Predictive Models for Biodiesel Performance and Emission Characteristics in Diesel Engines: A Review

Abstract

:1. Introduction

2. Biodiesel

2.1. Production and Main Components of Biodiesel

2.2. Main Properties Affecting the Performance of Biodiesel in Diesel Engines

2.2.1. Density and Kinematic Viscosity

2.2.2. Cetane Number

2.2.3. Thermophysical Properties

3. Classification of Prediction and Optimization Techniques for Biodiesel Properties and Engine Performance

3.1. Statistical Modeling and Regression Methods

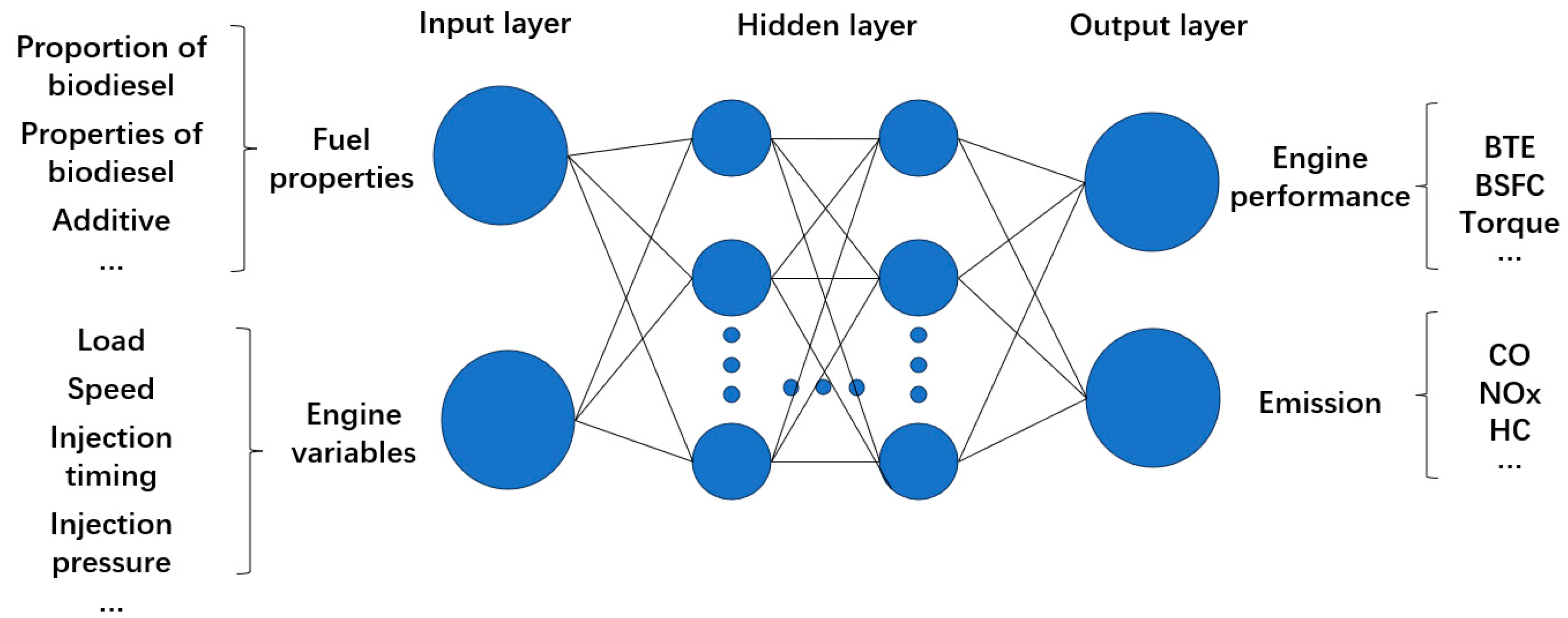

3.2. Machine Learning and Artificial Intelligence Methods

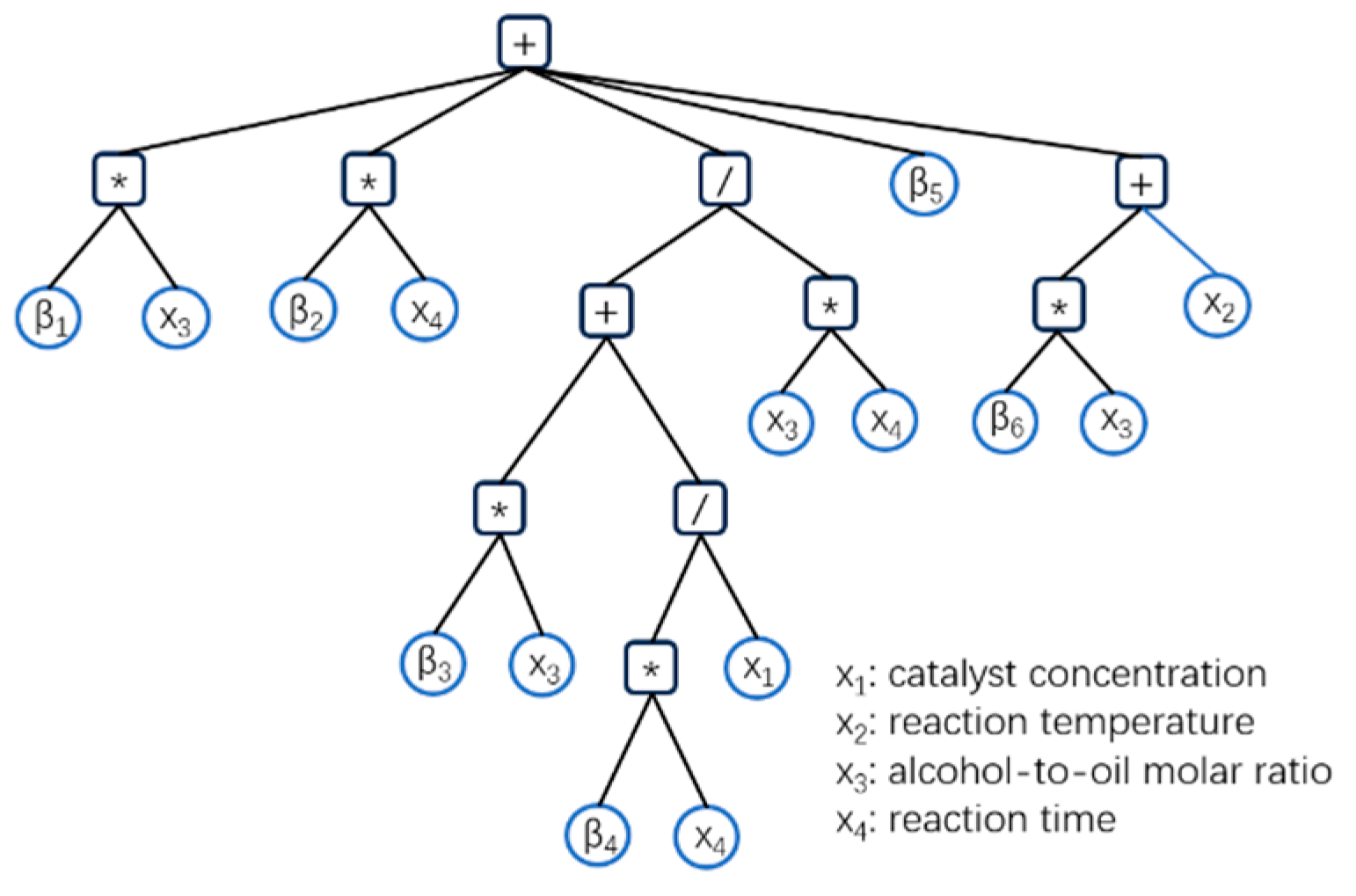

3.3. Evolutionary Algorithms and Optimization Methods

3.4. Scientific Modeling and Simulation Methods

4. Recent Research Case Analysis

4.1. Properties of Biodiesel

4.1.1. Density and Kinematic Viscosity

4.1.2. CN

4.1.3. Thermophysical Properties

4.2. Performance and Emissions of Biodiesel in Diesel Engines

4.2.1. Combustion Characteristics

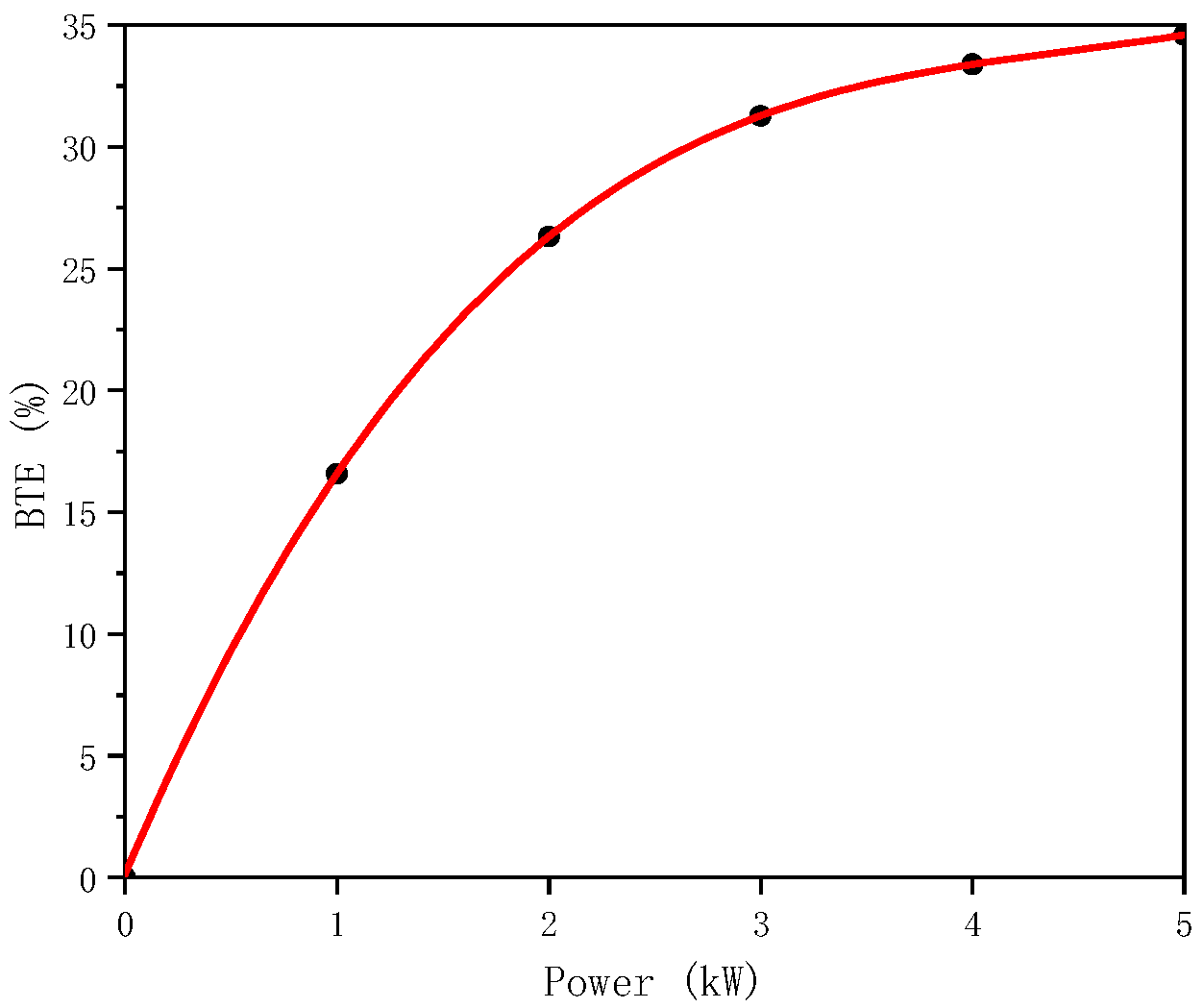

4.2.2. BTE and BSFC

4.2.3. Torque

4.2.4. Emissions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ANFIS | Adaptive neuro-fuzzy inference system |

| ANN | Artificial neural network |

| BRT | Enhanced regression tree |

| BSFC | Brake specific fuel consumption |

| BTE | Brake thermal efficiency |

| CFD | Computational fluid dynamics |

| CN | Cetane number |

| CO | Carbon monoxide |

| CTE | Coefficient of thermal expansion |

| FAMEs | Fatty acid methyl esters |

| GA | Genetic algorithm |

| GEP | Gene expression programming |

| GP | Genetic programming |

| GPR | Gaussian process regression |

| HC | Hydrocarbons |

| LSSVM | Least square support vector machine |

| ML | Machine learning |

| NOx | Nitrogen oxide |

| PM | Particulate matter |

| PSO | Particle swarm optimization |

| RMSE | Root mean square error |

| RSM | Response surface methodology |

| SVM | Support vector machine |

References

- Su, Y.; Zhang, P.; Su, Y. An Overview of Biofuels Policies and Industrialization in the Major Biofuel Producing Countries. Renew. Sustain. Energy Rev. 2015, 50, 991–1003. [Google Scholar] [CrossRef]

