Innovation Potentials and Pathways Merging AI, CPS, and IoT

Abstract

:1. Introduction

- RQ1: How can the status and state-of-the-art of development in the areas of production (CPS, additive manufacturing, Industry 4.0, etc.), transportation (PI, IoT) and artificial intelligence (AI) be described?

- RQ2: Applying the method of technology forecasting and evaluation, what looming innovations and prognoses can be derived from that?

- RQ3: What interactions and innovation potentials can be assumed bringing the three areas of production, transportation and artificial intelligence together?

2. State of the Art and Recent Advances

2.1. Production

2.2. Transportation

- In the first generation of cruise control applications, the system steadily maintained a constant, preset speed level. This was only steering the gas and propulsion system of the truck.

- Second, the system was able to follow a preceding vehicle with a present distance length with varying speed, therefore already combing the management of gas, automated gearshift and brake.

- Third is the competence of current dynamic cruise control systems to anticipate the route characteristics via GPS positioning in combination with map material. This allows the system e.g., to decelerate and upshift before downhill passages or accelerate and downshift before uphill road segments. This combines gas, brake, gearshift as well as GPS and navigation capabilities. The driver is furthermore only steering and supervising the comprehensive system.

2.3. Artificial Intelligence

- Cost savings: AI applications are expected to achieve cost savings, especially in the area of personnel costs as robotics and automated intralogistics and transportation applications are expected to provide faster and durable—and therefore finally cheaper—solutions in the logistics domain.

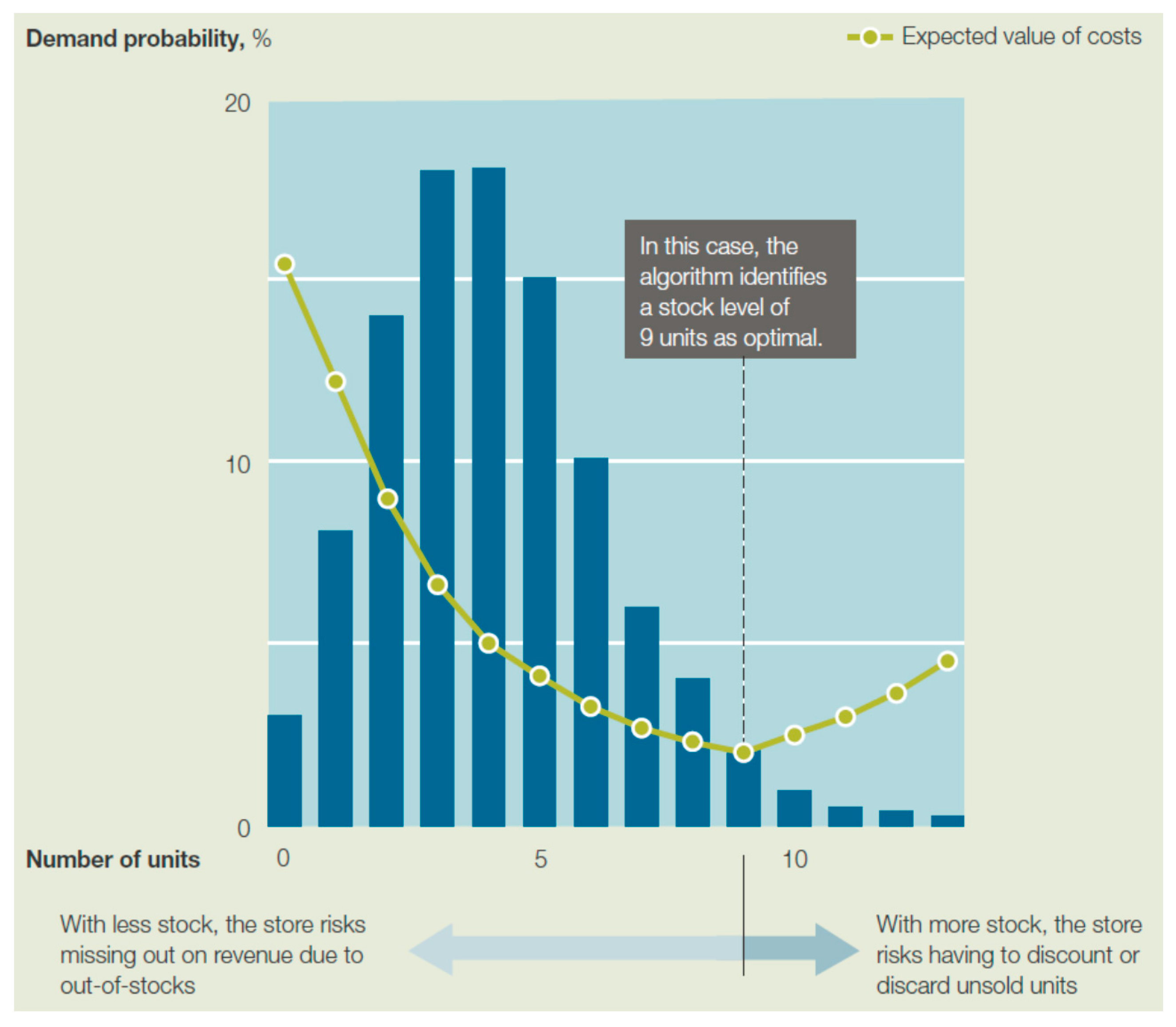

- Earnings increases: In many cases AI applications are expected also to increase revenue volumes—whether directly by increasing available product items at the point of sale (avoiding out of stock situations), or indirectly by allowing retailers to match customer preferences and expectations better and therefore increase customer satisfaction and re-buy rates. This is already partly obvious in the online shopping environment as well as with new automated customer support systems such as ‘Google Home/Assistant‘ or ‘Amazon Alexa/Echo’ [47,48].

