Transforming Medicinal Oil into Advanced Gel: An Update on Advancements

Abstract

:1. Introduction

1.1. Background

1.2. Importance of Herbal Formulations

1.3. Evolution of Gel Formulations

2. Traditional Ayurvedic Oil Preparations

2.1. Historical Perspective

2.2. Key Components and Principles

2.3. Challenges in Traditional Formulations

3. Advantages of Traditional Medicine

3.1. Therapeutic Benefits

3.2. Need for Innovation

4. Gel-Based Formulations

4.1. Overview of Gel-Based Drug Delivery Systems

4.2. Advantages of Gels over Traditional Dosage Forms

4.3. Applications of Gels in Pharmaceuticals

5. Integration of Ayurvedic Principles into Gel Formulations

6. Emerging Techniques for Gel Formation

6.1. Nanotechnology in Gel Development

6.2. Encapsulation Strategies

6.3. Novel Polymers and Excipients

6.4. Role of Surfactants in Gel Formation

7. Enhancing Efficacy through Formulation Modifications

7.1. Bioavailability Enhancement

7.2. Controlled Release Mechanisms

7.3. Addressing Stability Issues

7.4. Customization for Specific Therapeutic Targets

8. Case Studies on Successful Transformations

8.1. Specific Examples of Ayurvedic Oil-to-Gel Conversion

8.2. Clinical Outcomes and Patient Responses

8.3. Clinical Trials, Safety and Efficacy

9. Commercial Potential of Patented Plant-Derived Medicinal Oil-Based Formulation

10. Challenges and Future Perspectives

11. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Katiyar, C.K. Ayurvedic Pharmaceutics, Manufacturing Processes and Novel Drug Delivery Systems in Ayurveda. In Translational Ayurveda; Rastogi, S., Ed.; Springer: Singapore, 2019; pp. 33–52. [Google Scholar] [CrossRef]

- Zaigham, H.; Tauheed, A.; Ali, A. Recent trend in traditional medicine dosage form and present status of Unani and Ayurvedic medicine. Int. J. Pharm. Sci. Res. 2019, 10, 1640–1649. [Google Scholar] [CrossRef]

- Baishya, R.; Hati Boruah, J.L.; Bordoloi, M.J.; Kumar, D.; Kalita, P. Novel drug delivery system in phytochemicals: Modern era of ancient science. In Herbal Medicine in India: Indigenous Knowledge, Practice, Innovation and Its Value; Sen, S., Chakraborty, R., Eds.; Springer: Singapore, 2020; pp. 175–189. [Google Scholar] [CrossRef]

- Ghosh, A.; Mishra, A.; Seth, A.; Maurya, S.K. Evaluation of anticonvulsant activity of polyherbal formulation based on ayurvedic formulation BrihadPanchagavyaGhrita. Indian J. Health Sci. Biomed. Res. KLEU 2016, 9, 158–164. [Google Scholar] [CrossRef]

- Gutte, R.K.; Deshmukh, V. Sectional study of nutritional psychology to identify the significance of the connection between mental health and nutraceutical functional ingredients. Funct. Food Ingred. Ment. Health 2023, 1, 1–3. [Google Scholar]

- Singh, V.; Roy, M.; Garg, N.; Kumar, A.; Arora, S.; Malik, D.S. An insight into the dermatological applications of neem: A review on traditional and modern aspect. Recent Adv. Anti-Infective Drug Discov. 2021, 16, 94–121. [Google Scholar] [CrossRef]

- Bhowmik, D.; Chiranjib, Y.J.; Tripathi, K.K.; Kumar, K.S. Herbal remedies of Azadirachtaindica and its medicinal application. J. Chem. Pharm. Res. 2010, 2, 62–72. [Google Scholar]

- Pandey, M.; Bajpai, M. Natural remedies for the treatment of arthritis: A review. Med. Plants Int. J. Phytomed. Relat. Ind. 2020, 12, 545–554. [Google Scholar] [CrossRef]

- Panse, R.J. Nutraceuticals as Modulators of Gut Microbiota: Role in Therapy. In Anxiety, Gut Microbiome, and Nutraceuticals, 1st ed.; Yashwant, V., Pathak, S., Con, S., Eds.; CRC Press: Boca Raton, FL, USA, 2023; pp. 187–212. [Google Scholar]

- Khaw-on, P.; Banjerdpongchai, R. Induction of intrinsic and extrinsic apoptosis pathways in the human leukemic MOLT-4 cell line by terpinen-4-ol. Asian Pac. J. Cancer Prev. 2012, 13, 3073–3076. [Google Scholar] [CrossRef]

- Jeenapongsa, R.; Yoovathaworn, K.; Sriwatanakul, K.M.; Pongprayoon, U.; Sriwatanakul, K. Anti-inflammatory activity of (E)-1-(3,4-dimethoxyphenyl) butadiene from ZingibercassumunarRoxb. J. Ethnopharmacol. 2023, 87, 143–148. [Google Scholar] [CrossRef]

- Kantawong, F.; Singhatong, S.; Srilamay, A.; Boonyuen, K.; Mooti, N.; Wanachantararak, P.; Kuboki, T. Properties of macerated herbal oil. Bioimpacts 2017, 7, 13–23. [Google Scholar] [CrossRef] [PubMed]

- Kader, G.; Nikkon, F.; Rashid, M.A.; Yeasmin, T. Antimicrobial activities of the rhizome extract of Zingiberzerumbet Linn. Asian Pac. J. Trop. Biomed. 2011, 1, 409–412. [Google Scholar] [CrossRef]

- Thome, R.G.; dos Santos, H.B.; dos Santos, F.V.; da Silva Oliveira, R.J.; de Camargos, L.F.; Pereira, M.N. Evaluation of healing wound and genotoxicity potentials from extracts hydroalcoholic of Plantago major and Siparunaguianensis. Exp. Biol Med. 2012, 237, 1379–1386. [Google Scholar] [CrossRef]

- Chanthaphon, S.; Chanthachum, S.; Hongpattarakere, T. Antimicrobial activities of essential oils and crude extracts from tropical Citrus spp. against food-related microorganisms. Songklanakarin J. Sci.Technol. 2008, 30 (Suppl. S1), 125–131. [Google Scholar]

- Srisook, K.; Salee, P.; Charoensuk, Y.; Srisook, E. In vitro anti-oxidant and anti-tyrosinase activities of the rhizomalextractsfrom Amomumbiflorum Jack. Thai J. Botany 2010, 2, 143–150. [Google Scholar]

- Zhang, Y.; Long, Y.; Yu, S.; Li, D.; Yang, M.; Guan, Y.; Zhang, D.; Wan, J.; Liu, S.; Shi, A.; et al. Natural volatile oils derived from herbal medicines: A promising therapy way for treating depressive disorder. Pharmacol. Res. 2021, 164, 105376. [Google Scholar] [CrossRef]

- Patil, S.; Varma, S.A.; Suragimath, G.; Abbayya, K.; Zope, S.A.; Kale, V. Evaluation of Irimedadi Taila as an adjunctive in treating plaque-induced gingivitis. J. Ayurveda Integr. Med. 2017, 9, 57–60. [Google Scholar] [CrossRef]

- Kumar, S.; Madaan, A.; Verma, R.; Gupta, A.; Sastry, J.L.N. In vitro anti-inflammatory effects of Mahanarayan oil formulations using dendritic cells based assay. Ann. Phytomed. 2014, 3, 40–45. [Google Scholar]

- Verma, J.; Mangal, G. New Perspectives of Ksheerabala Taila (oil): A Critical Review. Int. J. Ayurveda Tradit. Med. 2019, 1, 24–30. Available online: https://ijatm.org/index.php/ijatm/article/view/6 (accessed on 1 January 2024).

- Belapurkar, P.; Goyal, P.; Tiwari-Barua, P. Immunomodulatory effects of triphala and its individual constituents: A review. Indian J. Pharm. Sci. 2014, 76, 467. [Google Scholar] [PubMed]

- Ghodela, N.K.; Prasad, P.; Dudhamal, T.S. Clinical Efficacy of Murivenna oil Parisheka in the management of soft tissue injury wsr to achillis tendinopathy—A case study. Eur. J. Biomed. 2017, 4, 496–498. [Google Scholar]

- Dhane, K.; Gupta, M.K.; Hyam, S.; Patil, A. Preparation and in-vitro and in-vivo Evaluation of Ayurvedic Formulation “Amruthotharam” Formulated by Classical and Modern Technique. Indian J. Pharm. Educ. Res. 2023, 57, S126–S134. [Google Scholar] [CrossRef]

- Singh, K.; Thakar, A.B. A clinical study to evaluate the role of Triphaladya Guggulu along with Punarnavadi Kashaya in the management of hypothyroidism. Ayu 2018, 39, 50. [Google Scholar] [CrossRef] [PubMed]

- Girija, P.V.; Renuka, N.K.; Vijayan, K.K. Terpenoids in Gulguluthikthakam Kashayam: An ayurvedic formulation. J. Pharmacogn. Phytochem. 2022, 11, 33–45. [Google Scholar]

- Dutt, V.; Srivastav, S.; Mittal, S.; Haque, M.R. Determination of microbial load, total Phenolic and flavonoids contents in polyherbal formulation “yograj guggulu vati”. J. Drug Deliv. Ther. 2020, 10, 1–5. [Google Scholar] [CrossRef]

- Samarasinghe, R.M.; Kanwar, R.K.; Kumar, K.; Kanwar, J.R. Antiarthritic and chondroprotective activity of Lakshadi Guggul in novel alginate-enclosed chitosan calcium phosphate nanocarriers. Nanomedicine 2014, 9, 819–837. [Google Scholar] [CrossRef] [PubMed]

