Reviews on Chinese Patents Regarding the Nickel/Metal Hydride Battery

Abstract

:1. Introduction

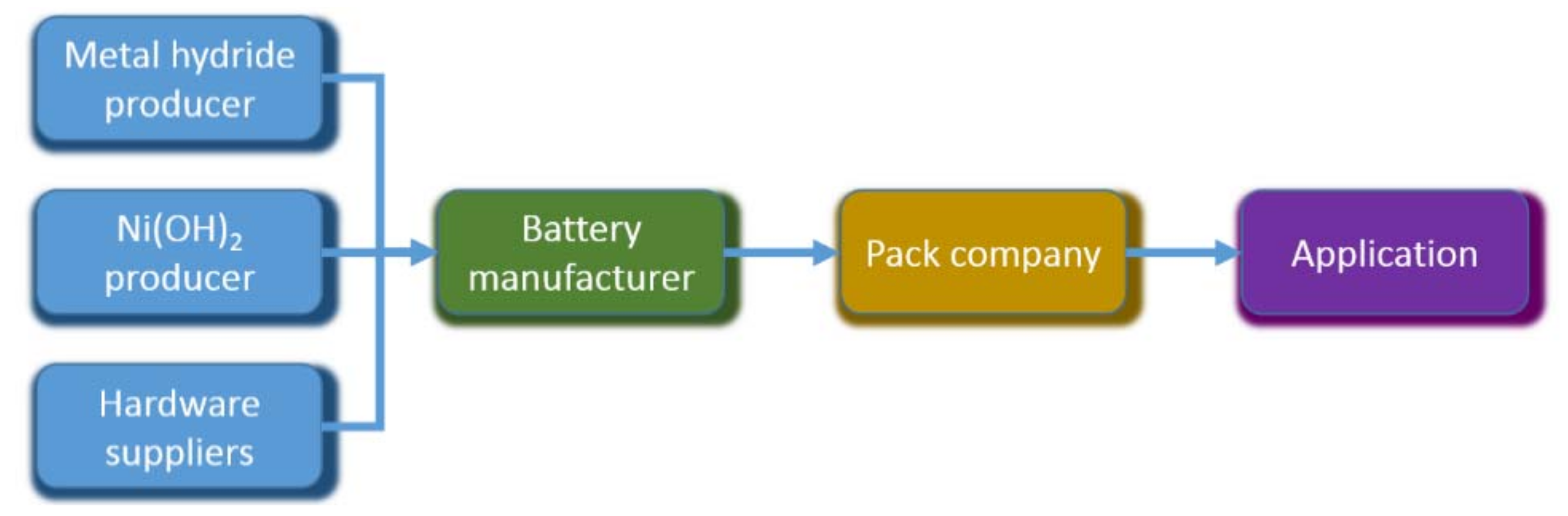

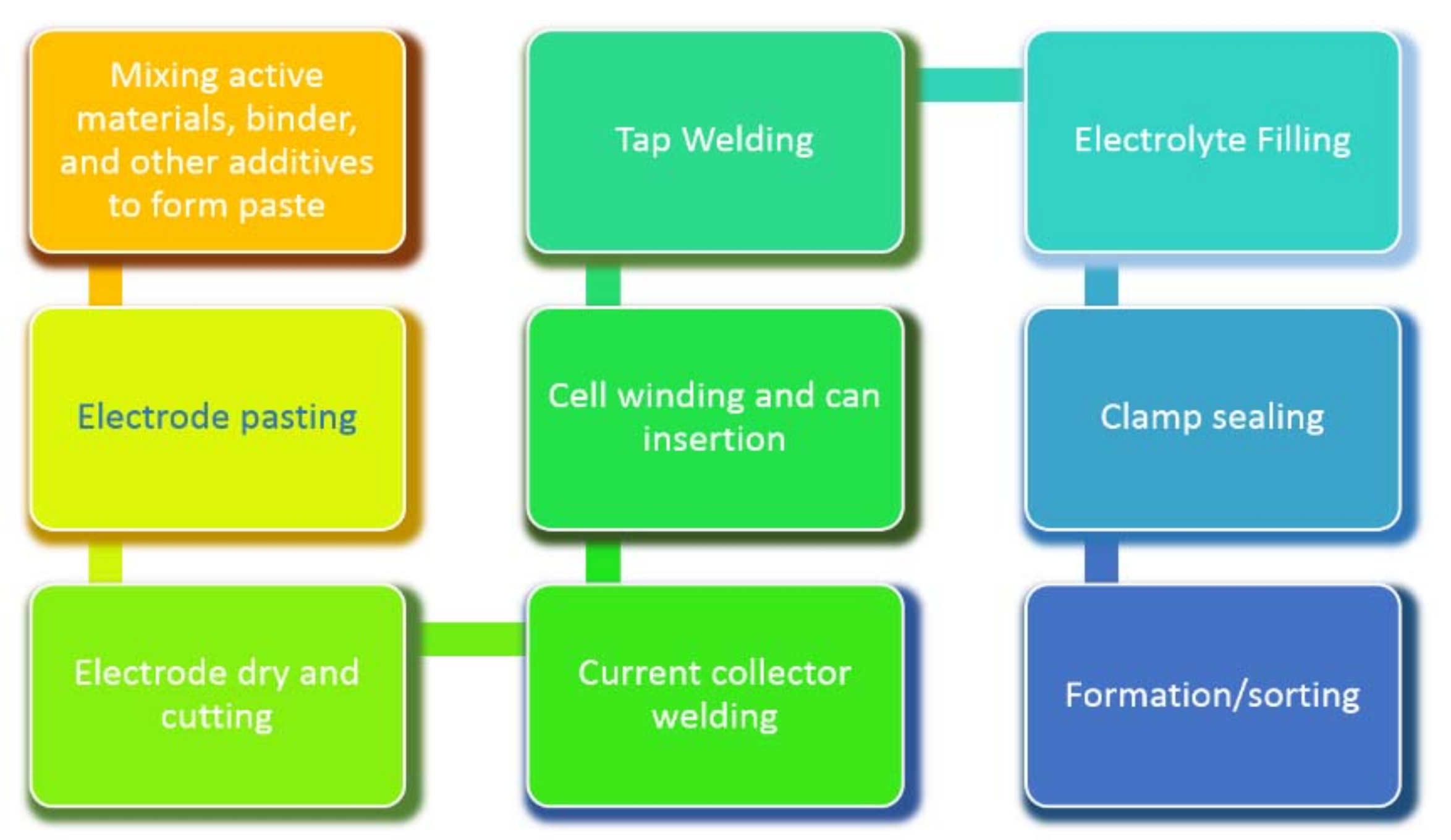

2. Nickel/Metal Hydride (Ni/MH) Battery Manufacturer

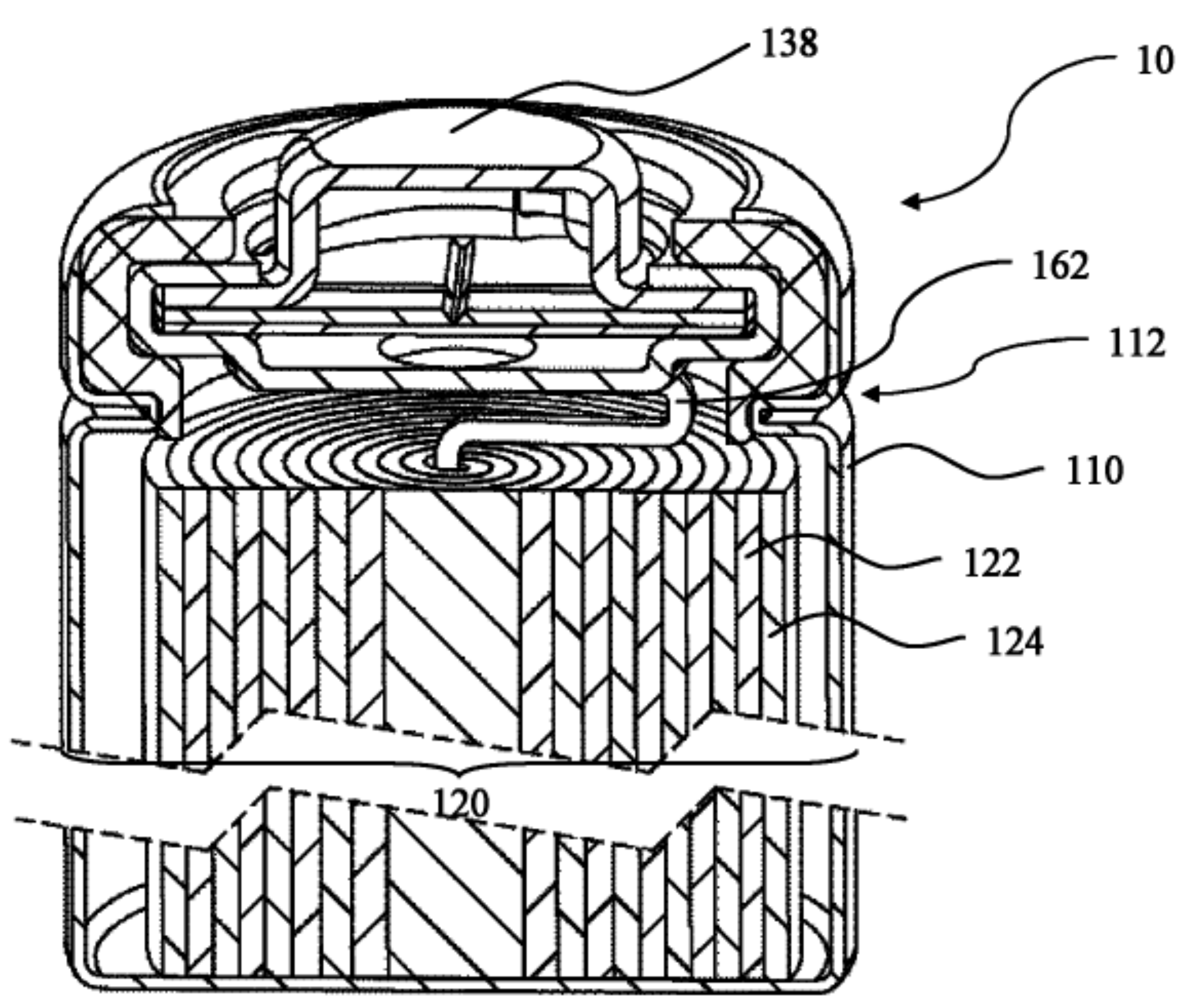

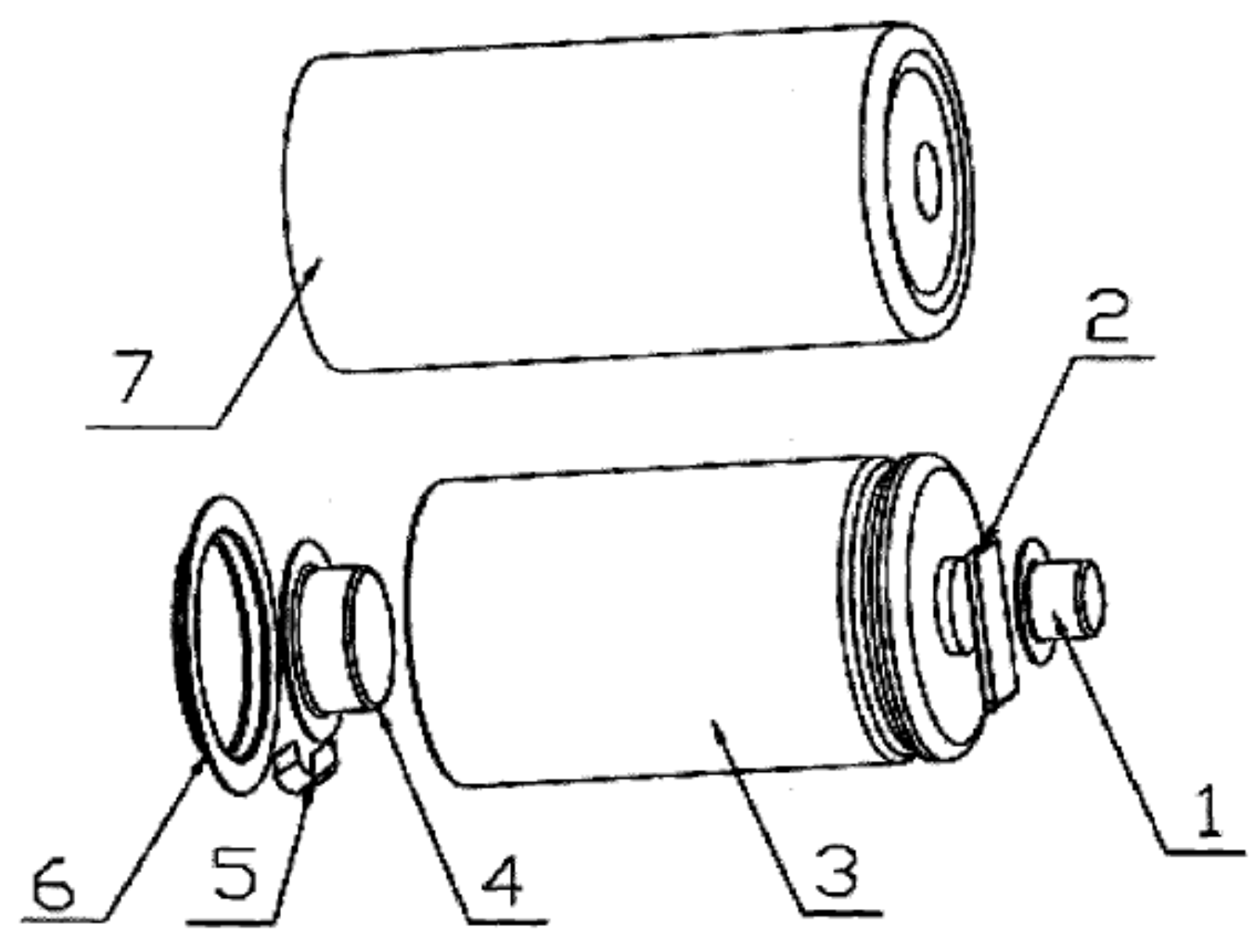

2.1. Gold Peak (GP)

2.2. Shenzhen HighPower

2.3. Corun

2.4. Suppo

2.5. BYD

2.6. Kan

2.7. Lexel

2.8. McNair

2.9. BetterPower

2.10. EPT

2.11. Grepow

2.12. JJJ

2.13. Great Power

2.14. Wewin

2.15. Other Battery Manufacturers

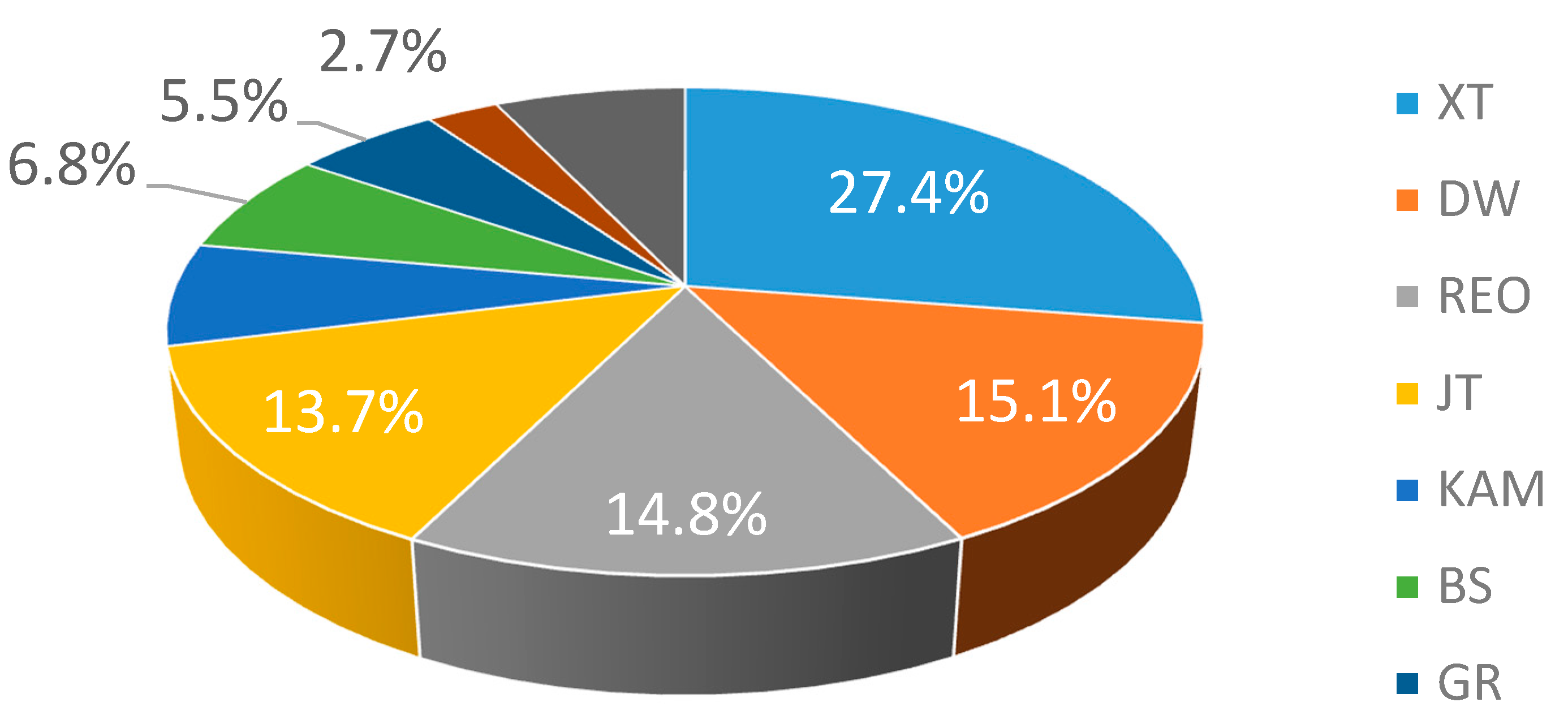

3. Metal Hydride Alloy Producer

3.1. Xiamen Tungsten

3.2. Doublewin

3.3. REO Metal Hydride

3.4. Jiangxi Tungsten

3.5. Kingpowers

3.6. Others

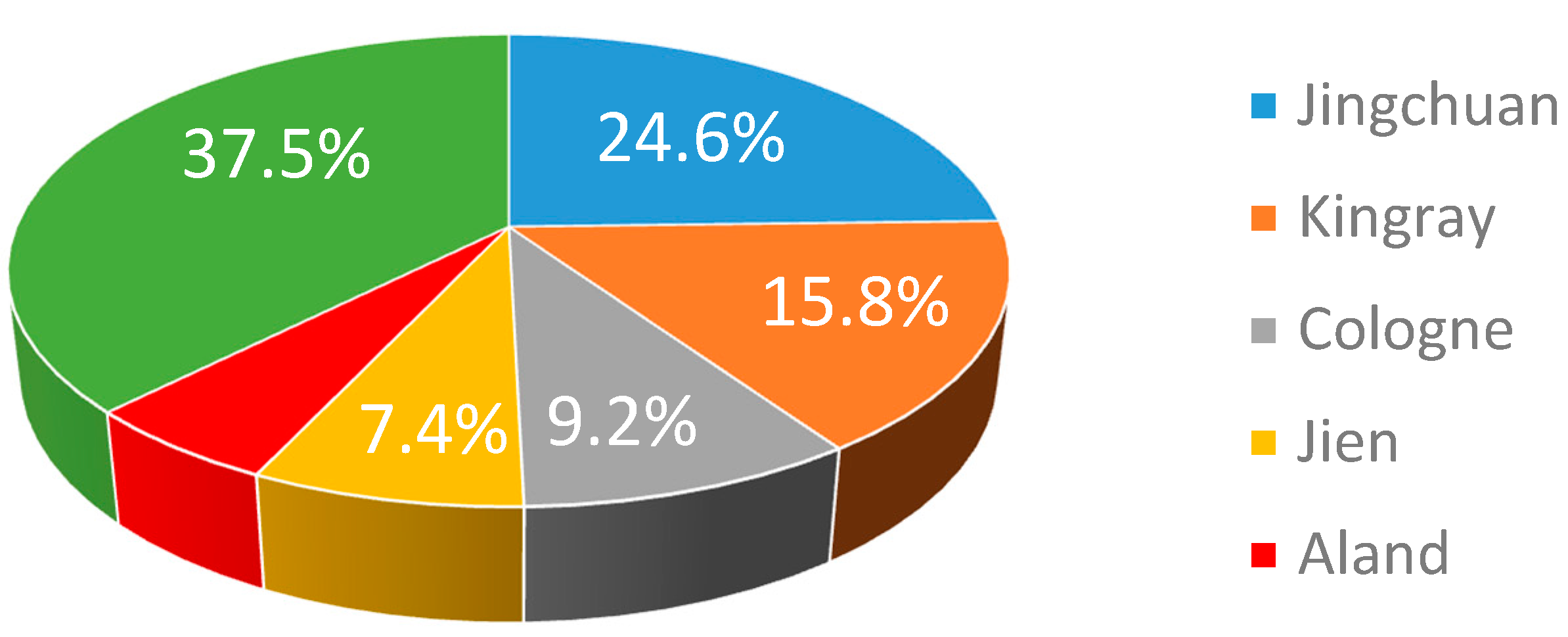

4. Ni(OH)2 Producer

4.1. Jinchuan

4.2. Kingray

4.3. Cologne

4.4. Jien

4.5. Aland

4.6. Others

5. Other Hardware Suppliers

5.1. Ni Foam

5.2. Separator

5.3. Stainless Steel Can

5.4. Negative Electrode Substrate

6. Applications

6.1. Consumer Type

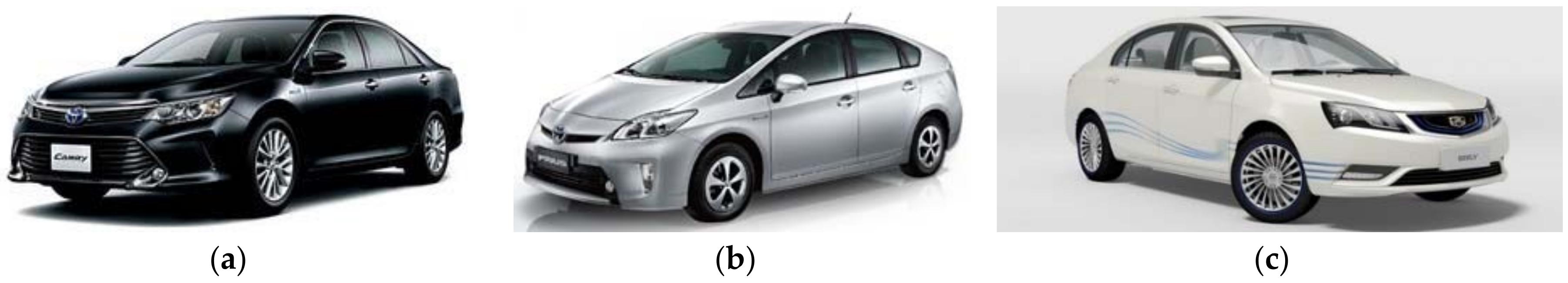

6.2. Transportation Type

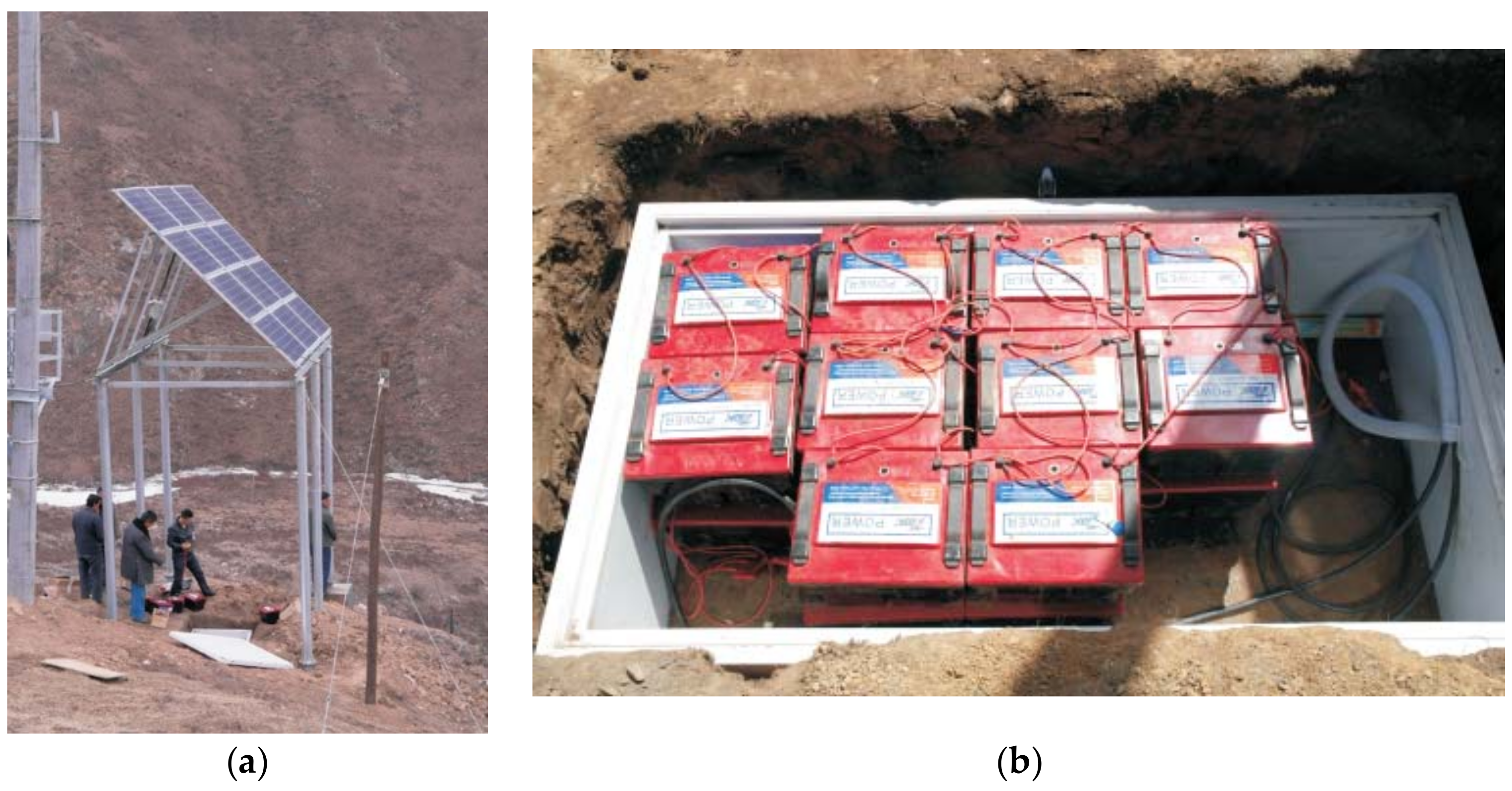

6.3. Stationary Type

7. Universities and Research Institutes

7.1. Beijing Institute of Technology

7.2. Beijing University of Chemical Technology

7.3. Tsinghua University

7.4. Tianjin University

7.5. Nankai University

7.6. Tianjin Polytechnic University

7.7. Shanghai Jao Tong University

7.8. Donghua University

7.9. Jilin University

7.10. Yanshan University

7.11. Sichuan University

7.12. University of Electronic Science and Technology of China (UESTC)

7.13. Zhejiang University

7.14. Zhejiang Normal University

7.15. South East University

7.16. Henan Polytechnic University

7.17. Guangdong University of Technology

7.18. South China University of Technology

7.19. Lanzhou University

7.20. Institute of Metal Research (IMR) in the Chinese Academy of Sciences

7.21. Changchun Institute of Applied Chemistry (CIAC) in the Chinese Academy of Sciences

7.22. Shanghai Institute of Microsystem and Information Technology (SIMIT) in the Chinese Academy of Sciences

7.23. Dalian Institute of Chemistry and Physics (DICP) in the Chinese Academy of Sciences

7.24. General Research Institute for Nonferrous Metals (GRINM)

7.25. Guangzhou Research Institute of Non-Ferrous Metals (GZRINM)

7.26. Baotou Rare Earth Research Institute (BRERI)

7.27. National Engineering Research Center for Nanotechnology (NERCN)

7.28. Guilin Geology and Mining Academe (GGMA)

7.29. Changsha Research Institute of Mining and Metallurgy (CRIMM)

7.30. China Electronics Technology Group Corporation (CETC) 18th Research Institute

7.31. Central Iron & Steel Research Institute (CISRI)

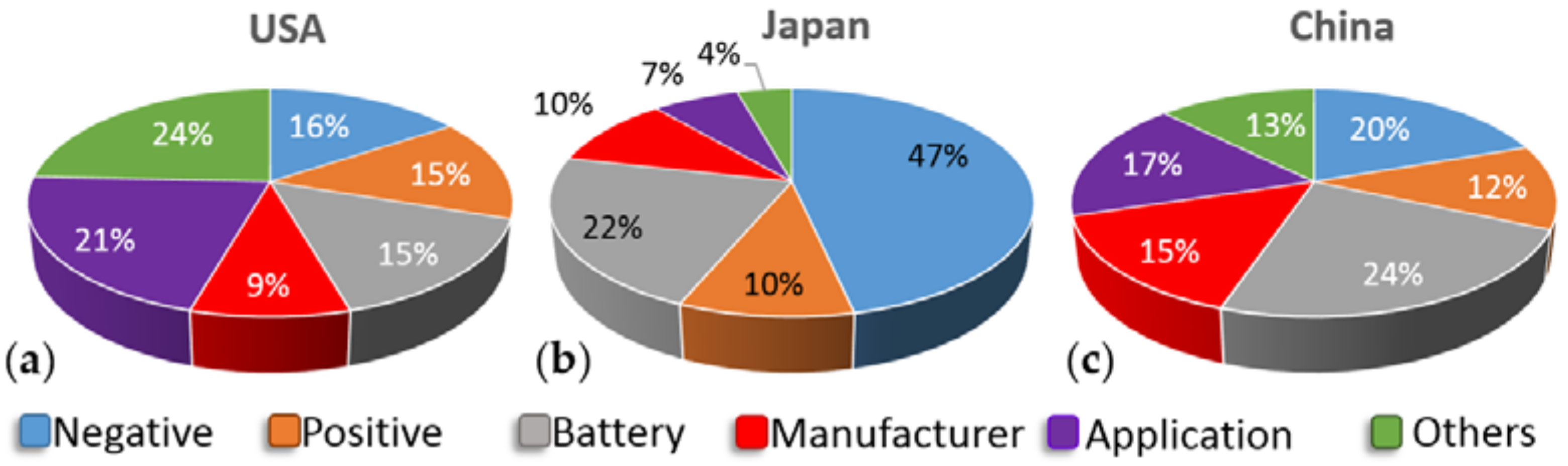

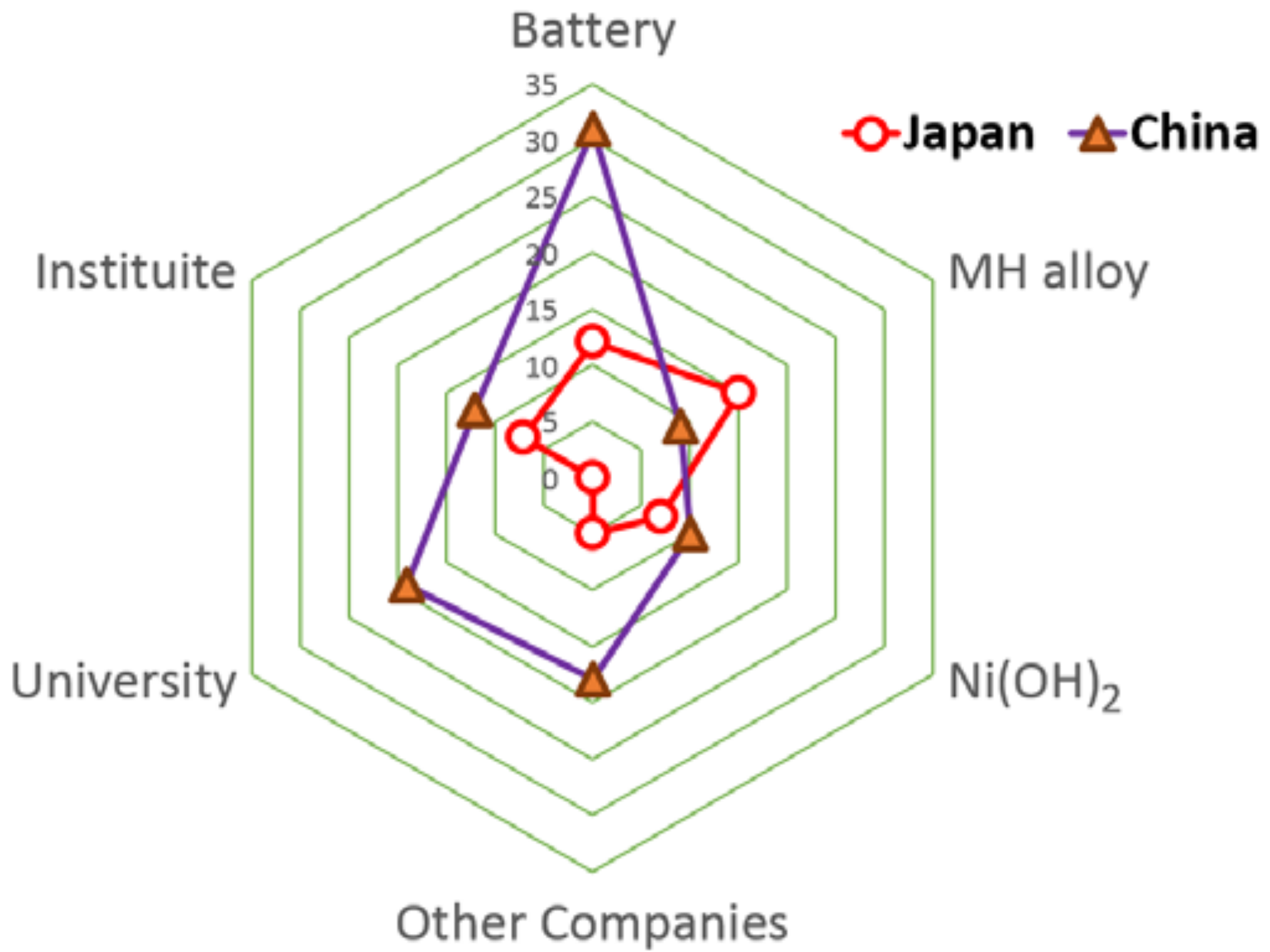

8. Comparisons

9. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| Ni/MH | Nickel/Metal Hydride |

| NiCd HEV | Nickel-Cadmium Hybrid Electrical Vehicle |

| MH | Metal Hydride |

| SIPO | State Intellectual Property Office of the People’s Republic of China |

| GP | Gold Peak |

| SZHP | Shenzhen HighPower |

| Li-PO | Lithium-Polymer |

| NPPS | Ni-Plated Perforated Steel |

| RE | Rare Earth |

| SBR | Styrene-Butadiene Rub |

| PTFE | Polytetrafluoroethylene |

| EV | Electrical Vehicle |

| REO | Rare-Earth OVONIC |

| PP | Polypropylene |

| CVD | Chemical Vapor Deposition |

| PE | Polyethylene |

| UPS | Un-Interrupted Power Supply |

| LED | Light Emitting Diode |

| UESTC | University of Electronic Science and Technology of China |

| CIAC | Changchun Institute of Applied Chemistry |

| SIMIT | Shanghai Institute of Microsystem and Information Technology |

| DICP | Dalian Institute of Chemistry and Physics |

| GNINM | General Research Institute for Nonferrous Metals |

| GZRINM | Guangzhou Research Institute of Non-Ferrous Metals |

| BRERI | Baotou Rare Earth Research Institute |

| NERCN | National Engineering Research Center for Nanotechnology |

| GGMA | Guilin Geology and Mining Academe |

| CRIMM | Changsha Research Institute of Mining and Metallurgy |

| CETC | China Electronics Technology Group Corporation |

| CISRI | Central Iron & Steel Research Institute |

References

- Zelinsky, M.; Koch, J. Batteries and Heat—A Recipe for Success? Available online: www.battcon.com/PapersFinal2013/16-Mike%20Zelinsky%20-%20Batteries%20and%20Heat.pdf (accessed on 5 July 2017).

