The Application of State-of-the-Art Analytic Tools (Biosensors and Spectroscopy) in Beverage and Food Fermentation Process Monitoring

Abstract

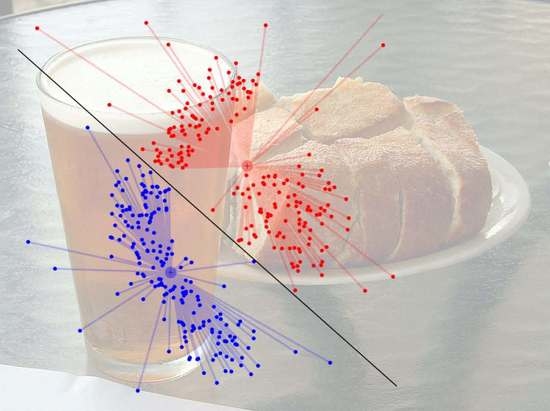

:1. Introduction

Background

2. Data Mining and Analysis

2.1. Univariate Analysis Limitations

2.2. Chemometrics

3. Applications

3.1. Biosensors

3.2. Ultrasound

3.3. Spectroscopy

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Castro-Puyana, M.; Pérez-Míguez, R.; Montero, L.; Herrero, M. Application of mass spectrometry-based metabolomics approaches for food safety, quality and traceability. TrAC Trends Anal. Chem. 2017, 93, 102–118. [Google Scholar] [CrossRef]

- Daniel, C. Infrared methods for high throughput screening of metabolites: Food and medical applications. Comb. Chem. High Throughput Screen. 2011, 14, 125–131. [Google Scholar]

- Cozzolino, D.; Cynkar, W.U.; Shah, N.; Smith, P. Multivariate data analysis applied to spectroscopy: Potential application to juice and fruit quality. Food Res. Int. 2011, 44, 1888–1896. [Google Scholar] [CrossRef]

- Cozzolino, D.; Cynkar, W.; Shah, N.; Smith, P. Technical solutions for analysis of grape juice, must, and wine: The role of infrared spectroscopy and chemometrics. Anal. Bioanal. Chem. 2011, 401, 1475–1484. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, D.; Dambergs, R.G.; Janik, L.; Cynkar, W.U.; Gishen, M. Analysis of grapes and wine by near infrared spectroscopy. J. Near Infrared Spectrosc. 2006, 14, 279–289. [Google Scholar] [CrossRef]

- Cortés, V.; Rodríguez, A.; Blasco, J.; Rey, B.; Besada, C.; Cubero, S.; Salvador, A.; Talens, P.; Aleixos, N. Prediction of the level of astringency in persimmon using visible and near-infrared spectroscopy. J. Food Eng. 2017, 204, 27–37. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, X.; Zhang, Z.; Zhu, R. Data fusion of near-infrared and mid-infrared spectra for identification of rhubarb. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 171, 72–79. [Google Scholar] [CrossRef] [PubMed]

- Chandra, S.; Chapman, J.; Power, A.; Roberts, J.; Cozzolino, D. Origin and regionality of wines—The role of molecular spectroscopy. Food Anal. Methods 2017. [Google Scholar] [CrossRef]

- Schalk, R.; Geoerg, D.; Staubach, J.; Raedle, M.; Methner, F.-J.; Beuermann, T. Evaluation of a newly developed mid-infrared sensor for real-time monitoring of yeast fermentations. J. Biosci. Bioeng. 2017, 123, 651–657. [Google Scholar] [CrossRef] [PubMed]

- Wakabayashi, I.; Groschner, K. Modification of the association between alcohol drinking and non-hdl cholesterol by gender. Clin. Chim. Acta 2009, 404, 154–159. [Google Scholar] [CrossRef] [PubMed]

- Moustafa, A.A.; Salem, H.; Hegazy, M.; Ali, O. Evaluating the efficiency of spectral resolution of univariate methods manipulating ratio spectra and comparing to multivariate methods: An application to ternary mixture in common cold preparation. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 137, 1363–1373. [Google Scholar] [CrossRef] [PubMed]

- Silva, A.P.; Jager, G.; Voss, H.-P.; van Zyl, H.; Hogg, T.; Pintado, M.; de Graaf, C. What’s in a name? The effect of congruent and incongruent product names on liking and emotions when consuming beer or non-alcoholic beer in a bar. Food Qual. Preference 2017, 55, 58–66. [Google Scholar] [CrossRef]

