Theoretical Investigations for Strain Relaxation and Growth Mode of InAs Thin layers on GaAs(111)A †

Abstract

:1. Introduction

2. Computational Methods

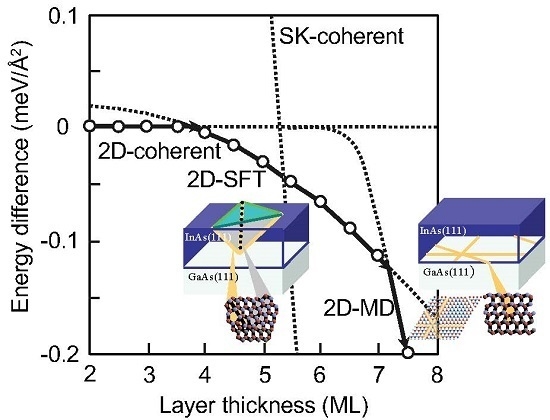

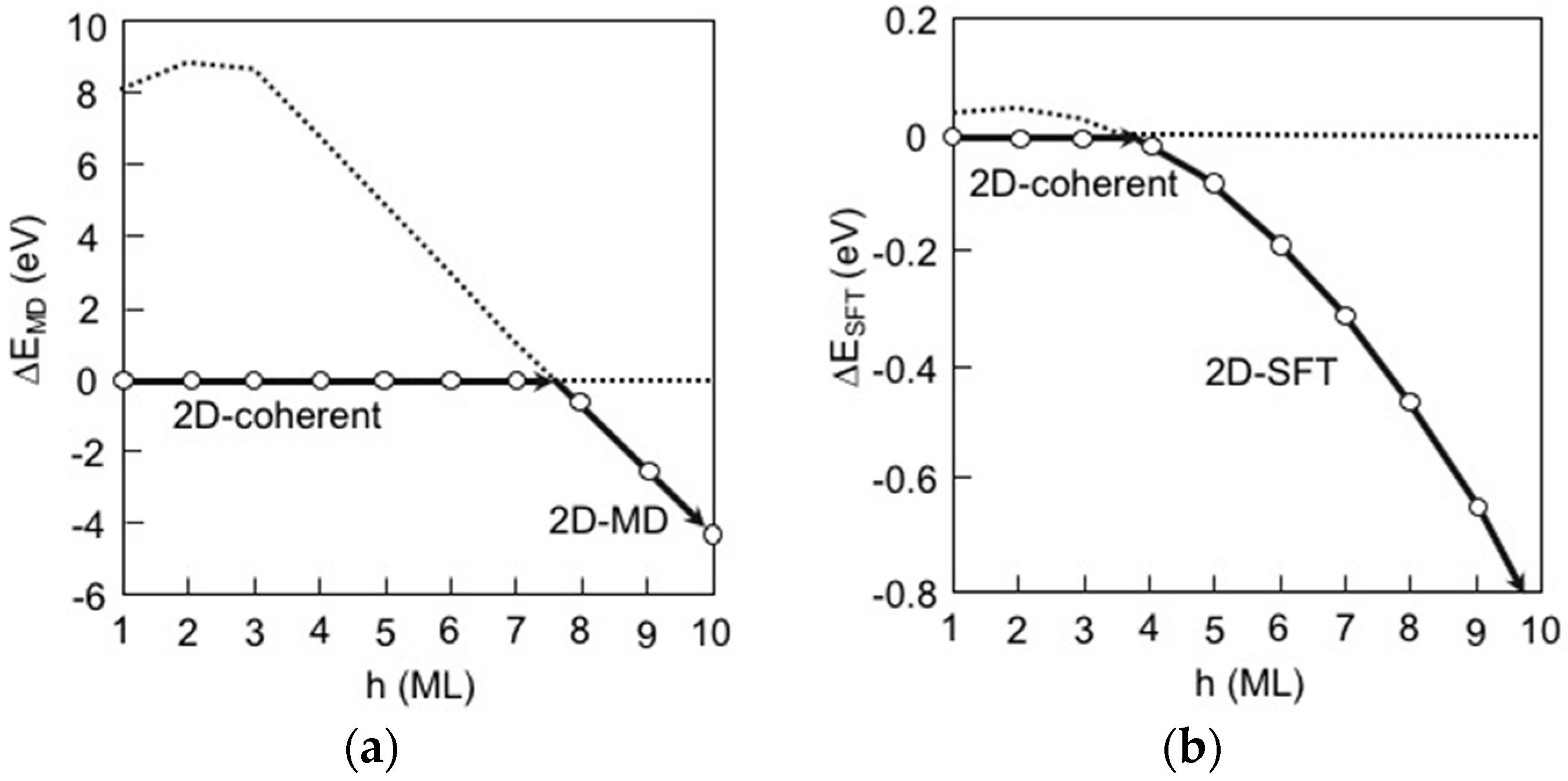

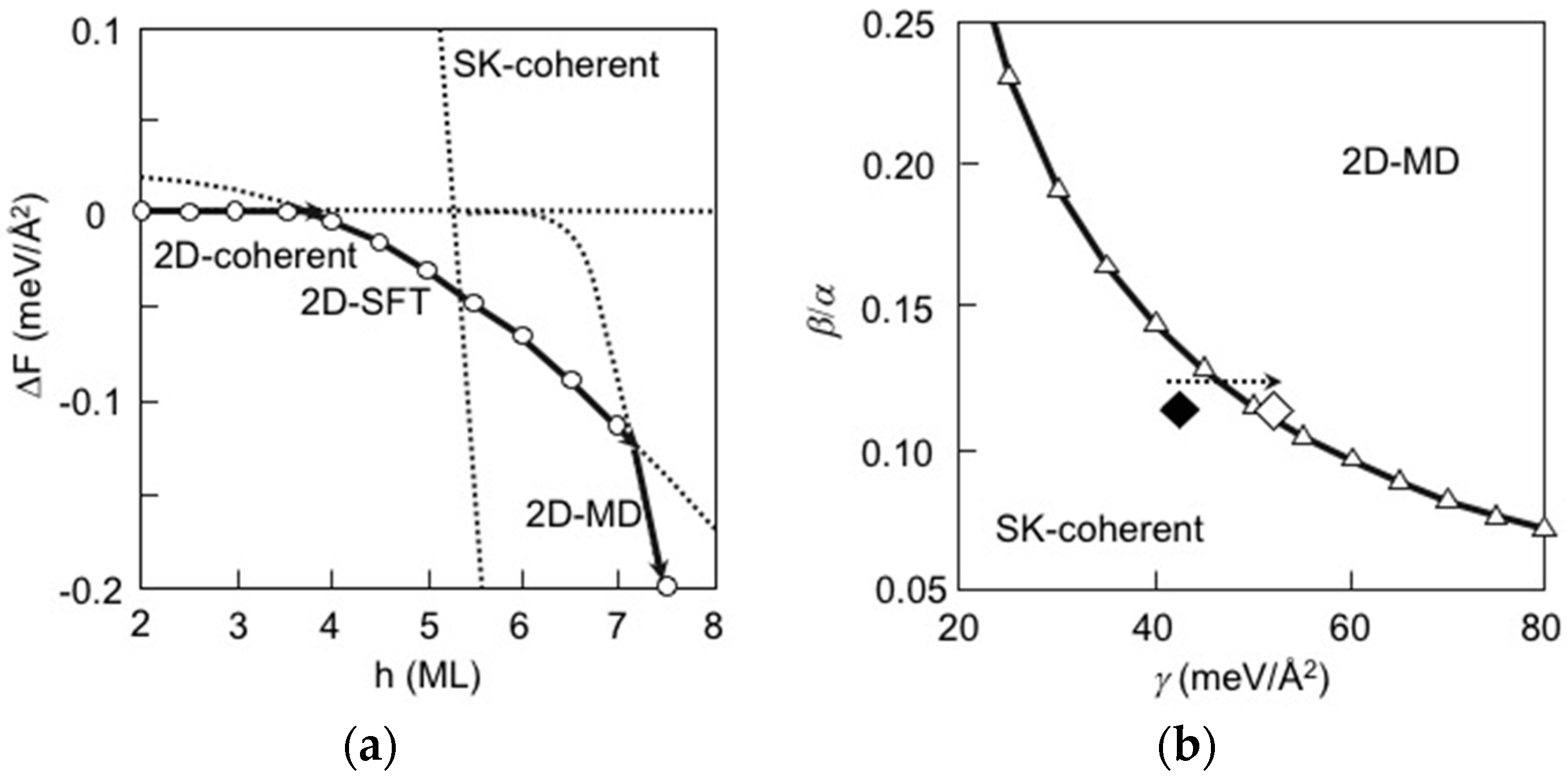

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Joyce, P.B.; Krzyzewski, T.J.; Bell, G.R.; Joyce, B.A.; Jones, T.A. Composition of InAs quantum dots on GaAs(001): Direct evidence for (In,Ga)As alloying. Phys. Rev. B 1998, 58, R15981–R15984. [Google Scholar] [CrossRef]

- Joyce, B.A.; Sudijono, J.L.; Belk, J.G.; Yamaguchi, H.; Zhang, X.M.; Dobbs, H.T.; Zangwill, A.; Vvedensky, D.D.; Jones, T.S. A scanning tunneling microscopy-reflection high energy electron diffraction-rate equation study of the molecular beam epitaxial growth of InAs on GaAs(001), (110) and (111)A—Quantum dots and two-dimensional modes. Jpn. J. Appl. Phys. 1997, 36, 4111–4117. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Belk, J.G.; Zhang, X.M.; Sudijono, J.L.; Fay, M.R.; Jones, T.S.; Pashley, D.W.; Joyce, B.A. Atomic-scale imaging of