Low-Velocity Impact Properties of Sandwich Structures with Aluminum Foam Cores and CFRP Face Sheets

Abstract

:1. Introduction

2. Materials

2.1. Face Sheets

2.2. PUR Quantities and Manufacturing Process

2.3. Core Types

2.4. Sandwich Configurations

2.5. Specimen Geometry

3. Methods

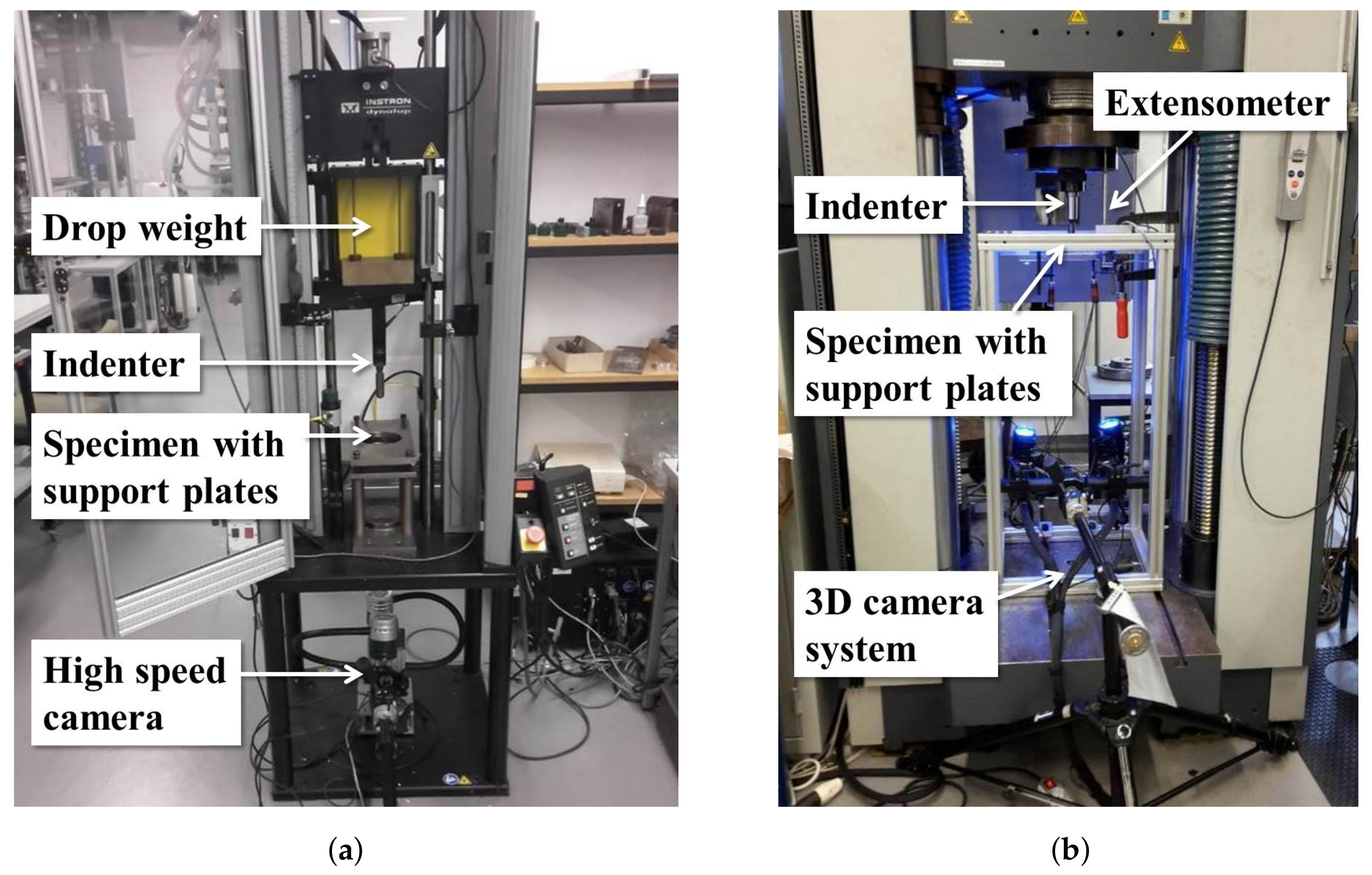

3.1. Low-Velocity Indentation

3.2. Quasi-Static Indentation

3.3. Digital Image Correlation (DIC)