- Young, K.; Ng, K.Y.S.; Bendersky, L. A Technical Report of the Robust Affordable Next Generation Energy Storage System-BASF Program. Batteries 2016, 2, 2. [Google Scholar] [CrossRef]

- Trapanese, M.; Franzitta, V.; Viola, A. Description of hysteresis of nickel metal hydride battery. In Proceedings of the 38th Annual Conference on IEEE Industrial Electronics Society (IECON) 2012, Montreal, QC, Canada, 25–28 October 2012; pp. 967–970. [Google Scholar]

- Köhler, U.; Kümpers, J.; Ullrich, M. High performance nickel-metal hydride and lithium-ion batteries. J. Power Sources 2002, 105, 139–144. [Google Scholar] [CrossRef]

- NiMH vs. Li-ion: A Battery Comparison. Available online: https://turbofuture.com/misc/Which-is-better-Nickel-Metal-Hydride-NiMH-or-Lithium-Ion-Li-ion-batteries (accessed on 5 July 2017).

- Trapanese, M.; Franzitta, V.; Viola, A. Description of hysteresis in lithium battery by classical Preisach model. Adv. Mater. Res. 2013, 622, 1099–1103. [Google Scholar]

- Trapanese, M.; Franzitta, V.; Viola, A. The Jiles Atherton model for description on hysteresis in lithium battery. In Proceedings of the 2013 Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 2772–2775. [Google Scholar]

- Teraoka, H. Development of Ni-MH ESS with Lifetime and Performance Estimation Technology. In Proceedings of the 34th International Battery Seminar & Exhibit, Fort Lauderdale, FL, USA, 20–23 March 2017. [Google Scholar]

- Teraoka, H. Ni-MH Stationary Energy Storage: Extreme Temperature & Long Life Developments. In Proceedings of the 33rd International Battery Seminar & Exhibit, Fort Lauderdale, FL, USA, 21–24 March 2016. [Google Scholar]

- Teraoka, H. Development of Highly Durable and Long Life Ni-MH Batteries for Energy Storage Systems. In Proceedings of the 32th International Battery Seminar & Exhibit, Fort Lauderdale, FL, USA, 9–12 March 2015. [Google Scholar]

- Ogawa, K. Toyota to start local production of NiMH battery cells in China by end of 2016. Nikkei Technology Online. 9 March 2016. Available online: http://techon.nikkeibp.co.jp/atclen/news_en/15mk/030900433/ (accessed on 2 November 2016).

- Chang, S.; Young, K.; Nei, J.; Fierro, C. Reviews on the U.S. Patents regarding nickel/metal hydride batteries. Batteries 2016, 2, 10. [Google Scholar] [CrossRef]

- Ouchi, T.; Young, K.; Moghe, D. Reviews on the Japanese Patent Applications regarding nickel/metal hydride batteries. Batteries 2016, 2, 21. [Google Scholar] [CrossRef]

- Patent Search and Analysis of SIPO. Available online: http://english.sipo.gov.cn/ (accessed on 2 November 2016).

- SooPAT Website. Available online: http://www2.soopat.com/Home/IIndex (accessed on 2 November 2016).

- Bai, W. The Current Status and Future Trends of Domestic and Foreign NiMH Battery Market. Available online: http://cbe.com/u/cms/201406/06163842rc01.pdf (accessed on 4 April 2017).

- You, P.; Cai, J.; Yu, H. Rechargeable Battery. Chinese Patent Application No. 201120521690, 13 December 2011. [Google Scholar]

- Wu, C.; Ling, P.; Chen, R. Method for Preparing Battery Roll Cores by Automatic Film Winding and Automatic Film Winder. Chinese Patent Application No. 201310582763, 18 November 2013. [Google Scholar]

- You, P.; Liu, B.; Su, Y. Battery. Chinese Patent Application No. 201210019480, 20 January 2012. [Google Scholar]

- Wu, C.; Chen, R.; Yu, H.; Lei, G. Battery Anode-Cathode Diaphragm, Preparation Method and Applications Thereof. Chinese Patent Application No. 201310482443, 15 October 2013. [Google Scholar]

- Wu, C.; Ling, P.; Chen, R.; Lei, G. Novel Battery Negative Electrode as Well as Preparation and Application Thereof. Chinese Patent Application No. 201310482441, 15 October 2013. [Google Scholar]

- Li, W.; Kong, L.; Wen, H.; Yang, W.; Li, X.; Xiong, S.; Han, X. Method for Making Battery Positive Plate and Positive Electrode Slurry Thereof. Chinese Patent Application No. 200710305063, 26 December 2007. [Google Scholar]

- Li, W.; Kong, L.; Wen, H.; Tian, X.; Han, X. Nickel-Hydrogen Battery and Preparation Method for Anode Material. Chinese Patent Application No. 200810068362, 8 July 2008. [Google Scholar]

- Zhou, Z.; Kong, L.; Li, W. Secondary battery anode piece and preparation method thereof. Chinese Patent Application No. 201110048145, 28 February 2011. [Google Scholar]

