A Model of Ultra-Short Pulsed Laser Ablation of Metal with Considering Plasma Shielding and Non-Fourier Effect

Abstract

:1. Introduction

2. Theoretical Model

2.1. Heat Conduction Equation for Two Different Stages

2.1.1. Heat Conduction Equation before Evaporation

2.1.2. Heat Conduction Equation after Evaporation

2.2. Plasma Expansion and Plasma Shielding

2.3. Properties of Al

2.4. Numerical Method

3. Results and Discussions

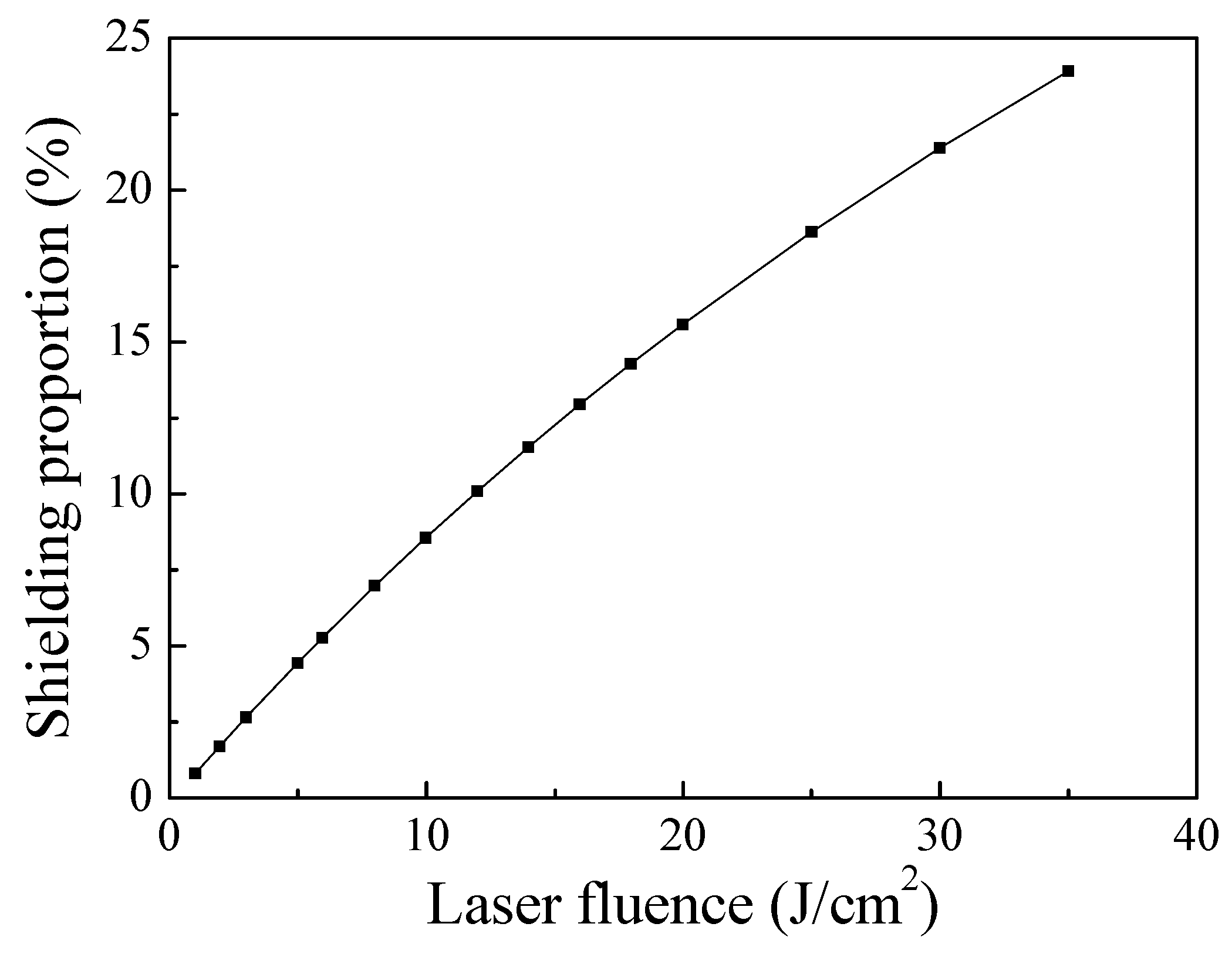

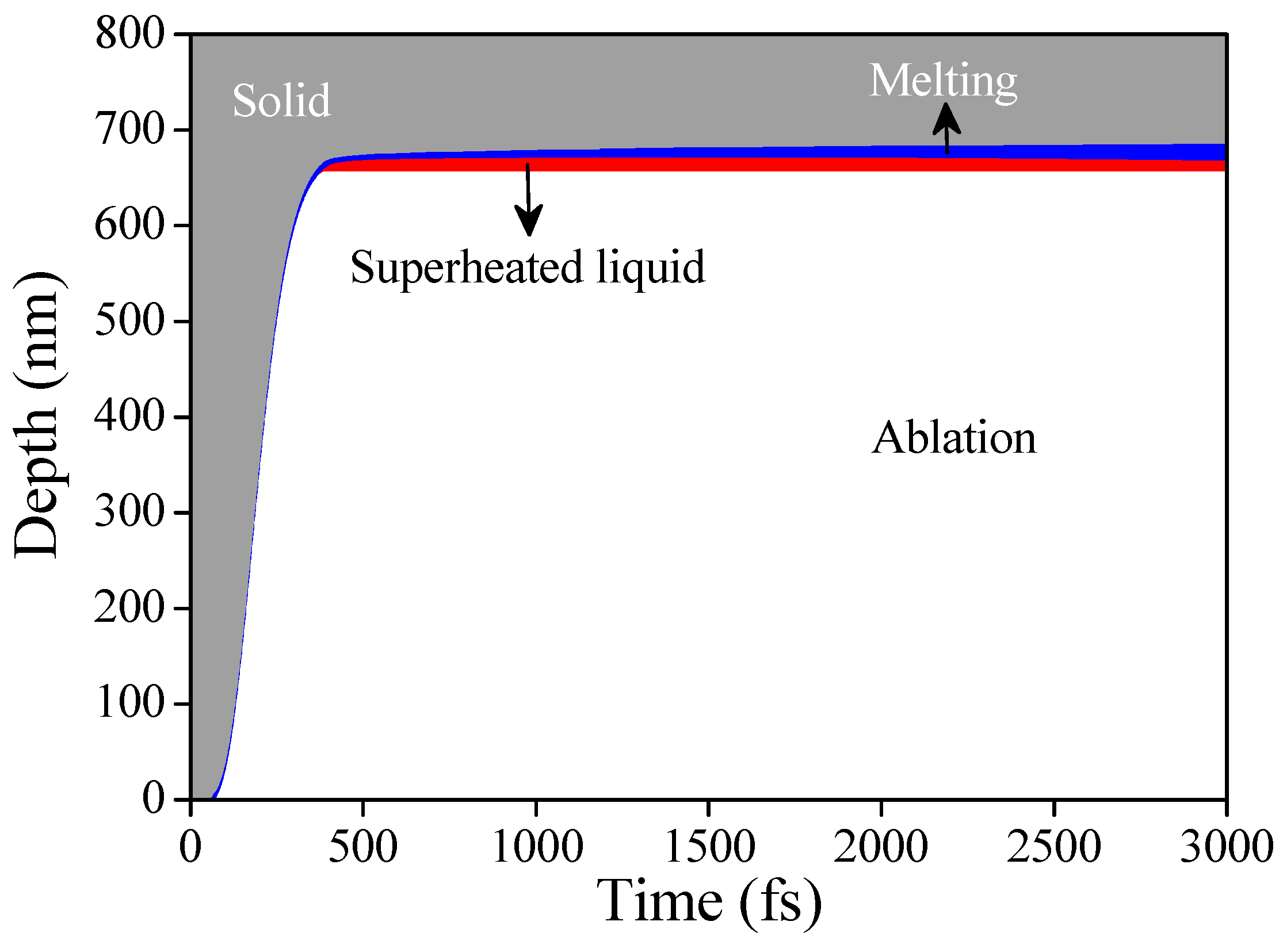

3.1. The Effect of Plasma Shielding

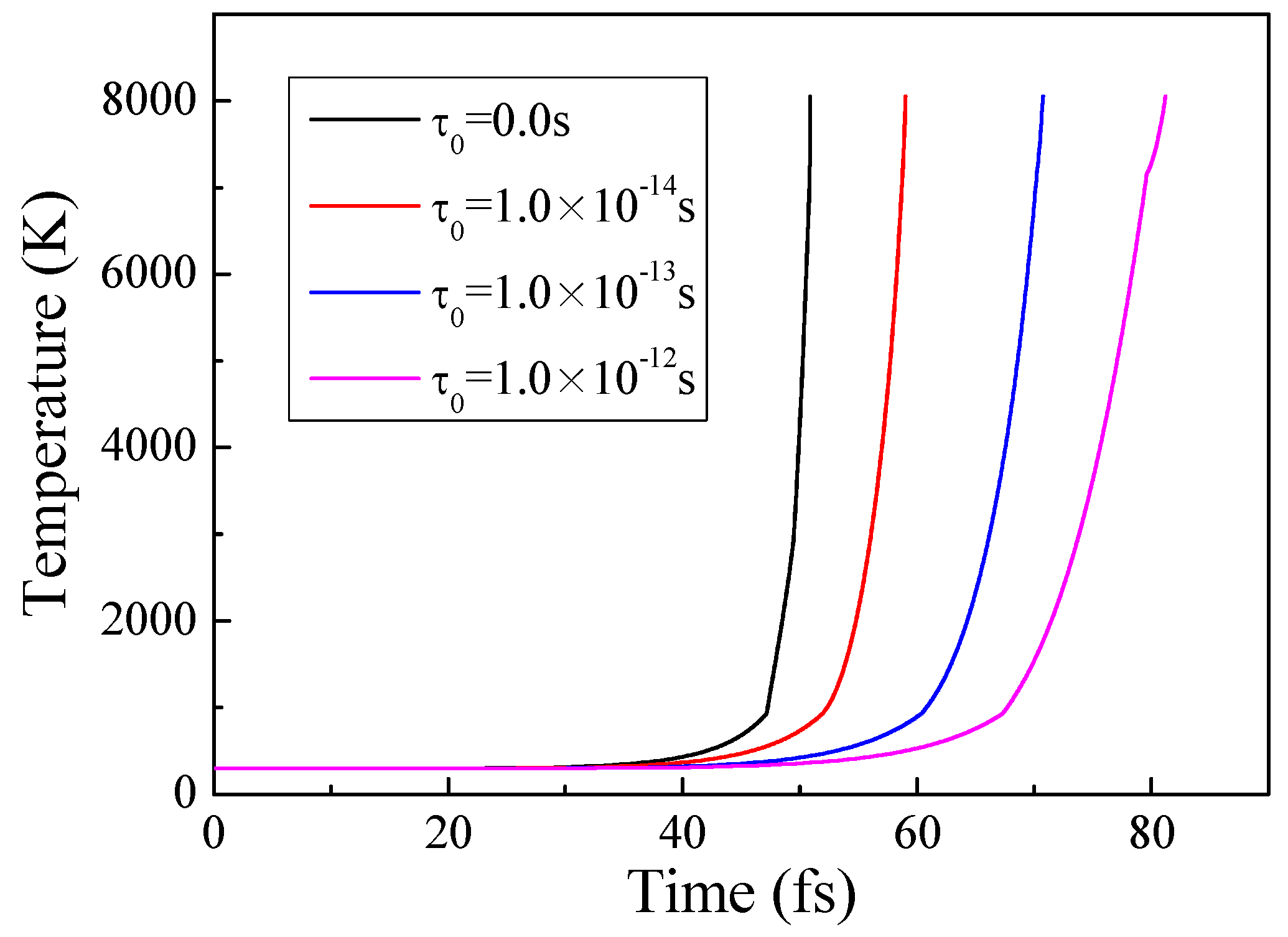

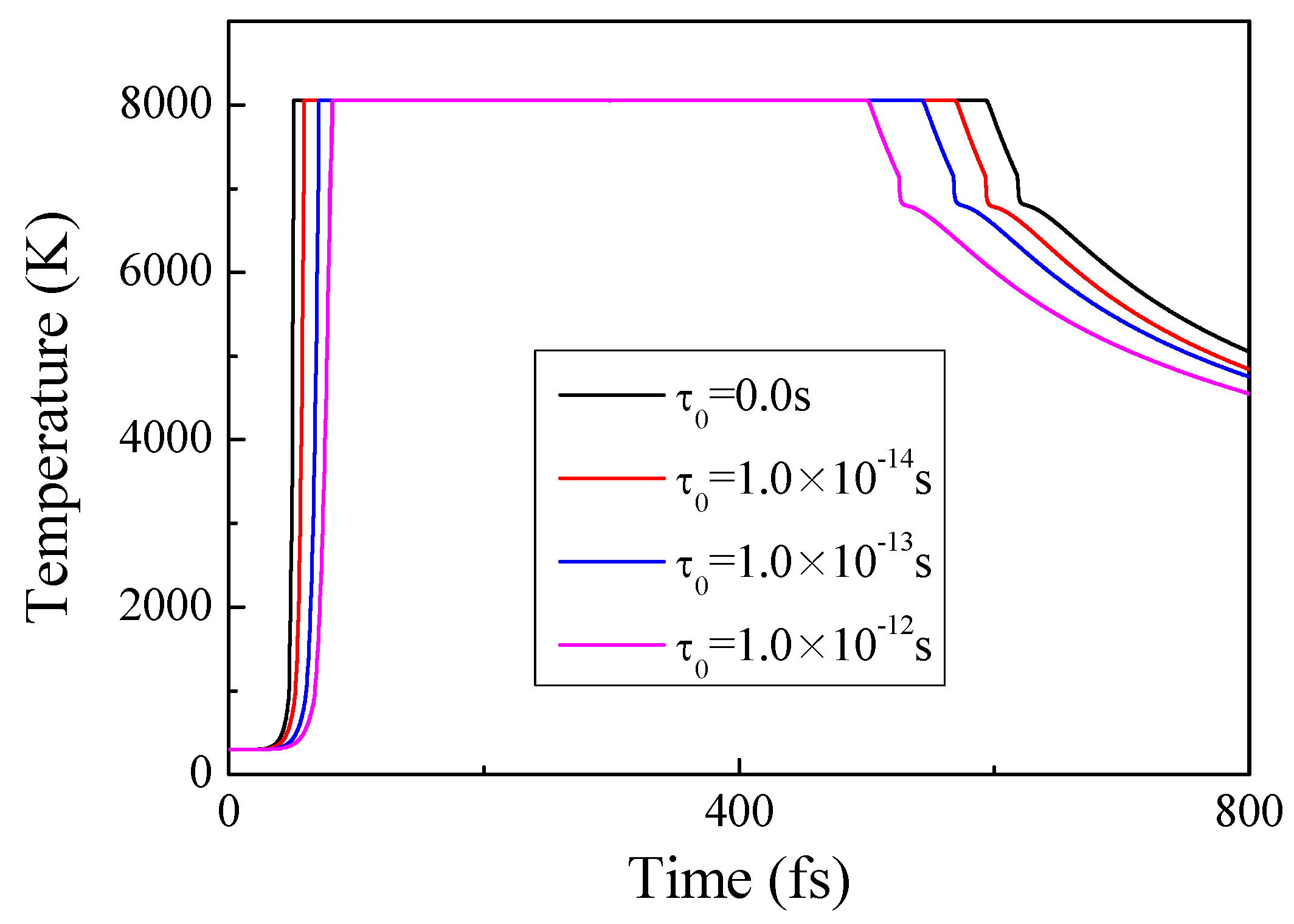

3.2. The Effect of Relaxation Time

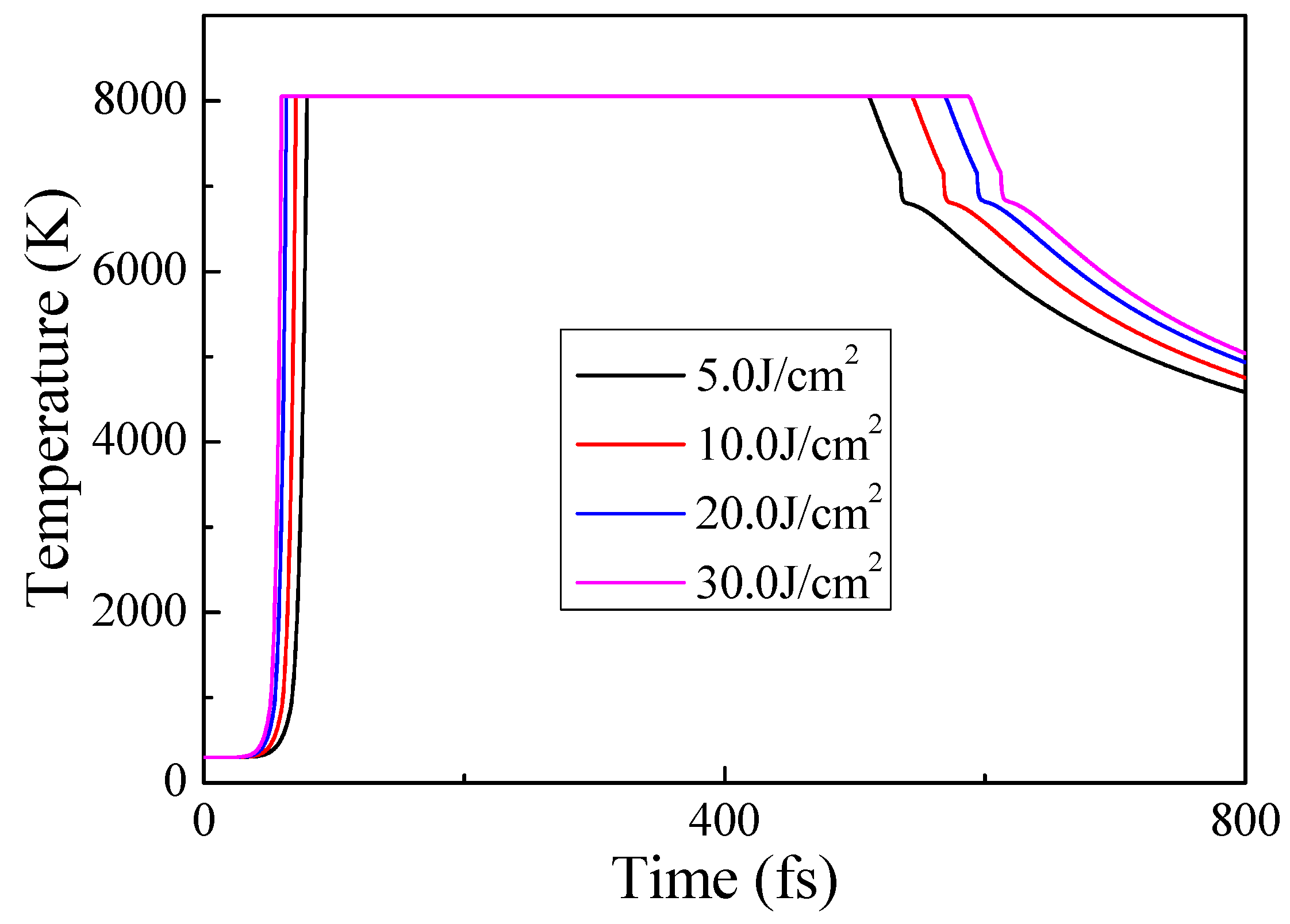

3.3. The Effect of Laser Fluence

3.4. Model Validation

4. Conclusions

- The plasma shielding is an important physical mechanism that cannot be ignored in the process of ultra-short pulsed laser ablation, especially at high laser fluence.

- The non-Fourier effect has a notable effect on the temperature characteristics and ablation depth of the target. The maintenance time of phase explosion decreases with the increase of relaxation time and the ablation depth is shallower with the increase of the relaxation time.

- The ablation depth increases with the increase of the laser fluence and the biggest difference in ablation depth under different laser fluences is at the FWHM of the laser, and the difference of ablation depth caused by other time is small.

- The ablation mechanism of ultra-short pulsed laser ablation is dominated by phase explosion and the ultra-short pulsed laser ablation can effectively reduce the heat affected zone compared to nanosecond pulsed laser ablation.

