A Technological Review of Direct Air Carbon Capture and Storage (DACCS): Global Standing and Potential Application in Australia

Abstract

:1. Introduction

2. DACCS: A Technological Overview

3. Two DACCS Technologies

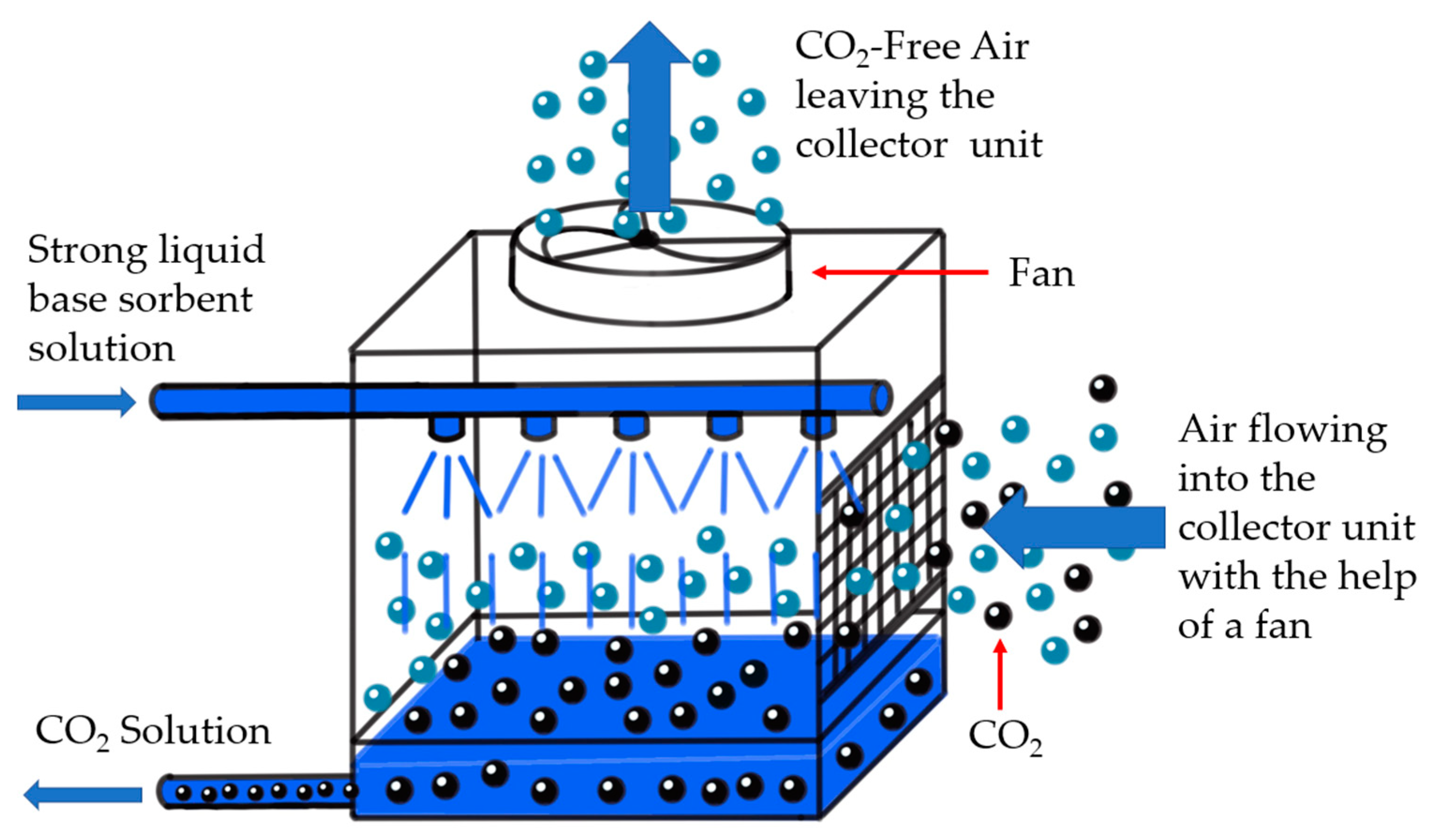

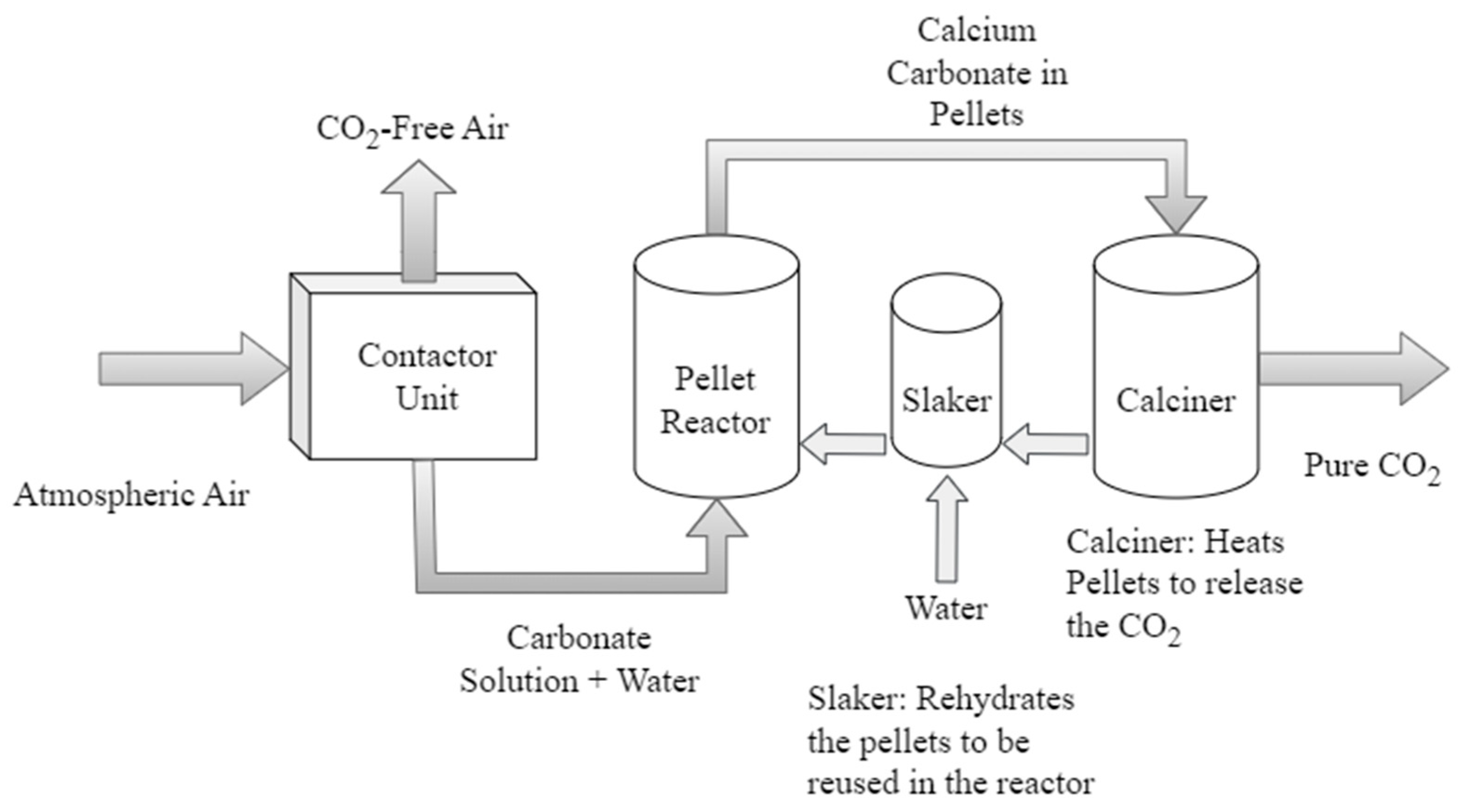

3.1. Absorption Using Liquid Sorbents

3.2. Adsorption Using Solid Sorbents

4. Comparing DACCS Absorption vs. Adsorption

4.1. Material Usage

4.2. Location and Infrastructure

4.3. Operational Considerations

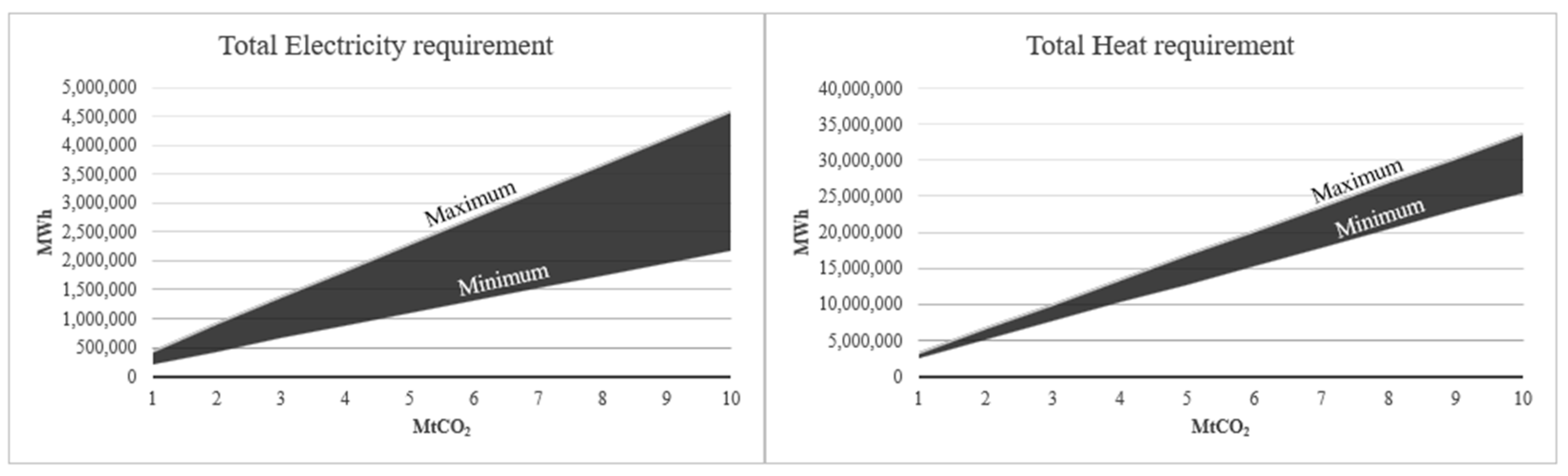

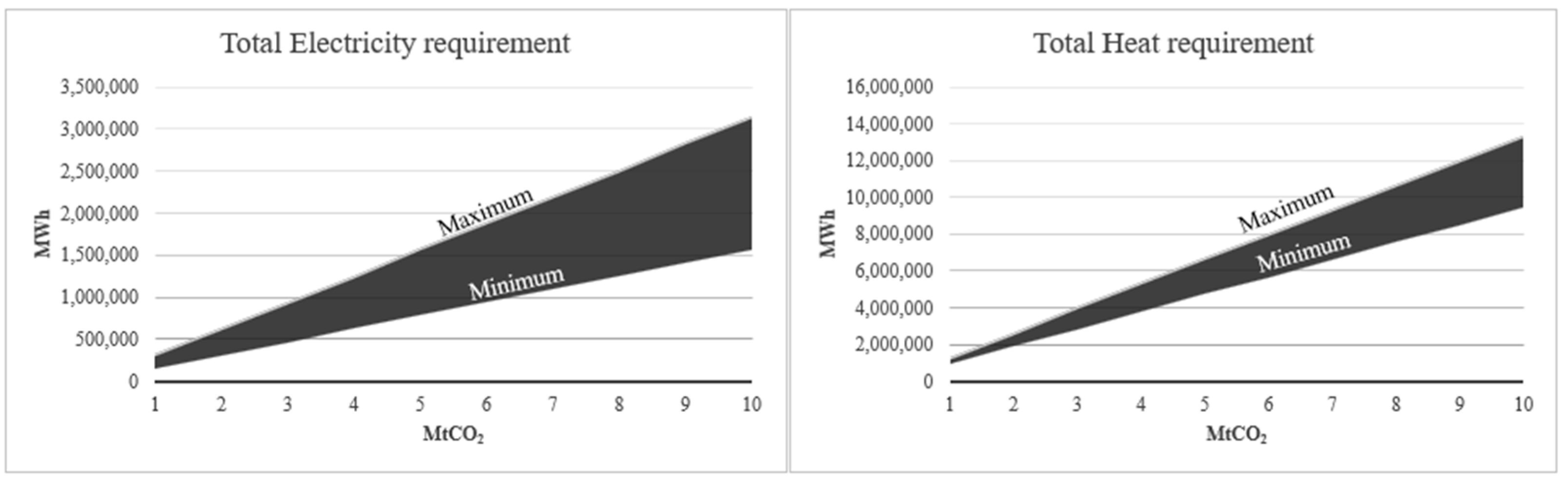

4.4. Energy Use

4.5. Carbon Capture Cost

4.6. Capital Cost

5. Global Aspects of DACCS: Commercialization and Institutional Framework

5.1. Commercialisation

5.2. Climate Change and CCS

6. The Australian Context for DACCS

6.1. Policy Settings

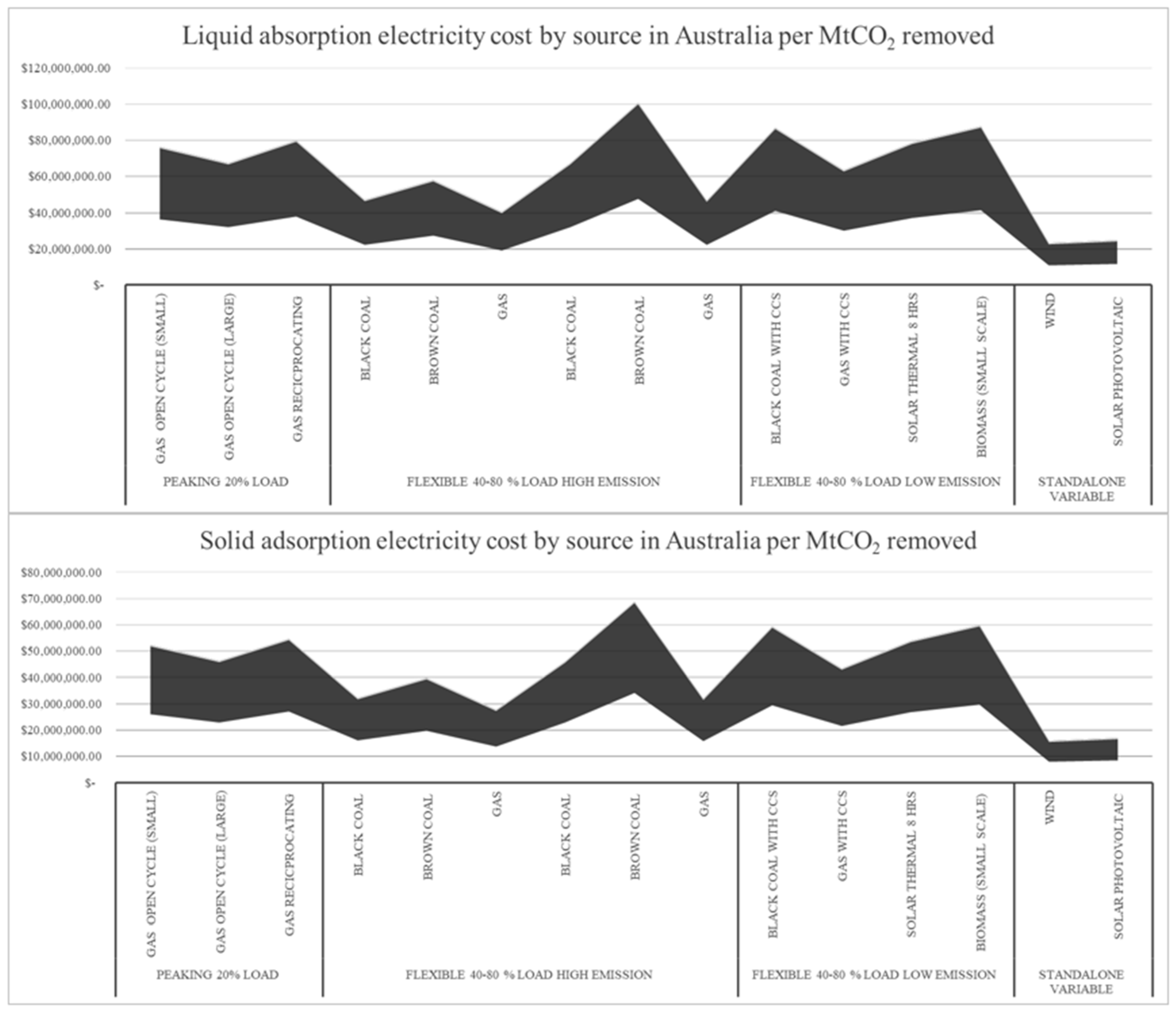

