Experimental Study on Flexural Behavior of RC Piles with Basalt Fiber-Reinforced Polymer Bars and Load Carrying Capacity Calculation

Abstract

:1. Introduction

2. Introduction of Modified BFRP Bars

3. Experimental Verification with the RC Piles Model under Static Loading

3.1. Overview of the Experiments

3.1.1. Adhesive Properties Test with Cement Base

- Based on the test requirements, a coarse aggregate with a diameter of 5 to 10 mm was selected, and the mixing ratio of the cement base materials was calculated.

- The non-bonded part of the BFRP and cement substrates is placed in the mold and vibrated, as shown in Figure 4a.

- The maintained specimen is mounted on the test machine and loaded at a rate of 3 kN/min until the following damage occurs: (a) the free end of the compound bar slips against the concrete cube; (b) concrete cube splits, causing damage.

- Once these events occur, stop testing and record the damage load and damage mode.

3.1.2. The Bending Test of RC Piles with BFRP Bars

3.2. Bond-Slip Experiment of BFRP Bar and Concrete

3.3. Flexural Behavior of RC Piles with BFRP

3.3.1. Experimental Disruption

3.3.2. Reinforcement Stress

3.3.3. Concrete Stress

3.3.4. Curvature

3.3.5. Bearing Capacity

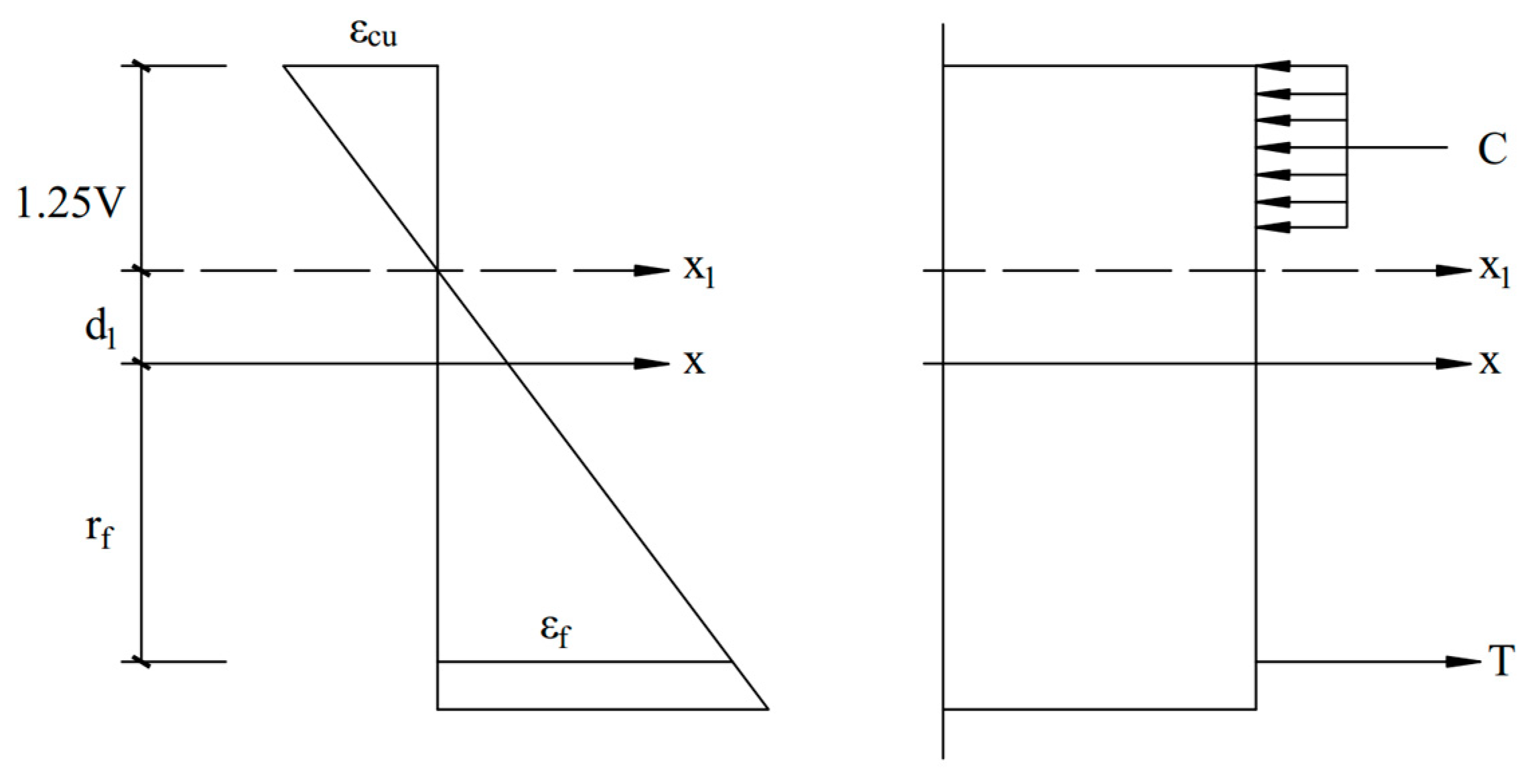

4. Calculation of Load-Carrying Capacity

4.1. Basic Assumptions

4.2. Calculation of Carrying Capacity of BFRP-Reinforced Concrete

4.3. Calculation of the Correction Factor β

4.4. Verification of Calculation Methods

5. Conclusions

- (1)

- Different types of BFRP and cement substrates have different bond strengths. Generally speaking, the larger the diameter of the bar, the higher the strength of the bond. It is recommended for commonly used diameter engineering anchors that M20 and M30 mortar have a BFRP bond strength of approximately 5–6 MPA and C30 concrete of about 8 MPa.

- (2)

