Film Cooling Effectiveness Downstream of Trailing Edge Slots Including Cutback Surface Protuberances †

Abstract

:1. Introduction

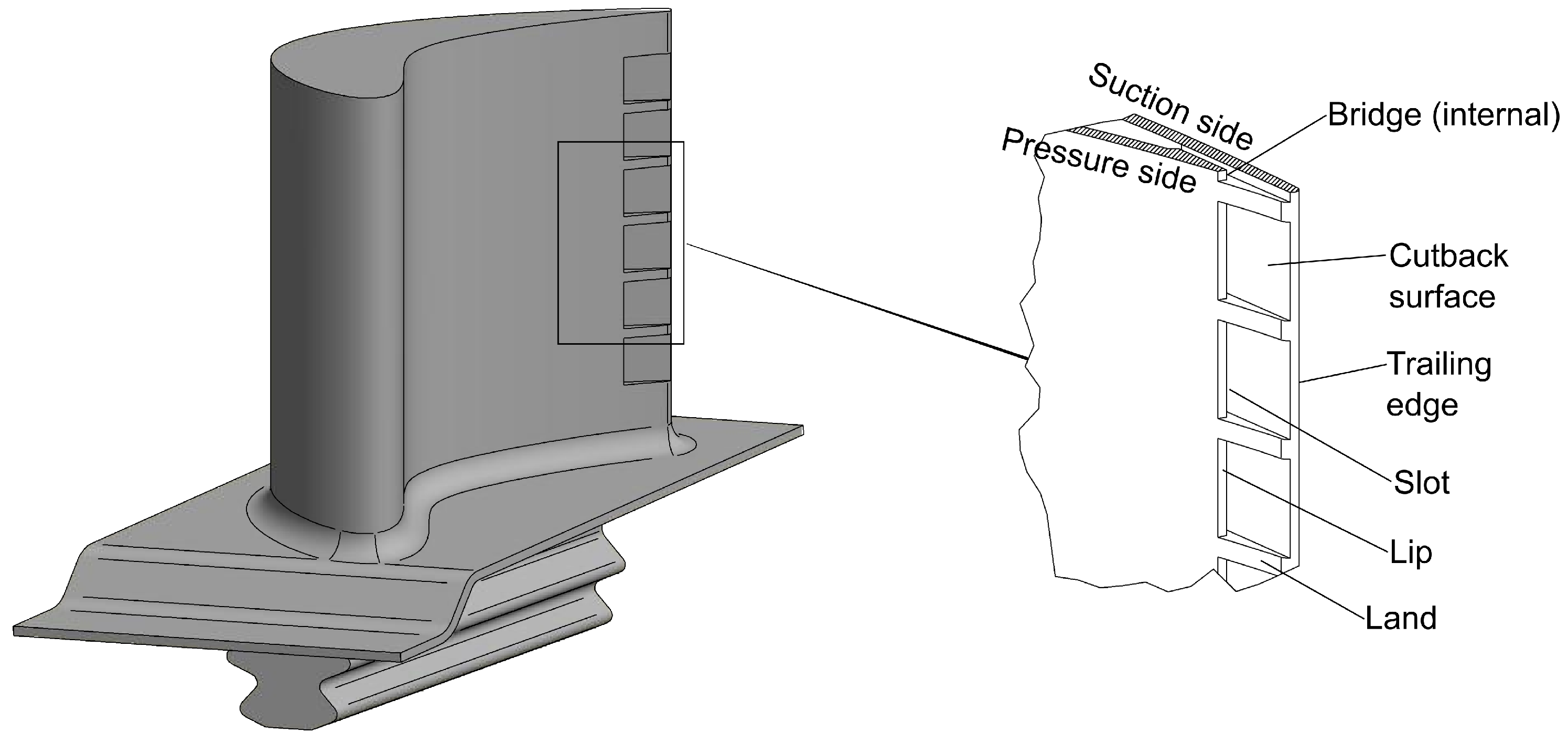

1.1. The Need for Trailing Edge Cooling Research

1.2. Literature Review

1.3. Aim of Work

2. Materials and Methods

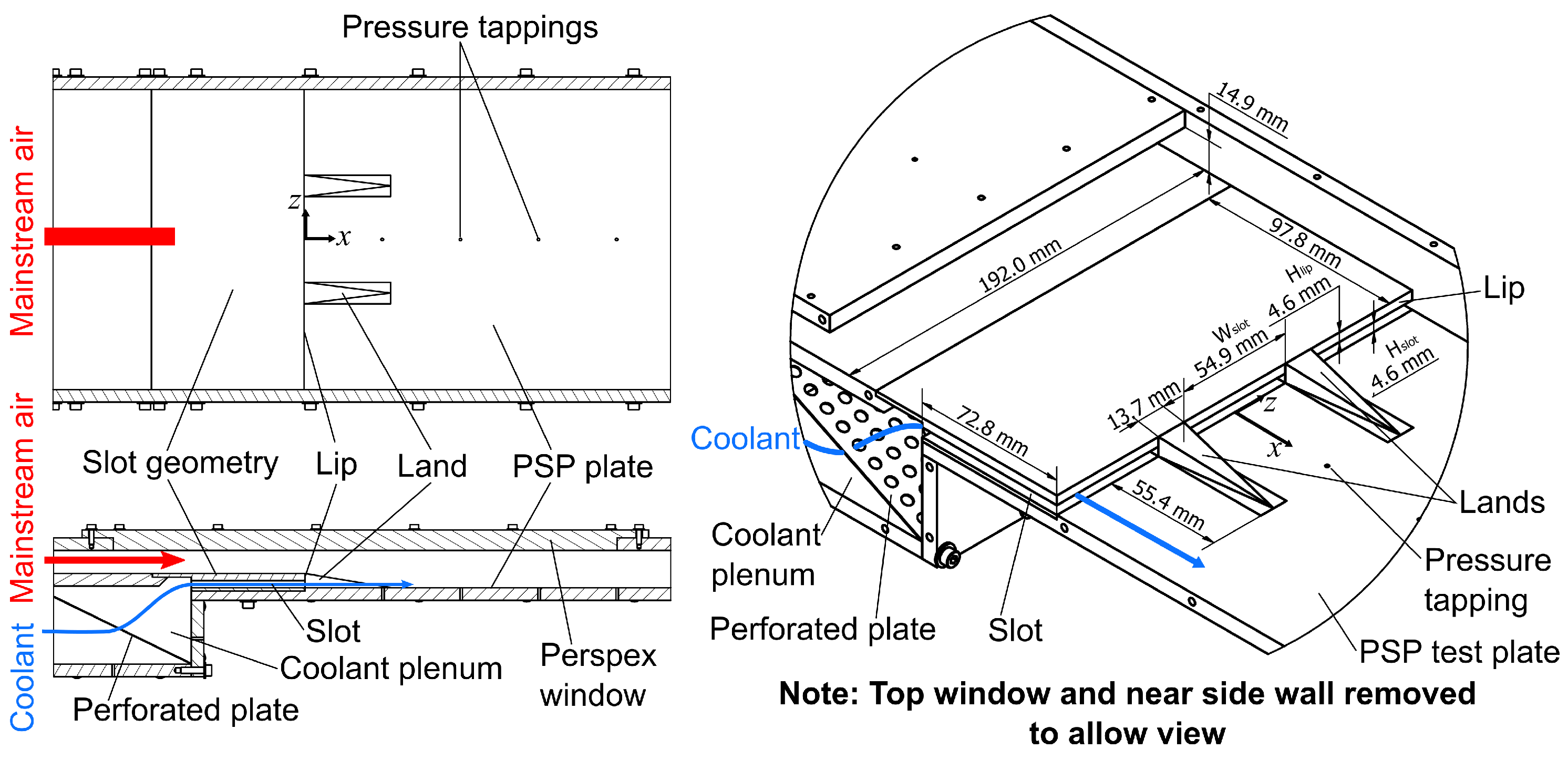

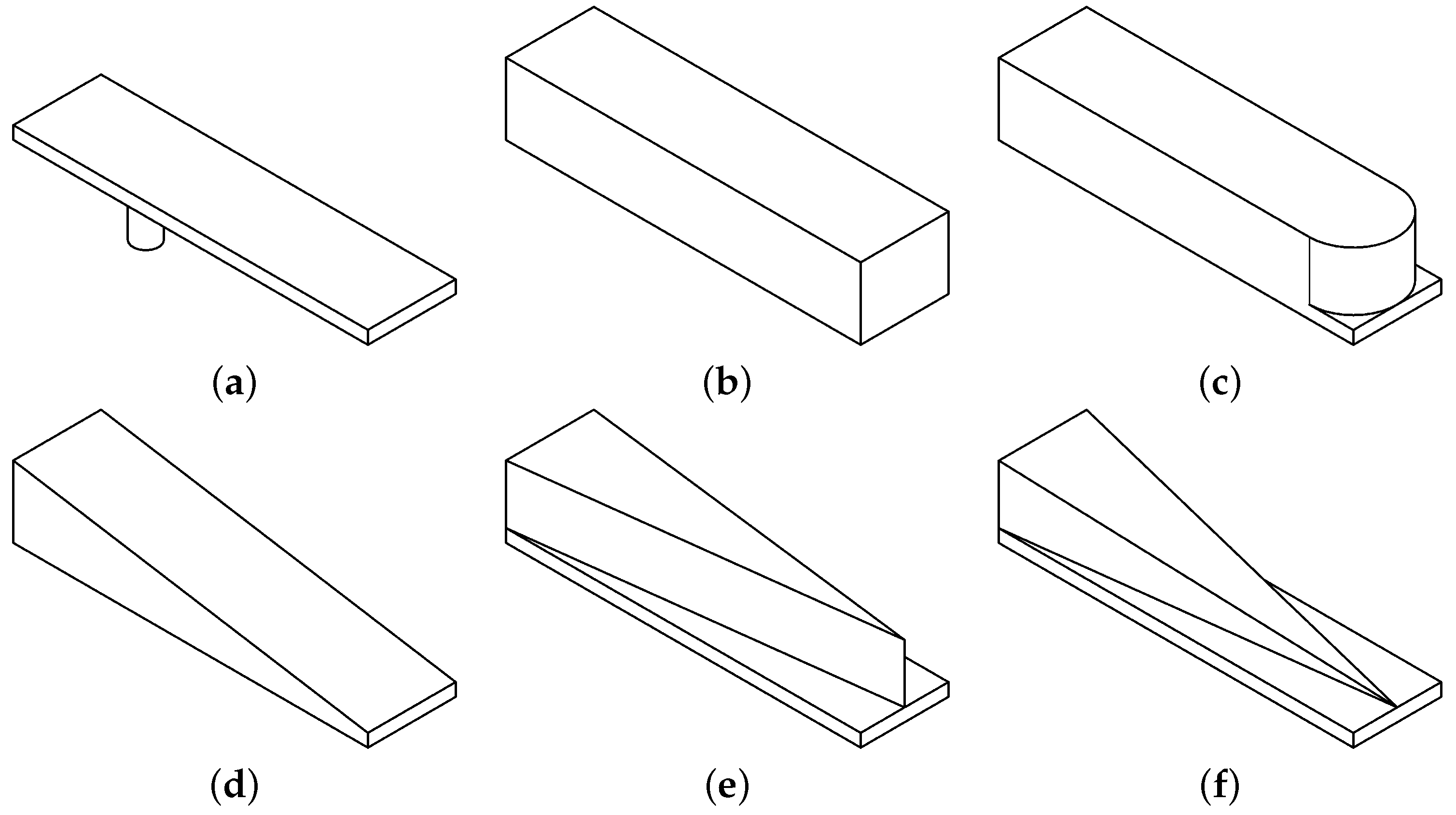

2.1. Experimental Set-Up

2.2. Measurement Technique

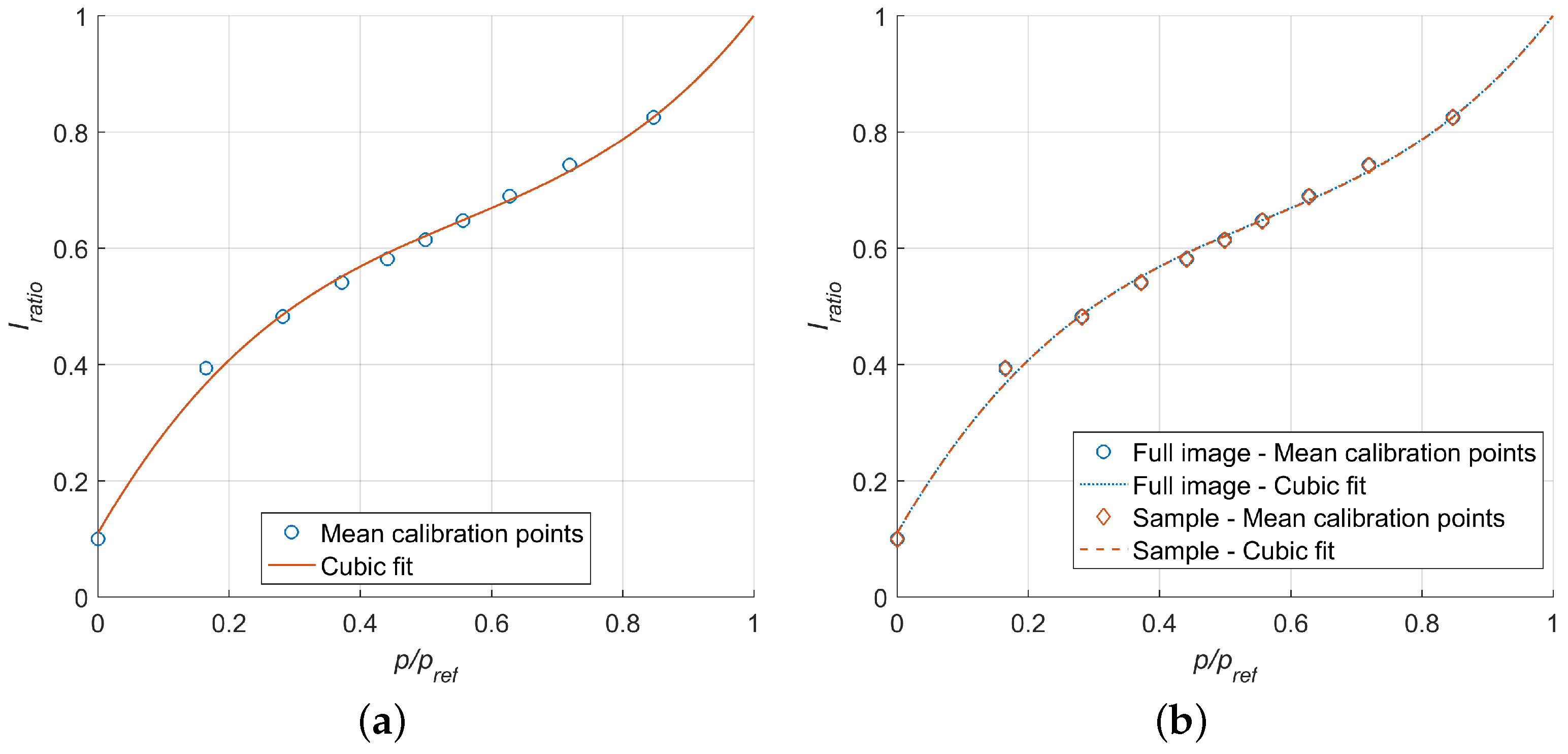

2.3. Calibration

2.4. Calculating Effectiveness

2.5. Operating Conditions

2.6. Experimental Uncertainties

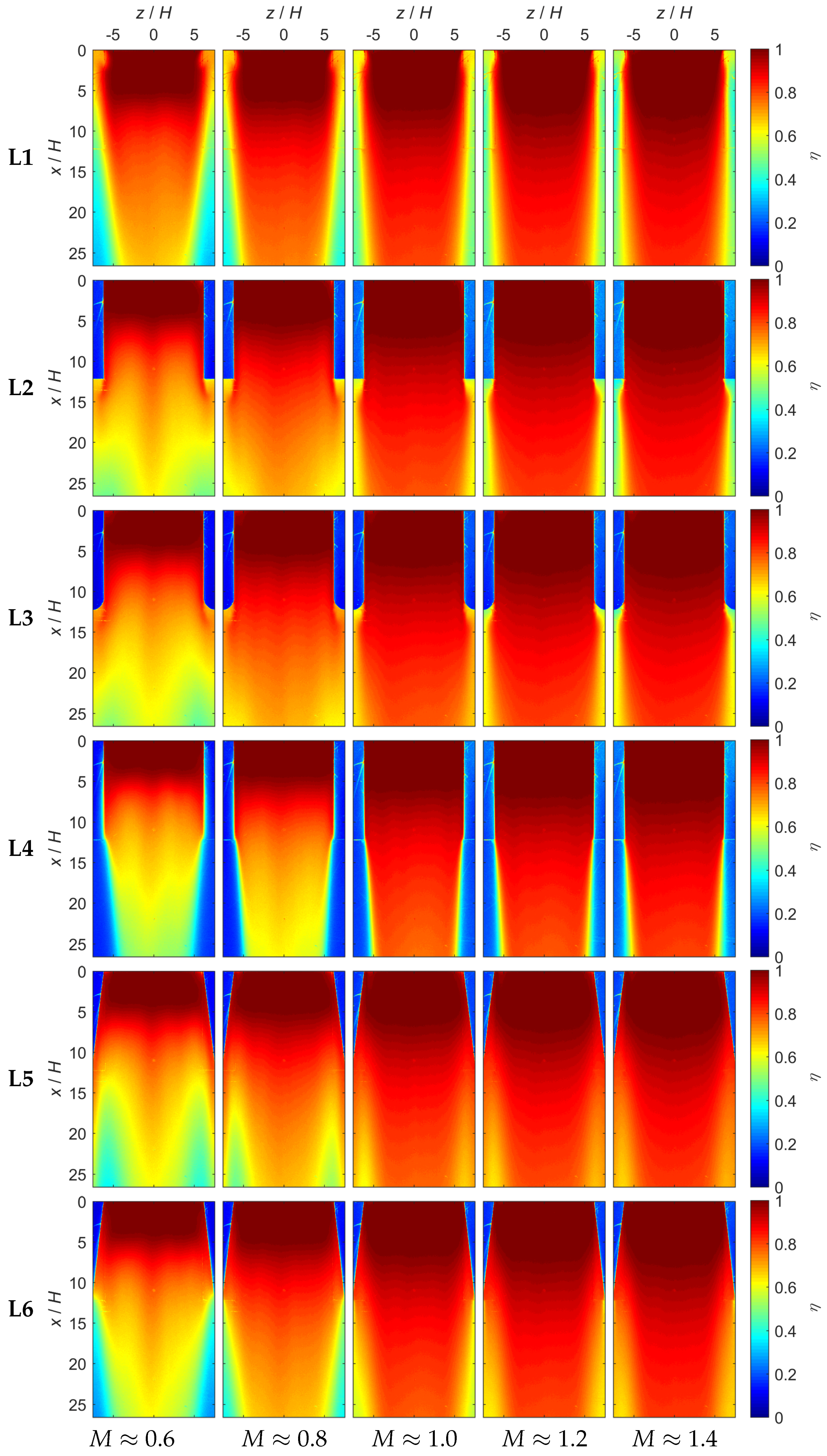

3. Results

4. Discussion

4.1. Land Effectiveness

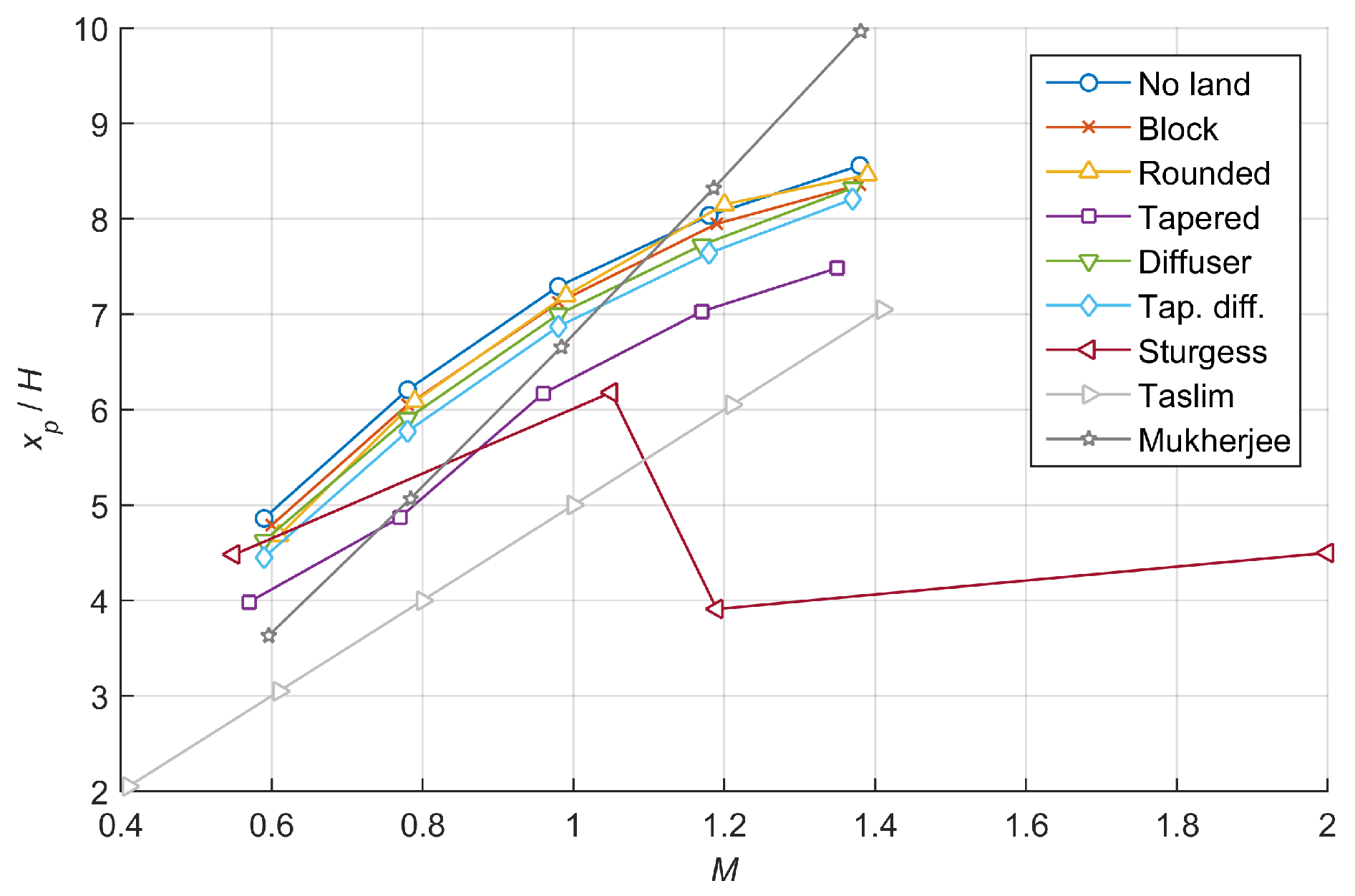

