Investigating the Forming Characteristics of 316 Stainless Steel Fabricated through Cold Metal Transfer (CMT) Wire and Arc Additive Manufacturing

Abstract

:1. Introduction

2. Experimentation Overview

2.1. Experimental System and Material

2.2. Experimental Procedure

3. Results and Discussion

3.1. The Feasible Travel Speed Intervals for Each Deposition Current in the CMT-WAAM Process

3.2. The Feasible Travel Speed Intervals for Each Deposition Current in the CMT+P-WAAM Process

4. Microstructure Characterization

5. Conclusions

- (1)

- The application of both direct current and pulse current proved effective in manufacturing stainless steel components and enhancing their microstructure through CMT-based WAAM.

- (2)

- The analysis of specimens from multiple layers indicated no visible discontinuity between the layers, indicating thorough fusion across layers.

- (3)

- The dimensions of the deposition beads, i.e., both their width and height, were observed to decrease as the travel speed increased. Experimental determination identified the optimal range of travel speeds for each deposition current, alongside the maximum allowable wire feed speed. Notably, a travel speed of up to 16 mm/s at a deposition current of 175 A was achievable when utilizing CMT pulse arcs.

- (4)

- When the CMT mode arc was used, the average grain size was 13.426 μm, but when the pulse arc was 9.429 μm, the grain size decreased obviously.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Han, Q.; Zhang, G.; Horváth, I. A layers-overlapping strategy for robotic wire and arc additive manufacturing of multi-layer multi-bead components with homogeneous layers. Int. J. Adv. Manuf. Technol. 2018, 96, 3331–3344. [Google Scholar] [CrossRef]

- Ma, G.; Zhao, G.; Li, Z.; Yang, M.; Xiao, W. Optimization strategies for robotic additive and subtractive manufacturing of large and high thin-walled aluminum structures. Int. J. Adv. Manuf. Technol. 2018, 101, 1275–1292. [Google Scholar] [CrossRef]

- Cunningham, C.; Flynn, J.; Shokrani, A.; Dhokia, V.; Newman, S. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Li, Y.; Huang, X.; Horváth, I.; Zhang, G. GMAW-based additive manufacturing of inclined multi-layer multi-bead parts with flat-position deposition. J. Am. Acad. Dermatol. 2018, 262, 359–371. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Bruckner, J.; Himmelbauer, K. Cold Metal Transfer-Ein neuer Prozess in der Fugetechnik. DVS Berichte 2005, 237, 32. [Google Scholar]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3% Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, S.W.; Gu, H.; Ma, P.; Zhai, Y. The effect of inter-layer cold working and post-deposition heat treatment on porosity in additively manufactured aluminum alloys. J. Am. Acad. Dermatol. 2016, 230, 26–34. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, S.W.; Gu, H.; Bai, J.; Zhai, Y.; Ma, P. The strengthening effect of inter-layer cold working and post-deposition heat treatment on the additively manufactured Al–6.3Cu alloy. Mater. Sci. Eng. A 2016, 651, 18–26. [Google Scholar] [CrossRef]

- Mehnen, J.; Ding, J.; Lockett, H.; Kazanas, P. Design study for wire and arc additive manufacture. Int. J. Prod. Dev. 20 2014, 19, 2–20. [Google Scholar] [CrossRef]

- Remache, D.; Dadouaille, F.; Lhabitant, S.; Falandry, D.; Toufine, A.; Al Ali, M.; Cohen, G. Numerical Analysis and Experimental Investigation of High Cycle Fatigue Behavior in Additively Manufactured Ti–6Al–4V Alloy. Buildings 2023, 13, 2011. [Google Scholar] [CrossRef]

- Ding, H.; Zou, B.; Wang, X.; Liu, J.; Li, L. Microstructure, mechanical properties and machinability of 316L stainless steel fabricated by direct energy deposition. Int. J. Mech. Sci. 2023, 243, 108046. [Google Scholar] [CrossRef]

- Benakis, M.; Costanzo, D.; Patran, A. Current mode effects on weld bead geometry and heat affected zone in pulsed wire arc additive manufacturing of Ti-6-4 and Inconel 718. J. Manuf. Process. 2020, 60, 61–74. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Coules, H.E.; Fairman, J.; Martina, F.; Kashoob, T.; Mamash, H.; Cozzolino, L.D. Microstructure and residual stress improvement in wire and arc additively manufactured parts through high-pressure rolling. J. Mater. Process. Technol. 2013, 213, 1782–1791. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Gao, H.; Wu, L. Modeling of bead section profile and overlapping beads with experimental validation for robotic GMAW-based rapid manufacturing. Robot. Comput.-Integr. Manuf. 2013, 29, 417–423. [Google Scholar] [CrossRef]