- Increased speed: Obviously especially in logistics and transportation contexts, an area of great expectations is also the dimension of speed, especially by a more aligned cooperation of different actors within operations and transportation processes—e.g., between picking, production, packing and outbound transportation. This may significantly decrease lead times and time to market rates with the application of AI and automation.

- Increased flexibility: Finally, especially with speedy AI applications, most logistics and SCM managers also expect increasing flexibility for intralogistics as well as transportation setups; this is a very valuable asset in logistics environments and can be especially crucial in peak times. For example especially in delay and ‘troubleshooting’ situations very complex and fast decisions have to be taken e.g., for or against express transportation, re-shipments or others—in such situations, AI decision support could be crucial for maintaining customer satisfaction and competitiveness for logistics service providers as well as manufacturers and retailers.

“In 1963, Dennis Gabor, Nobel laureate for his invention of the holograph, said ‘The future cannot be predicted, but futures can be invented’ (Gabor, 1963). This statement has become a mantra in recent times, attributed to many who are simply rephrasing Gabor. Alas, the slogan, wonderful though it may sound, is false. The most successful inventions transform the world in ways that are impossible to foresee at the time of the invention. The statement should really be yet another of my laws: My law of prediction: ‘The future cannot be predicted, not even by trying to invent it. Although inventions can change the future, their long-term impact cannot be predicted.’ So, invent all you like, just don’t try to predict the impact several decades later.”[50]