- Meza-Valle, K.Z.; Saucedo-Acuna, R.A.; Tovar-Carrillo, K.L.; Cuevas-Gonzalez, J.C.; Zaragoza-Contreras, E.A.; Melgoza-Lozano, J. Characterization and topical study of Aloe vera hydrogel on wound-healing process. Polymers 2021, 13, 3958. [Google Scholar] [CrossRef] [PubMed]

- Abazari, M.; Akbari, T.; Hasani, M.; Sharifikolouei, E.; Raoufi, M.; Foroumadi, A.; Sharifzadeh, M.; Firoozpour, L.; Khoobi, M. Polysaccharide-based hydrogels containing herbal extracts for wound healing applications. Carbohydr. Polym. 2022, 294, 119808. [Google Scholar] [CrossRef] [PubMed]

- Yuniarsih, N.; Hidayah, H.; Gunarti, N.S.; Kusumawati, A.H.; Farhamzah, F.; Sadino, A.; Alkandahri, M.Y. Evaluation of Wound-Healing Activity of Hydrogel Extract of Sansevieria trifasciata Leaves (Asparagaceae). Adv. Pharmacol. Pharma. Sci. 2023, 2023, 7680518. [Google Scholar] [CrossRef]

- Sabbagh, F.; Kim, B.S. Recent advances in polymeric transdermal drug delivery systems. J. Control. Release 2022, 341, 132–146. [Google Scholar] [CrossRef]

- Wong, W.F.; Ang, K.P.; Sethi, G.; Looi, C.Y. Recent Advancement of Medical Patch for Transdermal Drug Delivery. Medicina 2023, 59, 778. [Google Scholar] [CrossRef]

- Wu, C.; Jiang, P.; Li, W.; Guo, H.; Wang, J.; Chen, J.; Prausnitz, M.R.; Wang, Z.L. Self-powered iontophoretic transdermal drug delivery system driven and regulated by biomechanical motions. Adv. Func. Mater. 2020, 30, 1907378. [Google Scholar] [CrossRef]

- Cassano, R.; Di Gioia, M.L.; Trombino, S. Gel-based materials for ophthalmic drug delivery. Gels 2021, 7, 130. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Meng, X.; Li, L.; Xia, Y.; Hu, X.; Fang, Y. The incorporated hydrogel of chitosan-oligoconjugated linoleic acid vesicles and the protective sustained release for curcumin in the gel. Int. J. Biol. Macromol. 2023, 227, 17–26. [Google Scholar] [CrossRef] [PubMed]

- Andleeb, M.; Shoaib Khan, H.M.; Daniyal, M. Development, characterization and stability evaluation of topical gel loaded with ethosomes containing Achillea millefolium L. extract. Front. Pharmacol. 2021, 12, 603227. [Google Scholar] [CrossRef] [PubMed]

- Gandhi, J.; Suthar, D.; Patel, H.; Shelat, P.; Parejiya, P. Development and characterization of microemulsion based topical gel of essential oil of clove (Syzygium aromaticum) for superficial fungal infections. Adv. Tradit. Med. 2021, 21, 519–534. [Google Scholar] [CrossRef]

- Nidhi, P.; Dev, K.; Negi, P.; Sourirajan, A. Development and evaluation of hydrogel formulation comprising essential oil of Mentha longifolia L. for oral candidiasis. Adv. Tradit. Med. 2023, 23, 777–787. [Google Scholar] [CrossRef]

- Ijaz, N.; Durrani, A.I.; Rubab, S.; Bahadur, S. Formulation and characterization of Aloe vera gel and tomato powder containing cream. Acta Ecol. Sin. 2022, 42, 34–42. [Google Scholar] [CrossRef]

- Kasparaviciene, G.; Kalveniene, Z.; Pavilonis, A.; Marksiene, R.; Dauksiene, J.; Bernatoniene, J. Formulation and characterization of potential antifungal oleogel with essential oil of thyme. Evid.-Based Complement. Altern. Med. 2018, 2018, 9431819. [Google Scholar] [CrossRef]

- Bhardwaj, S.; Bhatia, S. Development and Characterization of Niosomal Gel System using Lallementia royaleana Benth. mucilage for the treatment of Rheumatoid Arthritis. Iran. J. Pharm. Res. 2020, 19, 465. [Google Scholar] [CrossRef] [PubMed]

- Budhiraja, A.; Dhingra, G. Development and characterization of a novel antiacne niosomal gel of rosmarinic acid. Drug Deliv. 2015, 22, 723–730. [Google Scholar] [CrossRef] [PubMed]

- Jung, B.O.; Chung, S.J.; Lee, S.B. Preparation and characterization of eugenol-grafted chitosan hydrogels and their antioxidant activities. J. Appl. Polym. Sci. 2006, 99, 3500–3506. [Google Scholar] [CrossRef]

- Gholamian, S.; Nourani, M.; Bakhshi, N. Formation and characterization of calcium alginate hydrogel beads filled with cumin seeds essential oil. Food Chem. 2021, 338, 128143. [Google Scholar] [CrossRef] [PubMed]

- Abdul Khalil, H.P.S.; Muhammad, S.; Yahya, E.B.; Amanda, L.K.M.; Abu Bakar, S.; Abdullah, C.K.; Aiman, A.R.; Marwan, M.; Rizal, S. Synthesis and Characterization of Novel Patchouli Essential Oil Loaded Starch-Based Hydrogel. Gels 2022, 8, 536. [Google Scholar] [CrossRef] [PubMed]

- Mostaghimi, M.; Majdinasab, M.; Golmakani, M.T.; Hadian, M.; Hosseini SM, H. Development and characterization of antimicrobial alginate hydrogel beads filled with cinnamon essential oil nanoemulsion. J. Biomater. Sci. Polym. Ed. 2023, 15, 2144–2160. [Google Scholar] [CrossRef] [PubMed]

- Altaf, F.; Niazi, M.B.K.; Jahan, Z.; Ahmad, T.; Akram, M.A.; Safdar, A.; Sher, F. Synthesis and characterization of PVA/starch hydrogel membranes incorporating essential oils aimed to be used in wound dressing applications. J. Polym. Environ. 2021, 29, 156–174. [Google Scholar] [CrossRef]

- Moghimipour, E.; Aghel, N.; Mahmoudabadi, A.Z.; Ramezani, Z.; Handali, S. Preparation and characterization of liposomes containing essential oil of Eucalyptus camaldulensis leaf. Jundishapur J. Nat. Pharm. Prod. 2012, 7, 117. [Google Scholar] [CrossRef]

- Valenti, D.; De Logu, A.; Loy, G.; Sinico, C.; Bonsignore, L.; Cottiglia, F.; Fadda, A.M. Liposome-incorporated Santolina insularis essential oil: Preparation, characterization and in vitro antiviral activity. J. Liposome Res. 2001, 11, 73–90. [Google Scholar] [CrossRef]

- Al-Ogaidi, I.; Aguilar, Z.P.; Lay Jr, J.O. Development of Biodegradable/Biocompatible Nanoliposome-Encapsulated Antimicrobial Essential Oils for Topical Creams and Gels. ACS Omega 2022, 7, 23875–23889. [Google Scholar] [CrossRef]

- Chen, J.; Ma, Y.; Tao, Y.; Zhao, X.; Xiong, Y.; Chen, Z.; Tian, Y. Formulation and evaluation of a topical liposomal gel containing a combination of zedoary turmeric oil and tretinoin for psoriasis activity. J. Liposome Res. 2020, 31, 130–144. [Google Scholar] [CrossRef]

- Kammoun, A.K.; Khedr, A.; Hegazy, M.A.; Almalki, A.J.; Hosny, K.M.; Abualsunun, W.A.; Bakhaidar, R.B. Formulation, optimization, and nephrotoxicity evaluation of an antifungal in situ nasal gel loaded with voriconazole–clove oil transferosomal nanoparticles. Drug Deliv. 2021, 28, 2229–2240. [Google Scholar] [CrossRef] [PubMed]

- Das, B.; Nayak, A.K.; Mallick, S. Thyme Oil–Containing Fluconazole-Loaded Transferosomal Bigel for Transdermal Delivery. AAPS PharmSciTech 2023, 24, 240. [Google Scholar] [CrossRef] [PubMed]

- Ghazwani, M.; Hani, U.; Alam, A.; Alqarni, M.H. Quality-by-Design-Assisted Optimization of Carvacrol Oil-Loaded Niosomal Gel for Anti-Inflammatory Efficacy by Topical Route. Gels 2023, 9, 401. [Google Scholar] [CrossRef] [PubMed]

- Kujur, A.; Kiran, S.; Dubey, N.K.; Prakash, B. Microencapsulation of Gaultheria procumbens essential oil using chitosan-cinnamic acid microgel: Improvement of antimicrobial activity, stability and mode of action. LWT Food Sci. Technol. 2017, 86, 132–138. [Google Scholar] [CrossRef]

- Sharma, A.; Sabharwal, P.; Dada, R. Herbal medicine—An introduction to Its history. In Herbal Medicine in Andrology, 1st ed.; Henkel, R., Agarwal, A., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Ijinu, T.P.; George, V.; Pushpangadan, P. History of research on medicinal plants in India. In Medicinal and Aromatic Plants of India; Mathe, A., Khan, I.A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; Volume 1, pp. 35–61. [Google Scholar] [CrossRef]

