Mechanical Processing of GFRP Waste into Large-Sized Pieces for Use in Concrete

Abstract

:1. Introduction

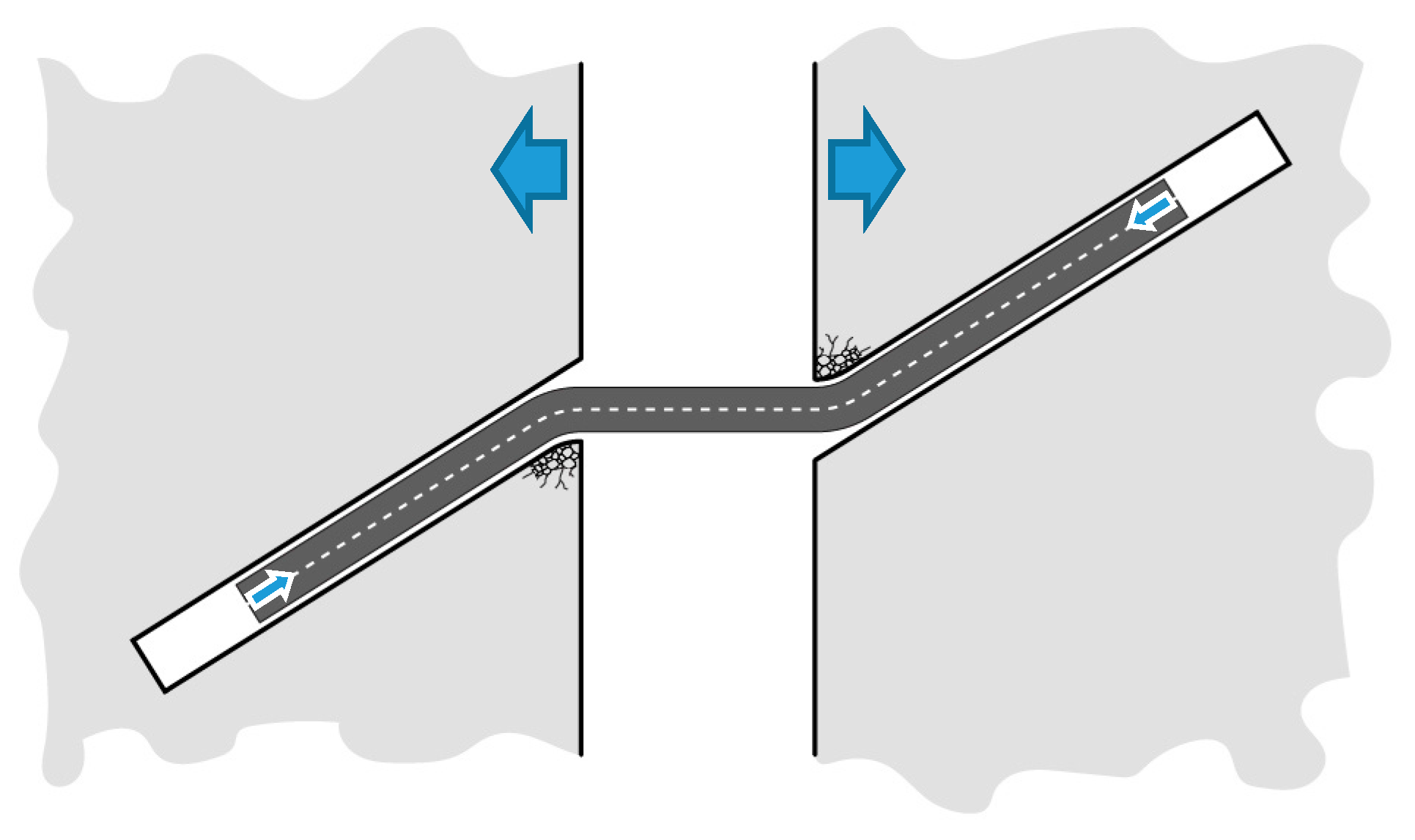

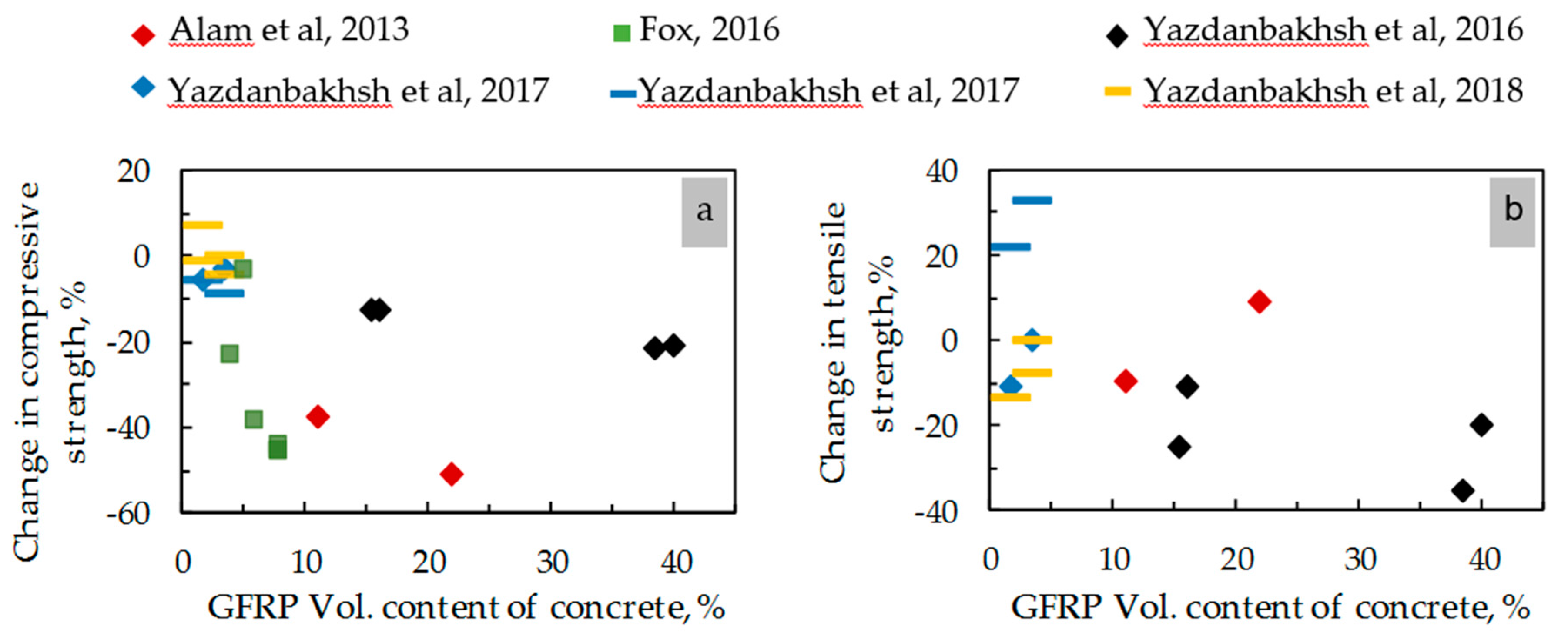

2. Use of Processed GFRP Waste in Concrete as Coarse Aggregate

3. Use of Processed GFRP Waste in Concrete as Discrete Reinforcing Elements

3.1. The Benefits and Challenges of Using the Existing Discrete Reinforcing Elements in Concrete

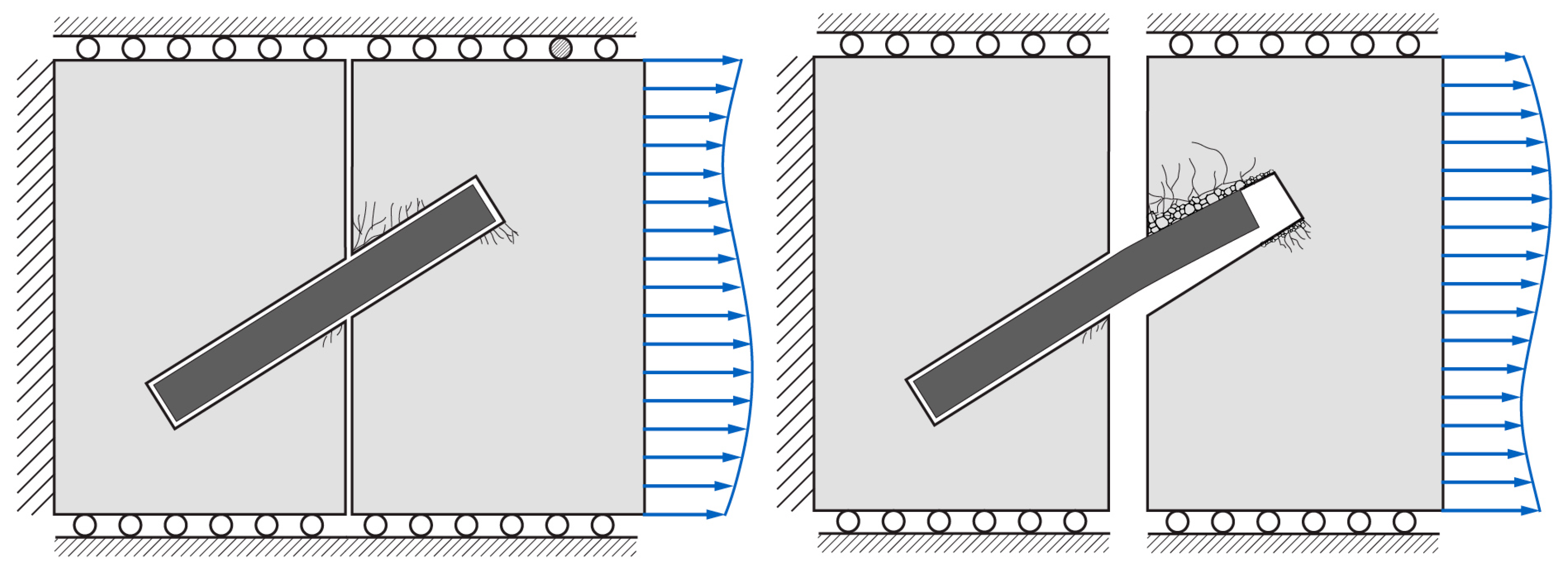

3.2. The Concept of “Needle” as Discrete Reinforcing Elements in Concrete

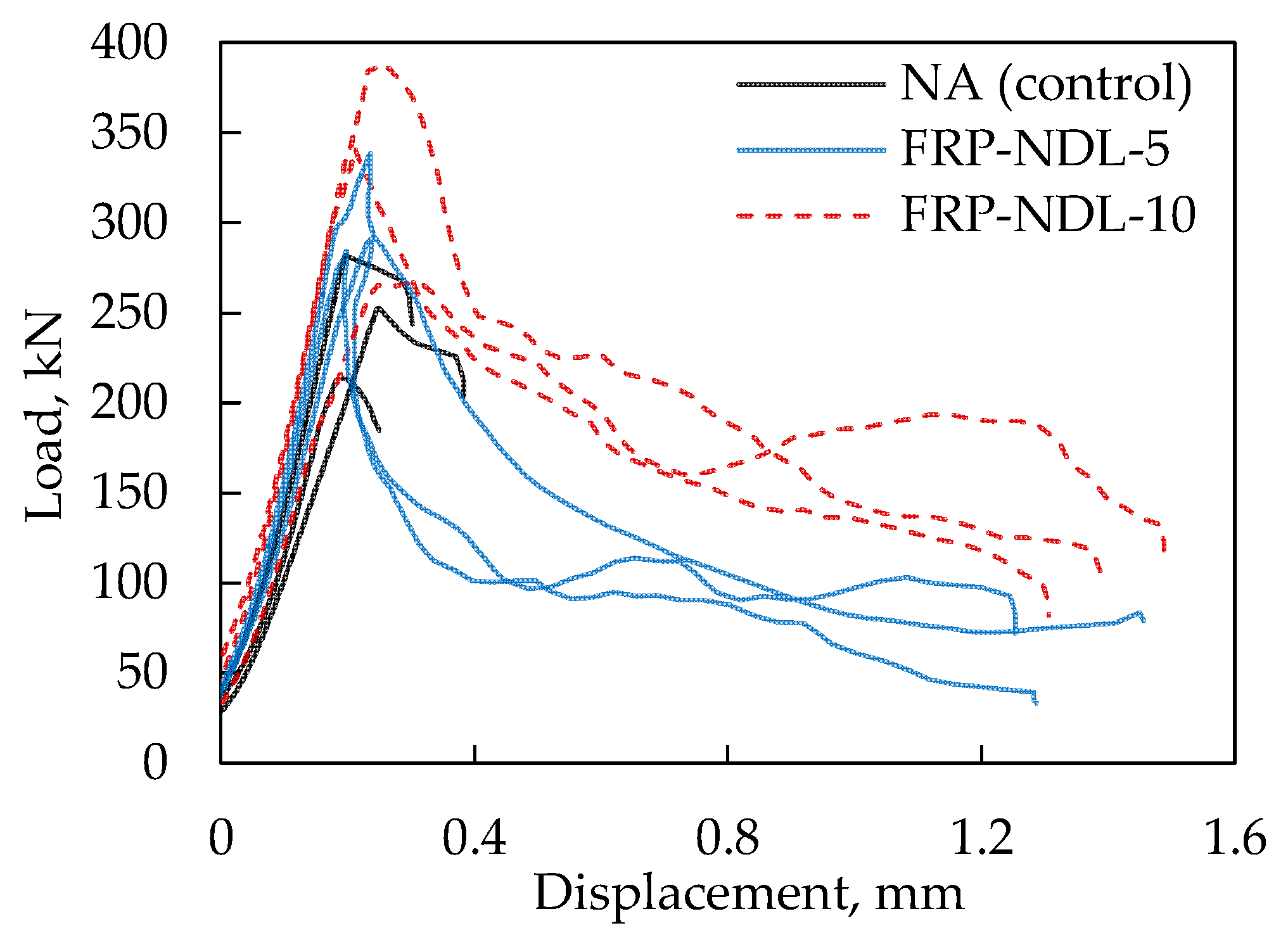