- Cozzolino, D.; Ares, G. The use of correlation, association and regression to analyse processes and products. In Mathematical and Statistical Methods in Food Science and Technology; John Wiley & Sons, Ltd.: San Francisco, CA, USA, 2013; pp. 19–30. [Google Scholar]

- Gishen, M.; Dambergs, R.G.; Cozzolino, D. Grape and wine analysis—Enhancing the power of spectroscopy with chemometrics. Aust. J. Grape Wine Res. 2005, 11, 296–305. [Google Scholar] [CrossRef]

- Esbensen, K.H. Multivariate Data Analysis in Practice; CAMO Process, AS: Oslo, Norway, 2002. [Google Scholar]

- Martens, H.; Naes, T. Multivariate Calibration; John Wiley & Sons Ltd.: New York, NY, USA, 1996. [Google Scholar]

- Cozzolino, D.; Cynkar, W.U.; Dambergs, R.G.; Shah, N.; Smith, P. A brief introduction to multivariate methods in grape and wine analysis. Int. J. Wine Res. 2009, 1, 123–130. [Google Scholar] [CrossRef]

- Brereton, R.G. Introduction to multivariate calibration in analytical chemistry. Analyst 2000, 125, 2125–2154. [Google Scholar] [CrossRef]

- Brereton, R.G. Experimental design. In Applied Chemometrics for Scientists; John Wiley & Sons, Ltd.: San Francisco, CA, USA, 2007; pp. 9–62. [Google Scholar]

- Siebert, K.J. Chemometrics in brewing—A review. J. Am. Soc. Brew. Chem. 2001, 59, 147–156. [Google Scholar]

- Munck, L.; Nørgaard, L.; Engelsen, S.B.; Bro, R.; Andersson, C.A. Chemometrics in food science—A demonstration of the feasibility of a highly exploratory, inductive evaluation strategy of fundamental scientific significance. Chemom. Intell. Lab. Syst. 1998, 44, 31–60. [Google Scholar] [CrossRef]

- Geladi, P. Chemometrics in spectroscopy. Part 1. Classical chemometrics. Spectrochim. Acta Part B Atomic Spectrosc. 2003, 58, 767–782. [Google Scholar] [CrossRef]

- Wold, S. Chemometrics; what do we mean with it, and what do we want from it? Chemom. Intell. Lab. Syst. 1995, 30, 109–115. [Google Scholar] [CrossRef]

- Corrêa, S.C.; Pinheiro, A.C.M.; Siqueira, H.E.; Carvalho, E.M.; Nunes, C.A.; Vilas Boas, E.V.d.B. Prediction of the sensory acceptance of fruits by physical and physical–chemical parameters using multivariate models. LWT—Food Sci. Technol. 2014, 59, 666–672. [Google Scholar] [CrossRef]

- Amiry, S.; Esmaiili, M.; Alizadeh, M. Classification of adulterated honeys by multivariate analysis. Food Chem. 2017, 224, 390–397. [Google Scholar] [CrossRef] [PubMed]

- Deng, B.-C.; Yun, Y.-H.; Liang, Y.-Z. Model population analysis in chemometrics. Chemom. Intell. Lab. Syst. 2015, 149, 166–176. [Google Scholar] [CrossRef]

- Scallan, E.; Hoekstra, R.M.; Angulo, F.J.; Tauxe, R.V.; Widdowson, M.-A.; Roy, S.L.; Jones, J.L.; Griffin, P.M. Foodborne illness acquired in the united states—Major pathogens. Emerg. Infect. Dis. 2011, 17, 7. [Google Scholar] [CrossRef] [PubMed]

- Ojha, K.S.; Mason, T.J.; O’Donnell, C.P.; Kerry, J.P.; Tiwari, B.K. Ultrasound technology for food fermentation applications. Ultrason. Sonochem. 2017, 34, 410–417. [Google Scholar] [CrossRef] [PubMed]

- Pereira, R.; Vicente, A. Environmental impact of novel thermal and non-thermal technologies in food processing. Food Res. Int. 2010, 43, 1936–1943. [Google Scholar] [CrossRef] [Green Version]

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Rayappan, J.B.B. Electronic noses for food quality: A review. J. Food Eng. 2015, 144, 103–111. [Google Scholar] [CrossRef]