4.1.1. Comparison with Literature

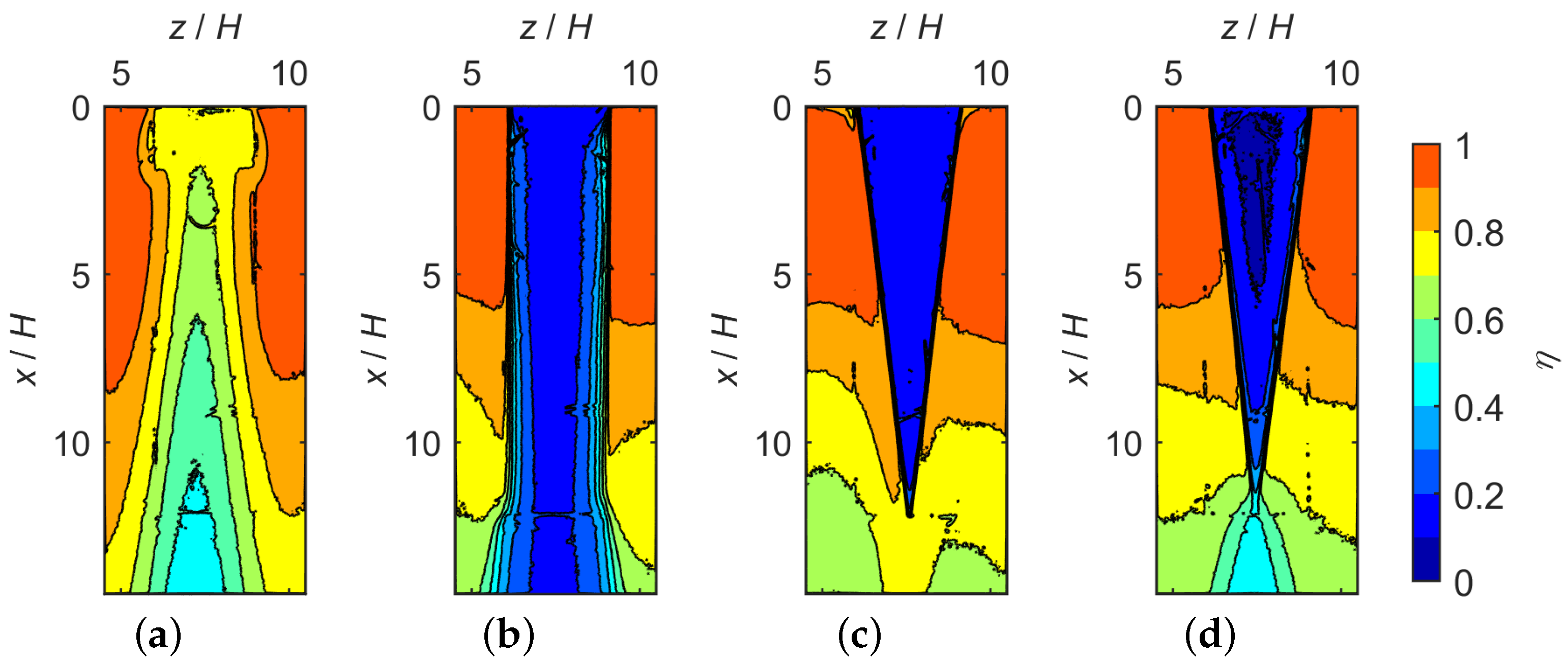

4.2. Effectiveness Downstream of Land

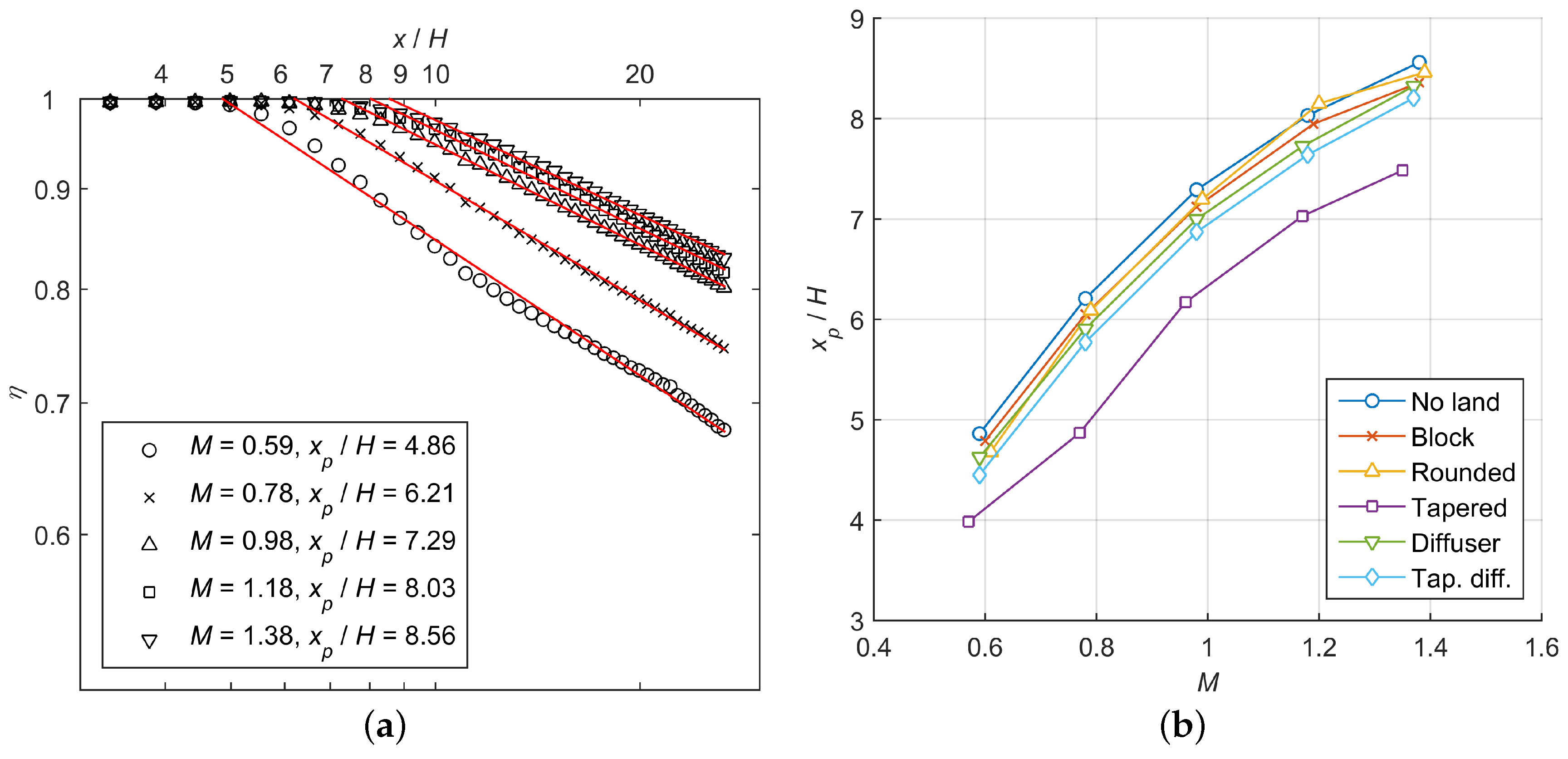

4.3. Centreline Effectiveness

4.3.1. Comparison with Literature

4.4. Spanwise Averaged Effectiveness

5. Conclusions

- Increasing M increased the length of the potential core and also reduced the rate at which effectiveness decayed.

- The length of the potential core, was mostly insensitive to the land geometry.

- A non-linear relationship was found between M and , which could be due to 3D effects in the flow.

- With all geometries, at all M tested, the coolant was largely unable to wash over the top surfaces of the lands, resulting in low effectiveness on the land top surface.