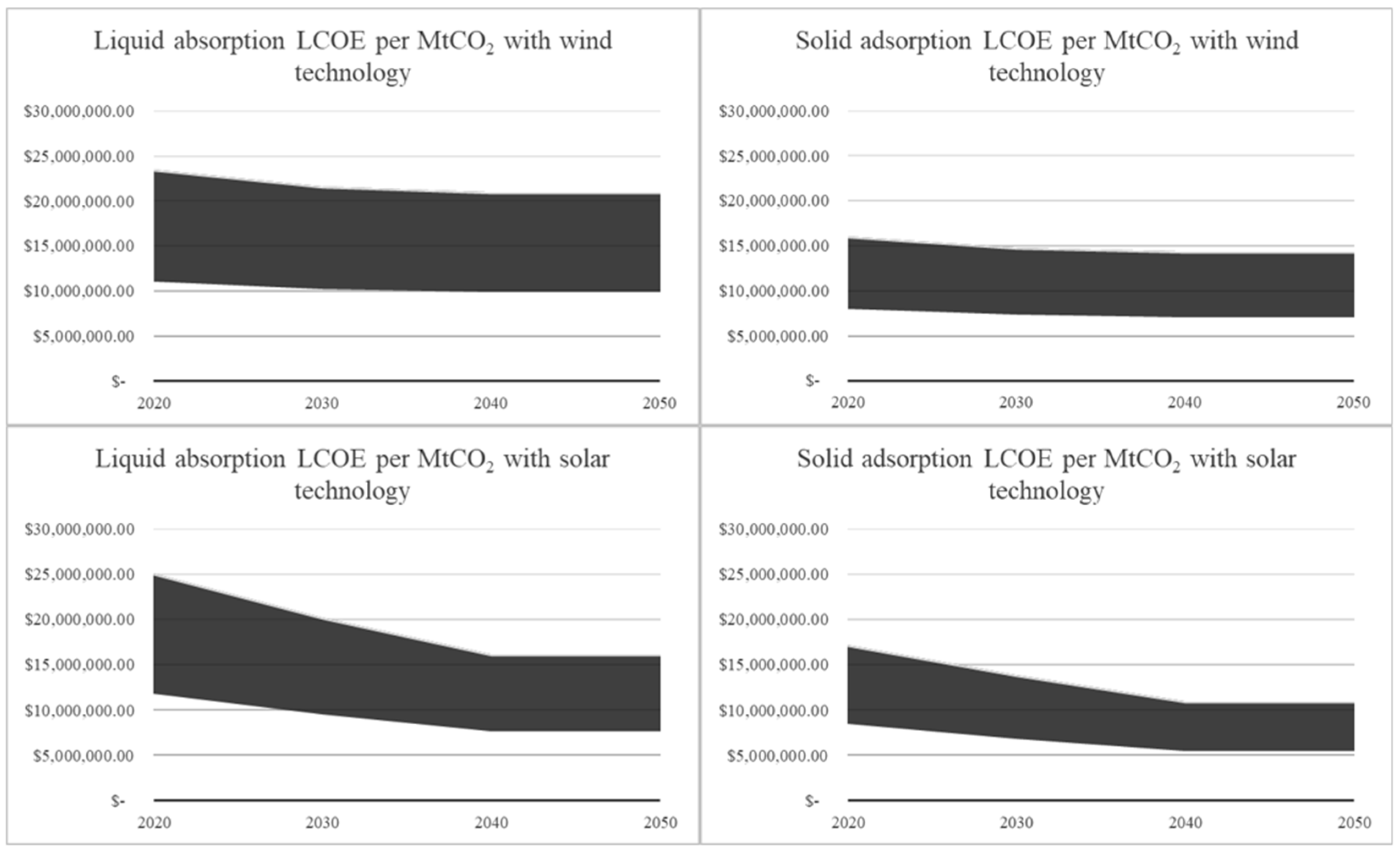

6.2. Economic Viability of DACCS

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gambhir, A.; Tavoni, M. Direct Air Carbon Capture and Sequestration: How It Works and How It Could Contribute to Climate-Change Mitigation. One Earth 2019, 1, 405–409. [Google Scholar] [CrossRef]

- Chen, C.; Tavoni, M. Direct air capture of CO2 and climate stabilization: A model based assessment. Clim. Chang. 2013, 118, 59–72. [Google Scholar] [CrossRef]

- Keith, D.W.; Holmes, G.; St Angelo, D.; Heidel, K. A Process for Capturing CO2 from the Atmosphere. Joule 2018, 2, 1573–1594. [Google Scholar] [CrossRef]

- Sanz-Pérez, E.S.; Murdock, C.R.; Didas, S.A.; Jones, C.W. Direct Capture of CO2 from Ambient Air. Chem. Rev. 2016, 116, 11840–11876. [Google Scholar] [CrossRef]