- Blanco Romía, M.; Alcalà Bernàrdez, M. Chapter 3—Multivariate Calibration for Quantitative Analysis A2-Sun, Da-Wen. In Infrared Spectroscopy for Food Quality Analysis and Contro; Academic Press: San Diego, CA, USA, 2009; pp. 51–82. [Google Scholar]

- Blanco, M.; Villarroya, I. NIR Spectroscopy: A rapid-response analytical tool. TrAC Trends Anal. Chem. 2002, 21, 240–250. [Google Scholar] [CrossRef]

- Næs, T.; Isaksson, T.; Fearn, T. A User-Friendly Guide to Multivariate Calibration and Classification; NIR Publications: Chichester, UK, 2002. [Google Scholar]

- Murray, I.; Cowe, I. Sample preparation In Near Infrared Spectroscopy in Agriculture. In Agronomy; Roberts, C.A., Workman, J., Reeves, J.B., Eds.; American Society of Agronomy, Crop Science Society of America, Soil Science Society of America: Madison, WI, USA, 2004; pp. 75–115. [Google Scholar]

- Murray, I. Forage analysis by near infrared spectroscopy. In Sward Management Handbook; Davies, A., Baker, R.D., Grant, S.A., Laidlaw, A.S., Eds.; British Grassland Society: Kenilworth, UK, 1993; pp. 285–312. [Google Scholar]

- Mark, H. Statistics in Spectroscopy, 2nd ed.; Elsevier: London, UK, 2003. [Google Scholar]

- Mark, H. Principles and Practice of Spectroscopic Calibration; John Wiley & Sons Ltd.: Toronto, ON, Canada, 1991. [Google Scholar]

- Haaland, D.M.; Thomas, E.V. Partial least-squares methods for spectral analysis. 1. Relation to other quantitative calibration methods and the extraction of qualitative information. Anal. Chem. 1988, 60, 193–1198. [Google Scholar] [CrossRef]

- Geladi, P.; Kowalski, B.R. Partial least-squares regression: A tutorial. Anal. Chim. Acta 1986, 185, 1–17. [Google Scholar] [CrossRef]

- Harris, D.C. Quantitative Chemical Analysis, 4th ed.; W.H. Freeman and Company: New York, NY, USA, 1995. [Google Scholar]

- Jurado, J.M.; Alcázar, A.; Muñiz-Valencia, R.; Ceballos-Magaña, S.G.; Raposo, F. Some practical considerations for linearity assessment of calibration curves as function of concentration levels according to the fitness-for-purpose approach. Talanta 2017, 172, 221–229. [Google Scholar] [CrossRef] [PubMed]

- Bettencourt da Silva, R.J.N. Spreadsheet for designing valid least-squares calibrations: A tutorial. Talanta 2016, 148, 177–190. [Google Scholar] [CrossRef] [PubMed]

- Roger, J.M.; Palagos, B.; Bertrand, D.; Fernandez-Ahumada, E. CovSel: Variable selection for highly multivariate and multi-response calibration. Chemom. Intell. Lab. Syst. 2011, 106, 216–223. [Google Scholar] [CrossRef]

- Clementi, S.; Cruciani, G.; Curti, G. Some applications of the partial least-squares method. Anal. Chim. Acta 1986, 191, 149–160. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, X.; Jin, X.; Li, C.; Wu, X.; Yang, S.; Ning, J.; Yanne, P. Determination of total iron-reactive phenolics, anthocyanins and tannins in wine grapes of skins and seeds based on near-infrared hyperspectral imaging. Food Chem. 2017, 237, 811–817. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.; Liu, L.; Hou, J. A multivariate statistical combination forecasting method for product quality evaluation. Inf. Sci. 2016, 355, 229–236. [Google Scholar] [CrossRef]

- Spiegelberg, J.; Rusz, J. Can we use PCA to detect small signals in noisy data? Ultramicroscopy 2017, 172, 40–46. [Google Scholar] [CrossRef] [PubMed]

- Nouri, M.; Gomez, C.; Gorretta, N.; Roger, J.M. Clay content mapping from airborne hyperspectral Vis-NIR data by transferring a laboratory regression model. Geoderma 2017, 298, 54–66. [Google Scholar] [CrossRef]