- Having no lands at all increased the spanwise averaged effectiveness since the coolant was able to spread into the gap left by the lands.

- Tapering the lands did not significantly encourage coolant flow to wash over the top.

- Tapering the lands pulled the mainstream flow down to the cutback surface, creating a wake of mainstream flow after the lands that the coolant flow was unable to penetrate.

- This also encouraged mixing with the flow on the cutback, reducing effectiveness next to the lands.

- The diffuser geometries performed well for , as the coolant was able to spread and fill out the increased cutback area, resulting in a higher spanwise average effectiveness than all other geometries, including the “no lands” geometry from approximately onwards up until the end of the lands.

- The non-tapered diffuser geometry performed best, but the tapered diffuser geometry more closely approximates the land on a real turbine blade with a very small reduction in effectiveness.

- At , the coolant was unable to fill the expanding cutback surface and the film decayed faster, resulting in a lower effectiveness than the “no lands” case at the end of the lands, although still better than the other geometries.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Abbreviations | |

| CCD | Charge-coupled device |

| MFC | Mass Flow Controller |

| MRI | Magnetic resonance imaging |

| PIV | Particle Image Velocimetry |

| PSP | Pressure sensitive paint |

| Greek | |

| η | Adiabatic film cooling effectiveness |

| ρ | Density [] |

| Roman | |

| A | Area [] |

| H | Equivalent to [] |

| Lip thickness [] | |

| Slot height [] | |

| I | Intensity image |

| Mass flow rate [] | |

| Molar flow rate [] | |

| M | Blowing ratio |

| Sturgess geometric parameter | |

| Molecular weight [] | |

| n | Mole fraction of oxygen |

| p | Pressure [] |

| Partial pressure of oxygen [] | |

| Reynolds number | |

| T | Temperature [] |

| u | Velocity [] |

| Slot width [] | |

| x | Downstream distance [] |

| Potential core length [] | |