- Long-Innes, R.; Struchtrup, H. Thermodynamic loss analysis of a liquid-sorbent direct air carbon capture plant. Cell Rep. Phys. Sci. 2022, 3, 100791. [Google Scholar] [CrossRef]

- Deutz, S.; Bardow, A. Life-cycle assessment of an industrial direct air capture process based on temperature–vacuum swing adsorption. Nat. Energy 2021, 6, 203–213. [Google Scholar] [CrossRef]

- Brilman, W. CO2 removal from air. Adv. Carbon Capture 2020, 523–543. [Google Scholar] [CrossRef]

- Ozkan, M. Direct Air Capture of CO2: A Response to Meet the Global Climate Targets. MRS Energy Sustain. 2021. [Google Scholar] [CrossRef]

- Rosa, L.; Sanchez, D.L.; Realmonte, G.; Baldocchi, D.; D’Odorico, P. The Water Footprint of Carbon Capture and Storage Technologies. Renew. Sustain. Energy Rev. 2021, 138, 110511. [Google Scholar] [CrossRef]

- van Leeuwin, H. ‘We are fooling ourselves on the timeline’: Rio’s warning on solar. Aust. Financ. Rev. 2023, 20, 17. [Google Scholar]

- Rae, M. Aussies Not ‘Fooling Ourselves’ on Solar. 2023. Available online: https://www.perthnow.com.au/business/aussies-not-fooling-ourselves-on-solar-c-9508765 (accessed on 23 January 2023).

- National Academies of Sciences, Engineering, and Medicine. Negative Emissions Technologies and Reliable Sequestration: A Research Agenda; National Academies Press: Washington, DC, USA, 2019. [Google Scholar]

- Fasihi, M.; Efimova, O.; Breyer, C. Techno-economic assessment of CO2 direct air capture plants. J. Clean. Prod. 2019, 224, 957–980. [Google Scholar] [CrossRef]

- Madhu, K.; Pauliuk, S.; Dhathri, S.; Creutzig, F. Understanding Environmental Trade-Offs and Resource Demand of Direct Air Capture Technologies through Comparative Life-Cycle Assessment. Nat. Energy 2021, 6, 1035–1044. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Baum, C.M.; Low, S.; Roberts, C.; Steinhauser, J. Climate policy for a Net-Zero future: Ten recommendations for Direct Air Capture. Environ. Res. Lett. 2022, 17, 074014. [Google Scholar] [CrossRef]

- Buongiorno, J.; Corradini, M.; Parsons, J.; Petti, D. Nuclear Energy in a Carbon-Constrained World: Big Challenge and Big Opportunities. IEEE Power Energy Mag. 2019, 17, 69–77. [Google Scholar] [CrossRef]

- Jacobson, M. The 7 Reasons Why Nuclear Energy is Not the Answer to Solve Climate Change. 2022. Available online: https://www.oneearth.org/the-7-reasons-why-nuclear-energy-is-not-the-answer-to-solve-climate-change/ (accessed on 11 September 2022).

- Kurmelovs, R. Explainer: Should Australia Build Nuclear Power Plants to Combat the Climate Crisis? The Guardian. 2021. Available online: https://www.theguardian.com/environment/2021/oct/13/explainer-should-australia-build-nuclear-power-plants-to-combat-the-climate-crisis (accessed on 11 September 2022).