3. Technology Forecasting and Evaluation

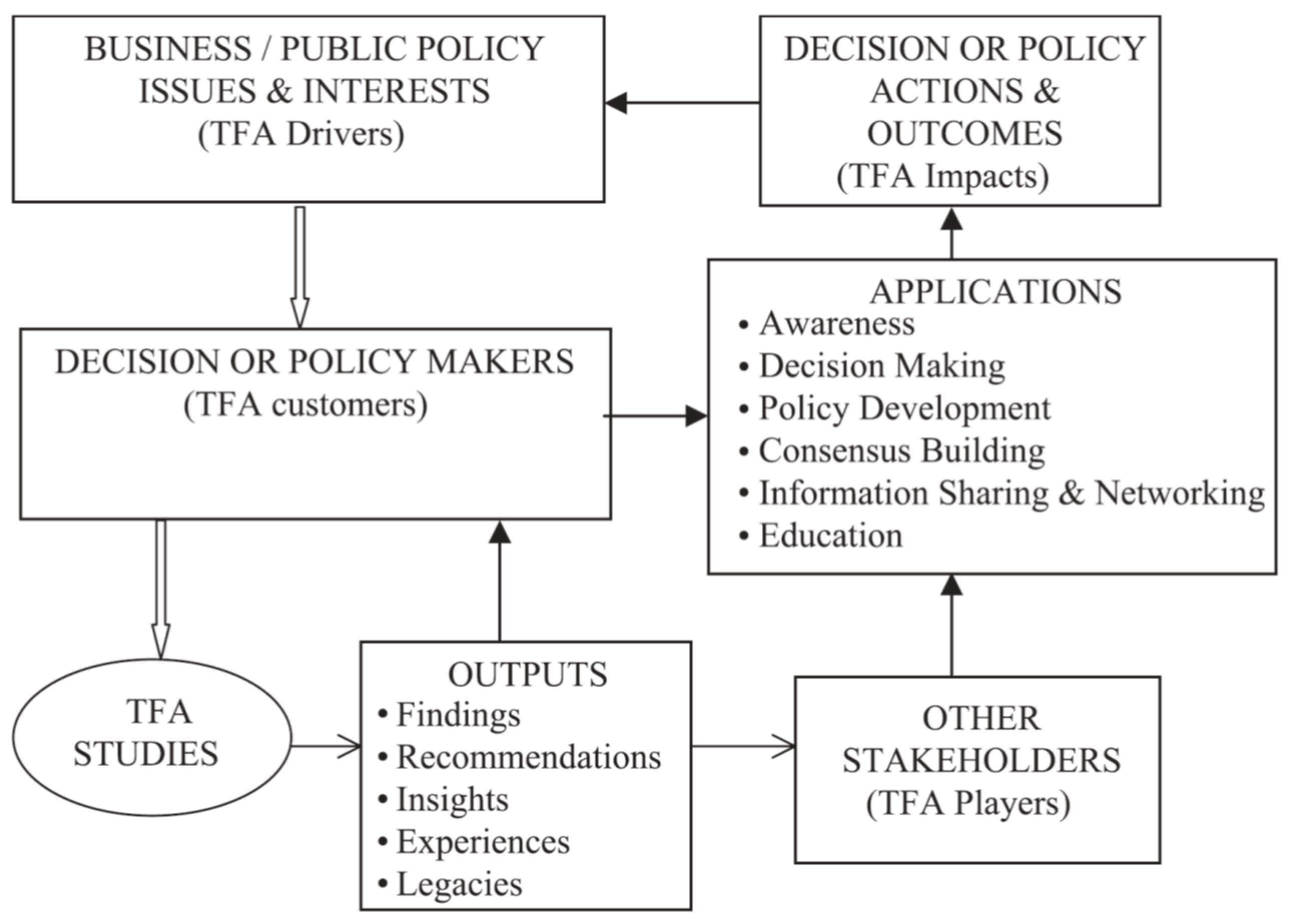

3.1. Theory and Method Framework

- Delphi method (expert interviews);

- Analytical hierarchy process AHP (expert opinions/prioritization);

- Patent analysis;

- Bibliometric analysis;

- Relevance trees;

- Growth curve;

- Extrapolation;

- Case studies;

- Scenario writing.

