Fabrication of Polypyrrole Hollow Nanospheres by Hard-Template Method for Supercapacitor Electrode Material

Abstract

:1. Introduction

2. Results and Discussion

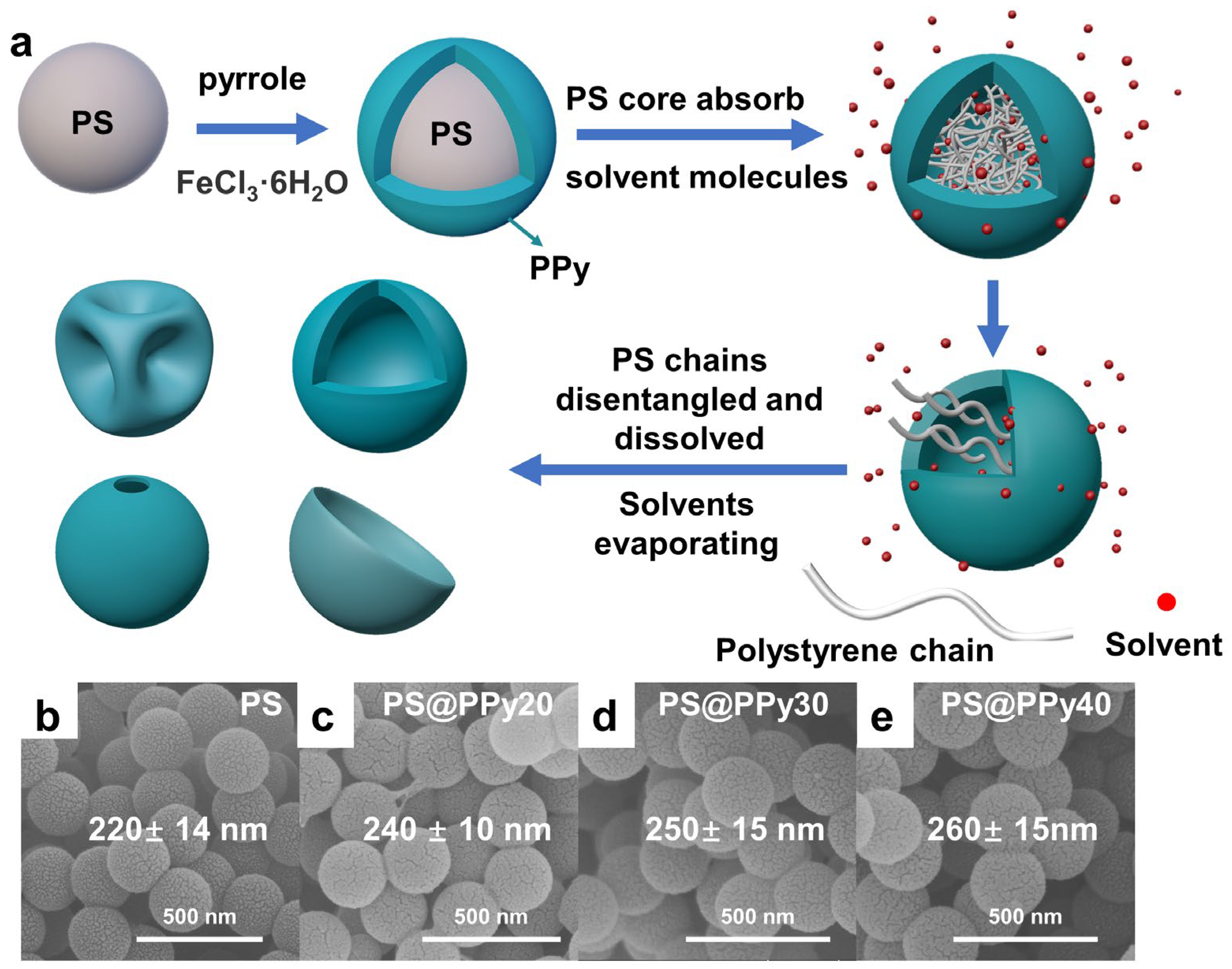

2.1. Synthesis Process and Structural Characterization of Hollow PPy Nanospheres

2.2. Electrochemical Performance of PPy in a Three-Electrode System

2.3. Semisolid-State Flexible Supercapacitor Device

3. Experimental Section

3.1. Chemicals

3.2. Preparation of Polystyrene (PS) Particles

3.3. Preparation of Polystyrene@polypyrrole (PS@PPy) Core–Shell Nanospheres and Hollow PPy Spheres

3.4. Characterization

3.5. Electrochemical Characterization

3.5.1. Three-Electrode System

3.5.2. Flexible Two-Electrode Cell

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Simon, P.; Gogotsi, Y. Materials for Electrochemical Capacitors. Nat. Mater. 2008, 7, 845–854. [Google Scholar] [CrossRef] [PubMed]

- Poonam; Sharma, K.; Arora, A.; Tripathi, S.K. Review of Supercapacitors: Materials and Devices. J. Energy Storage 2019, 21, 801–825. [Google Scholar] [CrossRef]

- González, A.; Goikolea, E.; Barrena, J.A.; Mysyk, R. Review on Supercapacitors: Technologies and Materials. Renew. Sustain. Energy Rev. 2016, 58, 1189–1206. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Zhu, J.; Lan, L.; Li, C.; Mao, J.; Wang, F.; Zhang, Z.; Wang, L. Ultra-low temperature flexible supercapacitor based on hierarchically structured pristine polypyrrole membranes. Chem. Eng. J. 2021, 420, 129712. [Google Scholar] [CrossRef]

- Zhang, C.; Jia, X.; Shu, K.; Lu, C.; Wallce, G.G. Conducting polymer composites for unconventional solid-state supercapacitors. J. Mater. Chem. A 2020, 8, 4677–4699. [Google Scholar]