- Zou, J.; Yang, R.; Zhang, L.; Cai, X.; Liao, X.; Li, W.; Jiang, Y.; Yang, J.; Qian, W.; Chen, Y.; et al. Hydrogen Storage Alloy Material for Nickel-Hydrogen Battery and Preparation Method. Chinese Patent Application No. 201210117357, 19 April 2012. [Google Scholar]

- Liang, D.; Zou, J.; Zhang, L.; Liao, X.; Cai, X.; Kong, L. Battery Plate and Manufacturing Method Thereof. Chinese Patent Application No. 201110202077, 18 July 2011. [Google Scholar]

- Li, W. Long Time Stored Nickel-Hydrogen Battery and Manufacturing Method Thereof. Chinese Patent Application No. 200510034847, 31 May 2005. [Google Scholar]

- Li, W.; Guo, Y.; Han, X.; Huang, W.; Liao, X. Refitting Cylindrical Nickel-Hydrogen Battery. Chinese Patent Application No. 200920129531, 16 January 2009. [Google Scholar]

- Wen, H.; Li, X.; Kong, L.; Yin, S.; Li, W. Battery Positive Pole Cap. Chinese Patent Application No. 200920136056, 24 March 2009. [Google Scholar]

- Yang, W.; Liao, X.; Kong, L.; Li, W. Battery. Chinese Patent Application No. 201010505937, 12 October 2010. [Google Scholar]

- Yang, W.; He, R.; Cai, X.; Liao, X.; Yu, L.; Zhou, T.; Li, W. Tab and Battery with Using the Same. Chinese Patent Application No. 201320217146, 25 April 2013. [Google Scholar]

- Zou, J.; Liang, D.; Zhang, L.; Cai, X.; Liao, X.; Kong, L. Nickel-Metal Hydride Battery. Chinese Patent Application No. 201110194572, 12 July 2011. [Google Scholar]

- Wu, W.; Yang, W.; Cai, X.; Liao, X. Maintainable Long-Service-Life Secondary Battery. Chinese Patent Application No. 201520120349, 28 February 2015. [Google Scholar]

- Mo, X.; Yu, L.; Cheng, J.; Li, W. Novel Ultrathin Battery and Preparation Method Thereof. Chinese Patent Application No. 201510201345, 24 April 2015. [Google Scholar]

- Li, W.; Guo, Y.; Han, X.; Huang, W.; Liao, X. Refitted Cylindrical Hydrogen Nickel Battery. Chinese Patent Application No. 200920129530, 16 January 2009. [Google Scholar]

- Wang, X.; Su, Y.; Zhou, D.; Wu, Q.; Wen, H.; Li, W. Method for Manufacturing Battery Negative Pole Piece. Chinese Patent Application No. 200910107202, 30 April 2009. [Google Scholar]

- Li, W.; Ma, W. Battery Centrifugal Liquid Filling Method Using Clamp. Chinese Patent Application No. 200510034697, 25 May 2005. [Google Scholar]

- Tang, Z. Capacitance Dividing Cabinet Accuracy Testing Device. Chinese Patent Application No. 201420019634, 13 January 2014. [Google Scholar]

- Cao, D.; Yang, K.; Sun, S.; Liao, X. Spot Welding Tool of Piece is Drawn Forth to Battery. Chinese Patent Application No. 201520645622, 25 August 2015. [Google Scholar]

- Mo, X.; Yu, L.; Cheng, J.; Li, W. A Battery Test Apparatus. Chinese Patent Application No. 201520463569, 30 June 2015. [Google Scholar]

- Zhong, F.; He, C.; Chen, F. Nickel-Metal Hydride Battery and Positive Plate Thereof. Chinese Patent Application No. 201020111306, 9 February 2010. [Google Scholar]

- Xiong, X.; Yang, S.; Zhou, J.; Zhong, F. A Making Technology for Nickel Hydrogen High-Temperature Charging Battery. Chinese Patent Application No. 200610136707, 17 November 2006. [Google Scholar]

- Zhang, J.; He, C.; He, Y.; Dai, G.; Chen, X.; Jiang, S.; Pi, Y. Spherical Shape Nickel Hydroxide for High-Temperature Nickel Electric Cell. Chinese Patent Application No. 200710035470, 30 July 2007. [Google Scholar]

- Zhang, J.; He, C.; He, Y.; Dai, G.; Chen, X.; Jiang, S.; Pi, Y. Spherical Shape Nickel Hydroxide for High-Temperature Nickel Electric Cell. Chinese Patent Application No. 200710035471, 30 July 2007. [Google Scholar]

- He, C.; Chen, F.; Yang, Y.; Zhang, Y. Manufacturing Methods of Secondary Battery Negative Electrode Slice, Negative Electrode and Secondary Battery, and Secondary Battery Manufactured by Same. Chinese Patent Application No. 201010585009, 13 December 2010. [Google Scholar]

- Zhong, F.; He, C.; Chen, F. Preparation Method of Negative Plate of Chemical Battery. Chinese Patent Application No. 201010107805, 9 February 2010. [Google Scholar]

- Gao, J.; Yang, S.; Zhou, J.; Yao, S.; Wang, Y. Special Electrolytic Solution for Alkaline Nickel-Hydrogen Battery. Chinese Patent Application No. 200810143053, 7 October 2008. [Google Scholar]

- Yang, S.; Wang, X.; Zhou, J.; Zhong, F. High-Power Charging Battery. Chinese Patent Application No. 200620052560, 20 October 2006. [Google Scholar]

- Yan, S.; Wang, X.; Zhou, J.; Zhou, F. High Power Charging Battery Manufacture Process. Chinese Patent Application No. 200610032432, 20 October 2006. [Google Scholar]