- Bourzac, K. We have the technology. Nature 2017, 550, 66–69. [Google Scholar] [CrossRef]

- Masterson, V. Companies are Sucking Carbon from the Atmosphere Using ‘Direct Air Capture’. How Does it Work? 2022. Available online: https://climatechampions.unfccc.int/companies-are-sucking-carbon-from-the-atmosphere-using-direct-air-capture-how-does-it-work/ (accessed on 16 January 2023).

- IEA. Direct Air Capture 2022. 2022. Available online: https://www.iea.org/reports/direct-air-capture-2022 (accessed on 16 January 2023).

- Directorate-General for Climate Action Carbon Removals: A Strong Ally to Achieve Climate Neutrality in the EU. Available online: https://climate.ec.europa.eu/news-your-voice/news/carbon-removals-strong-ally-achieve-climate-neutrality-eu-2023-02-17_en (accessed on 19 April 2023).

- Climeworks. The Next Step towards a Climate-Positive World: Orca! 2021. Available online: https://climeworks.com/roadmap/orca (accessed on 17 January 2023).

- Ramkumar, A. Climate Startup Removes Carbon From Open Air in Industry First. 2023. Available online: https://www.wsj.com/articles/climate-startup-removes-carbon-from-open-air-in-industry-first-11673492767 (accessed on 16 January 2023).

- Calma, J. Construction Begins on ‘Mammoth’ Direct Air Capture Plant. 2022. Available online: https://www.theverge.com/2463 (accessed on 16 January 2023).

- O’Beirne, P.; Battersby, F.; Mallett, A.; Aczel, M.; Makuch, K.; Workman, M.; Heap, R. The UK Net-Zero Target: Insights into Procedural Justice for Greenhouse Gas Removal. Environ. Sci. Policy 2020, 112, 264–274. [Google Scholar] [CrossRef]

- Black and Veatch and Global Thermostat. Black and Veatch Awarded DOE Funding to Build Global Thermostat DACProject to Capture 100,000 Tons of CO2. Global Thermostat. 2021. Available online: https://globalthermostat.com/2021/07/black-veatch-awarded-doe-funding-to-build-global-thermostat-dac-project-to-capture-100000-tons-of-co2/ (accessed on 17 January 2023).

- Hiar, C.; Anchondo, C. DOE Releases Record Funding for Removing Carbon. 2022. Available online: https://www.eenews.net/articles/doe-releases-record-funding-for-removing-carbon/ (accessed on 2 August 2022).

- Carbon Engineering. Oxy Low Carbon Ventures, Rusheen Capital Management Create Development Company 1PointFive to Deploy Carbon Engineering’s Direct Air Capture Technology. 2020. Available online: https://carbonengineering.com/news-updates/new-development-company-1pointfive-formed/ (accessed on 17 January 2023).

- Günther, A. ISIpedia. 2021. Available online: https://www.isipedia.org/report/the-paris-agreement-and-ndcs-are-the-national-mitigation-targets-sufficient-to-stay-below-the-1-5-2-c-limit/?origin=isipedia-rss (accessed on 2 August 2022).

- One Point Five. Construction of World’s Largest Direct Air Capture Plant in the Texas Permian Basin. 2022. Available online: https://www.1pointfive.com/worlds-largest-direct-air-capture-plant-in-the-texas-permian-basin (accessed on 17 January 2023).

- United Nations. The Paris Agreement. 2021. Available online: https://www.un.org/en/climatechange/paris-agreement (accessed on 3 August 2022).

- Vogt-Schilb, A.; Hallegatte, S. Climate policies and nationally determined contributions: Reconciling the needed ambition with the political economy. Wiley Interdiscip. Rev. Energy Environ. 2017, 6, 256–587. [Google Scholar]

- Raftery, A.E.; Zimmer, A.; Frierson, D.M.W.; Startz, R.; Liu, P. Less than 2 °C warming by 2100 unlikely. Nat. Clim. Chang. 2017, 7, 637–641. [Google Scholar] [CrossRef]

- Qiu, Y.; Lamers, P.; Daioglou, V.; McQueen, N.; de Boer, H.-S.; Harmsen, M.; Wilcox, J.; Bardow, A.; Suh, S. Environmental trade-offs of direct air capture technologies in climate change mitigation toward 2100. Nat. Commun. 2022, 13, 3635. [Google Scholar] [CrossRef]

- Liu, P.R.; Raftery, A.E. Country-based rate of emissions reductions should increase by 80 percent beyond nationally determined contributions to meet the 2 °C target. Commun. Earth Environ. 2021, 2, 29. [Google Scholar] [CrossRef]

- Martin-Roberts, E.; Scott, V.; Flude, S.; Johnson, G.; Haszeldine, R.S.; Gilfillan, S. Carbon capture and storage at the end of a lost decade. One Earth 2021, 4, 1569–1584. [Google Scholar] [CrossRef]

- Fuhrman, J.; Clarens, A.; Calvin, K.V.; Doney, S.C.; Edmonds, J.A.; O’Rourke, P.; Patel, P.L.; Pradhan, S.; Shobe, W.; McJeon, H.C. The role of direct air capture and negative emissions technologies in the Shared Socioeconomic Pathways towards +1.5 °C and +2 °C futures. Environ. Res. Lett. 2021, 16, 114012. [Google Scholar] [CrossRef]

