Some Microstructural Aspects of Ductile Fracture of Metals

Abstract

:1. Introduction

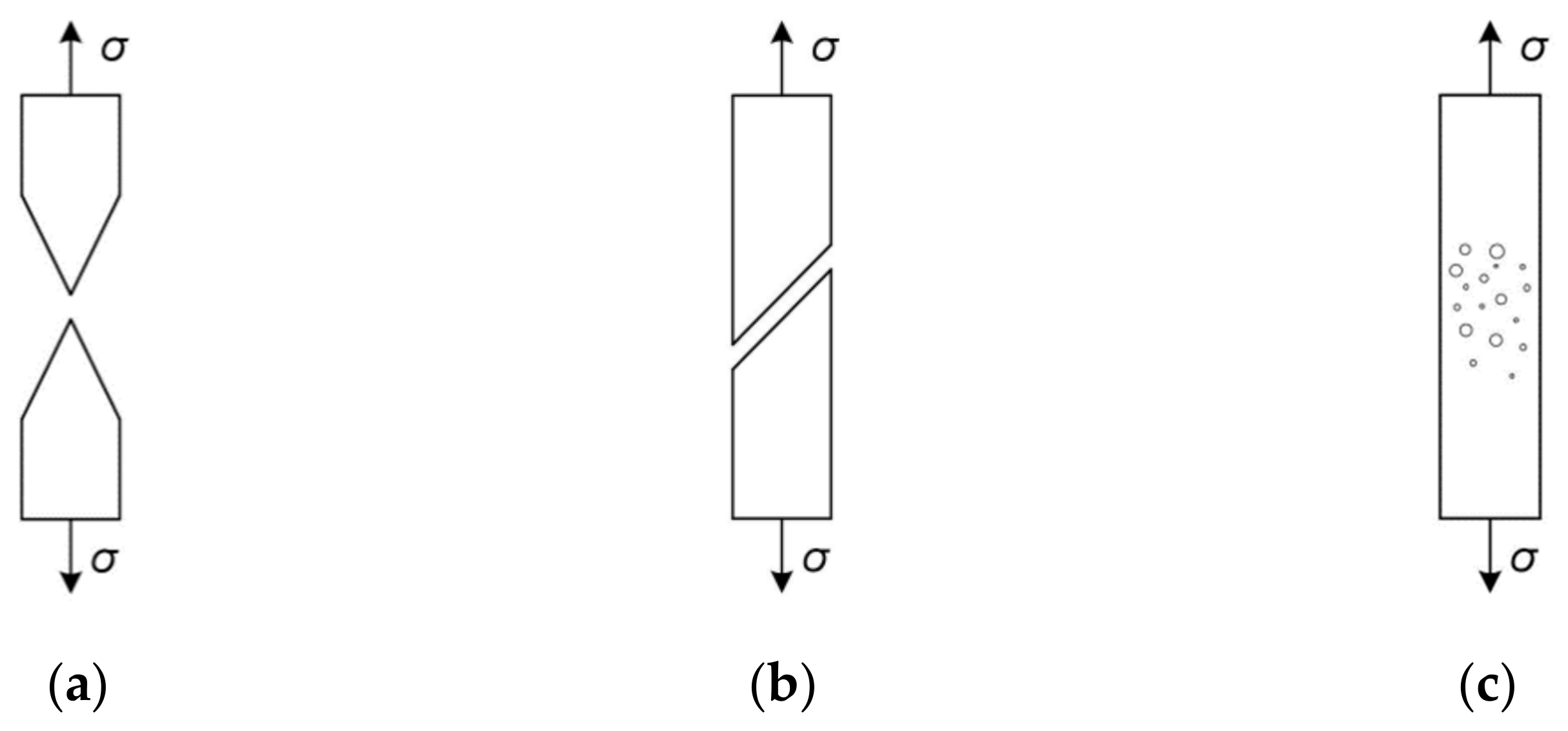

2. Mechanisms of Structural Metals Failure

3. Some Measures of Stress State and Microstructural Parameters Used for the Ductile Fracture Characterization

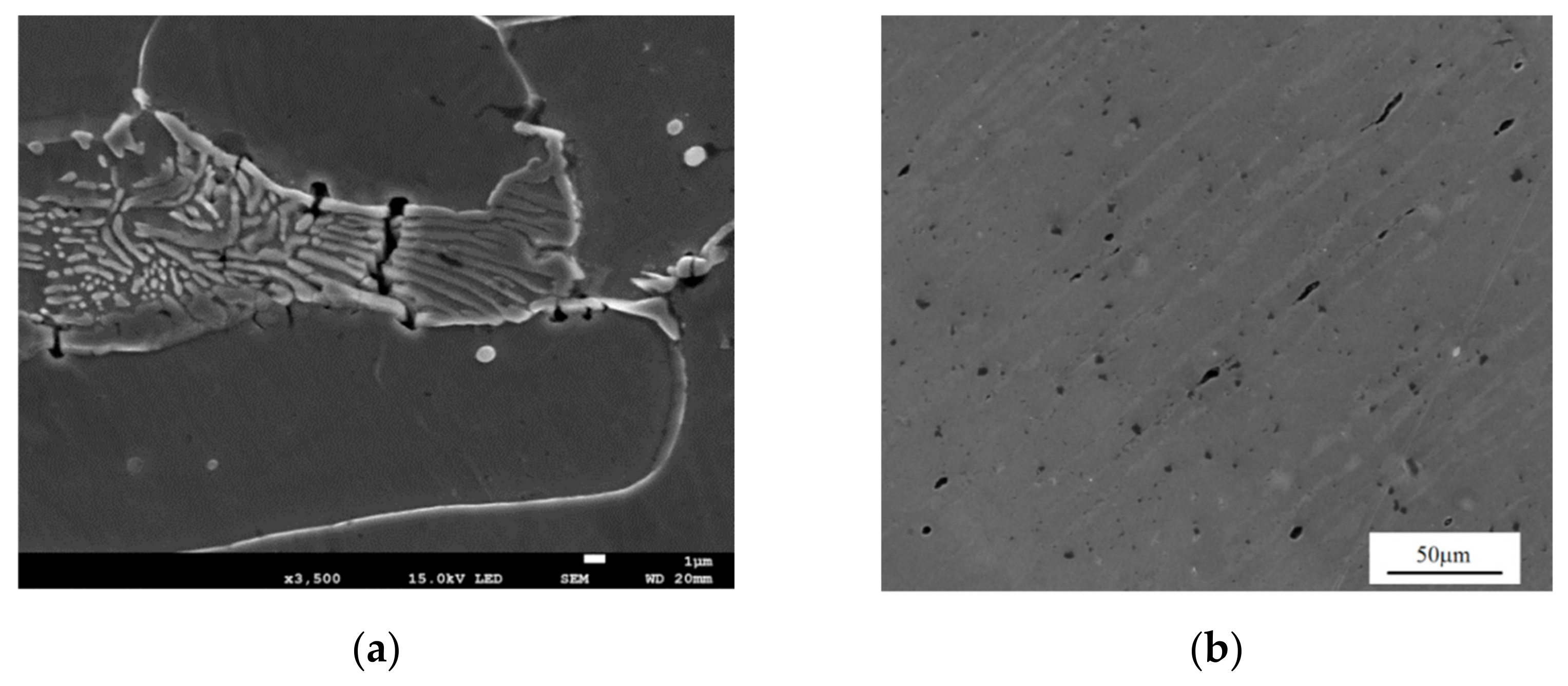

4. Void Nucleation in Metals

5. Cavity Growth

6. Cavity Coalescence and Failure

7. Effect of Selected Loading Conditions on Void Development

8. Conclusions and Suggestions for Future Research

- Criteria for void nucleation under low triaxiality conditions;

- Effect of Lode parameter on void initiation, growth, and coalescence;

- In situ observations of void coalescence with the use of modern research methods (e.g., microtomography), which will allow the verification of the existing coalescence criteria, or the development of new ones;

- Assessment of the effect of loading conditions (temperature, strain rate, etc.) on the critical values of stress and strain necessary for the void initiation and growth;

- Development of a set of standardized parameters describing the criteria of nucleation, growth, and coalescence of voids, in relation to engineering materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| void diameter | |

| initial void diameter | |

| Burgers vector | |

| void volume fraction | |

| the rate of increase in the total fraction of voids | |

| actual void volume fraction | |

| initial void volume fraction (for unstrained material) | |

| critical void volume fraction at the onset of coalescence initiation | |

| the rate of increase in the fraction of voids resulting from their rapid joining under shear stresses | |

| void volume fraction at failure | |

| the rate of increasing the fraction of existing voids | |

| the rate of increase in nucleated voids’ volume fraction | |

| anisotropy coefficient | |

| multiplier in power hardening law | |

| coefficient depending on the particle shape | |

| coefficient depending on the shape (aspect ratio) of the particle and its orientation in relation to the loading direction | |