- The positive transverse stress is consistent with the reasonableness of the cross-section hypothesis of circular reinforced concrete BFRP members. The pile load is broken in four stages, and the cracking load is 51% to 67% of the normal limit load. The deformation of the main rod increases with the increase in load but decreases in the pressurized region. This mutation indicates that the concrete in the pressure zone is starting to become plastic, but it still has a high carrying capacity.

- (3)

- According to the calculation method of bending bearing capacity of the GFRP concrete circular pile, the ultimate bearing capacity obtained by the indoor test is compared with that of the calculated test. A formula for calculating the bearing capacity of BFRP-reinforced concrete structures with circular cross-sections is obtained, and the coefficient beta = 2.6 is obtained by experiment. The calculated values have good agreement with test results compared with previously published studies in this field.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Altalmas, A.; El, R.A.; Abed, F. Bond degradation of basalt fiber-reinforced polymer (BFRP) bars exposed to accelerated aging conditions. Constr. Build. Mater. 2015, 81, 162–171. [Google Scholar] [CrossRef]

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-based fiber-reinforced materials and structural applications in civil engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- ElMessalami, N.; Abed, F.; El Refai, A. Response of concrete columns reinforced with longitudinal and transverse BFRP bars under concentric and eccentric loading. Compos. Struct. 2021, 255, 113057. [Google Scholar] [CrossRef]

- Kang, J.W.; Zhao, W.; Hu, Y.; Zhou, Q.; Wang, Z. Application of Basalt Fiber and Its Composite Reinforcement in Geotechnical Engineering; China Architecture Press: Beijing, China, 2021. [Google Scholar]

- Hassan, M.; Benmokrane, B.; ElSafty, A.; Fam, A. Bond durability of basalt-fiber-reinforced-polymer (BFRP) bars embedded in concrete in aggressive environments. Compos. Part B Eng. 2016, 106, 262–272. [Google Scholar] [CrossRef]