- Zhang, M.; Song, Y.; Yang, D.; Qin, Z.; Guo, D.; Bian, L.; Sang, X.; Sun, X.; Liu, X. Redox Poly-Counterion Doped Conducting Polymer for Pseudocapacitive Energy Storage. Adv. Funct. Mater. 2021, 31, 2006203. [Google Scholar] [CrossRef]

- Simon, P.; Gogotsi, Y. Perspectives for electrochemical capacitors and related devices. Nat. Mater. 2020, 19, 1151–1163. [Google Scholar] [CrossRef] [PubMed]

- Mathis, T.S.; Kurra, N.; Wang, X.; Pinto, D.; Simon, P.; Gogotsi, Y. Energy Storage Data Reporting in Perspective—Guidelines for Interpreting the Performance of Electrochemical Energy Storage Systems. Adv. Energy Mater. 2019, 9, 1902007. [Google Scholar] [CrossRef]

- Yuan, X.; Remita, N. Conjugated Polymer Polypyrrole Nanostructures: Synthesis and Photocatalytic Applications. Top Curr. Chem. 2022, 380, 32. [Google Scholar] [CrossRef]

- Wang, F.; Wu, X.; Yuan, X.; Liu, Z.; Zhang, Y.; Fu, L.; Zhu, Y.; Zhou, Q.; Wu, Y.; Huang, W. Latest advances in supercapacitors: From new electrode materials to novel device designs. Chem. Soc. Rev. 2017, 46, 6816–6854. [Google Scholar] [CrossRef]

- Yang, Y.; Chu, Y.; Yang, F.; Zhang, Y. Uniform hollow conductive polymer microspheres synthesized with the sulfonated polystyrene template. Mater. Chem. Phys. 2015, 92, 164–171. [Google Scholar] [CrossRef]

- Song, G.; Liu, L.; Han, J.; Wang, C.; Wang, G. Polypyrrole single and double-shelled nanospheres templated by pyrrole-Hg(II) complex: Synthesis, characterization, formation mechanism and electrochemical performance. Synth. Met. 2014, 197, 126–133. [Google Scholar] [CrossRef]

