Machine Learning and Optimality in Multi Storey Reinforced Concrete Frames

Abstract

:1. Introduction

1.1. Initial Considerations

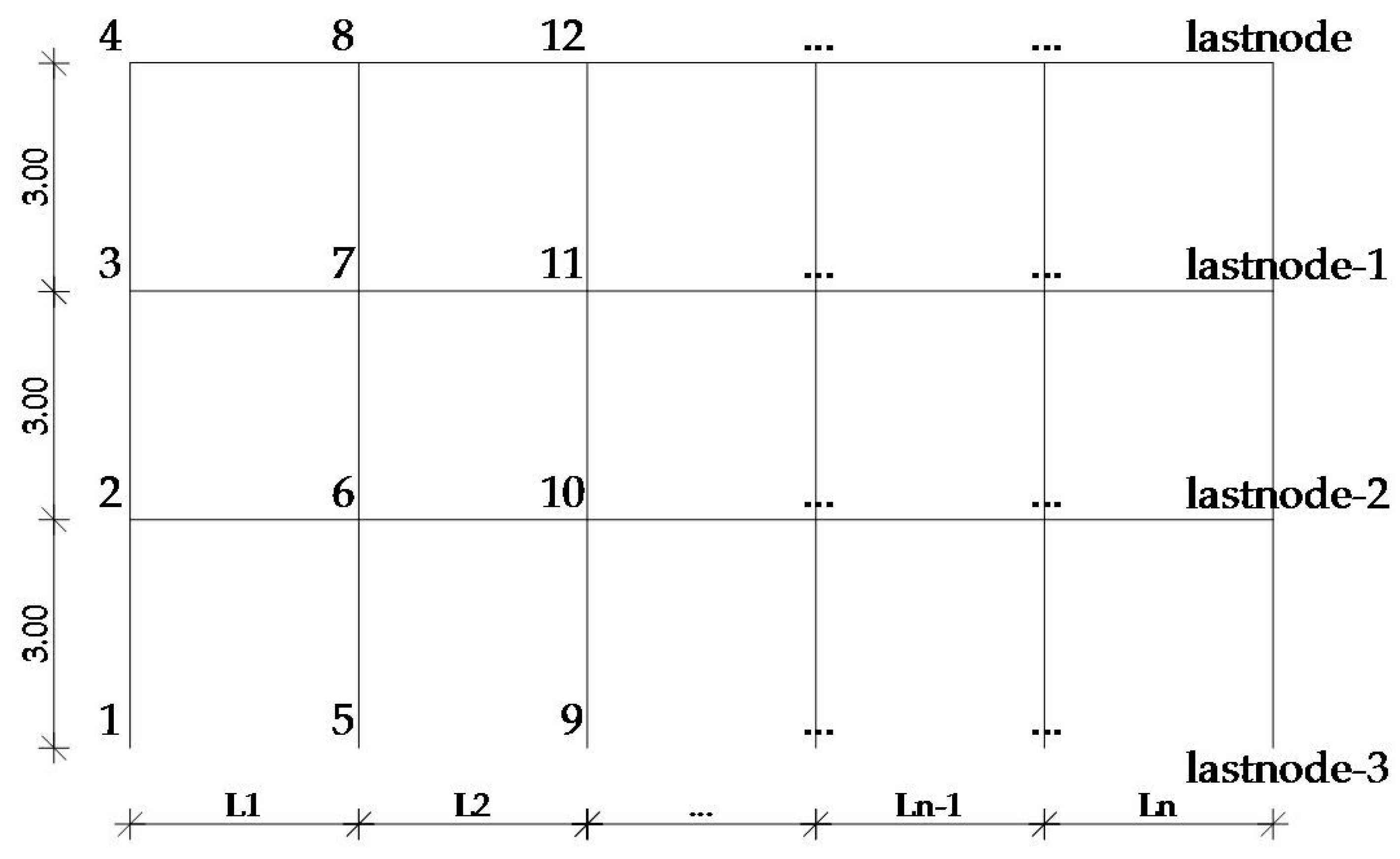

1.2. Programming Logic Followed for the Construction of the FEM Algorithm

Beam nodes second floor: [3:(numberofstoreys + 1):(lastnode − (numberofstoreys − 2))]

Beam nodes third floor: [4:(numberofstoreys + 1):(lastnode)]

2. Optimization Procedure and Variables

- Variable related to the form of the frames whose change influences the number of bays (eight possible choices leading to a total number of beam-column elements between five and 19).

