Investigating the CO2 Geological Sequestration Potential of Extralow-Permeability Reservoirs: Insights from the Es1 Member of the Shahejie Formation in the Dawa Oilfield

Abstract

:1. Introduction

2. Geological Setting

3. Storage Potential of Extralow-Permeability Reservoirs

3.1. Storage Space of the Sand Body

3.2. Sand Body Distribution

4. CO2 Sequestration and Its Controlling Factors

4.1. Controlling Factors of CO2 Sequestration

4.1.1. Sealing Properties of the Caprock

4.1.2. Sealing Properties of the Faults

4.1.3. Formation Temperature–Pressure–Fluid Medium

4.2. Pilot Test of CO2 Sequestration

4.3. Reservoir Numerical Simulation

4.4. Reservoir Engineering Design

5. Results and Predictions of CO2 Sequestration

6. Conclusions

- (1)

- The physical attributes of Shahejie Formation (Es1 member) have been elucidated to be low to extralow-permeability homogeneous reservoirs. The reservoir lithology is fine sandstone and siltstone, with high compositional and structural maturity, an average porosity of 14.8%, an average permeability of 1.48 mD, an average pore radius of 5.31 μm, a displacement pressure generally less than 0.1 MPa, a mercury saturation greater than 70% at the maximum pressure, a desorption efficiency greater than 24%, and a reservoir coefficient of variation of approximately 0.5, which suggests a low- to extralow-permeability homogeneous reservoir.

- (2)

- The optimal CO2 injection rate is determined to be 0.08 HCPV/a. The Shuang 229-36-62 well was subjected to stepwise increasing injection for 72 days, and a total of 3204 m3 of CO2 gas was injected. The density of the injected liquid CO2 was relatively high near the wellhead, close to 1.0 g/cm3, and gradually decreased to approximately 0.78 g/cm3 near a depth of 2000 m underground, which indicates that the injected liquid is transformed into a supercritical state upon entering the formation, with the optimal CO2 injection rate of 0.08 HCPV/a.

- (3)

- The cap rock and fault sealing characteristics of the Shuang 229 block have been successfully evaluated, indicating that it is conducive for sustainable geological storage of CO2. The discharge pressure of the Shuang 229 block cap layer is >2.0 MPa, and the fault can withstand a maximum gas column height of >200 m, with satisfactory capping and fault sealing characteristics and a normal temperature-pressure gradient in the strata.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Capuano, D. Annual Energy Outlook; US Energy Information Administration: Washington, DC, USA, 2019.

- Mitchell, J.F.B. The “greenhouse” effect and climate change. Rev Geophys. 1989, 27, 115–139. [Google Scholar] [CrossRef]

- Mikhaylov, A.; Moiseev, N.; Aleshin, K.; Burkhardt, T. Global climate change and greenhouse effect. Entrep. Sustain. Issues 2020, 7, 2897. [Google Scholar] [CrossRef] [PubMed]

- British Petroleum Company. BP Statistical Review of World Energy; BP Company: London, UK, 2018. [Google Scholar]

- Bachu, S. Sequestration of CO2 in geological media: Criteria and approach for site selection in response to climate change. Energy Convers Manag. 2000, 41, 953–970. [Google Scholar] [CrossRef]

- Socolow, R.; Hotinski, R.; Greenblatt, J.B.; Pacala, S. Solving the climate problem: Technologies available to curb CO2 emissions. Environ. Sci. Policy Sustain. Dev. 2004, 46, 8–19. [Google Scholar] [CrossRef]

- Hoffert, M.I.; Caldeira, K.; Jain, A.K.; Haites, E.F.; Harvey, L.D.; Potter, S.D.; Wuebbles, D.J. Energy implications of future stabilization of atmospheric CO2 content. Nature 1998, 395, 881–884. [Google Scholar] [CrossRef]

- Alrassas, A.M.; Vo Thanh, H.; Ren, S.; Sun, R.; Al-Areeq, N.M.; Kolawole, O.; Hakimi, M.H. CO2 Sequestration and enhanced oil recovery via the water alternating gas scheme in a mixed transgressive sandstone-carbonate reservoir: Case study of a large middle east oilfield. Energy Fuels 2022, 36, 10299–10314. [Google Scholar] [CrossRef]

- Safaei-Farouji, M.; Thanh, H.V.; Dashtgoli, D.S.; Yasin, Q.; Radwan, A.E.; Ashraf, U.; Lee, K.K. Application of robust intelligent schemes for accurate modelling interfacial tension of CO2 brine systems: Implications for structural CO2 trapping. Fuel 2022, 319, 123821. [Google Scholar] [CrossRef]