| maximum value of principal stress in the particle | |

| maximum value of the stress normal to the phases contact surface | |

| exponent in power hardening law | |

| stress concentration factor, correction factor in GTN model | |

| Tvergaard coefficients | |

| polar coordinate measured from the “head” of dislocation pile-up | |

| characteristic length | |

| standard deviation | |

| coefficient expressing the ratio of the void elongation to the specimen elongation rate (on a macroscopic scale) in Brown and Embury model, | |

| Young’s modulus of the matrix | |

| matrix plastic equivalent modulus of elasticity | |

| Lode parameter | |

| particle radius | |

| void radius growth rate | |

| initial particle radius | |

| actual particle radius | |

| remote normal stress | |

| total volume of material | |

| volume of voids and second phase particles | |

| void aspect ratio | |

| coefficient in Brown–Embury model, coefficient depending on matrix hardening exponent in Thomason model | |

| radial coordinate of particle surface in Thomason model | |

| surface energy | |

| generalized radial coordinate in Thomason model | |

| strain | |

| strain rate | |

| critical strain of particle–matrix separation | |

| increase in effective plastic strain | |

| void nucleation strain | |

| plastic strain | |

| longitudinal strain of the cylinder in McClintock model | |

| stress state triaxiality ratio | |

| Lode angle | |

| stress concentration factor at the interface of phases | |

| coefficient of normal stress concentration inside the particle | |

| coefficient in Beremin nucleation model, depending on particle shape | |

| shear modulus | |

| coefficient depending on the elastic parameters of particle, matrix, and the geometric characteristics of particle | |

| stress | |

| yield stress | |

| principal stresses | |

| maximum value of global tensile principal stress | |

| rate of the maximum global principal stress increase | |

| critical stress, dependent on the nucleation mechanism, matrix, particle, and the interface strength | |

| critical stress at the phase interface | |

| mean value of void nucleation stress | |

| theoretical strength of the particle material | |

| von Mises equivalent stress | |

| rate of von Mises equivalent stress increase | |

| Hill’s equivalent stress | |

| maximum local normal stress at the “head” of dislocation pile-up | |

| mean stress (hydrostatic pressure) | |

| critical normal stress in Thomason model | |

| yield stress at pure shear | |

| ratio of void length to the distance between neighboring voids | |

| equivalent plastic strain | |

| damage function of the particle–matrix interface | |

| equivalent Poisson coefficient |

References

- British Standard Institution. Guidance on Some Methods for the Derivation of Acceptance Levels for Defects in Fusion Welded Joints; BS PD6493; British Standard Institution: London, UK, 1991. [Google Scholar]

- British Standards Institution. Guide on Methods for Assessing the Acceptability of Flaws in Fusion Welded Structures; BS7910; British Standards Institution: London, UK, 2001. [Google Scholar]

- British Energy Generation. R6: Assessment of the Integrity of Structures Containing Defects; British Energy Generation: London, UK, 2001. [Google Scholar]

- Koçak, M.; Webster, S.; Janosch, J.J.; Ainsworth, R.A.; Koerc, R. (Eds.) FITNET: Fitness for Service. Fracture–Fatigue–Creep–Corrosion; GKSS Research Centre Geesthacht: Geesthacht, Germany, 2008. [Google Scholar]

- European Union Brite-Euram Programme. SINTAP: Structural Integrity Assessment Procedure for European Industry; Project No. Be95-1426; British Steel: North Lincolnshire, UK, 1999.

- Besson, J.; Bugat, S.; Berdin, C.; Desmorat, R.; Feyel, F.; Forest, S.; Lorentz, E.; Maire, E.; Pardoen, T.; Pineau, A.; et al. Local Approach to Fracture, 1st ed.; Les Presses de l’École des Mines: Paris, France, 2004. [Google Scholar]

- Bao, Y.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Puttick, K.E. Ductile fracture in metals. Philos. Mag. 1959, 4, 964–969. [Google Scholar] [CrossRef]

- Rogers, H.C. The tensile fracture of ductile metals. Trans. Met. Soc. 1960, 218, 498–506. [Google Scholar]

- Lassance, D.; Fabrègue, D.; Delannay, F.; Pardoen, T. Micromechanics of room and high temperature fracture in 6xxx Al alloys. Prog. Mater. Sci. 2007, 52, 62–129. [Google Scholar] [CrossRef]