- Akiel, M.S.; El-Maaddawy, T.; El Refai, A. Serviceability and moment redistribution of continuous concrete members reinforced with hybrid steel-BFRP bars. Constr. Build. Mater. 2018, 175, 672–681. [Google Scholar] [CrossRef]

- At, A.; Wa, B. Bond Durability and Service Life Prediction of BFRP Bars to Steel FRC under Aggressive Environmental Conditions. Compos. Struct. 2021, 269, 114034. [Google Scholar]

- Bao, R.H.; Xiang, D.Z. Experiment Study of BFRP bars’ Mechanical Properties. Appl. Mech. Mater. 2012, 174–177, 830–833. [Google Scholar]

- Wu, G.; Zhu, Y.; Dong, Z.; Wang, X.; Wu, Z. Experimental study on the corrosion resistance performance of BFRP bars in the alkaline environment. China Civ. Eng. J. 2014, 47, 32–41. [Google Scholar]

- Wu, G.; Dong, Z.Q.; Wang, X.; Zhu, Y.; Wu, Z.S. Prediction of Long-Term Performance and Durability of BFRP Bars under the Combined Effect of Sustained Load and Corrosive Solutions. J. Compos. Constr. 2015, 19, 04014058. [Google Scholar] [CrossRef]

- Bai, X.Y.; Jing, D.S.; Wang, H.G. Research status of basalt fiber-reinforced polymer anchor in slope support engineering. Sci. Technol. Eng. 2020, 20, 12702–12710. [Google Scholar]

- Shaikh, F.U.A. Review of mechanical properties of short fibre reinforced geopolymer composites. Constr. Build. Mater. 2013, 43, 37–49. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G. Resistance of basalt fibers to elevated temperatures and water or alkaline solution immersion. Polym. Compos. 2018, 39, 2385–2393. [Google Scholar] [CrossRef]

- John, V.J.; Dharmar, B. Influence of basalt fibers in the mechanical behavior of concrete—A review. Struct. Concr. Suco. 2020, 22, 491–502. [Google Scholar] [CrossRef]

- Cakir, F. Evaluation of mechanical properties of chopped glass/basalt fibers reinforced polymer mortars. Case Stud. Constr. Mater. 2021, 15, e00612. [Google Scholar] [CrossRef]

- GB/T26745-2021; Basalt Fiber Composites for Civil Engineering Structure. China National Standard: Beijing, China, 2021.

- Yu, E.Y.; Yu, T.M.; Zhao, X.; Liao, J.; Ying, K. Effects of basalt fiber powder on mechanical properties and microstructure of concrete. Case Stud. Constr. Mater. 2022, 17, e01286. [Google Scholar] [CrossRef]

- Ding, Z.; Lu, Z.X.; Li, Y. Feasibility of basalt fiber reinforced inorganic adhesive for concrete strengthening. Adv. Mater. Res. 2011, 287–290, 1197–1200. [Google Scholar] [CrossRef]

- Bi, Q.W. Microstructure of Basalt Fiber Reinforced Concrete and Experimental Study on Bearing Capacity of Fiber Reinforced Concrete Beams with BFRP Reinforcement. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2012. [Google Scholar]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- El Refai, A.; Abed, F.; Altalmas, A. Bond durability of basalt fiber-reinforced polymer bars embedded in concrete under direct pullout conditions. J. Compos. Constr. 2015, 5, 04014078. [Google Scholar] [CrossRef]

- Ma, H.L.; Cui, C.; Li, X.; Hu, S.L. Study on mechanical properties of steel fiber reinforced autoclaved lightweight shell-aggregate concrete. Mater. Des. 2013, 52, 565–571. [Google Scholar] [CrossRef]

- Sadeghian, P.; Fillmore, B. Strain distribution of basalt FRP-wrapped concrete cylinders. Case Stud. Constr. Mater. 2018, 9, e00171. [Google Scholar] [CrossRef]

