Flip Chip Bonding of a Quartz MEMS-Based Vibrating Beam Accelerometer

Abstract

:1. Introduction

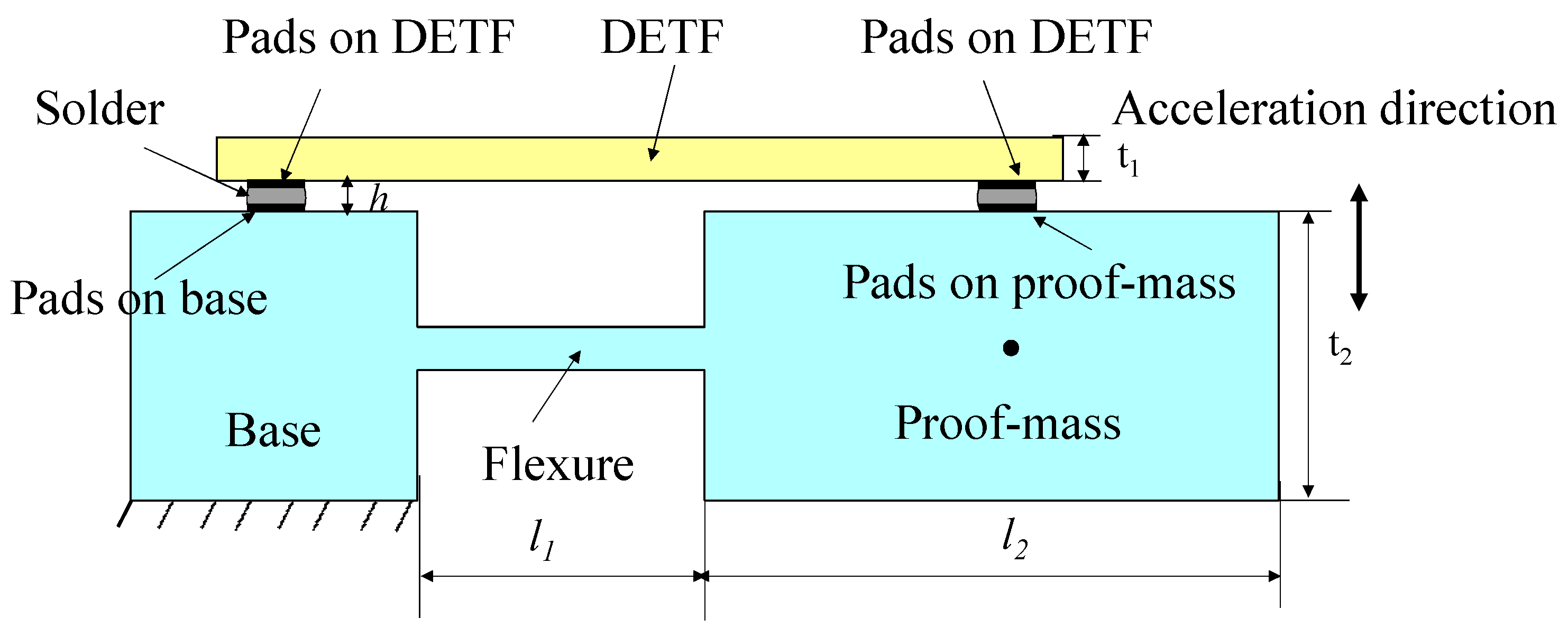

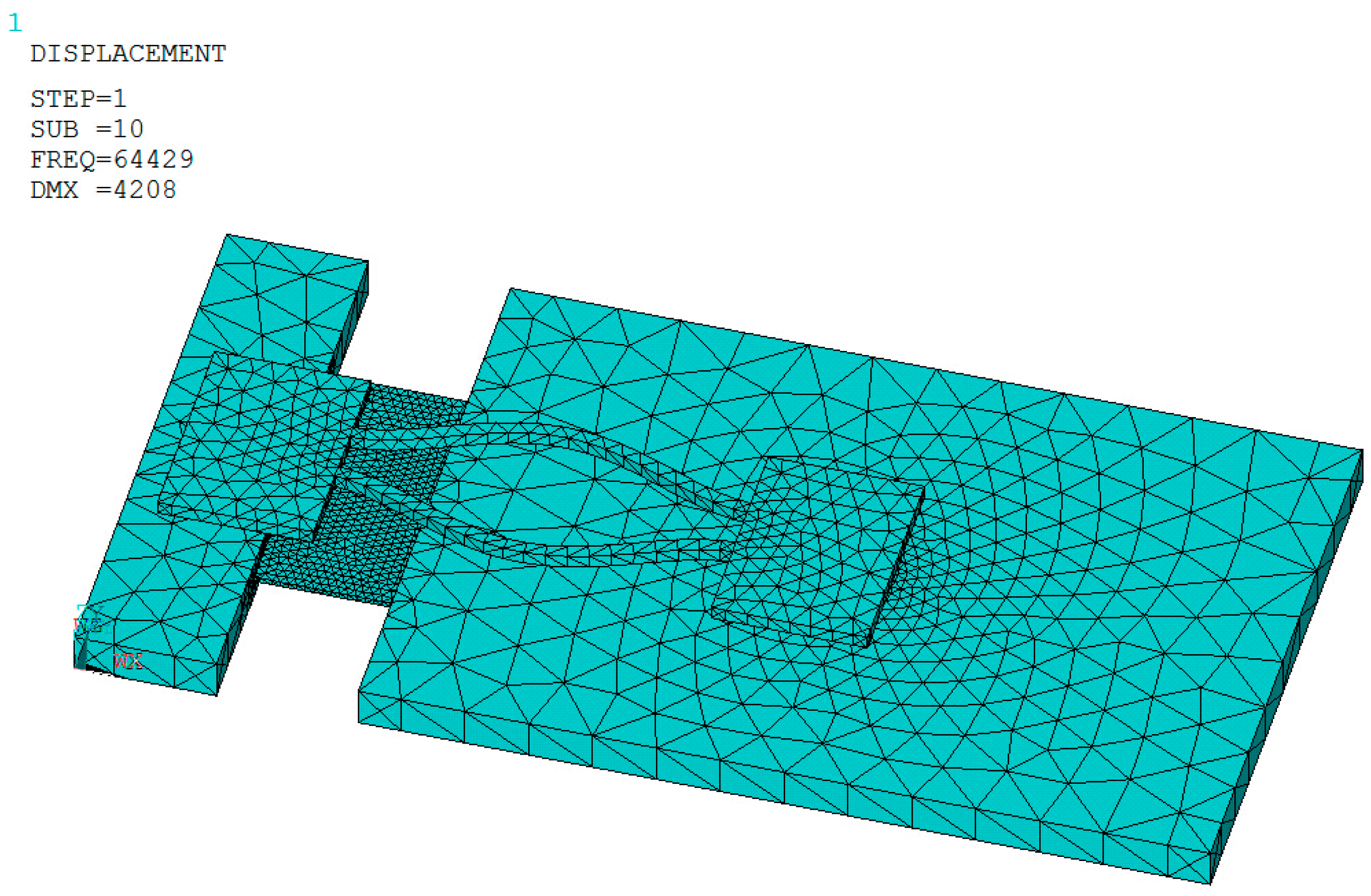

2. Design and Fabrication

2.1. Structure Design

2.2. Fabrication

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yang, B.; Wang, X.; Dai, B.; Liu, X. A new Z-axis resonant micro-accelerometer based on electrostatic stiffness. Sensors 2015, 15, 687–702. [Google Scholar] [CrossRef] [PubMed]

- Caspani, A.; Comi, C.; Corigliano, A.; Langfelder, G.; Zega, V.; Zerbini, S. A differential resonant micro accelerometer for out-of-plane measurements. Proced. Eng. 2014, 87, 640–643. [Google Scholar] [CrossRef]

- Yang, B.; Zhao, H.; Dai, B.; Liu, X. A new silicon biaxial decoupled resonant micro-accelerometer. Microsyst. Technol. 2014, 21, 109–115. [Google Scholar] [CrossRef]

- Comi, C.; Corigliano, A.; Ghisi, A.; Zerbini, S. A resonant micro accelerometer based on electrostatic stiffnesss variation. Meccanica 2013, 48, 1893–1900. [Google Scholar] [CrossRef]