- Zhou, C.; Luo, Y.; Yang, S.; Zhou, J. Cover-Cap for Cylindrical Battery and Cylindrical Battery. Chinese Patent Application No. 201410485861, 22 September 2014. [Google Scholar]

- Zhou, C.; Lu, D.; Zhou, J.; Liu, L. Cap for Circular Battery. Chinese Patent Application No. 201420207528, 25 April 2014. [Google Scholar]

- Zhong, F.; Ho, C.; Chen, F. Cylindrical battery. Chinese Patent Application No. 200980000348, 25 September 2009. [Google Scholar]

- Chen, F.; He, C.; Zhong, F. Cylindrical battery. Chinese Patent Application No. 200920066023, 25 September 2009. [Google Scholar]

- He, Y.; Lin, Y.; Tang, Z.; Zhang, C. Method and System for Classifying Battery Pole Pieces. Chinese Patent Application No. 201010202222, 18 June 2010. [Google Scholar]

- Chen, F.; He, C.; Zhong, F. Forming and Capacity Dividing Method. Chinese Patent Application No. 201010107736, 9 February 2010. [Google Scholar]

- Xiao, J.; Zhong, F.; Quan, G.; Yang, C.; Liu, B. Automatic Cap Welding All-In-One Machine. Chinese Patent Application No. 201510553196, 1 September 2015. [Google Scholar]

- Xiao, J.; Zhong, F.; Quan, G.; Yang, C.; Liu, B. Automatic Integrated Liquid Filling Machine. Chinese Patent Application No. 201510551892, 1 September 2015. [Google Scholar]

- Yang, S.; Liu, T.; Li, L.; Zhou, C. Forming Method of Nickel-Metal Hydride Battery. Chinese Patent Application No. 201410490021, 23 September 2014. [Google Scholar]

- Pang, L.; Chen, X.; Ye, D. Method for Preparing Cobalt Clad Beta-NiOOH by Liquid Phase Oxidation Method. Chinese Patent Application No. 201010565217, 30 November 2010. [Google Scholar]

- Huang, N.; Pang, L.; Fu, L. Conductive Skeleton for Negative Pole of Nickel-Hydrogen Battery. Chinese Patent Application No. 201020536041, 20 September 2010. [Google Scholar]

- Guo, J.; Guo, S.; Xia, C. High-Capacity Hydrogen-Bearing Alloy Powder with Long Service Life for High-Performance Secondary MH-Ni Battery. Chinese Patent Application No. 00123177, 31 October 2000. [Google Scholar]

- Huang, N.; Pang, L. Cylindrical Nickel-Hydrogen High Charge Retention Battery. Chinese Patent Application No. 200920014000, 27 May 2009. [Google Scholar]

- Li, W.; Zhou, W.; Wang, C. Method for Processing Cobalt Coated Nickel Hydroxide. Chinese Patent Application No. 02151988, 19 November 2002. [Google Scholar]

- Lu, H. High-Temperature Ni/H2 Battery and Its Manufacture. Chinese Patent Application No. 99116113, 5 April 1999. [Google Scholar]

- Zhou, W. Alkaline Secondary Battery Positive Electrode Material and Alkaline Secondary Battery. Chinese Patent Application No. 200510126001, 28 November 2005. [Google Scholar]

- Gu, M.; Zhang, X.; Zhou, W. Nickel Anode Accumulator Anode Slurry and Method for Preparing Anode Accumulator Using the Same. Chinese Patent Application No. 200710122892, 9 July 2007. [Google Scholar]

- Li, W.; Wang, C. Alkaline Secondary Cell. Chinese Patent Application No. 03140045, 2 August 2003. [Google Scholar]

- Zhou, W.; Chen, S.; Yu, F. Method for Preparing Alkaline Secondary Cell Anode Active Matter. Chinese Patent Application No. 200610109529, 4 August 2006. [Google Scholar]

- Cao, C. Composite Nickel Powder, Preparation Thereof, Nickel Anode and Alkaline Accumulator. Chinese Patent Application No. 200710198727, 10 December 2007. [Google Scholar]

- Zhu, Z. Positive Electrode Material, Positive Electrode and Battery Containing the Material and Preparing Process Thereof. Chinese Patent Application No. 200510087099, 26 July 2005. [Google Scholar]

- Zhou, W. Anode Active Substance and Its Preparing Method and Anode and Battery. Chinese Patent Application No. 200610141071, 29 September 2006. [Google Scholar]

- Deng, X.; Cheng, X.; Zhang, F.; Gong, Q. Hydrogen Storage Alloy Type Hydrogenation Catalyst and Preparation Method Thereof. Chinese Patent Application No. 200710077544, 3 December 2007. [Google Scholar]

- Geng, W. Hydrogen Storage Alloy Powder Surface Processing Method. Chinese Patent Application No. 200610111583, 28 August 2006. [Google Scholar]

- Feng, H. Surface Processing Method for Hydrogen Storage Alloy Powder. Chinese Patent Application No. 200810097956, 16 May 2008. [Google Scholar]

- Feng, H.; Geng, W. Method for Preparing Hydrogen Storage Alloy. Chinese Patent Application No. 200910106438, 27 March 2009. [Google Scholar]

- Yan, H. High Power Nickel-Hydrogen Accumulator Negative Electrode Active Substance and Its Preparation Method and Nickel-Hydrogen Accumulator. Chinese Patent Application No. 200510035315, 13 June 2005. [Google Scholar]

- Geng, W. Composite Particle, Nickel-Hydrogen Secondary Cell Negative-Pole and Cell and Method for Making Same. Chinese Patent Application No. 200510126115, 30 November 2005. [Google Scholar]

- Geng, W. Active Material for Nickel-Hydrogen Battery Cathode and Preparation Method Thereof. Chinese Patent Application No. 200710147646, 31 August 2007. [Google Scholar]

- Liu, T.; Tan, S. Steel Belt, Cell Negative Pole Using Said Steel Belt and Cell and Their Preparing Method. Chinese Patent Application No. 200510068305, 30 April 2005. [Google Scholar]

- Liu, T.; Tan, S. Steel Strip, Cell Cathode Using Same and Cell and Their Manufacture Methods. Chinese Patent Application No. 200510117681, 8 November 2005. [Google Scholar]

- Feng, H. Cathode Active Substance and Preparation Method Thereof, Cathode and Battery. Chinese Patent Application No. 200810146427, 28 August 2008. [Google Scholar]

- Geng, W. Nickel-Hydrogen Secondary Battery Negative Electrode and Battery and Producing Method. Chinese Patent Application No. 200510126002, 28 November 2005. [Google Scholar]

- Deng, X.; Cheng, X.; Zhang, F.; Gong, Q. Preparation Method of Hydrogen Storage Material. Chinese Patent Application No. 200810094115, 4 May 2008. [Google Scholar]

- Li, W.; Yan, H. Nickel-Hydrogen Battery Negative Pole and Battery Using Same and Preparing Method. Chinese Patent Application No. 200410101265, 17 December 2004. [Google Scholar]

- Xie, H.; Huang, Z. Electrode Material of Nickel-Hydrogen Battery and Preparation Method Thereof and Nickel-Hydrogen Battery. Chinese Patent Application No. 201010294722, 28 September 2010. [Google Scholar]

- Li, C.; Jiang, L.; Li, Q.; Gong, Q. Battery Isolating Film and Method for Producing the Same. Chinese Patent Application No. 200610170396, 29 December 2006. [Google Scholar]

- Xie, H.; Huang, Z. Nickel-Hydrogen Battery Diaphragm, and Preparation Method and Nickel-Hydrogen Battery Thereof. Chinese Patent Application No. 201010219090, 30 June 2010. [Google Scholar]

- Xie, H. Electrolyte of Nickel Hydrogen Battery and Nickel Hydrogen Battery. Chinese Patent Application No. 201010260261, 19 August 2010. [Google Scholar]

- Xie, H. Nickel Hydrogen Secondary Battery. Chinese Patent Application No. 200910188446, 27 November 2009. [Google Scholar]

- Zhang, J.; Wang, H.; Wang, C. Cylindrical Alkaline Secondary Battery and its Seal Ring Module. Chinese Patent Application No. 03238936, 10 March 2003. [Google Scholar]

- Lun, Y.; He, Y.; Deng, S. Secondary Battery. Chinese Patent Application No. 200820213846, 21 November 2008. [Google Scholar]

- Lun, Y. Secondary Battery. Chinese Patent Application No. 200920129200, 12 January 2009. [Google Scholar]

- Zhu, Z.; Sun, L. Battery Assembling Cap. Chinese Patent Application No. 200620017913, 23 August 2006. [Google Scholar]

- Lun, Y. Electrode Terminal, Battery Cover Cap Containing the Electrode Terminal and Battery Thereof. Chinese Patent Application No. 200820094941, 21 June 2008. [Google Scholar]

- He, Z.; Liu, W. Battery Metal Flow Collection Band. Chinese Patent Application No. 200420102334, 3 December 2004. [Google Scholar]

- Huang, Z.; Chen, Q. Hydrogen Storage Alloy and Hydrogen Storage Alloy Cathode Including the Same. Chinese Patent Application No. 200610127740, 1 September 2006. [Google Scholar]

- Zhang, F. Hydrogen Storage Alloy and Its Preparation Method. Chinese Patent Application No. 200610167384, 31 December 2006. [Google Scholar]

- Pan, Y.; Geng, W. Hydrogen Storage Alloy, Preparation Thereof, and Cathode and Battery Using the Hydrogen Storage Alloy. Chinese Patent Application No. 200710147642, 31 August 2007. [Google Scholar]

- Yang, Y. Hydrogen Storage Alloy, Preparation Method Thereof and Negative Pole and Battery Containing Hydrogen Storage Alloy. Chinese Patent Application No. 200810126837, 26 June 2008. [Google Scholar]

- Wang, B.; Gao, M.; Liu, Y.; Chen, J.; Feng, R. High-Power Nickel-Metal Hydride Battery and Manufacturing Method Thereof. Chinese Patent Application No. 201210405985, 23 October 2012. [Google Scholar]

- Jin, Z.; Wang, Z.; He, R.; Wu, Y.; Wu, D.; Liu, W.; Liu, J.; Fan, C. Nickel-Hydrogen Battery Positive Plate. Chinese Patent Application No. 201520589228, 7 August 2015. [Google Scholar]

- Wang, B.; Pan, H.; Gao, M. Secondary Battery with High-Rate Discharge Characteristic. Chinese Patent Application No. 201220543651, 23 October 2012. [Google Scholar]

- Wang, B.; Pan, H.; Gao, M. High-Power Nickel-Metal Hydride Battery. Chinese Patent Application No. 201220545556, 23 October 2012. [Google Scholar]

- Wang, B.; Pan, H.; Guo, M. Secondary Battery Capable of Improving High-Rate Discharge Property of Secondary Battery. Chinese Patent Application No. 201220543416, 23 October 2012. [Google Scholar]

- Wang, B.; Gao, M.; Liu, Y.; Chen, J.; Feng, R. Secondary Battery with Improved High-Ratio Discharge Performance and Production Method of Secondary Battery. Chinese Patent Application No. 201210406152, 23 October 2012. [Google Scholar]

- Pan, Y.; Che, J.; Zhu, W.; Pan, W. Electromagnetic Clutch Driving Winder. Chinese Patent Application No. 201120327340, 2 September 2011. [Google Scholar]

- Pan, Y.; Chen, J.; Zhu, W.; Pan, W. Chute Device for Shunting of Negative Plates. Chinese Patent Application No. 201120327287, 2 September 2011. [Google Scholar]

- Pan, Y.; Chen, J.; Zhu, W.; Pan, W. Polar Plate Receiving Device. Chinese Patent Application No. 201120327407, 2 September 2011. [Google Scholar]

- Pan, Y.; Chen, J.; Zhu, W.; Pan, W. Connecting Device for Eliminating Stress of Automatic Spot Welding Machine. Chinese Patent Application No. 201120327257, 2 September 2011. [Google Scholar]

- Jin, Z.; Liu, J.; Wu, Y.; Pan, G.; Zhang, W. Automatic Battery Cap Press. Chinese Patent Application No. 201520168069, 24 March 2015. [Google Scholar]

- Gao, X.; Xie, X.; Zhang, P.; Liao, S.; Yang, Y. High Temperature Composite Additive Agent for Nickel Base Charging Battery. Chinese Patent Application No. 200610061895, 27 July 2006. [Google Scholar]

- Gao, X.; Liao, S.; Xie, X.; Yang, Y. Nickel Hydrogen Charging Battery. Chinese Patent Application No. 200710073554, 16 March 2007. [Google Scholar]

- Long, Q.; Xie, J.; Xie, X. Voltage Internal Resistance General-Purpose Tester. Chinese Patent Application No. 201220068181, 28 February 2012. [Google Scholar]

- Long, Q.; Xie, J.; Yuan, H.; Wang, J. Nickel-Hydrogen Battery Thermistor of Group Tester. Chinese Patent Application No. 201520856256, 30 October 2015. [Google Scholar]

- Peng, H.; Zeng, S.; Xie, H.; Xie, J. Battery Cleaning Machine. Chinese Patent Application No. 201220056525, 21 February 2012. [Google Scholar]

- Peng, H.; Yan, Y.; Wang, J. Whitewashed Device is Scraped to Nickel-Hydrogen Battery Negative Pole. Chinese Patent Application No. 201520845461, 28 October 2015. [Google Scholar]

- Luo, Q.; Xie, X. Nickel-Hydrogen Battery Capable of Being Used in Low-Temperature Environment and Preparation Method Thereof. Chinese Patent Application No. 201210043538, 24 February 2012. [Google Scholar]

- Yu, Y.; Peng, H. Rechargeable Nickel-Hydrogen Battery. Chinese Patent Application No. 201220056523, 21 February 2012. [Google Scholar]

- Gao, X.; Che, Y. Sealed Ni/MH Battery. Chinese Patent Application No. 99243344, 23 September 1999. [Google Scholar]

- Li, Z.; Li, Q.; Yang, S. A Nickel-Hydrogen High-Temperature Battery and Its Making Method. Chinese Patent Application No. 200810027050, 27 March 2008. [Google Scholar]

- Li, Z.; Li, Q.; Chen, H. Nickel Hydrogen Quick Charging Battery and its Making Method. Chinese Patent Application No. 200810027053, 27 March 2008. [Google Scholar]

- Li, Z.; Li, Q.; Tian, X.; Liu, Y. Nickel-Hydrogen Low Self-Discharge Battery. Chinese Patent Application No. 200810027054, 27 March 2008. [Google Scholar]

- Long, X.; Ye, K.; Guan, T.; Zhang, Y.; Bin, J. Method of Manufacturing Nickel-Metal Hydride Battery. Chinese Patent Application No. 201110191333, 8 July 2011. [Google Scholar]

- Fan, Z.; Guan, D.; Long, X.; Ye, K.; Zhang, Y. Method for Preparing Nickel Battery. Chinese Patent Application No. 200910188936, 15 December 2009. [Google Scholar]

- Long, X.; Ye, K.; Fan, Z. Positive Base Material of Battery. Chinese Patent Application No. 200920144753, 27 February 2009. [Google Scholar]

- Long, X.; Ye, K.; Fan, Z. Nickel-Metal Hydride Battery Cathode Alkali Treatment Method. Chinese Patent Application No. 200910136112, 30 April 2009. [Google Scholar]

- Long, X.; Ye, K.; Fan, Z. Nickel-Hydrogen Power Battery Cathode. Chinese Patent Application No. 200920151587, 30 April 2009. [Google Scholar]

- Fan, Z.; Long, X.; Ye, K. Battery Anti-Explosion System. Chinese Patent Application No. 200910036407, 4 January 2009. [Google Scholar]

- Fan, Z.; Long, X.; Ye, K. High Temperature Failure Rubber. Chinese Patent Application No. 200910036691, 15 January 2009. [Google Scholar]

