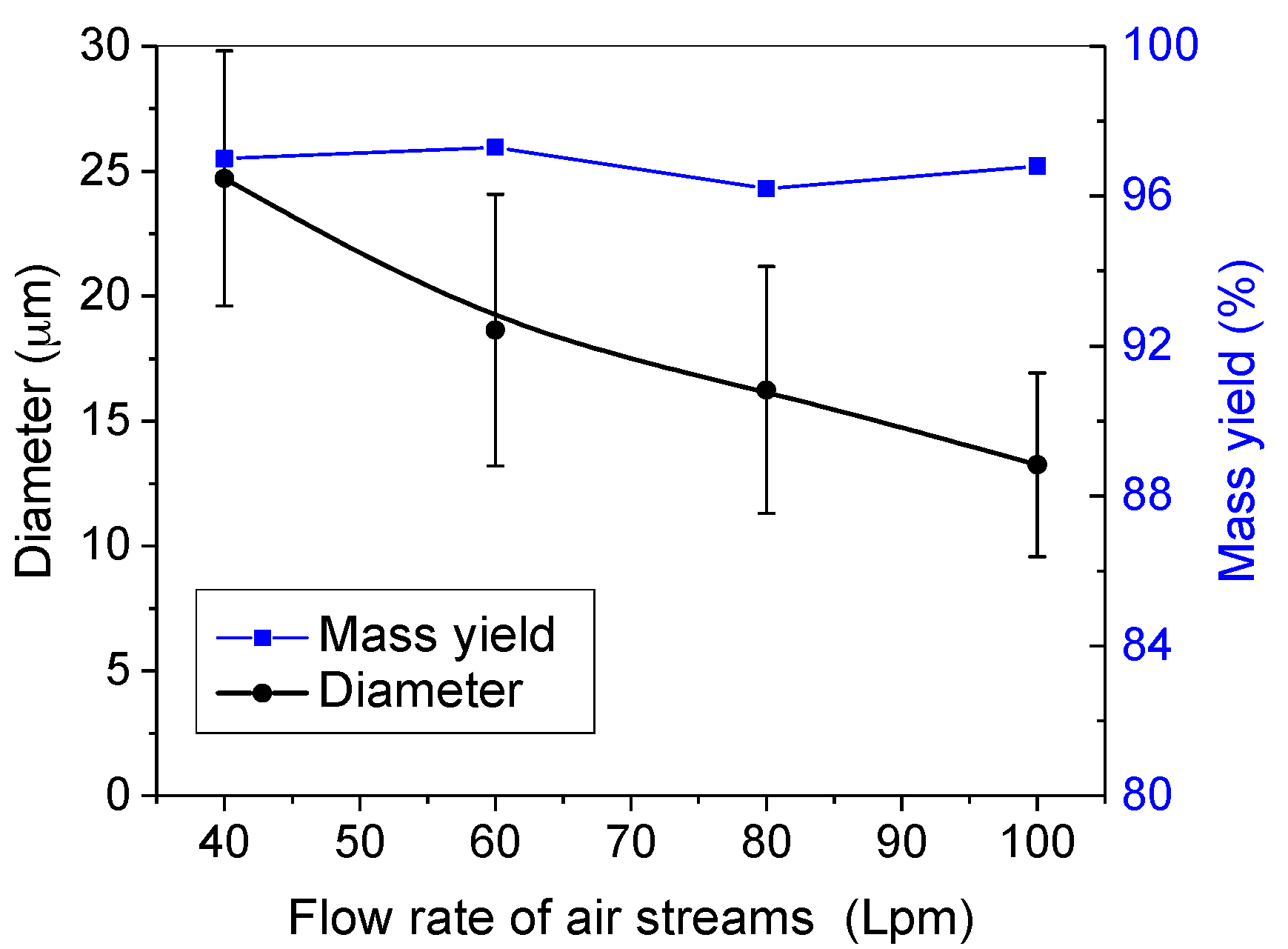

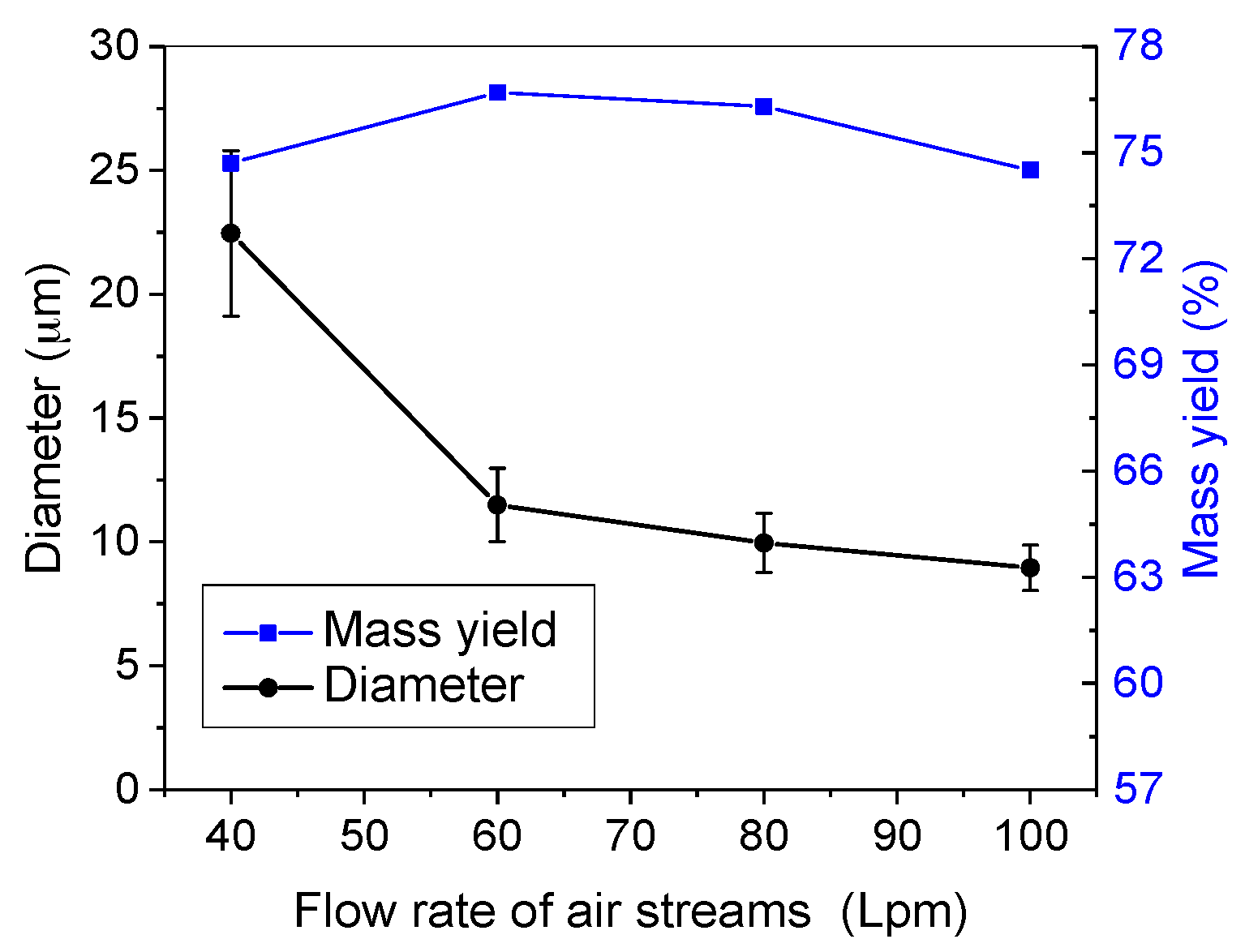

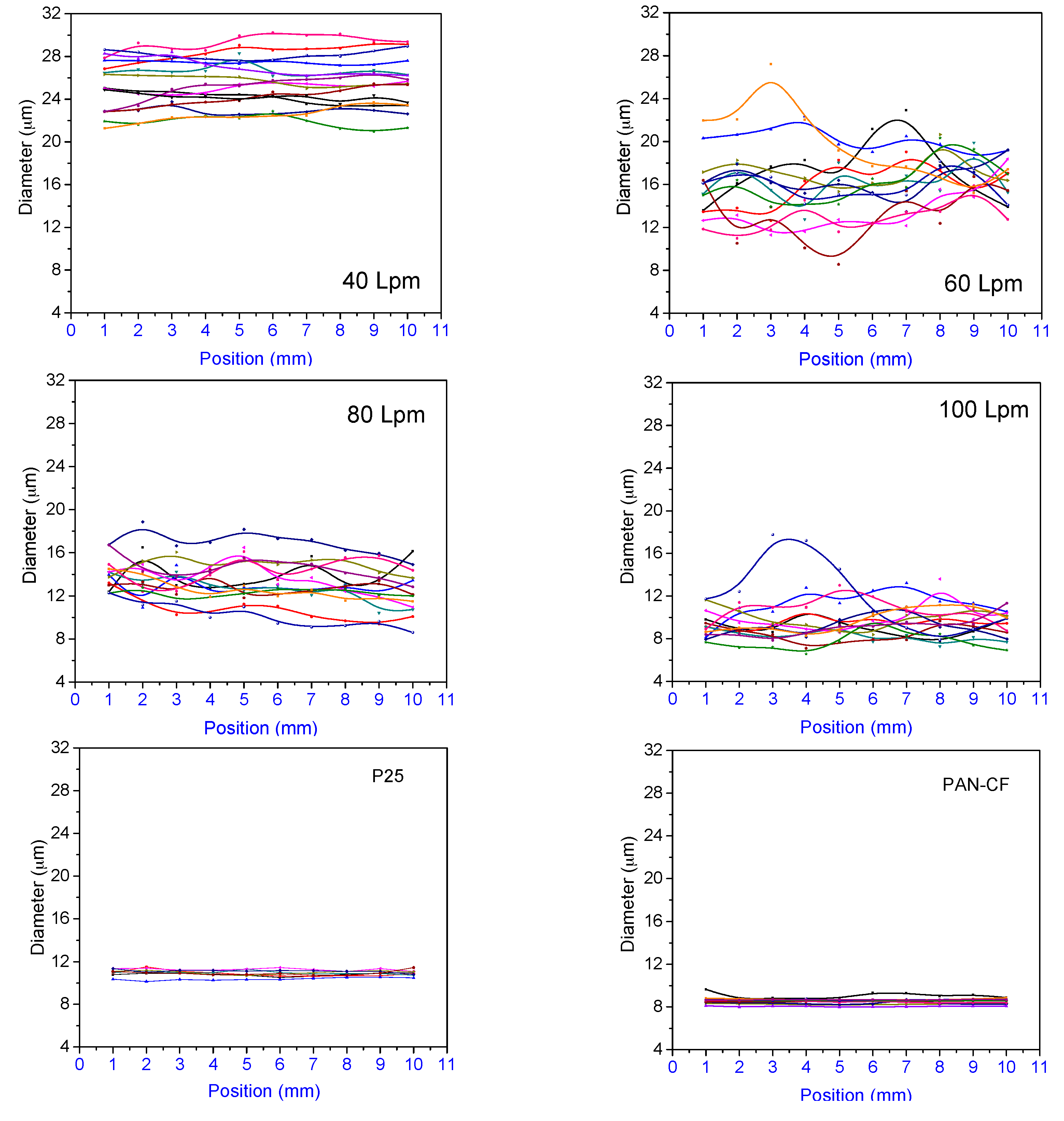

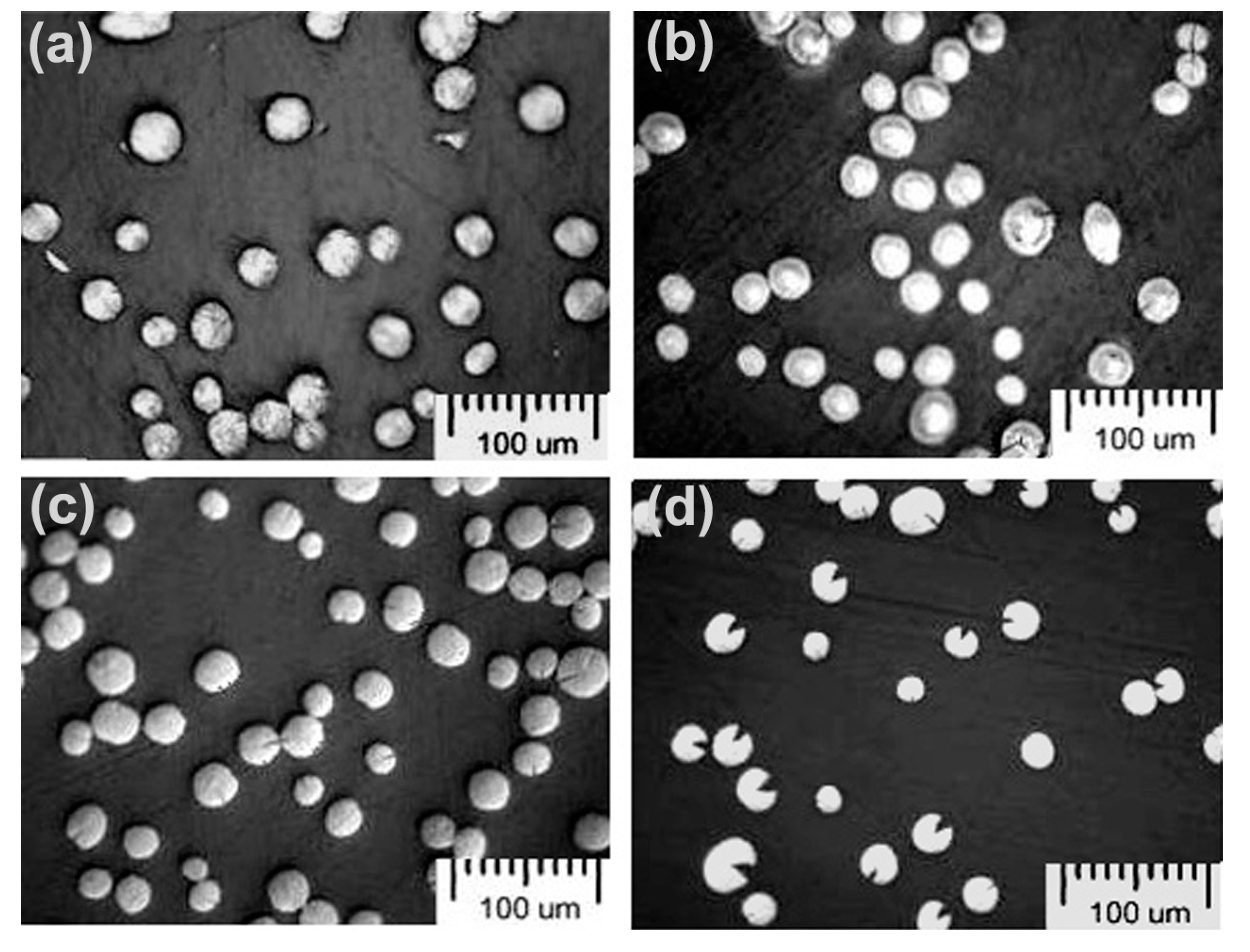

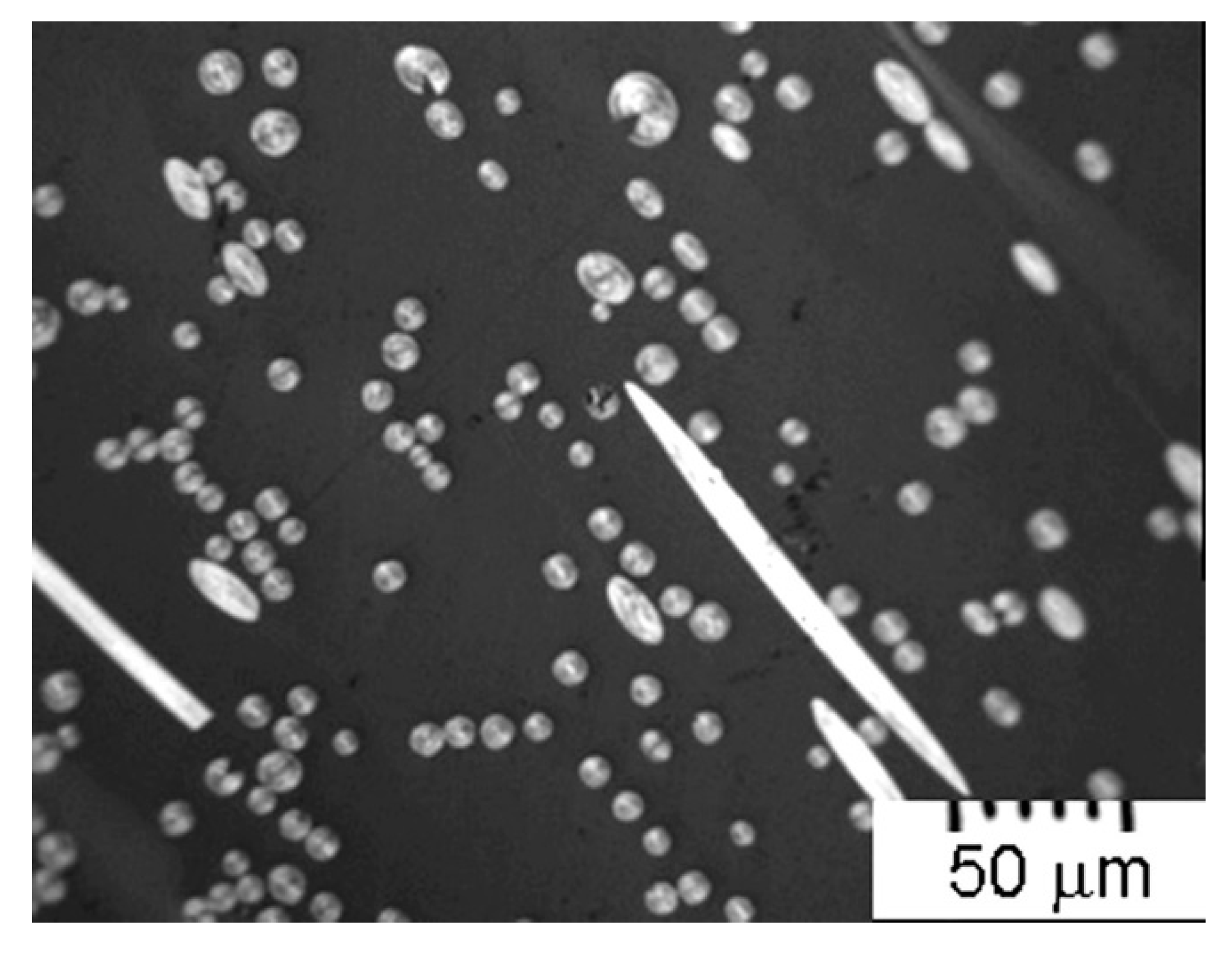

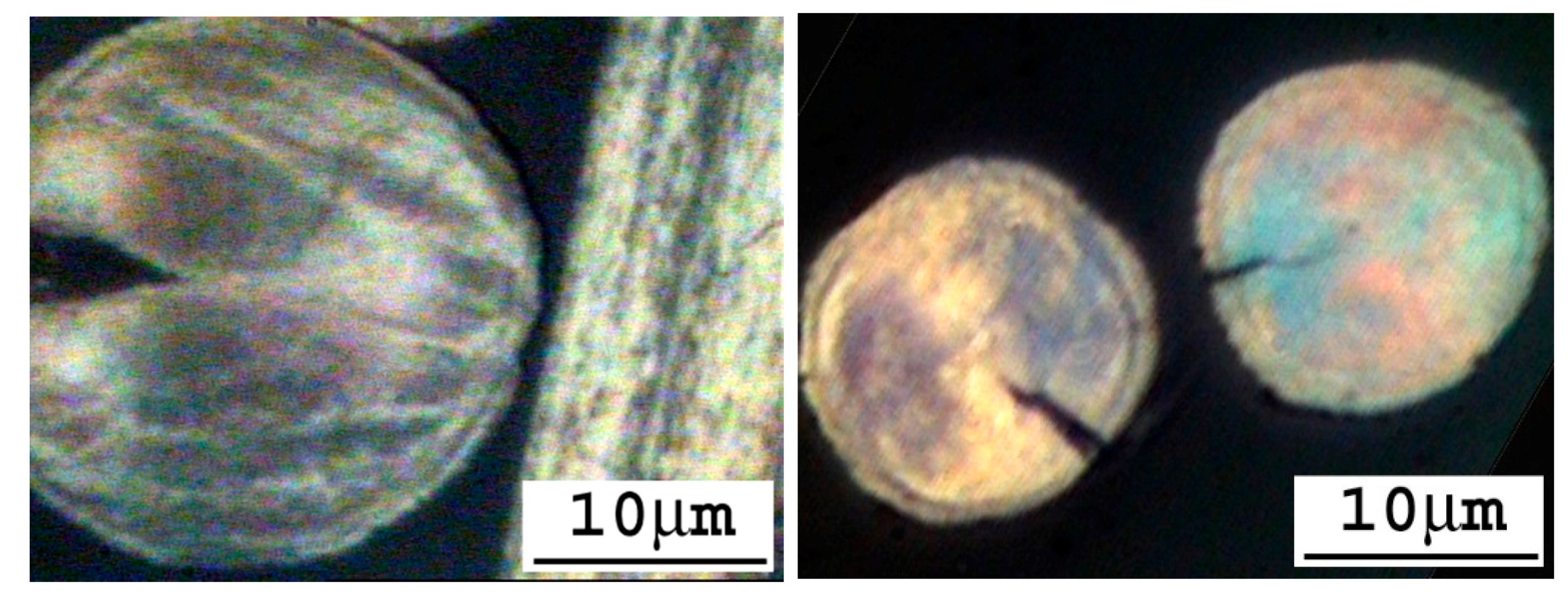

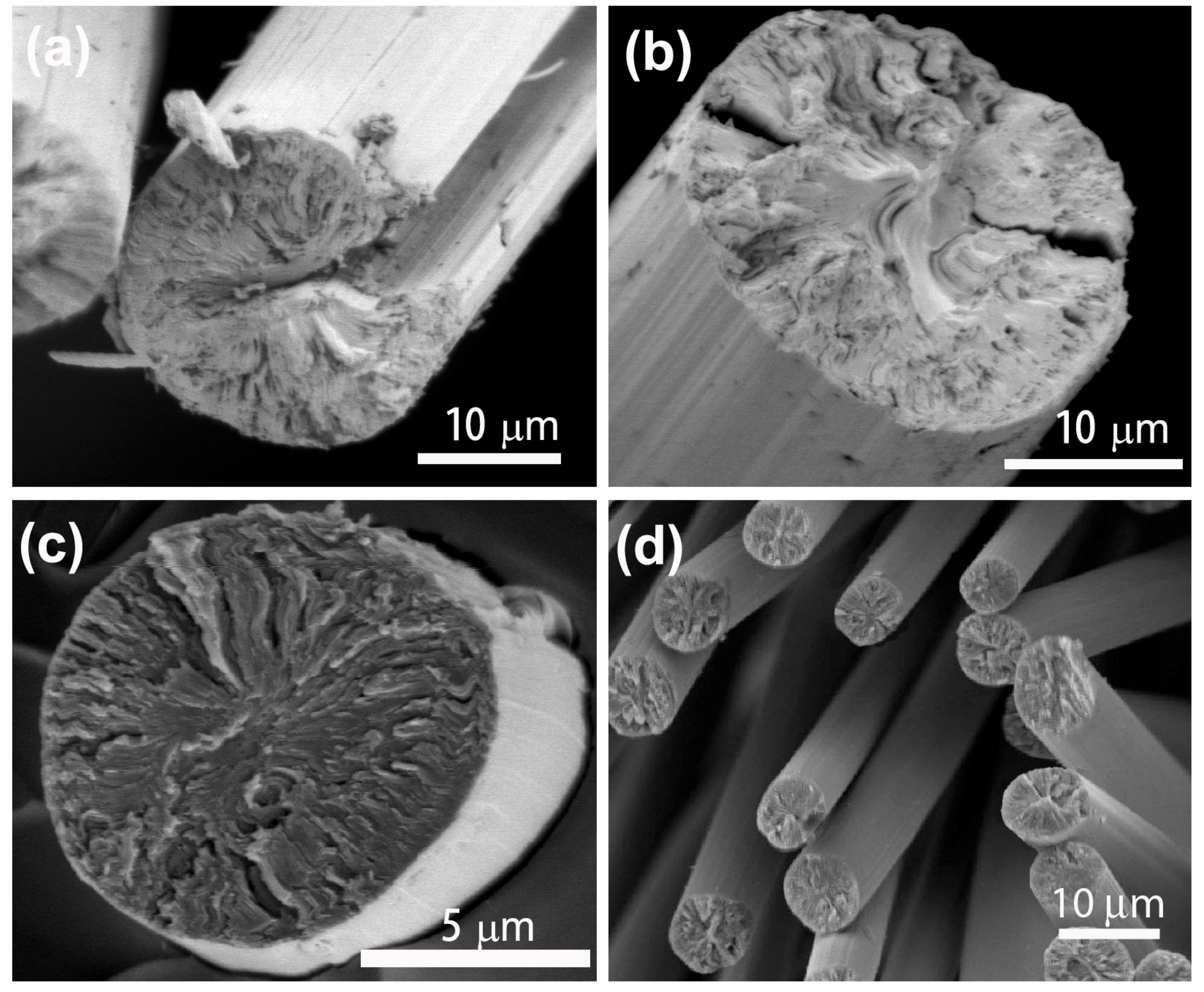

2.1. Characteristics of the Spun Fibers

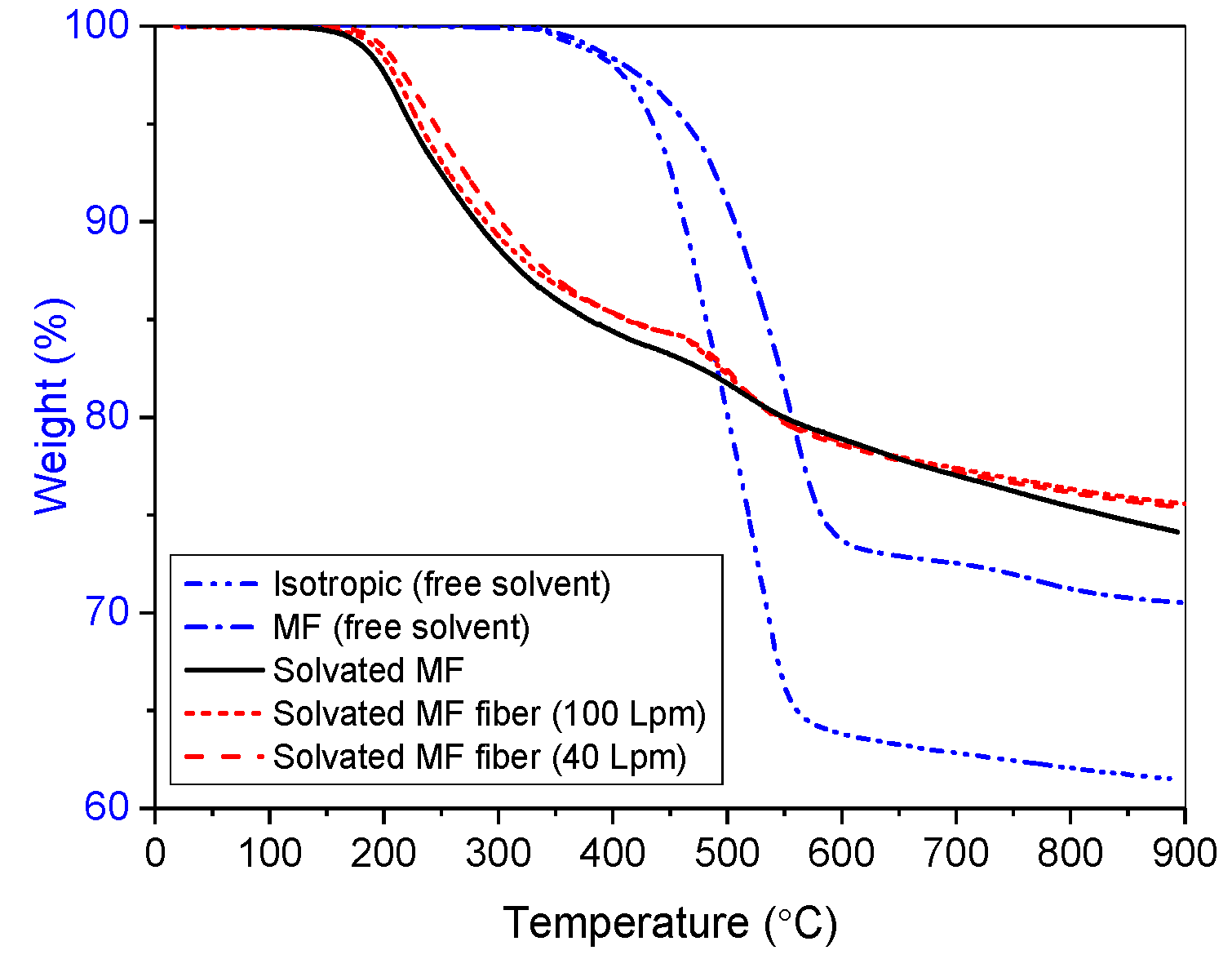

2.2. Stabilization and Carbonization of the Spun Fibers

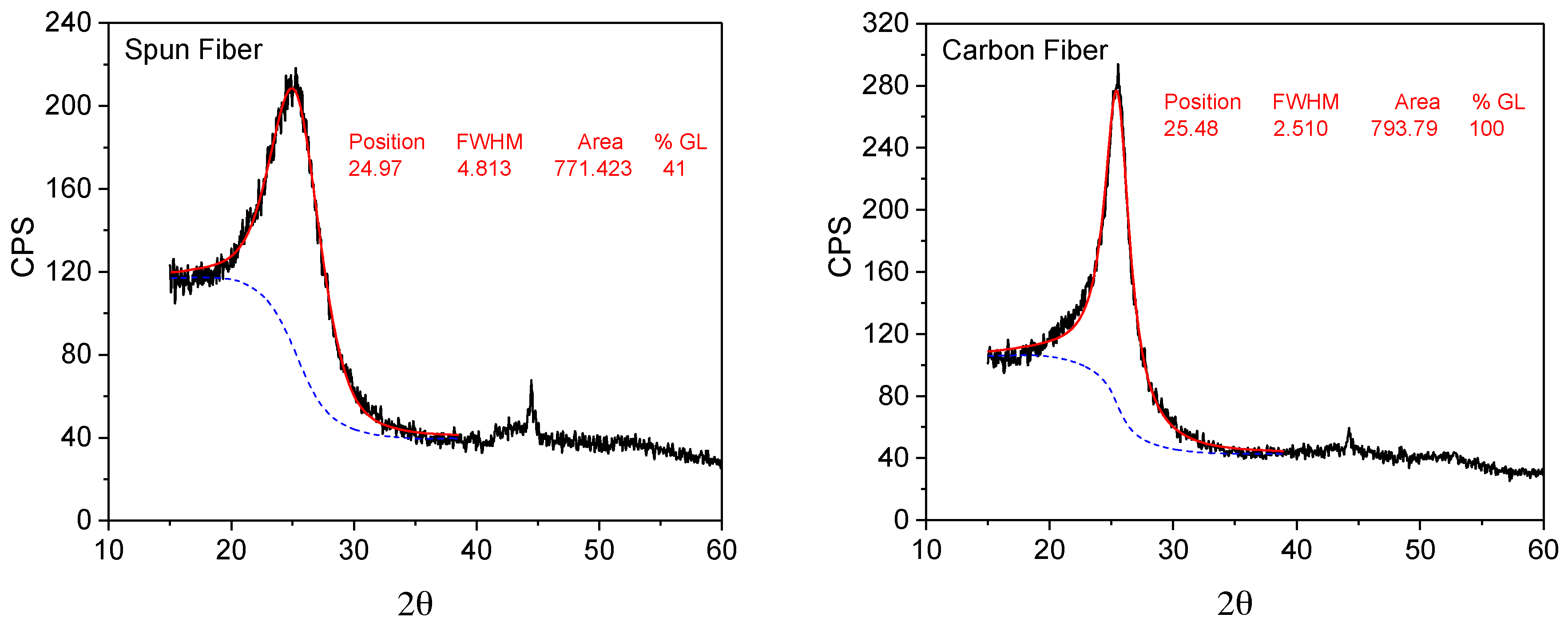

2.3. Structure Evolution

2.4. Characteristics of Carbonized Fibers

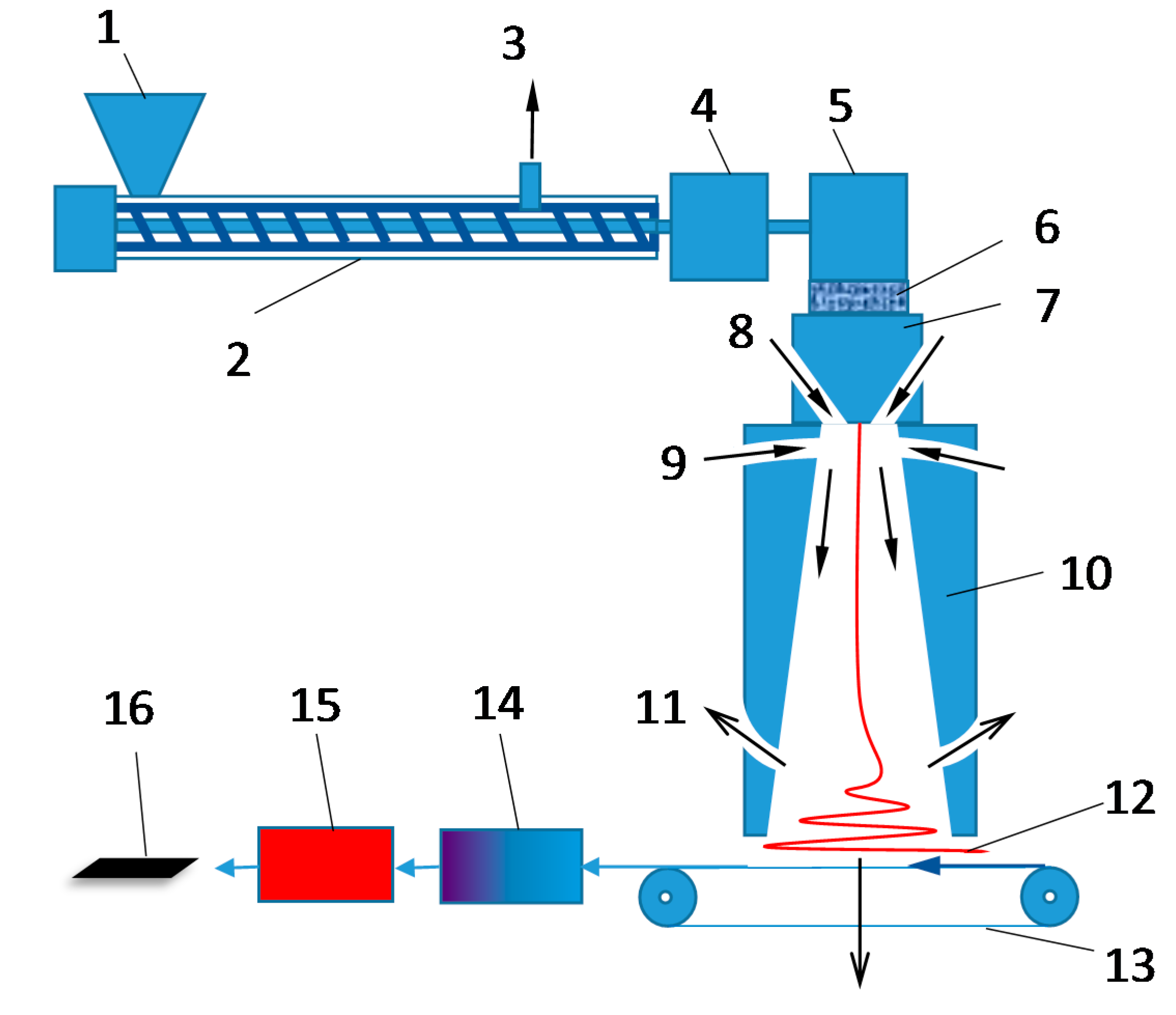