- Jensen, A.L.; Kjelgaard-Hansen, M. Method comparison in the clinical laboratory. Vet. Clin. Pathol. 2003, 35, 276–286. [Google Scholar] [CrossRef]

- Norris, K.H.; Ritchie, G.E. Assuring specificity for a multivariate near-infrared (NIR) calibration: The example of the Chambersburg Shoot-out 2002 data set. J. Pharm. Biomed. Anal. 2008, 48, 1037–1041. [Google Scholar] [CrossRef] [PubMed]

- Williams, P.C. Implementation of Near-Infrared technology, in Near Infrared Technology in the Agricultural and Food Industries; Williams, P.C., Norris, K.H., Eds.; American Association of Cereal Chemists: St. Paul, MN, USA, 2001; pp. 145–169. [Google Scholar]

- Fearn, T. Validation. NIR News 1997, 8, 7–8. [Google Scholar] [CrossRef]

- Fearn, T. Assessing Calibrations: SEP, RPD, RER and R2. NIR News 2002, 13, 12–13. [Google Scholar] [CrossRef]

- Nicolaï, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review. Postharvest Biol. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

- Karoui, R.; Downey, G.; Blecker, C. Mid-Infrared Spectroscopy Coupled with Chemometrics: A Tool for the Analysis of Intact Food Systems and the Exploration of Their Molecular Structure-Quality Relationships—A Review. Chem. Rev. 2010, 110, 6144–6168. [Google Scholar] [CrossRef] [PubMed]

- Savitzky, A.; Golay, M.J.E. Smoothing and Differentiation of Data by Simplified Least Squares Procedures. Anal. Chem. 1964, 36, 1627–1639. [Google Scholar] [CrossRef]

- Duckworth, J. Mathematical data processing. In Near Infrared Spectroscopy in Agriculture; Roberts, C.A., Workman, J., Reeved, J.B., Eds.; American Society of Agronomy, Crop Science Society of America, Soil Science Society of America: Madison, WI, USA, 2004; pp. 115–135. [Google Scholar]

- Dhanoa, M.S.; Lister, S.J.; Sanderson, R.; Barnes, R.J. The link between multiplicative scatter correction (msc) and standard normal variate (snv) transformations of NIR spectra. J. Near Infrared Spectrosc. 1994, 2, 43–47. [Google Scholar] [CrossRef]

- Perez, S.; Fabregas, E. Amperometric bienzymatic biosensor for l-lactate analysis in wine and beer samples. Analyst 2012, 137, 3854–3861. [Google Scholar] [CrossRef] [PubMed]

- Thakur, M.S.; Ragavan, K.V. Biosensors in food processing. J. Food Sci. Technol. 2013, 50, 625–641. [Google Scholar] [CrossRef] [PubMed]

- Chandra, S.; Siraj, S.; Wong, D.K.Y. Recent advances in biosensing for neurotransmitters and disease biomarkers using microelectrodes. ChemElectroChem 2017, 4, 822–833. [Google Scholar] [CrossRef]

- Pandurić, N.; Šalić, A.; Zelić, B. Fully integrated biotransformation of fumaric acid by permeabilized baker’s yeast cells with in situ separation of L-malic acid using ultrafiltration, acidification and electrodialysis. Biochem. Eng. J. 2017, 125, 221–229. [Google Scholar] [CrossRef]

- Simó, G.; Vila-Crespo, J.; Fernández-Fernández, E.; Ruipérez, V.; Rodríguez-Nogales, J.M. Highly efficient malolactic fermentation of red wine using encapsulated bacteria in a robust biocomposite of silica-alginate. J. Agric. Food Chem. 2017, 65, 5188–5197. [Google Scholar] [CrossRef] [PubMed]

- Mira de Orduña, R.; Patchett, M.L.; Liu, S.-Q.; Pilone, G.J. Growth and arginine metabolism of the wine lactic acid bacteria lactobacillus buchneri andoenococcus oeni at different ph values and arginine concentrations. Appl. Environ. Microbiol. 2001, 67, 1657–1662. [Google Scholar] [CrossRef] [PubMed]

- Mazzei, F.; Botrè, F.; Favero, G. Peroxidase based biosensors for the selective determination of d,L-lactic acid and L-malic acid in wines. Microchem. J. 2007, 87, 81–86. [Google Scholar] [CrossRef]