- Kulkarni, A.; Nair, A.; Hirode, K.; Chavan, M.; Jain, M.; Majumdar, P.; Ali, A.; Jamkhedkar, S. Indian Traditional Foods from an Ayurvedic Perspective. In Ethnic Knowledge and Perspectives of Medicinal Plants, 1st ed.; Munir, O., Kandikre Ramaiah, S., Maryam, S., Volkan, A., Francisco, M.H.-M., Eds.; Apple Academic Press: New York, NY, USA, 2023; Volume 2, pp. 395–424. [Google Scholar] [CrossRef]

- Pisani-Conway, C. Ayurveda for Modern Obstetrics. Clin. Obstet. Gynecol. 2021, 64, 589–601. [Google Scholar] [CrossRef] [PubMed]

- Prasad, A.; Kothari, N. Cow products: Boon to human health and food security. Trop. Anim. Health Prod. 2022, 54, 12. [Google Scholar] [CrossRef] [PubMed]

- Benny, G.A.; Varghese, T.; Vijayakumar, S.; Robin, D.T. Effective management of Colles fracture using Murivenna and Abha Guggulu–A case report. J. Ayurveda Integr. Med. 2023, 14, 100786. [Google Scholar] [CrossRef] [PubMed]

- Manjiri, M.A.; Asadpour, A.A.; Yousefi, M.; Jamali, J.; Davachi, B.; Ahmadpour, M.R.; Salari, R. The effects of Cynodon dactylon (Poaceae family) and Dolichos biflorus (Fabaceae family) extracts on decreasing size and excretion of kidney and urinary tract stones: A randomized, double-blind controlled trial. J. Complement. Integr. Med. 2022, 20, 214–222. [Google Scholar] [CrossRef]

- Rashid, K.; Raj, V.B.; Kumar, P.S.; Nishad, K.M. Hair care promising herbs: A review. Pharm. Res. 2020, 10, 677–688. [Google Scholar]

- Prakash, B.; Kedia, A.; Mishra, P.K.; Dubey, N.K. Plant essential oils as food preservatives to control moulds, mycotoxin contamination and oxidative deterioration of agri-food commodities–Potentials and challenges. Food Control 2015, 47, 381–391. [Google Scholar] [CrossRef]

- Srivastava, Y.; Semwal, A.D.; Dhiman, A. A comprehensive review on processing, therapeutic benefits, challenges, and economic scenario of unconventional oils. J. Food Process. Preserv. 2021, 45, e15152. [Google Scholar] [CrossRef]

- Katz, J.S.; Chou, D.K.; Christian, T.R.; Das, T.K.; Patel, M.; Singh, S.N.; Wen, Y. Emerging challenges and innovations in surfactant-mediated stabilization of biologic formulations. J. Pharmaceut Sci. 2022, 111, 919–932. [Google Scholar] [CrossRef] [PubMed]

- Varghese, V.; Shukkoor, M.A.; Jose, D. Pain Relief and Functional Improvement with Murivenna Bandage in Osteoarthritis of Knee Joint-A Case Report. Int. J. AYUSH Case Rep. 2023, 7, 425–430. [Google Scholar]

- Gupta, A.K.; Mahanta, V.; Sherkhane, R.; Gupta, S.K. Iontophoresis with Murivenna kwatha as an adjunctive therapy in the management of Vata kantaka (Plantar fasciitis): A case report. J. Ayurveda Case Rep. 2020, 3, 148–152. [Google Scholar]

- Mukherjee, P.K.; Banerjee, S.; Kar, A.; Chanda, J. Drugs from our ancestors: Tradition to innovation. In Herbal Medicine in India: Indigenous Knowledge, Practice, Innovation and its Value; Saikat, S., Raja, C., Eds.; Springer: Singapore, 2020; pp. 263–280. [Google Scholar] [CrossRef]

- Suhail, M.; Rosenholm, J.M.; Minhas, M.U.; Badshah, S.F.; Naeem, A.; Khan, K.U.; Fahad, M. Nanogels as drug-delivery systems: A comprehensive overview. Ther. Deliv. 2019, 10, 697–717. [Google Scholar] [CrossRef]

- Peers, S.; Montembault, A.; Ladaviere, C. Chitosan hydrogels for sustained drug delivery. J. Control. Release 2020, 326, 150–163. [Google Scholar] [CrossRef]

- Li, D.; Li, J.; Dong, H.; Li, X.; Zhang, J.; Ramaswamy, S.; Xu, F. Pectin in biomedical and drug delivery applications: A review. Int. J. Biol. Macromol. 2021, 185, 49–65. [Google Scholar] [CrossRef]

- Ciolacu, D.E.; Nicu, R.; Ciolacu, F. Cellulose-based hydrogels as sustained drug-delivery systems. Materials 2020, 13, 5270. [Google Scholar] [CrossRef]

- Zhang, L.; Xiao, Q.; Xiao, Z.; Zhang, Y.; Weng, H.; Chen, F.; Xiao, A. Hydrophobic modified agar: Structural characterization and application in encapsulation and release of curcumin. Carbohydr. Polym. 2023, 308, 120644. [Google Scholar] [CrossRef]

- Awadhiya, A.; Tyeb, S.; Rathore, K.; Verma, V. Agarose bioplastic-based drug delivery system for surgical and wound dressings. Eng. Life Sci. 2017, 17, 204–214. [Google Scholar] [CrossRef]

- Zhang, L.; Ye, S.; Chen, F.; Xiao, Q.; Weng, H.; Xiao, A. Super absorbent glutaric anhydride-modified agar: Structure, properties, and application in biomaterial delivery. Int. J. Biol. Macromol. 2023, 231, 123524. [Google Scholar] [CrossRef]

- Lee, W.K.; Lim, Y.-Y.; Leow, A.T.-C.; Namasivayam, P.; Abdullah, J.O.; Ho, C.-L. Factors affecting yield and gelling properties of agar. J. Appl. Phycol. 2017, 29, 1527–1540. [Google Scholar] [CrossRef]

- Prabaharan, M. Prospective of guar gum and its derivatives as controlled drug delivery systems. Int. J. Biol. Macromol. 2011, 49, 117–124. [Google Scholar] [CrossRef]

- Li, L.; Ni, R.; Shao, Y.; Mao, S. Carrageenan and its applications in drug delivery. Carbohydr. Polym. 2014, 103, 1–11. [Google Scholar] [CrossRef]

- Prajapati, V.D.; Jani, G.K.; Moradiya, N.G.; Randeria, N.P.; Nagar, B.J. Locust bean gum: A versatile biopolymer. Carbohydr. Polym. 2013, 94, 814–821. [Google Scholar] [CrossRef]

- Kaity, S.; Ghosh, A. Carboxymethylation of locust bean gum: Application in interpenetrating polymer network microspheres for controlled drug delivery. Ind. Eng. Chem. Res. 2013, 52, 10033–10045. [Google Scholar] [CrossRef]

- Kaity, S.; Isaac, J.; Kumar, P.M.; Bose, A.; Wong, T.W.; Ghosh, A. Microwave assisted synthesis of acrylamide grafted locust bean gum and its application in drug delivery. Carbohydr. Polym. 2013, 98, 1083–1094. [Google Scholar] [CrossRef]

- Petri, D.F. Xanthan gum: A versatile biopolymer for biomedical and technological applications. J. Appl. Polym. Sci. 2015, 132, 42035. [Google Scholar] [CrossRef]

- Shalviri, A.; Liu, Q.; Abdekhodaie, M.J.; Wu, X.Y. Novel modified starch–xanthan gum hydrogels for controlled drug delivery: Synthesis and characterization. Carbohydr. Polym. 2010, 79, 898–907. [Google Scholar] [CrossRef]

- Hasnain, M.S.; Jameel, E.; Mohanta, B.; Dhara, A.K.; Alkahtani, S.; Nayak, A.K. Alginates: Sources, structure, and properties. In Alginates in Drug Delivery; Academic Press: Cambridge, MA, USA, 2020; pp. 1–17. [Google Scholar]

- Thomas, D.; Mathew, N.; Nath, M.S. Starch modified alginate nanoparticles for drug delivery application. Int. J. Biol. Macromol. 2021, 173, 277–284. [Google Scholar] [CrossRef]

- Shaikh, M.A.J.; Alharbi, K.S.; Almalki, W.H.; Imam, S.S.; Albratty, M.; Meraya, A.M.; Gupta, G. Sodium alginate based drug delivery in management of breast cancer. Carbohydr. Polym. 2022, 292, 119689. [Google Scholar] [CrossRef]

- De, A.; Nayak, A.K.; Kundu, A.; Das, B.; Samanta, A. Gum arabic-based nanomaterials in drug delivery and biomedical applications. In Biopolymer-Based Nanomaterials in Drug Delivery and Biomedical Applications; Academic Press: Cambridge, MA, USA, 2021; pp. 165–182. [Google Scholar]

- Gerola, A.P.; Silva, D.C.; Matsushita, A.F.; Borges, O.; Rubira, A.F.; Muniz, E.C.; Valente, A.J. The effect of methacrylation on the behavior of Gum Arabic as pH-responsive matrix for colon-specific drug delivery. Eur. Polym. J. 2016, 78, 326–339. [Google Scholar] [CrossRef]

- Pandit, A.H.; Mazumdar, N.; Imtiyaz, K.; Alam Rizvi, M.M.; Ahmad, S. Self-healing and injectable hydrogels for anticancer drug delivery: A study with multialdehyde gum arabic and succinic anhydride chitosan. ACS Appl. Bio Mater. 2020, 3, 8460–8470. [Google Scholar] [CrossRef]