- Koroglu, A.; Ozdemir, T.; Usanmaz, A. Comparative study of the mechanical properties of fiber-reinforced denture base resin. J. Appl. Polym. Sci. 2009, 113, 716–720. [Google Scholar] [CrossRef]

- Tang, Y.S.; Cang, J.G.; Yao, Y.D.; Chen, C. Displacement measurement of a concrete bridge under traffic loads with fibre-reinforced polymer-packaged optical fibre sensors. Adv. Mech. Eng. 2020, 12, 168781402091053. [Google Scholar] [CrossRef]

- Tang, Y.S.; Jiang, T.F.; Wan, Y. Structural monitoring method for RC column with distributed self-sensing BFRP bars. Case Stud. Constr. Mater. 2022, 17, e01616. [Google Scholar] [CrossRef]

- Chai, L.J.; Guo, L.P.; Chen, B.; Carpinteri, A.; Scorza, D.; Vantadori, S. Effects of BFRP Bar Diameter and Cover Thickness on Fracture Behavior of BFRP Bar–Reinforced Ecological High-Ductility Cementitious Composites. J. Test. Eval. 2021, 49, 4086–4101. [Google Scholar] [CrossRef]

- Zhou, R.; Zhou, F.; Du, Y.; Liao, B.; Feng, G.; Zhu, D. Effect of seawater on bond performance between BFRP bars and seawater sea-sand concrete. Constr. Build. Mater. 2024, 415, 135050. [Google Scholar] [CrossRef]

- He, W.D. Static and Fatigue Ehavior of RC Flexural Members Strengthened with BFRP Grids. Ph.D. Thesis, Southeast University, Nanjing, China, 2021. [Google Scholar]

- Jin, L.; Zheng, M.; Zhang, R.; Du, X. Investigation on the Impact Response of Concrete Beams Reinforced with Hybrid Steel–BFRP Bars. J. Compos. Constr. 2024, 4, 04023029. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Wu, Z. Fatigue degradation and life prediction of basalt fiber-reinforced polymer composites after saltwater corrosion. Mater. Des. 2019, 163, 107529. [Google Scholar] [CrossRef]

- Song, K.J.; Yu, Y.; Liu, Y.T.; Zhao, J. Flexural Performance Study of Basalt-Fiber-Reinforced Polymer Bar Basalt-Fiber-Reinforced Concrete Beams. Buildings 2023, 13, 2583. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical Properties of High Performance Concrete Reinforced with Basalt Fiber and Polypropylene Fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, Q.; Teng, J.H. Bond Performance of Anti-Corrosion Bar Embedded in Ceramsite Concrete in Freeze–Thaw Cycles and Corrosive Environments. Buildings 2023, 13, 884. [Google Scholar] [CrossRef]

- Shi, J.; Zhu, H.; Wu, Z. Bond Behavior between Basalt Fiber–Reinforced Polymer Sheet and Concrete Substrate under the Coupled Effects of Freeze-Thaw Cycling and Sustained Load. J. Compos. Constr. 2013, 17, 530–542. [Google Scholar] [CrossRef]

- Sagar, B.; Sivakumar, M.V.N. Performance evaluation of basalt fibre-reinforced polymer rebars in structural concrete members—A review. Innov. Infrastruct. Solut. 2021, 6, 75. [Google Scholar] [CrossRef]

- Abushanab, A.; Alnahhal, W.; Farraj, M. Experimental and finite element studies on the structural behavior of BFRC continuous beams reinforced with BFRP bars. Compos. Struct. 2022, 2, 281. [Google Scholar] [CrossRef]

- JTG/T776.4; Basalt fiber and Its Products for Highway Engineering. China National Standard: Beijing, China, 2010.

- DB22T2797.1; Design and Construetion Code for Basalt Fiber Composite Rebar and Basalt Fiber Reinforced Concrete. Jilin Local Standard: Jilin, China, 2017.

- GB/T 10120; Metallic Materials-Stress Relaxation Test. China National Standard: Beijing, China, 1996.

