General Design Procedure for Free and Open-Source Hardware for Scientific Equipment

Abstract

:1. Introduction

2. Generalized Procedure

- Evaluate existing similar scientific tools for their physical functions and base the design of the FOSH design off of replicating the physical effects, not pre-existing designs. If necessary, evaluate a proof of concept.

- Design, involving the following design principles:

- Use only free and open-source software tool chains and open hardware for the fabrication of the device.

- Attempt to minimize the number and type of parts and the complexity of the tool.

- Minimize the amount of material and the cost of production.

- Maximize the use of components that can be distributed digitally manufactured from using widespread and accessible tools such as the RepRap 3D printer.

- Create parametric designs with pre-designed components, which enable design customization.

- All components that are not easily and economically fabricated with existing open hardware equipment in a distributed fashion should be chosen from off-the-shelf parts, which are readily available throughout the world.

- Validate the design for the targeted function(s).

- Document the design, manufacture, assembly, calibration, and operation of the device meticulously. This should include the raw source of the design (e.g., computer aided design files (CAD)), not only the files used for production (e.g., stereolithography files (STL)).

- Share all of the documentation in the open-access literature.

3. Details of Each Procedure Step

3.1. Literature Review & Proof of Concept

3.2. Design, Involving the Following Design Principles

3.2.1. Use of Only Free and Open-Source Tool Chain

3.2.2. Minimize Complexity

3.2.3. Minimize Material Consumption

3.2.4. Maximize Components that Can Be Digitally Manufactured and Distributed

3.2.5. Create Parametric Designs

3.2.6. Off-the-Shelf Parts

3.3. Validation

3.4. Proper Documentation

- Share design files in the most universal type.

- Include a fully detailed bill of materials, including prices and sourcing information.

- If software is involved, make sure the code is clear and understandable to a layman.

- Include many photos such that nothing is obscured; these can be used as a reference while manufacturing.

- In the methods section, the entire manufacturing process must be detailed, as these are instructions for users to replicate the design.

- Share on many file hosting sites (see step 5 below), but also be sure to specify a license. This gives users information on what fair use of the design constitutes.