3.2. Application

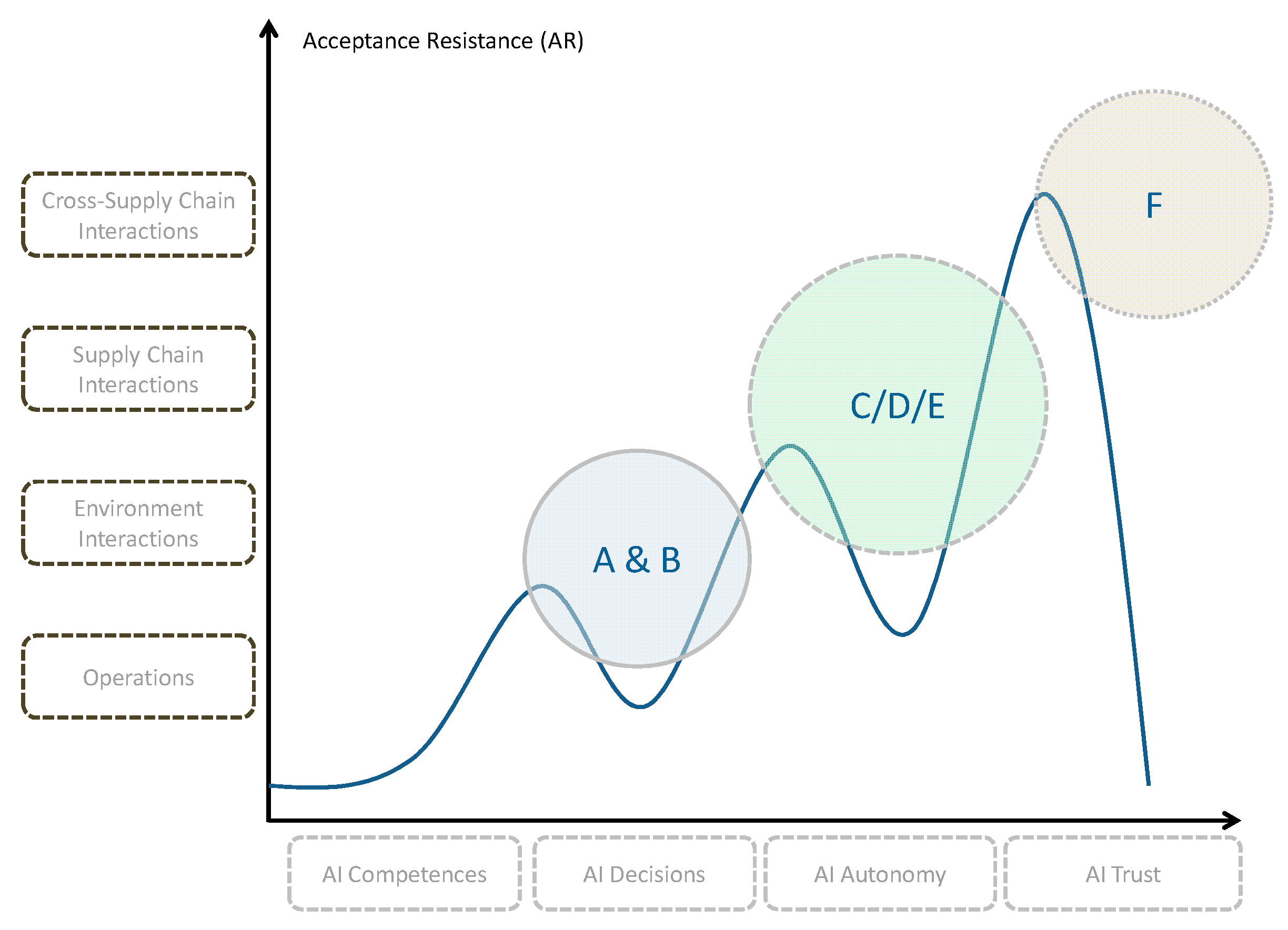

4. Discussion of Innovation Fields

4.1. Field A—‘Advanced CPS’

4.2. Field B—‘Advanced Transportation Planning’

4.3. Field C—‘Expert/AI CPS’

4.4. Field D—‘Expert/AI Transportation Systems’

4.5. Field E—‘Integrated SCM Sytems’

4.6. Field F—‘Global Meta-SCM Systems’

5. Case Analysis Autonomous Truck Driving and Maintenance

5.1. Theory Framework

5.2. Description Status Quo

5.3. Technology Forecasting

6. Conclusions and Outlook

Conflicts of Interest

References

- Mikusz, M. Towards an Understanding of Cyber-Physical Systems as Industrial Software-Product-Service Systems. Procedia CIRP 2014, 16, 385–389. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, G.; Zou, Y.; Qin, S.; Fu, S. Review of job shop scheduling research and its new perspectives under Industry 4.0. J. Intell. Manuf. 2017, 1–22. [Google Scholar] [CrossRef]

- Riedl, M.; Zipper, H.; Meier, M.; Diedrich, C. Cyber-physical systems alter automation architectures. Annu. Rev. Control 2014, 38, 123–133. [Google Scholar] [CrossRef]

- Bordel, B.; Alcarria, R.; Robles, T.; Martin, D. Cyber-physical systems: Extending pervasive sensing from control theory to the Internet of Things. Pervasive Mob. Comput. 2017, 40, 156–184. [Google Scholar] [CrossRef]

- Frazzon, E.M.; Hartmann, J.; Makuschewitz, T.; Scholz-Reiter, B. Towards Socio-Cyber-Physical Systems in Production Networks. Procedia CIRP 2013, 7, 49–54. [Google Scholar] [CrossRef]

- Meech, J.; Parreira, J. An interactive simulation model of human drivers to study autonomous haulage trucks. Procedia Comput. Sci. 2011, 6, 118–123. [Google Scholar] [CrossRef]

- Merat, N.; de Waard, N. Human factors implications of vehicle automation: Current understanding and future directions. Trans. Res. Part F Traffic Psychol. Behav. 2014, 27, 193–195. [Google Scholar] [CrossRef]

- Montreuil, B. Towards a Physical Internet: Meeting the Global Logistics Sustainability Grand Challenge. Logist. Res. 2011, 3, 71–87. [Google Scholar] [CrossRef]

- Gunsekaran, A.; Ngai, E.W.T. Expert systems and artificial intelligence in the 21st century logistics and supply chain management. Expert Syst. Appl. 2014, 41, 1–4. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, C.K.M.; Chan, H.K.; Choy, K.L.; Zhang, W. Swarm intelligence applied in green logistics: A literature review. Eng. Appl. Artif. Intell. 2014, 37, 154–169. [Google Scholar] [CrossRef]

- Klumpp, M. Automation and Artificial Intelligence in Business Logistics Systems: Human Reactions and Collaboration Requirements. Int. J. Logist. 2017, 1–19. [Google Scholar] [CrossRef]

- Armstrong, S.; Bostrom, N.; Shulman, C. Racing to the precipice: A model of artificial intelligence development. AI Soc. 2016, 31, 201–206. [Google Scholar] [CrossRef]

- Silver, D.; Schrittwieser, J.; Smionyan, K.; Antonoglou, I.; Huang, A.; Guez, A.; Hubert, T.; Baker, L.; Lai, M.; Bolton, A.; et al. Mastering the game of Go without human knowledge. Nature 2017, 550, 354–359. [Google Scholar] [CrossRef] [PubMed]

- Bostrom, N. Superintelligence—Paths, Dangers, Strategies; Oxford University Press: Oxford, UK, 2014. [Google Scholar]

- Kosir, A.; Strle, G. Emotion Elicitation in a Socially Intelligent Service: The Typing Tutor. Computers 2017, 6, 14. [Google Scholar] [CrossRef]

- Klumpp, M. Artificial Divide: The New Challenge of Human-Artificial Performance in Logistics. In Innovative Produkte und Dienstleistungen in der Mobilität; Proff, H., Fojcik, T.M., Eds.; Springer Gabler: Heidelberg/Berlin, Germany, 2017; pp. 583–593. [Google Scholar]

- Müller, C.; Grunewald, M.; Spengler, T.S. Redundant configuration of automated flow lines based on “Industry 4.0”-technologies. J. Bus. Econ. 2017, 87, 877–898. [Google Scholar] [CrossRef]

- Liu, X.F.; Shahriar, M.K.; Al Sunny, S.M.N.; Leu, M.C.; Hu, L. Cyber-physical manufacturing cloud: Architecture, virtualization, communication, and testbed. J. Manuf. Syst. 2017, 43, 352–364. [Google Scholar] [CrossRef]

- Shames, I.; Farokhi, F.; Summers, T.H. Security analysis of cyber-physical systems using H2 norm. IET Control Theory Appl. 2017. [Google Scholar] [CrossRef]

- Shoukry, Y.; Nuzzo, P.; Puggelli, A.; Sangiovanni-Vincentelli, A.L.; Seshia, S.A.; Tabuada, P. Secure state estimation for cyber physical systems under sensor attacks: A satisfiability modulo theory approach. IEEE Trans. Autom. Control 2017, 62, 4917–4932. [Google Scholar] [CrossRef]