strain relaxation via misfit dislocation in highly mismatched semiconductor heteroepitaxy: InAs/GaAs(111)A. Phys. Rev. B 1997, 55, 1337–1340. [Google Scholar] [CrossRef]

- Ichimura, M. Stillinger-Weber potentials for III–V compound semiconductors and their application to the critical thickness calculation for InAs/GaAs. Phys. Stat. Solidi (a) 1996, 153, 431–437. [Google Scholar] [CrossRef]

- Moll, N.; Scheffler, M.; Pehlke, E. The influence of surface stress on the equilibrium shape of strained quantum dots. Phys. Rev. B 1998, 58, 4566–4571. [Google Scholar] [CrossRef]

- Wang, L.G.; Kratzer, P.; Moll, N.; Scheffler, M. Size, shape, and stability of InAs quantum dots on the GaAs(001) substrate. Phys. Rev. B 2000, 62, 1897–1904. [Google Scholar] [CrossRef]

- Patella, F.; Nufris, S.; Arciprete, F.; Fanfoni, M.; Placidi, E.; Segarlata, A.; Balzarotti, A. Tracing the two- to three-dimensional transition in the InAs/GaAs(001) heteroepitaxial growth. Phys. Rev. B 2003, 67, 205308. [Google Scholar] [CrossRef]