3.5. Share Aggressively

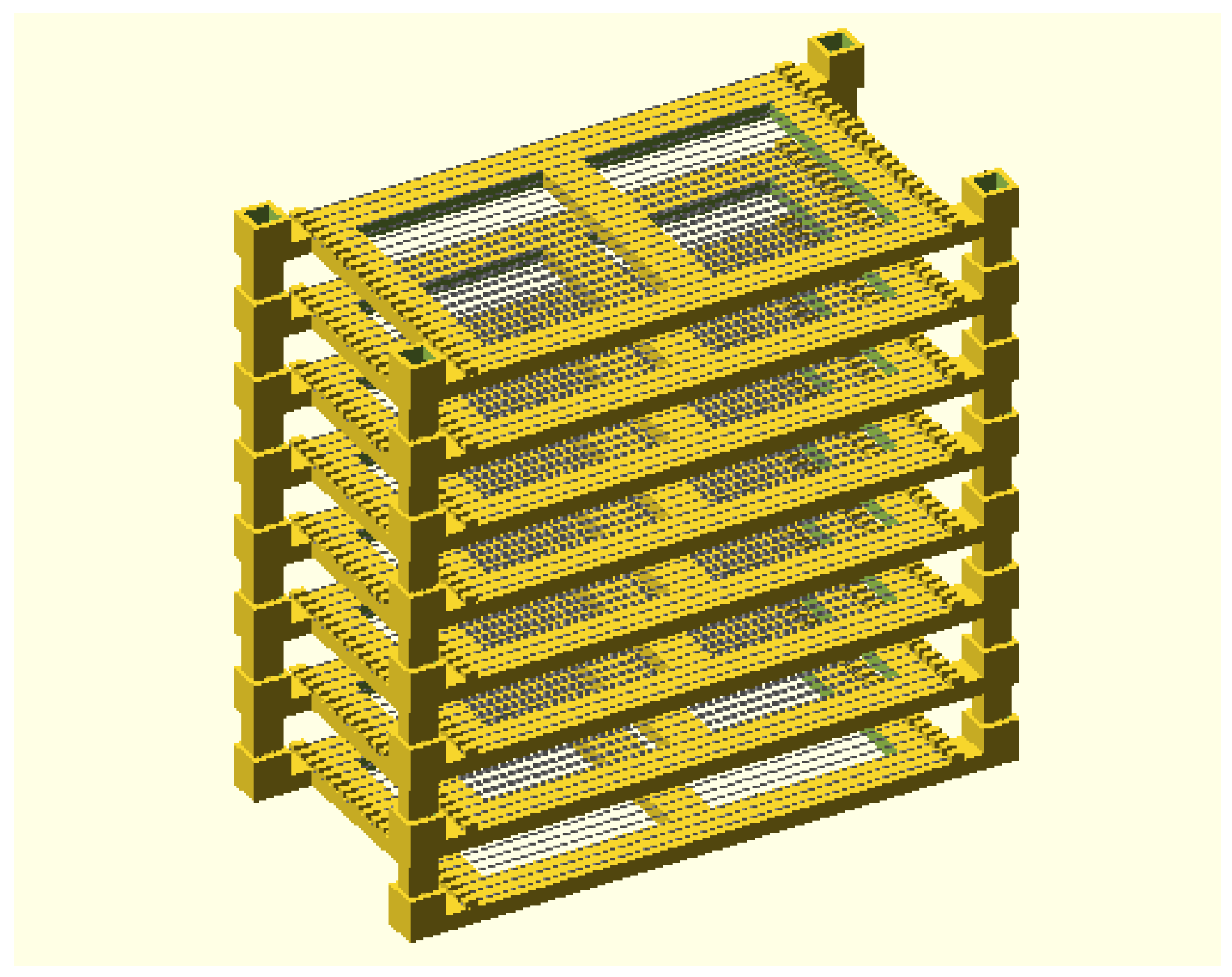

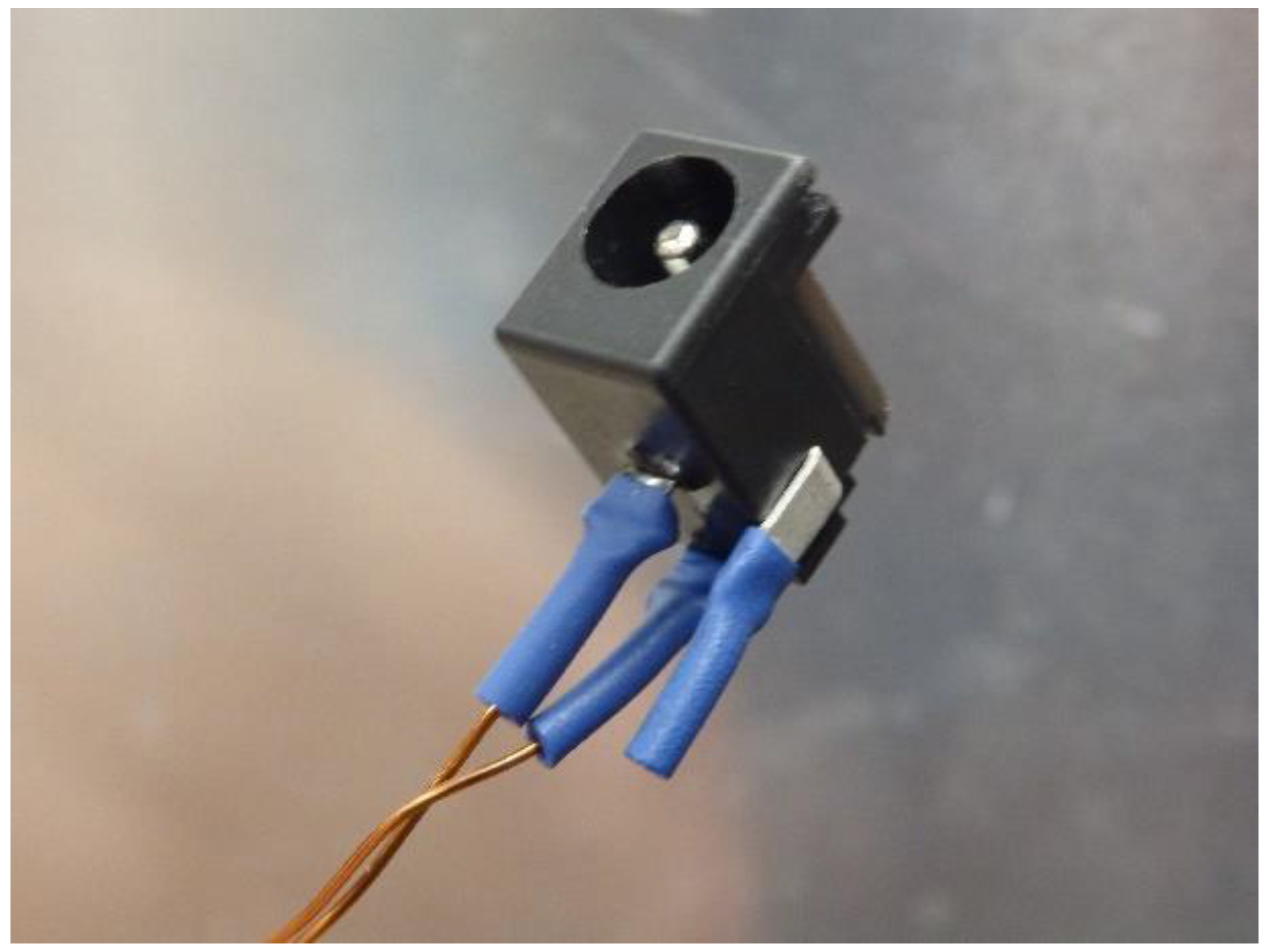

4. Case Study: Slide Dryer

- Poor documentation and construction notes

- Not scalable

- Overly complex

- The performance of the device is not characterized.

- Wire Resistance: The measured resistivity of the heating element (in Ohm/mm).

- Wire Diameter: The diameter of the heating element (in mm).

- Supply V: The voltage of the power supply (in V).

- Supply I: Maximum allowable current from the power supply (in A).

- Slide count: The desired number of slides to dry (number).

- Slide Dimensions: Width and length of the slides (in mm)

- Printer Dimensions: The 3D print bed surface area X and Y size of the 3D printer to be used.