3. Materials and Methods

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chand, S. Review Carbon fibers for composites. J. Mater. Sci. 2000, 35, 1303–1313. [Google Scholar] [CrossRef]

- Huang, X. Fabrication and properties of carbon fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Oak Ridge National Laboratory. Transportation Technology Program. Annual Report; 2008. Available online: https://energy.gov/sites/prod/files/2014/03/f8/ornl_ttp_report_fy08.pdf (accessed on 12 February 2017).

- Sullivan, R.A. Automotive carbon fiber: Opportunities and challenges. JOM 2006, 11, 77–79. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Harper, D.P.; Bozell, J.J.; Rials, T.G. Role of physicochemical structure of organosolv hardwood and herbaceous lignins on carbon fiber performance. ACS Sustain. Chem. Eng. 2016, 4, 5785–5798. [Google Scholar] [CrossRef]

- Baker, D.A.; Rials, T.G. Recent advances in low-cost carbon fiber manufacture from lignin. J. Appl. Polym. Sci. 2013, 130, 713–728. [Google Scholar] [CrossRef]

- Khayyam, H.; Fakhrhoseini, S.M.; Church, J.S.; Milani, A.S.; Bab-Hadiashar, A.; Jazar, R.; Naebe, M. Predictive Modelling and Optimization of Carbon Fiber Mechanical Properties through High Temperature Furnace. Appl. Therm. Eng. 2017. Available online: http://dx.doi.org/10.1016/j.applthermaleng.2017.06.071 (accessed on 1 July 2017).

- Liu, J.; Yue, Z.; Fong, H. Continuous nanoscale carbon fibers with superior mechanical strength. Small 2009, 5, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Chae, H.G.; Newcomb, B.A.; Gulgunje, P.V.; Liu, Y.; Gupta, K.K.; Kamath, M.G.; Lyons, K.M.; Ghoshal, S.; Pramanik, C.; Giannuzzi, L. High strength and high modulus carbon fibers. Carbon 2015, 93, 81–87. [Google Scholar] [CrossRef]