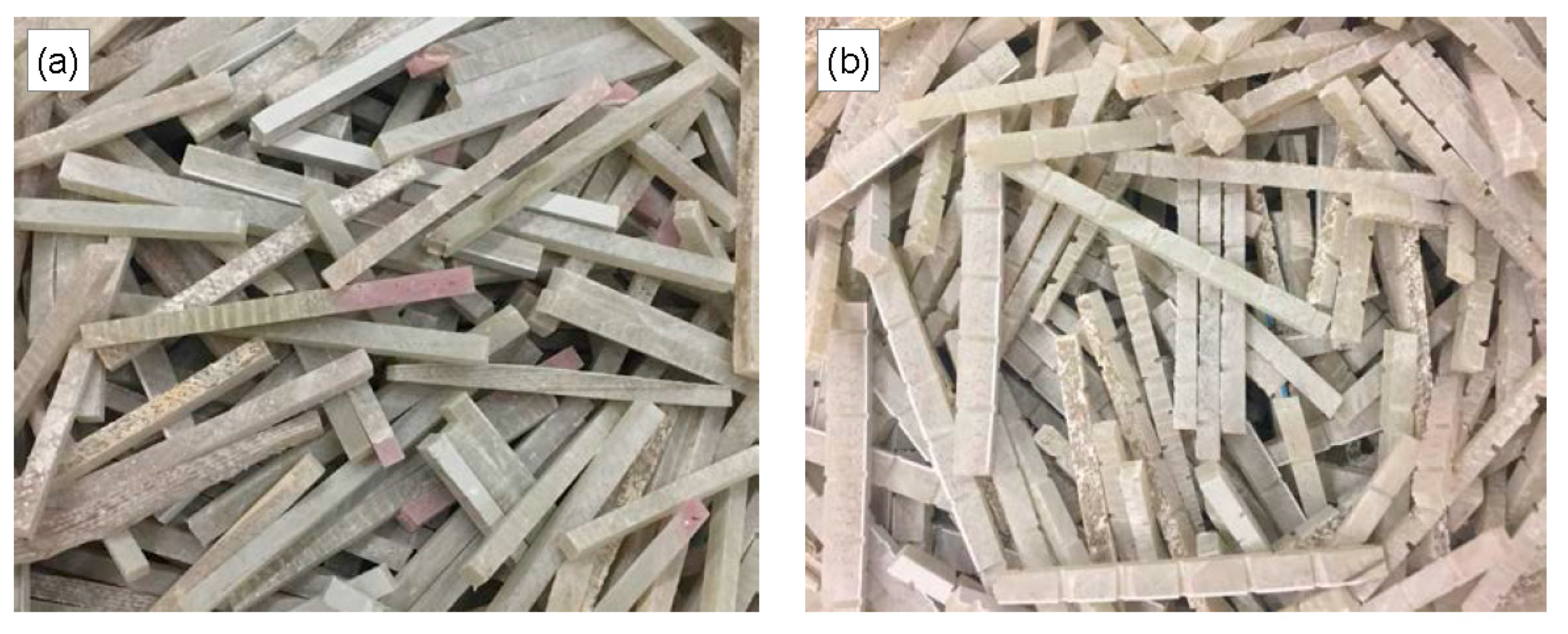

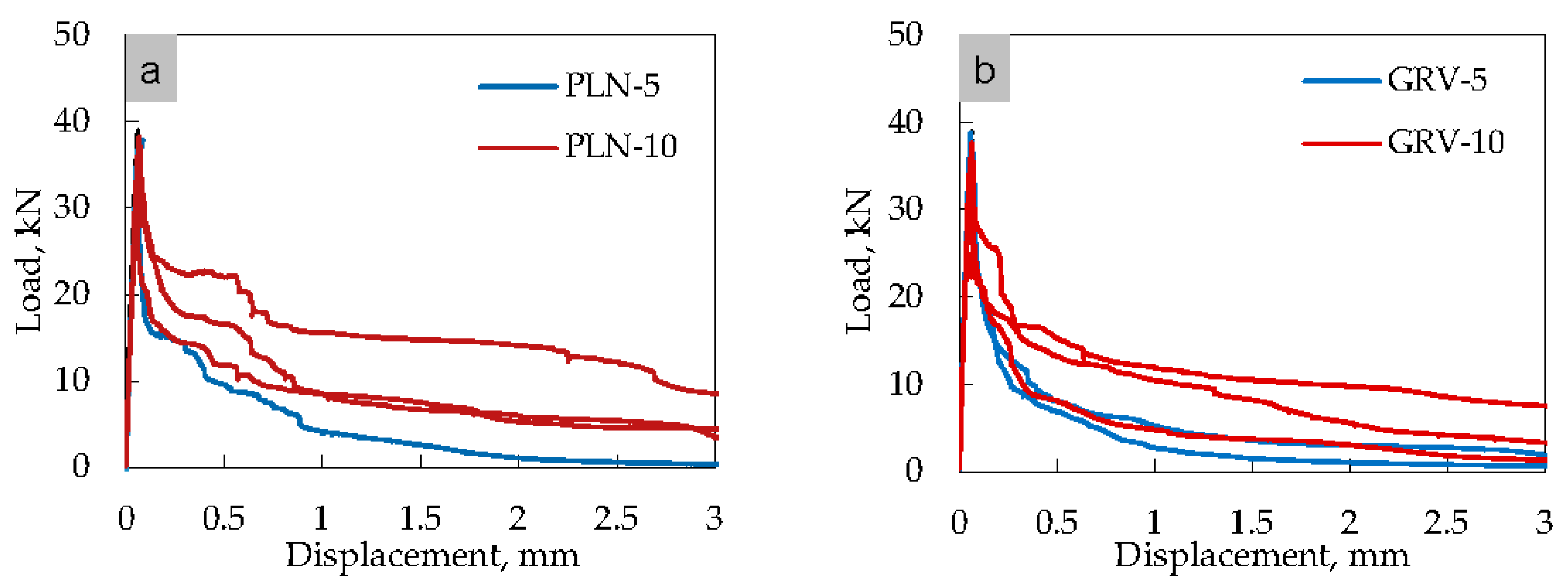

3.3. Past Studies on Recycling GFRP Waste into Needles for Use in Concrete

4. Summary of the Past Studies

5. Guidance for Future Research

Acknowledgment

Conflicts of Interest

References

- Reynolds, N.; Pharaoh, M. An introduction to composites recycling. In Management, Recycling and Reuse of Waste Composites; Goodship, V., Ed.; Woodhead Publishing: Cambridge, UK, 2010; pp. 3–19. [Google Scholar]