- Hao, J.; Liu, H.; Han, S.; Lian, J. MoS2 Nanosheet-Polypyrrole Composites Deposited on Reduced Graphene Oxide for Supercapacitor Applications. ACS Appl. Nano Mater. 2021, 4, 1330–1339. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Y.; Zhang, D.; Hu, X.; Zhang, L.; Zhao, C.; He, Y.; Zhang, W.; Yang, N.; Ma, Z. Structural Tuning of a Flexible and Porous Polypyrrole Film by a Template-Assisted Method for Enhanced Capacitance for Supercapacitor Applications. ACS Appl. Mater. Interfaces 2021, 13, 17726–17735. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Liu, P.; Ju, L.; Wang, L.; Zhao, S. Polypyrrole nanocapsules via interfacial polymerization. Macromol. Res. 2010, 18, 648–652. [Google Scholar] [CrossRef]

- Li, Z.; Li, B.; Yu, C.; Wang, H.; Li, Q. Recent Progress of Hollow Carbon Nanocages: General Design Fundamentals and Diversified Electrochemical Applications. Adv. Sci. 2023, 10, 2206605. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Ji, N.; Li, X.; Zhang, R.; Qiao, Y.; Xiong, J.; Liu, J.; Lu, X. Kinetics Driven by Hollow Nanoreactors: An Opportunity for Controllable Catalysis. Angew. Chem. Int. Ed. 2023, 62, e2022213612. [Google Scholar]

- Liu, X.; Wu, H.; Ren, F.; Qiu, G.; Tang, M. Controllable fabrication of SiO2/polypyrrole core–shell particles and polypyrrole hollow spheres. Mater. Chem. Phys. 2008, 109, 5–9. [Google Scholar] [CrossRef]

- Bai, M.; Jian, Y.; Wickline, S.A.; Xia, Y. Colloidal Hollow Spheres of Conducting Polymers with Smooth -Surface and Uniform, Controllable Sizes. Small 2009, 5, 1747–1752. [Google Scholar]

- Lee, J.; Lee, D.; Lee, S.; Kim, J.; Cheong, I. One-Step Synthetic Route for Conducting Core−Shell Poly(styrene/pyrrole) Nanoparticles. Macromolecules 2009, 42, 4511–4519. [Google Scholar] [CrossRef]

- Yun, S.; Kim, G.; Lee, C.; Jo, N.; Kang, Y.; Ryu, K. Synthesis and Control of the Shell Thickness of Polyaniline and Polypyrrole Half Hollow Spheres Using the Polystyrene Cores. J. Nanomater. 2012, 9, 1687–4110. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, C.; Li, Y.; Wang, Z. Controlled preparation of core–shell polystyrene/polypyrrole nanocomposite particles by a swelling–diffusion–interfacial polymerization method. Colloid. Polym. Sci. 2012, 290, 979–985. [Google Scholar] [CrossRef]

- Kim, M.; Moon, J.; Yoo, P.; Park, J. Hollow Polypyrrole Films: Applications for Energy Storage Devices. J. Electrochem. Soc. 2012, 159, A1052–A1056. [Google Scholar] [CrossRef]

- Zhang, J.; Qiu, T.; Ren, S.; Yuan, H.; He, L.; Li, X. Simple synthesis of polypyrrole-polystyrene hybrid hollow spheres. Mater. Chem. Phys. 2012, 134, 1072–1078. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, C.; Xu, C.; Zhu, Z.; Chen, C. Hollow polypyrrole nanosphere embedded in nitrogen-doped graphene layers to obtain a three-dimensional nanostructure as electrode material for electrochemical supercapacitor. Ionics 2017, 23, 147–156. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Z.; Wang, Q.; Guo, J.; Zhao, Q.; Lu, Y. MnO2@polypyrrole composite with hollow microsphere structure for electrode material of supercapacitors. J. Electroanal. Chem. 2021, 901, 115780. [Google Scholar] [CrossRef]

- Hsieh, T.; Hung, P.; Wang, C.; Chou, Y.; Wu, P. Controlled synthesis of uniform hollow polypyrrole microcapsules by a cosolvent approach. SN Appl. Sci. 2019, 1, 319. [Google Scholar] [CrossRef]

