Balancing Control Strategy for Li-Ion Batteries String Based on Dynamic Balanced Point

Abstract

:1. Introduction

2. Li-Ion Battery Equalizer Circuit

2.1. Circuit Description

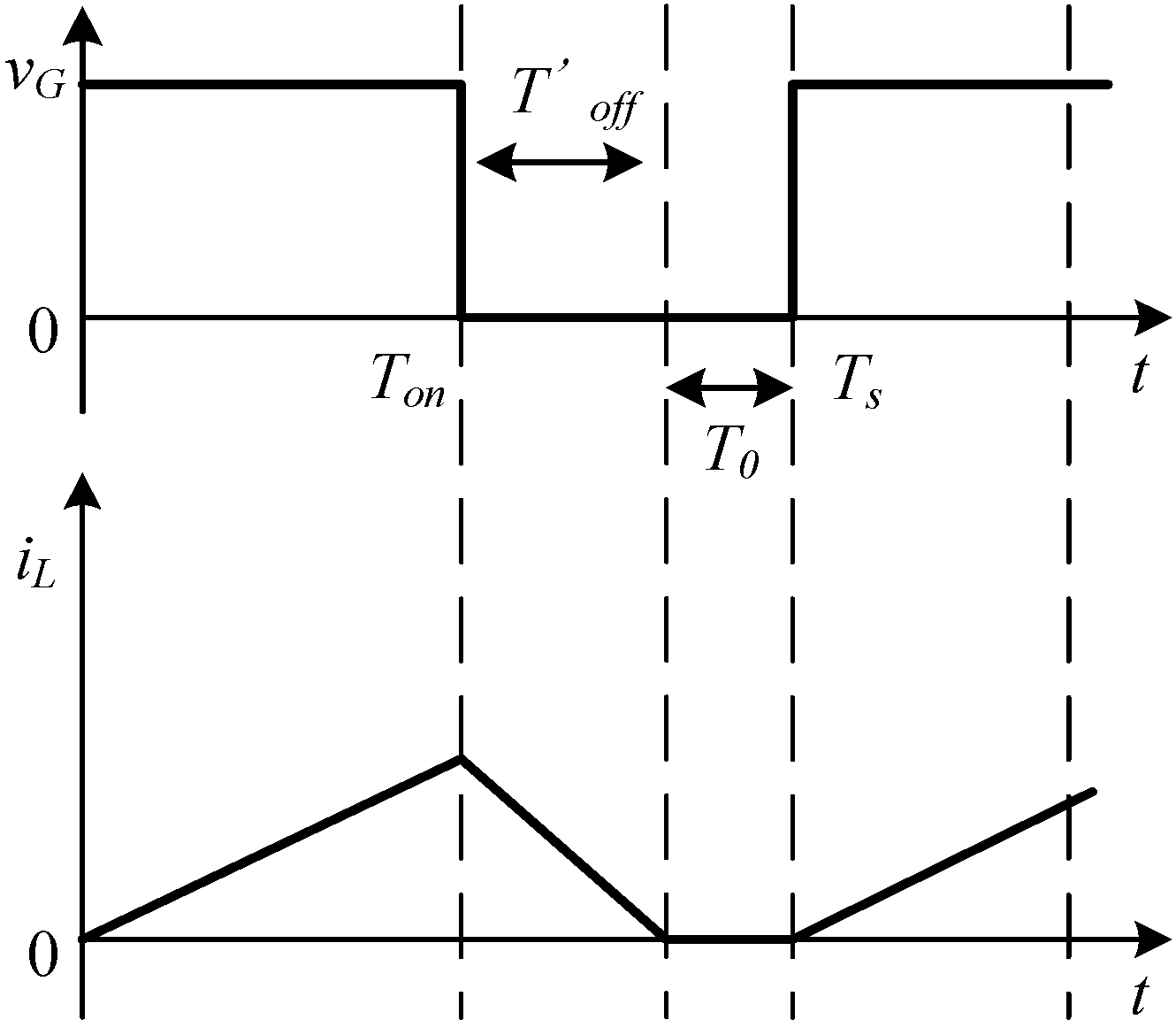

2.2. Operating Principle

3. Purposed Control Strategy

3.1. Dynamic Balanced Point

3.2. Balancing Control Method

3.2.1. Duty Cycle Derivation

3.2.2. Inductance Value Calculation

3.2.3. Control Algorithm

3.2.4. Frequency Value Calculation

4. Simulation Performance

| Battery | B1 | B2 | B3 | B4 |

|---|---|---|---|---|

| Capacitance | 500 μF | 500 μF | 500 μF | 500 μF |

| Resistance | 0.5 mΩ | 0.5 mΩ | 0.5 mΩ | 0.5 mΩ |

| Initial voltage | 3.40 V | 3.00 V | 2.90 V | 3.30 V |

| Maximum voltage difference | 0.50 V | |||

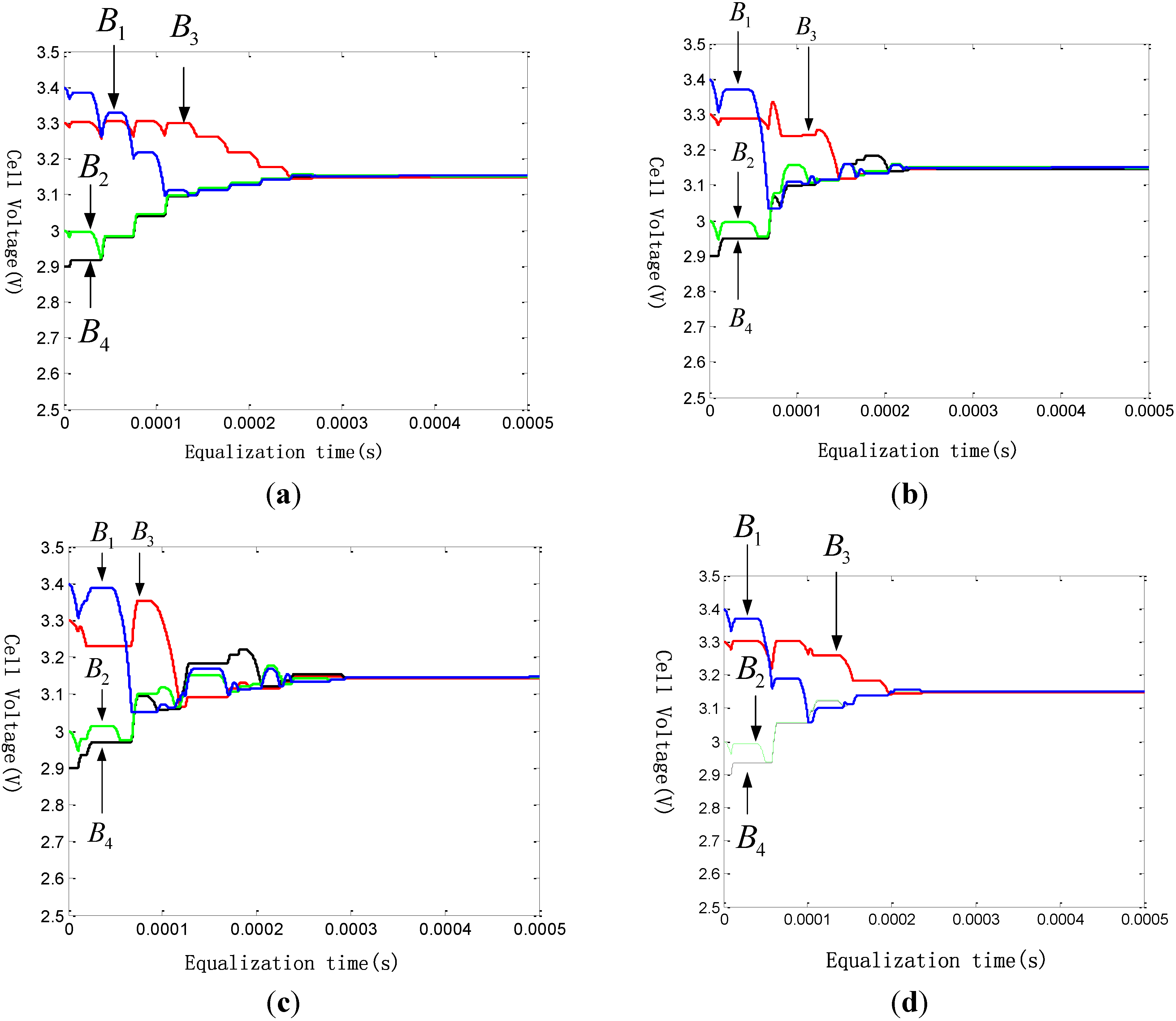

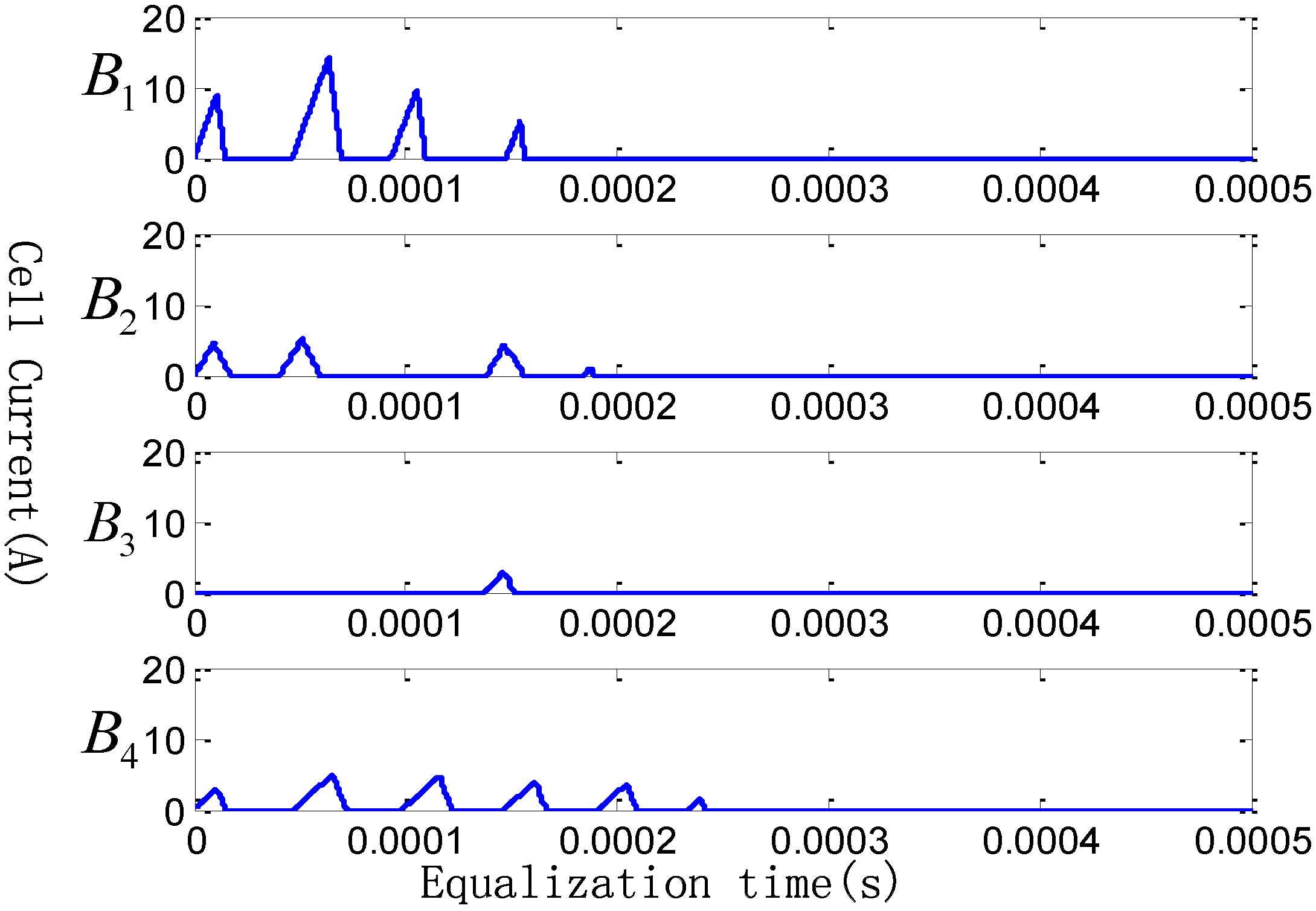

4.1. Balanced Frequency Analysis

4.2. Charging State

4.3. Discharging State

5. Experiment Result