- Grant, N.; Hawkes, A.; Mittal, S.; Gambhir, A. The policy implications of an uncertain carbon dioxide removal potential. Joule 2021, 5, 2593–2605. [Google Scholar] [CrossRef]

- Romanak, K.; Fridahl, M.; Dixon, T. Attitudes on Carbon Capture and Storage (CCS) as a Mitigation Technology within the UNFCCC. Energies 2021, 14, 629. [Google Scholar] [CrossRef]

- IPCC. (n.d.) FAQ Chapter 1—Global Warming of 1.5 °C. Available online: https://www.ipcc.ch/sr15/faq/faq-chapter-1/ (accessed on 11 September 2022).

- Masson-Delmotte, V.; Zhai, P.; Pörtner, H.-O.; Roberts, D.; Skea, J.; Shukla, P.; Pirani, A.; Moufouma-Okia, W.; Péan, C.; Pidcock, R.; et al. Global Warming of 1.5 °C: An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty Edited by Science Officer Science Assistant Graphics Officer. 2019. Available online: https://www.ipcc.ch/site/assets/uploads/sites/2/2019/06/SR15_Full_Report_High_Res.pdf (accessed on 12 September 2022).

- Fuhrman, J.; McJeon, H.; Patel, P.; Doney, S.C.; Shobe, W.M.; Clarens, A.F. Food–energy–water implications of negative emissions technologies in a +1.5 °C future. Nat. Clim. Chang. 2020, 10, 920–927. [Google Scholar] [CrossRef]

- Haszeldine, R.S.; Flude, S.; Johnson, G.; Scott, V. Negative Emissions Technologies and Carbon Capture and Storage to Achieve the Paris Agreement Commitments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2018, 376, 20160447. [Google Scholar] [CrossRef]

- Kikstra, J.S.; Nicholls, Z.R.J.; Smith, C.J.; Lewis, J.; Lamboll, R.D.; Byers, E.; Sandstad, M.; Meinshausen, M.; Gidden, M.J.; Rogelj, J.; et al. The IPCC Sixth Assessment Report WGIII Climate Assessment of Mitigation Pathways: From Emissions to Global Temperatures. 2022. Available online: https://egusphere.copernicus.org/preprints/2022/egusphere-2022-471/ (accessed on 6 August 2022).

- IPCC. Climate Change 2022: Mitigation of Climate Change. 2022. Available online: https://www.ipcc.ch/report/ar6/wg (accessed on 29 August 2022).

- Pareliussen, J.; Crowe, D.; Kruse, T.; Glocker, D. Policies to Reach Net Zero Emissions in the United Kingdom. Available online: https://www.oecd-ilibrary.org/content/paper/f6625f01-en (accessed on 19 April 2023).

- Australian Government Affirming Australia’s Net Zero Emissions by 2050 Target. Available online: https://www.dcceew.gov.au/about/news/affirming-australias-net-zero-emissions-by-2050-target (accessed on 30 August 2022).

- Australian Energy Regulator. Gas Market Prices. 2020. Available online: https://www.aer.gov.au/wholesale-markets/wholesale-statistics/gas-market-prices (accessed on 14 October 2022).

- Socolow, R.; Desmond, M.; Aines, R.; Blackstock, J.; Bolland, O.; Kaarsberg, T.; Lewis, N.; Mazzotti, M.; Pfeffer, A.; Sawyer, K. Direct air capture of CO2 with chemicals: A technology assessment for the APS Panel on Public Affairs. Am. Phys. Soc. 2011. Available online: https://infoscience.epfl.ch/record/200555?ln=en (accessed on 16 January 2023).

- Ishimoto, Y.; Sugiyama, M.; Kato, E.; Moriyama, R.; Tsuzuki, K.; Kurosawa, A. Putting Costs of Direct Air Capture in Context. SSRN Electron. J. 2017. [Google Scholar] [CrossRef]

- Gertner, J. The Dream of Carbon Air Capture Edges toward Reality. 2021. Available online: https://e360.yale.edu/features/488dream-of-co2-air-capture-edges-toward-reality (accessed on 6 March 2022).

- Lucas, A. Fossil Networks and Dirty Power: The Politics of Decarbonisation in Australia. In Handbook of Anti-Environmentalism; Edward Elgar Publishing: Cheltenham, UK, 2022; pp. 192–215. Available online: https://www.elgaronline.com/view/edcoll/9781839100215/9781839100215.00020.xm526 (accessed on 4 August 2022).

- Australian Government. Electricity Generation. 2020. Available online: https://www.energy.gov.au/data/electricity-generation (accessed on 4 August 2022).

- Geoengineering Monitor. Carbon Capture Use and Storage (Technology Briefing). Available online: https://www.geoengineeringcapture-use-and-storage/ (accessed on 7 August 2022).

- De la Garza, A. Carbon Removal Is Having a Moment. Not Everyone is Thrilled. 2021. Available online: https://time.com/6125303/direct-air-carbon-capture-infrastructure/ (accessed on 8 August 2022).