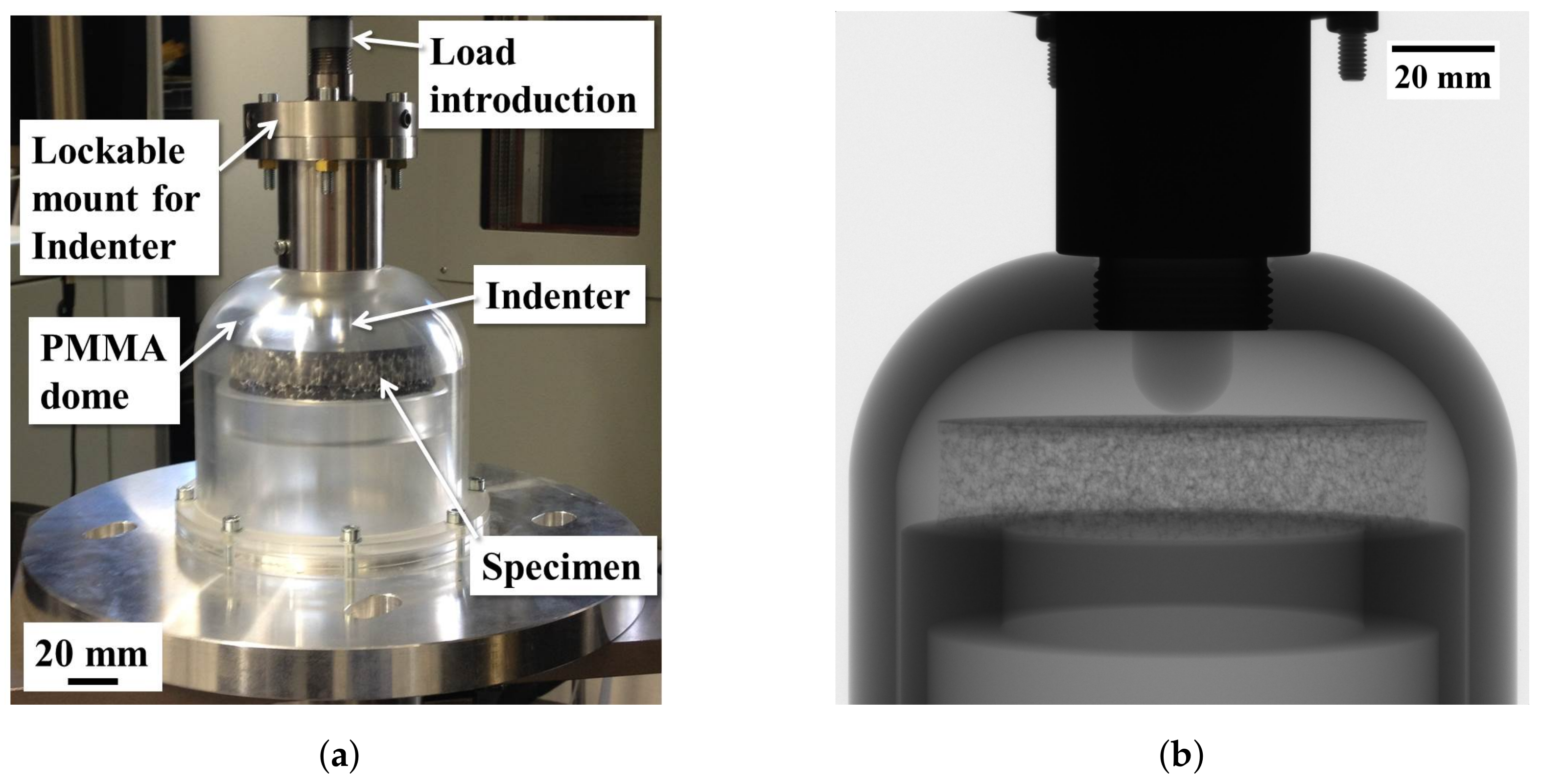

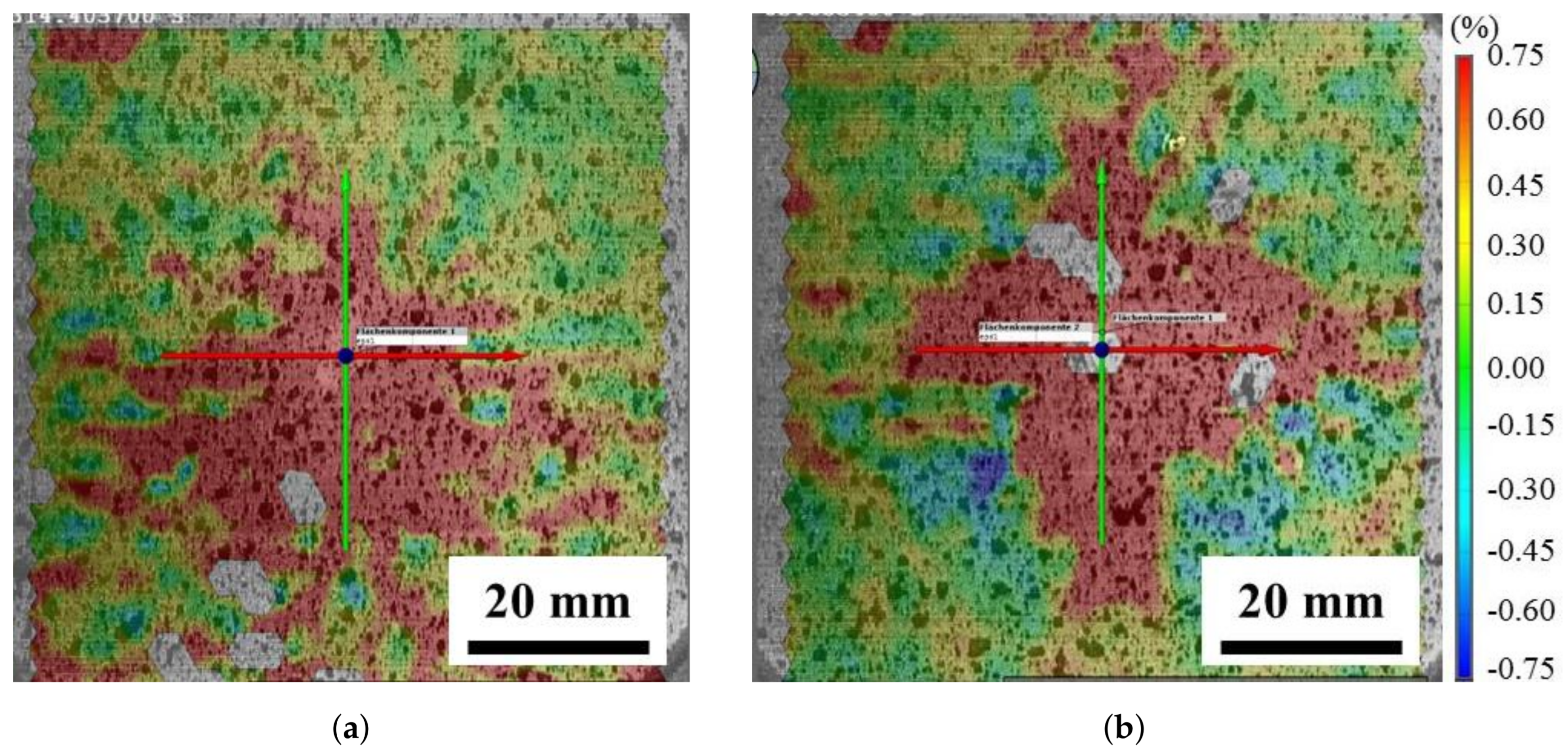

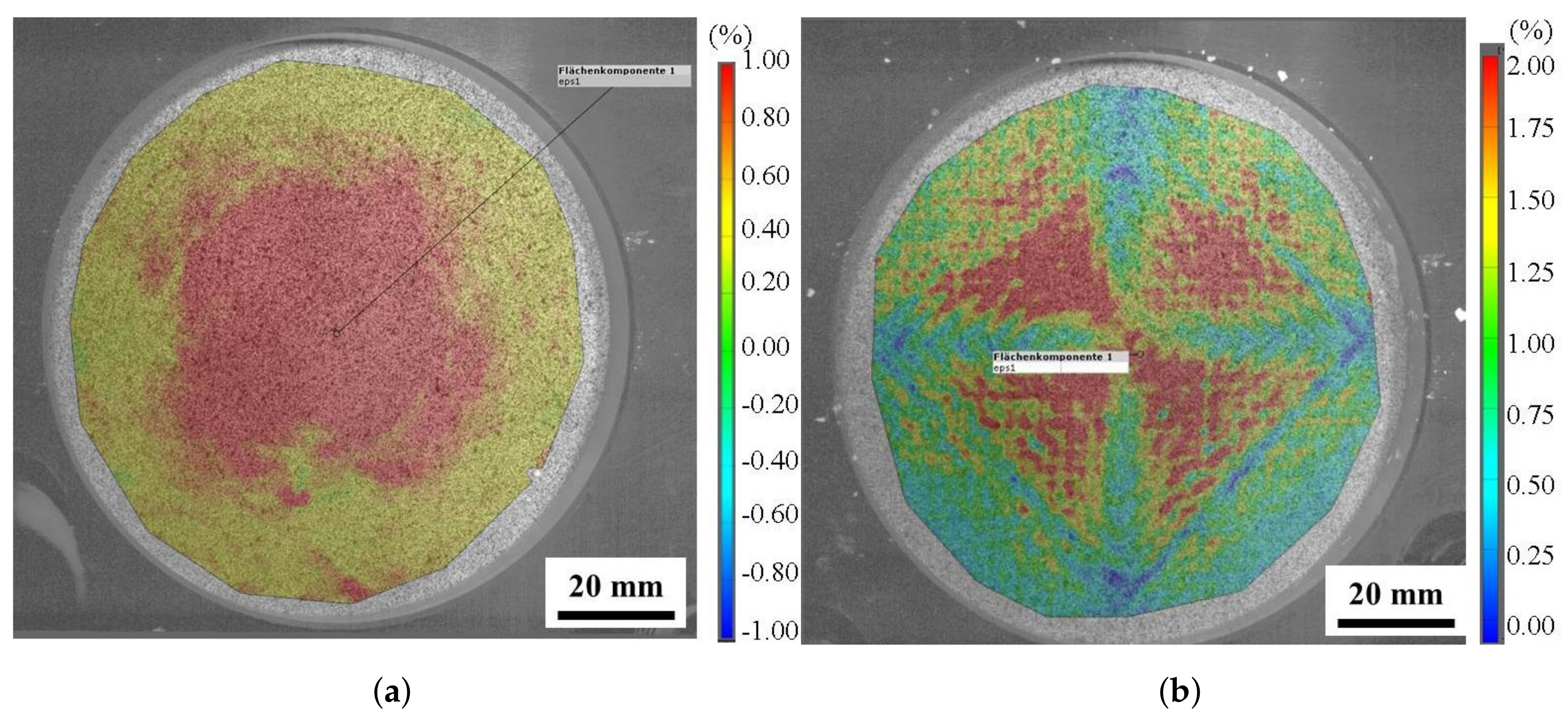

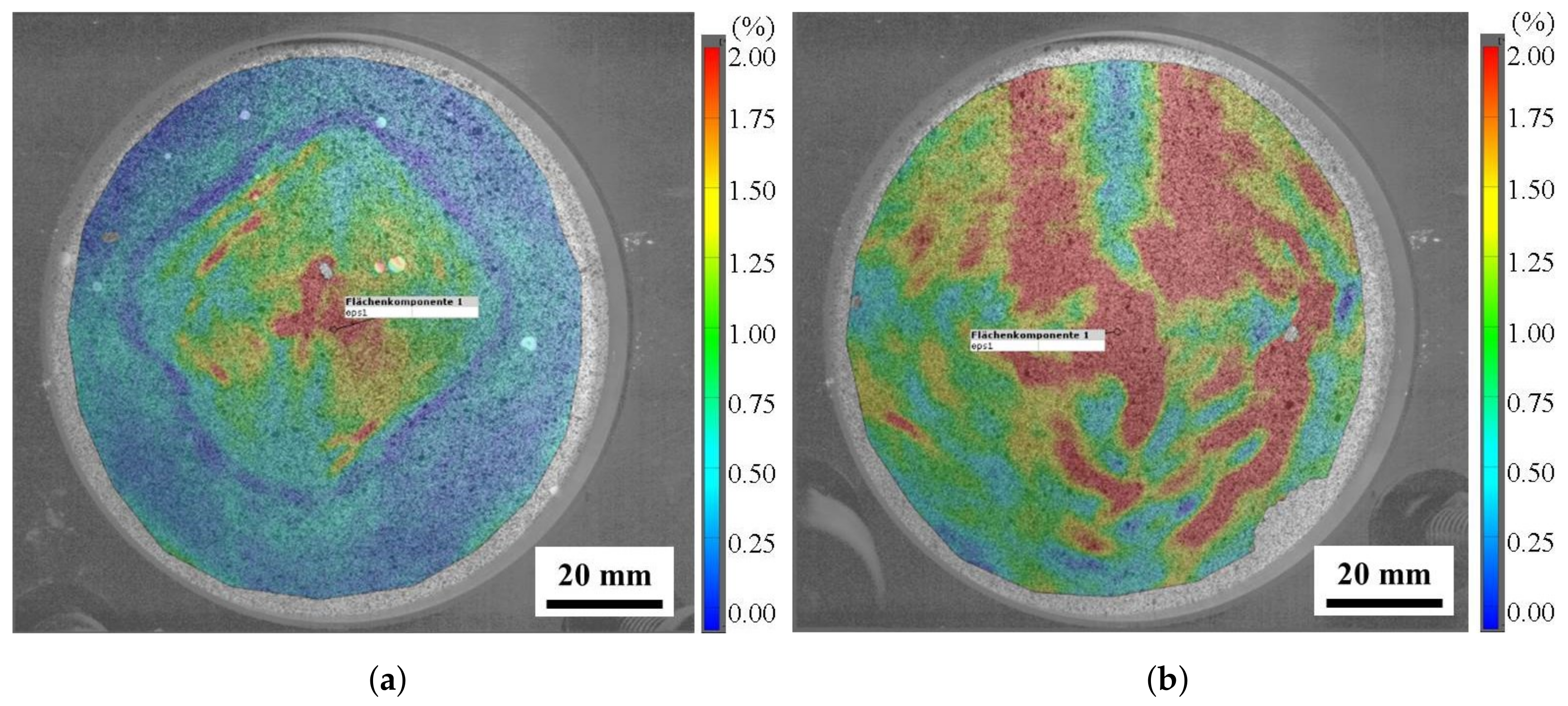

3.4. In Situ CT Indentation

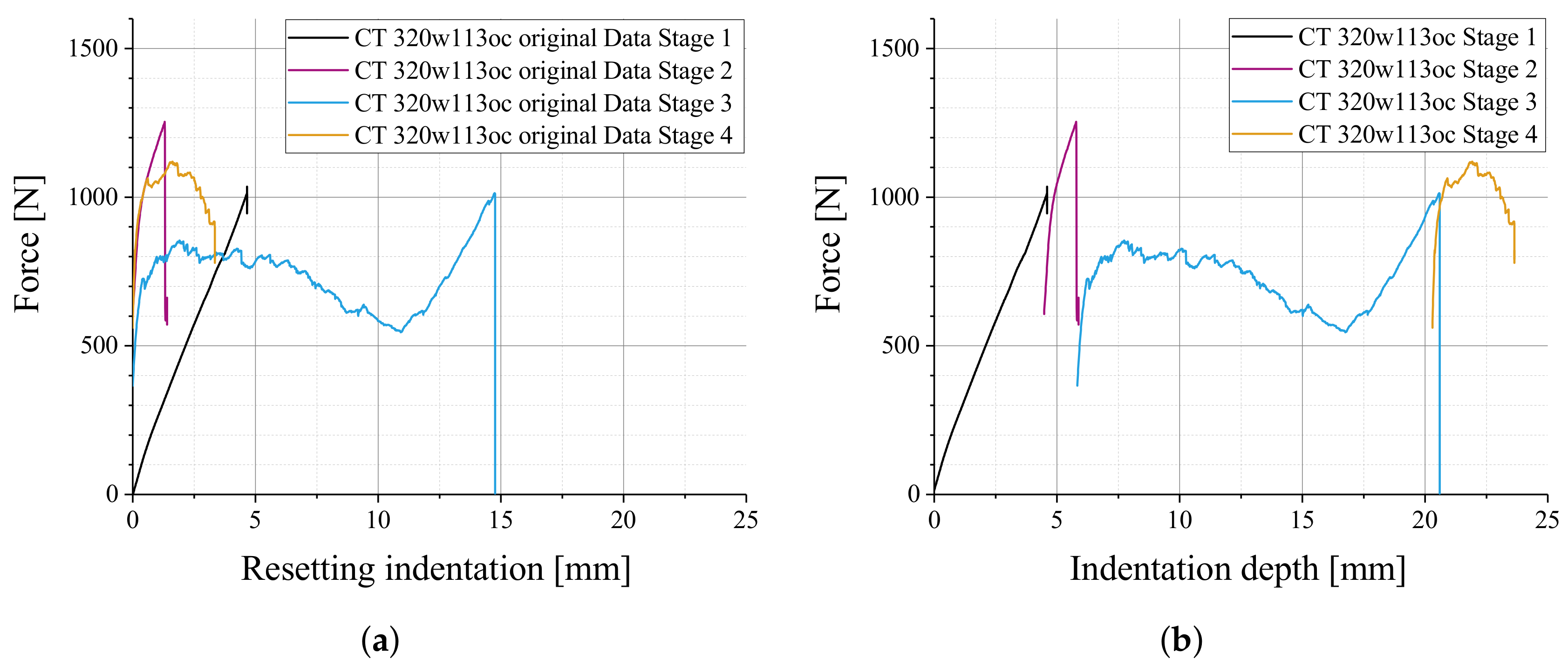

4. Results

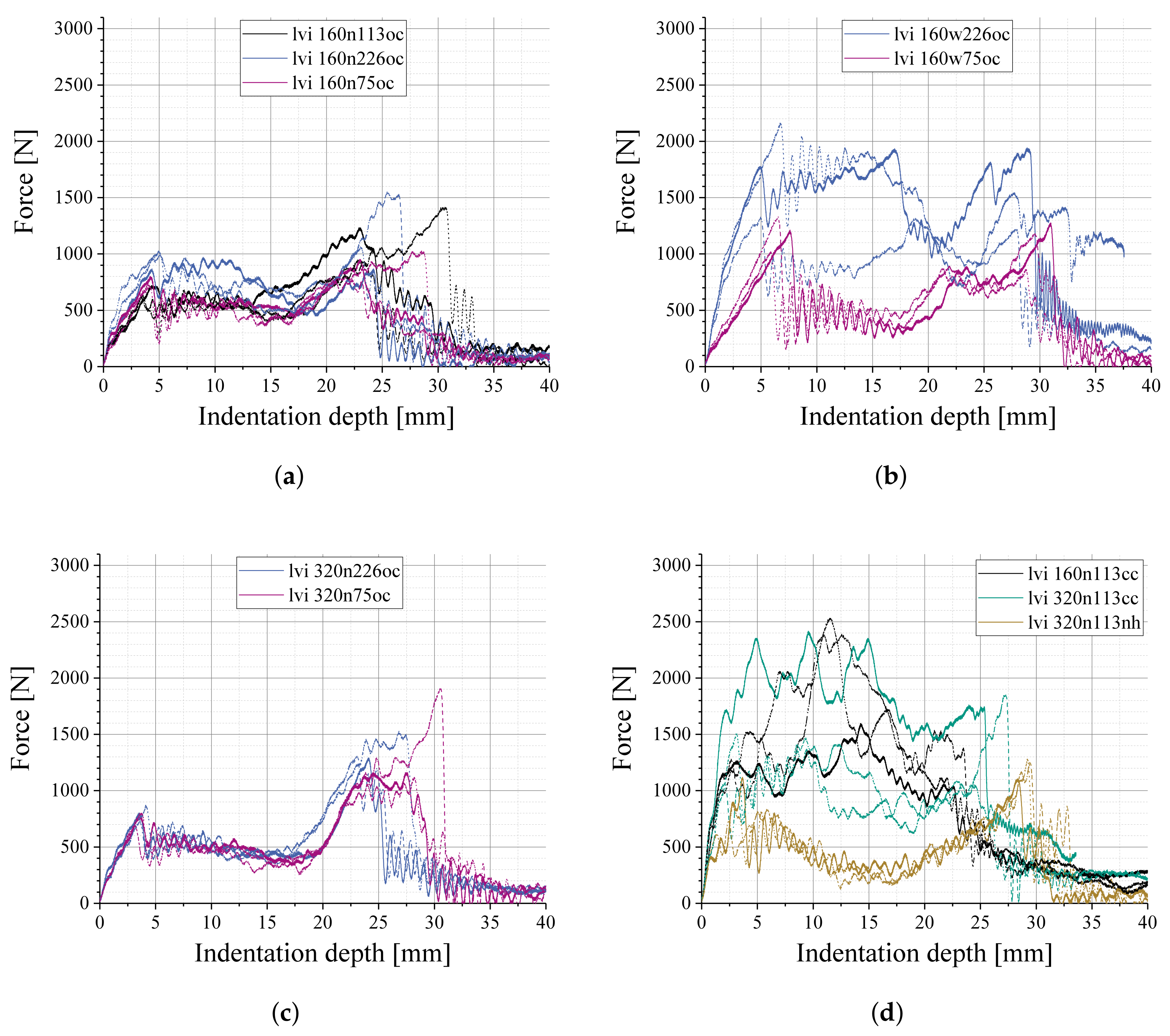

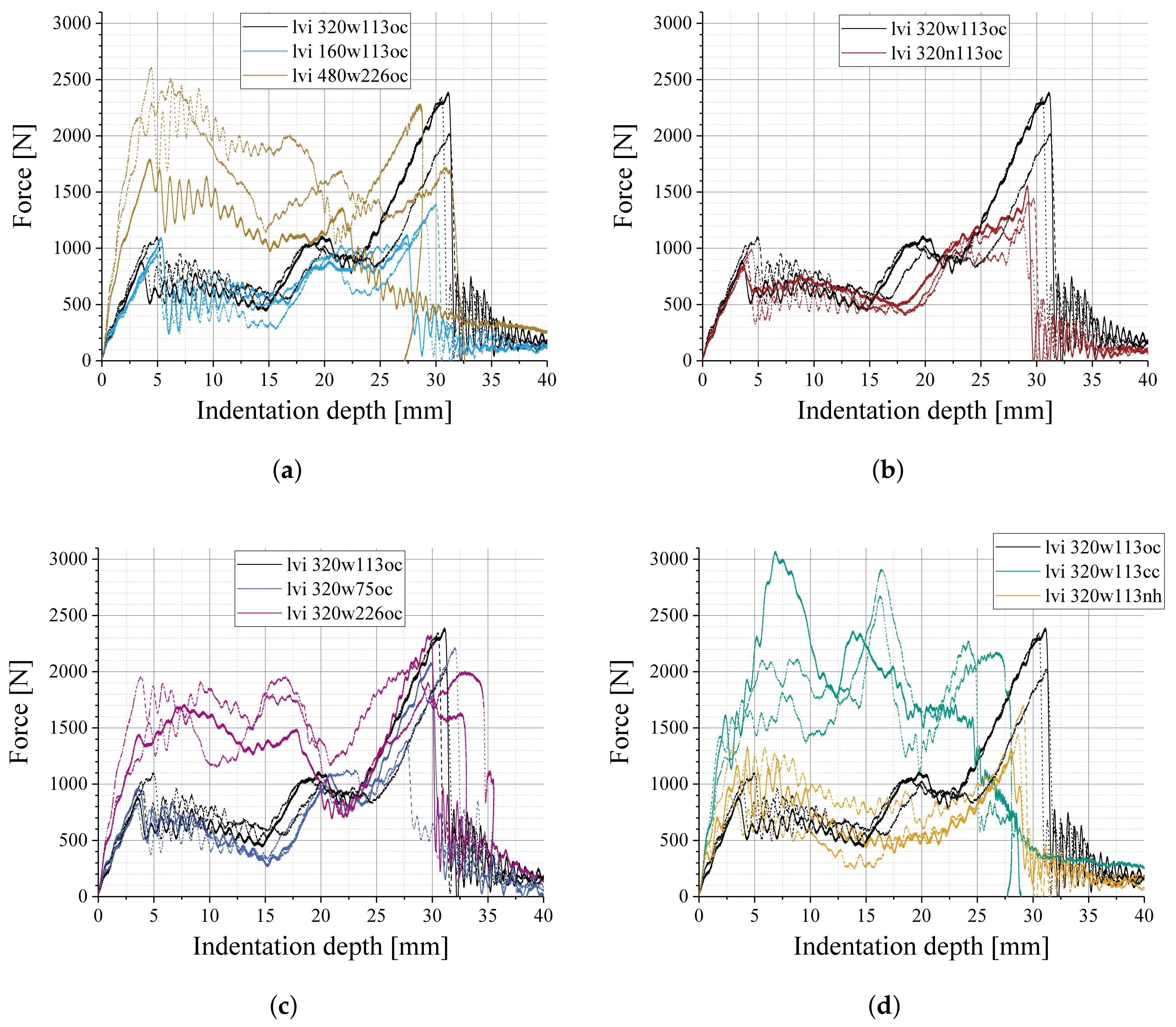

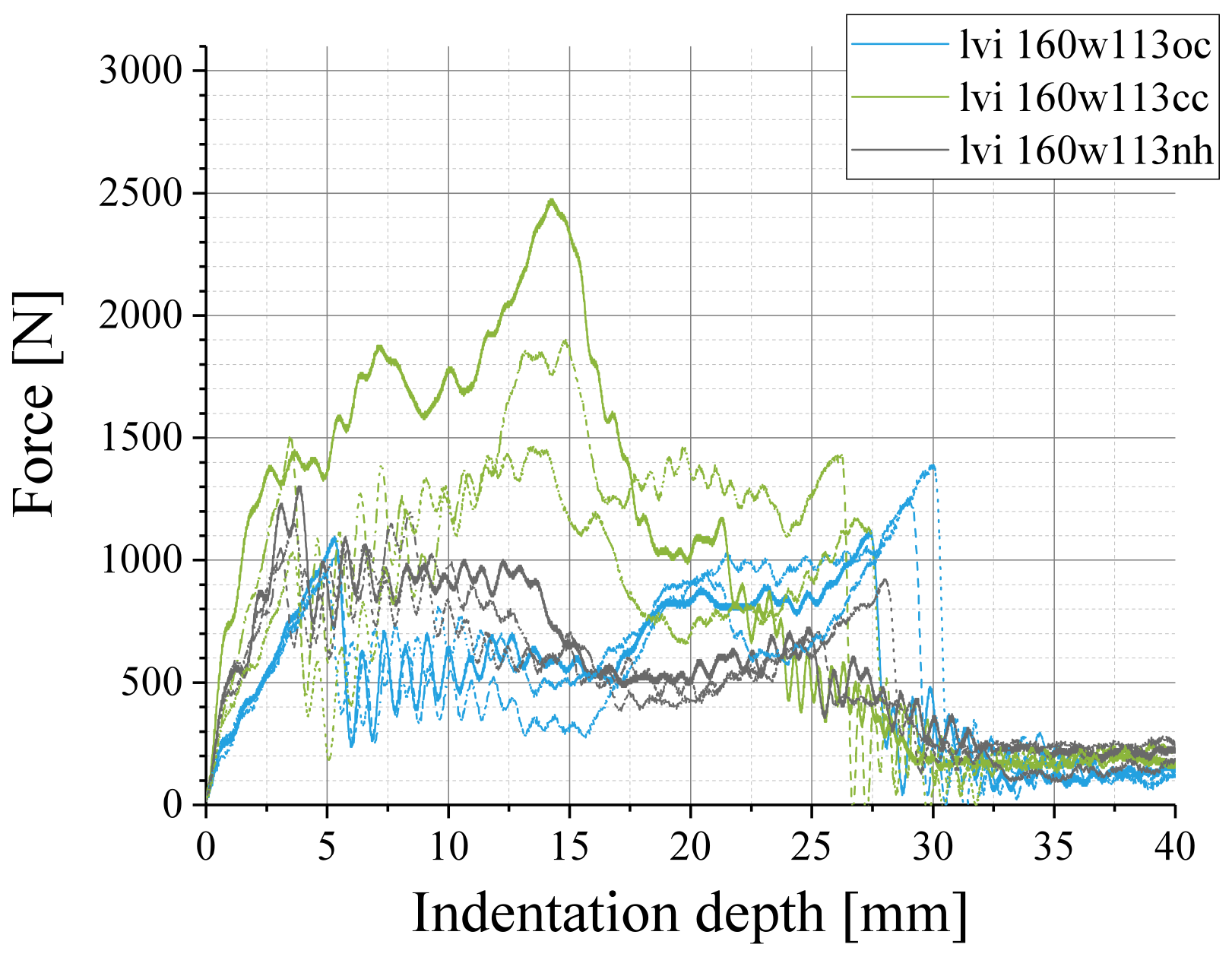

4.1. Low-Velocity Indentation

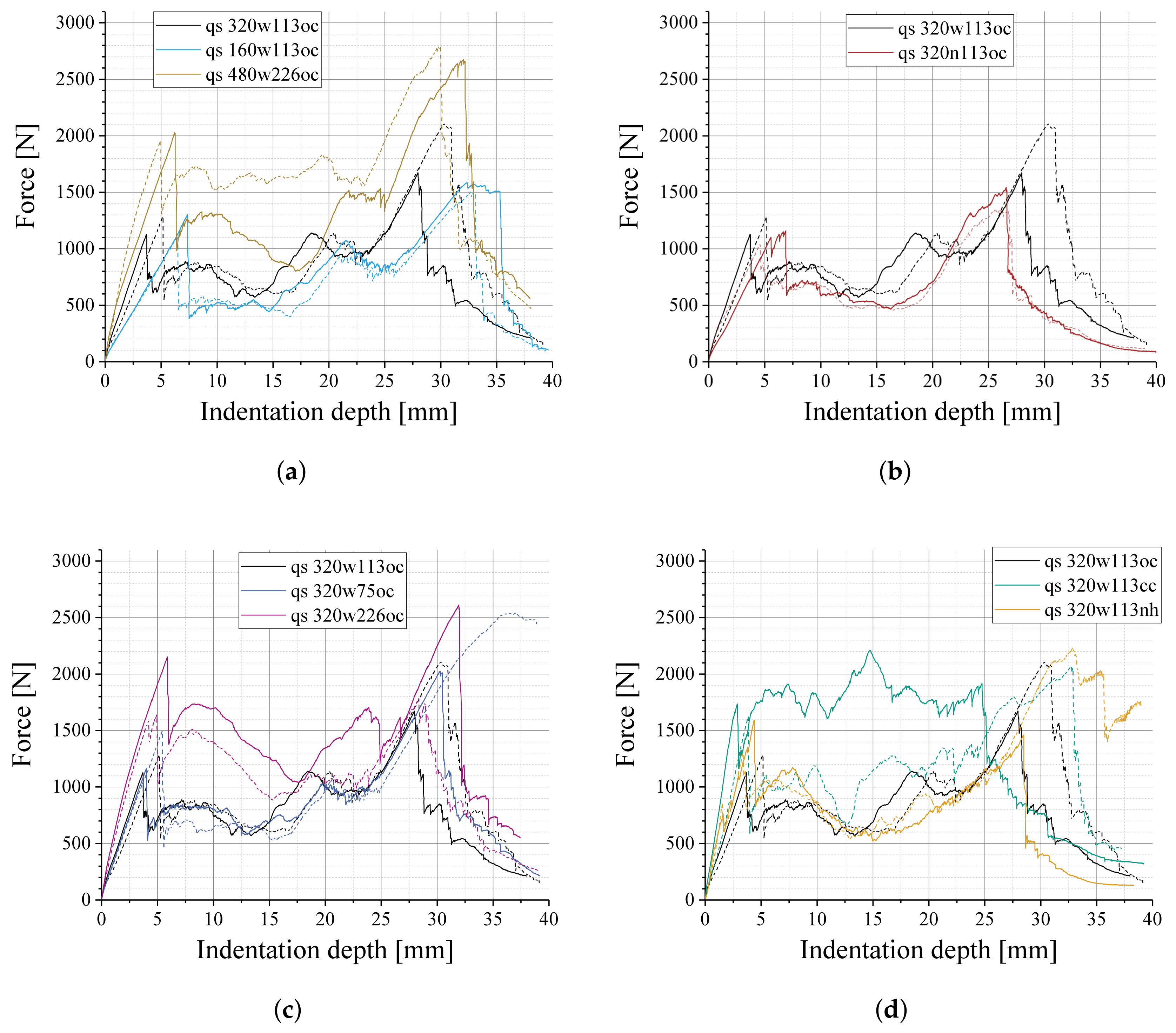