- de Souza, T.A.Z.; Pinto, G.M.; Julio, A.A.V.; Coronado, C.J.R.; Perez-Herrera, R.; Siqueira, B.O.P.S.; da Costa, R.B.R.; Roberts, J.J.; Palacio, J.C.E. Biodiesel in South American Countries: A Review on Policies, Stages of Development and Imminent Competition with Hydrotreated Vegetable Oil. Renew. Sustain. Energy Rev. 2022, 153, 111755. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Dimaratos, A.M.; Rakopoulos, C.D.; Rakopoulos, D.C. Combustion Instability during Starting of Turbocharged Diesel Engine Including Biofuel Effects. J. Energy Eng. 2017, 143, 4016047. [Google Scholar] [CrossRef]

- Setiawan, I.C.; Setiyo, M. Renewable and Sustainable Green Diesel (D100) for Achieving Net Zero Emission in Indonesia Transportation Sector. Automot. Exp. 2022, 5, 1–2. [Google Scholar] [CrossRef]

- Maawa, W.N.; Mamat, R.; Najafi, G.; De Goey, L.P.H. Performance, Combustion, and Emission Characteristics of a CI Engine Fueled with Emulsified Diesel-Biodiesel Blends at Different Water Contents. Fuel 2020, 267, 117265. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Combustion Noise Radiation during the Acceleration of a Turbocharged Diesel Engine Operating with Biodiesel or N-Butanol Diesel Fuel Blends. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2012, 226, 971–986. [Google Scholar] [CrossRef]

- Khan, I.U. Analysis of Biodiesel and Fatty Acids Using State-of-the-Art Methods from Non-Edible Plants Seed Oil; Nicotiana Tobaccum and Olea Ferruginia. Process Saf. Environ. Prot. 2024, 186, 25–36. [Google Scholar] [CrossRef]

- Krishnasamy, A.; Bukkarapu, K.R. A Comprehensive Review of Biodiesel Property Prediction Models for Combustion Modeling Studies. Fuel 2021, 302, 121085. [Google Scholar] [CrossRef]

- Palani, Y.; Devarajan, C.; Manickam, D.; Thanikodi, S. Performance and Emission Characteristics of Biodiesel-Blend in Diesel Engine: A Review. Environ. Eng. Res. 2022, 27, 200338. [Google Scholar] [CrossRef]

- Bukkarapu, K.R.; Krishnasamy, A. A Critical Review on Available Models to Predict Engine Fuel Properties of Biodiesel. Renew. Sustain. Energy Rev. 2022, 155, 111925. [Google Scholar] [CrossRef]

- Suvarna, M.; Jahirul, M.I.; Aaron-Yeap, W.H.; Augustine, C.V.; Umesh, A.; Rasul, M.G.; Günay, M.E.; Yildirim, R.; Janaun, J. Predicting Biodiesel Properties and Its Optimal Fatty Acid Profile via Explainable Machine Learning. Renew. Energy 2022, 189, 245–258. [Google Scholar] [CrossRef]