- Witten, E. Composites Market Report 2015 Market Developments, Trends, Outlook and Challenges; Federation of Reinforced Plastics (AVK): Frankfurt, Germany, 2015. [Google Scholar]

- Holmes, M. US demand for fibre reinforced plastic composites to rise. In Reinforced Plastics; Elsevier: Oxford, UK, 2013; Available online: http://www.materialstoday.com/composite-industry/news/us-demand-for-fibre-reinforced-plastic-composites (accessed on 13 February 2018).

- Bank, L.C. Composites for Construction; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Beauson, J.; Lilholt, H.; Brøndsted, P. Recycling solid residues recovered from glass fibre-reinforced composites—A review applied to wind turbine blade materials. J. Reinf. Plast. Compos. 2014, 33, 1542–1556. [Google Scholar] [CrossRef]

- Hardee, C. Improving wind blade manufacturability. Wind Systems, 2 February 2018; 26–30. [Google Scholar]

- Hunt, H.; Wanner, C.; Hensley, J. U.S. Wind Industry Annual Market report—Year Ending 2015; American Wind Energy Association (AWEA): Washington, DC, USA, 2016. [Google Scholar]

- Yazdanbakhsh, A.; Bank, L. A critical review of research on reuse of mechanically recycled FRP production and end-of-life waste for construction. Polymers 2014, 6, 1810–1826. [Google Scholar] [CrossRef]

- Job, S.; Leeke, G.; Mativenga, P.T.; Oliveux, G.; Pickering, S.; Shuaib, N.A. Composite Recycling—Where Are We Now? Composites UK: Hertfordshire, UK, 2016. [Google Scholar]

- Tittarelli, F.; Kawashima, S.; Tregger, N.; Moriconi, G.; Shah, S.P. Effect of GRP by-product addition on plastic and hardened properties of cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010. [Google Scholar]

- Tittarelli, F.; Shah, S.P. Effect of low dosages of waste GRP dust on fresh and hardened properties of mortars: Part 1. Constr. Build. Mater. 2013, 47, 1532–1538. [Google Scholar] [CrossRef]

- Asokan, P.; Osmani, M.; Price, A.D.F. Assessing the recycling potential of glass fibre reinforced plastic waste in concrete and cement composites. J. Clean. Prod. 2009, 17, 821–829. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Yazdanbakhsh, A.; Bank, L.C.; Chen, C. Use of recycled FRP reinforcing bar in concrete as coarse aggregate and its impact on the mechanical properties of concrete. Constr. Build. Mater. 2016, 121, 278–284. [Google Scholar] [CrossRef]