- Pineau, A.; Benzerga, A.A.; Pardoen, T. Failure of metals I: Brittle and ductile fracture. Acta Mater. 2016, 107, 424–483. [Google Scholar] [CrossRef] [Green Version]

- Asby, M.F. Work hardening of dispersion hardened crystals. Philos. Mag. 1966, 14, 1157–1178. [Google Scholar] [CrossRef]

- Bauer, R.W.; Wilsdorf, H.G.F. Void initiation in ductile fracture. Scr. Met. 1973, 7, 1213–1220. [Google Scholar] [CrossRef]

- Pang, W.W.; Zhang, P.; Zhang, G.C.; Xu, A.G.; Zhao, X.G. Dislocation creation and void nucleation in FCC ductile metals under tensile loading: A general microscopic picture. Sci. Rep. 2014, 4, 6981. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goods, S.H.; Brown, L.M. Overview No. 1: The nucleation of cavities by plastic deformation. Acta Met. 1979, 27, 1–15. [Google Scholar] [CrossRef]

- Pineau, A.; Pardoen, T. Comprehensive Structural Integrity; Elsevier: Amsterdam, The Netherlands, 2007; pp. 684–797. [Google Scholar]

- Beremin, F.M. Cavity formation from inclusions in ductile fracture of A508 steel. Met. Trans. A 1981, 12, 723–731. [Google Scholar] [CrossRef]

- Argon, A.S.; Im, J.; Safoglu, R. Cavity formation from inclusions in ductile fracture. Met. Mater. Trans. A 1975, 6, 825–837. [Google Scholar] [CrossRef]

- Argon, A.S. Formation of cavities from nondeformable second phase particles in low temperature ductile fracture. J. Eng. Mater. Technol. 1976, 98, 60–68. [Google Scholar] [CrossRef]

- Argon, A.S.; Im, J. Separation of second phase particles in spheroidized 1045 steel, Cu-0.6pct Cr alloy, and maraging steel in plastic straining. Met. Trans. A 1975, 6, 839–851. [Google Scholar] [CrossRef]

- Eshelby, J.D. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. Lond. A 1957, 241, 376–396. [Google Scholar]

- Babout, L.; Brechet, Y.; Maire, E.; Fougères, R. On the competition between particle fracture and particle decohesion in metal matrix composites. Acta Mater. 2004, 52, 4517–4525. [Google Scholar] [CrossRef]

- Brown, L.M.; Clarke, D.R. Work hardening due to internal stresses in composite materials. Acta Met. 1975, 23, 821–830. [Google Scholar] [CrossRef]

- Lee, B.J.; Mear, M.E. Stress concentration induced by an elastic spheroidal particle in a plastically deforming solid. J. Mech. Phys. Solids 1999, 47, 1301–1336. [Google Scholar] [CrossRef]

- Margolin, B.Z.; Shvetsova, V.A.; Karzof, G. Brittle fracture of nuclear pressure vessel steels—I. Local criterion for cleavage fracture. Int. J. Press. Vessel. Pip. 1997, 72, 73–87. [Google Scholar] [CrossRef]

- Chen, J.; Cao, R. Micromechanism of Cleavage Fracture of Metals. A Comprehensive Microphysical Model for Cleavage Cracking in Metals, 1st ed.; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Hancock, J.W.; Cowling, M.J. Role of state of stress in crack–tip failure processes. Met. Sci. 1980, 14, 293–304. [Google Scholar] [CrossRef]

- Griffith, A.A. The phenomena of rupture and flow in solids. Philos Trans. R. Soc. Lond. Ser. A 1921, 221, 163–198. [Google Scholar]

- Gurland, J.; Plateau, J. The mechanism of ductile rupture of metals containing inclusions. Trans. ASM 1963, 56, 442–454. [Google Scholar]

- Kwon, D.; Asaro, R. A study of void nucleation, growth, and coalescence in spheroidized 1518 steel. Met. Trans. A 1990, 21, 117–134. [Google Scholar] [CrossRef]

- Bugat, S.; Besson, J.; Pineau, A. Micromechanical modeling of the behaveior of duplex stainless steels. Comput. Mater. Sci. 1999, 16, 158–166. [Google Scholar] [CrossRef]