- Babiceanu, R.F.; Seker, R. Trustworthiness requirements for manufacturing cyber-physical systems. Procedia Manuf. 2017, 11, 973–981. [Google Scholar] [CrossRef]

- Abdo, H.; Kaouk, M.; Flaus, J.-M.; Masse, F. A safety/security risk analysis approach of Industrial Control Systems: A cyber bowtie—Combining new version of attack tree with bowtie analysis. Comput. Secur. 2018, 72, 175–195. [Google Scholar] [CrossRef]

- Alcaraz, C.; Lopez, J.; Choo, K.-K.R. Resilient interconnection in cyber-physical control systems. Comput. Secur. 2017, 71, 2–14. [Google Scholar] [CrossRef]

- Akkaya, I.; Derler, P.; Emoto, S.; Lee, E.A. Systems engineering for cyber-physical systems using aspects. Proc. IEEE 2016, 104, 997–1012. [Google Scholar] [CrossRef]

- Zanero, S. Cyber-Physical Systems. Computer 2017, 50, 15–16. [Google Scholar] [CrossRef]

- Bernhart, W.; Winterhoff, M.; Hoyes, C.; Chivukuly, V.; Garrelfs, J.; Jung, S.; Galander, S. Autonomous Driving; Roland Berger: Munich, Germany, 2014. [Google Scholar]

- Hjälmdahl, M.; Krupenia, S.; Thorslund, B. Driver behaviour and driver experience of partial and fully automated truck platooning—A simulator study. Eur. Transp. Res. Rev. 2017, 9, 8. [Google Scholar] [CrossRef]

- Bertoncello, M.; Wee, D. Ten Ways Autonomous Driving Could Redefine the Automotive World; McKinsey & Company: New York, NY, USA, 2015. [Google Scholar]

- Tylor, P. Data Mining for Vehicle Telemetry. Appl. Artif. Intell. 2016, 30, 233–256. [Google Scholar] [CrossRef]

- Fors, C.; Kircher, K.; Ahlström, C. Interface design of eco-driving support systems—Truck drivers’ preferences and behavioural compliance. Trans. Res. Part C 2015, 58, 706–720. [Google Scholar] [CrossRef]

- Sugimachi, T.; Fukao, T.; Suzuki, Y.; Kawashima, H. Development of Autonomous Platooning System for Heavy-duty Trucks. In Proceedings of the 7th IFAC Symposium on Advances in Automotive Control, Tokyo, Japan, 4–6 September 2013; Volume 46, pp. 52–57. [Google Scholar]

- Zhang, B.; Wilschut, E.S.; Willemsen, D.M.C.; Alkim, T.; Martens, M.H. The Effect of See-Through Truck on Driver Monitoring Patterns and Responses to Critical Events in Truck Platooning. In Advances in Human Aspects of Transportation, Proceedings of the International Conference on Applied Human Factors and Ergonomics, Los Angeles, CA, USA, 17–21 July 2017; Advances in Intelligent Systems and Computing; Stanton, N., Ed.; Springer: Cham, UK, 2018; Volume 597, pp. 842–852. [Google Scholar]

- Bishop, R.; Bevly, D.; Humphreys, L.; Boyd, S.; Murray, D. Evaluation and Testing of Driver-Assistive Truck Platooning—Phase 2 Final Results. Trans. Res. Rec. 2017, 2615. [Google Scholar] [CrossRef]

- Price, D.A. Robots for the long haul. Econ Focus 2017, 1, 13–15. [Google Scholar]

- Pan, Y. Heading toward Artificial Intelligence 2.0. Engineering 2016, 2, 409–413. [Google Scholar] [CrossRef]

- Norman, D. Design, Business Models, and Human-Technology Teamwork. Res.-Technol. Manag. 2017, 60, 26–30. [Google Scholar] [CrossRef]

- Hamet, P.; Tremblay, J. Artificial intelligence in medicine. Metabolism 2017, 69, S36–S40. [Google Scholar] [CrossRef] [PubMed]

- Hanson, R. Economics of the Singularity. IEEE Spectr. 2008, 45, 45–50. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep learning in neural networks: An overview. Neural Netw. 2015, 61, 85–117. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, S. Smarter than Us—The Rise of Machine Intelligence; MIRI: Berkeley, CA, USA, 2014. [Google Scholar]

- Barrat, J. Our Final Invention—Artificial Intelligence and the End of the Human Era; Griffin: New York, NY, USA, 2013. [Google Scholar]

- Silver, D.; Huang, A.; Maddison, C.J.; Guez, A.; Sifre, L.; van den Driessche, G. Mastering the game of Go with deep neural networks and tree search. Nature 2016, 529, 484–489. [Google Scholar] [CrossRef] [PubMed]

- Borowiec, S. AlphaGo Seals 4-1 Victory Over Go Grandmaster Lee Sedol. Available online: https://www.theguardian.com/technology/2016/mar/15/googles-alphago-seals-4-1-victory-over-grandmaster-lee-sedol (accessed on 30 October 2017).