- Wang, J.; Shang, Y.; Chen, J.; Sun, Z.; Chen, D. Micro-machined resonant out-of-plane accelerometer with a differential structure fabricated by silicon-on-insulator-MEMS technology. Micro Nano Lett. 2012, 7, 1230–1233. [Google Scholar] [CrossRef]

- Langdon, R.M. Resonator sensors—a review. J. Phys. E Sci. Instrum. 1985, 18, 103–115. [Google Scholar] [CrossRef]

- Eernisse, E.P.; Ward, R.W.; Wiggins, R.B. Survey of quartz bulk resonator sensor technologies. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1988, 35, 323–330. [Google Scholar] [CrossRef] [PubMed]

- Le Traon, O.; Janiaud, D.; Pernice, M.; Masson, S.; Muller, S.; Tridera, J.-Y. A new quartz monolithic differential vibrating beam accelerometer. In Proceedings of the IEEE/ION PLANS 2006, San Diego, CA, USA, 25–27 April 2006; pp. 6–15.

- Loret, T.; Hardy, G.; Vallée, C.; Demutrecy, V.; Kerrien, T.; Cochain, S.; Boutoille, D.; Taïbi, R.; Blondeau, R. Navigation grade accelerometer with quartz vibrating beam. In Proceedings of the Inertial Sensors and Systems Symposium (ISS), 2014 DGON, Karlsruhe, Germany, 16–17 Sepember 2014; pp. 1–14.

- Reedy, E.D.; Kass, W.J. Finite-element analysis of a quartz digital accelerometer. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1990, 37, 464–474. [Google Scholar] [CrossRef] [PubMed]

- Clayton, L.D.; Eernisse, E.P.; Ward, R.W.; Wiggins, R.B. Miniature crystalline quartz electromechanical structures. Sens. Actuators 1989, 20, 171–177. [Google Scholar] [CrossRef]

- Wale, M.J.; Edge, C. Self-aligned flip-chip assembly of photonic devices with electrical and optical connections. IEEE Trans. Compon. Hybrids Manuf. Technol. 1990, 13, 780–786. [Google Scholar] [CrossRef]

- Landry, M.; Patra, S.K.; Lee, Y.C. Experiment and modeling of the self-alignment mechanism in flip-chip soldering. In Manufacturing Processes and Materials Challenges in Microelectronic Packaging; Chen, W.T., Engel, P.A., Jahsman, W.E., Eds.; American Society of Mechanical Engineers: New York, NY, USA, 1991; pp. 49–56. [Google Scholar]

- Lin, W.; Patra, S.K.; Lee, Y.C. Design of solder joints for self-aligned optoelectronic assemblies. IEEE Trans. Compon. Packag. Manuf. Technol. Part B Adv. Packag. 1995, 18, 543–551. [Google Scholar] [CrossRef]

- Lu, H.; Bailye, C. Dynamic analysis of flip-chip self-alignment. IEEE Trans. Adv. Packag. 2005, 28, 475–480. [Google Scholar] [CrossRef]

- Sutanto, J.; Anand, S.; Patel, C.; Muthuswamy, J. Novel first-level interconnect techniques for flip chip on MEMS devices. J. Microelectromech. Syst. 2012, 21, 132–144. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Horsley, D.A.; Cohn, M.B.; Pisano, A.P.; Howe, R.T. Batch transfer of microstructures using flip-chip solder bonding. J. Microelectromech. Syst. 1999, 8, 27–33. [Google Scholar] [CrossRef]

- Salalha, W.; Zussman, E.; Bar-Yoseph, Z.P. Investigation of flip-chip bonding for MEMS applications. J. Elctron. Packag. 2004, 126, 48–51. [Google Scholar] [CrossRef]

- Waber, T.; Pahl, W.; Schmidt, M.; Feiertag, G.; Stufler, S.; Dudek, R.; Leidl, A. Flip-chip packaging of piezoresistive barmometric pressure sensors. In Proceedings of the SPIE 8763, Smart Sensors, Actuators, and MEMS VI, Grenoble, France, 24 April 2013.