- The comparison between the simulation results and the experimental results in literature shows that the model without considering the plasma shielding and the non-Fourier effect may result in overestimation of the ablation depth. On the contrary, the simulation results based on the model considering plasma shielding and the non-Fourier effect are in better agreement with the experimental results which indicates that the model with considering the plasma shielding and the non-Fourier effect can better simulate the ultra-short pulsed laser ablation process.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| specific heat, J/(kg·K) | |

| vaporization coefficient | |

| laser fluence, J/m2 | |

| Planck constant, J·s | |

| length of plasma shielding, m | |

| incident laser intensity, W/m2 | |

| the first ionization potential, eV | |

| the laser intensity reaching the target surface, W/m2 | |

| maximum laser intensity, W/m2 | |

| thermal conductivity, W/(m·K) | |

| Boltzmann constant, J/K | |

| length of target, m | |

| latent heat of vaporization, J/kg | |

| mass of a Al atom, kg | |

| number density of neutral atoms, 1/m3 | |

| ion density, 1/m3 | |

| extinction coefficient | |

| refractive index | |

| boiling pressure, Pa | |

| heat flux vector, W/m3 | |

| heating term, W/m3 | |

| ablation depth, m | |

| room temperature, K | |

| time for the surface to reach the boiling temperature, s | |

| boiling point, K | |

| critical temperature, K | |

| melting point, K | |

| the time to reach the maximum laser intensity, s | |

| pulse time, s | |

| temperature of the plasma, K | |

| surface temperature, K | |

| velocity of evaporation, m/s | |

| initial velocity of the plasma, m/s | |

| expansion velocity of the plasma, m/s | |

| expansion distance of the plasma, m | |

| average ionic charge | |

| absorption coefficient, 1/m | |

| absorptivity | |

| emissivity of target surface | |

| density, kg/m3 | |

| density at surface temperature, kg/m3 | |

| Stefan-Boltzmann constant, W/(m2·K4) | |

| electrical conductivity, S/m | |

| relaxation time, s | |

| frequency of the laser, Hz |

References

- Shirk, D.; Molian, P.A. A review of ultrashort pulsed laser ablation of materials. J. Laser Appl. 1998, 10, 18–28. [Google Scholar] [CrossRef]

- Mao, Y.D.; Xu, M.T. Non-Fourier heat conduction in a thin gold film heated by an ultra-fast-laser. Sci. China Technol. Sci. 2015, 58, 638–649. [Google Scholar] [CrossRef]

- Amoruso, S.; Ausanio, G.; Bruzzese, R.; Vitiello, M.; Wang, X. Femtosecond laser pulse irradiation of solid targets as a general route to nanoparticle formation in a vacuum. Phys. Rev. B 2005, 71, 033406. [Google Scholar] [CrossRef]

- Tsakiris, N.; Anoop, K.K.; Ausanio, G.; Gill-Comeau, M.; Bruzzese, R.; Amoruso, S.; Lewis, L.J. Ultrashort laser ablation of bulk copper targets: Dynamics and size distribution of the generated nanoparticles. J. Appl. Phys. 2014, 115, 243301. [Google Scholar] [CrossRef]

- Liu, Z.; Ning, F.; Cong, W.; Jiang, Q.; Li, T.; Zhang, H.; Zhou, Y. Energy consumption and saving analysis for laser engineered net shaping of metal powders. Energies 2016, 9, 763. [Google Scholar] [CrossRef]

- Liebig, C.M.; Srisungsitthisunti, P.; Weiner, A.M.; Xu, X. Enhanced machining of steel using femtosecond pulse pairs. Appl. Phys. A 2010, 101, 487–490. [Google Scholar] [CrossRef]

- Herman, P.R.; Oettl, A.; Chen, K.P.; Marjoribanks, R.S. Laser micromachining of transparent fused silica with 1-ps pulses and pulse trains. In Proceedings of the SPIE—The International Society for Optical Engineering, San Jose, CA, USA, 4 June 1999. [Google Scholar] [CrossRef]

- Derrien, T.J.; Krüger, J.; Itina, T.E.; Höhm, S.; Rosenfeld, A.; Bonse, J. Rippled area formed by surface plasmon polaritons upon femtosecond laser double-pulse irradiation of silicon. Opt. Express 2014, 117, 77–81. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.; Wu, J.; Zhang, Y.; Cheng, Y.; Li, J.; Ou, Y. Research progress of laser-supported space micropropulsion technology. J. Propuls. Technol. 2018, 39, 2415–2428. (In Chinese) [Google Scholar]

- Piñon, V.; Fotakis, C.; Nicolas, G.; Anglos, D. Double pulse laser-induced breakdown spectroscopy with femtosecond laser pulses. Spectrochim. Acta Part B 2008, 63, 1006–1010. [Google Scholar] [CrossRef]

- Miyamoto, I.; Horn, A.; Gottmann, J.; Wortmann, D.; Yoshino, F. Fusion welding of glass using femtosecond laser pulses with high-repetition rates. J. Laser Micro Nanoeng. 2007, 2, 57–63. [Google Scholar] [CrossRef]

- Cao, Y.; Zhao, X.; Shin, Y.C. Analysis of nanosecond laser ablation of aluminum with and without phase explosion in air and water. J. Laser Appl. 2013, 25, 032002. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, N.; Befekadu, G.K.; Pasiliao, C.L. Modeling pulsed laser ablation of aluminum with finite element analysis considering material moving front. Int. J. Heat Mass Transf. 2017, 113, 1246–1253. [Google Scholar] [CrossRef]

- Zhang, Y.; Tzou, D.Y.; Chen, J.K. Micro- and Nanoscale Heat Transfer in Femtosecond Laser Processing of Metals. In High-Power and Femtosecond Lasers: Properties, Materials and Applications, 1st ed.; Nova Science Publisher: New York, NY, USA, 2009; pp. 159–206. [Google Scholar]

- Qi, H.T.; Xu, H.Y.; Guo, X.W. The Cattaneo-type time fractional heat conduction equation for laser heating. Comput. Math. Appl. 2013, 66, 824–831. [Google Scholar] [CrossRef]