| z | Spanwise displacement [] |

| Subscripts | |

| ∞ | Mainstream flow |

| Air coolant | |

| At atmospheric conditions | |

| Adiabatic wall | |

| c | Coolant flow |

| In darkness | |

| m | Mainstream flow |

| Air-nitrogen mixture | |

| Nitrogen coolant | |

| Ratio | |

| At Reference conditions | |

| Static | |

| On the surface | |

References

- Haselbach, F.; Parker, R. Hot End Technology for Advanced, Low Emission Large Civil Aircraft Engines. In Proceedings of the 28th International Congress of the Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012; Volume 2, p. 3.

- Sargison, J.E. Development of a Novel Film Cooling Hole Geometry. Ph.D. Thesis, University of Oxford, Oxford, UK, 2001. [Google Scholar]

- Cresci, I.; Ireland, P.T.; Bacic, M.; Tibbott, I.; Rawlinson, A. Velocity and Turbulence Intensity Profiles Downstream of a Long Reach Endwall Double Row of Film Cooling Holes in a Gas Turbine Combustor Representative Environment. In Proceedings of the ASME Turbo Expo 2015, Montreal, QC, Canada, 15–19 June 2015; ASME: New York, NY, USA, 2015. [Google Scholar]

- Goldstein, R.J. Film cooling. Adv. Heat Transf. 1971, 7, 321–379. [Google Scholar]

- Kacker, S.C.; Whitelaw, J.H. The dependence of the impervious wall effectiveness of a two-dimensional wall-jet on the thickness of the upper lip boundary layer. Int. J. Heat Mass Transf. 1967, 10, 1623–1624. [Google Scholar] [CrossRef]