- Giovanola, J.H.; Cannizzaro, D.; Doglione, R.; Rossoll, A. Ductile fracture by void nucleation at tempering carbides. In Fracture of Nano and Engineering Materials and Structures; Gdoutos, E.E., Ed.; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Brown, L.M.; Stobbs, W.M. The work-hardening of copper-silica. V. Equilibrium plastic relaxation by secondary dislocations. Philos. Mag. 1976, 34, 351–372. [Google Scholar] [CrossRef]

- Shabrov, M.N.; Sylven, E.; Kim, S.; Sherman, D.H.; Chuzhoy, L.; Briant, C.L.; Needleman, A. Void nucleation by inclusion cracking. Met. Mater. Trans. A 2004, 35, 1745–1755. [Google Scholar] [CrossRef]

- Babout, L.; Maire, E.; Fougères, R. Damage initiation in model metallic materials: X-ray tomography and modelling. Acta Mater. 2004, 52, 2475–2487. [Google Scholar] [CrossRef]

- François, D.; Pineau, A.; Zaoui, A. Ductile fracture. In Mechanical Behaviour of Materials. Volume II: Fracture Mechanics and Damage, 2nd ed.; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Alexandre, F.; Deyber, S.; Vaissaud, J.; Pineau, A. Probabilistic Life of DA 718 for Aircraft Engine Disks. In Proceedings of the International Symposium on Superalloys and Various Derivatives, Pittsburgh, PA, USA, 2–5 October 2005; pp. 97–110. [Google Scholar]

- Hubert, G.; Brechet, Y.; Pardoen, T. Void growth and void nucleation controlled ductility in quasi eutectic cast aluminium alloys. Acta Mater. 2005, 53, 2739–2749. [Google Scholar] [CrossRef]

- Dong, M.J.; Prioul, C.; François, D. Damage effect on the fracture toughness of nodular cast iron. Part I: Damage characterization and plastic flow stress modeling. Met. Mater. Trans. A 1997, 28, 2245–2254. [Google Scholar] [CrossRef]

- Needleman, A. A Continuum model for void nucleation by inclusion debonding. J. Appl. Mech. 1987, 54, 525–531. [Google Scholar] [CrossRef]

- Wciślik, W.; Pała, T. Selected aspects of cohesive zone modeling in fracture mechanics. Metals 2021, 11, 302. [Google Scholar] [CrossRef]

- Siegmund, T.; Brocks, W. A numerical study on the correlation between the work of separation and the dissipation rate in ductile fracture. Eng. Fract. Mech. 2000, 67, 139–154. [Google Scholar] [CrossRef]

- Andersen, R.G.; Tekoğlu, C.; Nielsen, K.L. Cohesive traction–separation relations for tearing of ductile plates with randomly distributed void nucleation sites. Int. J. Fract. 2020, 224, 187–198. [Google Scholar] [CrossRef]

- Chu, C.; Needleman, A. Void nucleation effects in biaxially stretched sheets. J. Eng. Mater. Technol. 1980, 102, 249–256. [Google Scholar] [CrossRef]

- Fisher, J.R. Void Nucleation in Spheroidized Steels during Tensile Deformation. Ph.D. Thesis, Brown University, Providence, RI, USA, 1980. [Google Scholar]

- Hahn, G.T.; Rosenfield, A.R. Metallurgical factors affecting fracture toughness of aluminium alloys. Met. Trans. A 1975, 6, 653–670. [Google Scholar] [CrossRef]

- Wciślik, W. Experimental and Numerical Determination and Analysis of Selected Parameters of the Gurson-Tvergaard-Needleman Model for S355 Steel and Complex Stress States. Ph.D. Thesis, Kielce University of Technology, Kielce, Poland, 2014. (In Polish). [Google Scholar]

- Wciślik, W. Numerical Determination of Critical Void Nucleation Strain in the Gurson-Tvergaard-Needleman Porous Material Model for Low Stress State Triaxiality Ratio. In Proceedings of the 23rd International Conference on Metallurgy and Materials, Brno, Czech Republic, 21–23 May 2014; pp. 794–800. [Google Scholar]

- Wciślik, W. Numerical simulation of void nucleation in S355 steel. Solid State Phenom. 2016, 250, 244–249. [Google Scholar] [CrossRef]

- Kossakowski, P.; Wciślik, W. Effect of stress triaxiality ratio on void nucleation strain in S235JR steel. Przeglad Mechaniczny 2013, 3, 15–21. (In Polish) [Google Scholar]

- Caceres, C.H.; Griffiths, J.R. Damage by the cracking of silicon particles in an Al-7Si-0.4Mg casting alloy. Acta Mater. 1996, 44, 25–33. [Google Scholar] [CrossRef]