- Vakili, A.; Yue, Z.; Fei, Y.; Cochran, H.; Allen, L.; Duran, M. Pitch based carbon fiber processing and composites. In Proceedings of the SAMPE Fall Technical Conference (39th ISTC), Cincinnati, OH, USA, 29 October–1 November 2007. [Google Scholar]

- Walter, M.; Kalback, H.; Romine, E.; Bourrat, X.M. Solvated Mesophase Pitches. U.S. Patent 5,259,947, 9 November 1993. [Google Scholar]

- Southard, W.M.; Romine, H.E.; Nanni, E.J.; Carel, M.W. Process for Making Solvated Mesophase Pitch. U.S. Patent 5,437,780, 1 August 1995. [Google Scholar]

- Yue, Z.; Liu, C.; Vakili, A. Solvated mesophase pitch-based carbon fibers: Thermal-oxidative stabilization of the spun fiber. J. Mater. Sci. 2017, 52, 8176–8187. [Google Scholar] [CrossRef]

- Silva, E. The Melt-Blowing Process. Available online: https://www.academia.edu/440299/The_melt-blowing_process_-_Nonwovens (accessed on 21 July 2017).

- Mochida, I.; Ling, L.; Korai, Y. Some factors for the high performances of mesophase pitch based carbon fibre. J. Mater. Sci. 1994, 29, 3050–3056. [Google Scholar] [CrossRef]

- Tomioka, T.; Arai, Y.; Hamada, T. Pitch-based carbon fibres derived from thermoset fibres oxidized with Cl2 containing air. J. Mater. Sci. 1995, 30, 1570–1576. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, J.; Liu, L.; Dong, Y.; Liu, A. Mesophase pitch-based carbon fiber spinning through a filter assembly and the microstructure evolution mechanism. J. Mater. Sci. 2014, 49, 191–198. [Google Scholar] [CrossRef]

- Ogale, A.A.; Lin, C.; Anderson, D.P.; Kearns, K.M. Orientation and dimensional changes in mesophase pitch-based carbon fibers. Carbon 2002, 40, 1309–1319. [Google Scholar] [CrossRef]

