Numerical Analysis of CNC Milling Chatter Using Embedded Miniature MEMS Microphone Array System

Abstract

:1. Introduction

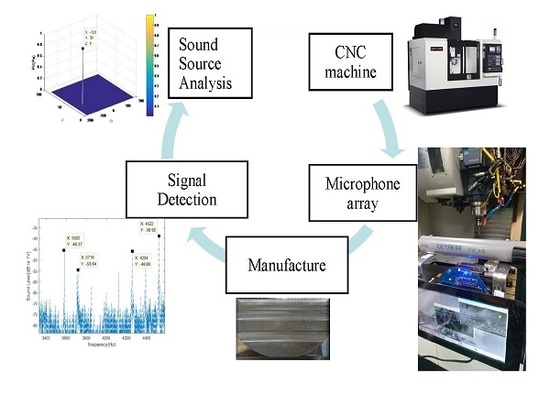

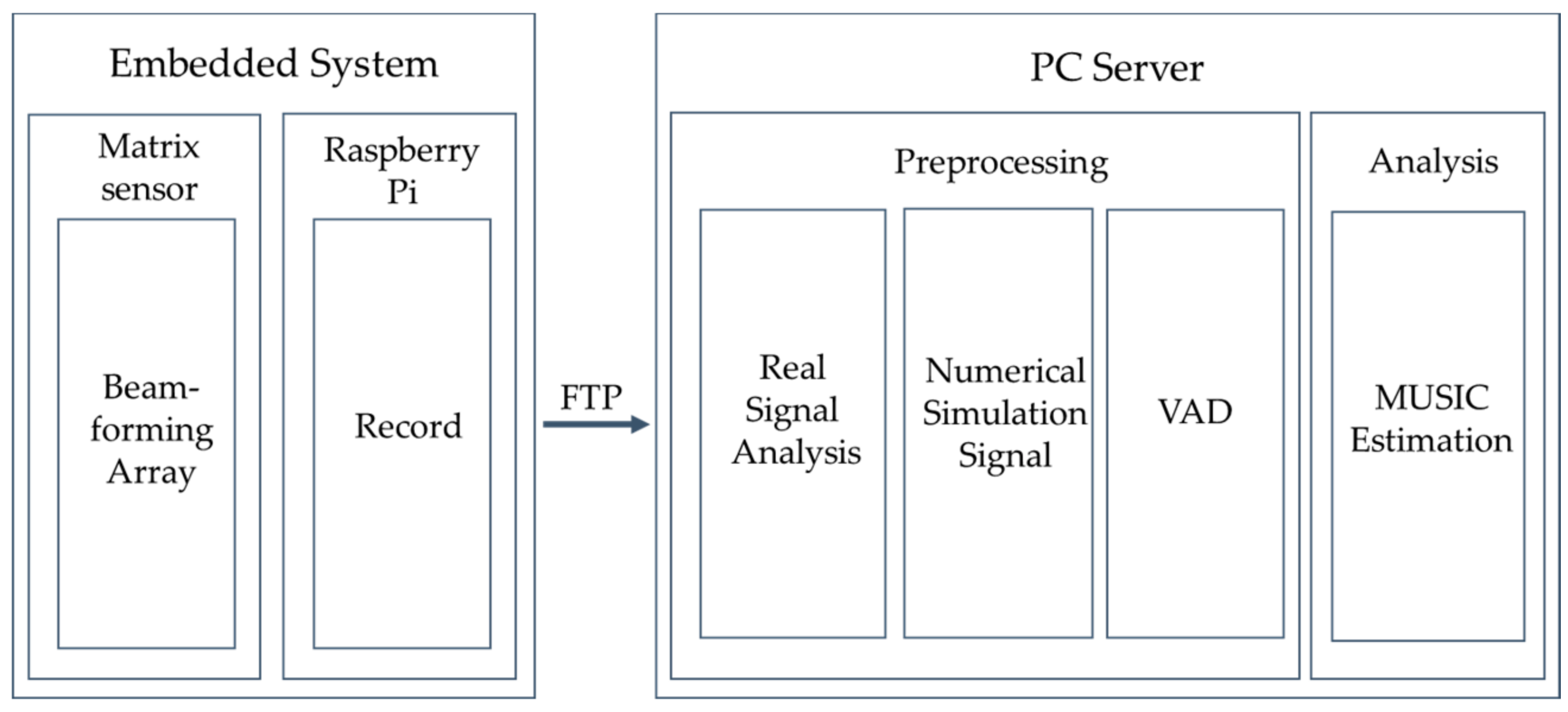

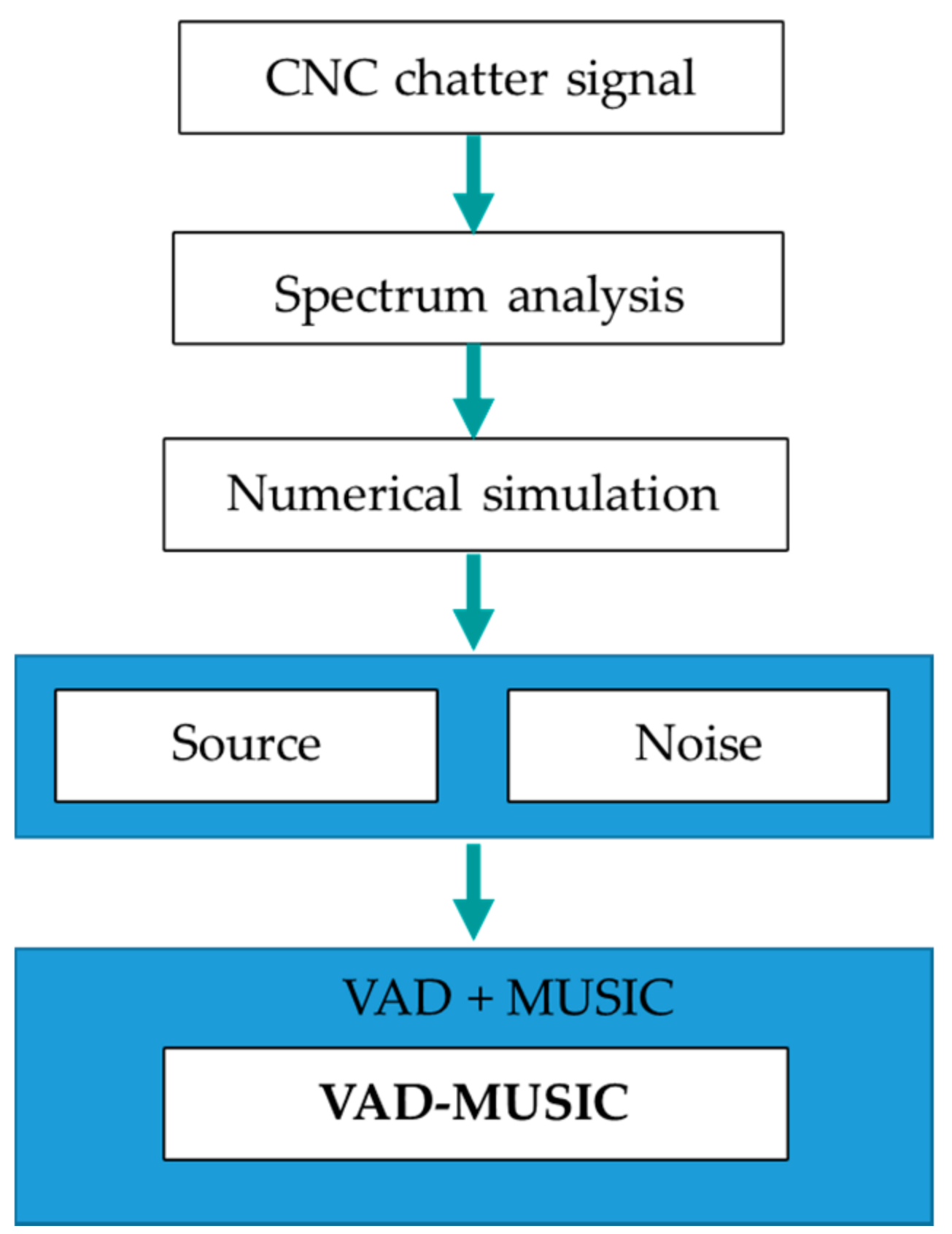

2. Method Description

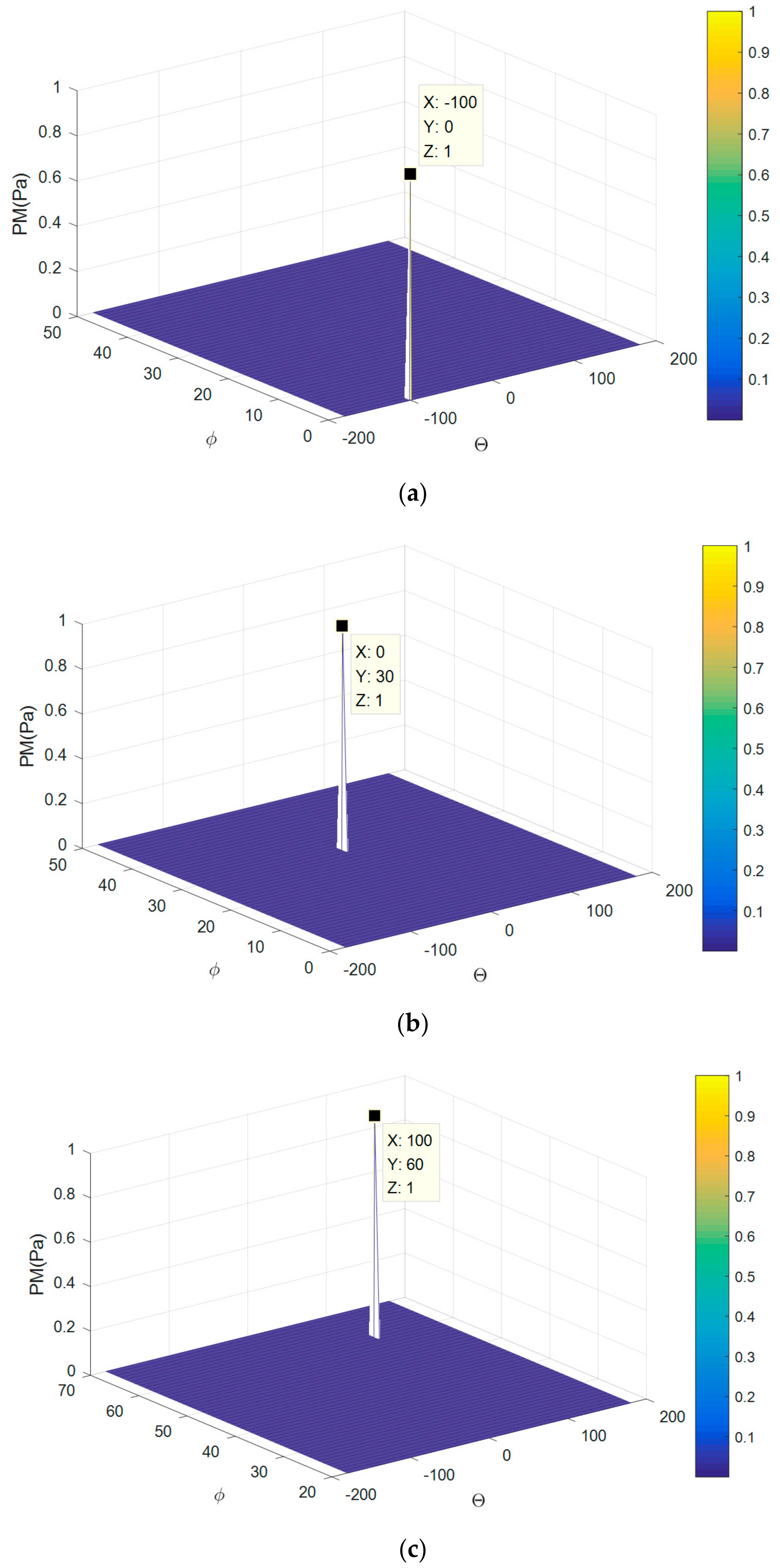

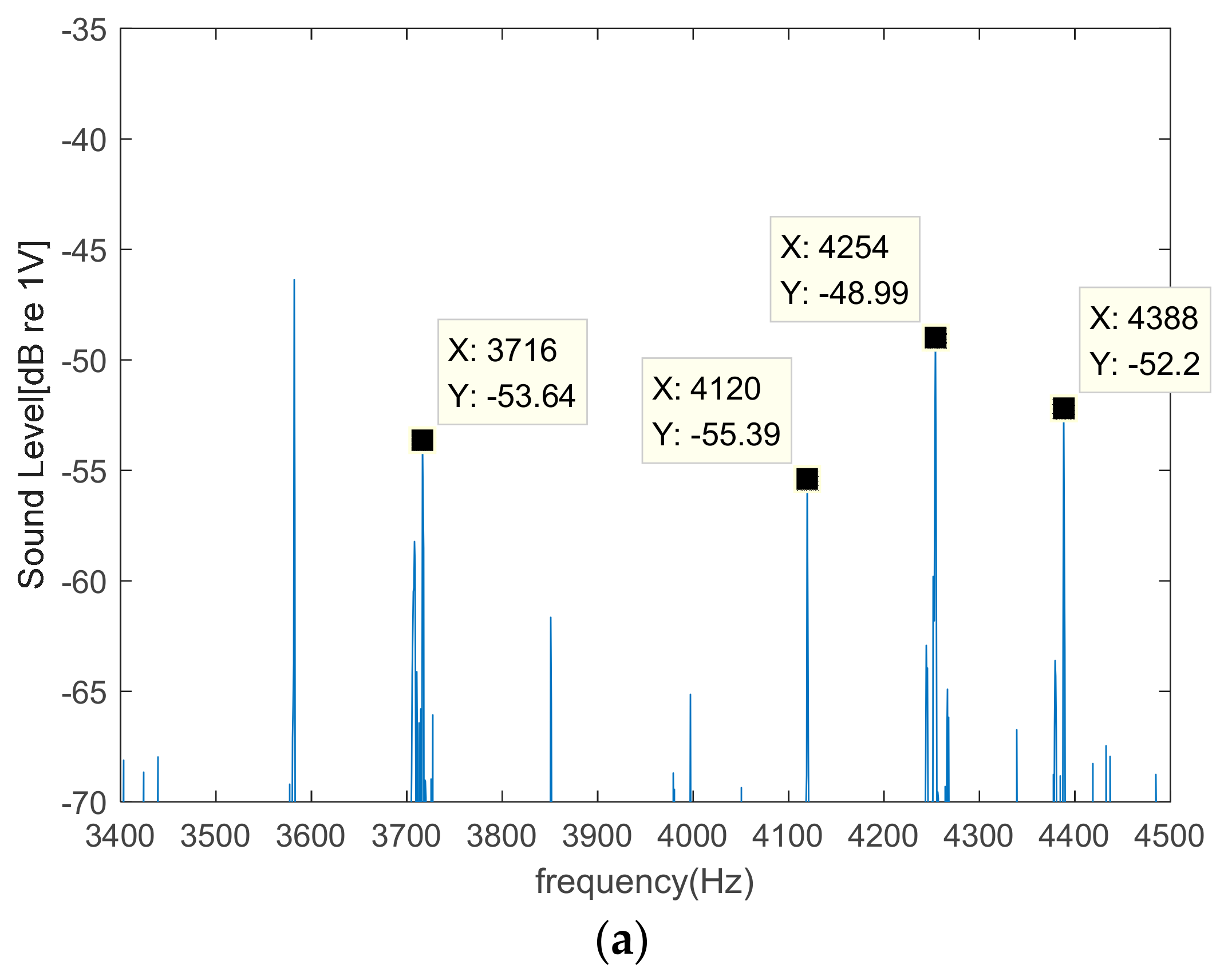