5. Results and Discussion

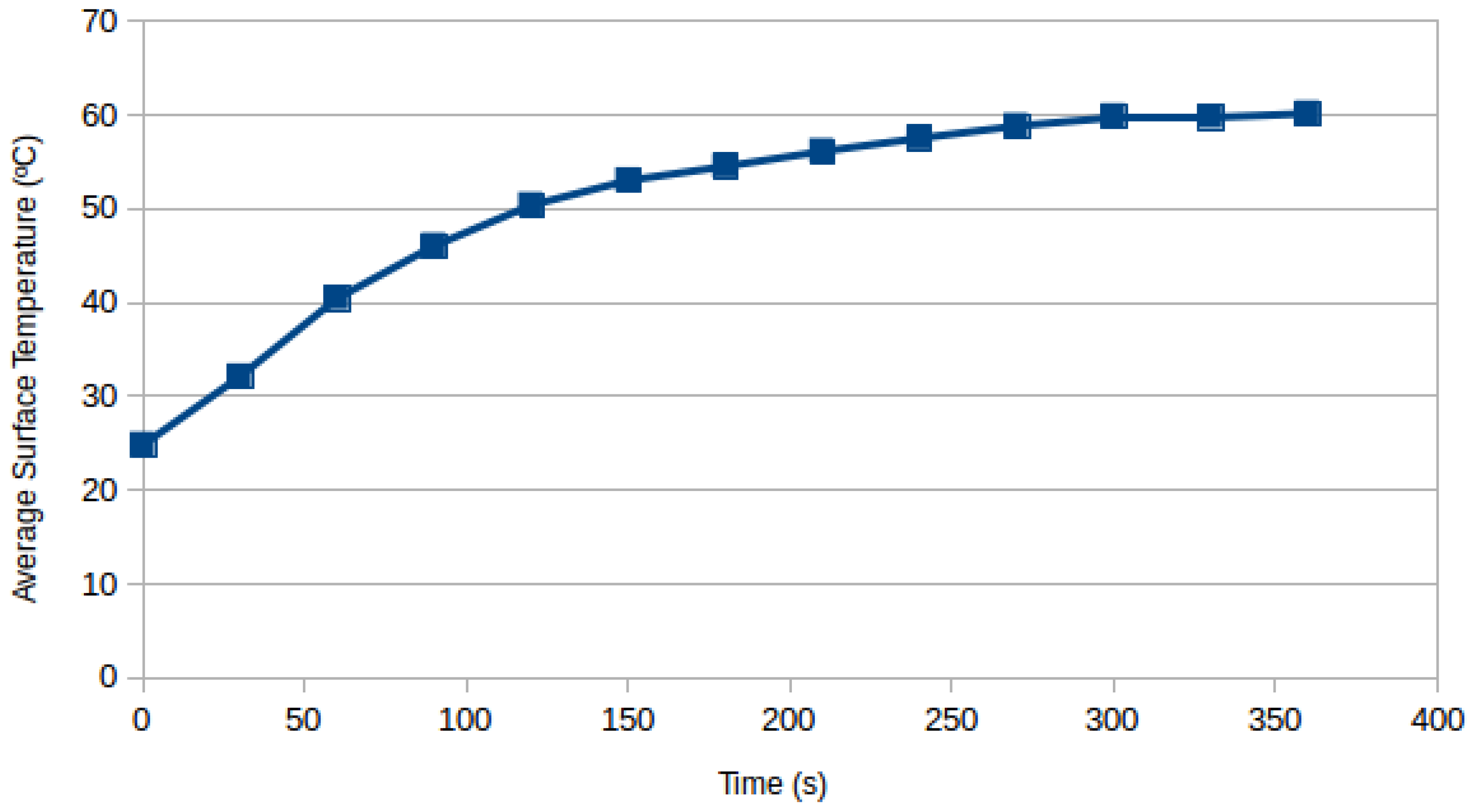

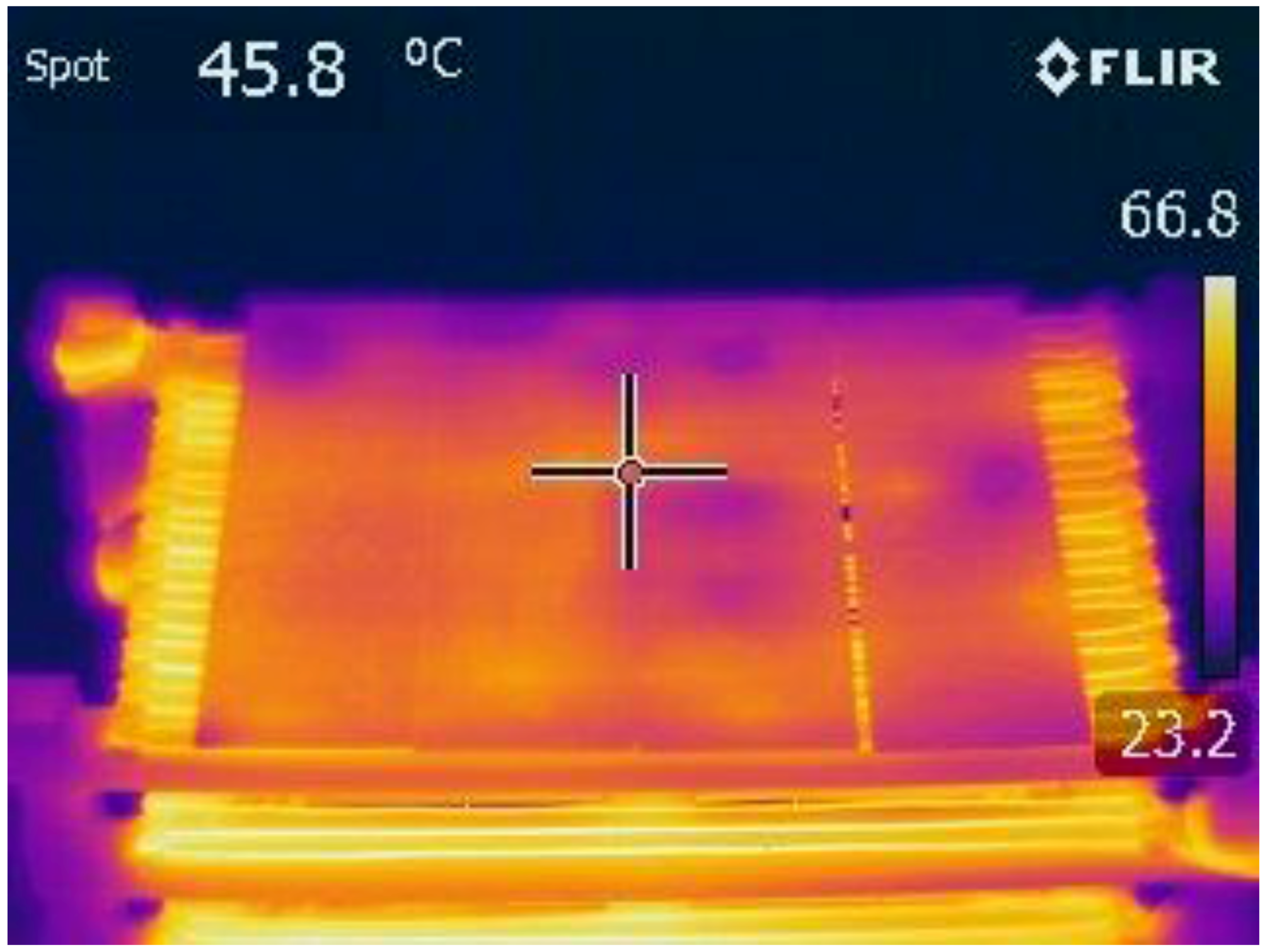

5.1. Drying Time and Temperature Uniformity

5.2. Customized Designs

5.3. Design Iterations

5.4. Safety

5.5. Techno-Economic Comparisons

5.6. Future Work

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pearce, J.M. Building Research Equipment with Free, Open-Source Hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs, 1st ed.; Elsevier: Waltham, MA, USA, 2014. [Google Scholar]

- Trivedi, D.K.; Pearce, J.M. Open Source 3-D Printed Nutating Mixer. Appl. Sci. 2017, 7, 942. [Google Scholar] [CrossRef]

- Liardon, J.L.; Barry, D.A. Adaptable Imaging Package for Remote Vehicles. HardwareX 2017, 2. [Google Scholar] [CrossRef]

- Dosemagen, S.; Liboiron, M.; Molloy, J. Gathering for Open Science Hardware. J. Open Hardw. 2016, 1, 4. [Google Scholar] [CrossRef]

- Wijnen, B.; Hunt, E.J.; Anzalone, G.C.; Pearce, J.M. Open-source syringe pump library. PLoS ONE 2014, 9, e107216. [Google Scholar] [CrossRef] [PubMed]

- Zykov, V.; Chan, A.; Lipson, H. Molecubes: An open-source modular robotics kit. In Proceedings of the IROS-2007 Self-Reconfigurable Robotics Workshop, San Diego, CA, USA, 2 November 2007. [Google Scholar]

- Baden, T.; Chagas, A.; Marzullo, T.; Prieto-Godino, L.; Euler, T. Open Laware: 3-D Printing Your Own Lab Equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar]