- Chen, Z.; Ye, S.; Evans, S.D.; Ge, Y.; Zhu, Z.; Tu, Y.; Yang, X. Confined Assembly of Hollow Carbon Spheres in Carbonaceous Nanotube: A Spheres-in-Tube Carbon Nanostructure with Hierarchical Porosity for High-Performance Supercapacitor. Small 2018, 14, 1704015. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Pan, N. Supercapacitors Performance Evaluation. Adv. Energy Mater. 2015, 5, 1401401. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, R.; Ge, Y.; Tu, Y.; Xia, Y.; Yang, X. N- and O-doped hollow carbonaceous spheres with hierarchical porous structure for potential application in high-performance capacitance. J. Power Sources 2017, 363, 356–364. [Google Scholar] [CrossRef]

- Qiu, J.; Shang, Y.; Xu, J.; Xia, Y. Template-Directed Synthesis of Colloidal Hollow Particles: Mind the Material Used for the Template. Small 2022, 18, 2204278. [Google Scholar] [CrossRef]

- Xu, J.; Qiu, J.; Zhang, H.; Hu, Y.; Xia, Y. Polystyrene-Silica Colloidal Janus Particles with Uniform Shapes and Complex Structures. Part. Part. Syst. Charact. 2022, 39, 2200085. [Google Scholar] [CrossRef]

- Miller-Chou, B.; Koenig, J. A review of polymer dissolution. Prog. Polym. Sci. 2003, 28, 1223–1270. [Google Scholar] [CrossRef]

- John, J.; Jayalekshmi, S. Polypyrrole with appreciable solubility, crystalline order and electrical conductivity synthesized using various dopants appropriate for device applications. Polym. Bull. 2023, 80, 6099–6116. [Google Scholar] [CrossRef]

- Lei, J.; Li, Z.; Lu, X.; Wang, W.; Bian, X.; Zheng, T.; Xue, Y.; Wang, C. Controllable fabrication of porous free-standing polypyrrole films via a gas phase polymerization. J. Colloid. Interface Sci. 2011, 364, 555–560. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Li, N.; Ji, L.; Li, Y.; Yang, X.; Lu, Y.; Tu, Y. N- and O-doped carbonaceous nanotubes from polypyrrole for potential application in high-performance capacitance. J. Power Sources 2014, 247, 660–666. [Google Scholar] [CrossRef]

- Lim, S.; Pandikumar, A.; Lim, Y.; Huang, N.; Lim, H. In-situ electrochemically deposited polypyrrole nanoparticles incorporated reduced graphene oxide as an efficient counter electrode for platinum-free dye-sensitized solar cells. Sci. Rep. 2014, 4, 5305. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Yang, F.; Xiong, T.; Adekoya, D.; Huang, Y.; Balogun, M. Polypyrrole Hollow Microspheres with Boosted Hydrophilic Properties for Enhanced Hydrogen Evolution Water Dissociation Kinetics. ACS Appl. Mater. Interfaces 2020, 12, 57093–57101. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Ahmad, Z.; Kim, Y.; Kim, W.; Ahn, H.; Lee, J.; Yoon, M. Decoupling Critical Parameters in Large-Range Crystallinity-Controlled Polypyrrole-Based High-Performance Organic Electrochemical Transistors. Chem. Mater. 2020, 32, 8606–8618. [Google Scholar] [CrossRef]

- Neoh, K.G.; Young, T.T.; Kang, E.T.; Tan, K.L. Structural and mechanical degradation of polypyrrole films due to aqueous media and heat treatment and the subsequent redoping characteristics. J. Appl. Polym. Sci. 1997, 64, 519–526. [Google Scholar] [CrossRef]

- Tan, K.L.; Tan, B.T.G.; Kang, E.T.; Neoh, K.G. The chemical nature of the nitrogens in polypyrrole and polyaniline: A comparative study by x-ray photoelectron spectroscopy. J. Chem. Phys. 1991, 94, 5382–5388. [Google Scholar] [CrossRef]

