Enhanced Electrical Tree Resistance of Polypropylene Cable Insulation by Introducing β-Crystals

Abstract

:1. Introduction

2. Experimental Arrangement

2.1. Sample Preparation and Mechanical Properties

2.2. Experimental Setup

3. Experimental Results

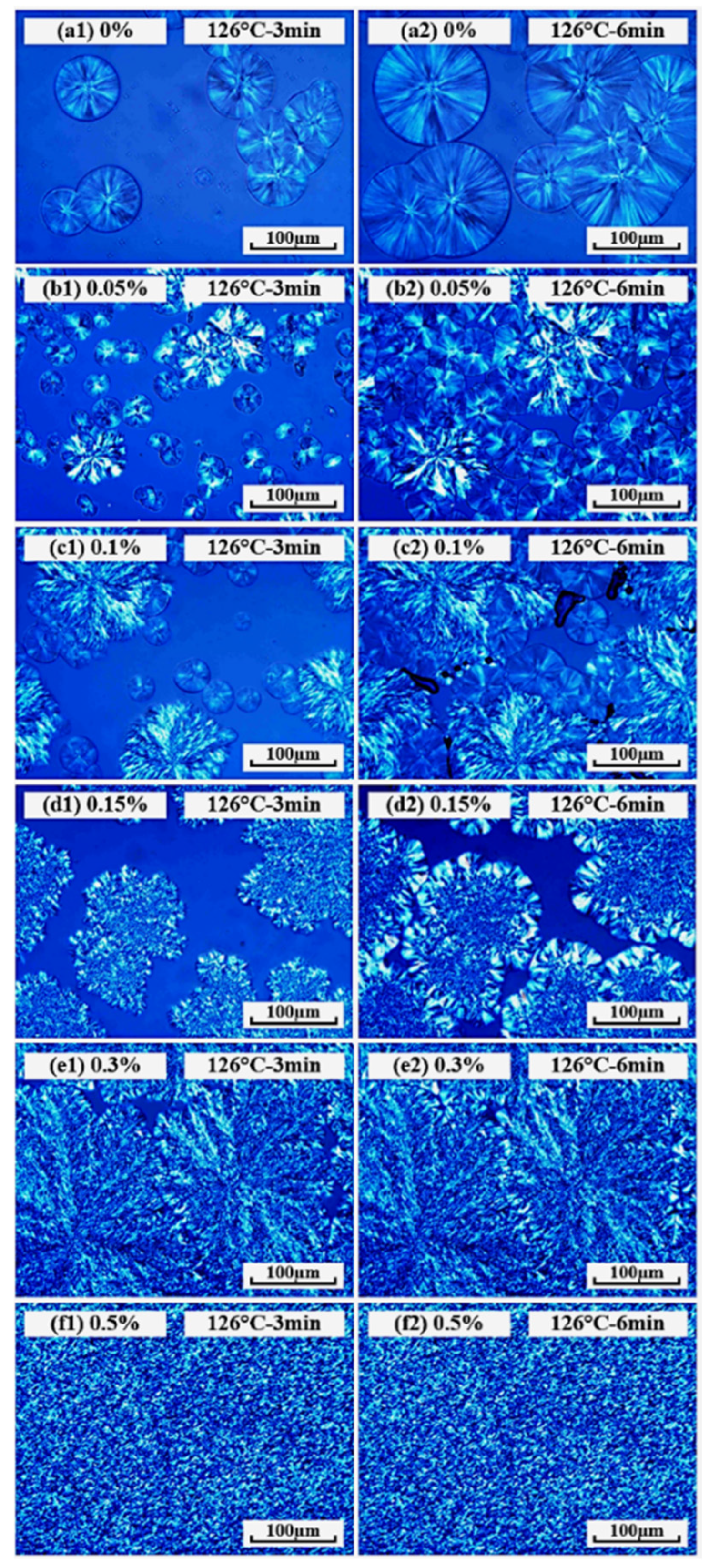

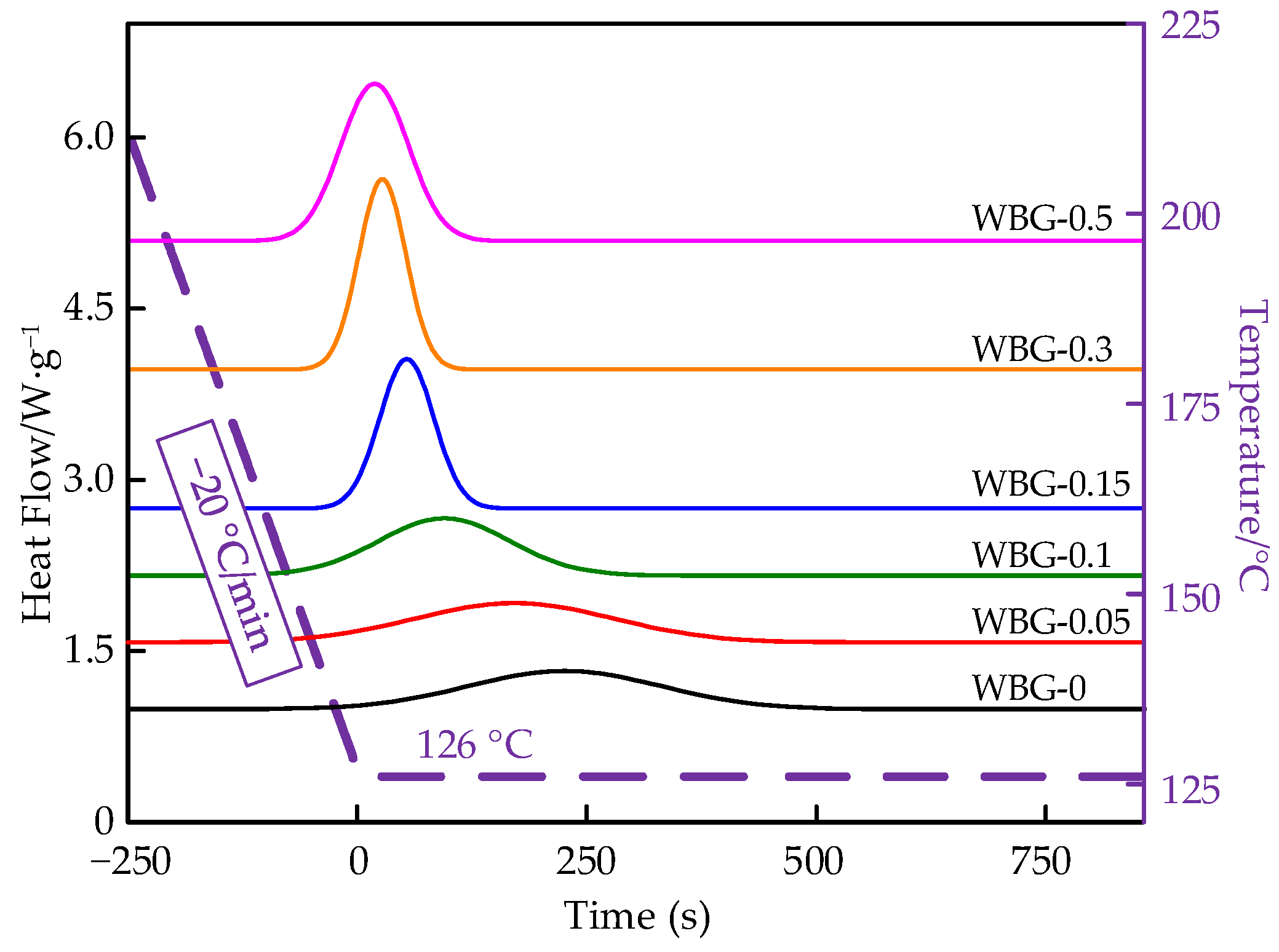

3.1. Effect of Nucleating Agent Content on Aggregate Structure

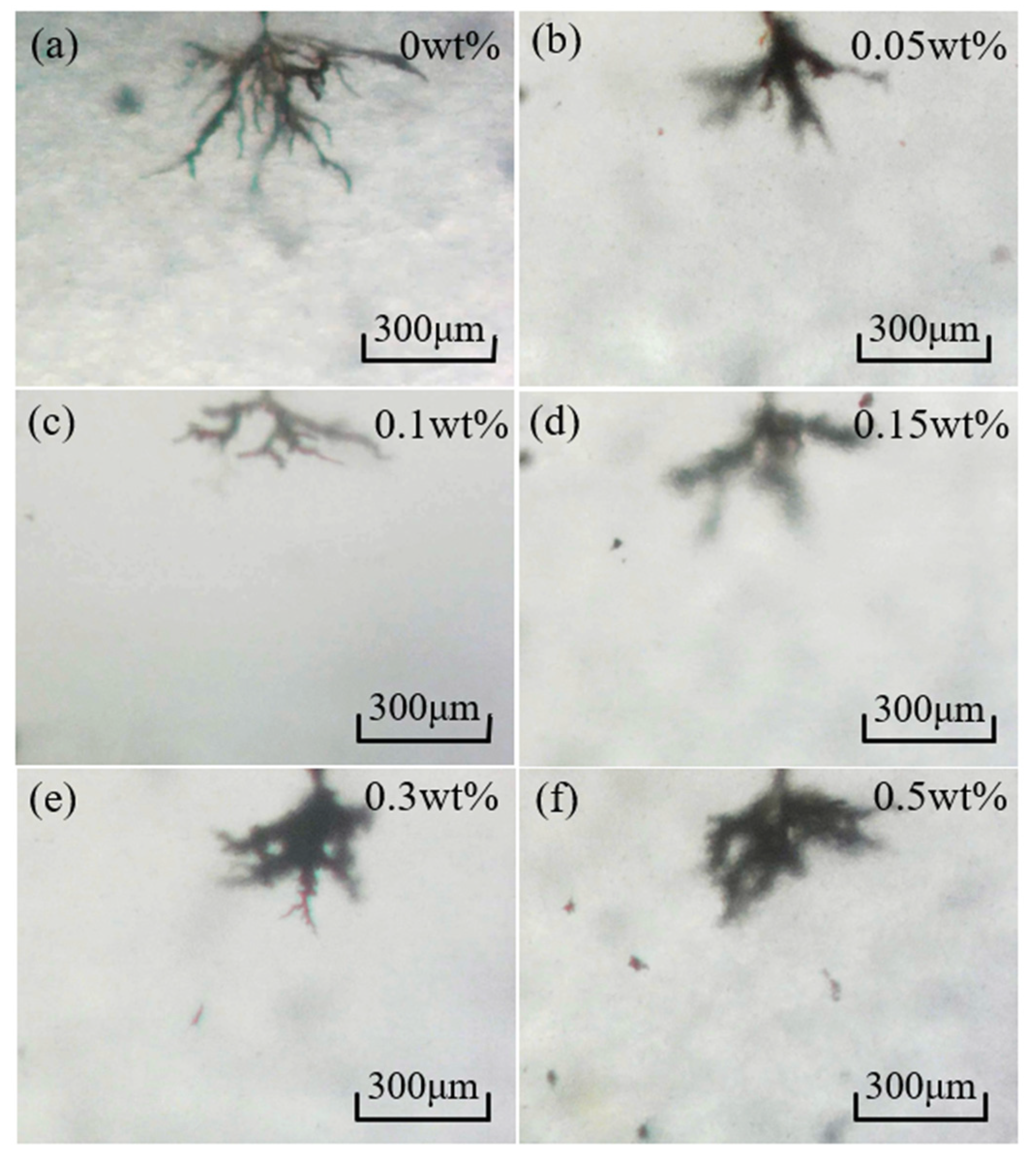

3.2. Effect of Nucleating Agent Content on Electrical Tree

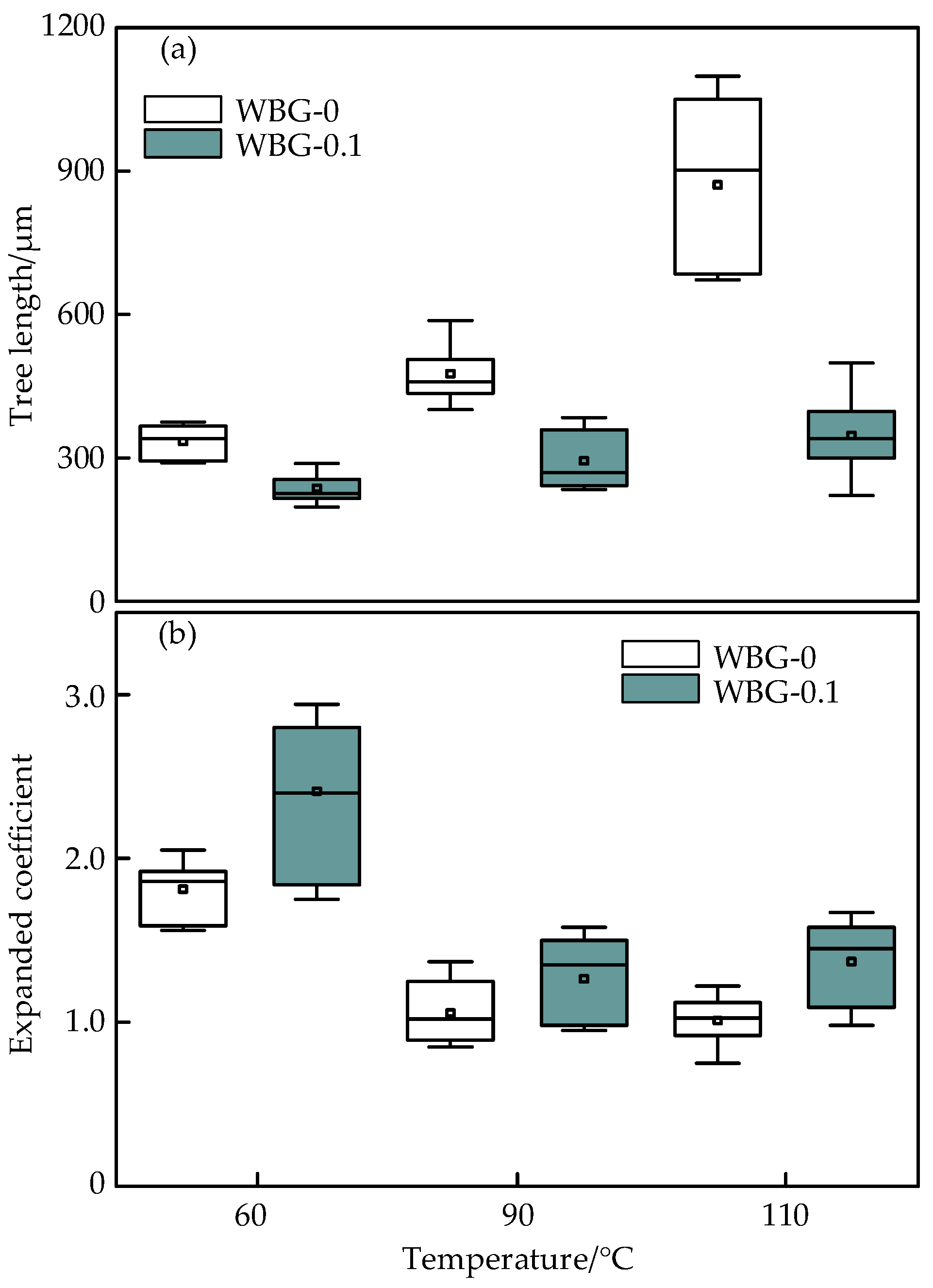

3.3. Effect of Temperature on Electrical Treeing