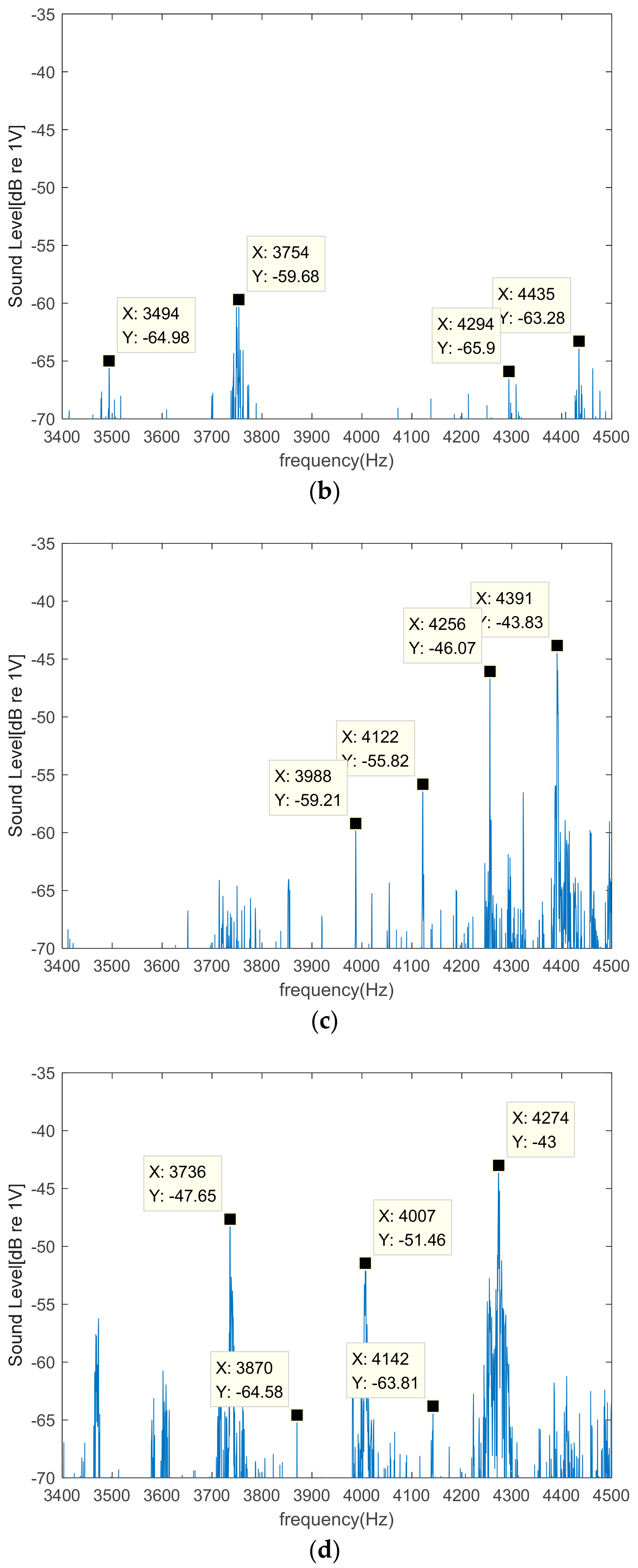

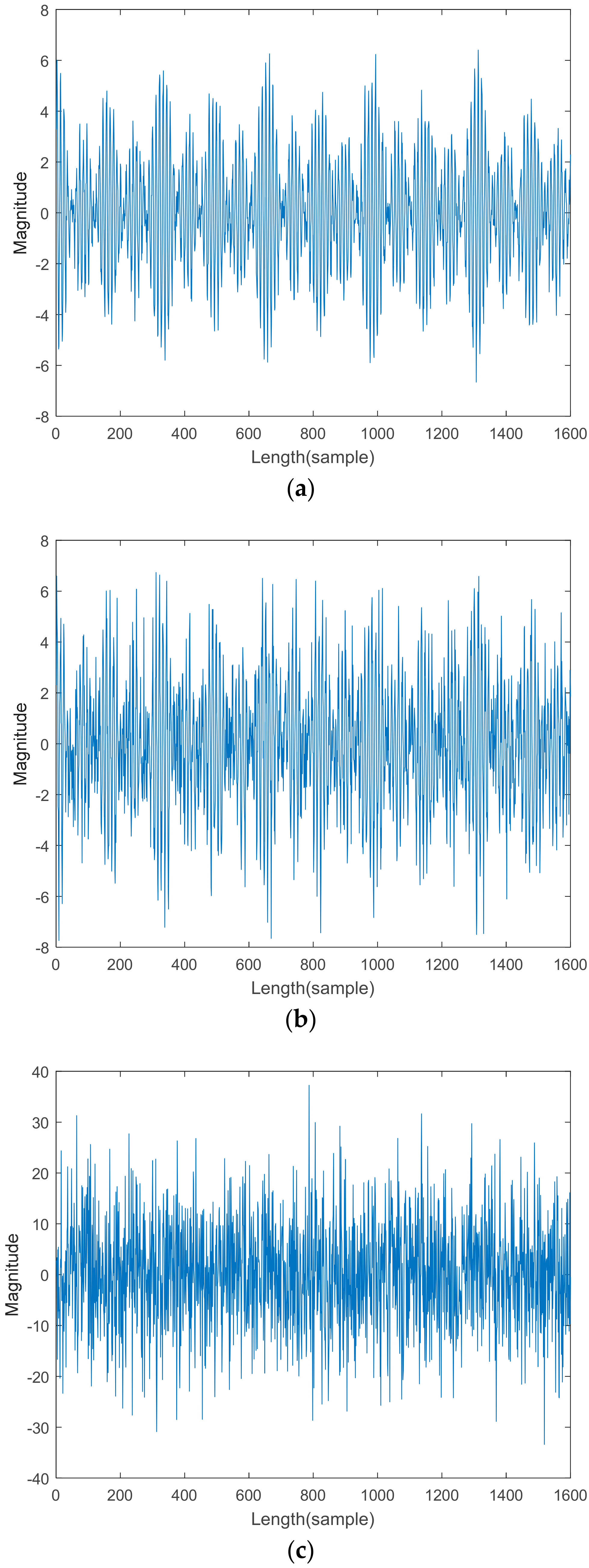

3. Results and Discussion

3.1. System Setup

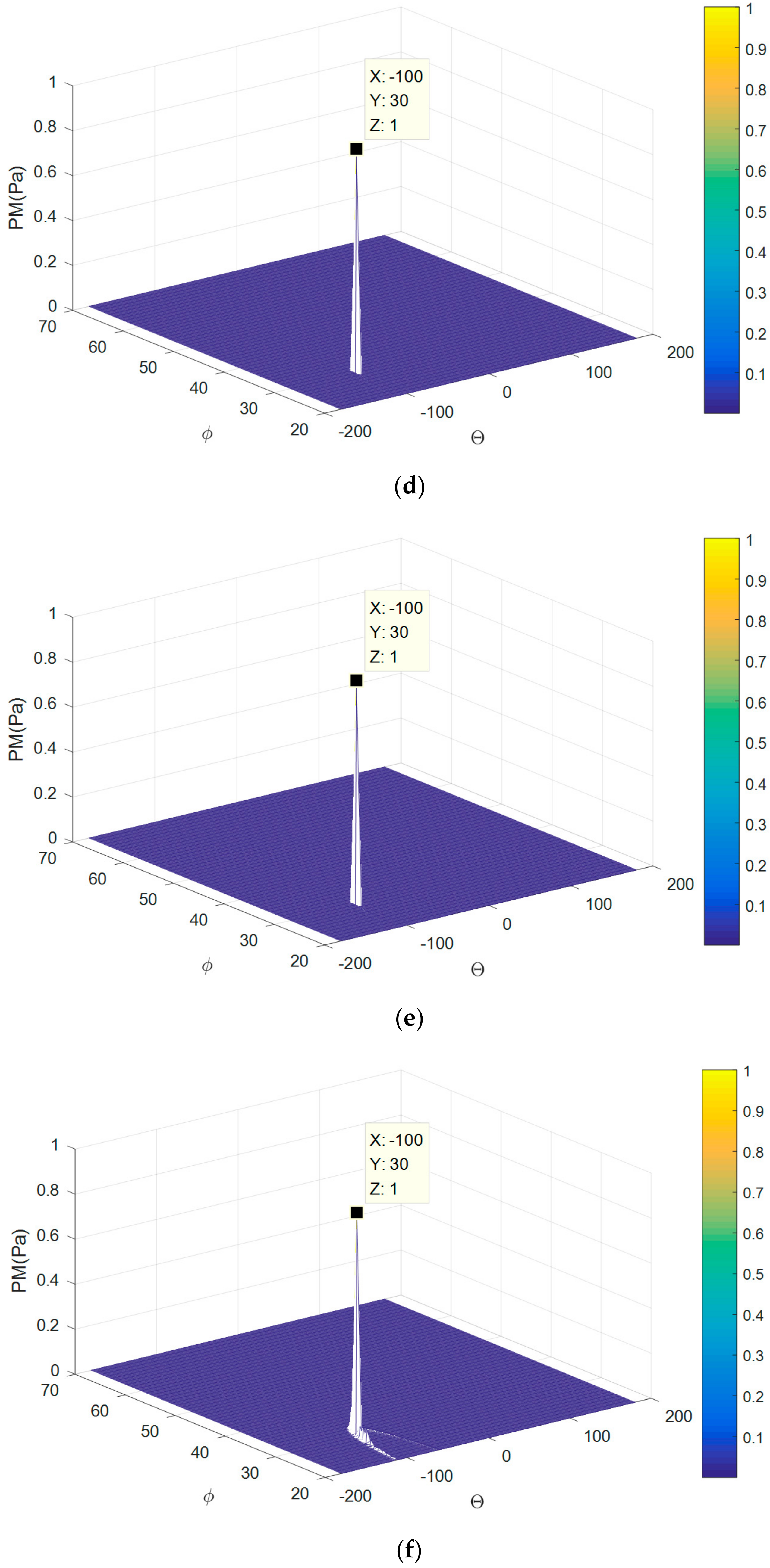

3.2. Comparison Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liu, Y.; Liu, Z. Development of Constrained Layer Damping Toolholder to Improve Chatter Stability in End Milling. Int. J. Mech. Sci. 2016, 117, 299–308. [Google Scholar] [CrossRef]

- George, W. Analysis of Tool Wear Effect on Chatter Stability in Turning. Int. J. Mech. Sci. 1995, 37, 391–404. [Google Scholar]

- Rafal, R.; Pawel, L. Chatter Identification Methods on the Basis of Time Series Measured During Titanium Superalloy Milling. Int. J. Mech. Sci. 2015, 99, 196–207. [Google Scholar] [CrossRef]

- Crocco, M.; Martelli, S. Audio Tracking in Noisy Environments by Acoustic Map and Spectral Signature. IEEE Trans. Cybern. 2017. [Google Scholar] [CrossRef] [PubMed]