- Variables related to the lengths of the beams. Each front beam length is considered to have a value between 3 and 7.5 m, with a step size of 0.5 m.

- Variables related to the cross sections of the beams of each storey that compose the structural frames. For all the frame scenarios, the following beam cross sections were considered: b = 350 mm h = 550 mm ρ = 1%, b = 350 mm h = 550 mm ρ = 2%, b = 350 mm h = 550 mm ρ = 3%, b = 350 mm h = 550 mm ρ = 4%, b = 350 mm h = 550 mm ρ = 5%, b = 350 mm h = 550 mm ρ = 6%, b = 350 mm h = 600 mm ρ = 1%, b = 350 mm h = 600 mm ρ = 2%, b = 350 mm h = 600 mm ρ = 3%, b = 350 mm h = 600 mm ρ = 4%, b = 350 mm h = 600 mm ρ = 5%, and b = 350 mm h = 600 mm ρ = 6% (where: b is the smaller dimension of the cross section, h is the larger dimension of the cross section, and ρ is the steel reinforcement ratio of the cross section).

- Variables related to the cross sections of the columns (each storey is examined separately) that compose the structural frames. For all the frame scenarios, the following column cross sections were considered: b = 350 mm h = 350 mm ρ = 1%, b = 350 mm h = 350 mm ρ = 2%, b = 350 mm h = 350 mm ρ = 3%, b = 350 mm h = 400 mm ρ = 1%, b = 350 mm h = 400 mm ρ = 2%, b = 350 mm h = 400 mm ρ = 3%, b = 400 mm h = 400 mm ρ = 1%, b = 400 mm h = 400 mm ρ = 2%, b = 400 mm h = 400 mm ρ = 3%, b = 400 mm h = 450 mm ρ = 1%, b = 400 mm h = 450 mm ρ = 2%, b = 400 mm h = 450 mm ρ = 3%, b = 450 mm h = 450 mm ρ = 1%, b = 450 mm h = 450 mm ρ = 2%, b = 450 mm h = 450 mm ρ = 3%, b = 450 mm h = 500 mm ρ = 1%, b = 500 mm h = 500 mm ρ = 1%, and b = 500 mm h = 550 mm ρ = 1%.