- Parhi, R. Drug delivery applications of chitin and chitosan: A review. Environ. Chem. Lett. 2020, 18, 577–594. [Google Scholar] [CrossRef]

- Aranaz, I.; Alcantara, A.R.; Civera, M.C.; Arias, C.; Elorza, B.; Heras Caballero, A.; Acosta, N. Chitosan: An overview of its properties and applications. Polymer 2021, 13, 3256. [Google Scholar] [CrossRef]

- Maurya, R.; Ramteke, S.; Guru, P.; Jain, N. K Oral Glucose-Responsive Nanocarrier System for Management of Diabetes. J. Endocrinol. Metab. 2022, 12, 146–160. [Google Scholar] [CrossRef]

- Bayat, M.; Mosavari, N. A New amphotericin B-loaded trimethyl chitosan nanoparticles as a drug delivery system and antifungal activity on Candida albicans biofilm. Arch. Razi Inst. 2021, 76, 571. [Google Scholar]

- Sinha, P.; Srivastava, S.; Mishra, N.; Singh, D.K.; Luqman, S.; Chanda, D.; Yadav, N.P. Development, optimization, and characterization of a novel tea tree oil nanogel using response surface methodology. Drug Dev. Ind. Pharm. 2016, 42, 1434–1445. [Google Scholar] [CrossRef]

- Fardous, J.; Yamamoto, E.; Omoso, Y.; Nagao, S.; Inoue, Y.; Yoshida, K.; Ikegami, Y.; Zhang, Y.; Shirakigawa, N.; Ono, F.; et al. Development of a gel-in-oil emulsion as a transdermal drug delivery system for successful delivery of growth factors. J. Biosci. Bioeng. 2021, 132, 95–101. [Google Scholar] [CrossRef]

- Tariq, L.; Arafah, A.; Ali, S.; Beigh, S.; Dar, M.A.; Dar, A.I.; Alsaffar, R.M.; Masoodi, M.H.; Rehman, M.U. Nanogel-Based transdermal drug delivery system: A therapeutic strategy with under discussed potential. Curr. Top. Med. Chem. 2023, 23, 44–61. [Google Scholar] [CrossRef]

- Siafaka, P.I.; Gundogdu, E.A.; Caglar, E.S.; Gonzalez-Alvarez, M.; Gonzalez-Alvarez, I. Polymer Based Gels: Recent and Future Applications in Drug Delivery Field. Curr. Drug Deliv. 2023, 20, 1288–1313. [Google Scholar] [CrossRef]

- Tadić, V.M.; Zugic, A.; Martinovic, M.; Stankovic, M.; Maksimovic, S.; Frank, A.; Nesic, I. Enhanced Skin Performance of Emulgel vs. Cream as Systems for Topical Delivery of Herbal Actives (Immortelle Extract and Hemp Oil). Pharmaceutics 2021, 13, 1919. [Google Scholar] [CrossRef]

- Sharma, R.; Prajapati, P.K. Predictive, preventive and personalized medicine: Leads from ayurvedic concept of Prakriti (human constitution). Curr. Pharmacol. Rep. 2020, 6, 441–450. [Google Scholar] [CrossRef]

- Shrivastava, S.; Soundararajan, P.; Agrawal, A. Ayurvedic Approach in Chronic Disease Management. In Integrative and Functional Medical Nutrition Therapy: Principles and Practices; Springer Nature: Cham, Switzerland, 2020; pp. 783–798. [Google Scholar]

- Kohli, D.; Champawat, P.S.; Mudgal, V.D. Asparagus (Asparagus racemosus L.) roots: Nutritional profile, medicinal profile, preservation, and value addition. J. Sci. Food Agric. 2023, 103, 2239–2250. [Google Scholar] [CrossRef]

- Pavoni, L.; Perinelli, D.R.; Bonacucina, G.; Cespi, M.; Palmieri, G.F. An overview of micro-and nanoemulsions as vehicles for essential oils: Formulation, preparation and stability. Nanomaterials 2020, 10, 135. [Google Scholar] [CrossRef]

- Liu, Q.; Huang, H.; Chen, H.; Lin, J.; Wang, Q. Food-grade nanoemulsions: Preparation, stability and application in encapsulation of bioactive compounds. Molecules 2019, 24, 4242. [Google Scholar] [CrossRef]

- Agarwal, A.; Madan, P.; Kumar, R.; Khundia, M.; Watel, V.R. A Review Study on Role of Abhyanga in Dincharya. World J. Pharm. Res. 2021, 10, 1774–1780. [Google Scholar]

- Bhattacharya, D.; Ghosh, B.; Mukhopadhyay, M. Development of nanotechnology for advancement and application in wound healing: A review. IET Nanobiotechnol. 2019, 13, 778–785. [Google Scholar] [CrossRef]

- Hosny, K.M.; Rizg, W.Y.; Alhakamy, N.A.; Alamoudi, A.J.; Mushtaq, R.Y.; Safhi, A.Y. Utilization of nanotechnology and experimental design in development and optimization of Aloe vera gel loaded with Finasteride–Garlic Oil–Nanotransfersomes. J. Drug Deliv. Sci. Technol. 2022, 68, 103130. [Google Scholar] [CrossRef]

- Alam, A.; Foudah, A.I.; Salkini, M.A.; Raish, M.; Sawale, J. Herbal Fennel Essential Oil Nanogel: Formulation, Characterization and Antibacterial Activity against Staphylococcus aureus. Gels 2022, 8, 736. [Google Scholar] [CrossRef]

- Sakkas, H.; Economou, V.; Gousia, P.; Bozidis, P.; Sakkas, V.A.; Petsios, S.; Papadopoulou, C. Antibacterial efficacy of commercially available essential oils tested against drug-resistant gram-positive pathogens. Appl. Sci. 2018, 8, 2201. [Google Scholar] [CrossRef]

- Tan, C.; Dadmohammadi, Y.; Lee, M.C.; Abbaspourrad, A. Combination of copigmentation and encapsulation strategies for the synergistic stabilization of anthocyanins. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3164–3191. [Google Scholar] [CrossRef]

- Lv, P.; Wang, D.; Chen, Y.; Zhu, S.; Zhang, J.; Mao, L.; Gao, Y.; Yuan, F. Pickering emulsion gels stabilized by novel complex particles of high-pressure-induced WPI gel and chitosan: Fabrication, characterization and encapsulation. Food Hydrocoll. 2020, 108, 105992. [Google Scholar] [CrossRef]

- Lopez-Mendez, T.B.; Santos-Vizcaino, E.; Pedraz, J.L.; Orive, G.; Hernandez, R.M. Cell microencapsulation technologies for sustained drug delivery: Latest advances in efficacy and biosafety. J. Control. Release 2021, 335, 619–636. [Google Scholar] [CrossRef]

- Kontturi, L.S.; Yliperttula, M.; Toivanen, P.; Maatta, A.; Maatta, A.M.; Urtti, A. A laboratory-scale device for the straightforward production of uniform, small sized cell microcapsules with long-term cell viability. J. Control. Release 2011, 152, 376–381. [Google Scholar] [CrossRef]

- Teramura, Y.; Iwata, H. Bioartificial pancreas: Microencapsulation and conformal coating of islet of Langerhans. Adv. Drug Deliv. Rev. 2010, 62, 827–840. [Google Scholar] [CrossRef]

- Manzoli, V.; Villa, C.; Bayer, A.L.; Morales, L.C.; Molano, R.D.; Torrente, Y.; Tomei, A.A. Immunoisolation of murine islet allografts in vascularized sites through conformal coating with polyethylene glycol. Am. J. Transplant. 2018, 18, 590–603. [Google Scholar] [CrossRef]

- Zhi, Z.L.; Kerby, A.; King, A.J.F.; Jones, P.M.; Pickup, J.C. Nano-scale encapsulation enhances allograft survival and function of islets transplanted in a mouse model of diabetes. Diabetologia 2012, 55, 1081–1090. [Google Scholar] [CrossRef]

- Pham-Hua, D.; Padgett, L.E.; Xue, B.; Anderson, B.; Zeiger, M.; Barra, J.M.; Hubert, M.T. Islet encapsulation with polyphenol coatings decreases pro-inflammatory chemokine synthesis and T cell trafficking. Biomaterials 2017, 128, 19–32. [Google Scholar] [CrossRef]

- Haque, M.R.; Kim, J.; Park, H.; Lee, H.S.; Lee, K.W.; Al-Hilal, T.A.; Byun, Y. Xenotransplantation of layer-by-layer encapsulated non-human primate islets with a specified immunosuppressive drug protocol. J. Control. Release 2017, 258, 10–21. [Google Scholar] [CrossRef]