| Battery | Initial Voltage (V) | Final Voltage (V) |

|---|---|---|

| 3.11 | 2.90 | |

| 3.09 | 2.90 | |

| 2.85 | 2.89 | |

| 3.21 | 2.90 |

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hatzell, K.B.; Sharma, A.; Fathy, H.K. A survey of long-term health modeling, estimation, and control of lithium-ion batteries: Challenges and opportunities. In Proceedings of the IEEE American Control Conference, Montreal, QC, Canada, 27–29 June 2012; pp. 584–591.

- Shafiei, A.; Williamson, S.S. Plug-in hybrid electric vehicle charging: Current issues and future challenges. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–8.

- Cassani, P.A.; Williamson, S.S. Significance of battery cell equalization and monitoring for practical commercialization of plug-in hybrid electric vehicles. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition, Washington, DC, USA, 15–19 February 2009; pp. 456–471.

- Lindemark, B. Individual cell voltage equalizers (ICE) for reliable battery performance. In Proceedings of the 13th Annual International Telecommunications Energy Conference, Kyoto, Japan, 5–8 November 1991; pp. 196–201.

- Moo, C.S.; Hsieh, Y.C.; Tsai, I.S. Charge equalization for series-connected batteries. IEEE Trans. Aerosp. Electron. Syst. 2003, 4, 704–710. [Google Scholar] [CrossRef]

- Kimball, J.W.; Krein, P.T. Analysis and design of switched capacitor converters. In Proceedings of the 20th Annual IEEE Applied Power Electronics Conference and Exposition, Austin, TX, USA, 6–10 March 2005; Volume 3, pp. 1473–1477.

- Hopkins, D.C.; Mosling, C.R.; Huang, S.T. The use of equalizing converters for serial charging of long battery strings. In Proceedings of the 6th Annual Applied Power Electronics Conference and Exposition, Dallas, TX, USA, 10–15 March 1991; pp. 493–498.

- Moore, S.W.; Schneider, P.J. A review of cell equalization methods for lithium ion and lithium polymer battery systems. In Proceedings of the SAE 2001 World Congress, Detrolt, MI, USA, 5–8 March 2001.

- Kim, M.-Y.; Kim, C.-H.; Cho, S.-Y.; Moon, G.-W. A cell selective charge equalizer using multi-output converter with auxiliary transformer. In Proceedings of the 2011 IEEE 8th International Conference on Power Electronics and ECCE Asia (ICPE & ECCE 2011), Jeju, Korea, 30 May–3 June 2011; pp. 310–317.

- Ji, X.; Cui, N.; Shang, Y.; Zhang, C.; Sun, B. Modularized charge equalizer using multiwinding transformers for Lithium-ion battery system. In Proceedings of the 2014 IEEE Conference Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–5.

- Gerislioglu, B.; Ozturk, F.; Sanli, A.E.; Gunlu, G. The multi-windings forward structure battery balancing. In Proceedings of the 2014 11th International Conference Electronics, Computer and Computation (ICECCO), Abuja, Nigeria, 29 September–1 October 2014; pp. 1–4.