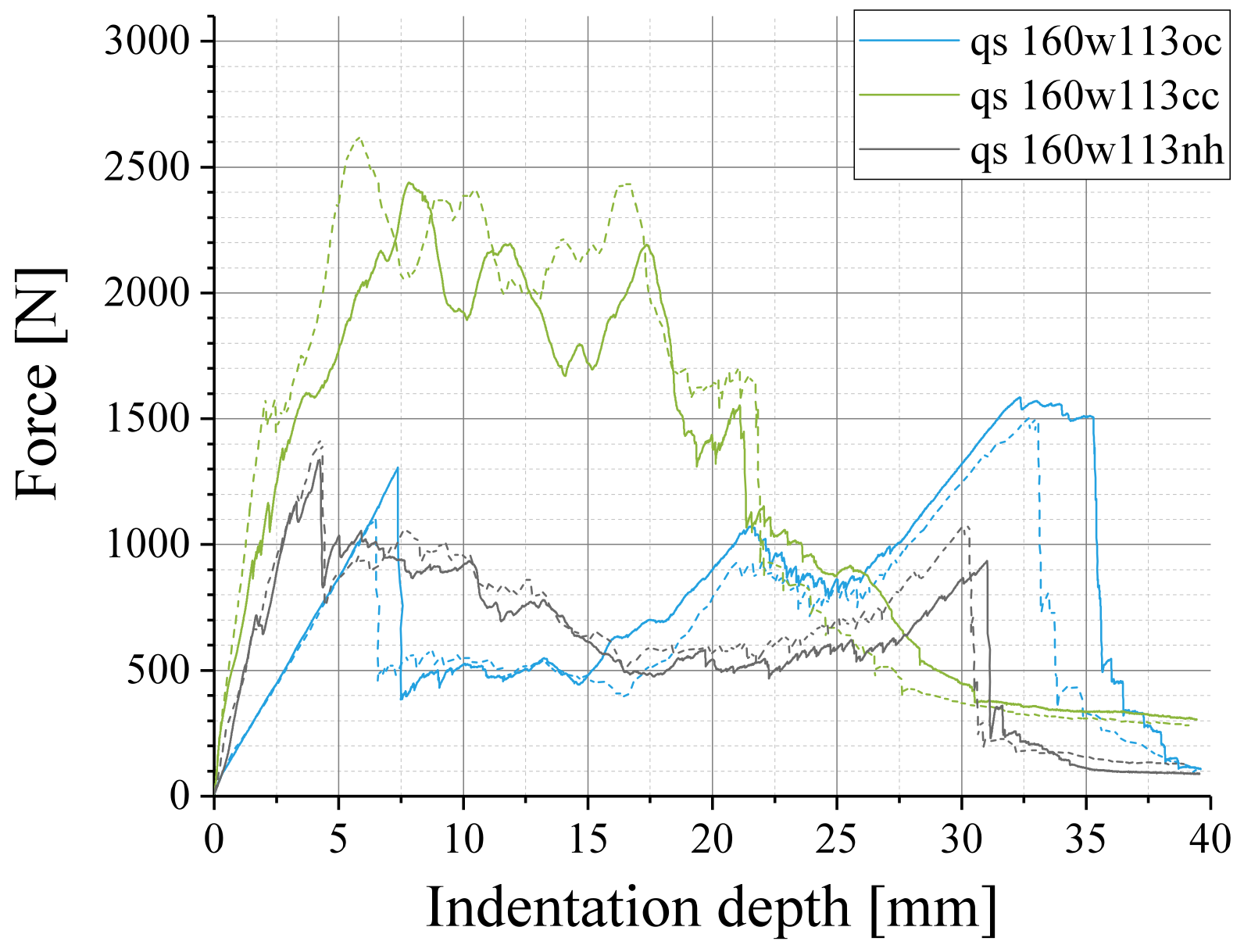

4.2. Quasi-Static Indentation

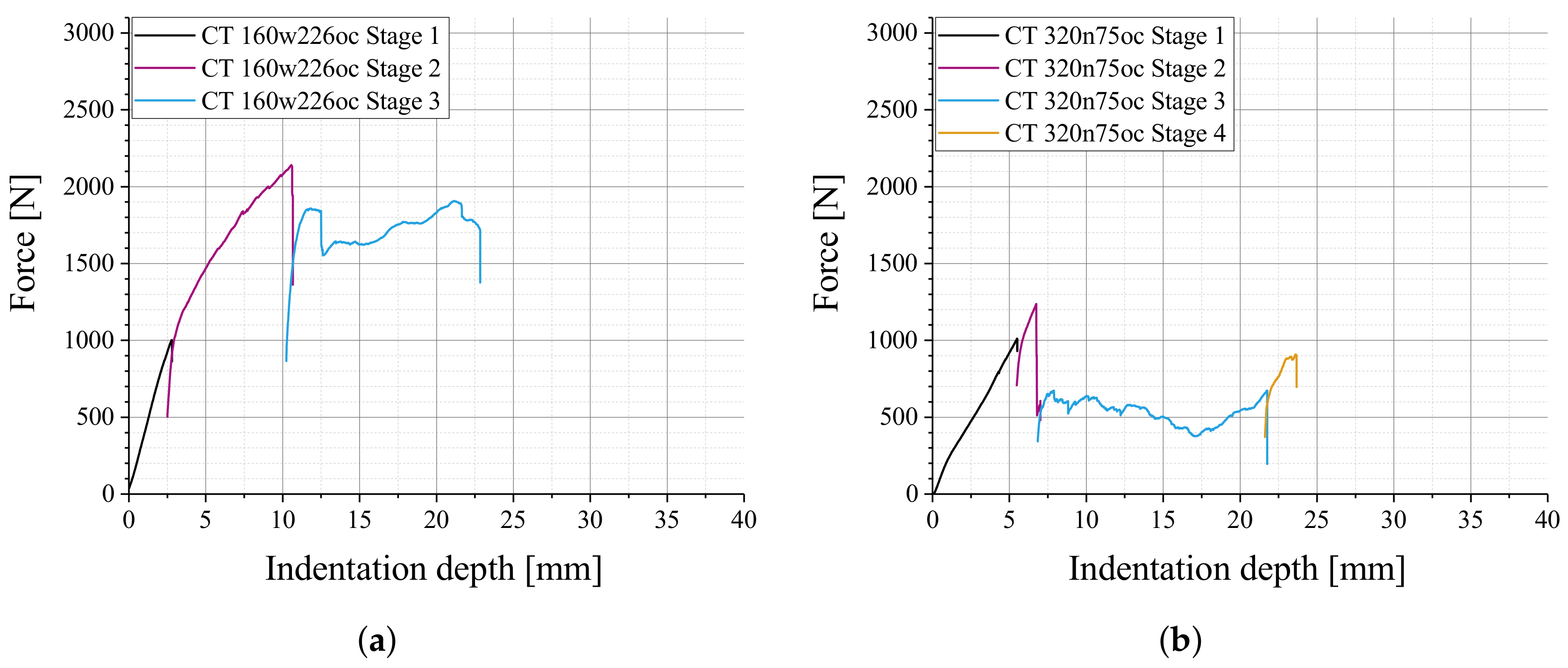

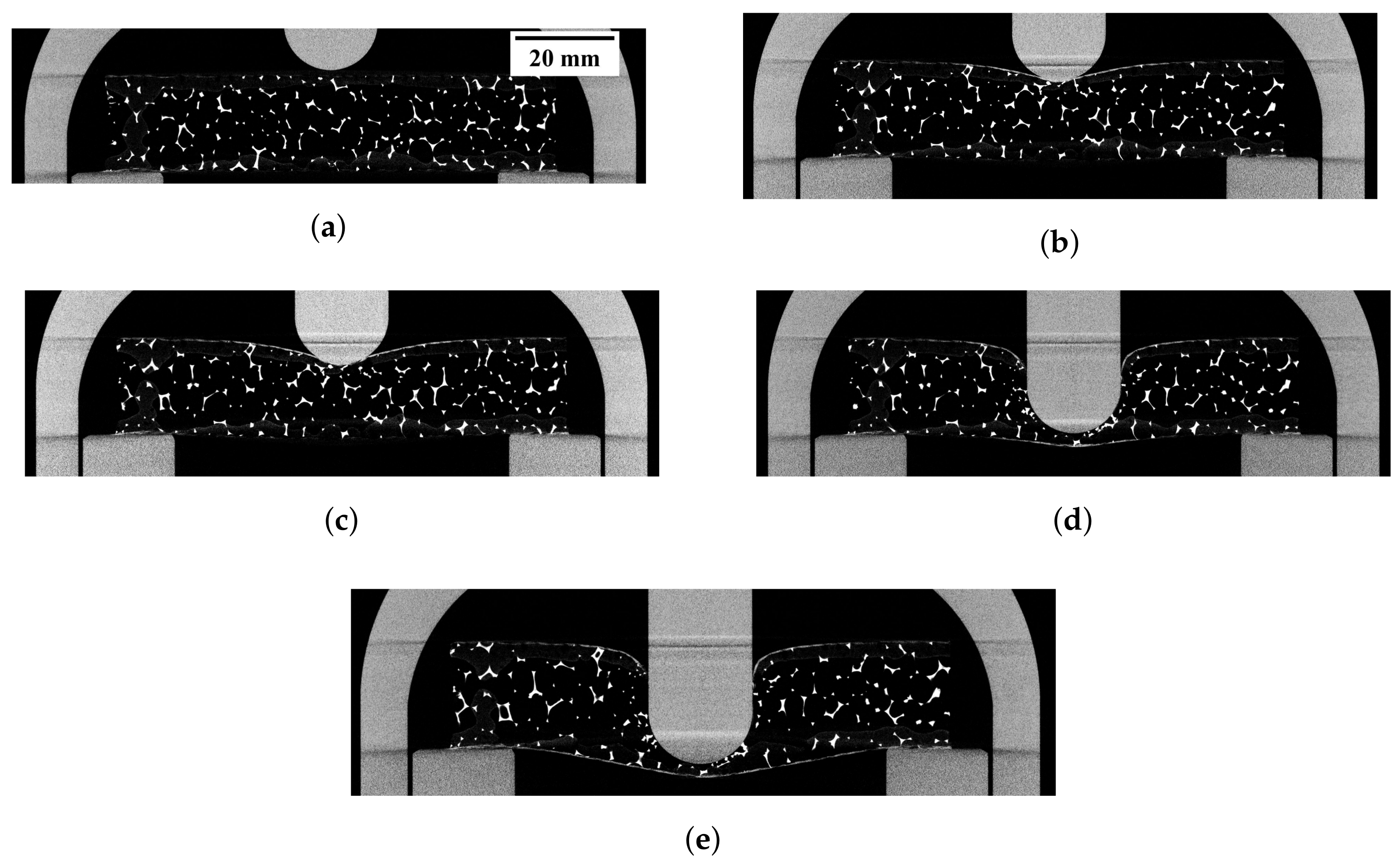

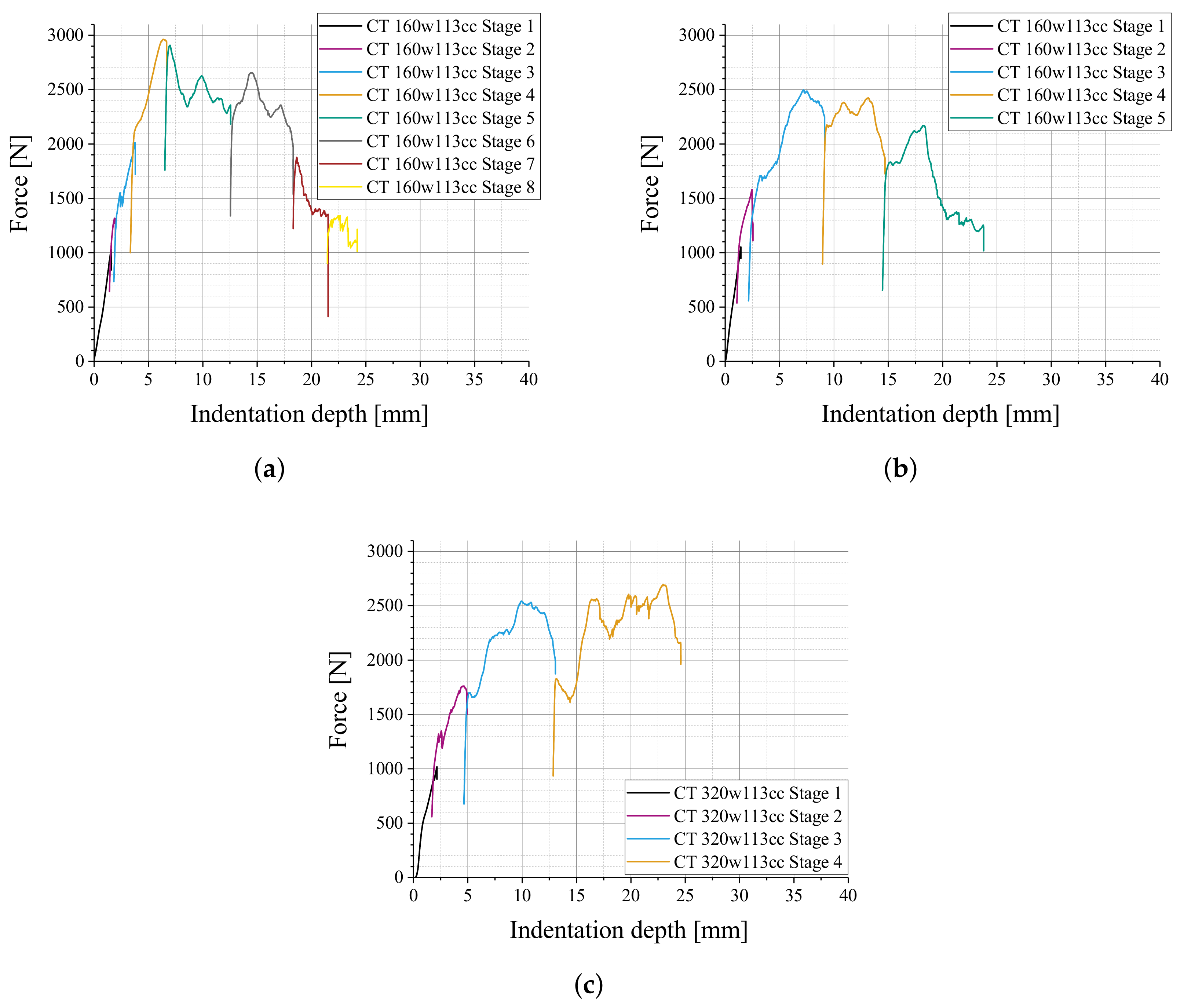

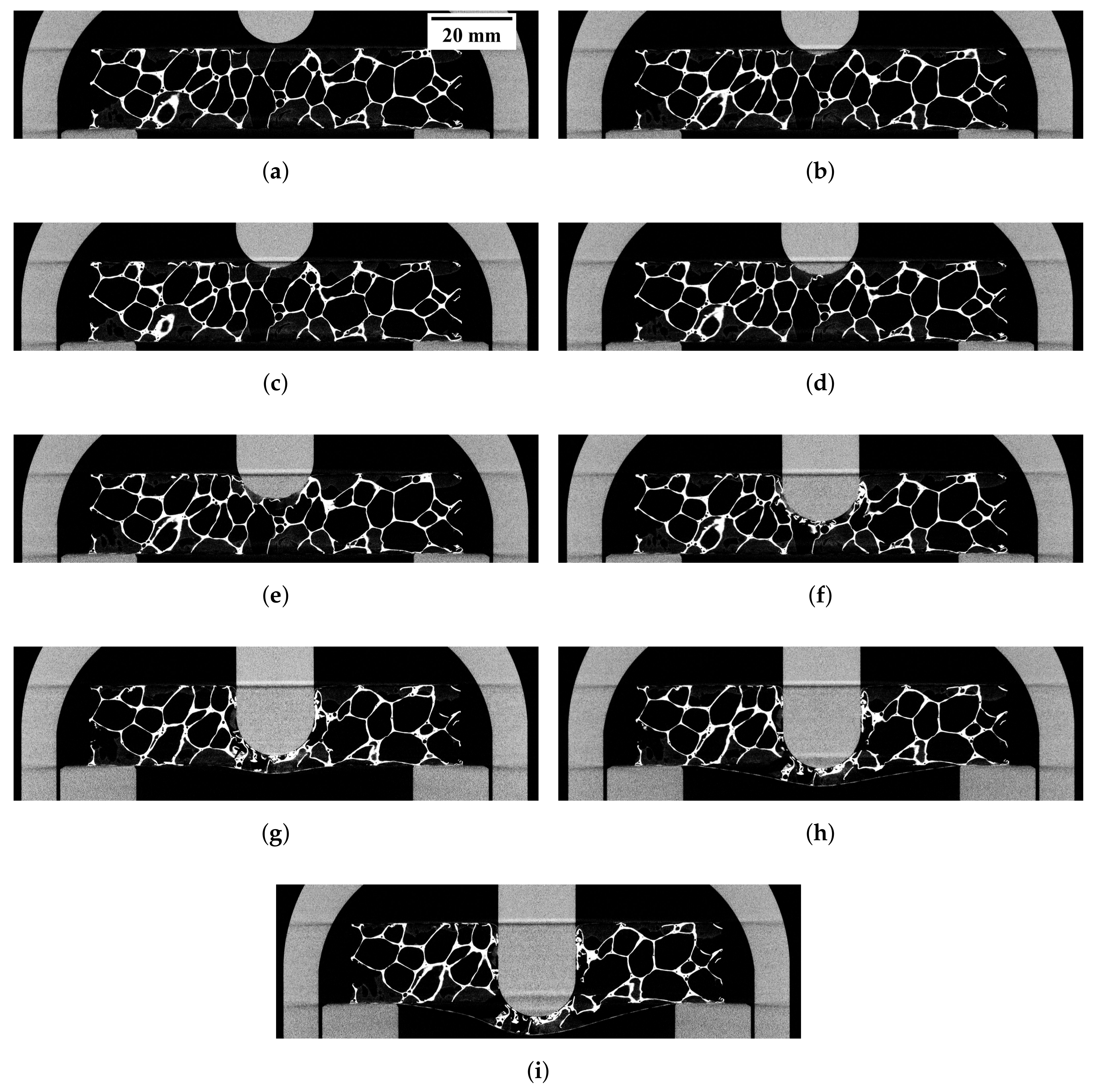

4.3. In Situ CT Indentation

5. Discussion

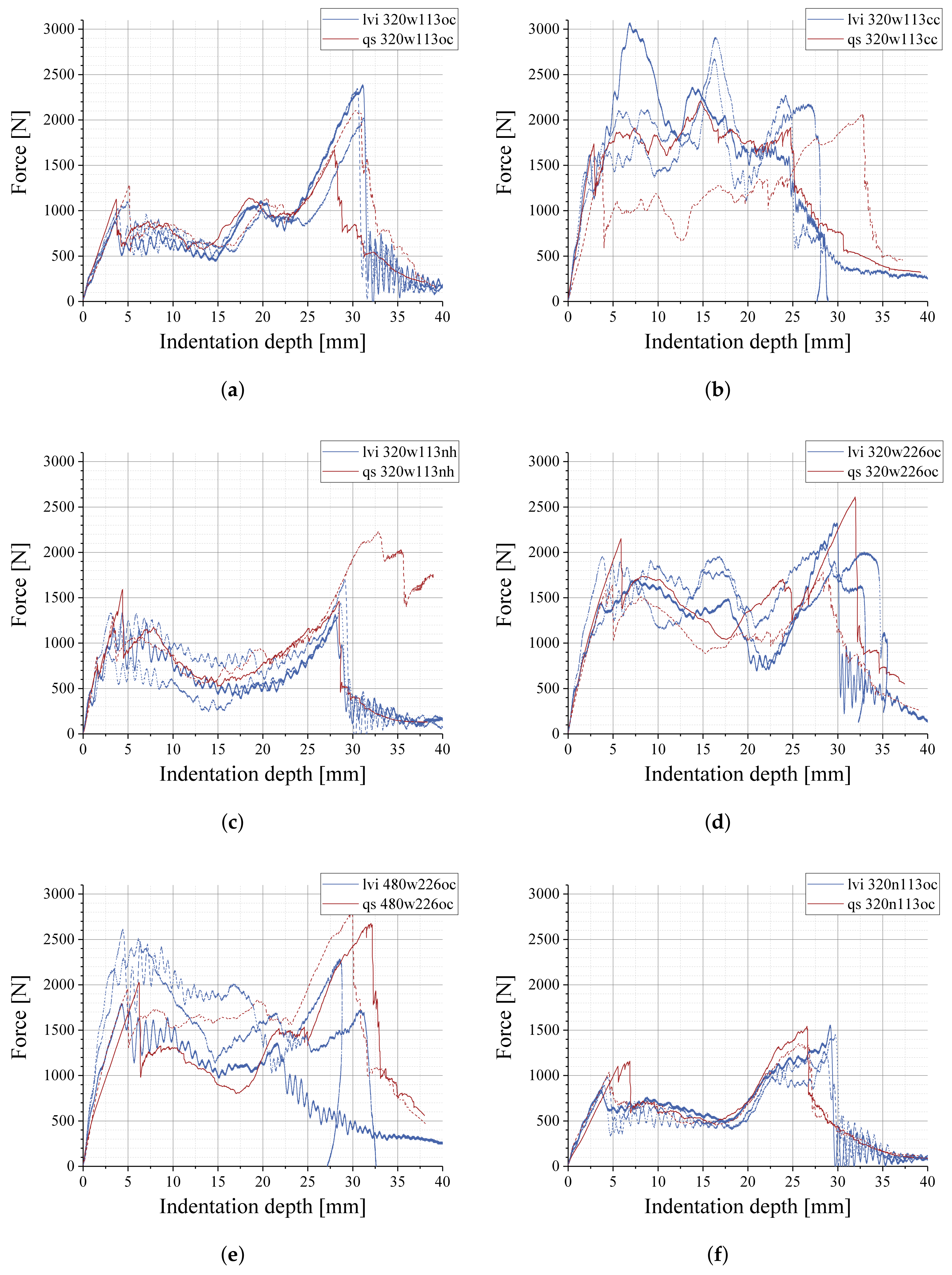

5.1. Conformity of LVI and Quasi-Static Indentation Behavior

5.2. Indentation Behavior