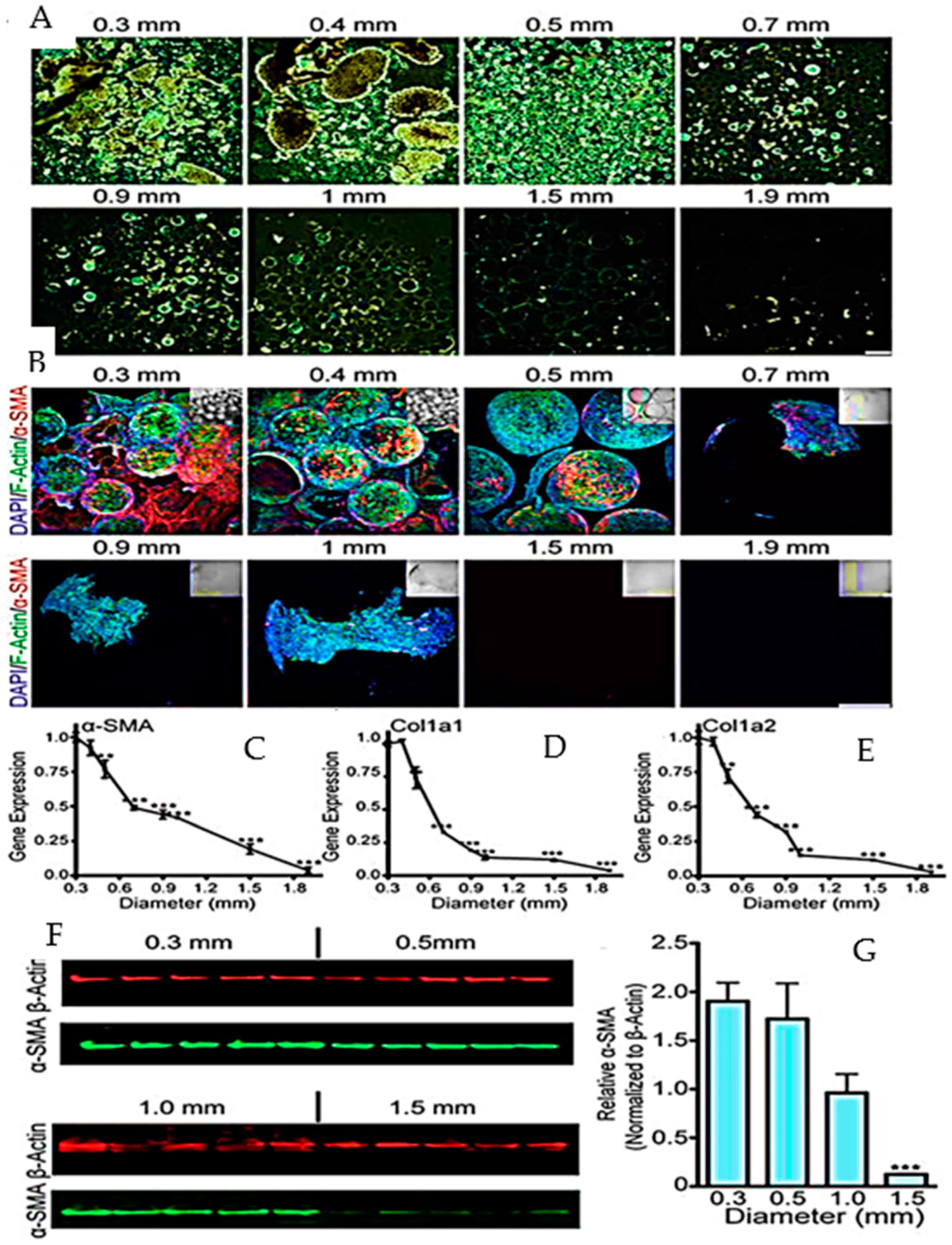

- Veiseh, O.; Doloff, J.C.; Ma, M.; Vegas, A.J.; Tam, H.H.; Bader, A.R.; Anderson, D.G. Size- and shape-dependent foreign body immune response to materials implanted in rodents and non-human primates. Nat. Mater. 2015, 14, 643–651. [Google Scholar] [CrossRef]

- Rahmani, F.; Atabaki, R.; Behrouzi, S.; Mohamadpour, F.; Kamali, H. The recent advancement in the PLGA-based thermo-sensitive hydrogel for smart drug delivery. Int. J. Pharm. 2023, 631, 122484. [Google Scholar] [CrossRef]

- Heidarian, P.; Kaynak, A.; Paulino, M.; Zolfagharian, A.; Varley, R.J.; Kouzani, A.Z. Dynamic nanocellulose hydrogels: Recent advancements and future outlook. Carbohydr. Polym. 2021, 270, 118357. [Google Scholar] [CrossRef]

- Idumah, C.I. Emerging advancements in xerogel polymeric bionanoarchitectures and applications. JCIS Open 2023, 9, 100073. [Google Scholar] [CrossRef]

- Sindhu, R.K.; Gupta, R.; Wadhera, G.; Kumar, P. Modern herbal nanogels: Formulation, delivery methods, and applications. Gels 2022, 8, 97. [Google Scholar] [CrossRef]

- Shaban, S.M.; Kang, J.; Kim, D.H. Surfactants: Recent advances and their applications. Comp. Commun. 2020, 22, 100537. [Google Scholar] [CrossRef]

- Abdulla, N.A.; Balata, G.F.; El-Ghamry, H.A.; Gomaa, E. Intranasal delivery of Clozapine using nanoemulsion-based in-situ gels: An approach for bioavailability enhancement. Saudi Pharm. J. 2021, 29, 1466–1485. [Google Scholar] [CrossRef]

- Soliman, O.A.; Mohamed, E.A.; Khatera, N.A. Enhanced ocular bioavailability of fluconazole from niosomal gels and microemulsions: Formulation, optimization, and in vitro–in vivo evaluation. Pharm. Dev. Technol. 2019, 24, 48–62. [Google Scholar] [CrossRef]

- Mo, C.; Luo, R.; Chen, Y. Advances in the Stimuli-Responsive Injectable Hydrogel for Controlled Release of Drugs. Macromol. Rapid Commun. 2022, 43, 2200007. [Google Scholar] [CrossRef]

- Panja, S.; Adams, D.J. Stimuli responsive dynamic transformations in supramolecular gels. Chem. Soc. Rev. 2021, 50, 5165–5200. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, H.; Wang, Y.; Zhang, Z.; Wang, Q. Preparation, characterization and release kinetics of a multilayer encapsulated Perilla frutescens L. essential oil hydrogel bead. Int. J. Biol. Macromol. 2023, 249, 124776. [Google Scholar] [CrossRef]

- Deng, X.; Chen, J.; Chen, W. Hydrogel particles as a controlled release delivery system for lavender essential oil using pH triggers. Colloids Surf. A Physicochem. Eng. Asp. 2020, 603, 125134. [Google Scholar] [CrossRef]

- Kwan, A.; Davidov-Pardo, G. Controlled release of flavor oil nanoemulsions encapsulated in filled soluble hydrogels. Food Chem. 2018, 250, 46–53. [Google Scholar] [CrossRef]

- Saidi, M.; Dabbaghi, A.; Rahmani, S. Swelling and drug delivery kinetics of click-synthesized hydrogels based on various combinations of PEG and star-shaped PCL: Influence of network parameters on swelling and release behavior. Polym. Bull. 2020, 77, 3989–4010. [Google Scholar] [CrossRef]

- Ali, A.; Hussain, M.A.; Haseeb, M.T.; Bukhari, S.N.A.; Tabassum, T.; Farid-ul-Haq, M.; Sheikh, F.A. A pH-responsive, biocompatible, and non-toxic citric acid cross-linked polysaccharide-based hydrogel from Salvia spinosa L. offering zero-order drug release. J. Drug Deliv. Sci. Technol. 2022, 69, 103144. [Google Scholar] [CrossRef]

- Jeong, H.S.; Kim, E.; Nam, C.; Choi, Y.; Lee, Y.J.; Weitz, D.A.; Choi, C.H. Hydrogel microcapsules with a thin oil layer: Smart triggered release via diverse stimuli. Adv. Funct. Mater. 2021, 31, 2009553. [Google Scholar] [CrossRef]

- Lee, P.I.; Kim, C.J. Probing the mechanisms of drug release from hydrogels. J. Control. Release 1991, 16, 229–236. [Google Scholar] [CrossRef]

- Setapa, A.; Ahmad, N.; Mohd Mahali, S.; Mohd Amin, M.C.I. Mathematical model for estimating parameters of swelling drug delivery devices in a two-phase release. Polymer 2020, 12, 2921. [Google Scholar] [CrossRef]

- Wu, J.; Xu, S.; Han, C.C.; Yuan, G. Controlled drug release: On the evolution of physically entrapped drug inside the electrospun poly (lactic-co-glycolic acid) matrix. J. Control. Release 2021, 331, 472–479. [Google Scholar] [CrossRef]

- Chavan, Y.R.; Tambe, S.M.; Jain, D.D.; Khairnar, S.V.; Amin, P.D. Redefining the importance of polylactide-co-glycolide acid (PLGA) in drug delivery. In Annales Pharmaceutiques Françaises; Elsevier Masson: Issy-les-Moulineaux, France, 2022; Volume 80, pp. 603–616. [Google Scholar]

- Ignacio, M.; Slater, G.W. Using fitting functions to estimate the diffusion coefficient of drug molecules in diffusion-controlled release systems. Phys. A Stat. Mech. 2021, 567, 125681. [Google Scholar] [CrossRef]

- Caccavo, D.; Cascone, S.; Lamberti, G.; Barba, A.A. Modeling the drug release from hydrogel-based matrices. Mol. Pharm. 2015, 12, 474–483. [Google Scholar] [CrossRef]

- Miere, F.; Vicas, S.I.; Timar, A.V.; Ganea, M.; Zdrinca, M.; Cavalu, S.; Fritea, L.; Vicas, L.; Muresan, M.; Pallag, A.; et al. Preparation and characterization of two different liposomal formulations with bioactive natural extract for multiple applications. Processes 2021, 9, 432. [Google Scholar] [CrossRef]

- Tan, C.; Wang, J.; Sun, B. Biopolymer-liposome hybrid systems for controlled delivery of bioactive compounds: Recent advances. Biotech. Adv. 2021, 48, 107727. [Google Scholar] [CrossRef]

- Sharma, S.; Mulrey, L.; Byrne, M.; Jaiswal, A.K.; Jaiswal, S. Encapsulation of essential oils in nanocarriers for active food packaging. Foods 2022, 11, 2337. [Google Scholar] [CrossRef]