- Pineau, A.; Joly, P. Local versus global approaches to elastic-plastic fracture mechanics. Application to ferritic steels and a cast duplex stainless steel. In Defect Assessment in Components—Fundamentals and Applications, 1st ed.; Blauel, J.G., Schwalbe, K.H., Eds.; Wiley: Hoboken, NJ, USA, 1991; pp. 381–414. [Google Scholar]

- Gurson, A.L. Continuum theory of ductile rupture by void nucleation and growth: Part I-yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 1977, 99, 2–15. [Google Scholar] [CrossRef]

- Xia, L.; Cheng, L. Transition from ductile tearing to cleavage fracture: A cell-model approach. Int. J. Fract. 1997, 87, 289–306. [Google Scholar] [CrossRef]

- He, R.; Steglich, D.; Heerens, J.; Wang, G.X.; Brocks, W.; Dahms, M. Influence of particle size and volume fraction on damage and fracture in Al-A13Ti composites and micromechanical modelling using the GTN model. Fatigue Fract. Eng Mater. Struct. 1998, 21, 1189–1201. [Google Scholar] [CrossRef]

- Lewis, C.A.; Withers, P.J. Weibull modelling of particle cracking in metal matrix composites. Acta Met. Mater. 1995, 43, 3685–3699. [Google Scholar] [CrossRef]

- Babout, L.; Maire, E.; Buffière, J.Y.; Fougères, R. Characterization by X-ray computed tomography of decohesion, porosity growth and coalescence in model metal matrix composites. Acta Mater. 2001, 49, 2055–2063. [Google Scholar] [CrossRef]

- Maire, E.; Bordreuil, C.; Babout, L.; Boyer, J.C. Damage initiation and growth in metals. Comparison between modeling and tomography experiments. J. Mech. Phys. Solids 2005, 53, 2411–2434. [Google Scholar] [CrossRef]

- Weck, A.; Wilkinson, D.S.; Maire, E.; Toda, H. Visualization by X-ray tomography of void growth and coalescence leading to fracture in model materials. Acta Mater. 2008, 56, 2919–2928. [Google Scholar] [CrossRef]

- McClintock, F.A. A criterion for ductile fracture by the growth of holes. ASME J. Appl. Mech. 1968, 35, 363–371. [Google Scholar] [CrossRef]

- Rice, J.R.; Tracey, D.M. On the ductile enlargement of voids in triaxial stress fields. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y. Accurate dilatation rates for spherical voids in triaxial stress fields. J. Appl. Mech. 1991, 58, 1084–1085. [Google Scholar] [CrossRef]

- Marini, B.; Mudry, F.; Pineau, A. Experimental study of cavity growth in ductile rupture. Eng. Fract. Mech. 1985, 6, 989–996. [Google Scholar] [CrossRef]

- Thomason, P.F. Ductile Fracture of Metals, 1st ed.; Pergamon Press: Oxford, UK, 1990. [Google Scholar]

- Budiansky, B.; Hutchinson, J.W.; Slutsky, S. Void growth and collapse in viscous solids. In Mechanics of Solids: The Rodney Hill 60th Anniversary Volume, 1st ed.; Hopkins, H.G., Sewell, M.J., Eds.; Pergamon: Oxford, UK, 1982; pp. 13–45. [Google Scholar]

- Thomason, P.F. A theoretical relation between KIC and basic material properties in ductile metals. Int. J. Fract. 1971, 4, 409–419. [Google Scholar]

- Brown, L.M.; Embury, J.D. A Model of Ductile Fracture in Two-Phase Materials. In Proceedings of the 3rd International Conference on the Strength of Metals and Alloys, Cambridge, UK, 20–25 August 1973; pp. 164–169. [Google Scholar]

- Sills, R.B.; Boyce, B.L. Void growth by dislocation adsorption. Mater. Res. Lett. 2020, 8, 103–109. [Google Scholar] [CrossRef]

- Tvergaard, V. Influence of voids on shear band instabilities under plane strain conditions. Int. J. Fract. 1981, 17, 389–407. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. Analysis of the cup–cone fracture in a round tensile bar. Acta Met. Mater. 1984, 32, 157–169. [Google Scholar] [CrossRef]

- Faleskog, J.; Gao, X.; Shih, C.F. Cell model for nonlinear fracture analysis—I. Micromechanics calibration. Int. J. Fract. 1998, 89, 355–373. [Google Scholar] [CrossRef]