- Giménez-Gómez, P.; Gutiérrez-Capitán, M.; Capdevila, F.; Puig-Pujol, A.; Fernández-Sánchez, C.; Jiménez-Jorquera, C. Robust l-malate bienzymatic biosensor to enable the on-site monitoring of malolactic fermentation of red wines. Anal. Chim. Acta 2017, 954, 105–113. [Google Scholar] [CrossRef] [PubMed]

- Vargas, E.; Ruiz, M.A.; Ferrero, F.J.; Campuzano, S.; Ruiz-Valdepeñas Montiel, V.; Reviejo, A.J.; Pingarrón, J.M. Automatic bionalyzer using an integrated amperometric biosensor for the determination of L-malic acid in wines. Talanta 2016, 158, 6–13. [Google Scholar] [CrossRef] [PubMed]

- Molinero-Abad, B.; Alonso-Lomillo, M.A.; Domínguez-Renedo, O.; Arcos-Martínez, M.J. Malate quinone oxidoreductase biosensors based on tetrathiafulvalene and gold nanoparticles modified screen-printed carbon electrodes for malic acid determination in wine. Sens. Actuators B Chem. 2014, 202, 971–975. [Google Scholar] [CrossRef]

- Molinero-Abad, B.; Alonso-Lomillo, M.A.; Domínguez-Renedo, O.; Arcos-Martínez, M.J. Simultaneous amperometric determination of malic and gluconic acids in wine using screen-printed carbon electrodes. Sens. Actuators B Chem. 2015, 211, 250–254. [Google Scholar] [CrossRef]

- Shkotova, L.V.; Piechniakova, N.Y.; Kukla, O.L.; Dzyadevych, S.V. Thin-film amperometric multibiosensor for simultaneous determination of lactate and glucose in wine. Food Chem. 2016, 197, 972–978. [Google Scholar] [CrossRef] [PubMed]

- Cinti, S.; Basso, M.; Moscone, D.; Arduini, F. A paper-based nanomodified electrochemical biosensor for ethanol detection in beers. Anal. Chim. Acta 2017, 960, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Gracin, L.; Jambrak, A.R.; Juretić, H.; Dobrović, S.; Barukčić, I.; Grozdanović, M.; Smoljanić, G. Influence of high power ultrasound on brettanomyces and lactic acid bacteria in wine in continuous flow treatment. Appl. Acoust. 2016, 103, 143–147. [Google Scholar] [CrossRef]

- Nguyen, T.M.P.; Lee, Y.K.; Zhou, W. Effect of high intensity ultrasound on carbohydrate metabolism of bifidobacteria in milk fermentation. Food Chem. 2012, 130, 866–874. [Google Scholar] [CrossRef]

- Tao, Y.; García, J.F.; Sun, D.-W. Advances in wine aging technologies for enhancing wine quality and accelerating wine aging process. Crit. Rev. Food Sci. Nutr. 2014, 54, 817–835. [Google Scholar] [CrossRef] [PubMed]

- Novoa-Díaz, D.; Rodríguez-Nogales, J.; Fernández-Fernández, E.; Vila-Crespo, J.; García-Álvarez, J.; Amer, M.; Chávez, J.; Turó, A.; García-Hernández, M.J.; Salazar, J. Ultrasonic monitoring of malolactic fermentation in red wines. Ultrasonics 2014, 54, 1575–1580. [Google Scholar] [CrossRef] [PubMed]

- Becker, T.; Mitzscherling, M.; Delgado, A. Ultrasonic velocity–a noninvasive method for the determination of density during beer fermentation. Eng. Life Sci. 2001, 1, 61–67. [Google Scholar] [CrossRef]

- Resa, P.; Elvira, L.; De Espinosa, F.M.; Gómez-Ullate, Y. Ultrasonic velocity in water–ethanol–sucrose mixtures during alcoholic fermentation. Ultrasonics 2005, 43, 247–252. [Google Scholar] [CrossRef] [PubMed]

- Winder, W.; Aulik, D.; Rice, A. An ultrasonic method for direct and simultaneous determination of alcohol and extract content of wines. Am. J. Enol. Vitic. 1970, 21, 1–11. [Google Scholar]

- Ogasawara, H.; Mizutani, K.; Ohbuchi, T.; Nakamura, T. Acoustical experiment of yogurt fermentation process. Ultrasonics 2006, 44, e727–e730. [Google Scholar] [CrossRef] [PubMed]