3. Reinforced Concrete Design Constraints

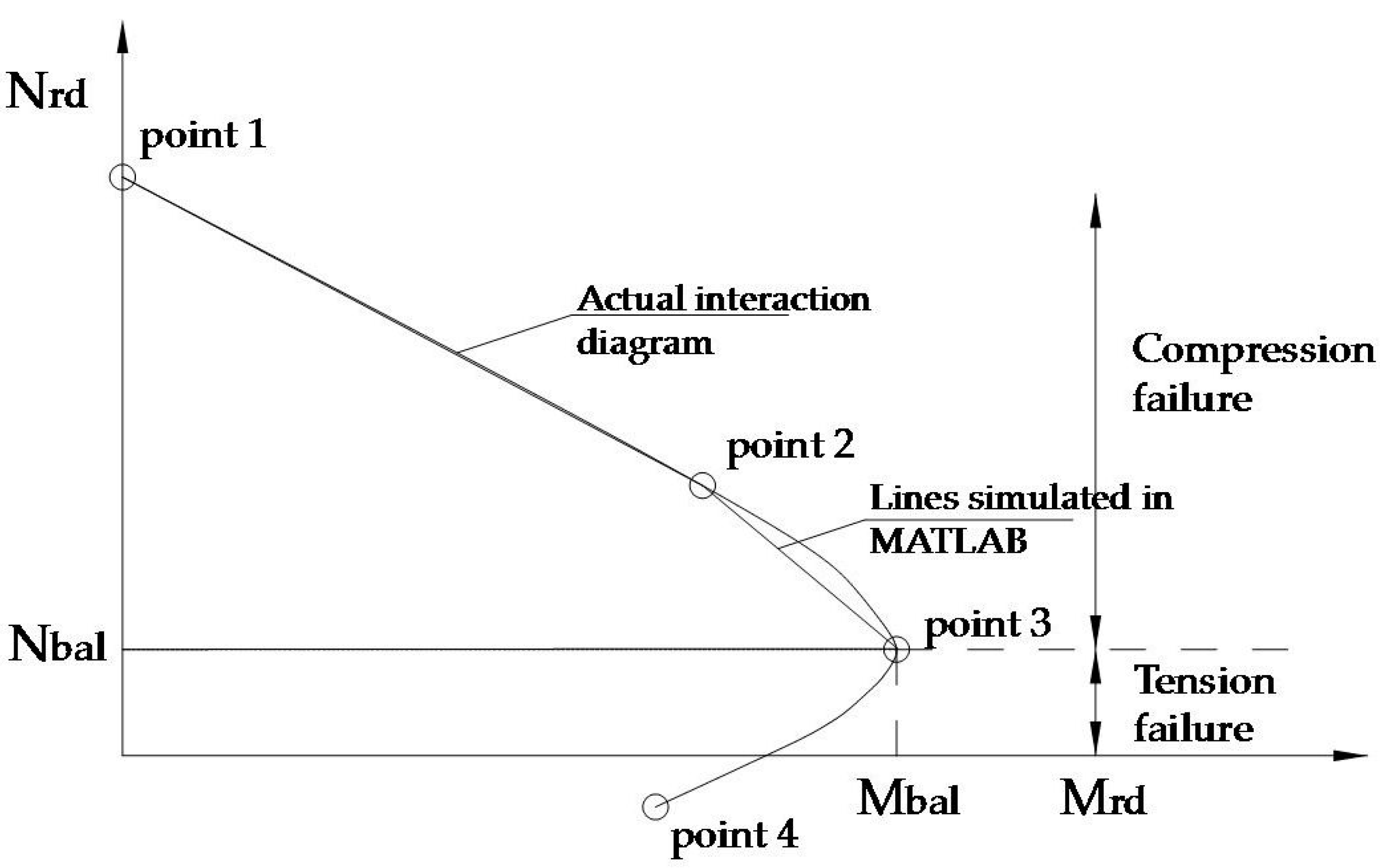

3.1. Modeling the RC Interaction Diagrams as a Separate Constraint

3.2. Other Constraints Considered for the Reinforced Concrete Elements

4. Objective Function

5. Discussion

5.1. Optimization Scenarios

- Clear column height: 3 m.

- RC forming cost: €75 per m2.

- Concrete cost (concrete grade C 25/30): €60 per m3.

- RC reinforcement cost per kg (rebar steel grade S500): €4708.2.

- RC cover: 35 mm.

5.2. Optimization Results and Conclusions

5.3. Machine Learning Applied on the Optima

- Optimal column area prediction network: network train ratio = 50%, network validation ratio = 25%, network test ratio = 25%, number of neurons = 900, number of hidden layers = 2, and transfer function = tan-sigmoid.

- Optimal number of bays prediction network: network train ratio = 50%, network validation ratio = 25%, network test ratio = 25%, number of neurons = 600, number of hidden layers = 2, and transfer function = log-sigmoid.

6. Further Discussion on the Results

Author Contributions

Conflicts of Interest

Appendix A

| Scenario | Number of Storeys | Load (kN/m) | Frame Length | Column 1 1st Storey | Beam 1 1st Storey | Column 2 1st Storey | Beam 2 1st Storey | Column 3 1st Storey | Beam 3 1st Storey | Column 4 1st Storey | Beam 4 1st Storey | Column 5 1st Storey | Beam 5 1st Storey | Column 6 1st Storey | Beam 1 6st Storey | Column 7 1st Storey | Number of Bays | Beam Length 1 | Beam Length 2 | Beam Length 3 | Beam Length 4 | Beam Length 5 | Beam Length 6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 15 | 15 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 8.077 | 6.923 | 0.000 | 0.000 | 0.000 | 0.000 |

| 2 | 2 | 35 | 15 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 7.500 | 7.500 | 0.000 | 0.000 | 0.000 | 0.000 |

| 3 | 2 | 55 | 15 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 6.923 | 8.077 | 0.000 | 0.000 | 0.000 | 0.000 |