- Koplik, J.; Needleman, A. Void growth and coalescence in porous plastic solids. Int. J. Solids Struct. 1988, 24, 835–853. [Google Scholar] [CrossRef]

- Benzerga, A.A.; Besson, J. Plastic potentials for anisotropic porous solids. Eur. J. Mech. A Solids 2001, 20, 397–434. [Google Scholar] [CrossRef]

- Gologanu, M.; Leblond, J.B.; Devaux, J. Approximate models for ductile metals containing non-spherical voids—Case of axisymmetric prolate ellipsoidal cavities. J. Mech. Phys. Solids 1993, 41, 1723–1754. [Google Scholar] [CrossRef]

- Gologanu, M.; Leblond, J.B.; Devaux, J. Approximate models for ductile metals containing non-spherical voids—Case of axisymmetric oblate ellipsoidal cavities. J. Eng. Mater. Technol. 1994, 116, 290–297. [Google Scholar] [CrossRef]

- Gologanu, M.; Leblond, J.B.; Devaux, J.; Perrin, G. Recent extensions of Gurson’s model for porous ductile metals. In Continuum Micromechanics, 1st ed.; Suquet, P., Ed.; Springer: Vienna, Austria, 1997; pp. 61–130. [Google Scholar]

- Madou, K.; Leblond, J.B. Numerical studies of porous ductile materials containing arbitrary ellipsoidal voids—I: Yield surfaces of representative cells. Eur. J. Mech. A Solids 2013, 42, 480–489. [Google Scholar] [CrossRef] [Green Version]

- Madou, K.; Leblond, J.B.; Morin, L. Numerical studies of porous ductile materials containing arbitrary ellipsoidal voids—II: Evolution of the length and orientation of the void axes. Eur. J. Mech. A Solids 2013, 42, 490–507. [Google Scholar] [CrossRef] [Green Version]

- Kailasam, M.; Ponte-Castaneda, P. A general constitutive theory for linear and nonlinear particulate media with microstructure evolution. J. Mech. Phys. Solids 1998, 46, 427–465. [Google Scholar] [CrossRef]

- Agoras, M.; Ponte-Castaneda, P. Anisotropic finite-strain models for porous viscoplastic materials with microstructure evolution. Int. J. Solids Struct. 2014, 51, 981–1002. [Google Scholar] [CrossRef] [Green Version]

- Keralavarma, S.M.; Benzerga, A.A. A constitutive model for plastically anisotropic solids with non-spherical voids. J. Mech. Phys. Solids 2010, 58, 874–901. [Google Scholar] [CrossRef]

- Keralavarma, S.M.; Hoelscher, S.; Benzerga, A.A. Void growth and coalescence in anisotropic plastic solids. Int. J. Solids Struct. 2011, 48, 1696–1710. [Google Scholar] [CrossRef] [Green Version]

- Siruguet, K.; Leblond, J.B. Effect of void locking by inclusions upon the plastic behavior of porous ductile solids. I: Theoretical modeling and numerical study of void growth. Int. J. Plast. 2004, 20, 225–254. [Google Scholar] [CrossRef]

- Siruguet, K.; Leblond, J.B. Effect of void locking by inclusions upon the plastic behavior of porous ductile solids. II: Theoretical modeling and numerical study of void coalescence. Int. J. Plast. 2004, 20, 255–268. [Google Scholar] [CrossRef]

- Needleman, A. Void growth in an elastic–plastic medium. J. Appl. Mech. 1972, 94, 964–970. [Google Scholar] [CrossRef]

- Tracey, D.M. Strain hardening and interaction effects on the growth of voids in ductile fracture. Eng. Fract. Mech. 1971, 3, 301–315. [Google Scholar] [CrossRef]

- Andersson, H. Analysis of a model for void growth and coalescence ahead of a moving crack tip. J. Mech. Phys. Solids 1977, 25, 217–233. [Google Scholar] [CrossRef]

- Tvergaard, V. Interaction of very small voids with larger voids. Int. J. Solids Struct. 1998, 35, 3989–4000. [Google Scholar] [CrossRef]

- Tvergaard, V.; Niordson, C. Nonlocal plasticity effects on interaction of different size voids. Int. J. Plast. 2004, 20, 107–120. [Google Scholar] [CrossRef]

- Tvergaard, V.; Hutchinson, J.W. Two mechanisms of ductile fracture: Void by void growth versus multiple void interaction. Int. J. Solids Struct. 2002, 39, 3581–3597. [Google Scholar] [CrossRef] [Green Version]