- Damase, T.R.; Stephens, D.; Spencer, A.; Allen, P.B. Open source and DIY hardware for DNA nanotechnology labs. J. Biol. Methods 2015, 2, e24. [Google Scholar] [CrossRef] [PubMed]

- Oh, J.; Hofer, R.; Fitch, W.T. An open source automatic feeder for animal experiments. HardwareX 2017, 1, 13–21. [Google Scholar] [CrossRef]

- McMunn, M.S. A time-sorting pitfall trap and temperature datalogger for the sampling of surface-active arthropods. HardwareX 2017, 1, 38–45. [Google Scholar] [CrossRef]

- Gali, H. An Open-Source Automated Peptide Synthesizer Based on Arduino and Python. Slas Technol. Trans. Life Sci. Innov. 2017, 22, 493–499. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Anzalone, N.C.; Faria, R.P.; Pearce, J.M. Open-source 3D-printable optics equipment. PLoS ONE 2013, 8, e59840. [Google Scholar] [CrossRef] [PubMed]

- Fobel, R.; Fobel, C.; Wheeler, A.R. DropBot: An open-source digital microfluidic control system with precise control of electrostatic driving force and instantaneous drop velocity measurement. Appl. Phys. Lett. 2013, 102, 193513. [Google Scholar] [CrossRef]

- Pearce, J.M.; Anzalone, N.C.; Heldt, C.L. Open-Source Wax RepRap 3-D Printer for Rapid Prototyping Paper-Based Microfluidics. J. Lab. Autom. 2016, 21, 510–516. [Google Scholar] [CrossRef] [PubMed]

- Schausberger, S.E.; Kaltseis, R.; Drack, M.; Cakmak, U.D.; Major, Z.; Bauer, S. Cost-Efficient Open Source Desktop Size Radial Stretching System With Force Sensor. IEEE Access 2015, 3, 556–561. [Google Scholar] [CrossRef]