- GB/T232; Metallic Materials-Bend Test. China National Standard: Beijing, China, 2010.

- GB50010; Code for Design of Concrete Structures. China National Standard: Beijing, China, 2010.

- JGJ94; Technical Code for Building Pile Foundation. China National Standard: Beijing, China, 2008.

- GB50330; Technical Code for Building Slope Engineering. China National Standard: Beijing, China, 2013.

- DBJ51/T175; Technical Standard for Application of Basalt Fiber and Its Composite Materials in Sichuan Province. Sichuan Local Standard: Chengdu, China, 2022.

- CJJ 192; Technical Specification for Shield-Cuttable Concrete Reinforcement. China National Standard: Beijing, China, 2012.

- Liang, S.; Zhao, W.; Hu, Y. Experimental Investigation of Flexural Behavior of Cylindrical Member of BFRP Reinforced Concrete. Railw. Eng. 2018, 12, 110950. [Google Scholar]

- American Concrete Institute. Guide for the Design and Con-Struction of Structural Concrete Reinforced with FRP bars:ACI 440. 1R-2015; American Concrete Institute: Farmington Hills, MI, USA, 2015. [Google Scholar]

- Zhang, J.Z.; Pang, Z.Y.; Shen, H. Calculation of the Flexural Capacity of GFRP-reinforced Concrete with Circular Section. Chin. J. Undergr. Space Eng. 2013, 6, 1304–1309. [Google Scholar]

| Parameters | 8 mm | 10 mm |

|---|---|---|

| Tensile strength (MPa) | 1139.4 | 1111.9 |

| Shear strength (MPa) | 120 | 159 |

| Retention rate of acid–base corrosion resistance (%) | 92.6 | 96 |

| Creep relaxation for 100 h (%) | 3.867 | 4.427 |

| Bending test (Bend damage angle°) | 49.3 | 45.4 |

| Type of Cement Base | Combination Ratio per Cubic Meter | Cement Model |

|---|---|---|

| Mortar (M20) | Cement/Sands/Water = 1:5:0.8 | 42.5 |

| Mortar (M30) | Cement/Sands/Water = 1:3.1:0.6 | 42.5 |

| Concrete (C30) | Cement: Sands/Aggregate/Water = 1:1.5:3.2:0.5 | 42.5 |

| No. | Section Size (mm) | Reinforcement | Reinforcement Ratio | Spacing of Reinforcement (mm) | Protection Layer Thickness (mm) |

|---|---|---|---|---|---|

| 1 | φ200 | 6φ8 | 0.96% | 48 | 40 |

| 2 | φ200 | 6φ10 | 1.5% | 45 | 40 |

| 3 | φ200 | 10φ8 | 1.6% | 26.6 | 40 |

| 4 | φ200 | 14φ8 | 2.24% | 16.9 | 40 |

| Model of Reinforcement (mm) | Stressed Area (mm2) | Sample 1 | Sample 2 | Sample 3 | Mean Value | |

|---|---|---|---|---|---|---|

| 8 | 1005.31 | Anchoring force (N) | 5024.3 | 6156.4 | 4888.2 | 5356.3 |

| Bond strength (MPa) | 5.00 | 6.12 | 4.86 | 5.33 | ||

| 10 | 1570.80 | Anchoring force (N) | 9196.6 | 9232.6 | 6636.4 | 8355.2 |

| Bond strength (MPa) | 5.86 | 5.88 | 4.23 | 5.33 |

| Model of Reinforcement (mm) | Stressed Area (mm2) | Sample 1 | Sample 2 | Sample 3 | Mean Value | |