- Waber, T.; Pahl, W.; Schmidt, M.; Feiertag, G.; Stufler, S.; Dudek, R.; Leidl, A. Temperature characterization of flip-chip packaged piezoresistive barometric pressure sensors. Microsyst. Technol. 2014, 20, 861–867. [Google Scholar] [CrossRef]

- Cheng, B.; Bruyker, D.D.; Chua, C.; Sahasrabuddhe, K.; Shubin, I.; Cunningham, E.J.; Luo, Y.; Böhringer, F.K.; Krishnamoorthy, V.A. Microspring characterization and flip-chip assembly reliability. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 187–196. [Google Scholar] [CrossRef]

- Bernabé, S.; Kopp, C.; Volpert, M.; Harduin, J.; Fédéli, M.J.; Ribot, H. Chip-to-chip optical interconnections between stacked self-aligned SOI photonic chips. Opt. Express 2012, 20, 7886–7894. [Google Scholar] [CrossRef] [PubMed]

- Chu, M.K.; Choi, K.W.; Ko, C.Y.; Lee, H.J.; Park, H.H.; Jeon, Y.D. Flip-chip bonding of MEMS scanner for laser display using electroplated AuSn solder bump. IEEE Trans. Adv. Packag. 2007, 30, 27–33. [Google Scholar] [CrossRef]

- Feiertag, G.; Winter, M.; Leidl, A. Flip chip packaging for MEMS microphones. Microsyst. Technol. 2010, 16, 817–823. [Google Scholar] [CrossRef]

- Liang, J.; Kohsaka, F.; Matsuo, T.; Ueda, T. Wet etched high aspect ratio microstructures on quartz for MEMS applications. IEEE Trans. Sens. Micromach. 2007, 127, 337–342. [Google Scholar] [CrossRef]

- Yost, F.G.; Karnowsky, M.M.; Drotning, W.D.; Gieske, J.H. Thermal expansion and elastic properties of high gold-tin alloys. Metall. Trans. A 1990, 21, 1885–1889. [Google Scholar] [CrossRef]

- Chuang, R.W.; Kim, D.; Park, J.; Lee, C.C. A fluxless process of producing tin-rich gold-tin joints in air. IEEE Trans. Compon. Packag. Technol. 2004, 27, 177–181. [Google Scholar] [CrossRef]

- Liang, J.; Li, X.; Li, H.; Ni, Y.; Li, K.; Huang, L.; Ueda, T. Design and fabrication of quartz micro-electro-mechanical system-based double-ended tuning fork with variable sections. Jpn. J. Appl. Phys. 2009, 50, 06GM06. [Google Scholar] [CrossRef]

- Liang, J.; Chai, Y.; Meng, G.; Chen, X. Surface electrode configurations for quartz MEMS double-ended tuning fork resonator. Micro Nano Lett. 2013, 8, 52–55. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, H.; Liang, J.; Huang, L. Design and performance analysis of oscillator circuit for high-impedance quartz vibrating beam. Sens. Mater. 2013, 25, 493–500. [Google Scholar]

- Toshiyoshi, H.; Fujita, H.; Ueda, T. A Piezoelectrically Operated Optical Chopper by Quartz Micromachining. J. Microelectromech. Syst. 1995, 4, 3–9. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, J.; Zhang, L.; Wang, L.; Dong, Y.; Ueda, T. Flip Chip Bonding of a Quartz MEMS-Based Vibrating Beam Accelerometer. Sensors 2015, 15, 22049-22059. https://doi.org/10.3390/s150922049

Liang J, Zhang L, Wang L, Dong Y, Ueda T. Flip Chip Bonding of a Quartz MEMS-Based Vibrating Beam Accelerometer. Sensors. 2015; 15(9):22049-22059. https://doi.org/10.3390/s150922049

Chicago/Turabian StyleLiang, Jinxing, Liyuan Zhang, Ling Wang, Yuan Dong, and Toshitsugu Ueda. 2015. "Flip Chip Bonding of a Quartz MEMS-Based Vibrating Beam Accelerometer" Sensors 15, no. 9: 22049-22059. https://doi.org/10.3390/s150922049