- Yilmaz, O.; Ugla, A.A. Microstructure characterization of SS308LSi components manufactured by GTAW-based additive manufacturing: Shaped metal deposition using pulsed current arc. Int. J. Adv. Manuf. Technol. 2017, 89, 13–25. [Google Scholar] [CrossRef]

- Paskual, A.; Álvarez, P.; Suárez, A. Study on arc welding processes for high deposition rate additive manufacturing. Procedia Cirp 2018, 68, 358–362. [Google Scholar]

- Han, Q.L.; Li, D.; Sun, H.; Zhang, G. Forming characteristics of additive manufacturing process by twin electrode gas tungsten arc. Int. J. Adv. Manuf. Technol. 2019, 104, 4517–4526. [Google Scholar] [CrossRef]

- Xu, X.; Mi, G.; Luo, Y.; Jiang, P.; Shao, X.; Wang, C. Morphologies, microstructures, and mechanical properties of samples produced using laser metal deposition with 316 L stainless steel wire. Opt. Lasers Eng. 2017, 94, 1–11. [Google Scholar] [CrossRef]

- Wang, T.; Mazánová, V.; Liu, X. Ultrasonic effects on gas tungsten arc based wire additive manufacturing of aluminum matrix nanocomposite. Mater. Des. 2022, 214, 110393. [Google Scholar] [CrossRef]

- Diao, M.; Guo, C.; Sun, Q.; Jiang, F.; Li, L.; Li, J.; Xu, D.; Liu, C.; Song, H. Improving mechanical properties of austenitic stainless steel by the grain refinement in wire and arc additive manufacturing assisted with ultrasonic impact treatment. Mater. Sci. Eng. A 2022, 857, 144044. [Google Scholar] [CrossRef]

- Rosli, N.A.; Alkahari, M.R.; bin Abdollah, M.F.; Maidin, S.; Ramli, F.R.; Herawan, S.G. Review on effect of heat input for wire arc additive manufacturing process. J. Mater. Res. Technol. 2021, 11, 2127–2145. [Google Scholar] [CrossRef]

| Elements | C | Cr | Ni | Mo | Si | Mn | P | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| (wt.%) | 0.0014 | 18.74 | 11.82 | 2.67 | 0.56 | 1.55 | 0.03 | 0.17 | Bal. |

| Process Parameters | Value |

|---|---|

| Deposition current I/A | 100, 125, 150, 175 |

| Arc length L/mm | 10 |

| Flow rate of the shielding gas Q (L/min) | 15 |

| Diameter of the metal wire d/mm | 1.2 |

| Arc travel speed v (mm/s) | 2 |

| Exp. (No.) | Deposition Current I (A) | Arc Travel Speed Vt (mm/s) | Forming Characteristic |