- Priyadarshini, B.M.; Antipina, M.N.; Fawzy, A.S. Formulation and characterisation of poly (lactic-co-glycolic acid) encapsulated clove oil nanoparticles for dental applications. IET Nanobiotechnol. 2018, 12, 311–317. [Google Scholar] [CrossRef]

- Martins, I.M.; Barreiro, M.F.; Coelho, M.; Rodrigues, A.E. Microencapsulation of essential oils with biodegradable polymeric carriers for cosmetic applications. Chem. Eng. J. 2014, 245, 191–200. [Google Scholar] [CrossRef]

- Hamed, S.F.; Hashim, A.F.; Hamid, H.A.A.; Abd-Elsalam, K.A.; Golonka, I.; Musiał, W.; El-Sherbiny, I.M. Edible alginate/chitosan-based nanocomposite microspheres as delivery vehicles of omega-3 rich oils. Carbohydr. Polym. 2020, 239, 116201. [Google Scholar] [CrossRef]

- Leong, M.H.; Tan, C.P.; Nyam, K.L. Effects of accelerated storage on the quality of kenaf seed oil in chitosan-coated high methoxyl pectin-alginate microcapsules. J. Food Sci. 2016, 81, C2367–C2372. [Google Scholar] [CrossRef]

- Naik, J.B.; Pardeshi, S.R.; Patil, R.P.; Patil, P.B.; Mujumdar, A. Mucoadhesive micro-/nano carriers in ophthalmic drug delivery: An overview. BioNanoScience 2020, 10, 564–582. [Google Scholar] [CrossRef]

- Luo, L.J.; Nguyen, D.D.; Lai, J.Y. Long-acting mucoadhesive thermogels for improving topical treatments of dry eye disease. Mater. Sci. Eng. C 2020, 115, 111095. [Google Scholar] [CrossRef]

- Desai, J.; Patel, R.; Desai, D. Investigation on Potential of Karanjin Loaded Emulgel for Improved Efficacy against Psoriasis. Ind. J. Pharm. Educ. Res. 2023, 57, 393–400. [Google Scholar] [CrossRef]

- Salem, M.A.; Manaa, E.G.; Osama, N. Coriander (Coriandrum sativum L.) essential oil and oil-loaded nano-formulations as an anti-aging potentiality via TGFβ/SMAD pathway. Sci. Rep. 2022, 12, 6578. [Google Scholar] [CrossRef]

- Shukr, M.; Metwally, G.F. Evaluation of topical gel bases formulated with various essential oils for antibacterial activity against methicillin-resistant Staphylococcus aureus. Trop. J. Pharm. Res. 2013, 12, 877–884. [Google Scholar] [CrossRef]

- Dutt, J.; Ganatra, B.; Suthar, N.; Malek, M.; Shukla, B.; Shukla, K.; Bhalani, M. A randomized and comparative study to assess safety and efficacy of supplemental treatment of a herbal formulation-Aayudh Advance comprising essential oils in patients with corona virus 2019 (COVID-19). Contemp. Clin. Trials Commun. 2021, 22, 100755. [Google Scholar] [CrossRef] [PubMed]

- Mali, G.V.; Dodamani, A.S.; Karibasappa, G.N.; Vishwakarma, P.; Jain, V.M. Comparative evaluation of arimedadi oil with 0.2% chlorhexidine gluconate in prevention of plaque and gingivitis: A randomized clinical trial. J. Clin. Diagn. Res. 2016, 10, ZC31. [Google Scholar] [CrossRef]

- Lis-Balchin, M.; Deans, S.G.; Eaglesham, E. Relationship between bioactivity and chemical composition of commercial essential oils. Flavour. Fragr. J. 1998, 13, 98–104. [Google Scholar] [CrossRef]

- Oliveira, T.S.; de Lima Silva, V.; Assuncao, L.S.; de Jesus Freitas, T.; Machado, B.A.; Otero, D.M.; Druzian, J.I. A patent data analysis in nanotechnology applied to essential oils. Recent Patents Nanotechnol. 2022, 16, 92–106. [Google Scholar] [CrossRef]

- Jadhav, C.A.; Vikhe, D.N.; Jadhav, R.S. Global and domestic market of herbal medicines: A review. Res. J. Sci. Technol. 2020, 12, 327–330. [Google Scholar] [CrossRef]

- Zhang, B.; Pei, W.; Cai, P.; Wang, Z.; Qi, F. Recent advances in Chinese patent medicines entering the international market. Drug Discov. Ther. 2022, 16, 258–272. [Google Scholar] [CrossRef]

- de Lima Silva, V.; Oliveira, T.S.; de Souza, C.O.; Druzian, J.I.; Machado, B.A.S.; Nunes, I.L.; Ribeiro, C.D.F. Technological Prospection of Oil Nanoparticles: Primary Characteristics and Profiles. Recent Patents Nanotechnol. 2020, 14, 2–14. [Google Scholar] [CrossRef]

- Isman, M.B.; Machial, C.M. Pesticides based on plant essential oils: From traditional practice to commercialization. Adv. Phytomed. 2006, 3, 29–44. [Google Scholar] [CrossRef]

- Barkat, M.A.; Goyal, A.; Barkat, H.A.; Salauddin, M.; Pottoo, F.H.; Anwer, E.T. Herbal medicine: Clinical perspective and regulatory status. Comb. Chem. High Throughput Screen. 2021, 24, 1573–1582. [Google Scholar] [CrossRef]

- Katiyar, C.K.; Dubey, S.K. Opportunities and challenges for Ayurvedic industry. Int. J. Ayurveda Res. 2023, 4, 123–131. [Google Scholar] [CrossRef]

- Rahul, M.; Thirupataiah, B.; Lakshminarayana, M.; Thulasi, R.; Rohit, K. Different aspects of quality control in the standardization of Ayurvedic formulation. In Recent Trends in Medical Pharmaceutical; Hegazi, A.G., Ed.; Innovat Publisher: Indore, India, 2022; Volume 1, pp. 106–120. [Google Scholar]

- Islam, N. Indigenous medicine as commodity: Local reach of Ayurveda in modern India. Curr. Sociol. 2010, 58, 777–798. [Google Scholar] [CrossRef]

- Fitzgerald, M.; Heinrich, M.; Booker, A. Medicinal plant analysis: A historical and regional discussion of emergent complex techniques. Front. Pharmacol. 2020, 10, 1480. [Google Scholar] [CrossRef]

- Sen, S.; Chakraborty, R. Toward the integration and advancement of herbal medicine: A focus on traditional Indian medicine. Bot. Targets Therap. 2015, 5, 33–44. [Google Scholar] [CrossRef]

- Yuan, H.; Ma, Q.; Ye, L.; Piao, G. The traditional medicine and modern medicine from natural products. Molecules 2016, 21, 559. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://iprsearch.ipindia.gov.in/PatentSearch/PatentSearch/ViewApplicationStatus (accessed on 17 February 2024).

- Pralhad, S.S.; Trinette, F. Herbal in Situ-Gel Implant Comprising Thyme Oil. WIPO 201821031701, 24 August 2018. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=IN289359415&_cid=P21-LSPXP4-20784-1 (accessed on 17 February 2024).

- Datt, R.; Kumar, R.; Pandey, S.; Shrivastava, P. Multifunctional Formulation Composed of Natural Ingredients and Its Preparation/Manufacturing Method. ES2885052T3, 13 December 2021. Available online: https://patents.google.com/patent/ES2885052T3/en (accessed on 17 February 2024).

- Song, Y.; Luo, Y.; Yuan, X.; Liu, Y.; Zhou, X.; Zhang, L. Mosquito Repelling Gel Composition with Natural Plant Essential Oil. CN103262839B, 3 December 2014. Available online: https://patents.google.com/patent/CN103262839B/en (accessed on 17 February 2024).

- Hoa, G.E. Topical Analgesic Pain Relief Formulations, Manufacture and Methods of Use Thereof. US20180311184A1, 1 November 2018. Available online: https://patents.google.com/patent/US20180311184A1/en (accessed on 17 February 2024).

- Markus, A.; Strongin, P.; Linder, C. Applications of Microencapsulated Essential Oils. US9717240B2, 1 August 2017. Available online: https://patents.google.com/patent/US9717240B2/en (accessed on 17 February 2024).