- Long, X.; Ye, K.; Fan, Z.; Guan, D.; Zhang, Y. Welding of Battery Nickel Sheets. Chinese Patent Application No. 200910041975, 19 August 2009. [Google Scholar]

- Long, X.; Ye, K. Nickel Battery with Multi-Layer Membrane. Chinese Patent Application No. 200820214287, 5 December 2008. [Google Scholar]

- Long, X.; Ye, K. Cell Casing with Active Layer and Cell Using Same. Chinese Patent Application No. 200820235079, 15 December 2008. [Google Scholar]

- Long, X.; Ye, K.; Fan, Z. Steel Shell of Cylindrical Cell. Chinese Patent Application No. 200920050216, 15 January 2009. [Google Scholar]

- Fan, Z.; Guan, D.; Long, X.; Ye, K.; Zhang, Y. Manufacturing Method of Cylindrical Battery. Chinese Patent Application No. 200910189079, 18 December 2009. [Google Scholar]

- Long, X.; Xu, X.; Zhou, W.; Cheng, Z. Flexibly-Packaged Elliptic Battery. Chinese Patent Application No. 201120441364, 9 November 2011. [Google Scholar]

- Long, X.; Xu, X.; Zhou, W.; Cheng, Z. Soft Packaging Cylindrical Battery. Chinese Patent Application No. 201120441377, 9 November 2011. [Google Scholar]

- Long, X.; Ran, G.; Long, Z. Automatic Dust Removal Machine. Chinese Patent Application No. 201510782747, 16 November 2015. [Google Scholar]

- Long, X.; Ran, G.; Long, Z. Automatic Edge-Folding Machine. Chinese Patent Application No. 201510786877, 16 November 2015. [Google Scholar]

- Long, X.; Li, J.; Guan, D.; Zhao, S.; Li, X. Combined Type Cell (9V). Chinese Patent Application No. 201430441530, 11 November 2014. [Google Scholar]

- Guan, S.; Wang, L.; Zhao, S.; Shi, S.; Xiong, K.; Guo, J.; Yuan, X.; Li, J. Electrolyte and Electrochemical Component Using Same. Chinese Patent Application No. 201310216070, 3 June 2013. [Google Scholar]

- Liang, D.; Meng, Z.; Wang, S.; Tang, Y. Formation-Free Nickel-Metal Hydride Battery and Manufacturing Method Thereof. Chinese Patent Application No. 201310293737, 12 July 2013. [Google Scholar]

- Yang, Z.; Peng, D.; Wang, S.; Liu, X.; Wang, W.; Ji, J. Manufacturing Process for Positive Plate of Nickel-Hydrogen Rechargeable Battery. Chinese Patent Application No. 200910190780, 10 October 2009. [Google Scholar]

- Liang, S.; Ciao, S.; Wang, W.; Ciao, H. A Negative Electrode Sheet for a Nickel-Hydrogen Battery and a Method for Producing the Same and a Nickel-Hydrogen Battery. Chinese Patent Application No. 201510452395, 28 July 2015. [Google Scholar]

- Zhou, J.; Wang, S. Manufacturing Technology of High Power Charging Battery. Chinese Patent Application No. 200310112211, 20 November 2003. [Google Scholar]

- Zheng, L. Cap Pressing Device for Batteries. Chinese Patent Application No. 201110103881, 25 April 2011. [Google Scholar]

- Liang, D.; Wang, W.; Tang, Y. Cylindrical Alkaline Battery and Sealing Ring Thereof. Chinese Patent Application No. 201420673268, 12 November 2014. [Google Scholar]

- Wei, N.; Peng, D.; Wang, S.; Yu, D.; Mo, Y. Charging Battery and Assembling Structure of Charging Battery Cover and Current Collector. Chinese Patent Application No. 201020690810, 30 December 2010. [Google Scholar]

- Hu, Y.; Jia, H.; Liu, M. Nickel-Hydrogen Battery Discharging at Low Temperature and High Multiplying Power and Preparation Method and Negative Plate Thereof. Chinese Patent Application No. 200910119762, 26 March 2010. [Google Scholar]

- Liu, M.; Jia, H.; Hu, Y. Low-Capacity Nickel-Metal Hydride Secondary Battery and Assembly Method Thereof. Chinese Patent Application No. 200910261710, 28 December 2009. [Google Scholar]

- Xu, Z.; Fan, Z. Novel Nickel-Hydrogen Power Battery. Chinese Patent Application No. 200520053766, 11 January 2005. [Google Scholar]

- Liu, M.; Liu, J. Wide-Temperature Range and High-Power Nickel-Hydrogen Battery and Preparation Technology Thereof. Chinese Patent Application No. 201511015536, 30 December 2015. [Google Scholar]

- Liu, M.; Liu, J. Low Internal Resistance Nickel-Hydrogen Battery. Chinese Patent Application No. 201521125143, 30 December 2015. [Google Scholar]

- Zhu, M.; Tao, G.; Zhu, Y.; Deng, X. Battery System. Chinese Patent Application No. 201620013831, 6 January 2016. [Google Scholar]

- Zhu, M.; Gao, D.; Guo, Q.; Huang, C. Battery System. Chinese Patent Application No. 201610009992, 6 January 2016. [Google Scholar]

- Liu, M.; Liu, J. A Cylindrical Nickel Metal Hydride Battery. Chinese Patent Application No. 201521118986, 12 December 2015. [Google Scholar]

- Liu, M.; Liu, J. Cylindrical Nickel-Metal Hydride Battery and Negative Pole Wet-Method Powder Scraping Process. Chinese Patent Application No. 201511010831, 30 December 2015. [Google Scholar]

- Li, M.; Lu, Y.; Ou, X.; Lian, W.; Xie, H.; Lin, Z.; Yang, F.; Tan, B. Nickel-Hydrogen Battery and Manufacturing Technique Thereof. Chinese Patent Application No. 92101326, 9 March 1992. [Google Scholar]

- Xu, J.; Zhang, H.; Ouyang, J. Injection Method for Battery Electrolyte. Chinese Patent Application No. 201110237409, 18 August 2011. [Google Scholar]

- Lin, Y.; Tan, W.; Tan, Y.; Li, W.; Chen, X.; Tan, G. Battery Sealing Machine. Chinese Patent Application No. 201110237406, 18 August 2011. [Google Scholar]

- Lin, Y.; Tan, W.; Tan, Y.; Li, W.; Chen, X.; Tan, G. Spreading Machine for Battery. Chinese Patent Application No. 201110237390, 18 August 2011. [Google Scholar]

- Chen, J.; Huang, Z.; Zhang, H.; Ouyang, J. Recovery Method of Ni-MH Battery Negative Pole Waste. Chinese Patent Application No. 201110237411, 18 August 2011. [Google Scholar]

- Huang, Z.; Huang, J.; Chen, J.; Huang, B.; Zhang, H.; Ouyang, J. An anti-Explosion Battery Cap. Chinese Patent Application No. 201120301061, 18 August 2011. [Google Scholar]

- Huang, J.; Huang, Z.; Chen, J.; Huang, B.; Zhang, H.; Ouyang, J. D-Type Low Capacity Battery Structure. Chinese Patent Application No. 201120301104, 18 August 2011. [Google Scholar]

- Zhang, H.; Huang, J.; Chen, J.; Huang, B.; Ouyang, J. Power Battery Current-Collecting Disc. Chinese Patent Application No. 201120301102, 18 August 2011. [Google Scholar]

- Nan, J.; Hou, X.; Xue, J. Nickel-Hydrogen Alkaline Battery and Preparation Method Thereof. Chinese Patent Application No. 200410077333, 9 December 2004. [Google Scholar]

- Zeng, X.; Xia, X.; Xue, J. Battery Plus Plate Current-Collector and Producing Technology Thereof. Chinese Patent Application No. 200610122367, 25 September 2006. [Google Scholar]

- Xia, X.; Nan, J.; Meng, X. Alkaline Battery Cover. Chinese Patent Application No. 200320117076, 13 October 2003. [Google Scholar]

- Liu, J.; Xia, X.; Xue, J. Negative Electrode of NiMH Battery and Its Making Process. Chinese Patent Application No. 02134370, 17 July 2002. [Google Scholar]

- Huang, T.; Wang, J. Composite Hydrogen Storage Alloy for NiMH Battery Cathode. Chinese Patent Application No. 200810197606, 12 November 2008. [Google Scholar]

- Wu, H.; Liu, X.; Huang, J. Nickel-Hydrogen Battery Pack Provided with Detection Device. Chinese Patent Application No. 201010229034, 16 July 2010. [Google Scholar]

- Liu, X.; Wu, H.; Huang, J. Nickel-Metal Hydride Battery Set with Detecting Device. Chinese Patent Application No. 201020261323, 17 July 2010. [Google Scholar]

- Wu, H.; Sun, J.; Yang, R.; Wang, T. Equalization Charging Device of Nickel-Metal Hydride Battery. Chinese Patent Application No. 201220070633, 29 February 2012. [Google Scholar]

- Wang, T.; Tu, J.; Yang, R. Charger with Nickel-Hydrogen Battery Overcharging Prevention Function. Chinese Patent Application No. 201220241474, 25 May 2012. [Google Scholar]

- Sun, J.; Jiang, Z. Nickel-Metal Hydride Battery Facilitating Heat Dissipation. Chinese Patent Application No. 201220241313, 25 May 2012. [Google Scholar]

- Sun, J.; Wu, H.; Yang, R. Nickel-Metal Hydride Battery with Anti-Overheating Function and Stable Structure. Chinese Patent Application No. 201220180479, 25 April 2012. [Google Scholar]

- Wu, H.; Sun, J.; Wang, T. Control Device for Preventing Nickel-Hydrogen Battery Overdischarge. Chinese Patent Application No. 201220180491, 25 April 2012. [Google Scholar]

- Sun, J.; Wu, H. Low-Cost Nickel-Metal Hydride Battery Provided with Electrodes of High Winding Performance. Chinese Patent Application No. 201220180477, 25 April 2012. [Google Scholar]

- Wu, H.; Sun, J.; Yang, R.; Wang, T. Square Nickel-Metal Hydride Battery, Battery Pack and Electric Vehicle Using Battery Pack. Chinese Patent Application No. 201220070631, 29 February 2012. [Google Scholar]

- Huang, J.; Huang, J.; Wu, H. Cathode Current Collecting Structure of Nickel-Hydrogen Battery. Chinese Patent Application No. 200920131330, 20 April 2009. [Google Scholar]

- Wu, H.; Sun, J.; Huang, J. Rechargeable Battery and Cap Thereof. Chinese Patent Application No. 201220292409, 21 June 2012. [Google Scholar]

- Sun, J.; Wu, H.; Jiang, M. High-Power Rechargeable Battery Current Collector and Rechargeable Battery Thereof. Chinese Patent Application No. 201220290378, 20 June 2012. [Google Scholar]

- Huang, J.; Huang, J.; Wu, H. Battery Negative Plate. Chinese Patent Application No. 200920131329, 20 April 2009. [Google Scholar]

- Sun, J.; Jiang, Z.; Huang, J. Positioning Clamping Device of Battery Pole Piece. Chinese Patent Application No. 201220290379, 20 June 2012. [Google Scholar]

- Sun, J.; Wu, H.; Jiang, M. Centrifugal Dryer Used for Battery Pole Piece. Chinese Patent Application No. 201220290372, 20 June 2012. [Google Scholar]

- Sun, J.; Wu, H.; Huang, J. Electrolyte Injector with Heating Function. Chinese Patent Application No. 201220290380, 20 June 2012. [Google Scholar]

- Chen, Y.; Yang, H.; Wu, C.; Chao, D. High Iron Hydrogen Storage Electrode Alloy, Preparation Method Thereof and Nickel-Hydrogen Battery Cathode Material. Chinese Patent Application No. 201110144878, 31 May 2011. [Google Scholar]

- Meng, Z.; He, Y.; Sun, W. Nickel-Metal Hydride Battery Pack for Pure Electric Bus. Chinese Patent Application No. 201410159453, 21 April 2014. [Google Scholar]

- Zhang, X.; Sun, W.; Lin, X.; Wu, Y. High-Temperature Nickel-Metal Hydride Battery. Chinese Patent Application No. 201010287314, 20 September 2010. [Google Scholar]

- Zhang, X.; Wu, Y.; Li, H.; Li, X.; Sun, W. High-Power Nickel-Hydrogen Battery. Chinese Patent Application No. 201120023136, 25 January 2011. [Google Scholar]

- Tang, C.; Cheng, S.; Hu, C.; Zhang, M.; Guo, H.; Wang, F.; Zhou, Z.; Li, P. Antioxidant for Alkaline Cell and Alkaline Cell Using Antioxidant. Chinese Patent Application No. 201310272023, 2 July 2013. [Google Scholar]

- Wang, L.; Sun, Y. Alkaline Secondary Cell Diaphragm and Its Producing Method. Chinese Patent Application No. 200410056887, 27 August 2004. [Google Scholar]

- Cao, Y.; Yang, T.; Guo, J. Manufacturing Method of Alkaline Battery Electrode and Battery Produced Using Said Method. Chinese Patent Application No. 01144538, 19 December 2001. [Google Scholar]

- Cao, Y.; Yang, T.; Guo, J. Manufacturing method of alkaline battery electrode and battery produced using said method. Chinese Patent Application No. 01144539, 19 December 2001. [Google Scholar]

- Cao, Y.; Xie, F. Secondary NiMH Battery. Chinese Patent Application No. 200620115719, 31 May 2006. [Google Scholar]

- Li, W. Manufacturing Method of Nickel Hydrogen Battery Negative Electrode Material. Chinese Patent Application No. 03100898, 27 January 2003. [Google Scholar]

- Wu, Y.; Deng, Z.; Zeng, Y.; He, L.; Deng, Z.; Zhu, D. Nickel-Hydrogen Power Battery and Preparation Method Therefor. Chinese Patent Application No. 201510434308, 22 July 2015. [Google Scholar]

- Wu, Y.; Zhu, D.; Lv, D.; Chang, J.; Wang, C.; Wen, X.; He, Y.; Xia, Z. Cylindrical Nickel-Hydrogen Power Cell. Chinese Patent Application No. 201220096555, 15 March 2012. [Google Scholar]

- Wu, Y.; Zhu, D.; Lv, D.; Chang, J.; Wang, C.; Wen, X.; He, Y.; Xia, Z. Nickel-Hydrogen Battery. Chinese Patent Application No. 201220096530, 15 March 2012. [Google Scholar]

- Wu, Y.; Zhu, D.; Lv, D.; Jing, J.; Wang, C.; Wen, X.; He, Y.; Xia, Z. Dual-Purpose Power Battery. Chinese Patent Application No. 201220096554, 15 March 2012. [Google Scholar]

- Wu, Y.; Zhu, D.; Lv, D.; Chang, J.; Wang, C.; Wen, X.; He, Y.; Xia, Z. Novel Nickel-Hydrogen Power Battery. Chinese Patent Application No. 201220096553, 15 March 2012. [Google Scholar]

- Wu, Y. High-Efficiency Nickel Metal Hydrogen Power Battery. Chinese Patent Application No. 201420456274, 14 August 2014. [Google Scholar]

- Wu, Y.; Zhu, D.; Lv, D.; Chang, J.; Wang, C.; Wen, X.; He, Y.; Xia, Z. Novel Square Ni-MH Power Battery. Chinese Patent Application No. 201220096552, 15 March 2012. [Google Scholar]

- Wu, Y.; Zhu, D.; Lv, D.; Chang, J.; Wang, C.; Wen, X.; He, Y.; Xia, Z. Composite Novel Nickel-Metal Hydride Battery. Chinese Patent Application No. 201220096558, 15 March 2012. [Google Scholar]