- Xiao, H.; Wang, W.; Bao, H.; Li, F.; Zhou, L. Biodiesel-Diesel Blend Optimized via Leave-One Cross-Validation Based on Kinematic Viscosity, Calorific Value, and Flash Point. Ind. Crops Prod. 2023, 191, 115914. [Google Scholar] [CrossRef]

- Yusoff, M.N.A.M.; Zulkifli, N.W.M.; Sukiman, N.L.; Chyuan, O.H.; Hassan, M.H.; Hasnul, M.H.; Zulkifli, M.S.A.; Abbas, M.M.; Zakaria, M.Z. Sustainability of Palm Biodiesel in Transportation: A Review on Biofuel Standard, Policy and International Collaboration Between Malaysia and Colombia. Bioenerg. Res. 2021, 14, 43–60. [Google Scholar] [CrossRef] [PubMed]

- Rakopoulos, C.D.; Antonopoulos, K.A.; Rakopoulos, D.C.; Hountalas, D.T.; Giakoumis, E.G. Comparative Performance and Emissions Study of a Direct Injection Diesel Engine Using Blends of Diesel Fuel with Vegetable Oils or Bio-Diesels of Various Origins. Energy Convers. Manag. 2006, 47, 3272–3287. [Google Scholar] [CrossRef]

- Gebremariam, S.N.; Marchetti, J.M. Economics of Biodiesel Production: Review. Energy Convers. Manag. 2018, 168, 74–84. [Google Scholar] [CrossRef]

- Mahlia, T.M.I.; Syazmi, Z.A.H.S.; Mofijur, M.; Abas, A.E.P.; Bilad, M.R.; Ong, H.C.; Silitonga, A.S. Patent Landscape Review on Biodiesel Production: Technology Updates. Renew. Sustain. Energy Rev. 2020, 118, 109526. [Google Scholar] [CrossRef]

- Avinash, A.; Sasikumar, P.; Pugazhendhi, A. Analysis of the Limiting Factors for Large Scale Microalgal Cultivation: A Promising Future for Renewable and Sustainable Biofuel Industry. Renew. Sustain. Energy Rev. 2020, 134, 110250. [Google Scholar] [CrossRef]

- Foteinis, S.; Chatzisymeon, E.; Litinas, A.; Tsoutsos, T. Used-Cooking-Oil Biodiesel: Life Cycle Assessment and Comparison with First- and Third-Generation Biofuel. Renew. Energy 2020, 153, 588–600. [Google Scholar] [CrossRef]

- Hajjari, M.; Tabatabaei, M.; Aghbashlo, M.; Ghanavati, H. A Review on the Prospects of Sustainable Biodiesel Production: A Global Scenario with an Emphasis on Waste-Oil Biodiesel Utilization. Renew. Sustain. Energy Rev. 2017, 72, 445–464. [Google Scholar] [CrossRef]

- Fonseca, J.M.; Teleken, J.G.; De Cinque Almeida, V.; Da Silva, C. Biodiesel from Waste Frying Oils: Methods of Production and Purification. Energy Convers. Manag. 2019, 184, 205–218. [Google Scholar] [CrossRef]

- Wang, W.; Gowdagiri, S.; Oehlschlaeger, M.A. The High-Temperature Autoignition of Biodiesels and Biodiesel Components. Combust. Flame 2014, 161, 3014–3021. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Sarakatsanis, C.K. Estimation of Biodiesel Cetane Number, Density, Kinematic Viscosity and Heating Values from Its Fatty Acid Weight Composition. Fuel 2018, 222, 574–585. [Google Scholar] [CrossRef]

- Giakoumis, E.G. A Statistical Investigation of Biodiesel Physical and Chemical Properties, and Their Correlation with the Degree of Unsaturation. Renew. Energy 2013, 50, 858–878. [Google Scholar] [CrossRef]

- Knothe, G. Improving Biodiesel Fuel Properties by Modifying Fatty Ester Composition. Energy Environ. Sci. 2009, 2, 759–766. [Google Scholar] [CrossRef]

- Li, F.; Liu, Z.; Ni, Z.; Wang, H. Effect of Biodiesel Components on Its Lubrication Performance. J. Mater. Res. Technol. 2019, 8, 3681–3687. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Exhaust Emissions of Diesel Engines Operating under Transient Conditions with Biodiesel Fuel Blends. Prog. Energy Combust. Sci. 2012, 38, 691–715. [Google Scholar] [CrossRef]

- Verma, S.; Upadhyay, R.; Shankar, R.; Pandey, S.P. Performance and Emission Characteristics of Micro-Algae Biodiesel with Butanol and TiO2 Nano-Additive over Diesel Engine. Sustain. Energy Technol. Assess. 2023, 55, 102975. [Google Scholar] [CrossRef]

- Mishra, S.; Bukkarapu, K.R.; Krishnasamy, A. A Composition Based Approach to Predict Density, Viscosity and Surface Tension of Biodiesel Fuels. Fuel 2021, 285, 119056. [Google Scholar] [CrossRef]

- Fathurrahman, N.A.; Ginanjar, K.; Devitasari, R.D.; Maslahat, M.; Anggarani, R.; Aisyah, L.; Soemanto, A.; Solikhah, M.D.; Thahar, A.; Wibowo, E.; et al. Long-Term Storage Stability of Incorporated Hydrotreated Vegetable Oil (HVO) in Biodiesel-Diesel Blends at Highland and Coastal Areas. Fuel Commun. 2024, 18, 100107. [Google Scholar] [CrossRef]

- Dunn, R.O. Effect of Temperature on the Oil Stability Index (OSI) of Biodiesel. Energy Fuels 2008, 22, 657–662. [Google Scholar] [CrossRef]

- Lanjekar, R.D.; Deshmukh, D. A Review of the Effect of the Composition of Biodiesel on NOx Emission, Oxidative Stability and Cold Flow Properties. Renew. Sustain. Energy Rev. 2016, 54, 1401–1411. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M. Determination of the Density and the Viscosities of Biodiesel–Diesel Fuel Blends. Renew. Energy 2008, 33, 2623–2630. [Google Scholar] [CrossRef]

- Ramírez-Verduzco, L.F.; García-Flores, B.E.; Rodríguez-Rodríguez, J.E.; del Rayo Jaramillo-Jacob, A. Prediction of the Density and Viscosity in Biodiesel Blends at Various Temperatures. Fuel 2011, 90, 1751–1761. [Google Scholar] [CrossRef]

- Ramírez Verduzco, L.F. Density and Viscosity of Biodiesel as a Function of Temperature: Empirical Models. Renew. Sustain. Energy Rev. 2013, 19, 652–665. [Google Scholar] [CrossRef]

- Krisnangkura, K.; Yimsuwan, T.; Pairintra, R. An Empirical Approach in Predicting Biodiesel Viscosity at Various Temperatures. Fuel 2006, 85, 107–113. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Sarakatsanis, C.K. A Comparative Assessment of Biodiesel Cetane Number Predictive Correlations Based on Fatty Acid Composition. Energies 2019, 12, 422. [Google Scholar] [CrossRef]

- Fassinou, W.F.; Sako, A.; Fofana, A.; Koua, K.B.; Toure, S. Fatty Acids Composition as a Means to Estimate the High Heating Value (HHV) of Vegetable Oils and Biodiesel Fuels. Energy 2010, 35, 4949–4954. [Google Scholar] [CrossRef]

- Zheng, X.; Qu, D.; Bao, Y.; Qin, G.; Liu, Y.; Luo, Q. Experimental Studies of Thermal Conductivity of Three Biodiesel Compounds: Methyl Pentanoate, Methyl Octanoate, and Methyl Decanoate. J. Chem. Eng. Data 2022, 67, 45–53. [Google Scholar] [CrossRef]

- Santos, D.Q.; de Lima, A.L.; de Lima, A.P.; Neto, W.B.; Fabris, J.D. Thermal Expansion Coefficient and Algebraic Models to Correct Values of Specific Mass as a Function of Temperature for Corn Biodiesel. Fuel 2013, 106, 646–650. [Google Scholar] [CrossRef]

- Veza, I.; Spraggon, M.; Fattah, I.M.R.; Idris, M. Response Surface Methodology (RSM) for Optimizing Engine Performance and Emissions Fueled with Biofuel: Review of RSM for Sustainability Energy Transition. Results Eng. 2023, 18, 101213. [Google Scholar] [CrossRef]