- Stajic, J. Artificial intelligence masters poker. Science 2017, 356, 497. [Google Scholar] [CrossRef] [PubMed]

- Moravčík, M.; Schmid, M.; Burch, N.; Lisý, V.; Morrill, D.; Bard, N.; Davis, T.; Waugh, K.; Johanson, M.; Bowling, M. DeepStack: Expert-Level Artificial Intelligence in No-Limit Poker. Science 2017, 356, 508–513. [Google Scholar] [CrossRef] [PubMed]

- Riley, T. Artificial intelligence goes deep to beat humans at poker. Science 2017. [Google Scholar] [CrossRef]

- Clauser, G. Wirecutter—What Is Alexa? Available online: https://thewirecutter.com/reviews/what-is-alexa-what-is-the-amazon-echo-and-should-you-get-one/ (accessed on 30 October 2017).

- Smart Home—7 Things Amazon Echo Can Do That Google Home Can’t. Available online: https://www.cnet.com/how-to/amazon-echo-things-alexa-can-do-that-google-home-cant (accessed on 30 October 2017).

- Glatzel, C.; Hopkins, M.; Lange, T.; Weiss, U. The Secret to Smarter Fresh-Food Replenishment? Machine Learning. Perspectives on Retail and Consumer Goods, 5/McKinsey Report. 2016. Available online: http://www.mckinsey.com/industries/retail/our-insights/the-secret-to-smarter-fresh-food-replenishment-machine-learning (accessed on 30 October 2017).

- Norman, D. Designing for People. Available online: http://www.jnd.org (accessed on 30 October 2017).

- Porter, A.L.; Ashton, B.; Clar, G.; Coates, J.F.; Cuhls, K.; Cunningham, S.W.; Ducatel, K.; van der Duin, P.; Georghiou, L.; Gordon, T.; et al. Technology futures analysis: Towards integration of the field and new methods. Technol. Forecast. Soc. Chang. 2004, 71, 287–303. [Google Scholar]

- Eto, H. The suitability of technology forecasting/foresight methods for decision systems and strategy—A Japanese view. Technol. Forecast. Soc. Chang. 2003, 70, 231–249. [Google Scholar] [CrossRef]

- Cheng, A.-C.; Chen, C.-J.; Chen, C.-Y. A fuzzy multiple criteria comparison of technology forecasting methods for predicting the new materials development. Technol. Forecast. Soc. Chang. 2008, 75, 131–141. [Google Scholar] [CrossRef]

- Daim, T.U.; Rueda, G.; Martin, H.; Gerdsri, P. Forecasting emerging technologies—Use of bibliometrics and patent analysis. Technol. Forecast. Soc. Chang. 2006, 73, 981–1012. [Google Scholar] [CrossRef]

- Canbolat, Y.B.; Gupta, G.; Matera, S.; Chelst, K. Analysing risk in sourcing design and manufacture of components and sub-systems to emerging markets. Int. J. Prod. Res. 2008, 46, 5145–5164. [Google Scholar] [CrossRef]

- Liu, C.; Cao, S.; Tse, W.; Xu, X. Augmented Reality-assisted Intelligent Window for Cyber-Physical Machine Tools. J. Manuf. Syst. 2017, 44, 280–286. [Google Scholar] [CrossRef]

- Imperial Logistics International. Available online: https://www.imperial-international.com (accessed on 30 October 2017).

- Han, J.H.; Wang, Y.; Naim, M. Reconceptualization of information technology flexibility for supply chain management: An empirical study. Int. J. Prod. Econ. 2017, 187, 196–215. [Google Scholar] [CrossRef]

- Huang, S.H.; Sheroan, S.K.; Keskar, H. Computer-assisted supply chain configuration based on supply chain operations reference (SCOR) model. Comput. Ind. Eng. 2005, 48, 377–394. [Google Scholar] [CrossRef]

- Mori, M.; Kobayashi, R.; Samejima, M.; Komoda, N. Risk-cost optimization for procurement planning in multi-tier supply chain by Pareto Local Search with relaxed acceptance criterion. Eur. J. Oper. Res. 2017, 261, 88–96. [Google Scholar] [CrossRef]

- Bijjahalli, S.; Ramasamy, S.; Sabatini, R. A Novel Vehicle-Based GNSS Integrity Augmentation System for Autonomous Airport Surface Operations. J. Intell. Robot. Syst. 2017, 87, 379–403. [Google Scholar] [CrossRef]

- Ding, K.; Jiang, P.; Su, S. RFID-enabled social manufacturing system for inter-enterprise monitoring and dispatching of integrated production and transportation tasks. Robot. Comput.-Integr. Manuf. 2018, 49, 120–133. [Google Scholar] [CrossRef]

- Zijm, W.M.H.; Klumpp, M. Logistics and supply chain management: Trends and developments. In Logistics and Supply Chain Innovation; Zijm, W.H.M., Klumpp, M., Clausen, U., ten Hompel, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–20. [Google Scholar]

- Phan, M.-H.; Kim, K.H. Negotiating truck arrival times among trucking companies and a container terminal. Trans. Res. Part E 2015, 75, 132–144. [Google Scholar] [CrossRef]