| 4 | 2 | 75 | 15 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 7.826 | 7.174 | 0.000 | 0.000 | 0.000 | 0.000 |

| 5 | 2 | 15 | 25 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 12.500 | 12.500 | 0.000 | 0.000 | 0.000 | 0.000 |

| 6 | 2 | 35 | 25 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 8.721 | 7.558 | 8.721 | 0.000 | 0.000 | 0.000 |

| 7 | 2 | 55 | 25 | 0.129 | 1.000 | 0.169 | 1.000 | 0.169 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 8.523 | 7.950 | 8.520 | 0.000 | 0.000 | 0.000 |

| 8 | 2 | 75 | 25 | 0.129 | 1.000 | 0.226 | 1.000 | 0.190 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 8.784 | 7.433 | 8.784 | 0.000 | 0.000 | 0.000 |

| 9 | 2 | 15 | 35 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 11.667 | 10.000 | 13.333 | 0.000 | 0.000 | 0.000 |

| 10 | 2 | 35 | 35 | 0.129 | 2.000 | 0.129 | 2.000 | 0.129 | 2.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 12.000 | 11.000 | 12.000 | 0.000 | 0.000 | 0.000 |

| 11 | 2 | 55 | 35 | 0.129 | 1.000 | 0.169 | 1.000 | 0.190 | 1.000 | 0.148 | 1.000 | 0.130 | 0.000 | 0.000 | 0.000 | 0.000 | 4 | 8.750 | 9.375 | 9.375 | 7.500 | 0.000 | 0.000 |

| 12 | 2 | 75 | 35 | 0.129 | 2.000 | 0.237 | 2.000 | 0.237 | 2.000 | 0.226 | 2.000 | 0.148 | 0.000 | 0.000 | 0.000 | 0.000 | 4 | 7.955 | 9.545 | 9.545 | 7.955 | 0.000 | 0.000 |

| 13 | 3 | 15 | 15 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 7.500 | 7.500 | 0.000 | 0.000 | 0.000 | 0.000 |

| 14 | 3 | 35 | 15 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 8.077 | 6.923 | 0.000 | 0.000 | 0.000 | 0.000 |

| 15 | 3 | 55 | 15 | 0.129 | 1.000 | 0.226 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 7.800 | 7.200 | 0.000 | 0.000 | 0.000 | 0.000 |

| 16 | 3 | 75 | 15 | 0.169 | 1.000 | 0.290 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 8.125 | 6.875 | 0.000 | 0.000 | 0.000 | 0.000 |

| 17 | 3 | 15 | 25 | 0.129 | 2.000 | 0.129 | 2.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 2 | 12.964 | 12.038 | 0.000 | 0.000 | 0.000 | 0.000 |

| 18 | 3 | 35 | 25 | 0.129 | 1.000 | 0.148 | 1.000 | 0.148 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 8.553 | 7.895 | 8.553 | 0.000 | 0.000 | 0.000 |

| 19 | 3 | 55 | 25 | 0.136 | 1.000 | 0.237 | 1.000 | 0.226 | 1.000 | 0.148 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 8.523 | 7.950 | 8.523 | 0.000 | 0.000 | 0.000 |

| 20 | 3 | 75 | 25 | 0.148 | 2.000 | 0.290 | 2.000 | 0.263 | 2.000 | 0.237 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 8.333 | 7.639 | 9.028 | 0.000 | 0.000 | 0.000 |

| 21 | 3 | 15 | 35 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 11.667 | 11.667 | 11.667 | 0.000 | 0.000 | 0.000 |

| 22 | 3 | 35 | 35 | 0.129 | 1.000 | 0.190 | 1.000 | 0.190 | 1.000 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 3 | 12.209 | 10.581 | 12.209 | 0.000 | 0.000 | 0.000 |

| 23 | 3 | 55 | 35 | 0.169 | 1.000 | 0.190 | 1.000 | 0.226 | 1.000 | 0.226 | 1.000 | 0.190 | 1.000 | 0.130 | 0.000 | 0.000 | 5 | 7.609 | 6.594 | 7.609 | 6.594 | 6.594 | 0.000 |

| 24 | 3 | 75 | 35 | 0.148 | 2.000 | 0.226 | 2.000 | 0.226 | 2.000 | 0.226 | 2.000 | 0.237 | 2.000 | 0.237 | 2.000 | 0.226 | 6 | 5.904 | 4.639 | 5.904 | 6.326 | 6.326 | 5.904 |