- Wu, Y.; Zhu, D.; Lv, D.; Chang, J.; Wang, C.; Wen, X.; He, Y.; Xia, Z. Novel Nickel-Metal Hydride Battery. Chinese Patent Application No. 201220096556, 15 March 2012. [Google Scholar]

- Deng, Z.; Zeng, Y.; He, L.; Wu, Y.; Wang, L.; Zhu, D. Large Capacity Ni-MH Power Battery. Chinese Patent Application No. 201520322087, 18 May 2015. [Google Scholar]

- Wu, Y. High-Temperature and Low-Temperature Nickel-Hydrogen Power Cell with Super-High Multiplying Power. Chinese Patent Application No. 201420456286, 14 August 2014. [Google Scholar]

- Deng, Z.; Zeng, Y.; He, L.; Wu, Y.; Wang, L.; Zhu, D. A High-Power Ni-MH Battery Suitable for a Wide Temperature Range. Chinese Patent Application No. 201520322089, 18 May 2015. [Google Scholar]

- Li, X. Negative Pole Polar Plate Recycle Device. Chinese Patent Application No. 201620139343, 23 February 2016. [Google Scholar]

- Zhang, T.; Chen, Y.; Zhang, P.; Gu, Y. Double Electric Pole Columns Power Type Square Body Nickel-Hydrogen Battery. Chinese Patent Application No. 200710156932, 20 November 2007. [Google Scholar]

- Zhang, T.; Chen, Y.; Zhang, P.; Gu, Y. Power Type Cube Nickel-Hydrogen Batteries of Module Electric Core. Chinese Patent Application No. 200710156935, 20 November 2007. [Google Scholar]

- Gu, Y.; Zhang, J.; Bai, Y.; Zhu, Y.; Mo, Z.; Qian, L. Nickel-Hydrogen Battery Positive Electrode Sheet Manufacturing Method and Manufacturing Apparatus Thereof. Chinese Patent Application No. 201210431784, 1 November 2012. [Google Scholar]

- Gu, Y.; Zhang, J.; Zhu, Y.; Mo, Z.; He, Y.; Qian, L. Low-Temperature Nickel-Hydrogen Battery and Preparation Method Thereof. Chinese Patent Application No. 201210431080, 1 November 2012. [Google Scholar]

- Gu, Y.; Zhang, J.; Chen, A.; Mo, Z.; Qian, L. High Temperature Nickel-Hydrogen Battery and Preparation Method Thereof. Chinese Patent Application No. 201210430545, 1 November 2012. [Google Scholar]

- Tian, X.; Zhou, S. Square Battery Shell. Chinese Patent Application No. 201320083480, 25 February 2013. [Google Scholar]

- Tian, X.; Zhou, S. Rectangular Battery and Manufacturing Method Thereof. Chinese Patent Application No. 201310058048, 25 February 2013. [Google Scholar]

- Tian, X.; Zhou, S. Square Battery. Chinese Patent Application No. 201320083860, 25 February 2013. [Google Scholar]

- Cao, S.; Jiang, Z.; Yin, L.; Huangfu, Y.; Wang, Y.; Jia, C.; Wu, F.; Zhao, X.; Zhang, L.; Zhang, W.; et al. Hybrid Cars Battery Module and its Battery Pack. Chinese Patent Application No. 201610875601, 30 September 2016. [Google Scholar]

- Cao, S.; Huangfu, Y.; Yin, L.; Wang, Y.; Jia, C.; Zhao, X.; Zhang, L.; Ji, Y.; Zhang, W.; Zheng, Z.; et al. Cell Connector. Chinese Patent Application No. 201610875603, 30 September 2016. [Google Scholar]

- Li, J.; Cao, S.; Jia, C.; Wu, F.; Yan, Q.; Zhang, W.; Hou, S. Nickel-Metal Hydride Battery Pack for Electric Bicycle. Chinese Patent Application No. 201020158887, 19 March 2010. [Google Scholar]

- Xu, S.; Liang, W.; Zhang, Z.; Yang, Y.; Cao, S.; Zhang, W.; Ma, Y.; Zhang, X.; Xu, G.; Xing, Z.; et al. Precharging Technique for Forming Nickel Hydrogen Battery. Chinese Patent Application No. 200610151962, 3 September 2006. [Google Scholar]

- Li, J.; Cao, S.; Jia, C.; Zhang, L.; Huangfu, Y.; Wang, Y.; Zhang, W.; Yang, T. Battery Micro-Short Low-Temperature Detection Method. Chinese Patent Application No. 201310118797, 8 April 2013. [Google Scholar]

- Li, J.; Cao, S.; Jia, C.; Chang, Z.; Huangfu, Y.; Wang, Y.; Yin, L.; Ma, Y. Electrode Slurry Mixing Method. Chinese Patent Application No. 201310118746, 8 April 2013. [Google Scholar]

- Li, J.; Cao, S.; Jia, C.; Huangfu, Y.; Zhang, W.; Chen, S.; Miao, R.; Wu, H. Cathode Coating Device. Chinese Patent Application No. 201320127460, 20 March 2013. [Google Scholar]

- Zhang, Z.; Zhang, X.; Xu, G. Multi-Way Paste-Applicator with Welding Headspace. Chinese Patent Application No. 200420065793, 1 July 2004. [Google Scholar]

- Li, J.; Cao, S.; Jia, C.; Wu, F.; Huangfu, Y.; Wang, Y.; Chen, S.; Du, J. Method for Eliminating Battery Plate Stress. Chinese Patent Application No. 201310118460, 8 April 2013. [Google Scholar]

- Cao, S.; Chang, Z.; Huang, F.; Li, J.; Li, J.; Shi, Q.; Xu, S.; Yang, Y. Nickel-Metal Hydride Battery Electrode Burr Punching Machine. Chinese Patent Application No. 201020158886, 19 March 2010. [Google Scholar]

- Cao, S.; Jiang, Z.; Chang, Z.; Huangfu, Y.; Yin, L.; Wang, Y.; Jian, C.; Zhao, X.; Li, J.; Ji, Y. Pole Piece Conveying Positioner. Chinese Patent Application No. 201520224145, 15 April 2015. [Google Scholar]

- Zhang, Z.; Xu, S.; Yang, Y.; Chang, Z.; Ma, Y.; Zhao, X.; Feng, H.; Liu, J.; Liu, Z. Ultrasonic Welding Machine of Current Collecting Belt of Positive Plate. Chinese Patent Application No. 201020154887, 19 March 2010. [Google Scholar]

- Cao, S.; Jiang, Z.; Chang, Z.; Huangfu, Y.; Yin, L.; Wu, F.; Wang, Y.; Jia, C.; Hu, D.; Zheng, Z. Battery Insulated Ring Assembly Device. Chinese Patent Application No. 201520224142, 15 April 2015. [Google Scholar]

- Li, J.; Cao, S.; Jia, C.; Huangfu, Y.; Wang, Y.; Yin, L.; Zhang, W. Cylindrical Battery Insulation Space Ring. Chinese Patent Application No. 201320128321, 20 March 2013. [Google Scholar]

- Li, J.; Cao, S.; Xu, G.; Ma, Y.; Jia, C.; Wang, Y.; Shi, Q.; Chang, Z. Connecting Component for Nickel-Hydrogen Battery Groups. Chinese Patent Application No. 201020154903, 19 March 2010. [Google Scholar]

- Zhao, P.; Chen, P.; Ma, G. High Power Nickel-Metal Hydride Battery. Chinese Patent Application No. 201120029381, 28 January 2011. [Google Scholar]

- Ma, G.; Cao, Y. Super-Wide-Temperature-Range Nickel-Hydrogen Battery and Manufacturing Method Therefor. Chinese Patent Application No. 201510746318, 15 November 2015. [Google Scholar]

- Chen, P.; Hu, Z.; Ma, G. Method for Manufacturing Ultra-High Temperature Overcharging-Resistance Long Service Life Nickel-Hydrogen Battery. Chinese Patent Application No. 201310173019, 11 May 2013. [Google Scholar]

- Hu, Z.; Chen, P.; Ma, G. Method for Manufacturing Ultra-High Temperature Long-Service Life Nickel-Hydrogen Batteries. Chinese Patent Application No. 201410816955, 24 December 2014. [Google Scholar]

- Cao, Y.; Ma, G. Novel Low Capacity Nickel-Hydrogen Battery of Structure. Chinese Patent Application No. 201520803268, 15 October 2015. [Google Scholar]

- Ma, G. A Flat Supporting Flame to Produce Cylindrical Ni-MH Battery. Chinese Patent Application No. 201710018936, 11 January 2017. [Google Scholar]

- Gao, P.; Huang, D.; Fan, H.; Wang, F.; Lou, L. Method for Improving Air Impermeability of Cylindrical Battery and Cylindrical Battery. Chinese Patent Application No. 201410791776, 19 December 2014. [Google Scholar]

- Hu, Z. Novel Structure of Safety Type Nickel-Metal Hydride Battery. Chinese Patent Application No. 201320565787, 12 September 2013. [Google Scholar]

- Hu, Z.; Chen, P.; Ma, G. Nickel-Metal Hydride Battery. Chinese Patent Application No. 201120029358, 28 January 2011. [Google Scholar]

- Ma, G.; Chen, P. Nickel Hydrogen-Nickel Cadmium Battery. Chinese Patent Application No. 201120029357, 28 January 2011. [Google Scholar]

- Peng, L. Rapid Liquid Feeding Device for Nickel-Metal Hydride Battery. Chinese Patent Application No. 201320565780, 12 September 2013. [Google Scholar]

- Tang, B.; Ma, G. A Gumming Device for on Battery Positive Plate Softening Machine. Chinese Patent Application No. 201520827309, 22 October 2015. [Google Scholar]

- Zhang, Y.; Zhu, Y.; Li, L. Super Power Nickel-Hydrogen Battery Overturning Traditional Technology. Chinese Patent Application No. 201310083759, 4 March 2013. [Google Scholar]

- Zhang, Y.; Ge, K.; Si, W. Novel Nickel-Metallic Oxide Cell Structure. Chinese Patent Application No. 201220358743, 23 July 2012. [Google Scholar]

- Zhang, Y. Nickel-Metal Hydride Battery Charger. Chinese Patent Application No. 201220358739, 23 July 2012. [Google Scholar]

- Zhang, Y.; Ge, K. A Prismatic Sealed Battery Module. Chinese Patent Application No. 201220358692, 23 July 2012. [Google Scholar]

- Zhang, Y. Sealing Structure for Square Metal-Casing Storage Battery Post. Chinese Patent Application No. 201220357573, 23 July 2012. [Google Scholar]

- Zhang, Y. Square Plastic-Casing Sealed Storage Battery. Chinese Patent Application No. 201220358740, 23 July 2012. [Google Scholar]

- Zhang, Y.; Ge, K. Steel Shell Battery Seal Structure. Chinese Patent Application No. 201220357555, 23 July 2012. [Google Scholar]

- Zhang, Y. Compound Sealing Device of Battery Electrode Column. Chinese Patent Application No. 201020609670, 16 November 2010. [Google Scholar]

- Xu, Y.; Qiu, J.; Ge, C.; He, X.; Liu, Q. Low-Capacity High-Power Nickel-Hydrogen Battery. Chinese Patent Application No. 200520073477, 6 July 2005. [Google Scholar]

- Xu, Y.; Ge, C.; Jiang, X.; Qiu, J.; He, X.; Xia, B.; Liu, Q. High Power Ni/MH Battery. Chinese Patent Application No. 200620069267, 8 February 2006. [Google Scholar]

- Li, G.; Xu, Y.; Dong, M.; Li, X.; Zhang, L. Battery Connecting Apparatus. Chinese Patent Application No. 200810168497, 30 September 2008. [Google Scholar]

- Li, G.; Xu, Y.; Yu, Z. Battery Group with Temperature Regulating Device. Chinese Patent Application No. 201010283138, 16 September 2010. [Google Scholar]

- Xu, Y.; Li, G.; Dong, M.; Li, X.; Lu, Y.; Yue, J. Liquid Cooling Device of Battery Set. Chinese Patent Application No. 200910115238, 20 April 2009. [Google Scholar]

- Dong, M.; Li, G.; Li, X.; Xu, Y.; Zhong, Z. Method for Charging Battery Pack. Chinese Patent Application No. 200910186454, 3 November 2009. [Google Scholar]

- Chen, D. Dynamic High-Capacity Nickel-Hydrogen Battery and Production Process Thereof. Chinese Patent Application No. 200910225295, 13 November 2009. [Google Scholar]

- Chen, D.; Chen, W.; Li, P.; Zhang, G.; Yin, C. Ni/MH Power Battery and Production Technology Thereof. Chinese Patent Application No. 201110201987, 19 July 2011. [Google Scholar]

- Chen, D.; Chen, W.; Li, P.; Zhang, G.; Yin, C. Nickel-Hydrogen Power Battery. Chinese Patent Application No. 201120254890, 19 July 2011. [Google Scholar]

- Chen, D.; Chen, W.; Li, P.; Zhang, L. Ultralow-Capacity Battery and Powder Pulling Die for Manufacturing Battery. Chinese Patent Application No. 201310268984, 1 July 2013. [Google Scholar]

- Chen, D.; Chen, W.; Li, P.; Zhang, G.; Yin, C. Method for Producing High Temperature Nickel-Metal Hydride Battery. Chinese Patent Application No. 201110455378, 31 December 2011. [Google Scholar]

- Chen, D.; Chen, W.; Li, P.; Zhang, G.; Yin, C. Manufacturing Method of Nickel-Metal Hydride Battery Capable of Being Stored for Long Time. Chinese Patent Application No. 201110455379, 31 December 2011. [Google Scholar]

- Chen, W.; Chen, D.; Li, P.; Zhang, G. Production Method for Positive Pole of High-Power Nickel-Metal Hydride Battery. Chinese Patent Application No. 201210289894, 15 August 2012. [Google Scholar]

- Chen, D.; Chen, W.; Li, P. Novel Welding Method for Anode Tab and Foamed Nickel of Battery. Chinese Patent Application No. 201310367366, 22 August 2013. [Google Scholar]

- Chen, D.; Chen, W.; Li, P.; Zhang, G.; Yin, C. Method for Preparing Anode of High-Power Nickel-Hydrogen Battery. Chinese Patent Application No. 201110174707, 27 June 2011. [Google Scholar]

- Chen, D.; Chen, W.; Li, P.; Zhang, G.; Yin, C. Battery Diaphragm with Improved Structure and Production Technology Thereof. Chinese Patent Application No. 201110211199, 27 July 2011. [Google Scholar]

- Chen, D.; Chen, W.; Li, P.; Zhang, G.; Yin, C. Nickel-Metal Hydride Battery Cathode Preparing Method. Chinese Patent Application No. 201110350094, 8 November 2011. [Google Scholar]

- Chen, D.; Chen, W.; Li, P.; Zhang, G.; Yin, C. High-Temperature Nickel-Metal Hydride Battery and Manufacturing Method Thereof. Chinese Patent Application No. 201110381832, 28 November 2011. [Google Scholar]

- Chen, W.; Chen, D.; Chen, X.; Lyu, G.; Liu, Y. Novel Battery Separation Membrane. Chinese Patent Application No. 201510249811, 16 May 2015. [Google Scholar]

- Chen, D.; Chen, W.; Chen, C.; Zhang, G. Rapid Charging Power Battery. Chinese Patent Application No. 201610571747, 20 July 2016. [Google Scholar]

- Zou, B.; Hu, X. Novel Knot Formula Nickel-Hydrogen Battery. Chinese Patent Application No. 201520557708, 29 July 2015. [Google Scholar]

- Zou, B.; Hu, X. Knot Formula Nickel-Hydrogen Battery. Chinese Patent Application No. 201520557757, 29 July 2015. [Google Scholar]