- Modak, S.M.; Baiju, N.; Caraos, L.A. Skin and Surface Disinfectant Compositions Containing Botanicals. US10542760B2, 28 January 2020. Available online: https://patents.google.com/patent/US10542760B2/en (accessed on 17 February 2024).

| Ayurvedic Oil | Composition | Application | Ref. |

|---|---|---|---|

| Arimedadi oil | Rubia cordifolia, Acacia catechu, Sesamum inidicum, Syzygium aromaticum | Anti-microbial | [18] |

| Mahanarayan oil | Clerodendrum phlomidis Linn F, Eclipta alba Hassk, Aegle marmelos Corr, Cedrus deodara (Roxb) Loud, Solanum xanthocarpum Schrad and Wendle, Saussurea lappa C B Clarke, Rubia cordifolia Linn, Teramnus labialis Spreng, Phaseolus trilobus Ait, Cyperus rotundus Linn, Mesua ferrea Linn, Erythrina indica Lam, Stereospermum suaveolens DC, Trianthema portulacastrum Linn, Inula racemosa Hook f, Pluchea lanceolata Oliver and Hierm, Parmelia perlata (Huds) Ach, Desmodium gangeticum DC, Oroxylum indicum Vent, Glycyrrhiza glabra Linn | Anti-inflammatory | [19] |

| Ksheerabala oil | Go-Ksheera (cow milk), Sida cordifolia and Tila Taila | Neurological, heart disease, anti-inflammatory, and hepato-protective activity | [20] |

| Triphala | Terminalia bellirica, Terminalia chebula and Emblica officinalis | Immunomodulator | [21] |

| Murivenna oil | Pongamia pinnata, Aloe vera, Piper betel, Moringa oleifera, Erythrina indica, Allium cepa, Spermacoce hispida, Asparagus racemosus, Cocos nucifera, and Oryza sativa | Anti-inflammatory | [22] |

| Bhringamalakadikera oil | Eclipta alba, Emblica officinalis, Glycyrrhiza glabra, Cow milk | Hair loss, baldness, graying of hairs | |

| Amruthotharam kashayam | Zingiber officinalis, Tinospora cordifolia, Terminalia chebula | Anti-inflammatory, metabolic disorders | [23] |

| Punarnavadi kashayam | Boerhavia diffusa, Zingiber officinale, Cidrus deodara, Commiphora mukul | Hypothyroidism | [24] |

| Gugguluthikthaka kashyam | Adhatoda vasica, Azadirachta indica, Acorus calamus, Aconitum heterophyllum, Alpinia calcarata, Anetham graveolens, Commiphora mukul, Celastrus paniculatus, Cedrus deodara, Cuminum cyminum, Cyprus rotundus, Curcuma longa, Cyclea peltata Embelia ribes, Holarrhena antidysenterica, Piper longum Piper nigrum, Piper brachystachyum, Picrorhiza kurroa, Plumbago zeylanica, Solanum indicum, Rubia cordifolia, Saussura lappa, Scindapsus officinale, Tinospora cordifolia, Trichosanthes dioica Trachyspermum roxburghianum, Zingiber officinale, Semecarpus anacardium | Anti-inflammatory | [25] |

| Yogaraja guggulu | Piper longum, Trachyspermum ammi, Carum carvi, Embelia ribes, Apium leptophyllum, Cuminum cyminum, Cedrus deodara, Piper chaba, Elettaria cardamomum, Saindhava lavana, Saussurea lappa, Pluchea lanceolata, Tribulus terrestris, Coriandrum sativum, Terminalia chebula, Terminalia bellirica, Emblica officinalis, Cyperus rotundus, Zingiber officinale, Piper nigrum, Piper longum, Cinnamomum zeylancium, Vetiveria zizanoides, Hordeum vulgare, Taxus wallichii, Cinnamomum tamala, Commiphora wightii | Neurological, musculoskeletal disorders | [26] |

| Lakshadi guggulu | Cissus quadrangularis, Withania somnifera, Azadirachta indica, Sida alba, and Terminalia arjuna. C. quadrangularis | Anti-fungal, anti-bacterial, anti-oxidant, analgesic and anti-inflammatory | [27] |

| Carrier | Material Used in Gel Formulation | Method of Preparation | Therapeutic Agent | Characterization | Application | Ref. |

|---|---|---|---|---|---|---|

| Nanoethosome gel | Ethosome- Lipid (1–3%) Ethanol (20–40%) Propylene glycol (20%) Extract (2%) Gel- Carbopol 940 Triethanolamines Nanoethosomes | Ethosome- Cold method followed by sonication Gel- Stirring method | Achillea millefolium L. (AM) hydroalcoholic extract | Ethosome- EE: 90 ± 0.74% Size: 240 nm PDI: 0.24 ± 0.017 Zeta: −31.1 mV Gel- pH: 5.5–6.1 Dp: 79.8% Viscosity: 4520–4760 cP | Anti-aging | [36] |

| Microemulsion gel | Microemulsion- Tween 80 Isopropyl alcohol Clove oil Water Gel- Carbopol 934 Microemulsion Glycerene | Microemulsion- Phase titration method Gel- Stirring method | Clove (Syzygium aromaticum) oil | Microemulsion- Size: 14.41 nm PDI: 0.0113 Zeta: 0.73 mV Gel- pH: 6.27 DR: 98.5 ± 0.35% Viscosity: 12.87 m·pas/s | Anti-fungal | [37] |

| Gel | Gel-Carbopol 940, Sodium carboxymethylcellulose | Gel- Stirring method | Mentha longifolia essential oil | Pseudo-plastic shear-thinning behavior Inhibitory activity against: Candida albicans (ATCC90028 and MTCC277) | Candidiasis | [38] |

| Cream | Oil phase- Liquid paraffin (5.0 mL) Stearic acid (4.8 g) Coconut oil (3.0 mL) The aqueous phase- Triethanolamine (1.5 mL) Glycerin (5.0 mL) Citric acid (0.4 g) Methylparaben (0.1 g) Water Aloe vera gel (2–8 mL) | Mixing | Aloe vera, tomato powder | pH: 7.3–7.6 Spreadability: 9–13 Acid values: 5.6–7.2 | Skin nourishment | [39] |

| Oleogel | Aerosil, paraffin, and olive oil | Stirring method | Thyme (Thymus vulgaris) essential oil | DL: 0.1% w/w MIC: Candida albicans (ATCC 60193) 0.01 to 0.3% | Anti-fungal | [40] |

| Niosome gel | Neosome- Non-ionic surfactants and cholesterol Gel- Mucilage of Lallemantia royaleana Benth and carbopol | Niosome– Ether injection method Gel- Stirring method | Ibuprofen, Lallemantia royaleana Benth | Neosome- Size: 3.2 ± 0.75 µm EE: 46 ± 1.0% DR: 45.5 ± 1.2 % Yield: 75.0 ± 0.87 Zeta: −66.32 mV Gel- Q: 1.548 ± 1.09 mg cm−2 Jss: 8.256 ± 1.15 mg cm−2 h−1 Log Kp: 0.433 ± 0.76 Edema inhibition: 18.66% | Anti-inflammatory | [41] |

| Neosome gel | Niosome- Span and cholesterol Gel- Carbopol 940 | Niosome- Reverse-phase evaporation technique Gel- Stirring method | Rosmarinic acid | Niosome- EE: 65% ± 3.99. DR: 70% in 12 h Gel- pH: 6.4 ± 0.159 Content uniformity: 90% Spreadability: 19.6 ± 1.118 g cm/s DR: 49.81 ± 1.76% MIC: 31.25 µg/mL S. aureus (MTCC 96), 31.25 µg/mL Propionobacterium acne (MTCC 1951) | Anti-bacterial | [42] |

| Hydrogel | Chitosan | Ionic gelation method | Eugenol oil | Graft yield (wt %): 21.7 ± 1.0% pH: 3–9 | Anti-oxidant | [43] |

| Hydrogel | Calcium alginate, and CaCl2 | Emulsion fabrication methods | Cumin (Cuminum cyminum L.) seeds essential oil | DR: 96.02 ± 0.96% (SGF) and 10.65 ± 1.23% (SIF) | Anti-fungal, anti-bacterial and anti-oxidant | [44] |

| Starch hydrogels | Carbopol and starch | Mixing | Patchouli (Pogostemon cablin Benth.) essential oil | Viscosity: 15.016 ± 59 cP Spreadability: 4.02 ± 0.34 g·cm/s pH: 6.81 to 7.23. | Anti-microbial, anti-inflammatory and anti-cancer | [45] |

| Nanoemulsion hydrogel | Alginate and CaCl2 | Mixing | Cinnamon (Cinnamomum verum) essential oil | Size: 146.20 ± 39.28 nm Zeta: −33.8 ± 0.72 mV | Anti-microbial | [46] |

| Hydrogel membranes | Esterification of polyvinyl alcohol (PVA) with starch and glutaraldehyde | Esterification | Essential oils of clove oil (Syzygium aromaticum), Oregano oil (Origanum vulgare), and tea tree (Melaleuca alternifolia) oil | ZOI: 39 ± 0.57 mm (MRSA) and 37 ± 0.29 mm (E. coli). Ts: 19.36 MPa WVTR: 36.22 g/m2h MRC: 95.50% | Anti-bacterial | [47] |

| Liposomal gel | Liposome- Soya lecithin and cholesterol (1:1) Gel- Hydroxyethylcellulose | Liposome- Freeze–thaw method stirring Gel- Stirring method | Eucalyptus camaldulensis essential oil | EE: 95 ± 0.57% MIV: 0.125 mL Size: 157.66 ± 0.57 nm | Anti-fungal | [48] |

| Liposome | Liposome- Soya phosphatidylcholine and cholesterol Gel- Hydroxyethylcellulose | Liposome- Film method and sonication Gel- Stirring method | Santolina insularis essential oil | EE: 80.00 ± 0.55 Size: 63 ± 12 nm | Anti-viral | [49] |

| Nanoliposome gel | Liposome- Soya lecithin, phytosterol, and α-tocopherol Gel- Xanthan gum | Liposome- Sonication, homogenization Gel- Stirring method | Eucalyptus (Eucalyptus globulus), tea tree (Melaleuca alternifolia) oil, clove (Syzygium aromaticum) oil, and coconut (Cocos nucifera L.) oil | Liposome- Size: 50–115 nm Zeta: −34 to −43 mV PDI: 0.190 ± 0.027 EE: 95% Gel- pH: 5.5–6.0 MIC: 15 (E. coli), 15.5 (B. subtilis) | Anti-microbial | [50] |