- ASTM C33. Standard Specification for Concrete Aggregates; STM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Shahria Alam, M.; Slater, E.; Billah, A.M. Green concrete made with RCA and FRP scrap aggregate: Fresh and hardened properties. J. Mater. Civ. Eng. 2013, 25, 1783–1794. [Google Scholar] [CrossRef]

- Fox, T.R. Recycling wind turbine blade composite material as aggregate in concrete. In Department of Industrial and Manufacturing Systems Engineering; Iowa State University: Ames, IA, USA, 2016. [Google Scholar]

- Murrell, S. Concrete Airport Pavements Make a Comeback; New York Construction News; McGraw Hill: New York, NY, USA, 1993. [Google Scholar]

- Roesler, J.R.; Altoubat, S.A.; Lange, D.A.; Rieder, K.-A.; Ulreich, G.R. Effect of synthetic fibers on structural behavior of concrete slabs-on-ground. ACI Mater. J. 2006, 103, 3–10. [Google Scholar]

- Soranakom, C.; Mobasher, B.; Destrée, X. Numerical Simulation of FRC Round Panel Tests and Full-Scale Elevated Slabs; ACI Special Publication: Farmington Hills, MI, USA, 2007; Volume 248. [Google Scholar]

- Bentur, A.; Mindess, S. Fiber Reinforced Cementitious Composites, 2nd ed.; Modern Concrete Technology; Taylor & Francis: New York, NY, USA, 2007. [Google Scholar]

- Behnood, A.; Verian, K.P.; Gharehveran, M.M. Evaluation of the splitting tensile strength in plain and steel fiber-reinforced concrete based on the compressive strength. Constr. Build. Mater. 2015, 98, 519–529. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Altoubat, S.; Rieder, K.A. Analytical study on shear strength of macro synthetic fiber reinforced concrete beams. Eng. Struct. 2015, 100, 622–632. [Google Scholar] [CrossRef]

- Jeknavorian, A.A. Innovations in chemical admixture technology as related to sustainability. In ACI Spring 2012 Convention; American Concrete Institute: Dallas, TX, USA, 2012. [Google Scholar]

- Choi, Y.; Yuan, R.L. Experimental relationship between splitting tensile strength and compressive strength of GFRC and PFRC. Cem. Concr. Res. 2005, 35, 1587–1591. [Google Scholar] [CrossRef]

- Nanni, A. Splitting-tension test for fiber reinforced concrete. ACI Mater. J. 1988, 85, 229–233. [Google Scholar]

- Wafa, F.; Ashour, S. Mechanical properties of high-strength fiber reinforced concrete. ACI Mater. J. 1992, 89, 449–455. [Google Scholar]

- Yazdanbakhsh, A.; Bank, L.C.; Chen, C.; Tian, Y. FRP-Needles as discrete reinforcement in concrete. ASCE J. Mater. Civ. Eng. 2017, 29, 1–9. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C.; Rieder, K.-A.; Tian, Y.; Chen, C. Concrete with discrete slender elements from mechanically recycled wind turbine blades. Resourc. Conserv. Recycl. 2017, 128, 11–21. [Google Scholar] [CrossRef]

- ASTM C1609. Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

| Ref. | Element Type | Size mm | Coarse Aggregate Replacement Ratio (Vol.) % | GFRP to Concrete Ratio (Vol.) % | Slump mm | Mpa | Mpa | Flexural Strength MPa |