- Zou, B.; Hu, X. Formula Nickel-Hydrogen Battery is Detained in Low Internal Resistance. Chinese Patent Application No. 201520557650, 29 July 2015. [Google Scholar]

- Zou, B.; Hu, X. Low-Cost Knot Formla Nickel-Hydrogen Battery. Chinese Patent Application No. 201520557651, 29 July 2015. [Google Scholar]

- Yang, Y.; Li, Q.; Li, X. Cladding Nickel Electrode and Preparation Method Thereof. Chinese Patent Application No. 201410272553, 18 June 2014. [Google Scholar]

- Yang, Y.; Li, X.; Lei, Y.; Wang, X. NiMH Battery Electrolyte Additive, and an Electrolyte Containing a Nickel Hydrogen Battery Additives. Chinese Patent Application No. 201610925948, 31 October 2016. [Google Scholar]

- Di, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. Ordinary Battery External Wrapping Film and Preparation Method Thereof. Chinese Patent Application No. 201610248734, 19 April 2016. [Google Scholar]

- Zhai, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. Low-Self-Discharging Battery Outer Wrapping Thin Film and Preparing Method Thereof. Chinese Patent Application No. 201610248753, 19 April 2016. [Google Scholar]

- Zhai, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. Film for Wrapping Exteriors of High Capacity Batteries and Preparation Process Thereof. Chinese Patent Application No. 201610248752, 19 April 2016. [Google Scholar]

- Zhai, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. External Coating Thin Film of Power Battery and Preparation Method Thereof. Chinese Patent Application No. 201610248748, 19 April 2016. [Google Scholar]

- Zhai, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. Film for Wrapping Exteriors of High-Temperature Batteries and Preparation Method Thereof. Chinese Patent Application No. 201610248738, 19 April 2016. [Google Scholar]

- Zhai, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. Special Sealant for Ordinary Batteries and Preparation Process Thereof. Chinese Patent Application No. 201610248732, 19 April 2016. [Google Scholar]

- Zhai, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. Special Sealant for High Capacity Batteries and Preparation Process Thereof. Chinese Patent Application No. 201610248740, 19 April 2016. [Google Scholar]

- Zhai, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. Special Sealant for High-Temperature Batteries and Preparation Process Thereof. Chinese Patent Application No. 201610248747, 19 April 2016. [Google Scholar]

- Zhai, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. Seal Gum Specially Used for Low-Self-Discharge Battery and Preparation Process of Same. Chinese Patent Application No. 201610248757, 19 April 2016. [Google Scholar]

- Zhai, E.; Qiu, C.; Chen, T.; Guan, S.; Li, J.; Zheng, X.; Yin, D. Sealant Special for Power Batteries and Preparation Process of Sealant. Chinese Patent Application No. 201610248751, 19 April 2016. [Google Scholar]

- Zhai, E. Anode Material of Nickel-Metal Hydride Battery. Chinese Patent Application No. 201410270953, 17 June 2014. [Google Scholar]

- Li, J. Preparation Method of High-Temperature Ni-MH Power Battery. Chinese Patent Application No. 201210538083, 13 December 2012. [Google Scholar]

- Huang, P.; Li, H.; Zhai, E. Preparation Method of Low Self-Discharge Nickel-Metal Hydride Battery. Chinese Patent Application No. 201410541530, 14 October 2014. [Google Scholar]

- Li, J. Pole-Piece-Free Non-Sinding High-Power-Capacity Nickel-Hydrogen Battery and Processing Technology Thereof. Chinese Patent Application No. 201210355458, 18 September 2012. [Google Scholar]

- Zhai, E.; Chen, T.; Li, J. High Voltage Nickel-Metal Hydride Battery Safety Protective Device. Chinese Patent Application No. 201510352510, 24 June 2015. [Google Scholar]

- Zhai, E.; Chen, T.; Li, J. Energy-Saving Type High-Power Nickel Metal Hydride Battery. Chinese Patent Application No. 201510352144, 24 June 2015. [Google Scholar]

- Zhai, E.; Chen, T.; Li, J. Heat Dissipation Type Nickel-Metal Hydride Battery. Chinese Patent Application No. 201510352233, 24 June 2015. [Google Scholar]

- Zhai, E.; Chen, T.; Li, J. Low-Power-Consumption Overvoltage Protective Device for Nickel-Metal Hydride Battery. Chinese Patent Application No. 201510352123, 24 June 2015. [Google Scholar]

- Zhai, E.; Chen, T.; Li, J. Environment-Friendly High-Capacity Nickel-Hydrogen Battery. Chinese Patent Application No. 201510352143, 24 June 2015. [Google Scholar]

- Zhai, D.; Guo, D.; Han, N.; Zhu, R.; Cui, W.; Wang, R. Glue Solution for Surface Treatment of Nickel-Metal Hydride (NiMH) Battery Plate and Gum Dipping Device. Chinese Patent Application No. 201010189698, 28 May 2010. [Google Scholar]

- Wang, R.; Wang, X.; Guo, D.; Fan, J. An Assembled Powder Scraping Apparatus for the Dary Method of Preparing Positive Electrode of Ni-MH Batteries. Chinese Patent Application No. 201120065653, 14 March 2011. [Google Scholar]

- Guan, Y.; Su, W.; Yuan, T. Square Nickel-Metal Hydride Battery. Chinese Patent Application No. 201120319631, 29 August 2011. [Google Scholar]

- Guan, Y.; Su, W.; Yuan, T. Environment-Friendly Nickel-Metal Hydride Battery. Chinese Patent Application No. 201120319658, 29 August 2011. [Google Scholar]

- Chen, P. High-Voltage Nickel-Metal Hydride Battery Structure. Chinese Patent Application No. 201320338290, 7 June 2013. [Google Scholar]

- Chen, P. High-Power Nickel-Hydrogen Battery. Chinese Patent Application No. 201120116046, 19 April 2011. [Google Scholar]

- Chen, P. A High-Power Ni-MH Battery. Chinese Patent Application No. 201420355227, 30 June 2014. [Google Scholar]

- Chen, P. A Non-Winding High-Capacity Ni-MH Battery. Chinese Patent Application No. 201420350094, 29 June 2014. [Google Scholar]

- Chen, P. High-Capacity Nickel-Hydrogen Battery Pack with Self-Provided Charger. Chinese Patent Application No. 201120168375, 24 May 2011. [Google Scholar]

- Chen, P. Multifunctional Charger with Various Input and Output Modes. Chinese Patent Application No. 201120124612, 25 April 2011. [Google Scholar]

- Liu, Q.; Gao, G.; He, J.; Liu, J.; Zhu, Z.; Jia, F. Nickel-Hydrogen Battery Negative Pole Slurry Scraping Device. Chinese Patent Application No. 201620012233, 7 January 2016. [Google Scholar]

- Gao, G.; He, J.; Liu, J.; Liu, Q.; Zhu, Z.; Jia, F. Nickel-Hydrogen Battery Positive Plate Dust Removal Rubberizing Device. Chinese Patent Application No. 201620076470, 26 January 2016. [Google Scholar]

- Wu, Y.; Liu, Q.; Gao, G.; Liu, J.; Zhu, Z.; Jia, F. Power Nickel-Hydrogen Battery. Chinese Patent Application No. 201620013206, 7 January 2016. [Google Scholar]

- Zhu, Z.; He, J.; Gao, G.; Liu, J.; Liu, Q.; Jia, F. Automatic Transportation of Nickel-Hydrogen Battery, Dust Absorption, Flash Removed. Chinese Patent Application No. 201620077158, 26 January 2016. [Google Scholar]

- Wu, Y.; He, J.; Liu, J.; Liu, Q.; Zhu, Z.; Jia, F. A Agitating Unit that is Used for Nickel-Hydrogen Battery Positive Pole to Join in Marriage Whitewashed Process. Chinese Patent Application No. 201620011848, 7 January 2016. [Google Scholar]

- Hu, H.; Hua, Y.; Li, J.; Lin, D.; Ye, H.; Zhan, B.; Zhan, J.; Zhou, H. Cylinder-Type Nickel-Metal Hydride Battery. Chinese Patent Application No. 201010114307, 11 February 2010. [Google Scholar]

- Zhan, B.; Luo, S.; Zhan, J.; Tang, B.; Wang, J. Preparation Method of Negative Electrode Plate of Nickel-Metal Hydride Battery. Chinese Patent Application No. 201210272493, 1 August 2012. [Google Scholar]

- Zhang, B.; Zhan, J. Temperature-Resisting Cylindrical Nickel-Metal Hydride Battery. Chinese Patent Application No. 201010114308, 11 February 2010. [Google Scholar]

- Shen, M.; Xia, P.; Yan, Q.; Zheng, L.; He, Z.; Cheng, F.; Zhou, H.; Zhan, B.; Zhan, J.; Luo, S. Nickel Hydroxide Anode Pole Piece of Large Current Nickel-Metal Hydride Battery. Chinese Patent Application No. 201120255986, 19 July 2011. [Google Scholar]

- He, Z.; Zheng, L.; Zhou, H.; Yan, L.; Zhan, B.; Zhan, J.; Luo, S. Special Nickel Hydroxide Positive Plate for SC Type Nickel-Metal Hydride Batteries. Chinese Patent Application No. 201020289229, 6 August 2010. [Google Scholar]

- Pan, C.; Zhou, H.; Chen, X. Method for Fabricating Nickel Electrode in Nickel Hydrogen Battery. Chinese Patent Application No. 200510036556, 18 August 2005. [Google Scholar]

- Xiang, K.; Chen, X.; Li, Y. Low-Capacity Nickel-Metal Hydride Battery. Chinese Patent Application No. 201020577092, 22 October 2010. [Google Scholar]

- Zhou, H.; Pan, C.; Xiang, K.; Cheng, X. Nickel-Hydrogen Dynamic Cell. Chinese Patent Application No. 200520121356, 30 December 2005. [Google Scholar]

- Wu, A.; Kuang, D. A High-Power Nickel-Hydrogen Cell. Chinese Patent Application No. 200320117714, 5 November 2003. [Google Scholar]

- Wu, A.; Kuang, D. Flanged Metal Expanding Guipure for Manufacturing Electrode. Chinese Patent Application No. 200320117712, 5 November 2003. [Google Scholar]

- Wu, A.; Kuang, D. Large Content High Power Nickel-Cadmium Charging Cell. Chinese Patent Application No. 200320117685, 4 November 2003. [Google Scholar]

- Yan, D.; Wang, J. Manufacture Technology of Positive Plate for Nickel-Hydrogen Cell. Chinese Patent Application No. 97120114, 4 November 1997. [Google Scholar]

- Yan, D.; Cui, W.; Chen, Q. Method for Manufacturing Ni(OH)2 Electrodes of Ni-H Battery. Chinese Patent Application No. 98101896, 26 May 1998. [Google Scholar]

- Ma, K.; Yan, D. Metal Strap Covered with Foam Nickel Material and Making Method Thereof. Chinese Patent Application No. 00109696, 22 June 2000. [Google Scholar]

- Wang, J.; Yang, X.; Cheng, Q. Winding Process of Foamed Nickel Electrode. Chinese Patent Application No. 97120113, 4 November 1997. [Google Scholar]

- Yan, D.; Cui, W.; Cheng, X. Method for Manufacturing Metal Hydride Electrode of Nickel-Hydrogen Battery. Chinese Patent Application No. 97121781, 22 December 1997. [Google Scholar]

- Gao, X.; Qin, X.; Lan, Y. Composite Hydrogen-Storing Electrode Material of Hydrogen-Storing Alloy/Nano Carbon Material and its Preparing Process. Chinese Patent Application No. 00107426, 12 May 2000. [Google Scholar]

- Yuan, H.; Wang, Y.; Wang, L. Magnesium-Base Hydrogen Storing Alloy Material. Chinese Patent Application No. 00109349, 31 May 2000. [Google Scholar]

- Gong, W.; Gong, Z.; Gen, M. High Energy Nickel-Metal Hydride Cell. Chinese Patent Application No. 03258177, 31 July 2003. [Google Scholar]

- Yan, J.; Wang, R.; Yan, D. Regeneration Method of Deactivated Negative Alloy Powder of Secondary Nickel-Hydrogen Battery. Chinese Patent Application No. 00132165, 19 December 2000. [Google Scholar]

- Yan, J.; Wang, R.; Yan, D. Recovering Method of Defective Positive and Negative Pole Material of Secondary Nickel-Hydrogen Battery. Chinese Patent Application No. 00132164, 19 December 2000. [Google Scholar]

- Chu, C.; Du, J.; Luo, Y. Anode Piece of Nickel-Metal Hydride Battery. Chinese Patent Application No. 200920168290, 4 September 2009. [Google Scholar]

- Yu, Y. Energy-Saving Monitoring System of Power Line Carrier Street Lamp. Chinese Patent Application No. 200920169294, 21 August 2009. [Google Scholar]

- Du, J.; Luo, Y.; Tu, Y. Nickel-Metal Hydride Battery Pole Piece and Battery Using the Same. Chinese Patent Application No. 200920168292, 4 September 2009. [Google Scholar]

- Du, J.; Luo, Y.; Tu, Y. Nickel-Metal Hydride High-Capacity Cylindrical Battery. Chinese Patent Application No. 200920168291, 4 September 2009. [Google Scholar]

- Du, J.; Luo, Y.; Ma, C. Low-Capacity Battery Bottom Mat. Chinese Patent Application No. 200920168289, 4 September 2009. [Google Scholar]

- Lin, J.; Yan, Y.; Luo, Y. Winding Structure for Nickel-Hydrogen Battery. Chinese Patent Application No. 201220272255, 11 June 2016. [Google Scholar]

- Tu, Y.; Yan, Y.; Luo, Y. Mold for Wet Slurry-Pulling of Nickel-Metal Hydride Battery Cathodes. Chinese Patent Application No. 201220272309, 11 June 2012. [Google Scholar]

- Wang, Y.; Li, W.; Sun, L. Electrode of Charging Battery and Method and Equipment for Making Electrode. Chinese Patent Application No. 97122056, 19 December 1997. [Google Scholar]

- Wang, J.; Wang, Y. Integrated Battery Device. Chinese Patent Application No. 98248410, 18 November 1998. [Google Scholar]

- Lin, J.; Yang, J.; Qian, W.; Zhang, Y.; Jiang, Y.; Zhang, P.; Chen, Y. Cu-Contained Rare Earth System AB5-Type Hydrogen Storage Alloy and Preparation Method Thereof. Chinese Patent Application No. 201210178222, 31 May 2012. [Google Scholar]

- Zhang, P.; Yang, J.; Qian, W.; Zhang, Y.; Jiang, Y.; Chen, Y.; Chen, Y.; Lin, J. Low Cost Hydrogen Storage Alloy, Preparation Method and Application Thereof. Chinese Patent Application No. 200910112283, 21 July 2009. [Google Scholar]

- Zhou, Z.; Huang, C.; Qian, W.; Yang, J.; Song, Y.; Cui, S.; Lin, C.; Zhang, Y.; Zhang, P. Low-Cost High-Performance Rare-Earth-Based AB5-Type Hydrogen Storage Alloy and Preparation Method Thereof. Chinese Patent Application No. 200910112323, 22 July 2009. [Google Scholar]

- Jiang, Y.; Chen, Y.; Chen, Y.; Zhang, Y.; Wu, Y. Non-Cobalt Low-Nickel Hydrogen Storage Alloy. Chinese Patent Application No. 201110032195, 28 January 2011. [Google Scholar]

- Chen, Y.; Yang, J.; Qian, W.; Zhang, Y.; Jiang, Y.; Chen, Y.; Zhang, P.; Lin, J. Low-Self-Discharge Hydrogen Storage Alloy and Preparation Method Thereof. Chinese Patent Application No. 201110032749, 28 January 2011. [Google Scholar]