- Singh Pali, H.; Sharma, A.; Kumar, N.; Singh, Y. Biodiesel Yield and Properties Optimization from Kusum Oil by RSM. Fuel 2021, 291, 120218. [Google Scholar] [CrossRef]

- Dubey, A.; Prasad, R.S.; Kumar Singh, J.; Nayyar, A. Optimization of Diesel Engine Performance and Emissions with Biodiesel-Diesel Blends and EGR Using Response Surface Methodology (RSM). Clean. Eng. Technol. 2022, 8, 100509. [Google Scholar] [CrossRef]

- Özgür, C. Optimization of Biodiesel Yield and Diesel Engine Performance from Waste Cooking Oil by Response Surface Method (RSM). Pet. Sci. Technol. 2021, 39, 683–703. [Google Scholar] [CrossRef]

- Saravanan, S.; Rajesh Kumar, B.; Varadharajan, A.; Rana, D.; Sethuramasamyraja, B.; Lakshmi Narayana rao, G. Optimization of DI Diesel Engine Parameters Fueled with Iso-Butanol/Diesel Blends—Response Surface Methodology Approach. Fuel 2017, 203, 658–670. [Google Scholar] [CrossRef]

- Kumar, S. Comparison of Linear Regression and Artificial Neural Network Technique for Prediction of a Soybean Biodiesel Yield. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 1425–1435. [Google Scholar] [CrossRef]

- Archontoulis, S.V.; Miguez, F.E. Nonlinear Regression Models and Applications in Agricultural Research. Agron. J. 2015, 107, 786–798. [Google Scholar] [CrossRef]

- Maheshwari, N.; Balaji, C.; Ramesh, A. A Nonlinear Regression Based Multi-Objective Optimization of Parameters Based on Experimental Data from an IC Engine Fueled with Biodiesel Blends. Biomass Bioenergy 2011, 35, 2171–2183. [Google Scholar] [CrossRef]

- Mairizal, A.Q.; Awad, S.; Priadi, C.R.; Hartono, D.M.; Moersidik, S.S.; Tazerout, M.; Andres, Y. Experimental Study on the Effects of Feedstock on the Properties of Biodiesel Using Multiple Linear Regressions. Renew. Energy 2020, 145, 375–381. [Google Scholar] [CrossRef]

- Kumbhar, V.; Pandey, A.; Sonawane, C.R.; El-Shafay, A.S.; Panchal, H.; Chamkha, A.J. Statistical Analysis on Prediction of Biodiesel Properties from Its Fatty Acid Composition. Case Stud. Therm. Eng. 2022, 30, 101775. [Google Scholar] [CrossRef]

- Alahmer, A.; Alahmer, H.; Handam, A.; Rezk, H. Environmental Assessment of a Diesel Engine Fueled with Various Biodiesel Blends: Polynomial Regression and Grey Wolf Optimization. Sustainability 2022, 14, 1367. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Peng, W.; Tabatabaei, M.; Kalogirou, S.A.; Soltanian, S.; Hosseinzadeh-Bandbafha, H.; Mahian, O.; Lam, S.S. Machine Learning Technology in Biodiesel Research: A Review. Prog. Energy Combust. Sci. 2021, 85, 100904. [Google Scholar] [CrossRef]

- Ishola, N.B.; Epelle, E.I.; Betiku, E. Machine Learning Approaches to Modeling and Optimization of Biodiesel Production Systems: State of Art and Future Outlook. Energy Convers. Manag. X 2024, 23, 100669. [Google Scholar] [CrossRef]

- Subramanian, K.; Sathiyagnanam, A.P.; Damodharan, D.; Sivashanmugam, N. Artificial Neural Network Based Prediction of a Direct Injected Diesel Engine Performance and Emission Characteristics Powered with Biodiesel. Mater. Today Proc. 2021, 43, 1049–1056. [Google Scholar] [CrossRef]

- Aydın, M.; Uslu, S.; Bahattin Çelik, M. Performance and Emission Prediction of a Compression Ignition Engine Fueled with Biodiesel-Diesel Blends: A Combined Application of ANN and RSM Based Optimization. Fuel 2020, 269, 117472. [Google Scholar] [CrossRef]

- Tuan Hoang, A.; Nižetić, S.; Chyuan Ong, H.; Tarelko, W.; Viet Pham, V.; Hieu Le, T.; Quang Chau, M.; Phuong Nguyen, X. A Review on Application of Artificial Neural Network (ANN) for Performance and Emission Characteristics of Diesel Engine Fueled with Biodiesel-Based Fuels. Sustain. Energy Technol. Assess. 2021, 47, 101416. [Google Scholar] [CrossRef]

- Karimmaslak, H.; Najafi, B.; Band, S.S.; Ardabili, S.; Haghighat-Shoar, F.; Mosavi, A. Optimization of Performance and Emission of Compression Ignition Engine Fueled with Propylene Glycol and Biodiesel–Diesel Blends Using Artificial Intelligence Method of ANN-GA-RSM. Eng. Appl. Comput. Fluid Mech. 2021, 15, 413–425. [Google Scholar] [CrossRef]

- Tuan, N.V.; Minh, D.Q.; Khoa, N.X.; Lim, O. A Study to Predict Ignition Delay of an Engine Using Diesel and Biodiesel Fuel Based on the ANN and SVM Machine Learning Methods. ACS Omega 2023, 8, 9995–10005. [Google Scholar] [CrossRef]

- Bukkarapu, K.R.; Krishnasamy, A. Biodiesel Composition Based Machine Learning Approaches to Predict Engine Fuel Properties. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2024, 238, 1844–1860. [Google Scholar] [CrossRef]

- Jin, X.; Li, S.; Ye, H.; Wang, J.; Wu, Y.; Zhang, D.; Ma, H.; Sun, F.; Pugazhendhi, A.; Xia, C. Investigation and Optimization of Biodiesel Production Based on Multiple Machine Learning Technologies. Fuel 2023, 348, 128546. [Google Scholar] [CrossRef]

- Bukkarapu, K.R.; Krishnasamy, A. Investigations on the Applicability of Machine Learning Algorithms to Optimize Biodiesel Composition for Improved Engine Fuel Properties. Int. J. Engine Res. 2024, 25, 1299–1314. [Google Scholar] [CrossRef]

- Raj Bukkarapu, K.; Krishnasamy, A. Support Vector Regression Approach to Optimize the Biodiesel Composition for Improved Engine Performance and Lower Exhaust Emissions. Fuel 2023, 348, 128604. [Google Scholar] [CrossRef]

- Almohana, A.I.; Almojil, S.F.; Kamal, M.A.; Alali, A.F.; Kamal, M.; Alkhatib, S.E.; Felemban, B.F.; Algarni, M. Theoretical Investigation on Optimization of Biodiesel Production Using Waste Cooking Oil: Machine Learning Modeling and Experimental Validation. Energy Rep. 2022, 8, 11938–11951. [Google Scholar] [CrossRef]

- Lionus Leo, G.M.; Jayabal, R.; Srinivasan, D.; Chrispin Das, M.; Ganesh, M.; Gavaskar, T. Predicting the Performance and Emissions of an HCCI-DI Engine Powered by Waste Cooking Oil Biodiesel with Al2O3 and FeCl3 Nano Additives and Gasoline Injection—A Random Forest Machine Learning Approach. Fuel 2024, 357, 129914. [Google Scholar] [CrossRef]

- Kumar, D.; Chhibber, V.K.; Singh, A. Emissions Prediction of Cashew Nut Shell Liquid Biodiesel Using Machine Learning. Natl. Acad. Sci. Lett. 2022, 45, 397–400. [Google Scholar] [CrossRef]

- Moayedi, H.; Aghel, B.; Foong, L.K.; Bui, D.T. Feature Validity during Machine Learning Paradigms for Predicting Biodiesel Purity. Fuel 2020, 262, 116498. [Google Scholar] [CrossRef]