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, X.Y.; Zhang, J.; Jiang, P.K. Material progress toward recyclable insulation of power cables part 2: Polypropylene-based thermoplastic materials. IEEE Trans. Dielectr. Electr. Insul. 2020, 36, 8–18. [Google Scholar] [CrossRef]

- Ran, Z.Y.; Du, B.X.; Xiao, M.; Liu, H.L.; Xing, J.W. Effect of Crystallization Regulation on the Breakdown Strength of Metallized Polypropylene Film Capacitors. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 175–182. [Google Scholar] [CrossRef]

- Kim, D.W.; Yoshino, K. Morphological characteristics and electrical conduction in syndiotactic polypropylene. J. Phys. D Appl. Phys. 2000, 33, 464–471. [Google Scholar] [CrossRef]

- Du, B.X.; Zhu, L.W.; Han, T. Effect of ambient temperature on electrical treeing and breakdown phenomenon of polypropylene with repetitive pulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2216–2224. [Google Scholar] [CrossRef]

- Li, Z.L.; Dai, F.M.; Wu, Y.; Du, B.X. Effect of Crystalline Morphology on Electrical Tree Morphology and Growth Characteristics of PP Insulation: From Mesoscopic to Macroscopic. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 989–996. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, M.; Huang, K.; Mu, Q.; Chen, G. Effect of β-crystals on the mechanical and electrica properties of β-nucleated isotactic polypropylene. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 714–721. [Google Scholar] [CrossRef]

- Zhu, L.W.; Li, Z.L.; Hou, K. Effect of radical scavenger on electrical tree in cross-linked polyethylene with large harmonic superimposed DC voltage. High Volt. 2023, 8, 739–748. [Google Scholar] [CrossRef]

- Ceres, B.V.; Schultz, J.M. Dependence of electrical breakdown on spherulite size in isotactic polypropylene. J. Appl. Polym. Sci. 1984, 29, 4183–4197. [Google Scholar] [CrossRef]

- Li, J.Y.; Yang, K.; Wu, K.N.; Jing, Z.H.; Dong, J.Y. Eco-friendly polypropylene power cable insulation: Present status and perspective. IET Nanodielectrics 2023, 6, 130–146. [Google Scholar] [CrossRef]