- Carter, C.R.; Dale, S.R. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Forslund, H.; Jonsson, P. The impact of forecast information quality on supply chain performance. Int. J. Oper. Prod. Manag. 2007, 27, 90–107. [Google Scholar] [CrossRef]

- Nürnberger, K.; Hochstrasser, M.; Holzapfel, F. Execution time analysis and optimization techniques in the model-based development of a flight control software. IET Cyber-Phys. Syst. Theory Appl. 2017, 2, 57–64. [Google Scholar] [CrossRef]

- Lyons, J.B.; Ho, N.; Koltai, K.; Masequesmay, G.; Skoog, M.; Cacanindin, A.; Johnson, W. A trust-based analysis of an Air Force collision avoidance system: Test pilots. Ergon. Des. 2016, 24, 9–12. [Google Scholar] [CrossRef]

- Hengstler, M.; Enkel, E.; Duelli, S. Applied artificial intelligence and trust—The case of autonomous vehicles and medical assistance devices. Technol. Forecast. Soc. Chang. 2016, 105, 105–120. [Google Scholar] [CrossRef]

- Jamson, A.H.; Merat, N.; Carsten, O.M.; Lai, F.C. Behavioural changes in drivers experiencing highly-automated vehicle control in varying traffic conditions. Trans. Res. Part C Emerg. Technol. 2013, 30, 116–125. [Google Scholar] [CrossRef]

- Lee, J.D.; See, K.A. Trust in technology: Designing for appropriate reliance. Hum. Factors 2004, 46, 50–80. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Hess, T.J.; Valacich, J.S. Why do we trust new technology? A study of initial trust formation with organizational information systems. J. Strateg. Inf. Syst. 2008, 17, 39–71. [Google Scholar] [CrossRef]

- Lee, H.-D.; Lee, B.-K.; Kim, W.-S.; Han, J.-S.; Shin, K.-S.; Han, C.-S. Human–robot cooperation control based on a dynamic model of an upper limb exoskeleton for human power amplification. Mechatronics 2014, 24, 168–176. [Google Scholar] [CrossRef]

- Weyer, J.; Fink, R.D.; Adelt, F. Human-machine cooperation in smart cars: An empirical investigation of the loss-of-control thesis. Saf. Sci. 2015, 72, 199–208. [Google Scholar] [CrossRef]

- Rauffet, P.; Lassalle, J.; Leroy, B.; Coppin, G.; Chauvina, C. The TAPAS project: Facilitating cooperation in hybrid combat air patrols including autonomous UCAVs. Procedia Manuf. 2015, 3, 974–981. [Google Scholar] [CrossRef] [Green Version]

- Rousseau, D.M.; Sitkin, S.B.; Burt, R.S.; Camerer, C. Not so different after all: A cross discipline view of trust. Acad. Manag. Rev. 1998, 23, 393–404. [Google Scholar] [CrossRef]

- Onnasch, L.; Wickens, C.D.; Li, H.; Manzey, D. Human performance consequences of stages and levels of automation: An integrated meta-analysis. Hum. Factors 2014, 56, 476–488. [Google Scholar] [CrossRef] [PubMed]

- Niedober, D.; Ho, N.; Masequesmay, G.; Koltai, K.; Skoog, M.; Cacanindin, A.; Johnson, W.; Lyons, J.B. Influence of cultural, organizational and automation factors on human-automation trust: A case study of Auto-GCAS engineers and developmental history. Int. Conf. Hum.-Comput. Interact. 2014, 8512, 473–484. [Google Scholar]

- König, M.; Neumayr, L. Users’ resistance towards radical innovations: The case of the self-driving car. Trans. Res. Part F Traffic Psychol. Behav. 2017, 44, 42–52. [Google Scholar] [CrossRef]

- Koo, J.; Kwac, J.; Ju, W.; Steinert, M.; Leifer, L.; Nass, C. Why did my car just do that? Explaining semi-autonomous driving actions to improve driver under-standing, trust, and performance. Int. J. Interact. Des. Manuf. 2015, 9, 269–275. [Google Scholar] [CrossRef]

- Richert, A.; Müller, S.; Schröder, S.; Jeschke, S. Anthropomorphism in social robotics: Empirical results on human–robot interaction in hybrid production workplaces. AI Soc. 2017, 1–12. [Google Scholar] [CrossRef]

- Chen, H.; Long, C.; Jiang, H.-B. Building a Belief-Desire-Intention Agent for Modeling Neural Networks. Appl. Artif. Intell. 2015, 29, 753–765. [Google Scholar] [CrossRef]

- Goertzel, B.; Pitt, J. Nine ways to bias open-source AGI toward friendliness. J. Evol. Technol. 2012, 22, 116–131. [Google Scholar]

- Gurkaynak, G.; Yilmaz, I.; Haksever, G. Stifling artificial intelligence: Human perils. Comput. Law Secur. Rev. 2016, 32, 749–758. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Makridakis, S. The forthcoming artificial intelligence (AI) revolution: Its impact on society and firms. Futures 2017, 90, 46–60. [Google Scholar] [CrossRef]

- Pyle, D.; San Jose, C. An Executive’s Guide to Machine Learning. McKinsey Q. June 2015. Available online: http://www.mckinsey.com/industries/high-tech/our-insights/an-executives-guide-to-machine-learning (accessed on 30 October 2017).