| Scenario | Column 1 2nd Storey | Column 2 2nd Storey | Column 3 2nd Storey | Column 4 2nd Storey | Column 5 2nd Storey | Column 6 2nd Storey | Column 7 2nd Storey | Column 1 3rd Storey | Column 2 3rd Storey | Column 3 3rd Storey | Column 4 3rd Storey | Column 5 3rd Storey | Column 6 3rd Storey | Column 7 3rd Storey | Cost (€) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 4564.126 |

| 2 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 4671.232 |

| 3 | 0.129 | 0.148 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 4797.345 |

| 4 | 0.129 | 0.190 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 5039.027 |

| 5 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 6665.498 |

| 6 | 0.129 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 7192.480 |

| 7 | 0.129 | 0.129 | 0.129 | 0.136 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 7435.705 |

| 8 | 0.129 | 0.148 | 0.129 | 0.169 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 7869.759 |

| 9 | 0.129 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 9021.519 |

| 10 | 0.129 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 9589.716 |

| 11 | 0.129 | 0.129 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 10,244.155 |

| 12 | 0.129 | 0.148 | 0.169 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 11,055.325 |

| 13 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 6847.017 |

| 14 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 7004.584 |

| 15 | 0.129 | 0.148 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 7284.292 |

| 16 | 0.129 | 0.190 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 7758.18 |

| 17 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.000 | 9993.10 |

| 18 | 0.129 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.129 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 10,806.77 |

| 19 | 0.129 | 0.190 | 0.148 | 0.129 | 0.000 | 0.000 | 0.000 | 0.129 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 11,389.19 |

| 20 | 0.148 | 0.237 | 0.226 | 0.169 | 0.000 | 0.000 | 0.000 | 0.129 | 0.148 | 0.148 | 0.129 | 0.000 | 0.000 | 0.000 | 12,307.80 |

| 21 | 0.129 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 0.129 | 0.129 | 0.129 | 0.129 | 0.000 | 0.000 | 0.000 | 13,544.88 |

| 22 | 0.148 | 0.169 | 0.129 | 0.148 | 0.000 | 0.000 | 0.000 | 0.148 | 0.129 | 0.129 | 0.148 | 0.000 | 0.000 | 0.000 | 14,623.87 |

| 23 | 0.129 | 0.129 | 0.190 | 0.129 | 0.129 | 0.148 | 0.000 | 0.129 | 0.148 | 0.130 | 0.130 | 0.129 | 0.148 | 0.000 | 16,036.79 |

| 24 | 0.129 | 0.129 | 0.136 | 0.169 | 0.187 | 0.187 | 0.148 | 0.129 | 0.129 | 0.136 | 0.129 | 0.148 | 0.129 | 0.129 | 17,457.05 |

References

- Hibbeler, R.C. Structural Analysis; Prentice Hall: Singapore, 2006. [Google Scholar]

- Adeli, H.; Sarma, K. Cost Optimization of Structures: Fuzzy Logic, Genetic Algorithms and Parallel Computing; John Wiley & Sons: Chichester, UK, 2006. [Google Scholar]

- Naaman, A.E. Minimum cost versus minimum weight of prestressed slabs. J. Struct. Div. ASCE 1976, 102, 1493–1505. [Google Scholar]

- Abendroth, R.E.; Salmon, C.G. Sensitivity study of optimum RC restrained end T-sections. J. Struct. Eng. ASCE 1986, 112, 1928–1943. [Google Scholar] [CrossRef]

- Erbatur, F.; Al Zaid, R.; Dahman, N.A. Optimization and sensitivity of prestressed concrete beams. Comput. Struct. 1992, 45, 881–886. [Google Scholar] [CrossRef]

- Krishnamoorthy, C.S.; Munro, J. Linear program for Optimal Design of Reinforced Concrete Frames. Proc. IABSE 1973, 3, 119–141. [Google Scholar]

- Lee, C.; Ahn, J. Flexural Design of Reinforced Concrete Frames by Genetic Algorithm. J. Struct. Eng. ASCE 2003, 129, 762–774. [Google Scholar] [CrossRef]