- Rahideh, H.; Malekzadeh, P.; Haghighi, M.R.G. Non-fourier heat conduction analysis with temperature-dependent thermal conductivity. ISRN Mech. Eng. 2011, 321605. [Google Scholar] [CrossRef]

- Zhang, L.; Shang, X. Analytical solution to non-Fourier heat conduction as a laser beam irradiating on local surface of a semi-infinite medium. Int. J. Heat Mass Transf. 2015, 85, 772–780. [Google Scholar] [CrossRef]

- Catteneo, C. A form of heat conduction equation which eliminates the paradox of instantaneous propagation. Compte Rendus 1958, 247, 431–433. [Google Scholar]

- Vernotte, P. Les paradoxes de la theorie continue de l’equation de la chaleur. Compte Rendus 1958, 246, 3154–3155. [Google Scholar]

- Vick, B.; ÖZisik, M.N. Growth and decay of a thermal pulse predicted by the hyperbolic heat conduction equation. J. Heat Transf. 1983, 105, 902–907. [Google Scholar] [CrossRef]

- Li, S.N.; Cao, B.Y. Mathematical and information-geometrical entropy for phenomenological Fourier and non-Fourier heat conduction. Phys. Rev. E 2017, 96, 032131. [Google Scholar] [CrossRef] [PubMed]

- Tang, D.W.; Araki, N. Non-Fourier heat conduction behavior in finite mediums under pulsed surface heating. Mater. Sci. Eng. A 2000, 292, 173–178. [Google Scholar] [CrossRef]

- Tzou, D.Y. Experimental support for the lagging behavior in heat propagation. J. Thermophys. Heat Transf. 1995, 9, 686–693. [Google Scholar] [CrossRef]

- Tzou, D.Y.; Chiu, K.S. Temperature-dependent thermal lagging in ultrafast laser heating. Int. J. Heat Mass Transf. 2001, 44, 1725–1734. [Google Scholar] [CrossRef]

- Zhang, D.; Li, L.; Li, Z.; Guan, L.; Tan, X. Non-Fourier conduction model with thermal source term of ultra short high power pulsed laser ablation and temperature evolvement before melting. Phys. B Condens. Matter 2005, 364, 285–293. [Google Scholar] [CrossRef]

- Chen, T.M. A hybrid Green’s function method for the hyperbolic heat conduction problems. Int. J. Heat Mass Transf. 2009, 52, 4273–4278. [Google Scholar] [CrossRef]

- Ahmadikia, H.; Moradi, A.; Fazlali, R.; Parsa, A.B. Analytical solution of non-Fourier and Fourier bioheat transfer analysis during laser irradiation of skin tissue. J. Mech. Sci. Technol. 2012, 26, 1937–1947. [Google Scholar] [CrossRef]

- Kumar, S.; Bag, S.; Baruah, M. Finite element model for femtosecond laser pulse heating using dual phase lag effect. J. Laser Appl. 2016, 28, 032008. [Google Scholar] [CrossRef]

- Noroozi, M.J.; Saedodin, S.; Ganji, D.D. A new solution for nonlinear dual phase lagging heat conduction problem. Alex. Eng. J. 2016, 55, 1745–1752. [Google Scholar] [CrossRef]

- Ma, J.; Sun, Y.; Yang, J. Analytical solution of non-Fourier heat conduction in a square plate subjected to a moving laser pulse. Int. J. Heat Mass Transf. 2017, 115, 606–610. [Google Scholar] [CrossRef]

- Soares, D. An enhanced explicit technique for the solution of non-Fourier heat transfer problems. Adv. Eng. Softw. 2018, 122, 13–21. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Wu, B.; Shin, Y.C. A simple model for high fluence ultra-short pulsed laser metal ablation. Appl. Surf. Sci. 2007, 253, 4079–4084. [Google Scholar] [CrossRef]

- Cheng, J.; Perrie, W.; Wu, B.; Tao, S.; Edwardson, S.P.; Dearden, G.; Watkins, K.G. Ablation mechanism study on metallic materials with a 10 ps laser under high fluence. Appl. Surf. Sci. 2009, 255, 8171–8175. [Google Scholar] [CrossRef]

- Hu, W.; Shin, Y.C.; King, G. Modeling of multi-burst mode pico-second laser ablation for improved material removal rate. Appl. Phys. A 2010, 98, 407–415. [Google Scholar] [CrossRef]

- Qiu, T.Q.; Tien, C.L. Femtosecond laser heating of multi-layer metals-I. Analysis. Int. J. Heat Mass Transf. 1994, 37, 2789–2797. [Google Scholar] [CrossRef]

- Tzou, D.Y.; Chen, J.K.; Beraun, J.E. Recent development of ultrafast thermoelasticity. J. Therm. Stress. 2005, 28, 563–594. [Google Scholar] [CrossRef]

- Singh, N. Two-temperature model of non-equilibrium electron relaxation: A review. Int. J. Mod. Phys. B 2010, 24, 1141–1158. [Google Scholar] [CrossRef]

- Qiu, T.Q.; Tien, C.L. Heat transfer mechanisms during short-pulse laser heating of metals. J. Heat Tranf. 1993, 115, 835–841. [Google Scholar] [CrossRef]