- Chiu, S.H.; Urban, P.L. Robotics-assisted mass spectrometry assay platform enabled by open-source electronics. Biosens. Bioelectr. 2015, 64, 260–268. [Google Scholar] [CrossRef] [PubMed]

- Chandra, H.; Allen, S.W.; Oberloier, S.W.; Bihari, N.; Gwamuri, J.; Pearce, J.M. Open-source automated mapping four-point probe. Materials 2017, 10, 110. [Google Scholar] [CrossRef] [PubMed]

- Wijnen, B.; Petersen, E.E.; Hunt, E.J.; Pearce, J.M. Free and open-source automated 3-D microscope. J. Microsc. 2016, 264, 238–246. [Google Scholar] [CrossRef] [PubMed]

- Wijnen, B.; Anzalone, G.C.; Pearce, J.M. Open-source mobile water quality testing platform. J. Water Sanit. Hyg. Dev. 2014, 4, 532–537. [Google Scholar] [CrossRef]

- Dhankani, K.; Pearce, J.M. Open Source Laboratory Sample Rotator Mixer and Shaker. HardwareX 2017, 1, 1–12. [Google Scholar] [CrossRef]

- Pocero, L.; Amaxilatis, D.; Mylonas, G.; Chatzigiannakis, I. Open source IoT meter devices for smart and energy-efficient school buildings. HardwareX 2017, 1, 54–67. [Google Scholar] [CrossRef]

- Thomson, C.C.; Jakubowski, M. Toward an Open Source Civilization:(Innovations Case Narrative: Open Source Ecology). Innovations 2012, 7, 53–70. [Google Scholar] [CrossRef]

- Jiang, J.; Claudel, C. A high performance, low power computational platform for complex sensing operations in smart cities. HardwareX 2017, 1, 22–37. [Google Scholar] [CrossRef]

- Harnett, C. Open source hardware for instrumentation and measurement. IEEE Instrum. Meas. Mag. 2011, 14. [Google Scholar] [CrossRef]

- Gibb, A.; Abadie, S. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers, 1st ed.; Addison-Wesley Professional: Boston, MA, USA, 2014. [Google Scholar]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper-Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific: Toh Tuck Link, Singapore, 2010; pp. 568–580. [Google Scholar]

- Kentzer, J.; Koch, B.; Thiim, M.; Jones, R.W.; Villumsen, E. An open source hardware-based mechatronics project: The replicating rapid 3-D printer. In Proceedings of the 4th International Conference on Mechatronics, Kuala Lumpur, Malaysia, 17–19 May 2011. [Google Scholar]

- Schelly, C.; Anzalone, G.; Wijnen, B.; Pearce, J.M. Open-source 3-D printing technologies for education: Bringing additive manufacturing to the classroom. J. Vis. Lang. Comput. 2015, 28, 226–237. [Google Scholar] [CrossRef]

- Zhang, C.; Wijnen, B.; Pearce, J.M. Open-source 3-D platform for low-cost scientific instrument ecosystem. J. Lab. Autom. 2016, 21, 517–525. [Google Scholar] [CrossRef] [PubMed]

- Moilanen, J.; Vaden, T. 3D Printing Community and Emerging Practices of Peer Production. First Monday 2013. [Google Scholar] [CrossRef]

- Coakley, M.F.; Hurt, D.E.; Weber, N.; Mtingwa, M.; Fincher, E.C.; Alekseyev, V.; Chen, D.T.; Yun, A.; Gizaw, M.; Swan, J.; et al. The NIH 3D print exchange: A public resource for bioscientific and biomedical 3D prints. 3D Print. Addit. Manuf. 2014, 1, 137–140. [Google Scholar] [CrossRef] [PubMed]

- Coakley, M.; Hurt, D.E. 3D Printing in the Laboratory: Maximize Time and Funds with Customized and Open-Source Labware. J. Lab. Autom. 2016, 21, 489–495. [Google Scholar] [CrossRef] [PubMed]

- Bonvoisin, J.; Galla, J.K.; Prendeville, S. Design Principles for Do-It-Yourself Production. In International Conference on Sustainable Design and Manufacturing; Springer: Bolongna, Italy, 2017; pp. 77–86. [Google Scholar]

- Fu, K.K.; Yang, M.C.; Wood, K.L. Design principles: Literature review, analysis, and future directions. J. Mech. Des. 2016, 138, 101103. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W. Engineering Design; Springer: London, UK, 2016. [Google Scholar]