|---|---|---|---|

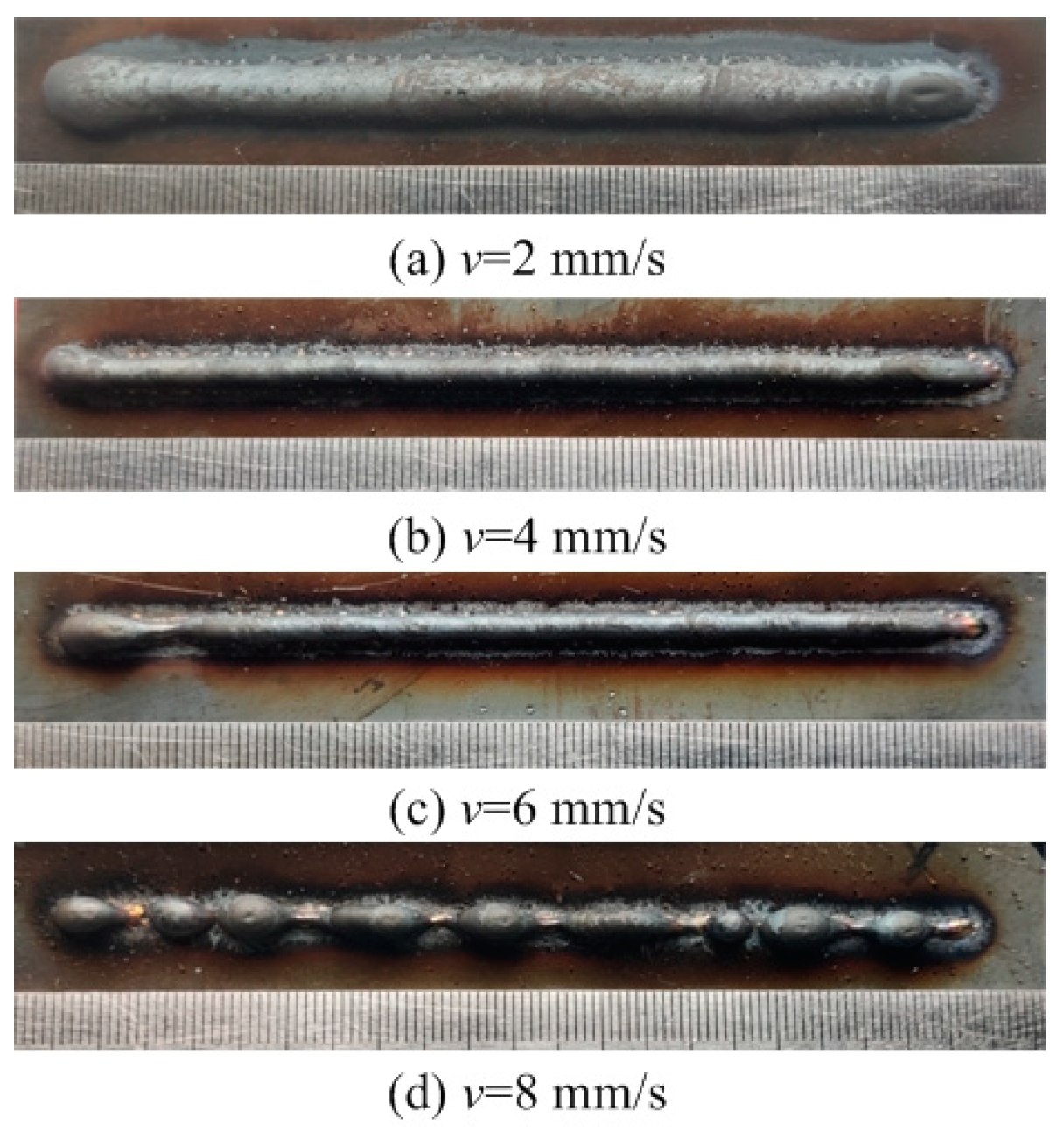

| Figure 2a | 100 | 2 | Well formed |

| Figure 2b | 100 | 4 | Well formed |

| Figure 2c | 100 | 6 | Narrow width |

| Figure 2d | 100 | 8 | Discontinuous |

| Figure 3a | 125 | 2 | Well formed |

| Figure 3b | 125 | 4 | Well formed |

| Figure 3c | 125 | 6 | Well formed |

| Figure 3d | 125 | 8 | Well formed |

| Figure 3e | 125 | 10 | Narrow width |

| Figure 3f | 125 | 12 | Discontinuous |

| Figure 4a | 150 | 2 | Well formed |

| Figure 4b | 150 | 4 | Well formed |

| Figure 4c | 150 | 6 | Well formed |

| Figure 4d | 150 | 8 | Narrow width |

| Figure 4e | 150 | 10 | Narrow width |

| Figure 4f | 150 | 12 | Narrow width |

| Figure 4g | 150 | 14 | Discontinuous |

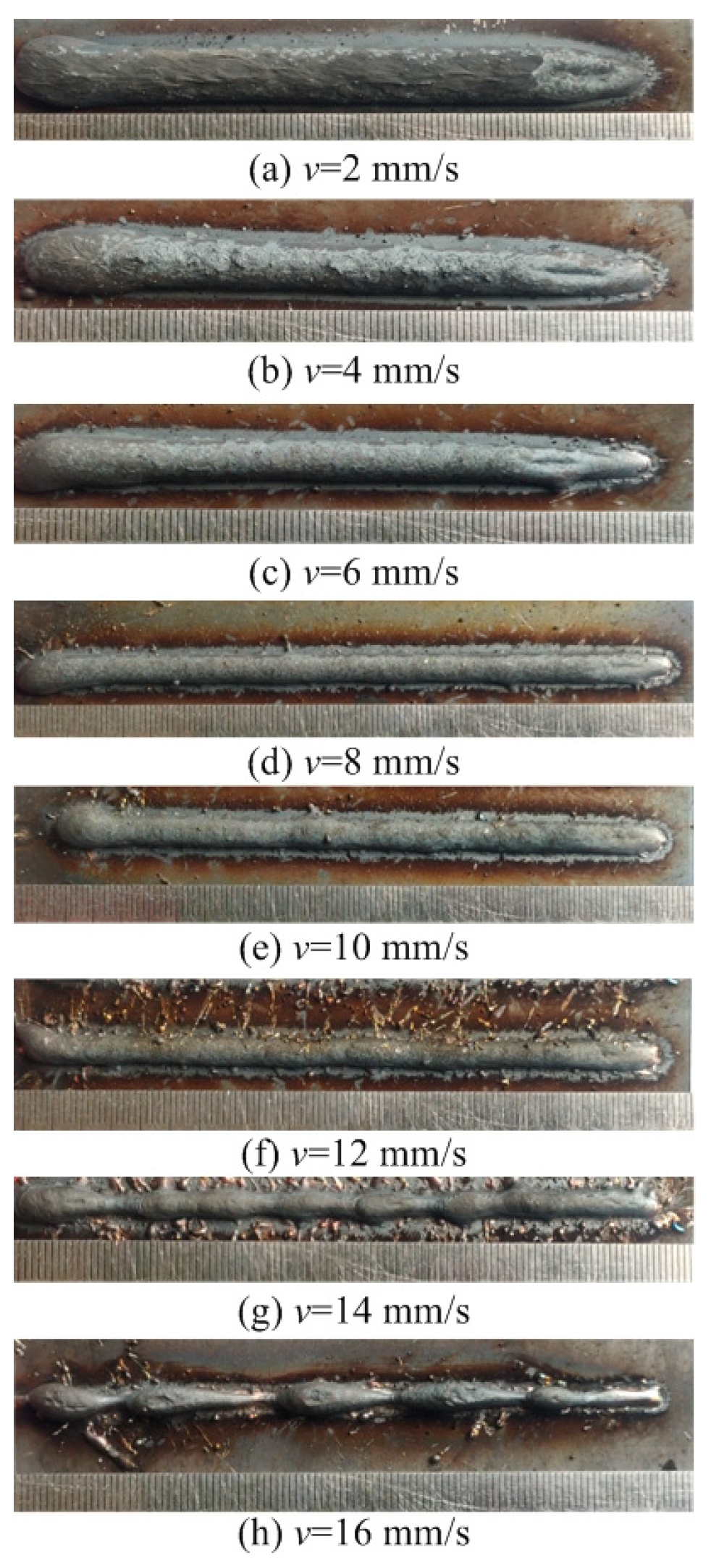

| Figure 5a | 175 | 2 | Well formed |

| Figure 5b | 175 | 4 | Well formed |

| Figure 5c | 175 | 6 | Well formed |

| Figure 5d | 175 | 8 | Well formed |

| Figure 5e | 175 | 10 | Well formed |

| Figure 5f | 175 | 12 | Well formed |

| Figure 5g | 175 | 14 | Well formed |

| Figure 5h | 175 | 16 | Narrow width |

| Figure 5i | 175 | 18 | Narrow width |

| Figure 5j | 175 | 20 | Narrow width |

| CMT Pulse Arc Parameters | Value |

|---|---|

| Peak current Im/A | 200 |

| Base current Ij/A | 100 |

| Duty cycle K/% | 50% |