- Hernández-Orallo, J. Evaluation in artificial intelligence: From task-oriented to ability-oriented measurement. Artif. Intell. Rev. 2017, 48, 397–447. [Google Scholar] [CrossRef]

- Zhang, M.; Shaukat, A.; Yue, T.; Norgren, R.; Okaritz, O. Uncertainty-Wise Cyber-Physical System test modeling. Softw. Syst. Model. 2017, 1–40. [Google Scholar] [CrossRef]

- Hawking, S. AI Will be ‘Either Best or Worst Thing’ for Humanity. Available online: https://www.theguardian.com/science/2016/oct/19/stephen-hawking-ai-best-or-worst-thing-for-humanity-cambridge (accessed on 30 October 2017).

| Game | Chronological Development |

|---|---|

| Backgammon | 1979: The backgammon program BKG by Hans Berliner defeats the world champion—the first computer program to defeat (in an exhibition match) a world champion in any game—though Berliner later attributes the win to luck with the dice rolls. 1992: The backgammon program TD-Gammon by Gerry Tesauro reaches championship level ability, using temporal differences learning (a form of reinforcement learning) and repeated plays against itself to improve. In the years since, backgammon programs have far surpassed the best human players. |

| Chess | 1997: Deep Blue beats the world chess champion, Garry Kasparov. Kasparov claims to have seen glimpses of true intelligence and creativity in some of the computer’s moves. Since then, chess engines have continued to improve. |

| Scrabble | As of 2002, Scrabble-playing software surpasses the best human players. |

| Jeopardy! | 2010: IBM’s Watson defeats the two all-time-greatest human Jeopardy! Champions, Ken Jennings and Brad Rutter. Jeopardy! Is a televised game show with trivia questions about history, literature, sports, geography, pop culture, science, and other topics. Questions are presented in the form of clues, and often involve wordplay. |

| Go | As of 2012, the Zen series of go-playing programs has reached rank 6 dan in fast games (the level of a very strong amateur player), using Monte Carlo tree search and machine learning techniques. Go-playing programs have been improving at a rate of about 1 dan/year in recent years. If this rate of improvement continues, they might beat the human world champion in about a decade. * * Addendum: AI application AlphaGo beat human world champion Lee Sedol in March 2016, [42,43]. Addendum II: The further improved AI application AlphaGo Zero was trained during 2017 without prior human knowledge, only with the game rules and by playing against itself—it is now unbeatable by humans and the strongest AI application regarding the game of Go [13]. |

| Poker | Addendum III: In 2017, also the first AI program was able to beat human players at head-up no-limit poker, in contrast to the above mentioned games of e.g., chess and go a non-perfect information setting [ 44,45,46]. Similarly to e.g., jeopardy! in this case it was expected to take much longer for AI instances to master such ‘human’ game settings including incomplete information and cheating. |

| Method | Desription | Advantages |

|---|---|---|

| Delphi method | Repeated implementation of expert interviews in a qualitative setting describing and evaluating the probability of situations in the future |

|

| Analytical hierarchy process | Pairwise comparisons of hierarchical decision criteria by experts; quantitative method requiring a predetermined hierarchy of criteria as well as group of experts applying the comparisons |

|

| Patent analysis | Tool for studying the information attached to patents as intellectual property, e.g., by using spreadsheet-based data analysis or software-based patent analysis tools |

|

| Bibliometric analysis | Statistical analysis of available (scientific) books and articles; citation analysis is based on constructing the citation graph, a network or graph representation of the citations between documents; many research fields use bibliometric methods to explore the impact of specific researchers, papers or ideas and thought schools |

|

| Relevance tree | Starting from an objective, the most appropriate path of the tree has to be identified by arranging the objectives, subobjectives and tasks in a hierarchical order; this should ensure that all possible ways of achieving the objectives are found; the relevance of individual tasks and subobjectives to the overall objective is evaluated |

|

| Growth curve | Application of a standard innovation and expansion model to nascent technologies e.g., by assuming specific growth rates or historical growth data |

|

| Extrapolation | Extension of existing (quantitative) data or (qualitative) knowledge based on historical events and data/knowledge |

|

| Case studies | Extended description of operational implementation based on an existing company or organizational setting |

|

| Scenario writing | Extended description of a comprehensive situation or application starting from a known point and technological status in time |

|

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klumpp, M. Innovation Potentials and Pathways Merging AI, CPS, and IoT. Appl. Syst. Innov. 2018, 1, 5. https://doi.org/10.3390/asi1010005

Klumpp M. Innovation Potentials and Pathways Merging AI, CPS, and IoT. Applied System Innovation. 2018; 1(1):5. https://doi.org/10.3390/asi1010005

Chicago/Turabian StyleKlumpp, Matthias. 2018. "Innovation Potentials and Pathways Merging AI, CPS, and IoT" Applied System Innovation 1, no. 1: 5. https://doi.org/10.3390/asi1010005