- Rajkumar, S.; Das, A.; Thangaraja, J. Integration of Artificial Neural Network, Multi-Objective Genetic Algorithm and Phenomenological Combustion Modelling for Effective Operation of Biodiesel Blends in an Automotive Engine. Energy 2022, 239, 121889. [Google Scholar] [CrossRef]

- Baghban, A.; Kardani, M.N.; Mohammadi, A.H. Improved Estimation of Cetane Number of Fatty Acid Methyl Esters (FAMEs) Based Biodiesels Using TLBO-NN and PSO-NN Models. Fuel 2018, 232, 620–631. [Google Scholar] [CrossRef]

- Slowik, A.; Kwasnicka, H. Evolutionary Algorithms and Their Applications to Engineering Problems. Neural Comput. Applic 2020, 32, 12363–12379. [Google Scholar] [CrossRef]

- Alam, T.; Qamar, S.; Dixit, A.; Benaida, M. Genetic Algorithm: Reviews, Implementations, and Applications. Int. J. Eng. Pedagog. 2020, 10, 57–77. [Google Scholar] [CrossRef]

- Kolakoti, A.; Jha, P.; Mosa, P.R.; Mahapatro, M.; Kotaru, T.G. Optimization and Modelling of Mahua Oil Biodiesel Using RSM and Genetic Algorithm Techniques. Math. Models Eng. 2020, 6, 134–146. [Google Scholar] [CrossRef]

- Onukwuli, D.O.; Esonye, C.; Ofoefule, A.U.; Eyisi, R. Comparative Analysis of the Application of Artificial Neural Network-Genetic Algorithm and Response Surface Methods-Desirability Function for Predicting the Optimal Conditions for Biodiesel Synthesis from Chrysophyllum Albidum Seed Oil. J. Taiwan Inst. Chem. Eng. 2021, 125, 153–167. [Google Scholar] [CrossRef]

- Shirneshan, A.; Bagherzadeh, S.A.; Najafi, G.; Mamat, R.; Mazlan, M. Optimization and Investigation the Effects of Using Biodiesel-Ethanol Blends on the Performance and Emission Characteristics of a Diesel Engine by Genetic Algorithm. Fuel 2021, 289, 119753. [Google Scholar] [CrossRef]

- Zhang, Q.; Ogren, R.M.; Kong, S.-C. A Comparative Study of Biodiesel Engine Performance Optimization Using Enhanced Hybrid PSO–GA and Basic GA. Appl. Energy 2016, 165, 676–684. [Google Scholar] [CrossRef]

- Bagal, D.K.; Patra, A.K.; Jeet, S.; Barua, A.; Pattanaik, A.K.; Patnaik, D. MCDM Optimization of Karanja Biodiesel Powered CI Engine to Improve Performance Characteristics Using Super Hybrid Taguchi-Coupled WASPAS-GA, SA, PSO Method. In Next Generation Materials and Processing Technologies; Bag, S., Paul, C.P., Baruah, M., Eds.; Springer: Singapore, 2021; pp. 491–503. [Google Scholar]

- Alviso, D.; Artana, G.; Duriez, T. Prediction of Biodiesel Physico-Chemical Properties from Its Fatty Acid Composition Using Genetic Programming. Fuel 2020, 264, 116844. [Google Scholar] [CrossRef]

- Kumar, V.; Kalita, K.; Madhu, S.; Ragavendran, U.; Gao, X.-Z. A Hybrid Genetic Programming–Gray Wolf Optimizer Approach for Process Optimization of Biodiesel Production. Processes 2021, 9, 442. [Google Scholar] [CrossRef]

- Ghanbari, M.; Najafi, G.; Ghobadian, B.; Yusaf, T.; Carlucci, A.P.; Kiani Deh Kiani, M. Performance and Emission Characteristics of a CI Engine Using Nano Particles Additives in Biodiesel-Diesel Blends and Modeling with GP Approach. Fuel 2017, 202, 699–716. [Google Scholar] [CrossRef]

- Zandie, M.; Ng, H.K.; Gan, S.; Muhamad Said, M.F.; Cheng, X. Review of the Advances in Integrated Chemical Kinetics-Computational Fluid Dynamics Combustion Modelling Studies of Gasoline-Biodiesel Mixtures. Transp. Eng. 2022, 7, 100102. [Google Scholar] [CrossRef]

- Maksom, M.S.; Nasir, N.F.; Asmuin, N.; Rahman, M.F.A.; Khairulfuaad, R. Biodiesel Composition Effects on Density and Viscosity of Diesel-Biodiesel Blend: A CFD Study. CFD Lett. 2020, 12, 100–109. [Google Scholar] [CrossRef]

- Dixit, S.; Kumar, A.; Kumar, S.; Waghmare, N.; Thakur, H.C.; Khan, S. CFD Analysis of Biodiesel Blends and Combustion Using Ansys Fluent. Mater. Today Proc. 2020, 26, 665–670. [Google Scholar] [CrossRef]

- Zandie, M.; Ng, H.K.; Gan, S.; Muhamad Said, M.F.; Cheng, X. A Comprehensive CFD Study of the Spray Combustion, Soot Formation and Emissions of Ternary Mixtures of Diesel, Biodiesel and Gasoline under Compression Ignition Engine-Relevant Conditions. Energy 2022, 260, 125191. [Google Scholar] [CrossRef]

- Zandie, M.; Ng, H.K.; Muhamad Said, M.F.; Cheng, X.; Gan, S. Performance of a Compression Ignition Engine Fuelled with Diesel-Palm Biodiesel-Gasoline Mixtures: CFD and Multi Parameter Optimisation Studies. Energy 2023, 274, 127346. [Google Scholar] [CrossRef]

- Gowrishankar, S.; Krishnasamy, A. CFD Analysis of Combustion and Emission Characteristics of Biodiesel under Conventional and Late-Injection Based Premixed Combustion Conditions. Fuel 2023, 351, 129021. [Google Scholar] [CrossRef]

- Thomas, J.J.; Manojkumar, C.V.; Sabu, V.R.; Nagarajan, G. Development and Validation of a Reduced Chemical Kinetic Model for Used Vegetable Oil Biodiesel/1-Hexanol Blend for Engine Application. Fuel 2020, 273, 117780. [Google Scholar] [CrossRef]

- Jung, J.W.; Lim, Y.C.; Suh, H.K. A Study on the Mechanism Reduction and Evaluation of Biodiesel with the Change of Mechanism Reduction Factors. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 3398–3413. [Google Scholar] [CrossRef]

- Zandie, M.; Ng, H.K.; Gan, S.; Muhamad Said, M.F.; Cheng, X. Development of a Reduced Multi-Component Chemical Kinetic Mechanism for the Combustion Modelling of Diesel-Biodiesel-Gasoline Mixtures. Transp. Eng. 2022, 7, 100101. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, X.; Lan, Z. A Reduced Reaction Mechanism of Biodiesel Surrogates with Low Temperature Chemistry for Multidimensional Engine Simulation. Combust. Flame 2020, 212, 377–387. [Google Scholar] [CrossRef]

- Razzaq, L.; Farooq, M.; Mujtaba, M.A.; Sher, F.; Farhan, M.; Hassan, M.T.; Soudagar, M.E.M.; Atabani, A.E.; Kalam, M.A.; Imran, M. Modeling Viscosity and Density of Ethanol-Diesel-Biodiesel Ternary Blends for Sustainable Environment. Sustainability 2020, 12, 5186. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Kalam, M.A.; Masjuki, H.H.; Razzaq, L.; Khan, H.M.; Soudagar, M.E.M.; Gul, M.; Ahmed, W.; Raju, V.D.; Kumar, R.; et al. Development of Empirical Correlations for Density and Viscosity Estimation of Ternary Biodiesel Blends. Renew. Energy 2021, 179, 1447–1457. [Google Scholar] [CrossRef]

- Nabipour, N.; Daneshfar, R.; Rezvanjou, O.; Mohammadi-Khanaposhtani, M.; Baghban, A.; Xiong, Q.; Li, L.K.B.; Habibzadeh, S.; Doranehgard, M.H. Estimating Biofuel Density via a Soft Computing Approach Based on Intermolecular Interactions. Renew. Energy 2020, 152, 1086–1098. [Google Scholar] [CrossRef]