- Tuncer, E.; Friedlander, B. Classical and Modern Direction of Arrival Estimation; Elsevier: Burlington, MA, USA, 2009. [Google Scholar]

- Ho, K.H.; Chan, Y.T. Solution and Performance Analysis of Geolocation by TDOA. IEEE Trans. Aerosp. Electron. Syst. 1993, 29, 1311–1322. [Google Scholar] [CrossRef]

- Knapp, C.H.; Carter, G.C. The Generalized Correlation Method for Estimation of Time Delay. IEEE Trans. Acoust. Speech Signal Process. 1976, 24, 320–327. [Google Scholar] [CrossRef]

- Den Broeck, B.V.; Bertrand, A. Time-Domain Generalized Cross Correlation Phase Transform Sound Source Localization for Small Microphone Arrays. In Proceedings of the 2012 5th European DSP Education and Research Conference (EDERC), Amsterdam, The Netherlands, 13–14 September 2012. [Google Scholar]

- Mathews, C.P.; Zoltowski, M.D. Eigenstructure Techniques for 2-D Angle Estimation with Uniform Circular Arrays. IEEE Trans. Signal Process. 1994, 42, 2395–2407. [Google Scholar] [CrossRef]

- Stoica, P.; Nehorai, A. MUSIC Maximum Likelihood and Cramer-Rao Bound. IEEE Trans. Acoust. Speech Signal Process. 1989, 37, 720–741. [Google Scholar] [CrossRef]

- Lee, H.B.; Wengrovitz, M.S. Resolution Threshold Beamspace MUSIC for Two Closely Spaced Emitters. IEEE Trans. Acoust. Speech Signal Process. 1990, 38, 723–738. [Google Scholar] [CrossRef]

- Ephraim, Y.; Malah, D. Speech Enhancement Using a Minimum Mean-Square Error Short-Time Spectral Amplitude Estimator. IEEE Trans. Acoust. Speech Signal Process. 1984, 32, 1109–1121. [Google Scholar] [CrossRef]

- Ephraim, Y.; Malah, D. Speech Enhancement Using a Minimum Mean-Square Error Log-Spectral Amplitude Estimator. IEEE Trans. Acoust. Speech Signal Process. 1985, 33, 443–445. [Google Scholar] [CrossRef]

- Sohn, J. A Statistical Model-Based Voice Activity Detection. IEEE Signal Process. Lett. 1999, 6, 1–3. [Google Scholar] [CrossRef]

- Cappe, O. Elimination of the Musical Noise Phenomenon with the Ephraim and Malah Noise Suppressor. IEEE Trans. Speech Audio Process. 1994, 2, 345–349. [Google Scholar] [CrossRef]

- Honghao, T. DOA Estimation Based on MUSIC Algorithm; Institutionen för Fysik och Elektroteknik: Kalmar, Sweden, 2014. [Google Scholar]

| Spindle Speed (rpm) | Depth of Cut (mm) | Feed Rate (mm/min) | |

|---|---|---|---|

| Data1 | 4000 | 1 | 600 |

| Data2 | 4000 | 5 | 600 |

| Data3 | 4000 | 5 | 500 |

| Data4 | 8000 | 5 | 500 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.-L.; Tsai, Y.-T. Numerical Analysis of CNC Milling Chatter Using Embedded Miniature MEMS Microphone Array System. Inventions 2018, 3, 5. https://doi.org/10.3390/inventions3010005

Wang P-L, Tsai Y-T. Numerical Analysis of CNC Milling Chatter Using Embedded Miniature MEMS Microphone Array System. Inventions. 2018; 3(1):5. https://doi.org/10.3390/inventions3010005

Chicago/Turabian StyleWang, Pang-Li, and Yu-Ting Tsai. 2018. "Numerical Analysis of CNC Milling Chatter Using Embedded Miniature MEMS Microphone Array System" Inventions 3, no. 1: 5. https://doi.org/10.3390/inventions3010005