- Patella, F.; Arciprete, F.; Placidi, E.; Fanfoni, M.; Sessi, V.; Balzarotti, A. Reflection high energy electron diffraction observation of surface mass transport at the two- to three-dimensional growth transition of InAs on GaAs(001). Appl. Phys. Lett. 2005, 87, 252101. [Google Scholar] [CrossRef]

- Patella, F.; Arciprete, F.; Placidi, E.; Fanfoni, M.; Balzarotti, A. Apparent critical thickness versus temperature for InAs quantum dot growth on GaAs(001). Appl. Phys. Lett. 2006, 88, 161903. [Google Scholar] [CrossRef]

- Hammerschmidt, T.; Kratzer, P.; Scheffler, M. Analytic many-body potential for InAs/GaAs surfaces and nanostructures: Formation energy of InAs quantum dots. Phys. Rev. B 2008, 77, 235303. [Google Scholar] [CrossRef]

- Arciprete, F.; Fanfoni, M.; Patella, F.; Della Pia, A.; Balzarotti, A.; Placidi, E. Temperature dependence of the size distribution function of InAs quantum dots on GaAs(001). Phys. Rev. B 2010, 81, 165306. [Google Scholar] [CrossRef]

- Schukin, V.; Ledentsov, N.; Rouvimov, S. Formation of three-dimensional islands in subcritical layer deposition in Stranski–Krastanow growth. Phys. Rev. Lett. 2013, 110, 176101. [Google Scholar] [CrossRef] [PubMed]