- Park, K.B.; Kim, H.S.; Moon, G.W. Single-magnetic cell-to-cell charge equalization converter with reduced number of transformer windings. IEEE Trans. Power Electron. 2012, 27, 2900–2911. [Google Scholar] [CrossRef]

- Baronti, F.; Fantechi, G.; Roncella, R. High-efficiency digitally controlled charge equalizer for series-connected cells based on switching converter and super-capacitor. IEEE Trans. Ind. Inform. 2013, 9, 1139–1147. [Google Scholar] [CrossRef]

- Kim, M.-Y.; Kim, J.-H.; Moon, G.-W. Center-cell concentration structure of a cell-to-cell balancing circuit with a reduced number of switches. IEEE Trans. Power Electron. 2014, 29, 5285–5297. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, Z.; Feng, Z.; Chen, J.; Qian, Z. An improved control strategy for the charge equalization of lithium ion battery. In Proceedings of the Twenty-Fourth Annual IEEE Applied Power Electronics Conference and Exposition, APEC 2009, Washington, DC, USA, 15–19 February 2009; pp. 186–189.

- Qi, J.; Lu, D.D.-C. Review of battery cell balancing techniques. In Proceedings of the Power Engineering Conference (AUPEC), 2014 Australasian Universities, Perth, Australia, 28 September–1 October 2014; pp. 1–6.

- Moo, C.-S.; Wu, T.-H.; Hou, C.-H.; Hsieh, Y.-C. Balanced discharging of power bank with buck-boost battery power modules. In Proceedings of the 2014 International Power Electronics Conference (IPEC-Hiroshima 2014—ECCE-ASIA), Hiroshima, Japan, 18–21 May 2014; pp. 1796–1800.

- Cadar, D.; Petreus, D.; Patarau, T.; Etz, R. Fuzzy controlled energy converter equalizer for lithium ion battery packs. In Proceedings of the International Conference on Power Engineering, Energy and Electrical Drives, Malaga, Spain, 11–13 May 2011; pp. 1–6.

- Zhou, C.Y.; Xu, J.P. Research on Battery Charge Equalization System Based on FPGA/NIOSS II. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, May 2008. [Google Scholar]

- Cassani, P.A.; Williamson, S.S. Design, testing, and validation of a simplified control scheme for a novel plug-in hybrid electric vehicle battery cell equalizer. IEEE Trans. Ind. Electron. 2010, 57, 3956–3962. [Google Scholar] [CrossRef]

- Ling, R.; Dong, Y.; Yan, H.B.; Wu, M.R.; Chai, Y. Fuzzy-PI control battery equalization for series connected lithium-ion battery strings. In Proceedings of the 7th International Power Electronics and Motion Control Conference, Harbin, China, 2–5 June 2012; Volume 4, pp. 2631–2635.

- Amjadi, Z.; Williamson, S.S. Novel control strategy design for multiple hybrid electric vehicle energy storage systems. In Proceedings of the 24th Annual IEEE Applied Power Electronics Conference and Exposition, Washington, DC, USA, 15–19 February 2009; pp. 597–602.

- Cao, J.; Schofield, N.; Emadi, A. Battery balancing methods: A comprehensive review. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–6.

- Erickson, R.W.; Maksimovic, D. Fundamentals of Power Electronics, 2nd ed.; University of Colorado Boulder: Boulder, CO, USA, 2001. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.-H.; Zhu, G.-R.; He, S.-J.; Qiu, S.; Ma, Y.; Wu, Q.-M.; Chen, W. Balancing Control Strategy for Li-Ion Batteries String Based on Dynamic Balanced Point. Energies 2015, 8, 1830-1847. https://doi.org/10.3390/en8031830

Zhang D-H, Zhu G-R, He S-J, Qiu S, Ma Y, Wu Q-M, Chen W. Balancing Control Strategy for Li-Ion Batteries String Based on Dynamic Balanced Point. Energies. 2015; 8(3):1830-1847. https://doi.org/10.3390/en8031830

Chicago/Turabian StyleZhang, Dong-Hua, Guo-Rong Zhu, Shao-Jia He, Shi Qiu, Yan Ma, Qin-Mu Wu, and Wei Chen. 2015. "Balancing Control Strategy for Li-Ion Batteries String Based on Dynamic Balanced Point" Energies 8, no. 3: 1830-1847. https://doi.org/10.3390/en8031830