- Ran, Z.Y.; Du, B.X.; Xiao, M. High-temperature Breakdown Performance Improvement of Polypropylene Films Based on Micromorphology Control. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1547–1554. [Google Scholar] [CrossRef]

- Ran, Z.Y.; Du, B.X.; Xiao, M.; Li, J. Crystallization Morphology-Dependent Breakdown Strength of Polypropylene Films for Converter Valve Capacitor. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 964–971. [Google Scholar] [CrossRef]

- Supaphol, P.; Dangseeyun, N. Srimoaon, Non-isothermal melt crystallization kinetics for poly(trimethylene terephthalate)/poly(butylene terephthalate) blends. Polym. Test. 2004, 23, 175–185. [Google Scholar] [CrossRef]

- Ketsamee, P.; Andritsch, T.; Vaughan, A. The Effects of Humidity on Dielectric Permittivity of Surface-Modified TiO₂− and MgO-Based Polypropylene Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 82–89. [Google Scholar] [CrossRef]

- Krache, R.; Benavente, R.; López-Majada, J.M.; Pereña, J.M.; Cerrada, M.L. Pérez, Competition between α, β, and γ polymorphs in a β-nucleated metallocenic isotactic polypropylene. Macromolecules 2007, 40, 6871–6878. [Google Scholar] [CrossRef]

- Su, J.G.; Du, B.X.; Li, J.; Li, Z.L. Electrical tree degradation in high-voltage cable insulation: Progress and challenges. High Volt. 2020, 5, 353–364. [Google Scholar] [CrossRef]

- An, Y.; Wang, S.; Li, R.; Shi, D.; Gao, Y.; Song, L. Effect of different nucleating agent on crystallization kinetics and morphology of polypropylene. e-Polymers 2019, 19, 32–39. [Google Scholar] [CrossRef]

- Zhao, X.; Dai, F.M.; Li, Z.L.; Yuan, Q.; Ke, D.; Zhang, S. Electrical tree characteristics dependent on crystallization process of iPP/POE blend insulation. In Proceedings of the 2022 IEEE International Conference on High Voltage Engineering and Applications (ICHVE), Chongqing, China, 25–29 September 2022; pp. 1–4. [Google Scholar]

- Zhou, S.F.; Fan, M.S.; Li, Z.L.; Du, B.X.; Yu, F.; Yan, H.D. Effect of β-Spherulite on Electrical Tree Characteristics of Isotactic Polypropylene Insulation. In Proceedings of the 3rd International Conference on Electrical Materials and Power Equipment, Chongqing, China, 11–15 April 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Wu, Y.; Du, B.X.; Li, Z.L.; Wang, H.Y.; Zheng, Z. Heterogeneous mesoscopic structure modulation enhancing dielectric strength of polypropylene insulation. Polymer 2023, 280, 126072. [Google Scholar] [CrossRef]

- Cho, K.; Li, F.K.; Choi, J. Crystallization and melting behavior of polypropylene and maleated polypropylene blends. Polymer 1999, 40, 1719–1729. [Google Scholar] [CrossRef]

- Du, B.X.; Hou, Z.H.; Li, J.; Li, Z.L. Effect of graphene nanoplatelets on space charge and breakdown strength of PP/ULDPE blends for HVDC cable insulation. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2405–2412. [Google Scholar] [CrossRef]

| Sample | WBG-II (wt%) |

|---|---|

| WBG-0 | 0 |

| WBG-0.05 | 0.05 |

| WBG-0.1 | 0.10 |

| WBG-0.15 | 0.15 |

| WBG-0.3 | 0.30 |

| WBG-0.5 | 0.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Tong, B.; Wang, H.; Zhu, P.; Rao, H.; Li, Z. Enhanced Electrical Tree Resistance of Polypropylene Cable Insulation by Introducing β-Crystals. Energies 2024, 17, 4610. https://doi.org/10.3390/en17184610

Yang Z, Tong B, Wang H, Zhu P, Rao H, Li Z. Enhanced Electrical Tree Resistance of Polypropylene Cable Insulation by Introducing β-Crystals. Energies. 2024; 17(18):4610. https://doi.org/10.3390/en17184610

Chicago/Turabian StyleYang, Zhuoran, Bin Tong, Han Wang, Peixuan Zhu, Huanyu Rao, and Zhonglei Li. 2024. "Enhanced Electrical Tree Resistance of Polypropylene Cable Insulation by Introducing β-Crystals" Energies 17, no. 18: 4610. https://doi.org/10.3390/en17184610