- Chen, J.K.; Beraun, J.E. Numerical study of ultrashort laser pulse interactions with metal films. Numer. Heat Transf. Part A Appl. 2001, 40, 1–20. [Google Scholar] [CrossRef]

- Jiang, L.; Tsai, H.L. Improved two-temperature model and its application in ultrashort laser heating of metal films. J. Heat Transf. 2005, 127, 1167–1173. [Google Scholar] [CrossRef]

- Chen, J.K.; Tzou, D.Y.; Beraun, J.E. A semiclassical two-temperature model for ultrafast laser heating. Int. J. Heat Mass Transf. 2006, 49, 307–316. [Google Scholar] [CrossRef]

- Carpene, E. Ultrafast laser irradiation of metals: Beyond the two-temperature model. Phys. Rev. B 2006, 74, 024301. [Google Scholar] [CrossRef]

- Fang, R.; Wei, H.; Li, Z.; Zhang, D. Improved two-temperature model including electron density of states effects for Au during femtosecond laser pulses. Solid State Commun. 2012, 152, 108–111. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Y.; Hu, M.; Chen, X. An improved three-dimensional two-temperature model for multi-pulse femtosecond laser ablation of aluminum. J. Appl. Phys. 2015, 117, 063104. [Google Scholar] [CrossRef]

- Shin, T.; Teitelbaum, S.W.; Wolfson, J.; Kandyla, M.; Nelson, K.A. Extended two-temperature model for ultrafast thermal response of band gap materials upon impulsive optical excitation. J. Chem. Phys. 2015, 143, 194705. [Google Scholar] [CrossRef] [PubMed]

- Qiu, T.Q.; Juhasz, T.; Suarez, C.; Bron, W.E.; Tien, C.L. Femtosecond laser heating of multi-layer metals-II. Experiments. Int. J. Heat Mass Transf. 1994, 37, 2799–2808. [Google Scholar] [CrossRef]

- Ciegis, R.; Dement’ev, A.; Jankeviciute, G. Numerical analysis of the hyperbolic two-temperature model. Lith. Math. J. 2008, 48, 46–60. [Google Scholar] [CrossRef]

- Zhou, L.; Li, L. Melting and resolidification of gold film irradiated by laser pulses less than 100 fs. Appl. Phys. A 2014, 116, 2157–2165. [Google Scholar] [CrossRef]

- Majchrzak, E.; Dziatkiewicz, J. Analysis of ultrashort laser pulse interactions with metal films using a two-temperature model. J. Appl. Math. Comput. Mech. 2015, 14, 31–39. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Zhao, S. Thermal ablation of thin gold films irradiated by ultrashort laser pulses. Appl. Phys. A 2016, 122, 436. [Google Scholar] [CrossRef]

- Dziatkiewicz, J.; Majchrzak, E. Numerical analysis of laser ablation using the axisymmetric two-temperature model. AIP Conf. Proc. 2018, 1922, 060004. [Google Scholar] [CrossRef]

- Hakkinen, H.; Landman, U. Superheating, melting, and annealing of copper surfaces. Phys. Rev. Lett. 1993, 71, 1023–1026. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, D.S.; Zhigilei, L.V. Combined atomistic-continuum modeling of short-pulse laser melting and disintegration of metal films. Phys. Rev. B 2003, 68, 064114. [Google Scholar] [CrossRef]

- Sonntag, S.; Roth, J.; Gaehler, F.; Trebin, H.R. Femtosecond laser ablation of aluminium. Appl. Surf. Sci. 2009, 255, 9742–9744. [Google Scholar] [CrossRef]

- Ji, P.; Zhang, Y. Melting and thermal ablation of a silver film induced by femtosecond laser heating: A multiscale modeling approach. Appl. Phys. A 2017, 123, 671. [Google Scholar] [CrossRef]

- Colombier, J.P.; Combis, P.; Bonneau, F.; Le Harzic, R.; Audouard, E. Hydrodynamic simulations of metal ablation by femtosecond laser irradiation. Phys. Rev. B 2005, 71, 165406. [Google Scholar] [CrossRef]

- Davydov, R.V.; Antonov, V.I. Simulation of femtosecond pulsed laser ablation of metals. J. Phys. Conf. Ser. 2016, 769, 012060. [Google Scholar] [CrossRef] [Green Version]

- Taylor, L.L.; Scott, R.E.; Qiao, J. Integrating two-temperature and classical heat accumulation models to predict femtosecond laser processing of silicon. Opt. Mater. Express 2018, 8, 648–658. [Google Scholar] [CrossRef]

- Fann, W.S.; Storz, R.; Tom, H.W.K.; Bokor, J. Direct measurement of nonequilibrium electron-energy distributions in subpicosecond laser-heated gold films. Phys. Rev. Lett. 1992, 68, 2834–2837. [Google Scholar] [CrossRef] [PubMed]

- Groeneveld, R.H.M.; Sprik, R.; Lagendijk, A. Femtosecond spectroscopy of electro-electron and electron-phonon energy relaxation in Ag and Au. Phys. Rev. B 1995, 51, 11433. [Google Scholar] [CrossRef]

- Schmidt, V.; Husinsky, W.; Betz, G. Ultrashort laser ablation of metals: Pump-probe experiments, the role of ballistic electrons and the two-temperature model. Appl. Surf. Sci. 2002, 197–198, 145–155. [Google Scholar] [CrossRef]