- Nilsiam, Y.; Pearce, J.M. Free and Open Source 3-D Model Customizer for Websites to Democratize Design with OpenSCAD. Designs 2017, 1, 5. [Google Scholar] [CrossRef]

- Feller, J.; Fitzgerald, B. Understanding Open Source Software Development London; Addison-Wesley: London, UK, 2002; pp. 143–159. [Google Scholar]

- Lakhani, K.R.; Wolf, R.G. Why hackers do what they do: Understanding motivation and effort in free/open source software projects. Perspect. Free Open Source Softw. 2005, 1, 3–22. [Google Scholar] [CrossRef]

- Hippel, E.V.; Krogh, G.V. Open source software and the “private-collective” innovation model: Issues for organization science. Organ. Sci. 2003, 14, 209–223. [Google Scholar] [CrossRef]

- Harjula, T.; Rapoza, B.; Knight, W.A.; Boothroyd, G. Design for disassembly and the environment. CIRP Ann. Manuf. Technol. 1996, 45, 109–114. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Kreiger, M.; Pearce, J.M. Environmental life cycle analysis of distributed three-dimensional printing and conventional manufacturing of polymer products. ACS Sustain. Chem. Eng. 2013, 1, 1511–1519. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Gebler, M.; Uiterkamp, A.J.S.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Faludi, J.; Bayley, C.; Bhogal, S.; Iribarne, M. Comparing environmental impacts of additive manufacturing vs traditional machining via life-cycle assessment. Rapid Prototyp. J. 2015, 21, 14–33. [Google Scholar] [CrossRef]

- Anzalone, G.C.; Wijnen, B.; Pearce, J.M. Multi-material additive and subtractive prosumer digital fabrication with a free and open-source convertible delta RepRap 3-D printer. Rapid Prototyp. J. 2015, 21, 506–519. [Google Scholar] [CrossRef]

- Petersen, E.E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Petersen, E.E.; Kidd, R.W.; Pearce, J.M. Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market. Technologies 2017, 5, 45. [Google Scholar] [CrossRef]

- Pearce, J. Quantifying the Value of Open Source Hardware Development. Mod. Econ. 2015, 6, 1–11. [Google Scholar] [CrossRef]

- Pearce, J.M. Return on investment for open source scientific hardware development. Sci. Public Policy 2015, 43, 192–195. [Google Scholar] [CrossRef]

- Lynch Open Source Syringe Pump Modifications. Available online: http://www.appropedia.org/Lynch_open_source_syringe_pump_modifications (accessed on 29 November 2017).

- Best Practices for Open-Source Hardware 1.0. Available online: https://www.oshwa.org/sharing-best-practices/ (accessed on 29 November 2017).

- Printable Part Sources. Available online: http://reprap.org/wiki/Printable_part_sources (accessed on 29 November 2017).

- Open Circuit Institute. Available online: http://opencircuitinstitute.org/ (accessed on 29 November 2017).

- Slide Warmers and Oven/Incubators. Available online: https://www.emsdiasum.com/microscopy/products/histology/heaters.aspx (accessed on 29 November 2017).

- Microscopic-Slide Drier. Available online: https://patents.google.com/patent/US1170739A (accessed on 29 November 2017).

- Шахтная аэрожёлобная сушилка. Available online: https://patents.google.com/patent/RU2589894C1 (accessed on 29 November 2017).

- Slide Staining and Heating Rack. Available online: https://patents.google.com/patent/US2101161A (accessed on 29 November 2017).

- Glass Slide Dryer. Available online: https://3dprint.nih.gov/discover/3dpx-004001 (accessed on 29 November 2017).

- VWR Slide Warmers Dryers. Available online: https://us.vwr.com/store/product/3617131/slide-warmers-dryers (accessed on 29 November 2017).

- Fischer Scientific Slide Warmers. Available online: https://www.fishersci.com/us/en/products/I9C8KUA7/slide-warmers.html (accessed on 29 November 2017).

- Thomas Scientific Slide Warmers. Available online: https://www.thomassci.com/search/go?ThomasDomain=www.thomassci.com&w=slide+warmers (accessed on 29 November 2017).

- Lab Scientific Slide Warmers. Available online: https://labscientific.com/Cytology/Tissue-Floating-Bath-and-Slides-Warmer/Slide-Warmers/ (accessed on 29 November 2017).