- Camp, C.V.; Pezeshk, S.; Hansson, H. Flexural Design of Reinforced Concrete Frames Using a Genetic Algorithm. J. Struct. Eng. ASCE 2003, 129, 105–115. [Google Scholar] [CrossRef]

- Guerra, A.; Kiousis, P. Design Optimization of reinforced concrete structures. Comput. Concr. 2006, 3, 313–334. [Google Scholar] [CrossRef]

- Yousif, S.T.; ALsaffar, I.S.; Ahmed, S.M. Optimum Design of Singly and Doubly Reinforced Concrete Beam Sections: Artificial Neural Network Application. Iraqi J. Civ. Eng. 2010, 6, 1–19. [Google Scholar]

- Bekas, G.K. Whole Life Cost and Optimization of Steel, Reinforced Concrete and Timber Buildings. Ph.D. Thesis, Department of Production Engineering and Management, Technical University of Crete, Crete, Greece, 2017. in preparation. [Google Scholar]

- Ferreira, A.J.M. MATLAB Codes for Finite Element Analysis—Solids and Structures; Springer: Porto, Portugal, 2009; pp. 89–102. [Google Scholar]

- Hutton, D.V. Fundamentals of Finite Element Analysis; Mc Graw Hill: New York, NY, USA, 2004; pp. 91–130. [Google Scholar]

- Cobb, F. Structural Engineer’s Pocket Book: Eurocodes, 3rd ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- Cheng, F.Y.; Truman, K.Z. Structural Optimization: Dynamic and Seismic Applications; Spon Press: New York, NY, USA, 2010. [Google Scholar]

- EN 1992-1-1: Eurocode 2: Design of Concrete Structures—Part 1–1: General Rules and Rules for Buildings; European Committee for Standardisation: Brussels, Belgium, 2004.

- Mosley, B. Reinforced Concrete Design to Eurocode 2; Palgrave Macmillan: New York, NY, USA, 2007. [Google Scholar]

- Westerberg, B. Commentary to Eurocode 2; European Concrete Platform ASBL: Brussels, Belgium, 2008. [Google Scholar]

- Bekas, G.K. Structural Optimization of Reinforced Concrete Columns. Master’s Thesis, School of Engineering, Design and Technology, University of Bradford, Bradford, UK, 2011. [Google Scholar]

- Mitchell, T. Machine Learning; McGraw Hill: New York, NY, USA, 1997. [Google Scholar]

- Trosset, M.W. An Introduction to Statistical Inference and Its Applications with R; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2009. [Google Scholar]

| Number of Storeys | Loading | Loading | Loading | Loading | Length of Frame |

|---|---|---|---|---|---|

| 2 | 15 kN/m | 35 kN/m | 55 kN/m | 75 kN/m | 15 m |

| 3 | 15 kN/m | 35 kN/m | 55 kN/m | 75 kN/m |

| Number of Storeys | Loading | Loading | Loading | Loading | Length of Frame |

|---|---|---|---|---|---|

| 2 | 15 kN/m | 35 kN/m | 55 kN/m | 75 kN/m | 25 m |

| 3 | 15 kN/m | 35 kN/m | 55 kN/m | 75 kN/m |

| Number of Storeys | Loading | Loading | Loading | Loading | Length of Frame |

|---|---|---|---|---|---|

| 2 | 15 kN/m | 35 kN/m | 55 kN/m | 75 kN/m | 35 m |

| 3 | 15 kN/m | 35 kN/m | 55 kN/m | 75 kN/m |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bekas, G.K.; Stavroulakis, G.E. Machine Learning and Optimality in Multi Storey Reinforced Concrete Frames. Infrastructures 2017, 2, 6. https://doi.org/10.3390/infrastructures2020006

Bekas GK, Stavroulakis GE. Machine Learning and Optimality in Multi Storey Reinforced Concrete Frames. Infrastructures. 2017; 2(2):6. https://doi.org/10.3390/infrastructures2020006

Chicago/Turabian StyleBekas, Georgios K., and Georgios E. Stavroulakis. 2017. "Machine Learning and Optimality in Multi Storey Reinforced Concrete Frames" Infrastructures 2, no. 2: 6. https://doi.org/10.3390/infrastructures2020006