5.3. Influence of Sandwich Configuration

6. Conclusions

- LVI tests were conducted on a variety of sandwich configurations, accompanied and compared to quasi-static indentation tests, which were furthermore supported by DIC and CT measurements.

- The quasi-static indentation behavior of the investigated sandwich configurations is generally equal to the LVI behavior, including consistent force-indentation graphs and face sheet deformation. It was thus possible to describe the LVI behavior of the specimens with the more detailed data gained from the quasi-static and in situ CT tests, including DIC measurements.

- The failure of the first face sheet, the crushing of the core, and the failure of the second face sheet can be allocated in the force-indentation graphs, determined by observations made through in situ CT indentation tests, and consistent with literature.

- The face sheet configuration was shown to cause the load peaks observed at the start and the end of the indentation progress, and influence the maximum load level. Face sheets with higher face sheet fiber area weight, which could be generalized as ”face sheet thickness”, showed larger maximum force values. A woven architecture was shown to cause slightly higher maximum forces and less scatter than an otherwise equal NCF architecture. The DIC deformation pattern of woven face sheets also differs from the deformation pattern of NCF face sheets.

- The core type was shown to determine the overall load level and the section between the load peaks. CC cores were shown to cause higher load levels than NH and OC core structures, although the CC density was also higher.

- The PUR quantity stiffens the core structure. A large PUR quantity thus has the same effect as a denser core structure.