- Byskov-Nielsen, J.; Savolainen, J.-M.; Christensen, M.S.; Balling, P. Ultra-short pulse laser ablation of copper, silver and tungsten: Experimental data and two-temperature model simulations. Appl. Phys. A 2011, 103, 447–453. [Google Scholar] [CrossRef]

- Christensen, B.H.; Vestentoft, K.; Balling, P. Short-pulse ablation rates and the two-temperature model. Appl. Surf. Sci. 2007, 253, 6347–6352. [Google Scholar] [CrossRef]

- Abdelmalek, A.; Bedrane, Z.; Amara, E. Thermal and non-thermal explosion in metals ablation by femtosecond laser pulse: Classical approach of the two temperature model. J. Phys. Conf. Ser. 2018, 987, 012012. [Google Scholar] [CrossRef]

- Porneala, C.; Willis, D.A. Effect of the dielectric transition on laser-induced phase explosion in metals. Int. J. Heat Mass Transf. 2006, 49, 1928–1936. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, D.; Wu, J.; He, Z.; Deng, X. A thermal model for nanosecond pulsed laser ablation of aluminum. AIP Adv. 2017, 7, 075010. [Google Scholar] [CrossRef]

- Marla, D.; Bhandarkar, U.V.; Joshi, S.S. Critical assessment of the issues in the modeling of ablation and plasma expansion processes in the pulsed laser deposition of metals. J. Appl. Phys. 2011, 109, 021101. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, D.Y. Liu, Advances in the study of non-Fourier heat conduction. Adv. Mech. 2000, 30, 446–456. (In Chinese) [Google Scholar]

- Peterlongo, A.; Miotello, A.; Kelly, R. Laser-pulse sputtering of aluminum: Vaporization, boiling, superheating, and gas-dynamic effects. Phys. Rev. E 1994, 50, 4716–4727. [Google Scholar] [CrossRef]

- Gragossian, A.; Tavassoli, S.H.; Shokri, B. Laser ablation of aluminum from normal evaporation to phase explosion. J. Appl. Phys. 2009, 105, 103304. [Google Scholar] [CrossRef]

- Marla, D.; Bhandarkar, U.V.; Joshi, S.S. A model of laser ablation with temperature-dependent material properties, vaporization, phase explosion and plasma shielding. Appl. Phys. A 2014, 116, 273–285. [Google Scholar] [CrossRef]

- Singh, R.K.; Narayan, J. Pulsed-laser evaporation technique for deposition of thin films-physics and theoretical model. Phys. Rev. B 1990, 41, 8843–8859. [Google Scholar] [CrossRef]

- Chen, F.F. Introduction to Plasma Physics and Controlled Fusion, 2nd ed.; Volume 1: Plasma Physics, Plenum Press: New York, NY, USA, 1985; pp. 1–5. [Google Scholar]

- Garrelie, F.; Aubreton, J.; Catherinot, A. Monte carlo simulation of the laser-induced plasma plume expansion under vacuum: Comparison with experiments. J. Appl. Phys. 1998, 83, 5075–5082. [Google Scholar] [CrossRef]

- Lide, D.R.; Haynes, W.M. CRC Handbook of Chemistry and Physics, 90th ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Wu, B.; Shin, C.Y. Absorption coefficient of aluminum near the critical point and the consequences on high-power nanosecond laser ablation. Appl. Phys. Lett. 2006, 89, 111902. [Google Scholar] [CrossRef]

- Desai, P.D.; James, H.M.; Ho, C.Y. Electrical resistivity of aluminum and manganese. J. Phys. Chem. Ref. Data 1984, 13, 1131–1172. [Google Scholar] [CrossRef]

| Parameters | Symbols | Values | Reference |

|---|---|---|---|

| Melting point/K | 933.47 | [76] | |

| Boiling point/K | 2792.15 | [76] | |

| Latent heat of vaporization/(J/kg) | 1.05 × 107 | [76] | |

| First ionization potential/eV | 5.98 | [76] | |

| Critical temperature/K | 8944.00 | [77] | |

| Evaporation coefficient | 0.82 | [67] | |

| Electrical conductivity/(S/m) | [77,78] | ||

| Thermal conductivity/(W/(m·K)) | [76] | ||

| Density/(kg/m3) | [76] | ||

| Specific heat/(J/(kg·K)) | [76] | ||

| refractive index | The calculation equation is shown in Reference [71] | [71] | |

| extinction coefficient | The calculation equation is shown in Reference [71] | [71] | |

| Absorption coefficient/(1/m) | [71] | ||

| Absorptivity | [71] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, S.; Wu, J.; Zhang, Y.; Wang, M.; Ou, Y. A Model of Ultra-Short Pulsed Laser Ablation of Metal with Considering Plasma Shielding and Non-Fourier Effect. Energies 2018, 11, 3163. https://doi.org/10.3390/en11113163

Tan S, Wu J, Zhang Y, Wang M, Ou Y. A Model of Ultra-Short Pulsed Laser Ablation of Metal with Considering Plasma Shielding and Non-Fourier Effect. Energies. 2018; 11(11):3163. https://doi.org/10.3390/en11113163

Chicago/Turabian StyleTan, Sheng, Jianjun Wu, Yu Zhang, Moge Wang, and Yang Ou. 2018. "A Model of Ultra-Short Pulsed Laser Ablation of Metal with Considering Plasma Shielding and Non-Fourier Effect" Energies 11, no. 11: 3163. https://doi.org/10.3390/en11113163