- Zhang, P.; Yang, J.; Qian, W.; Jiang, L.; Lin, Z. Low-Cost AB5 Type Hydrogen Storage Alloy Having Ultrahigh Capacity Characteristic, and Preparation Method and Application Thereof. Chinese Patent Application No. 201210412250, 25 October 2012. [Google Scholar]

- Lin, J.; Yang, J.; Qian, W.; Zhang, Y.; Jiang, Y.; Zhang, P.; Chen, Y. Low Temperature Power Type Hydrogen Storage Alloy for Nickel-Metal Hydride Battery. Chinese Patent Application No. 201210143770, 10 May 2012. [Google Scholar]

- Jiang, Y.; Yang, J.; Zhang, Y.; Ding, X.; Chen, Y.; Chen, Y.; Lin, Y.; Zhou, Y. Over-Stoichiometric Low-Cost Hydrogen Storage Alloy, and Preparation Method and Application Thereof. Chinese Patent Application No. 200810210684, 8 August 2008. [Google Scholar]

- Zhang, P.; Yang, J.; Qian, W.; Zhang, Y.; Jiang, Y. Rare Earth Magnesium-Based Hydrogen Storage Alloy with Low Cost and Long Life and Applications Thereof. Chinese Patent Application No. 201110319482, 29 October 2011. [Google Scholar]

- Kakeya, T.; Kodama, M.; Kanemoto, M.; Okuda, D.; Zhang, P.; Lin, Z.; Yang, J.; Qian, W.; Jiang, L. Hydrogen Storage Alloy and Manufacturing Method Thereof. Chinese Patent Application No. 201410409393, 19 August 2014. [Google Scholar]

- Huang, Z.; Qian, W.; Chen, H.; Zhang, Y.; Zhu, G. Method for Preparing Hydrogen Storing Alloy Powder. Chinese Patent Application No. 200710008544, 2 February 2007. [Google Scholar]

- Huang, Z.; Qian, W.; Chen, H.; Zhang, Y.; Zhu, G. Vacuum Induction Smelting Furnace. Chinese Patent Application No. 200820145393, 29 August 2008. [Google Scholar]

- Huang, C.; Qian, W.; Chen, H.; Zhang, Y.; Zhu, G. Vacuum Induction Smelting Furnance. Chinese Patent Application No. 200810071672, 29 August 2008. [Google Scholar]

- Chen, Y.; Zhang, Y.; Jiang, Y. Method for Preparing Magnesium-Based Cathode of Nickel-Hydrogen Battery. Chinese Patent Application No. 200910111626, 27 April 2009. [Google Scholar]

- Min, D.; Chen, Y.; Yang, L.; He, C. Discharging Dust-Collecting Device for Hydrogen Storage Alloy Powder Mixer. Chinese Patent Application No. 201120206564, 17 June 2011. [Google Scholar]

- Min, D.; Chen, Y.; Yang, L.; Tao, J. Dust Collection Control System Beneficial to Production. Chinese Patent Application No. 201120206503, 17 June 2011. [Google Scholar]

- Min, D.; Chen, Y.; Luo, T.; Yang, L.; He, C. Cleaning Device Capable of Effectively Disposing Impurities on Vibrating Screen. Chinese Patent Application No. 201120206511, 17 June 2011. [Google Scholar]

- Min, D.; Chen, Y.; Luo, T.; Yang, L.; Tao, J. Cooling Mould Set Beneficial for Crystallization of Alloys. Chinese Patent Application No. 201120206500, 17 June 2011. [Google Scholar]

- Min, D.; Chen, Y.; Luo, T.; He, C. Sheet Producing Device for Fast Testing Electrochemistry Performance of Hydrogen Storage Alloy Powder. Chinese Patent Application No. 201120206636, 17 June 2011. [Google Scholar]

- Min, D.; Chen, Y.; Luo, T.; Tao, J. Automated Pouring System for Vacuum Melting Furnace. Chinese Patent Application No. 201120206514, 17 June 2011. [Google Scholar]

- Chen, Y.; Liu, L.; Min, D. A2B7 Hydrogen Storage Alloy for Nickel-Hydride Battery and Preparation Method Thereof. Chinese Patent Application No. 201310228766, 8 June 2013. [Google Scholar]

- Min, D.; Liu, L.; Chen, Y. Rare Earth-Magnesium-Nickel System Heterogeneous Hydrogen Storage Alloys Used for Nickel-Hydrogen Batteries and Preparing Method Thereof. Chinese Patent Application No. 201410222437, 23 May 2014. [Google Scholar]

- Zhu, X.; Zhao, X.; Ji, L.; Wang, Y.; Li, Q. High-Capacity Hydrogen Storage Alloy Electrode Material and Production Method Thereof. Chinese Patent Application No. 201310268222, 28 June 2013. [Google Scholar]

- Ji, L.; Zhao, X.; Zhu, X.; Han, S.; Wang, Y.; Li, Q.; Liu, Y.; Jing, Y.; Xu, J. Hydrogen Storage Alloy for Nickel-Metal Hydride Battery. Chinese Patent Application No. 201310728257, 26 December 2013. [Google Scholar]

- Zhu, X.; Xu, J.; Zhao, X. Hydrogen Storage Alloy for Nickel-Metal Hydride Battery and Manufacturing Method of Hydrogen Storage Alloy. Chinese Patent Application No. 201510879635, 3 December 2015. [Google Scholar]

- Han, S.; Shen, W.; Zhu, X.; Zhou, Y. Method for Improving Electrochemical Performance of Hydrogen Storage Alloy Powder by Utilizing Electropolymerization Polyaniline. Chinese Patent Application No. 201110158364, 2 June 2011. [Google Scholar]

- Han, S.; Zhang, Z.; Zhu, X.; Li, J.; Xu, S.; Yang, Y.; Jing, T.; Wang, X. Preparation Method of High Content Rare Earth-Magnesium Base Composite Hydrogen Storage Alloy for NiMH Battery. Chinese Patent Application No. 200410092078, 2 November 2004. [Google Scholar]

- Zhang, P. Method for Preparing AB5 Type Mixed Rare-Earth Hydrogen-Bearing Alloy Powder. Chinese Patent Application No. 200710123188, 2 July 2007. [Google Scholar]

- Wang, C.; Jiang, B.; Chi, X.; Shen, X.; Liu, L.; Zhang, Y. Low-Cobalt and Praseodymium-Neodymium-Free AB5 Type Hydrogen Storage Alloy with Low Cost and Preparation Method Thereof. Chinese Patent Application No. 201210215478, 27 June 2012. [Google Scholar]

- Wang, C.; Jiang, B.; Chi, X.; Shen, X.; Liu, L.; Zhang, Y. Praseodymium-Neodymium-Free Low-Cost Superlong Life Type Hydrogen Storage Alloy and Preparation Method Thereof. Chinese Patent Application No. 201210362335, 26 September 2012. [Google Scholar]

- Guo, J.; Jiang, B.; Sun, C.; Wang, Z. Rare Earth Hydrogen Storage Alloy Containing Mg and Preparing Method Thereof. Chinese Patent Application No. 200710157452, 15 October 2007. [Google Scholar]

- Wang, C.; Guo, J.; Jiang, B.; Shen, X. Magnesium-Containing Superlattice Hydrogen Storage Alloy and Preparation Method Thereof. Chinese Patent Application No. 201110152699, 8 June 2011. [Google Scholar]

- Wang, C.; Jiang, B.; Chi, X.; Shen, X.; Liu, L.; Zhang, Y. Praseodymium-Free, Neodymium-Free and Cobalt-Free High Capacity Superlattice Hydrogen Storage Alloy Containing Magnesium. Chinese Patent Application No. 201310362901, 16 August 2013. [Google Scholar]

- Guo, J.; Jiang, B.; Sun, C.; Wang, C. Preparation Method of AB5 Type Hydrogen-Storage Alloy Used on Ni/MH Battery. Chinese Patent Application No. 200810246900, 30 December 2008. [Google Scholar]

- Wang, C.; Guo, J.; Jiang, B.; Shen, X. Method for Treating Hydrogen Storage Alloy Waste Residues. Chinese Patent Application No. 201110151658, 8 June 2011. [Google Scholar]

- Wang, C.; Guo, J.; Jiang, B.; Shen, X. Method for Recycling Metals from Waste Nickel-Hydrogen Batteries. Chinese Patent Application No. 201110173754, 25 June 2011. [Google Scholar]

- Miao, G.; Ren, H.; Zhou, X.; Sun, X. Preparation Method of High Performance Hydrogen Storage Alloy Powder. Chinese Patent Application No. 200810150430, 23 July 2008. [Google Scholar]

- Gao, J.; Zhang, Y.; Shang, H.; Yang, T.; Zhai, T.; Li, Y. High-Capacity RE-Mg-Ti-Co-Al System AB2 Type Hydrogen Storage Electrode Alloy Applied to NiMH Batteries of Hybrid Electric Vehicles and Preparation Method of Alloy. Chinese Patent Application No. 201510008846, 8 January 2015. [Google Scholar]

- Gao, J.; Yong, H.; Zhang, Y.; Shang, H.; Li, Y.; Yuan, Z. RE-Mg-Ni-Ti-Cu-Al-B Series AB Type Electrode Alloy Used for Ni-MH Battery and Preparation Method. Chinese Patent Application No. 201610454477, 22 June 2016. [Google Scholar]

- Gao, J.; Shang, H.; Li, J.; Xu, C. Low-Magnesium RE-Mg-Ti-Al-B Series Hydrogen-Storage Alloy for Ni-MH Secondary Battery and Preparation Method. Chinese Patent Application No. 201410085723, 11 March 2014. [Google Scholar]

- Gao, J.; Yuan, Z.; Yang, T.; Liao, Y.; Ma, X. Nano-Graphite Compoujnded High-Capacity RE-Mg-Ni-Based Hydrogen Storage Material and Preparation Method Thereof. Chinese Patent Application No. 201510554498, 2 September 2015. [Google Scholar]

- Gao, J. Automatic Split Charging Device of Hydrogen-Storage Alloy Powder. Chinese Patent Application No. 201320585007, 23 September 2013. [Google Scholar]

- Huang, Y.; Wu, J.; Liu, H.; Li, R.; Xie, Y.; Yang, K. La-Mg-Ni Negative Electrode Hydrogen Storage Material Used in Power-Type Nickel-Metal Hydride Battery. Chinese Patent Application No. 201110339760, 1 November 2011. [Google Scholar]

- Liu, H.; Li, R.; Wu, J. La-Mg-Ni Negative Hydrogen Storage Material for Nickel-Hydrogen Batteries. Chinese Patent Application No. 200910163893, 14 August 2009. [Google Scholar]

- Liu, H.; Wu, J. AB5 Type Negative Pole Hydrogen Storing Material. Chinese Patent Application No. 200810175124, 30 October 2008. [Google Scholar]

- Liu, H.; Wu, J. AB5 Type Negative Pole Hydrogen Storing Material and Preparation Method Thereof. Chinese Patent Application No. 200510083535, 8 July 2005. [Google Scholar]

- Liu, H.; Wu, J.; Liu, J. AB5 Negative Pole Hydrogen Storing Material. Chinese Patent Application No. 200510083537, 8 July 2005. [Google Scholar]

- Liu, H.; Wu, J.; Wang, M. AB5 Type Negative Pole Hydrogen-Storage Material. Chinese Patent Application No. 200510099899, 9 September 2005. [Google Scholar]

- Liu, H.; Wu, J. AB5 Type Negative Pole Hydrogen-Storage Material. Chinese Patent Application No. 200510099901, 9 September 2005. [Google Scholar]

- Liu, H.; Wu, J. AB5 Type Negative Pole Hydrogen-Storage Material. Chinese Patent Application No. 200510099902, 9 September 2005. [Google Scholar]

- Liu, H.; Wu, J. Pr5Co19 Type Cathode Hydrogen Storage Material and Application Thereof. Chinese Patent Application No. 200810181720, 4 December 2008. [Google Scholar]

- Liu, H.; Tian, B. AB3.5 Type Hydrogen-Storing Negative Pole Material and its Preparation Process and Use. Chinese Patent Application No. 200610148600, 22 November 2006. [Google Scholar]

- Liu, H.; Liu, J. Novel Collector of Hydrogen Battery. Chinese Patent Application No. 201020676945, 23 December 2010. [Google Scholar]

- Liu, H.; Liu, J. Current-Collecting Sheet with Novel Structure for Hydrogen Battery. Chinese Patent Application No. 201020676956, 23 December 2010. [Google Scholar]

- Liu, H.; Liu, J. Easy-To-Weld Current-Collecting Sheet of Hydrogen Cell. Chinese Patent Application No. 201020676958, 23 December 2010. [Google Scholar]

- Liu, H.; Liu, J. Easily-Welded Current-Collecting Sheet for Hydrogen Battery. Chinese Patent Application No. 201020676935, 23 December 2010. [Google Scholar]

- Yang, S.; Wang, X.; Zhou, J.; Zhou, F. Solar Energy Nickel-Hydrogen Charging Battery Manufacture Process. Chinese Patent Application No. 200610032433, 20 October 2006. [Google Scholar]

- Fierro, C.; Fetcenko, M.A.; Young, K.; Ovshinsky, S.R.; Sommers, B.; Harrison, C. Nickel Hydroxide Positive Electrode Material Exhibiting Improved Conductivity and Engineered Activation Energy. U.S. Patent 6,228,535, 8 May 2001. [Google Scholar]

- Gao, W.; Wang, Q.; Gong, J.; Meng, X.; Wang, T.; Zhang, X.; Yang, Z.; Fan, G.; Wang, W.; Chen, J. Method for Preparing Pure-Phase Spherical Nickel Hydroxide. Chinese Patent Application No. 201410551376, 17 October 2014. [Google Scholar]

- Gao, W.; Wang, Q.; Fan, G.; Wang, W.; Chen, J.; Ma, M.; Zhao, S.; Tao, S. Method for Removing Sulfate Radicals in Nickel Hydroxide. Chinese Patent Application No. 201510803603, 20 November 2015. [Google Scholar]

- Zhou, T.; Geng, W.; Xin, H.; Wu, Y.; Zhao, M.; Zhang, J.; Lai, J.; Wang, R.; Wang, Y.; Cui, W. Nickel Hydroxide Raw Material Iron Removing Process and Pneumatic Stirring and Precipitating Impurity Removing Tank Adopting Nickel Hydroxide Raw Material Iron Removing Process. Chinese Patent Application No. 201510812812, 20 November 2015. [Google Scholar]

- Yin, Z.; Xu, Y.; Zhang, H.; Han, H. Method for Producing Spherical Nickel Hydroxide. Chinese Patent Application No. 200510017529, 20 April 2005. [Google Scholar]

- Xu, Y.; Yin, Z.; Kang, B. Method for Producing Nickel Hydroxide Used for High Temperature Battery. Chinese Patent Application No. 200510017528, 20 April 2005. [Google Scholar]

- Xu, Y.; Kang, B.; Yin, Z.; Wei, L.; Wang, M.; Han, H.; Zhang, H.; Yuan, J. Spherical Nickel Hydroxide with Composite Cobalt Layer Being Coated and Preparation Method. Chinese Patent Application No. 200510017530, 20 April 2005. [Google Scholar]

- Chang, Z.; Shangguan, E.; Wu, F.; Tang, H.; Cheng, D.; Xu, Y.; Yin, Z. Method for Electrolyzing Nickel Hydroxide Covering Hydroxyl Cobalt Oxide Layer. Chinese Patent Application No. 200710054761, 28 June 2007. [Google Scholar]

- Chang, Z.; Shangguan, N.; Wu, F.; Tang, H.; Cheng, D.; Xu, Y.; Yin, Z. Method for Electrolytic Preparing Hydroxy Cobalt Nickel Oxide. Chinese Patent Application No. 200710054762, 28 June 2007. [Google Scholar]