- Zepeda-Ruiz, L.A.; Maroudas, D.; Weinberg, W.H. Semicoherent interface formation and structure in InAs/GaAs(111)A heteroepitaxy. Surf. Sci. 1998, 418, L68–L72. [Google Scholar] [CrossRef]

- Ohtake, A.; Ozeki, M. Strain relaxation in InAs/GaAs(111)A heteroepitaxy. Phys. Rev. Lett. 2000, 84, 4665–4668. [Google Scholar] [CrossRef] [PubMed]

- Kanisawa, K.; Butcher, M.J.; Tokura, Y.; Yamaguchi, H.; Hirayama, Y. Local density of states in zero-dimensional semiconductor structures. Phys. Rev. Lett. 2001, 87, 196804. [Google Scholar] [CrossRef] [PubMed]

- Potin, V.; Ruterana, P.; Nouet, G.; Pond, R.C.; Morkoç, H. Mosaic growth of GaN on (0001) sapphire: A high-resolution electron microscopy and crystallographic study of threading dislocations from low-angle to high-angle grain boundaries. Phys. Rev. B 2000, 61, 5587–5589. [Google Scholar] [CrossRef]

- Béré, A.; Serra, A. Atomic structure of dislocation cores in GaN. Phys. Rev. B 2002, 65, 205323. [Google Scholar] [CrossRef]

- Kawamoto, K.; Suda, T.; Akiyama, T.; Nakamura, K.; Ito, T. An empirical potential approach to dislocation formation and structural stability in GaNxAs1−x. Appl. Surf. Sci. 2005, 244, 182–185. [Google Scholar] [CrossRef]

- Kobayashi, R.; Nakayama, T. First-principles study on crystal and electronic structures of stacking-fault tetrahedron in epitaxial Si films. J. Cryst. Growth 2004, 278, 500–504. [Google Scholar] [CrossRef]

- Shiraishi, K.; Oyama, N.; Okajima, K.; Miyagishima, N.; Takeda, K.; Yamaguchi, H.; Ito, T.; Ohno, T. First principles and macroscopic theories of semiconductor epitaxial growth. J. Cryst. Growth 2002, 237–239, 206–211. [Google Scholar] [CrossRef]

- Khor, K.E.; Das Sarma, S. Proposed universal interatomic potential for elemental tetrahedrally bonded semiconductors. Phys. Rev. B 1988, 38, 3318–3822. [Google Scholar] [CrossRef]

- Ito, T.; Khor, K.E.; Das Sarma, S. Systematic approach to developing empirical potentials for compound semiconductors. Phys. Rev. B 1990, 41, 3893–3896. [Google Scholar] [CrossRef]

- Ito, T. Simple criterion for wurtzite-zinc-blende polytypism in semiconductors. Jpn. J. Appl. Phys. 1998, 37, L1217–L1220. [Google Scholar] [CrossRef]

- People, B.; Bean, J.C. Calculation of critical layer thickness versus lattice mismatch for GexSi1−x/Si strained-layer heterostructures. Appl. Phys. Lett. 1985, 47, 322–324. [Google Scholar] [CrossRef]

- Zhou, N.; Zhou, L. A fusion-crystalization mechanism for nucleation of misfit dislocations in FCC epitaxial films. J. Cryst. Growth 2006, 289, 681–685. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ito, T.; Akiyama, T.; Nakamura, K. Theoretical Investigations for Strain Relaxation and Growth Mode of InAs Thin layers on GaAs(111)A. Condens. Matter 2016, 1, 4. https://doi.org/10.3390/condmat1010004

Ito T, Akiyama T, Nakamura K. Theoretical Investigations for Strain Relaxation and Growth Mode of InAs Thin layers on GaAs(111)A. Condensed Matter. 2016; 1(1):4. https://doi.org/10.3390/condmat1010004

Chicago/Turabian StyleIto, Tomonori, Toru Akiyama, and Kohji Nakamura. 2016. "Theoretical Investigations for Strain Relaxation and Growth Mode of InAs Thin layers on GaAs(111)A" Condensed Matter 1, no. 1: 4. https://doi.org/10.3390/condmat1010004