|---|---|---|---|---|---|---|---|---|

| Alam et al. 2013 [16] | - | - | 0.0 | 0.0 | 160 | 50.03 | 2.32 | 4.13 |

| Flat GRA | sl < 25 | 25.0 | 11.1 | 210 | 31.2 | 2.1 | 2.91 | |

| Flat GRA | sl < 25 | 50.0 | 22.0 | 220 | 24.47 | 2.53 | 2.38 | |

| Fox, 2016 [17] | - | - | 0.0 | 0.0 | - | 40.5 | - | - |

| GRA | sl = 13 | 50.0 | 7.8 | - | 22.3 | - | - | |

| GRA | sl = 13, 25 | 50.0 | 7.8 | - | 22.1 | - | - | |

| GRA | sl = 25 | 50.0 | 7.8 | - | 22.6 | - | - | |

| GRA | sl = 25 | 25.0 | 3.9 | - | 31.2 | - | - | |

| GRA | sl = 25 | 37.5 | 5.9 | - | 25.0 | - | - | |

| GRA | sl = 25 | 50.0 | 7.8 | - | 22.1 | - | - | |

| GRA | sl = 25 | 32.5 | 5.1 | - | 39.2 | - | - | |

| GRA | sl = 25 | 32.5 | 5.1 | - | - | 3.8 | - | |

| Yazdanb-akhsh et al. 2016 [14] | - | - | 0.0 | 0.0 | - | 37.5 | 4.0 | - |

| GRA | D = 19,25 | 40.0 | 15.4 | - | 32.8 | 3.0 | - | |

| GRA | D = 6,10,13,19,25 | 100.0 | 38.5 | - | 29.5 | 2.6 | - | |

| - | - | 0.0 | 0.0 | - | 46.3 | 4.5 | - | |

| GRA | D = 19, 25 | 40.0 | 16.0 | - | 40.4 | 4.0 | - | |

| GRA | D = 6,10,13,19,25 | 100.0 | 40.0 | - | 36.6 | 3.6 | - | |

| Yazdanb-akhsh et al. 2017 [28] | - | - | 0.0 | 0.0 | 70 | 40.2 | 3.42 | - |

| GRA | D = 6,10,13,19 | 5.0 | 1.8 | 70 | 37.9 | 3.06 | - | |

| GRA | D = 6,10,13,19 | 10.0 | 3.5 | 65 | 38.9 | 3.42 | - | |

| Needle | D = 6 L = 100 | 5.0 | 1.8 | 75 | 38.0 | 4.18 | - | |

| Needle | D = 6 L = 100 | 10.0 | 3.5 | 70 | 36.7 | 4.55 | - | |

| Yazdanb-akhsh, 2018 [29] | - | - | 0.0 | 0.0 | 125 | 36.0 | 3.35 | 5.0 |

| 160 | ||||||||

| Plain needle | L = 100 | 5.0 | 1.8 | 115 | 35.5 | 2.89 | 4.5 | |

| sl = 6 | 110 | |||||||

| Plain needle | L = 100 | 10.0 | 3.5 | 125 | 36.1 | 3.35 | 4.6 | |

| sl = 6 | 110 | |||||||

| Grooved needle | L = 100 | 5.0 | 1.8 | 115 | 38.6 | 2.91 | 5.0 | |

| sl = 6 | 120 | |||||||

| Grooved needle | L = 100 | 10.0 | 3.5 | 110 | 34.4 | 3.09 | 4.7 | |

| sl = 6 | 95 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yazdanbakhsh, A.; Bank, L.C.; Tian, Y. Mechanical Processing of GFRP Waste into Large-Sized Pieces for Use in Concrete. Recycling 2018, 3, 8. https://doi.org/10.3390/recycling3010008

Yazdanbakhsh A, Bank LC, Tian Y. Mechanical Processing of GFRP Waste into Large-Sized Pieces for Use in Concrete. Recycling. 2018; 3(1):8. https://doi.org/10.3390/recycling3010008

Chicago/Turabian StyleYazdanbakhsh, Ardavan, Lawrence C. Bank, and Yuan Tian. 2018. "Mechanical Processing of GFRP Waste into Large-Sized Pieces for Use in Concrete" Recycling 3, no. 1: 8. https://doi.org/10.3390/recycling3010008