- Bui, M.; Adjiman, C.S.; Bardow, A.; Anthony, E.J.; Boston, A.; Brown, S.; Mac Dowell, N. Carbon capture and storage (CCS): The way forward. Energy Environ. Sci. 2018, 11, 1062–1176. [Google Scholar] [CrossRef]

- Gibbins, J.; Chalmers, H. Carbon capture and storage. Energy Policy 2008, 36, 4317–4322. [Google Scholar] [CrossRef]

- Koottungal, L. World EOR survey. Oil Gas J. 2014, 112, 79–91. [Google Scholar]

- Hitesh, M.; Marshall, C.; Khosrow, B. The potential for additional carbon dioxide flooding projects in the United States. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 19–23 April 2008. Paper Number: SPE-113975-MS. [Google Scholar]

- Hill, L.B.; Li, X.C.; Wei, N. CO2-EOR in China: A comparative review. Int. J. Greenhouse Gas Control. 2020, 103, 103173. [Google Scholar] [CrossRef]

- Yuan, S.Y.; Ma, D.S.; Li, J.S.; Zhou, T.Y.; Jie, Z.M.; Han, H.S. Progress and prospects of carbon dioxide capture, EOR-utilization and storage industrialization. Pet. Explor. Dev. 2022, 49, 955–962. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Fan, Z.Q.; Wang, Q.L.; Xue, Z.Q.; Wang, Y.D. Lattice Boltzmann Multiphase Flow Simulations for CO2-Enhanced Oil Recovery Using Various Modes of Immiscible CO2 Injection. Energy Fuels 2023, 37, 12154–12165. [Google Scholar] [CrossRef]

- Koottungal, L. Worldwide EOR survey. Oil Gas J. 2008, 106, 47–59. [Google Scholar]

- Song, X.M.; Wang, F.; Ma, D.S.; Gao, M.; Zhang, Y.M. Progress and prospect of carbon dioxide capture, utilization and storage in CNPC oilfields. Pet. Explor. Dev. 2023, 50, 206–218. [Google Scholar] [CrossRef]

- Luo, R.; Hu, Y.; Li, B.; Zhu, W. Practice of increasing production rate by injecting CO2 into oil and gas fields in China. Spec. Oil Gas Reserv. 2013, 20, 1–7. [Google Scholar]

- Gao, Y.; Zhao, M.; Wang, J.; Zong, C. Performance and gas breakthrough during CO2 immiscible flooding in ultra-low permeability reservoirs. Pet. Explor. Dev. 2014, 41, 79–85. [Google Scholar] [CrossRef]

- Yu, K.; Liu, W.; Chen, Z. CO2 Miscible Flooding Technology in Continental Low Permeability Reservoir. Master’s Thesis, Petroleum Industry Press, Beijing, China, 2016. [Google Scholar]

- Wang, X. CO2 Flooding Technology in Low Permeability Sandstone Reservoir. Master’s Thesis, Petroleum Industry Press, Beijing, China, 2017. [Google Scholar]

- Xu, B.; Li, J.; Li, X.; Wang, C.; Liu, K.; Xu, M.; Jing, J.; Nie, L. Evaluation of hydrocarbon accumulation conditions for shale gas from the Eastern Sag of the Liaohe Oilfield and its gas-bearing properties. Acta Pet. Sin. 2011, 32, 450–458. [Google Scholar]

- Geng, D. Diagenesis and the Favorable Reservoir Prediction of Qingshui Sag, Liaohe Depression. Ph.D. Thesis, Northeast Petroleum University, Daqing, China, 2013. [Google Scholar]

- Xu, R. Study on Qingshui Sag Faults’ Characteristics and Its Controlling Role in Oil & Gas Accumulation. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2018. [Google Scholar]

| Well | Depth /m | Porosity /% | Permeability /10−3 μm2 | Displacement Pressure /MPa | Maximum Pore Throat Radius /μM | Average Pore Throat Radius/μM |

|---|---|---|---|---|---|---|

| Shuang 229-38-32 | 3937.66 | 7.9 | 0.057 | 8.147 | 0.090 | 0.053 |

| 3867.40 | 7.6 | 0.065 | 12.051 | 0.059 | 0.024 | |

| 3847.94 | 4.8 | 0.041 | 21.058 | 0.037 | 0.016 |

| Fault NO. | Separation (m) | Extend (km) | Fault Attitude | Sandstone Docking Index | Mudstone Coating Coefficient | Fault Sealing | ||