| Liposomal gel | Liposome- Soya lecithin, phytosterol, and α-tocopherol Gel- Carbopol | Tretinoin (TRE) and zedoary turmeric oil (ZTO) | Liposome- Size: 257.41 ± 7.58 nm Zeta: −38.77 ± 0.81 mV PDI: 0.10 ± 0.04 EE: % 64.63 ± 1.00 (ZTO), 90.33 ± 0.72 (TRE) DL: % 9.09 ± 0.14 (ZTO), 1.43 ± 0.02 (TRE) Gel- Skin permeation: 11.9533 ± 1.3934 μg/cm2 (ZTO) and 6.7033 ± 1.3803 μg/cm2 (TRE) reduction in vaginal epithelial mitotic activity | Psoriasis | [51] | |

| Nano-transferosome in situ gel | Transferosome- Soya lecithin and Tween 80 Gel- Deacetylated gellan gum | Transferosome- Thin-layer evaporation technique Gel- Stirring method | Voriconazole-Clove (Syzygium aromaticum) oil | Transferosome- Size: 102.96 nm Zeta: −38.77 ± 0.81 mV PDI: 0.10 ± 0.04 EE: % 71.70 DL: % 9.09 ± 0.14, 1.43 ± 0.02 Gel- ZOI: 21.76 mm DR: 82.5% Dp: 5.4-fold increase | Anti-fungal | [52] |

| Transferosomal gel | Transferosome- Soya lecithin and cholesterol | Transferosome- Thin-layer evaporation technique Gel- Stirring method | Thyme (Thymus vulgaris) Oil and fluconazole (FO) | Transferosome- Size: 76.37 nm Zeta: −20.3 mV PDI: 0.233 EE: 52.38 ± 1.76% DL: % 9.09 ± 0.14, 1.43 ± 0.02 Gel- permeation flux: 4.101 μg/cm2/h Activity increases: 1.67-fold against Candida albicans compared to FO | Anti-fungal | [53] |

| Niosomal gel | Niosome- Cholesterol and surfactant, Gel- Carbopol | Niosome- Thin-film hydration technology Gel- Stirring method | Carvacrol oil | Niosome- Size: 180.23 nm Zeta: −31.70 mV PDI: 0.265 EE: 90.61% DR: 70.24 ± 1.21% Gel- Skin penetration: 25.0 µm | Anti-inflammation | [54] |

| Microgel | Chitosan and cinnamic acid | Ionic gelation | Gaultheria procumbens essential oil | EE: 65–70% DL: 30–35% DR: 26.66–88.33% 200 ppm inhibits: 17.85% aflatoxin B1 synthesis | Anti-microbial | [55] |

| Gelling Agent | Source | Binding Blocks | Pharmaceutical Application | Other Uses | Ref. |

|---|---|---|---|---|---|

| Pectin | Plant cell walls and fruits, e.g., apple, guava, and citrus fruit | (1 → 4)-α-D-galacturonic acid and natural sugar | Pectin-inorganic composite, pectin-organic polymer composite, and pectin-based hybrid materials (obtained by grafting reaction) for drug delivery | Food, agriculture, medicines, and biomedicine | [72] |

| Cellulose | -Wood pulp (cellulose nanocrystals and nanofibrils) Acetobacter xylinum (bacterial cellulose) | Homopolymer of D-glucose β-(1, 4) | Methylcellulose (MC), carboxymethylcellulose (CMC), ethyl cellulose (EC), hydroxyethyl cellulose (HEC), hydroxypropyl cellulose (HPC), and hydroxypropyl methylcellulose (HPMC) used as an excipient in different dosage forms | Biofilm, packaging, Implant, filtration, and composite | [73] |

| Agar | Gelatinous polysaccharides in the cell wall of many red algal species | Agarose (D-galactose and 3,6-anhydrous-L-galactose) and agaropectin (D- and L-galactose) | Hydrophobic modified agar for encapsulation and release of curcumin Agarose bioplastic for surgical and wound dressings Glutaric anhydride-modified agar for super-absorbent | Gelling, thickening, and stabilizing agent | [74,75,76,77] |

| Guar gum | Water-soluble polysaccharide derived from the seeds of Cyamopsis tetragonolobus, family Leguminosae | (1 → 4)-β-d-mannopyranosyl units with α-d-galactopyranosyl units attached by (1 → 6) linkages | Poly(acrylamide)-graft-guar gum for pH-sensitive microgel Hydrolyzed poly(acrylamide)-graft-GG for intestinal drug delivery | Film-forming and controlled drug-release abilities | [78] |

| Carrageenan (CG) | Red seaweeds of the Rhodophyceae class | Sulfated linear polysaccharide of D-galactose and 3, 6-anhydrous-d-galactose | Gelcarin® GP-379 (τ-CG) and Viscarin® GP-209 (λ-CG) for control drug delivery | Stabilizer in micro/nanoparticles systems and gelling agent | [79] |

| Carob gum or locust bean gum | Endosperm of the seeds of Ceratonia siliqua Linn. | Galactomannan (galactose and mannose) | Sodium carboxymethyl ether of locust bean gum for control drug release Acrylamide-grafted locust bean gum for controlled-release matrix tablet | Preparation of implants, films, beads, viscous liquid and gel formulations | [80,81,82] |

| Xanthan gum | Produced mainly by the bacterium Xanthomonas campestris | d-mannose (β-1,4), d-glucuronic acid (β-1,2) and d-mannose | Starch–xanthan gum for drug delivery Xanthan gum-based graft copolymers for water treatment and drug delivery | Emulsion stabilizer, texture modifiers, | [83,84] |

| Alginate | Brown marine algae, Pseudomonas sp. and Azotobacter sp. | Linear copolymeric blocks of l-guluronic acid and d-mannuronic acid residues. | Starch-modified alginate for drug delivery Sodium alginate for designing of nanocarrier | Stabilizer, thickening agent and emulsifying agent. | [85,86,87] |

| Gum Arabic | Acacia nilotica | Combination of saccharides and glycoproteins | pH-responsive matrix for colon-specific drug delivery Multi-aldehyde gum Arabic for anti-cancer drug delivery | Hard gummies, chocolates, and gums | [88,89,90] |

| Chitosan | Exoskeleton of crustacea, insect cuticles, algae and in the cell wall of fungi | N-acetyl D-glucosamine and 2-amino 2-deoxy-β-d-glucopyranose | Mannosylated chitosan for peptide delivery Trimethyl chitosan for fungal drug delivery | Water treatment, food processing, pharmaceutical/biomedicine, textiles and agriculture | [91,92,93,94] |

| S. No | Patent/Application No. | Country | Title | Ref. |

|---|---|---|---|---|

| 1 | 487445 | India | Herbal gel formulation from the extract of curcumin and annona muricata linn and the manufacturing method | [168] |

| 2 | 435835 | India | An in situ gel formulation comprising carica papaya extracts for use in treatment of chronic periodontitis and method of synthesizing the same | |

| 3 | 440711 | India | A system and process for synthesizing oil-based liposomal gel for vitiligo and its composition | |

| 4 | 438991 | India | Liposomal gel formulation comprising 5-fluorouracil and clove oil for the treatment of skin cancer and method of preparation | |

| 5 | 508000 | India | Microemulgel composition comprising clove oil for the treatment of fungal infection and method of preparation | |

| 6 | 492666 | India | Formulation and evaluation of nano-emulgel containing moringa oleifera seed oil for wound healing | |

| 7 | 445175 | India | Pharmaceutical composition with synergistic combination of thymus serphyllum essential oil and antibiotic | |

| 8 | 471183 | India | Formulation comprising ozonized oil in the treatment of a tumor | |

| 9 | 505804 | India | Tretradydrocurcumin niosomal in situ gel for ocular drug delivery | |

| 10 | 424456 | India | Pharmaceutical composition of thymoquinone and essential oil particulate emulsified systems | |

| 11 | 201821031701 | India | Herbal in situ gel implant comprising thyme oil | [169] |

| 12 | 202311051599 | India | A topical lumpy skin disease (lsd) wound-healing herbal gel and preparation method | |

| 13 | 202141025017 | India | Herbal gel for treatment of acne | |

| 14 | 202221059726 | India | Herbal gel formulation for acne treatment and preparation method | |

| 15 | 202111003298 | India | Herbal nanoemulsion gel and a process for the preparation | |

| 16 | ES2885052T3 | Spain | Multifunctional formulation composed of natural ingredients and its preparation/manufacturing method | [170] |

| 17 | CN103262839B | China | Mosquito-repelling gel composition with natural plant essential oil | [171] |

| 18 | US20180311184A1 | US | Topical analgesic pain relief formulations, manufacture and use | [172] |

| 19 | US9717240B2 | US | Applications of microencapsulated essential oils | [173] |

| 20 | US10542760B2 | US | Skin and surface disinfectant compositions containing botanicals | [174] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maurya, R.; Misro, L.; Boini, T.; Radhakrishnan, T.; Nair, P.G.; Gaidhani, S.N.; Jain, A. Transforming Medicinal Oil into Advanced Gel: An Update on Advancements. Gels 2024, 10, 342. https://doi.org/10.3390/gels10050342

Maurya R, Misro L, Boini T, Radhakrishnan T, Nair PG, Gaidhani SN, Jain A. Transforming Medicinal Oil into Advanced Gel: An Update on Advancements. Gels. 2024; 10(5):342. https://doi.org/10.3390/gels10050342

Chicago/Turabian StyleMaurya, Rahul, Lakshminarayana Misro, Thirupataiah Boini, Thulasi Radhakrishnan, Parvathy G. Nair, Sudesh N. Gaidhani, and Ankit Jain. 2024. "Transforming Medicinal Oil into Advanced Gel: An Update on Advancements" Gels 10, no. 5: 342. https://doi.org/10.3390/gels10050342