| Pulse f/Hz | 20 |

| Authors | Method | Filling Material | Wire Feed Speed |

|---|---|---|---|

| Colegrove et al. [14] | GMA-AM | 0.8 mm diameter wire of ER70S-6 | 10 m/min |

| Xiong et al. [15] | GMA-AM | 1.2 mm diameter wire of H08Mn2Si | 6 m/min |

| Yilmaz and Ugla [16] | GTA-AM | 0.8 mm diameter wire of ER308LSi | 3.5 m/min |

| Paskual et al. [17] | GTA-AM | 1.2 mm diameter wire of AISI 316 L | Not mentioned |

| Han et al. [18] | GTA-AM | 1.2 mm diameter wire of H08Mn2Si | 5 m/min |

| This study | CMT-AM | 1.2 mm diameter wire of 316 | Not mentioned |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Fan, D. Investigating the Forming Characteristics of 316 Stainless Steel Fabricated through Cold Metal Transfer (CMT) Wire and Arc Additive Manufacturing. Materials 2024, 17, 2184. https://doi.org/10.3390/ma17102184

Feng Y, Fan D. Investigating the Forming Characteristics of 316 Stainless Steel Fabricated through Cold Metal Transfer (CMT) Wire and Arc Additive Manufacturing. Materials. 2024; 17(10):2184. https://doi.org/10.3390/ma17102184

Chicago/Turabian StyleFeng, Yi, and Ding Fan. 2024. "Investigating the Forming Characteristics of 316 Stainless Steel Fabricated through Cold Metal Transfer (CMT) Wire and Arc Additive Manufacturing" Materials 17, no. 10: 2184. https://doi.org/10.3390/ma17102184