- Stillhart, C.; Kuentz, M. Comparison of high-resolution ultrasonic resonator technology and raman spectroscopy as novel process analytical tools for drug quantification in self-emulsifying drug delivery systems. J. Pharm. Biomed. Anal. 2012, 59, 29–37. [Google Scholar] [CrossRef] [PubMed]

- Grassi, S.; Amigo, J.M.; Lyndgaard, C.B.; Foschino, R.; Casiraghi, E. Beer fermentation: Monitoring of process parameters by ft-nir and multivariate data analysis. Food Chem. 2014, 155, 279–286. [Google Scholar] [CrossRef] [PubMed]

- Giovenzana, V.; Beghi, R.; Guidetti, R. Rapid evaluation of craft beer quality during fermentation process by vis/nir spectroscopy. J. Food Eng. 2014, 142, 80–86. [Google Scholar] [CrossRef]

- Iñón, F.A.; Garrigues, S.; de la Guardia, M. Combination of mid- and near-infrared spectroscopy for the determination of the quality properties of beers. Anal. Chim. Acta 2006, 571, 167–174. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, Q.; Zhao, J.; Pan, W.; Chen, Q. Real-time monitoring of process parameters in rice wine fermentation by a portable spectral analytical system combined with multivariate analysis. Food Chem. 2016, 190, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-Y.; Cho, B.-K. Rapid monitoring of the fermentation process for korean traditional rice wine ‘makgeolli’ using ft-nir spectroscopy. Infrared Phys. Technol. 2015, 73, 95–102. [Google Scholar] [CrossRef]

- Cavinato, A.G.; Mayes, D.M.; Ge, Z.; Callis, J.B. Noninvasive method for monitoring ethanol in fermentation processes using fiber-optic near-infrared spectroscopy. Anal. Chem. 1990, 62, 1977–1982. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Wang, J.; Lin, G.; Suo, H.; Zhao, C. Short-wave near-infrared spectrometer for alcohol determination and temperature correction. J. Anal. Methods Chem. 2012, 2012, 7. [Google Scholar] [CrossRef] [PubMed]

- Nordon, A.; Mills, A.; Burn, R.T.; Cusick, F.M.; Littlejohn, D. Comparison of non-invasive nir and raman spectrometries for determination of alcohol content of spirits. Anal. Chim. Acta 2005, 548, 148–158. [Google Scholar] [CrossRef]

- Liu, L.; Cozzolino, D.; Cynkar, W.U.; Dambergs, R.G.; Janik, L.; O’Neill, B.K.; Colby, C.B.; Gishen, M. Preliminary study on the application of visible–near infrared spectroscopy and chemometrics to classify riesling wines from different countries. Food Chem. 2008, 106, 781–786. [Google Scholar] [CrossRef]

- Urbano-Cuadrado, M.; Luque de Castro, M.D.; Pérez-Juan, P.M.; García-Olmo, J.; Gómez-Nieto, M.A. Near infrared reflectance spectroscopy and multivariate analysis in enology. Anal. Chim. Acta 2004, 527, 81–88. [Google Scholar] [CrossRef]

- Martelo-Vidal, M.J.; Vázquez, M. Determination of polyphenolic compounds of red wines by uv–vis–nir spectroscopy and chemometrics tools. Food Chem. 2014, 158, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Regmi, U.; Palma, M.; Barroso, C.G. Direct determination of organic acids in wine and wine-derived products by fourier transform infrared (ft-ir) spectroscopy and chemometric techniques. Anal. Chim. Acta 2012, 732, 137–144. [Google Scholar] [CrossRef] [PubMed]

- Sen, I.; Ozturk, B.; Tokatli, F.; Ozen, B. Combination of visible and mid-infrared spectra for the prediction of chemical parameters of wines. Talanta 2016, 161, 130–137. [Google Scholar] [CrossRef] [PubMed]

- Malacarne, M.; Bergamo, L.; Bertoldi, D.; Nicolini, G.; Larcher, R. Use of fourier transform infrared spectroscopy to create models forecasting the tartaric stability of wines. Talanta 2013, 117, 505–510. [Google Scholar] [CrossRef] [PubMed]