- The effects caused by each sandwich configuration parameter superpose, as was shown for an example of face sheet thickness and core structure.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CFRP | carbon fiber reinforced plastic |

| CT | X-ray computed tomography |

| GFRP | glass fiber reinforced plastic |

| LVI | low-velocity impact |

| NCF | non-crimp fabric |

| PMMA | poly(methyl methacrylate), acrylic glass |

| PUR | polyurethane |

Appendix A. Force-Indentation Graphs of Further Sandwich Configurations

References

- Zenkert, D. (Ed.) The Handbook of Sandwich Construction; Engineering Materials Advisory Services Ltd. (EMAS): Cradley Heath, UK, 1997. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Allen, H.G. Analysis and Design of Structural Sandwich Panels: Commonwealth and International Library: Structures and Solid Body Mechanics Division; Elsevier: Oxford, UK, 1969. [Google Scholar]

- Bonanno, A.; Crupi, V.; Epasto, G.; Guglielmino, E.; Palomba, G. Aluminum honeycomb sandwich for protective structures of earth moving machines. Procedia Struct. Integr. 2018, 8, 332–344. [Google Scholar] [CrossRef]

- Dietrich, S.; Kuppinger, J.; Elsner, P.; Weidenmann, K. Small mass impact testing of sandwich structures. Mater. Test. 2010, 52, 765–770. [Google Scholar] [CrossRef]

- Crupi, V.; Montanini, R. Aluminium foam sandwiches collapse modes under static and dynamic three-point bending. Int. J. Impact Eng. 2007, 34, 509–521. [Google Scholar] [CrossRef]

- Crupi, V.; Epasto, G.; Guglielmino, E. Impact response of aluminum foam sandwiches for light-weight ship Structures. Metals 2011, 1, 98–112. [Google Scholar] [CrossRef]

- Crupi, V.; Epasto, G.; Guglielmino, E. Comparison of aluminium sandwiches for lightweight ship structures: Honeycomb vs. foam. Mar. Struct. 2013, 30, 74–96. [Google Scholar] [CrossRef]

- Crupi, V.; Kara, E.; Epasto, G.; Guglielmino, E.; Aykul, H. Prediction model for the impact response of glass fibre reinforced aluminium foam sandwiches. Int. J. Impact Eng. 2015, 77, 97–107. [Google Scholar] [CrossRef]

- Crupi, V.; Epasto, G.; Guglielmino, E. Internal damage investigation of composites subjected to low-velocity impact. Exp. Tech. 2016, 40, 555–568. [Google Scholar] [CrossRef]

- Crupi, V.; Kara, E.; Epasto, G.; Guglielmino, E.; Aykul, H. Theoretical and experimental analysis for the impact response of glass fibre reinforced aluminium honeycomb sandwiches. J. Sandw. Struct. Mater. 2016, 20, 42–69. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, Z.; Yu, J. Low-velocity perforation behavior of composite sandwich panels with aluminum foam core. J. Sandw. Struct. Mater. 2013, 15, 92–109. [Google Scholar] [CrossRef]

- Mines, R.; Worrall, C.M.; Gibson, A.G. Low velocity perforation behaviour of polymer composite sandwich panels. Int. J. Impact Eng. 1998, 21, 855–879. [Google Scholar] [CrossRef]

- Han, M.S.; Cho, J.U. Impact damage behavior of sandwich composite with aluminum foam core. Trans. Nonferr. Met. Soc. China 2014, 24, s42–s46. [Google Scholar] [CrossRef]

- Wang, J.; Chen, B.; Wang, H.; Waas, A.M. Experimental study on the compression-after-impact behavior of foam-core sandwich panels. J. Sandw. Struct. Mater. 2015, 17, 446–465. [Google Scholar] [CrossRef]

- Topac, O.T.; Gozluklu, B.; Gurses, E.; Coker, D. Experimental and computational study of the damage process in CFRP composite beams under low-velocity impact. Compos. Part A 2017, 92, 167–182. [Google Scholar] [CrossRef]

- Singh, H.; Gupta, M.; Mahajan, P. Reduced order multiscale modeling of fiber reinforced polymer composites including plasticity and damage. Mech. Mater. 2017, 111, 35–56. [Google Scholar] [CrossRef]

- Yudhanto, A.; Wafai, H.; Lubineau, G.; Yaldiz, R.; Verghese, N. Characterizing the influence of matrix ductility on damage phenomenology in continuous fiber-reinforced thermoplastic laminates undergoing quasi-static indentation. Compos. Struct. 2018, 186, 324–334. [Google Scholar] [CrossRef]

- Namala, K.K.; Mahajan, P.; Bhatnagar, N. Digital image correlation of low-velocity impact on a glass/epoxy composite. Int. J. Comput. Methods Eng. Sci. Mech. 2014, 15, 203–217. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Cantwell, W.J. The influence of core properties on the perforation resistance of sandwich structures—An experimental study. Compos. Part B 2012, 43, 3231–3238. [Google Scholar] [CrossRef]

- Rupp, P.; Wafzig, F.; Weidenmann, K.A. The interface of CFRP face sheets and aluminum foam cores in hybrid sandwich panels manufactured by a PUR spraying process. In Proceedings of the 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Rupp, P.; Elsner, P.; Weidenmann, K.A. Specific bending stiffness of in-mould-assembled hybrid sandwich structures with carbon fibre reinforced polymer face sheets and aluminium foam cores manufactured by a polyurethane-spraying process. J. Sandw. Struct. Mater. 2017. [Google Scholar] [CrossRef]

- Rupp, P.; Elsner, P.; Weidenmann, K.A. Failure mode maps for four-point-bending of hybrid sandwich structures with carbon fiber reinforced plastic face sheets and aluminum foam cores manufactured by a polyurethane spraying process. J. Sandw. Struct. Mater. 2017. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. FIJI: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [PubMed]

| Component | Parameters | Sign |

|---|---|---|

| Face sheet fiber area weight | 160 g/m | 160 |

| 320 g/m | 320 | |

| 480 g/m | 480 | |

| Face sheet fiber architecture | woven | w |

| non-crimp fabric (NCF) | n | |

| polyurethane (PUR) quantity | 75.5 g/m | 75 |

| 113.3 g/m | 113 | |

| 226.6 g/m | 226 | |

| Core type | open-cell aluminum foam | oc |

| closed-cell aluminum foam | cc | |

| Nomex honeycomb | nh |

| Configuration | Effective Density (g/cm) | Maximum Impact Force (N) | Absorbed Impact Energy (J) |

|---|---|---|---|

| 160n75oc | 0.168 ± 0.005 | 1118.1 ± 281.1 | 18.87 ± 3.01 |

| 160n113oc | 0.179 ± 0.008 | 1275.0 ± 199.4 | 21.03 ± 4.45 |

| 160n113cc | 0.286 ± 0.017 | 2052.7 ± 475.5 | 33.82 ± 4.08 |

| 160n226oc | 0.192 ± 0.005 | 1165.2 ± 226,5 | 20.63 ± 2.69 |

| 160w75oc | 0.168 ± 0.016 | 1300.7 ± 290.3 | 22.22 ± 4.82 |

| 160w113oc | 0.188 ± 0.004 | 1371.5 ± 188.4 | 23.80 ± 4.92 |

| 160w113cc | 0.289 ± 0.040 | 2181.5 ± 480.4 | 38.79 ± 10.15 |

| 160w113nh | 0.126 ± 0.002 | 1285.3 ± 106.2 | 22.17 ± 1.91 |

| 160w226oc | 0.248 ± 0.013 | 1727.7 ± 326.6 | 38.11 ± 9.48 |

| 320n75oc | 0.180 ± 0.002 | 1444.9 ± 328.3 | 21.30 ± 3.40 |

| 320n113oc | 0.181 ± 0.003 | 1426.1 ± 141.3 | 22.57 ± 1.19 |

| 320n113cc | 0.295 ± 0.029 | 2109.2 ± 524.5 | 41.03 ± 15.73 |

| 320n113nh | 0.126 ± 0.003 | 1404.1 ± 267.8 | 19.99 ± 5.02 |

| 320n226oc | 0.188 ± 0.004 | 1492.1 ± 254.2 | 21.03 ± 5.76 |

| 320w75oc | 0.199 ± 0.008 | 2054.7 ± 418.7 | 30.29 ± 10.29 |

| 320w113oc | 0.211 ± 0.013 | 2109.3 ± 289.9 | 31.09 ± 2.35 |

| 320w113cc | 0.298 ± 0.027 | 2590.6 ± 435.2 | 47.45 ± 4.82 |

| 320w113nh | 0.143 ± 0.002 | 1662.8 ± 350.0 | 27.16 ± 7.64 |

| 320w226oc | 0.263 ± 0.014 | 2160.3 ± 316.2 | 47.35 ± 6.12 |

| 480w226oc | 0.279 ± 0.026 | 2478.3 ± 396.2 | 48.55 ± 9.96 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rupp, P.; Imhoff, J.; Weidenmann, K.A. Low-Velocity Impact Properties of Sandwich Structures with Aluminum Foam Cores and CFRP Face Sheets. J. Compos. Sci. 2018, 2, 24. https://doi.org/10.3390/jcs2020024

Rupp P, Imhoff J, Weidenmann KA. Low-Velocity Impact Properties of Sandwich Structures with Aluminum Foam Cores and CFRP Face Sheets. Journal of Composites Science. 2018; 2(2):24. https://doi.org/10.3390/jcs2020024

Chicago/Turabian StyleRupp, Peter, Jonas Imhoff, and Kay André Weidenmann. 2018. "Low-Velocity Impact Properties of Sandwich Structures with Aluminum Foam Cores and CFRP Face Sheets" Journal of Composites Science 2, no. 2: 24. https://doi.org/10.3390/jcs2020024