- Mukherjee, D.K. Film Cooling With Injection Through Slots. J. Eng. Gas Turbines Power 1976, 98, 556–559. [Google Scholar] [CrossRef]

- Sturgess, G.J. Design of Combustor Cooling Slots for High Film Effectiveness: Part I-Film General Development. J. Eng. Gas Turbines Power 1986, 108, 354–360. [Google Scholar] [CrossRef]

- Sturgess, G.J.; Pfeifer, G.D. Design of Combustor Cooling Slots for High Film Effectiveness: Part II-Film Initial Region. J. Eng. Gas Turbines Power 1986, 108, 361–369. [Google Scholar] [CrossRef]

- Taslim, M.E.; Spring, S.D.; Mehlman, B.P. Experimental investigation of film cooling effectiveness for slots of various exit geometries. J. Thermophys. Heat Transf. 1992, 6, 302–307. [Google Scholar] [CrossRef]

- Martini, P.; Schulz, A.; Bauer, H.J. Film Cooling Effectiveness and Heat Transfer on the Trailing Edge Cutback of Gas Turbine Airfoils With Various Internal Cooling Designs. J. Turbomach. 2005, 128, 196–205. [Google Scholar] [CrossRef]

- Murata, A.; Nishida, S.; Saito, H.; Iwamoto, K.; Okita, Y.; Nakamata, C. Effects of Surface Geometry on Film Cooling Performance at Airfoil Trailing Edge. J. Turbomach. 2012, 134, 051033. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, H. Study of Trailing-Edge Cooling Using Pressure Sensitive Paint Technique. J. Propuls. Power 2011, 27, 700–709. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, H. An experimental investigation on the trailing edge cooling of turbine blades. Propuls. Power Res. 2012, 1, 36–47. [Google Scholar] [CrossRef]

- Ling, J.; Elkins, C.J.; Eaton, J.K. The Effect of Land Taper Angle on Trailing Edge Slot Film Cooling. J. Turbomach. 2015, 137, 071003. [Google Scholar] [CrossRef]

- Wong, T.H.; Ireland, P.T.; Self, K.P. Film Cooling Effectiveness Measurements on Engine Representative Trailing Edge Slots Including Cutback Surface Protuberances. ETC2015-254. In Proceedings of the 11th European Turbomachinery Conference, Madrid, Spain, 23–27 March 2015; ETC: Madrid, Spain, 2015. [Google Scholar]

- Wong, T.H.; Ireland, P.T.; Self, K.P. Film Cooling Effectiveness Measurements on Trailing Edge Cutback Surface and Lands Following Novel Cross Corrugated Slot Geometry. In Proceedings of the ASME Turbo Expo 2016, Seoul, Korea, 13–17 June 2016; ASME: New York, NY, USA.

- Gurram, N.; Ireland, P.T.; Wong, T.H.; Self, K.P. Study of Film Cooling in the Trailing Edge Region of a Turbine Rotor Blade in High Speed Flow Using Pressure Sensitive Paint. In Proceedings of the ASME Turbo Expo 2016, Seoul, Korea, 13–17 June 2016; ASME: New York, NY, USA.

- Telisinghe, J.C.; Ireland, P.T.; Jones, T.V.; Barrett, D.; Son, C. Comparative Study between a Cut-Back and Conventional Trailing Edge Film Cooling System. In Proceedings of the ASME Turbo Expo 2006: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2006; ASME: New York, NY, USA.

- Quinn, M.K.; Gongora-Orozco, N.; Kontis, K.; Ireland, P. Application of pressure-sensitive paint to low-speed flow around a U-bend of strong curvature. Exp. Therm. Fluid Sci. 2013, 48, 58–66. [Google Scholar] [CrossRef]

- Han, J.C.; Rallabandi, A. Turbine Blade Film Cooling Using PSP Technique. Front. Heat Mass Transf. 2010, 1, 013001. [Google Scholar] [CrossRef]

- Caciolli, G.; Facchini, B.; Picchi, A.; Tarchi, L. Comparison between PSP and TLC steady state techniques for adiabatic effectiveness measurement on a multiperforated plate. Exp. Therm. Fluid Sci. 2013, 48, 122–133. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wong, T.H.; Ireland, P.T.; Self, K.P. Film Cooling Effectiveness Downstream of Trailing Edge Slots Including Cutback Surface Protuberances. Int. J. Turbomach. Propuls. Power 2016, 1, 4. https://doi.org/10.3390/ijtpp1010004

Wong TH, Ireland PT, Self KP. Film Cooling Effectiveness Downstream of Trailing Edge Slots Including Cutback Surface Protuberances. International Journal of Turbomachinery, Propulsion and Power. 2016; 1(1):4. https://doi.org/10.3390/ijtpp1010004

Chicago/Turabian StyleWong, Tsun Holt, Peter T. Ireland, and Kevin P. Self. 2016. "Film Cooling Effectiveness Downstream of Trailing Edge Slots Including Cutback Surface Protuberances" International Journal of Turbomachinery, Propulsion and Power 1, no. 1: 4. https://doi.org/10.3390/ijtpp1010004