- Wazir, A.H.; Kakakhel, L. Preparation and characterization of pitch-based carbon fibers. New Carbon Mater. 2009, 24, 83–88. [Google Scholar] [CrossRef]

- Lu, S.; Blanco, C.; Rand, B. Large diameter carbon fibres from mesophase pitch. Carbon 2002, 40, 2109–2116. [Google Scholar] [CrossRef]

- Mora, E.; Blanco, C.; Santamarı́a, R.; Granda, M. A novel method to obtain a petroleum-derived mesophase pitch suitable as carbon fibre precursor. Carbon 2003, 41, 445–452. [Google Scholar] [CrossRef]

- MInus, M.; Kumar, S. The processing, properties, and structure of carbon fibers. JOM 2005, 57, 52–58. [Google Scholar] [CrossRef]

- Watanabe, F.; Korai, Y.; Mochida, I.; Nishimura, Y. Structure of melt-blown mesophase pitch-based carbon fiber. Carbon 2000, 38, 741–747. [Google Scholar] [CrossRef]

- Vakili, A.; Rossillon, D. Process for Collection of Continuous Fibers as a Uniform Batt. U.S. Patent 8,206,640, 26 June 2012. [Google Scholar]

- Morgan, P. Carbon Fibers and Their Composites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Singer, L.S.; Mitchell, S. Diffusion of oxygen into pitch. Carbon 1997, 35, 599–604. [Google Scholar] [CrossRef]

- Matsumoto, T.; Mochida, I. A structural study on oxidative stabilization of MP pitch fibers derived from coal tar. Carbon 1992, 30, 1041–1046. [Google Scholar] [CrossRef]

- Lavin, J.G. Chemical reactions in the stabilization of mesophase pitch-based fibers. Carbon 1992, 30, 351–357. [Google Scholar] [CrossRef]

- Bresee, R.R.; Qureshi, U.A. Influence of process conditions on melt blown web structure. Part IV—Fiber diameter. J. Eng. Fibers Fabr. 2006, 1, 32–46. [Google Scholar]

- Otani, S. Mechanism of the carbonization of mesophase carbon fiber at the low temperature range. Carbon 1967, 5, 219–220. [Google Scholar] [CrossRef]

- Mochida, I.; Toshima, H.; Korai, Y.; Hino, T. Oxygen distribution in the mesophase pitch fiber after oxidative stabilization. J. Mater. Sci. 1989, 24, 389–394. [Google Scholar] [CrossRef]

- Gerald, J.D.F.; Pennock, G.M.; Taylor, G.H. Domain structure in MP (mesophase pitch)-based fibres. Carbon 1991, 29, 139–164. [Google Scholar] [CrossRef]

- Donnet, J.B.; Qin, R.Y. Study of carbon fiber surfaces by scanning tunnelling microscopy, part I. Carbon fibers from different precursors and after various heat treatment temperatures. Carbon 1992, 30, 787–796. [Google Scholar] [CrossRef]

- Yoon, S.H.; Takano, N.; Korai, Y.; Mochida, I. Crack formation in mesophase pitch based carbon fibers: Part I Some influential factors for crack formation. J. Mater. Sci. 1997, 32, 2753–2758. [Google Scholar] [CrossRef]

- Yoon, S.H.; Korai, Y.; Mochida, I. Crack formation in mesophase pitch based carbon fibres: Part II Detailed structure of pitch based carbon fibres with some types of open cracks. J. Mater. Sci. 1997, 32, 2759–2769. [Google Scholar] [CrossRef]

- Matsumoto, M.; Iwashita, T.; Arai, Y.; Tomioka, T. Effect of spinning conditions on structures of pitch-based carbon fiber. Carbon 1993, 31, 715–720. [Google Scholar] [CrossRef]

- Matsumoto, T. Mesophase pitch and its carbon fibers. Pure Appl. Chem. 1985, 57, 1553–1562. [Google Scholar] [CrossRef]

- Alway-Cooper, R.M.; Anderson, D.P.; Ogale, A.A. Carbon black modification of mesophase pitch-based carbon fibers. Carbon 2013, 59, 40–48. [Google Scholar] [CrossRef]

- Wang, P.H.; Liu, J.; Yue, Z.R.; Li, R.Y. Thermal oxidative stabilization of polyacrylonitrile precursor fiber—Progression of morphological structure and mechanical properties. Carbon 1992, 30, 113–120. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Abolhasani, M.M.; Li, Q.; Khayyam, H.; Naebe, M. Cheetah skin structure: A new approach for carbon-nano-patterning of carbon nanotubes. Compos. Part A 2017, 95, 304–314. [Google Scholar] [CrossRef]

- Yue, Z.; Vakili, A.; Duran, M.P. Surface treatments of solvated mesophase pitch-based carbon fibers. J. Mater. Sci. 2017, 52, 10250–10260. [Google Scholar] [CrossRef]

- Bright, A.A.; Singer, L.S. The electronic and structural characteristics of carbon fibers from mesophase pitch. Carbon 1979, 17, 59–69. [Google Scholar] [CrossRef]

- Liu, C. Mesophase Pitch-Based Carbon Fiber and Its Composites: Preparation and Characterization. Master’s Thesis, The University of Tennessee, Knoxville, TN, USA, 2011. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, Z.; Liu, C.; Vakili, A. Meltblown Solvated Mesophase Pitch-Based Carbon Fibers: Fiber Evolution and Characteristics. C 2017, 3, 26. https://doi.org/10.3390/c3030026

Yue Z, Liu C, Vakili A. Meltblown Solvated Mesophase Pitch-Based Carbon Fibers: Fiber Evolution and Characteristics. C. 2017; 3(3):26. https://doi.org/10.3390/c3030026

Chicago/Turabian StyleYue, Zhongren, Chang Liu, and Ahmad Vakili. 2017. "Meltblown Solvated Mesophase Pitch-Based Carbon Fibers: Fiber Evolution and Characteristics" C 3, no. 3: 26. https://doi.org/10.3390/c3030026