- Pustokhina, I.; Seraj, A.; Hafsan, H.; Mostafavi, S.M.; Alizadeh, S.M. Developing a Robust Model Based on the Gaussian Process Regression Approach to Predict Biodiesel Properties. Int. J. Chem. Eng. 2021, 2021, 5650499. [Google Scholar] [CrossRef]

- Giwa, S.O.; Taziwa, R.T.; Sharifpur, M. Dependence of Composition-Based Approaches on Hybrid Biodiesel Fuel Properties Prediction Using Artificial Neural Network and Random Tree Algorithms. Renew. Energy 2023, 218, 119324. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Wu, X.-E. Determination of Cetane Number from Fatty Acid Compositions and Structures of Biodiesel. Processes 2022, 10, 1502. [Google Scholar] [CrossRef]

- Bemani, A.; Xiong, Q.; Baghban, A.; Habibzadeh, S.; Mohammadi, A.H.; Doranehgard, M.H. Modeling of Cetane Number of Biodiesel from Fatty Acid Methyl Ester (FAME) Information Using GA-, PSO-, and HGAPSO- LSSVM Models. Renew. Energy 2020, 150, 924–934. [Google Scholar] [CrossRef]

- Ghiasi, M.M.; Mohammadzadeh, O.; Zendehboudi, S. Reliable Connectionist Tools to Determine Biodiesel Cetane Number Based on Fatty Acids Methyl Esters Content. Energy Convers. Manag. 2022, 264, 115601. [Google Scholar] [CrossRef]

- Rahaju, S.M.N.; Hananto, A.L.; Paristiawan, P.A.; Mohammed, A.T.; Opia, A.C.; Idris, M. Comparison of Various Prediction Model for Biodiesel Cetane Number Using Cascade-Forward Neural Network. Automot. Exp. 2023, 6, 4–13. [Google Scholar] [CrossRef]

- Noushabadi, A.S.; Dashti, A.; Raji, M.; Zarei, A.; Mohammadi, A.H. Estimation of Cetane Numbers of Biodiesel and Diesel Oils Using Regression and PSO-ANFIS Models. Renew. Energy 2020, 158, 465–473. [Google Scholar] [CrossRef]

- Samuel, O.D.; Kaveh, M.; Verma, T.N.; Okewale, A.O.; Oyedepo, S.O.; Abam, F.; Nwaokocha, C.N.; Abbas, M.; Enweremadu, C.C.; Khalife, E.; et al. Grey Wolf Optimizer for Enhancing Nicotiana tabacum L. Oil Methyl Ester and Prediction Model for Calorific Values. Case Stud. Therm. Eng. 2022, 35, 102095. [Google Scholar] [CrossRef]

- Giuliano Albo, P.A.; Lago, S.; Wolf, H.; Pagel, R.; Glen, N.; Clerck, M.; Ballereau, P. Density, Viscosity and Specific Heat Capacity of Diesel Blends with Rapeseed and Soybean Oil Methyl Ester. Biomass Bioenergy 2017, 96, 87–95. [Google Scholar] [CrossRef]

- Ait Belale, R.; M’hamdi Alaoui, F.E.; Chhiti, Y.; Sahibeddine, A.; Munoz Rujas, N.; Aguilar, F. Study on the Thermophysical Properties of Waste Cooking Oil Biodiesel Fuel Blends with 1-Butanol. Fuel 2021, 287, 119540. [Google Scholar] [CrossRef]

- Magalhães, A.M.S.; Brentan, B.M.; Meirelles, A.J.A.; Maximo, G.J. Thermal Properties of Ethylic Biodiesel Blends and Solid Fraction Prediction Using Artificial Neural Networks. Fluid Phase Equilibria 2023, 574, 113885. [Google Scholar] [CrossRef]

- Kiran, A.V.; Jayapriya, J.; Ravi, M. Evaluation and Predictive Model Development of Oxidative Stability of Biodiesel on Storage. Chem. Eng. Commun. 2016, 203, 676–682. [Google Scholar] [CrossRef]

- Santos, S.M.; Nascimento, D.C.; Costa, M.C.; Neto, A.M.B.; Fregolente, L.V. Flash Point Prediction: Reviewing Empirical Models for Hydrocarbons, Petroleum Fraction, Biodiesel, and Blends. Fuel 2020, 263, 116375. [Google Scholar] [CrossRef]

- Cunha, C.L.; Torres, A.R.; Luna, A.S. Multivariate Regression Models Obtained from Near-Infrared Spectroscopy Data for Prediction of the Physical Properties of Biodiesel and Its Blends. Fuel 2020, 261, 116344. [Google Scholar] [CrossRef]

- Hoang, A.T. Prediction of the Density and Viscosity of Biodiesel and the Influence of Biodiesel Properties on a Diesel Engine Fuel Supply System. J. Mar. Eng. Technol. 2021, 20, 299–311. [Google Scholar] [CrossRef]

- Zheng, Y.; Shadloo, M.S.; Nasiri, H.; Maleki, A.; Karimipour, A.; Tlili, I. Prediction of Viscosity of Biodiesel Blends Using Various Artificial Model and Comparison with Empirical Correlations. Renew. Energy 2020, 153, 1296–1306. [Google Scholar] [CrossRef]

- Gopinath, A.; Puhan, S.; Nagarajan, G. Theoretical Modeling of Iodine Value and Saponification Value of Biodiesel Fuels from Their Fatty Acid Composition. Renew. Energy 2009, 34, 1806–1811. [Google Scholar] [CrossRef]

- Zheng, X.; Bao, Y.; Qu, D.; Liu, Y.; Qin, G. Measurement and Modeling of Thermal Conductivity for Short Chain Methyl Esters: Methyl Butyrate and Methyl Caproate. J. Chem. Thermodyn. 2021, 159, 106486. [Google Scholar] [CrossRef]

- Dharmalingam, B.; Annamalai, S.; Areeya, S.; Rattanaporn, K.; Katam, K.; Show, P.-L.; Sriariyanun, M. Bayesian Regularization Neural Network-Based Machine Learning Approach on Optimization of CRDI-Split Injection with Waste Cooking Oil Biodiesel to Improve Diesel Engine Performance. Energies 2023, 16, 2805. [Google Scholar] [CrossRef]

- Patnaik, S.; Khatri, N.; Rene, E.R. Artificial Neural Networks-Based Performance and Emission Characteristics Prediction of Compression Ignition Engines Powered by Blends of Biodiesel Derived from Waste Cooking Oil. Fuel 2024, 370, 131806. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S.; Simsek, H. Proportional Impact Prediction Model of Animal Waste Fat-Derived Biodiesel by ANN and RSM Technique for Diesel Engine. Energy 2022, 239, 122389. [Google Scholar] [CrossRef]

- Sharma, P. Artificial Intelligence-based Model Prediction of Biodiesel-fueled Engine Performance and Emission Characteristics: A Comparative Evaluation of Gene Expression Programming and Artificial Neural Network. Heat Trans 2021, 50, 5563–5587. [Google Scholar] [CrossRef]

- Sule, A.; Abdul Latiff, Z.; Azman Abas, M.; Rozi Mohammed Perang, M.; Veza, I.; Faizullizam Roslan, M. Investigation of Dual Impact of Nanoparticles-Ethanol as Additive to Biodiesel-Diesel Fuel on an Engine Using Artificial Neural Network Prediction Model. Mater. Today Proc. 2023, S2214785323050629. [Google Scholar] [CrossRef]

- Kumar, V.; Choudhary, A.K. Prediction of the Performance and Emission Characteristics of Diesel Engine Using Diphenylamine Antioxidant and Ceria Nanoparticle Additives with Biodiesel Based on Machine Learning. Energy 2024, 301, 131746. [Google Scholar] [CrossRef]

- Pitchaiah, S.; Juchelková, D.; Sathyamurthy, R.; Atabani, A.E. Prediction and Performance Optimisation of a DI CI Engine Fuelled Diesel–Bael Biodiesel Blends with DMC Additive Using RSM and ANN: Energy and Exergy Analysis. Energy Convers. Manag. 2023, 292, 117386. [Google Scholar] [CrossRef]