- Teslić, N.; Berardinelli, A.; Ragni, L.; Iaccheri, E.; Parpinello, G.P.; Pasini, L.; Versari, A. Rapid assessment of red wine compositional parameters by means of a new waveguide vector spectrometer. LWT—Food Sci. Technol. 2017, 84, 433–440. [Google Scholar] [CrossRef]

- Grassi, S.; Amigo, J.M.; Lyndgaard, C.B.; Foschino, R.; Casiraghi, E. Assessment of the sugars and ethanol development in beer fermentation with ft-ir and multivariate curve resolution models. Food Res. Int. 2014, 62, 602–608. [Google Scholar] [CrossRef]

- Musingarabwi, D.M.; Nieuwoudt, H.H.; Young, P.R.; Eyéghè-Bickong, H.A.; Vivier, M.A. A rapid qualitative and quantitative evaluation of grape berries at various stages of development using fourier-transform infrared spectroscopy and multivariate data analysis. Food Chem. 2016, 190, 253–262. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, D.; Kwiatkowski, M.J.; Waters, E.J.; Gishen, M. A feasibility study on the use of visible and short wavelengths in the near-infrared region for the non-destructive measurement of wine composition. Anal. Bioanal. Chem. 2007, 387, 2289–2295. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, D.; Cynkar, W.; Shah, N.; Smith, P. Quantitative analysis of minerals and electric conductivity of red grape homogenates by near infrared reflectance spectroscopy. Comput. Electron. Agric. 2011, 77, 81–85. [Google Scholar] [CrossRef]

- Cozzolino, D.; Kwiatkowski, M.J.; Dambergs, R.G.; Cynkar, W.U.; Janik, L.J.; Skouroumounis, G.; Gishen, M. Analysis of elements in wine using near infrared spectroscopy and partial least squares regression. Talanta 2008, 74, 711–716. [Google Scholar] [CrossRef] [PubMed]

- Anjos, O.; Santos, A.J.A.; Estevinho, L.M.; Caldeira, I. Ftir–atr spectroscopy applied to quality control of grape-derived spirits. Food Chem. 2016, 205, 28–35. [Google Scholar] [CrossRef] [PubMed]

- Lachenmeier, D.W. Rapid quality control of spirit drinks and beer using multivariate data analysis of fourier transform infrared spectra. Food Chem. 2007, 101, 825–832. [Google Scholar] [CrossRef]

- Pizarro, C.; González-Sáiz, J.M.; Esteban-Díez, I.; Orio, P. Prediction of total and volatile acidity in red wines by fourier-transform mid-infrared spectroscopy and iterative predictor weighting. Anal. Bioanal. Chem. 2011, 399, 2061–2072. [Google Scholar] [CrossRef] [PubMed]

- Castritius, S.; Geier, M.; Jochims, G.; Stahl, U.; Harms, D. Rapid determination of the attenuation limit of beer using middle-infrared (mir) spectroscopy and a multivariate model. J. Agric. Food Chem. 2012, 60, 6341–6348. [Google Scholar] [CrossRef] [PubMed]

- Shen, F.; Ying, Y.; Li, B.; Zheng, Y.; Hu, J. Prediction of sugars and acids in chinese rice wine by mid-infrared spectroscopy. Food Res. Int. 2011, 44, 1521–1527. [Google Scholar] [CrossRef]

- Friedel, M.; Patz, C.-D.; Dietrich, H. Comparison of different measurement techniques and variable selection methods for ft-mir in wine analysis. Food Chem. 2013, 141, 4200–4207. [Google Scholar] [CrossRef] [PubMed]

- Romera-Fernández, M.; Berrueta, L.A.; Garmón-Lobato, S.; Gallo, B.; Vicente, F.; Moreda, J.M. Feasibility study of ft-mir spectroscopy and pls-r for the fast determination of anthocyanins in wine. Talanta 2012, 88, 303–310. [Google Scholar] [CrossRef] [PubMed]

- Llario, R.; Iñón, F.A.; Garrigues, S.; de la Guardia, M. Determination of quality parameters of beers by the use of attenuated total reflectance-fourier transform infrared spectroscopy. Talanta 2006, 69, 469–480. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Xu, E.; Long, J.; Zhang, Y.; Wang, F.; Xu, X.; Jin, Z.; Jiao, A. Monitoring of fermentation process parameters of chinese rice wine using attenuated total reflectance mid-infrared spectroscopy. Food Control 2015, 50, 405–412. [Google Scholar] [CrossRef]