- Erlandsson, R.; Inganäs, O.; Lundström, I.; Salaneck, W.R. XPS and electrical characterization of BF4−-doped polypyrrole exposed to oxygen and water. Synth. Met. 1985, 10, 303–318. [Google Scholar] [CrossRef]

- Li, Z.; Cai, J.; Cizek, P.; Niu, H.; Dua, Y.; Tong, T. A self-supported, flexible, binder-free pseudo-supercapacitor electrode material with high capacitance and cycling stability from hollow, capsular polypyrrole fibers. J. Mater. Chem. A 2015, 3, 16162–16167. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, P.; Nautiyal, A.; Li, S.; Liu, N.; Yin, J.; Deng, K.; Yang, X. Tunable Three-Dimensional Nanostructured Conductive Polymer Hydrogels for Energy-Storage Applications. ACS Appl. Mater. Interfaces 2019, 11, 4258–4426. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Liu, X.; Shang, T.; Deng, Y.; Wang, N.; Dong, X.; Zhao, J.; Chen, D.; Tao, Y.; Yang, Q.H. Reassembly of MXene Hydrogels into Flexible Films towards Compact and Ultrafast Supercapacitors. Adv. Funct. Mater. 2021, 31, 2102874. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, N.; Liu, Y.; Zhou, X.; Pu, B.; Qing, Y.; Zhang, M.; Jiang, X.; Huang, J.; Tang, Q.; et al. MXene/Graphdiyne nanotube composite films for Free-Standing and flexible Solid-State supercapacitor. Chem. Eng. J. 2022, 450, 138398. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, J.; Wang, X.; Lu, B.; Chen, M.; Liu, M. Construction and characterizations of hollow carbon microsphere@polypyrrole composite for the high performance supercapacitor. J. Energy Storage 2018, 18, 62–71. [Google Scholar] [CrossRef]

- Liu, T.; Fin, L.; Yu, M.; Wang, H.; Zhai, T.; Lu, X.; Tong, Y.; Li, Y. Polyaniline and Polypyrrole Pseudocapacitor Electrodes with Excellent Cycling Stability. Nano Lett. 2014, 14, 2522–2527. [Google Scholar] [CrossRef]

- Song, Y.; Liu, T.; Xu, X.; Feng, D.; Li, Y.; Liu, X. Pushing the Cycling Stability Limit of Polypyrrole for Supercapacitors. Adv. Funct. Mater. 2015, 25, 4626–4632. [Google Scholar] [CrossRef]

- Ahmad, Z.; Kim, W.; Kumar, S.; Yoon, T.; Lee, J. Nanocomposite Supercapacitor Electrode from Sulfonated Graphene Oxide and Poly(pyrrole-(biphenyldisulfonic acid)-pyrrole). ACS Appl. Energy Mater. 2020, 3, 6743–6751. [Google Scholar] [CrossRef]

- Li, S.; Zhao, C.; Shu, K.; Wang, C.; Guo, Z.; Wallace, G.G.; Liu, H. Mechanically strong high performance layered polypyrrole nano fibre/graphene film for flexible solid state supercapacitor. Carbon 2014, 79, 554–562. [Google Scholar] [CrossRef]

- Cao, J.; Wang, Y.; Chen, J.; Li, X.; Walsh, F.C.; Ouyang, J.; Jia, D.; Zhou, Y. Three-dimensional graphene oxide/polypyrrole composite electrodes fabricated by one-step electrodeposition for high performance supercapacitors. J. Mater. Chem. A 2015, 3, 14445–14457. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, Y.; Deng, Q.; Zhou, J.; Pei, Z.; Xue, Q.; Huang, Y.; Wang, Z.; Li, H.; Huang, Q.; et al. Highly Flexible, Freestanding Supercapacitor Electrode with Enhanced Performance Obtained by Hybridizing Polypyrrole Chains with MXene. Adv. Energy Mater. 2016, 6, 1600969. [Google Scholar] [CrossRef]

- Meng, C.; Liu, C.; Chen, L.; Hu, C.; Fan, S. Highly Flexible and All-Solid-State Paperlike Polymer Supercapacitors. Nano. Lett. 2010, 10, 4025–4031. [Google Scholar] [CrossRef] [PubMed]