|---|---|---|---|---|---|---|

| 8 | 1005.31 | Anchoring force (N) | 7144.5 | 4590.5 | 6044.4 | 5926.5 |

| Bond strength (MPa) | 5.01 | 4.78 | 4.91 | 4.90 | ||

| 10 | 1570.80 | Anchoring force (N) | 7872.5 | 7500.3 | 7716.5 | 7696.4 |

| Bond strength (MPa) | 7.11 | 4.57 | 6.01 | 5.90 |

| Model of Reinforcement (mm) | Stressed Area (mm2) | Sample 1 | Sample 2 | Sample 3 | Mean Value | |

|---|---|---|---|---|---|---|

| 8 | 1005.31 | Anchoring force (N) | 8321.8 | 9624.6 | 8800.6 | 8915.67 |

| Bond strength (MPa) | 6.64 | 5.33 | 7.73 | 6.57 | ||

| 10 | 1570.80 | Anchoring force (N) | 10,425 | 8368.5 | 12137 | 10,310.17 |

| Bond strength (MPa) | 8.28 | 9.57 | 8.75 | 8.81 |

| No. | Reinforcement | Reinforcement Ratio/ρsf | Initial Cleavage | Normal Use Status | Disruption | |||

|---|---|---|---|---|---|---|---|---|

| Load kN·m | Curvature mm | Load kN·m | Curvature mm | Load kN·m | Curvature mm | |||

| 1# | 6φ8 | 0.96% | 5.04 | 1.9 | 7.5 | 6 | 12.6 | 11.2 |

| 2# | 6φ10 | 1.50% | 5.04 | 2.0 | 9.0 | 6 | 22.7 | 21.2 |

| 3# | 10φ8 | 1.60% | 5.04 | 1.9 | 9.8 | 6 | 12.6 | 10.1 |

| 4# | 14φ8 | 2.24% | 2.5 | 1.0 | 10.3 | 6 | 17.6 | 8.7 |

| No. | Calculation (kN·m) | Measurement (kN·m) | Ratio | Average |

|---|---|---|---|---|

| 1 | 9.66 | 3.75 | 2.576 | 2.502 |

| 2 | 11.48 | 4.5 | 2.551 | |

| 3 | 12.04 | 4.875 | 2.469 | |

| 4 | 13.58 | 5.625 | 2.414 |

| Data Sources | Specimens | Reinforcement | ρsf% | ME | MP | MC | MA | MZ | MM/ MP | ME/ MC | ME/ MA | ME/ Mz |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| This paper | 1 | 6φ8 | 0.96 | 3.75 | 3.86 | 2.22 | 2.78 | 7.16 | 0.97 | 1.69 | 1.35 | 0.52 |

| 2 | 6φ10 | 1.50 | 4.5 | 4.61 | 3.53 | 4.25 | 8.50 | 0.98 | 1.27 | 1.06 | 0.53 | |

| 3 | 10φ8 | 1.60 | 4.875 | 4.82 | 3.29 | 4.39 | 8.92 | 1.01 | 1.48 | 1.11 | 0.55 | |

| 4 | 14φ8 | 2.24 | 5.625 | 5.43 | 4.60 | 5.68 | 10.05 | 1.04 | 1.22 | 0.99 | 0.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Pan, Q.; Wei, Y.; Luo, Y. Experimental Study on Flexural Behavior of RC Piles with Basalt Fiber-Reinforced Polymer Bars and Load Carrying Capacity Calculation. Buildings 2024, 14, 1328. https://doi.org/10.3390/buildings14051328

Chen J, Pan Q, Wei Y, Luo Y. Experimental Study on Flexural Behavior of RC Piles with Basalt Fiber-Reinforced Polymer Bars and Load Carrying Capacity Calculation. Buildings. 2024; 14(5):1328. https://doi.org/10.3390/buildings14051328

Chicago/Turabian StyleChen, Jibin, Qiang Pan, Yao Wei, and Yibin Luo. 2024. "Experimental Study on Flexural Behavior of RC Piles with Basalt Fiber-Reinforced Polymer Bars and Load Carrying Capacity Calculation" Buildings 14, no. 5: 1328. https://doi.org/10.3390/buildings14051328