|---|---|---|---|---|---|---|---|---|

| Direction | Proneness | Dip | ||||||

| 1 | 600–1300 | >10 | NE | NW | 70–85 | 0 | 3 | Good |

| 2 | 20–200 | 5 | NW | NE | 65–80 | 0.03 | 3.5 | Good |

| 3 | 20–200 | 3 | NW | NE | 65–80 | 0.02 | 3.9 | Good |

| 4 | 30–300 | 1.8 | NW | NE | 65–80 | 0.05 | 4.5 | Good |

| 5 | 0–50 | 1.4 | NE | NW | 75–80 | 0.18 | 6.3 | Medium |

| 6 | 20–100 | >3 | ~EM | S | 65–80 | 0.16 | 15.7 | Medium |

| 7 | 50–100 | 1.6 | ~EM | S | 75–80 | 0.12 | 7.5 | Medium |

| 8 | 50–100 | >3 | ~EM | S | 75–80 | 0.11 | 8.3 | Medium |

| 9 | 15–40 | 1.8 | ~EM | N | 60–80 | 0.11 | 10.3 | Medium |

| 10 | 10–50 | 0.6 | ~EM | N | 70–80 | 0.23 | 8.9 | Poor |

| Trap Name | Sand Sets | Closing Height | SGR Minimum (%) | Depth of Weak Points (m) | Pressure of Weak Point (MPa) | Height of Weak Point (m) | Maximum Hydrocarbon Height (m) | Maximum Pressure (MPa) |

|---|---|---|---|---|---|---|---|---|

| Shuang -246 | III | 600 | 31.4 | −3514 | 1.35 | 428 | 442 | 41.4 |

| IV | 550 | 15.9 | −3755 | 0.30 | 93.9 | 198.9 | 43.1 | |

| Wa-128 | III | 650 | 40.1 | −3538 | 1.6 | 447.6 | 595.6 | 43.1 |

| IV | 550 | 17.5 | −3427 | 1.05 | 309.9 | 336.9 | 40.1 | |

| V | 400 | 20 | −3697 | 0.76 | 236 | 383 | 42.9 | |

| Wa-111 | III | 570 | 20.3 | −3164 | 0.21 | 67 | 381 | 36.3 |

| IV | 580 | 12.8 | −3171 | 0.15 | 48 | 219 | 36.3 | |

| V | 450 | 6.7 | −3349 | 0.22 | 72 | 221 | 38.4 |

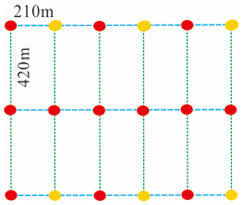

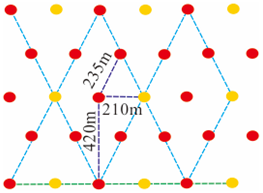

| Well Pattern Types | Scheme 1: Rectangular Inverse Nine Points | Scheme 2: Rhombus Inverse Nine Points |

|---|---|---|

| Distance between injection wells | 210–420 m | 210–235 m |

| Well network model |  |  |

| Number of injection wells (Pit 128 well area) | 5 injected 24 extracted | 11 injected 39 extracted |

| Connectivity factor | 51–68% | 60–78% |

| Injection capacity | 8.58 × 104 t/year | 20.82 × 104 t/year |

| Recovery ratio | 1.0 PV cumulative injection, 27% injection rate | 1.5 PV cumulative injection, 40% injection rate |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Wang, E.; Wang, D.; Zhang, T. Investigating the CO2 Geological Sequestration Potential of Extralow-Permeability Reservoirs: Insights from the Es1 Member of the Shahejie Formation in the Dawa Oilfield. Energies 2024, 17, 2221. https://doi.org/10.3390/en17092221

Li C, Wang E, Wang D, Zhang T. Investigating the CO2 Geological Sequestration Potential of Extralow-Permeability Reservoirs: Insights from the Es1 Member of the Shahejie Formation in the Dawa Oilfield. Energies. 2024; 17(9):2221. https://doi.org/10.3390/en17092221

Chicago/Turabian StyleLi, Chao, Ende Wang, Dawei Wang, and Ting Zhang. 2024. "Investigating the CO2 Geological Sequestration Potential of Extralow-Permeability Reservoirs: Insights from the Es1 Member of the Shahejie Formation in the Dawa Oilfield" Energies 17, no. 9: 2221. https://doi.org/10.3390/en17092221