- Agar Scientific Slide Warmers. Available online: http://www.agarscientific.com/slide-warmers-for-24-slides-and-56-slides.html (accessed on 29 November 2017).

- Irwin, J.D.; Nelms, D.I. Basic Engineering Circuit Analysis, 10th ed.; Wiley: Hoboken, NJ, USA, 2011; p. 27. ISBN 978-0-470-63322-9. [Google Scholar]

- Remington Industries. 20H200P 20 AWG Magnet Wire, Enameled Copper Wire, 200 Degree, 1.0 lb., 0.0343″ Diameter, 314′ Length, Natural. Available online: http://a.co/gbuYXLf (accessed on 29 November 2017).

- LEDMO Power Supply, Transformers, LED Adapter, 12V, 5A Max, 60 Watt Max, for LED Strip. Available online: http://a.co/2FwKrqr (accessed on 29 November 2017).

- LulzBot TAZ 5. Available online: https://www.lulzbot.com/store/printers/lulzbot-taz-5 (accessed on 29 November 2017).

- Open Source Slide Dryer. OSF. Available online: https://osf.io/rm2ah/ (accessed on 4 December 2017).

- Appropedia. Available online: http://www.appropedia.org/ (accessed on 2 December 2017).

- Pearce, J.M. Impacts of Open Source Hardware in Science and Engineering. Bridge 2017, 47, 24–31. [Google Scholar]

- Dryden, M.D.; Fobel, R.; Fobel, C.; Wheeler, A.R. Upon the Shoulders of Giants: Open-Source Hardware and Software in Analytical Chemistry. Anal. Chem. 2017, 89, 4330–4338. [Google Scholar] [CrossRef] [PubMed]

| Part | Link | Quantity | Cost |

|---|---|---|---|

| HIPS Filament | https://www.lulzbot.com/store/filament/hips | 120 g | $4.79 |

| 20 AWG Magnet wire | http://a.co/gbuYXLf | 10.6 m | $2.16 |

| 12 V 5 A Power Supply | http://a.co/7YzVkHB | 1 | $8.89 |

| Barrel Jack | https://www.digikey.com/short/q7wbrm | 1 | $0.76 |

| Shrink Tube | https://www.digikey.com/short/q300mc | 30 mm | $0.03 |

| Name | Cost (US$) | Capacity | US$/Slide | Max Temp. | Drying Time |

|---|---|---|---|---|---|

| FOSH 30 slide drier | 16.63 | 30 slides | 0.55 | 58 | 3.21 min |

| FOSH 66 slide drier | 23.82 | 66 slides | 0.36 | 42 | 4.58 min |

| FOSH 66 Slide drier (24 V) | 41.12 | 66 slides | 0.62 | 66 | 2.16 min |

| SHUR/Dry Slide Dryer III [56] | 5245.00 | 38 slides | 138.03 | 70 | 1.00 min * |

| Large Size Economical Slide Warmer [56] | 1274.00 | 66 slides | 19.30 | 100 | 1.37 min * |

| Slide Drying Bench, Electrothermal [61] | 1131.21 | 50 slides | 22.62 | 100 | 1.37 min * |

| Scientific Device Slide Heater [62] | 1080.00 | 20 slides | 54.00 | 65 | 1.66 min * |

| Slide Warmer [63] | 301.00 | 23 slides | 13.09 | 70 | 1.63 min * |

| XH-2002 [64] | 350.00 | 23 slides | 15.22 | 75 | 1.31 min * |

| Slide Warmers for 24 slides [65] | 317.00 | 24 slides | 13.22 | 70 | 1.63 min * |

| Slide warmer 23 slides [56] | 225.00 | 23 slides | 9.78 | 70 | 1.63 min * |

| Slide warmer 66 slides [56] | 285.00 | 66 slides | 4.32 | 70 | 1.63 min * |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oberloier, S.; Pearce, J.M. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs 2018, 2, 2. https://doi.org/10.3390/designs2010002

Oberloier S, Pearce JM. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs. 2018; 2(1):2. https://doi.org/10.3390/designs2010002

Chicago/Turabian StyleOberloier, Shane, and Joshua M. Pearce. 2018. "General Design Procedure for Free and Open-Source Hardware for Scientific Equipment" Designs 2, no. 1: 2. https://doi.org/10.3390/designs2010002