- Chee, W.K.; Lim, H.N.; Harrison, I.; Chong, K.F.; Zainal, Z.; Ng, C.H.; Huang, N.M. Performance of Flexible and Binderless Polypyrrole/Graphene Oxide/Zinc Oxide Supercapacitor Electrode in a Symmetrical Two-Electrode Configuration. Electrochim. Acta 2015, 157, 88–94. [Google Scholar] [CrossRef]

- Mao, J.; Liu, C.; Cheng, C.; Zhang, W.; Liao, X.; Wang, J.; Li, L.; Yang, X.; He, Y.; Ma, Z. A Porous and Interconnected Polypyrrole Film with High Conductivity and Ion Accessibility as Electrode for Flexible All-Solid-State Supercapacitors. ChemElectroChem 2019, 6, 5479–5485. [Google Scholar] [CrossRef]

- Zhu, J.; Xu, Y.; Wang, J.; Wang, J.; Bai, Y.; Du, X. Morphology controllable nano-sheet polypyrrole-graphene composites for high-rate supercapacitor. Phys. Chem. Chem. Phys. 2015, 17, 19885–19894. [Google Scholar] [CrossRef]

- Okubo, M.; Ise, E.; Yamashita, T. Production of micron-sized monodispersed polymer particles by seeded polymerization for the dispersion of highly monomer-swollen particles prepared with submicron-sized polymer seed particles utilizing the dynamic swelling method. Appl. Polym. Sci. Part. A Polym. Chem. 1998, 36, 2513–2519. [Google Scholar] [CrossRef]

| Solvent | Polarity | Solubility Parameter cal0.5 cm−1.5 | Boiling Point (°C) | Vapor Pressure (kPa) | Morphology (PS@PPy20) | Morphology (PS@PPy30) | Morphology (PS@PPy40) |

|---|---|---|---|---|---|---|---|

| Cyclohexane | 0.1 | 7.3 | 80.7 | 13.33 | intact | intact | intact |

| Toluene | 2.4 | 8.9 | 110.6 | 4.00 | collapsed | buckling | intact |

| Tetrahydrofuran | 4.2 | 9.5 | 66.0 | 23.46 | collapsed | buckling | intact |

| Chloroform | 4.4 | 9.21 | 61.2 | 26.45 | collapsed | buckling | buckling |

| Acetone | 5.4 | 9.8 | 56.5 | 30.56 | intact | hollow | buckling |

| N,N-dimethylformamide | 6.4 | 12.1 | 153.0 | 0.50 | buckling | hollow | intact |

| C | N | O | Cl | -NH- | -NH+- | -NH= | |

|---|---|---|---|---|---|---|---|

| PS@PPy30 | 71.6% | 15% | 10.9% | 2.5% | 31.5% | 68.5% | / |

| DMF PS@PPy20 | 62% | 6.1% | 27.2% | 4.7% | 67.6% | 25.4% | 7% |

| DMF PS@PPy30 | 59% | 11.5% | 28% | 1.5% | 68% | 28% | 4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, R.; Zhao, X.; Lu, R.; You, M.; Chen, X.; Yang, X. Fabrication of Polypyrrole Hollow Nanospheres by Hard-Template Method for Supercapacitor Electrode Material. Molecules 2024, 29, 2331. https://doi.org/10.3390/molecules29102331

Hong R, Zhao X, Lu R, You M, Chen X, Yang X. Fabrication of Polypyrrole Hollow Nanospheres by Hard-Template Method for Supercapacitor Electrode Material. Molecules. 2024; 29(10):2331. https://doi.org/10.3390/molecules29102331

Chicago/Turabian StyleHong, Renzhou, Xijun Zhao, Rongyu Lu, Meng You, Xiaofang Chen, and Xiaoming Yang. 2024. "Fabrication of Polypyrrole Hollow Nanospheres by Hard-Template Method for Supercapacitor Electrode Material" Molecules 29, no. 10: 2331. https://doi.org/10.3390/molecules29102331