- Taheri-Garavand, A.; Heidari-Maleni, A.; Mesri-Gundoshmian, T.; Samuel, O.D. Application of Artificial Neural Networks for the Prediction of Performance and Exhaust Emissions in IC Engine Using Biodiesel-Diesel Blends Containing Quantum Dot Based on Carbon Doped. Energy Convers. Manag. X 2022, 16, 100304. [Google Scholar] [CrossRef]

- Khoobbakht, M.; Soleymani, M.; Kheiralipour, K.; Karimi, M. Predicting Performance Characteristics of an Engine Fueled by Algal Biodiesel-Diesel Using Response Surface Methodology. Renew. Energy Res. Appl. 2024, 5, 269–279. [Google Scholar] [CrossRef]

- Umeuzuegbu, J.C.; Okiy, S.; Nwobi-Okoye, C.C.; Onukwuli, O.D. Computational Modeling and Multi-Objective Optimization of Engine Performance of Biodiesel Made with Castor Oil. Heliyon 2021, 7, e06516. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Taghizadeh-Alisaraei, A.; Ghobadian, B.; Abbaszadeh-Mayvan, A. Artificial Neural Network Modeling of Performance, Emission, and Vibration of a CI Engine Using Alumina Nano-Catalyst Added to Diesel-Biodiesel Blends. Renew. Energy 2020, 149, 951–961. [Google Scholar] [CrossRef]

- Sharma, P.; Sharma, A.K.; Balakrishnan, D.; Manivannan, A.; Chia, W.Y.; Awasthi, M.K.; Show, P.L. Model-Prediction and Optimization of the Performance of a Biodiesel—Producer Gas Powered Dual-Fuel Engine. Fuel 2023, 348, 128405. [Google Scholar] [CrossRef]

- Agrawal, T.; Gautam, R.; Agrawal, S.; Singh, V.; Kumar, M.; Kumar, S. Optimization of Engine Performance Parameters and Exhaust Emissions in Compression Ignition Engine Fueled with Biodiesel-Alcohol Blends Using Taguchi Method, Multiple Regression and Artificial Neural Network. Sustain. Futures 2020, 2, 100039. [Google Scholar] [CrossRef]

- Kumar, A.N.; Kishore, P.S.; Raju, K.B.; Ashok, B.; Vignesh, R.; Jeevanantham, A.K.; Nanthagopal, K.; Tamilvanan, A. Decanol Proportional Effect Prediction Model as Additive in Palm Biodiesel Using ANN and RSM Technique for Diesel Engine. Energy 2020, 213, 119072. [Google Scholar] [CrossRef]

- Kumar Singh, N.; Singh, Y.; Sharma, A.; Kumar, S. Diesel Engine Performance and Emission Analysis Running on Jojoba Biodiesel Using Intelligent Hybrid Prediction Techniques. Fuel 2020, 279, 118571. [Google Scholar] [CrossRef]

- Benaissa, S.; Adouane, B.; Ali, S.M.; Mohammad, A. Effect of Hydrogen Addition on the Combustion Characteristics of Premixed Biogas/Hydrogen-Air Mixtures. Int. J. Hydrogen Energy 2021, 46, 18661–18677. [Google Scholar] [CrossRef]

- Kamta Legue, D.R.; Ayissi, Z.M.; Babikir, M.H.; Obounou, M.; Ekobena Fouda, H.P. Experimental and Simulation of Diesel Engine Fueled with Biodiesel with Variations in Heat Loss Model. Energies 2021, 14, 1622. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, L.; Song, E.; Wang, J.; Zare, A.; Bodisco, T.A.; Brown, R.J. Development of a Reduced Multi-Component Combustion Mechanism for a Diesel/Natural Gas Dual Fuel Engine by Cross-Reaction Analysis. Fuel 2021, 293, 120388. [Google Scholar] [CrossRef]

- Karami, R.; Rasul, M.G.; Khan, M.M.K.; Mahdi Salahi, M.; Anwar, M. Experimental and Computational Analysis of Combustion Characteristics of a Diesel Engine Fueled with Diesel-Tomato Seed Oil Biodiesel Blends. Fuel 2021, 285, 119243. [Google Scholar] [CrossRef]

- Işcan, B. ANN Modeling for Justification of Thermodynamic Analysis of Experimental Applications on Combustion Parameters of a Diesel Engine Using Diesel and Safflower Biodiesel Fuels. Fuel 2020, 279, 118391. [Google Scholar] [CrossRef]

- Alhikami, A.F.; Yao, C.-E.; Wang, W.-C. A Study of the Spray Ignition Characteristics of Hydro-Processed Renewable Diesel, Petroleum Diesel, and Biodiesel Using a Constant Volume Combustion Chamber. Combust. Flame 2021, 223, 55–64. [Google Scholar] [CrossRef]

- Sharma, P.; Sahoo, B.B. Precise Prediction of Performance and Emission of a Waste Derived Biogas–Biodiesel Powered Dual–Fuel Engine Using Modern Ensemble Boosted Regression Tree: A Critique to Artificial Neural Network. Fuel 2022, 321, 124131. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Hountalas, D.T.; Giakoumis, E.G.; Andritsakis, E.C. Performance and Emissions of Bus Engine Using Blends of Diesel Fuel with Bio-Diesel of Sunflower or Cottonseed Oils Derived from Greek Feedstock. Fuel 2008, 87, 147–157. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G.; Rakopoulos, D.C. Investigating the Emissions during Acceleration of a Turbocharged Diesel Engine Operating with Bio-Diesel or n-Butanol Diesel Fuel Blends. Energy 2010, 35, 5173–5184. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Rakopoulos, D.C. Assessment of NOx Emissions during Transient Diesel Engine Operation with Biodiesel Blends. J. Energy Eng. 2014, 140, A4014004. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G. Impact of Properties of Vegetable Oil, Bio-Diesel, Ethanol and n -Butanol on the Combustion and Emissions of Turbocharged HDDI Diesel Engine Operating under Steady and Transient Conditions. Fuel 2015, 156, 1–19. [Google Scholar] [CrossRef]

- Giakoumis, E.G. A Statistical Investigation of Biodiesel Effects on Regulated Exhaust Emissions during Transient Cycles. Appl. Energy 2012, 98, 273–291. [Google Scholar] [CrossRef]

- Singh, N.K.; Singh, Y.; Sharma, A.; Rahim, E.A. Prediction of Performance and Emission Parameters of Kusum Biodiesel Based Diesel Engine Using Neuro-Fuzzy Techniques Combined with Genetic Algorithm. Fuel 2020, 280, 118629. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, G.; Chao, Y.; Chen, L.; Ghanbari, A. Simultaneous Prediction of CO2, CO, and NOx Emissions of Biodiesel-Hydrogen Blend Combustion in Compression Ignition Engines by Supervised Machine Learning Tools. Energy 2023, 282, 128972. [Google Scholar] [CrossRef]

| NOx (g/kWh) | Smoke Opacity | CO2 (kg/kWh) | BTE (%) | BSFC (kg/kWh) | |

|---|---|---|---|---|---|

| Predicted | 16.918 | 10.228 | 0.624 | 35.874 | 0.253 |

| Actual | 17.178 | 10.55 | 0.646 | 35.5 | 0.2572 |

| % Error | 1.51 | 3.05 | 3.41 | 1.05 | 1.63 |

| Combustion Mode | Cylinder Pressure (Error %) | Heat Release Rate (Error %) | Fuel Distribution | Temperature Distribution |

|---|---|---|---|---|

| Conventional | 1.50% | 13% | Near piston bowl | Higher overall |

| Late injection | 10% | 15% | Throughout the combustion chamber | Lower temperatures |

| Ref. | Algorithm/Model Type | Input Parameters | Output Parameters | Fuel Composition |

|---|---|---|---|---|

| [75] | GP | Fatty acid composition | Kinematic viscosity, flash point, cold flow properties, CN and iodine numbers | Various biodiesel compositions |

| [88] | RSM | Ethanol, diesel, biodiesel blend ratios | Density, viscosity | Ethanol–diesel–biodiesel blends |