- Temple, J. Carbon Removal Hype is Becoming a Dangerous Distraction. 2021. Available online: https://www.technologyreview.com/2021/07/08/1027908/carbon-removal-hype-is-a-dangerous-distraction-climate-change/ (accessed on 4 August 2022).

- Ranjan, M.; Herzog, H.J. Feasibility of air capture. Energy Procedia 2011, 4, 2869–2876. [Google Scholar] [CrossRef]

- Schreyer, F.; Luderer, G.; Rodrigues, R.; Pietzcker, R.C.; Baumstark, L.; Sugiyama, M.; Brecha, R.J.; Ueckerdt, F. Common but differentiated leadership: Strategies and challenges for carbon neutrality by 2050 across industrialized economies. Environ. Res. Lett. 2020, 15, 114016. [Google Scholar] [CrossRef]

- Graham, P.; Hayward, J.; Foster, J.; Havas, L. GenCost 2021–2022 Consultation Draft. 2021. Available online: https://publications.csiro.au/publications/publication/PIcsiro:EP2021-3374 (accessed on 8 October 2022).

- Mazengarb, M. CSIRO GenCost: Wind and Solar Still Reign Supreme as Cheapest Energy Sources. 2021. Available online: https://reneweconomy.com.au/csiro-gencost-wind-and-solar-still-reign-supreme-as-cheapest-energy-sources/ (accessed on 14 October 2022).

- Owen, A.; Burke, J.; Serin, E. Who pays for BECCS and DACCS in the UK: Designing equitable climate policy. Clim. Policy 2022, 22, 1050–1068. [Google Scholar] [CrossRef]

- Geroe, S. Technology not taxes: A viable Australian path to Net Zero emissions? Energy Policy 2022, 165, 112945. [Google Scholar] [CrossRef]

| Unit Operation | Min GJ/tCO2 | Max GJ/tCO2 | Type |

|---|---|---|---|

| Contactor Fans | 0.32 | 1.18 | Electricity |

| Solvent Pump | 0.048 | 0.065 | Electricity |

| Slaker | 0.005 | 0.005 | Electricity |

| Causticizer/clarifier | 0.109 | 0.109 | Electricity |

| Air Separation Unit | 0.3 | 0.3 | Electricity |

| Heater/dryer | 3.18 | 3.18 | Thermal/Heat |

| Oxy-fired calciner | 6 | 9 | Thermal/Heat |

| Total | 9.962 | 13.839 |

| Unit Operation | Min GJ/tCO2 | Max GJ/tCO2 | Type |

|---|---|---|---|

| Desorption Heat (100 °C) | 3.4 | 4.8 | Heat |

| Air Contactor Fans | 0.55 | 1.12 | Electricity |

| Desorption Vacuum Pump | 1.10 × 10−2 | 1.40 × 10−2 | Electricity |

| Total | 3.961 | 5.934 |

| Absorption Process | Adsorption Process | |

|---|---|---|

| System Type Material | Liquid Solvent Potassium Hydroxide/Sodium Hydroxide | Solid Sorbent Amine Compound/Carbonate Salts |

| Operation | Continuous | Batch Operation |

| Temperature required for separation of CO2 from solvent/sorbent material | 900 °C | 100 °C |

| Footprint for MtCO2/year | 2.42 ha | 1.2–1.7 ha |

| Energy requirement GJ/tCO2 | 10–13.8 | 3.95–5.92 |

| Capture Cost USD/tCO2 | 140–264 | 88–228 |

| Capital Cost for a 1 MtCO2/year plant (Million USD) | 675–1255 * | 633–1708 * |

| Liquid Absorption | Solid Absorption | |||

|---|---|---|---|---|

| United States | Australia | United States | Australia | |

| Electricity USD/tCO2 | 13 to 28 | 36 to 77 | 9 to 19 | 26 to 53 |

| Heating USD/tCO2 | 30 to 40 | 86 to 115 | 11 to 16 | 32 to 45 |

| Total USD/tCO2 | 43 to 68 | 123 to 192 | 20 to 35 | 58 to 98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garza, D.; Dargusch, P.; Wadley, D. A Technological Review of Direct Air Carbon Capture and Storage (DACCS): Global Standing and Potential Application in Australia. Energies 2023, 16, 4090. https://doi.org/10.3390/en16104090

Garza D, Dargusch P, Wadley D. A Technological Review of Direct Air Carbon Capture and Storage (DACCS): Global Standing and Potential Application in Australia. Energies. 2023; 16(10):4090. https://doi.org/10.3390/en16104090

Chicago/Turabian StyleGarza, Domingo, Paul Dargusch, and David Wadley. 2023. "A Technological Review of Direct Air Carbon Capture and Storage (DACCS): Global Standing and Potential Application in Australia" Energies 16, no. 10: 4090. https://doi.org/10.3390/en16104090

APA StyleGarza, D., Dargusch, P., & Wadley, D. (2023). A Technological Review of Direct Air Carbon Capture and Storage (DACCS): Global Standing and Potential Application in Australia. Energies, 16(10), 4090. https://doi.org/10.3390/en16104090