- Kutyła-Olesiuk, A.; Wawrzyniak, U.E.; Jańczyk, M.; Wróblewski, W. Electrochemical sensor arrays for the analysis of wine production. Procedia Eng. 2014, 87, 580–583. [Google Scholar] [CrossRef]

- Stashenko, H.; Macku, C.; Shibamoto, T. Monitoring volatile chemicals formed from must during yeast fermentation. J. Agric. food Chem. 1992, 40, 2257–2259. [Google Scholar] [CrossRef]

- Salanitro, J.; Muirhead, P. Quantitative method for the gas chromatographic analysis of short-chain monocarboxylic and dicarboxylic acids in fermentation media. Appl. Microbiol. 1975, 29, 374–381. [Google Scholar] [PubMed]

- Liu, J.; Han, B.; Deng, S.; Sun, S.; Chen, J. Changes in proteases and chemical compounds in the exterior and interior of sufu, a Chinese fermented soybean food, during manufacture. LWT—Food Sci. Technol. 2018, 87, 210–216. [Google Scholar] [CrossRef]

- Sánchez-Paniagua López, M.; Redondo-Gómez, E.; López-Ruiz, B. Electrochemical enzyme biosensors based on calcium phosphate materials for tyramine detection in food samples. Talanta 2017, 175, 209–216. [Google Scholar] [CrossRef] [PubMed]

- Giménez-Gómez, P.; Gutiérrez-Capitán, M.; Capdevila, F.; Puig-Pujol, A.; Fernández-Sánchez, C.; Jiménez-Jorquera, C. Monitoring of malolactic fermentation in wine using an electrochemical bienzymatic biosensor for l-lactate with long term stability. Anal. Chim. Acta 2016, 905, 126–133. [Google Scholar] [CrossRef] [PubMed]

| Chemicals Monitored | Fermentation Process | Techniques | Authors |

|---|---|---|---|

| Volatile flavour chemicals—acetates, ethyl esters, C4–C8 fatty acids | Grapes during yeast fermentation | Gas chromatography | Stashenko et al. [111] |

| Short chain monocarboxylic and dicarboxylic acids-butyl esters of volatile (C1–C7) and nonvolatile (lactic, succinic, and fumaric) acids | Microbial fermentation | Gas chromatography flame ionisation detection. | Salanitro and Muirhead [112] |

| Proteases and ethanol, ethylene glycol, glucose, isopropanol, and mannitol | Fermented soybean foods | Electrophoresis and 1H NMR methods | Liu et al. [113] |

| Malolactic fermentation compounds | Wine fermentation | Pulse-echo ultrasound of 1 MHz measurement using sound velocity | Resa et al. [77] |

| Oligosaccharides, improved fermentation rates, accelerated lactose hydrolysis | Probiotic fermented milk | 20 kHz low-frequency ultrasound technique | Nguyen et al. [73] |

| Total sugar content, alcohol, and pH | Rice Wine | UV-Vis and NIR spectroscopy coupled with multivariate analysis | Ouyang et al. [84] |

| Tyramine | Cheese | Electrochemical enzyme biosensor based on calcium phosphate | Sanchez-Paniagua Lopez et al. [114] |

| l-Lactic acid | Wine | Electrochemical bienzymatic | Gimenez-Gomez et al. [115] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chandra, S.; Chapman, J.; Power, A.; Roberts, J.; Cozzolino, D. The Application of State-of-the-Art Analytic Tools (Biosensors and Spectroscopy) in Beverage and Food Fermentation Process Monitoring. Fermentation 2017, 3, 50. https://doi.org/10.3390/fermentation3040050

Chandra S, Chapman J, Power A, Roberts J, Cozzolino D. The Application of State-of-the-Art Analytic Tools (Biosensors and Spectroscopy) in Beverage and Food Fermentation Process Monitoring. Fermentation. 2017; 3(4):50. https://doi.org/10.3390/fermentation3040050

Chicago/Turabian StyleChandra, Shaneel, James Chapman, Aoife Power, Jess Roberts, and Daniel Cozzolino. 2017. "The Application of State-of-the-Art Analytic Tools (Biosensors and Spectroscopy) in Beverage and Food Fermentation Process Monitoring" Fermentation 3, no. 4: 50. https://doi.org/10.3390/fermentation3040050