| [89] | Empirical Correlations | Biodiesel blend ratios | Density, viscosity | Ternary biodiesel blends |

| [90] | ANN, LSSVM | Intermolecular interactions, temperature | Density | Various biofuels |

| [91] | GPR | Molecular weight, carbon number, double bonds, fatty acid types | Kinematic viscosity, cloud point, pour point, iodine value | Various biodiesel compositions |

| [92] | ANN, Random Tree | Biodiesel composition, fatty acid profile | Kinematic viscosity, density, flash point, oxidation stability, acid value, and calorific values | Hybrid biodiesel fuels |

| [93] | Empirical Correlation | Fatty acid composition | CN | Various biodiesel compositions |

| [94] | LSSVM, GA, PSO, HGAPSO | FAME composition | CN | Various biodiesel compositions |

| [95] | ANN, SVM | FAME composition | CN | Various biodiesel compositions |

| [96] | ANN | FAME composition | CN | Various biodiesel compositions |

| [97] | ANFIS, PSO | Fatty acid composition | CN | Various biodiesel and diesel oils |

| [98] | Grey Wolf Optimizer, Experimental | Fuel Composition, Temperature | Calorific value | Nicotiana Tabacum L. oil methyl ester |

| [38] | Experimental Analysis | Temperature, Pressure, Fuel Composition | Thermal conductivity | Methyl pentanoate, methyl octanoate, methyl decanoate |

| [99] | Experimental Analysis | Temperature, Pressure, Fuel Blend Ratio | Density, viscosity, specific heat | Rapeseed and soybean oil methyl ester blends |

| [100] | Empirical Correlation, PC-SAFT | Temperature, Pressure, Fuel Blend Ratio | Density, viscosity, specific heat, isothermal compress-ibility | Waste cooking oil biodiesel, 1-butanol |

| [101] | ANN | Temperature, Composition | Solid fraction, cold flow properties | Ethylic biodiesel blends |

| [49] | Multiple Regression | Fatty acid composition | CN, density, kinematic viscosity, Heating value | Various biodiesel compositions |

| [102] | Regression Model | Storage time, antioxidant concentration, saponification value, acid value | Viscosity | Jatropha and Pongamia biodiesel |

| [103] | Empirical Models | Chemical structure, composition | Flash point | HC, biodiesel, petroleum fractions |

| [104] | Multivariate Regression | Near-infrared spectroscopy data | Cold filter plugging point, kinematic viscosity | Biodiesel and blends |

| [105] | ML | Temperature, pressure, composition | Density, viscosity | Biodiesel and diesel blends |

| [106] | ANN, Empirical Models | Temperature, blend ratio | Viscosity | Various biodiesel blends |

| [107] | Multiple Regression | Fatty acid composition | Iodine value, saponification value | Various biodiesel compositions |

| [108] | Experimental, Modeling | Temperature, Pressure | Thermal conductivity | Methyl butyrate, methyl caproate |

| Ref. | Theme | Algorithm/Model Type | Input Parameters | Output Parameters | Fuel Composition |

|---|---|---|---|---|---|

| [54] | Engine performance and emissions | ANN, RSM | Engine load, biodiesel ratio, injection pressure | BTE, BSFC, EGT, NOx, CO, HC, smoke | Biodiesel–diesel blends |

| [77] | Engine performance and emissions | GP | Fuel blend ratio, engine load | BTE, BSFC, NOx, CO, smoke | Biodiesel–diesel blends with nanoparticles |

| [109] | Engine performance and emissions | ANN | Injection timing, fuel blend ratio, engine speed | BTE, BSFC, NOx, CO, HC | Waste cooking oil biodiesel |

| [110] | Engine performance and emissions | ANN | Engine load, fuel type | BTE, CO, HC, NOx, smoke | Waste cooking oil biodiesel blends |

| [111] | Engine performance and emissions | ANN, RSM | Engine load, biodiesel ratio | BTE, BSFC, NOx, CO, smoke | Animal fat-derived biodiesel |

| [112] | Engine performance and emissions | ANN, GEP | Engine load, fuel injection parameters, blending ratio | BTE, BSFC, CO, NOx, UHC | Linseed oil biodiesel blends |

| [113] | Engine performance and emissions | ANN | Engine load, fuel, additive, CN | BTE, HC, CO, NOx, smoke | Palm biodiesel–diesel blends with nanoparticles and ethanol |

| [114] | Engine performance and emissions | Random Forest, SVM, ANN | Additive concentration, fuel blend, engine load | BTE, NOx, CO, HC, Smoke | Biodiesel with diphenylamine and ceria nanoparticles |

| [115] | Engine performance and emissions | ANN, RSM | Engine load, fuel blend ratio, DMC additive concentration | BTE, BSFC, NOx, CO, exergy efficiency | Diesel–Bael biodiesel with DMC additive |

| [116] | Engine performance and emissions | ANN | Engine load, quantum dot concentration, fuel blend ratio | BTE, BSFC, NOx, CO, HC | Biodiesel–diesel blends with carbon-doped quantum dots |

| [117] | Engine performance and emissions | RSM | Engine load, fuel blend ratio | BTE, BSFC, NOx, CO | Algal biodiesel–diesel blends |

| [118] | Engine performance and emissions | ANN, GA | Engine load, biodiesel blend ratio, injection pressure | BTE, BSFC, NOx, CO, Smoke | Castor oil biodiesel blends |

| [119] | Engine performance and emissions | ANN | Engine load, alumina nano-catalyst concentration, fuel blend ratio | BTE, NOx, CO, UHC, vibration | Diesel–biodiesel with alumina nano-catalyst |

| [120] | Engine performance and emissions | ANN, RSM | Engine load, producer gas flow rate, biodiesel ratio | BTE, BSFC, NOx, CO, smoke | Biodiesel-producer gas dual-fuel |

| [121] | Engine performance and emissions | ANN, Multiple Regression, Taguchi | Engine load, biodiesel–alcohol blend ratio | BTE, BSFC, NOx, CO, smoke | Biodiesel–alcohol blends |

| [122] | Engine performance and emissions | ANN, RSM | Engine load, decanol proportion, fuel blend ratio | BTE, BSFC, NOx, CO, smoke | Palm biodiesel–decanol blends |

| [123] | Engine performance and emissions | ANFIS, GA, PSO | Engine load, fuel injection timing, fuel injection pressure, biodiesel blend | BTE, UHC, NOx | Jojoba biodiesel blends |

| [57] | Combustion characteristics | ANN, SVM | Engine load, fuel type, injection timing | Ignition delay (ID) | Diesel and biodiesel blends |

| [124] | Combustion characteristics | Chemical kinetic model | Hydrogen concentration, biogas–air ratio | Ignition delay, combustion duration, flame speed | Biogas–hydrogen–air mixtures |

| [125] | Combustion characteristics | CFD | Engine load, fuel type, heat loss parameters | Heat release rate, cylinder pressure, exhaust gas temperature | Various biodiesel blends |

| [126] | Combustion characteristics, Emission | Chemical kinetic model | Engine load, air–fuel ratio, fuel type | Heat release rate, NOx, CO | Diesel–natural gas dual fuel |

| [127] | Combustion characteristics | ANN, CFD | Engine load, fuel blend ratio, engine speed | Heat release rate, cylinder pressure, ignition delay | Diesel–tomato seed oil biodiesel blends |

| [128] | Combustion characteristics | ANN | Engine load, fuel type | cylinder pressure, heat release rate, ignition delay | Diesel–safflower biodiesel blends |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ai, W.; Cho, H.M. Predictive Models for Biodiesel Performance and Emission Characteristics in Diesel Engines: A Review. Energies 2024, 17, 4805. https://doi.org/10.3390/en17194805

Ai W, Cho HM. Predictive Models for Biodiesel Performance and Emission Characteristics in Diesel Engines: A Review. Energies. 2024; 17(19):4805. https://doi.org/10.3390/en17194805

Chicago/Turabian StyleAi, Wenbo, and Haeng Muk Cho. 2024. "Predictive Models for Biodiesel Performance and Emission Characteristics in Diesel Engines: A Review" Energies 17, no. 19: 4805. https://doi.org/10.3390/en17194805