- Faleskog, J.; Shih, C.F. Micromechanics of coalescence—I. Synergistic effects of elasticity, plastic yielding and multi–size–scale voids. J. Mech. Phys. Solids 1997, 45, 21–50. [Google Scholar] [CrossRef]

- Seo, D.; Toda, H.; Kobayashi, M.; Uesugi, K.; Takeuchi, A.; Suzuki, Y. In situ observation of void nucleation and growth in a steel using X-ray tomography. ISIJ Int. 2015, 55, 1474–1482. [Google Scholar] [CrossRef] [Green Version]

- Maire, E.; Withers, P.J. Quantitative X-ray tomography. Int. Mater. Rev. 2014, 59, 1–43. [Google Scholar] [CrossRef] [Green Version]

- Thomason, P.F. A theory of ductile fracture by internal necking of cavities. J. Inst. Met. 1968, 96, 360–365. [Google Scholar]

- Benzerga, A.A. Micromechanics of coalescence in ductile fracture. J. Mech. Phys. Solids 2002, 50, 1331–1362. [Google Scholar] [CrossRef]

- Tekoglu, C.; Leblond, J.B.; Pardoen, T. A criterion for the onset of void coalescence under combined tension and shear. J. Mech. Phys. Solids 2012, 60, 1363–1381. [Google Scholar] [CrossRef]

- Torki, M.E.; Benzerga, A.A.; Leblond, J.B. On void coalescence under combined tension and shear. J. Appl. Mech. 2015, 82, 071005. [Google Scholar] [CrossRef]

- McClintock, F.A. Plasticity aspects of fracture. In Fracture: An Advanced Treatise; Liebowitz, H., Ed.; Academic Press: New York, NY, USA, 1973; Volume 3, pp. 47–225. [Google Scholar]

- Richelsen, A.B.; Tvergaard, V. Dilatant plasticity or upper bound estimates for porous ductile solids. Acta Met. Mater. 1994, 42, 2561–2577. [Google Scholar] [CrossRef]

- Betegon, C.; Rodriguez, C.; Belzunce, F.J. Analysis and modelisation of short crack growth by ductile fracture micromechanisms. Fatigue Fract. Eng. Mater. Struct. 1997, 20, 633–644. [Google Scholar] [CrossRef]

- Devaux, J.; Joly, P.; Leblond, J.B. Simulation by the Local Approach of the Ductile Crack Growth in a Pressure Vessel Steel Using an Improved Gurson-Tvergaard Model. In Proceedings of the 21st MPA Seminar, Stuttgart, Germany, 5–6 October 1995. [Google Scholar]

- Steglich, D.; Brocks, W. Micromechanical modelling of damage and fracture of ductile materials. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 1175–1188. [Google Scholar] [CrossRef]

- Skallerud, B.; Zhang, Z.L. A 3D numerical study of ductile tearing and fatigue crack growth under nominal cyclic plasticity. Int. J. Solids Struct. 1997, 34, 3141–3161. [Google Scholar] [CrossRef]

- Zhang, Z.L. A sensitivity analysis of material parameters for the Gurson constitutive model. Fatigue Fract. Eng. Mater. Struct. 1996, 19, 561–570. [Google Scholar] [CrossRef]

- Hao, S.; Brocks, W.; Heerens, J.; Hellmann, D. Simulation of 3D Ductile Crack Growth by the Gurson-Tvergaard-Needleman Model. In Proceedings of the ECF11: Mechanisms and Mechanics of Damage and Failure, Poitiers-Futuroscope, Poitiers, France, 3–6 September 1996; pp. 805–810. [Google Scholar]

- McVeigh, C.; Vernerey, F.; Liu, W.K.; Moran, B.; Olson, G. An interactive microvoid shear localization mechanism in high strength steels. J. Mech. Phys. Solids 2007, 55, 225–244. [Google Scholar] [CrossRef]

- Nahshon, K.; Hutchinson, J.W. Modification of the Gurson model for shear failure. Eur. J. Mech. A Solids 2008, 27, 1–17. [Google Scholar] [CrossRef]

- Rice, J.R.; Johnson, M.A. The role of large crack tip geometry changes in plane strain fracture. In Inelastic Behavior of Solids; Kanninen, M.F., Adler, W.F., Rosenfield, A.R., Jaffee, R.I., Eds.; McGraw-Hill: New York, NY, USA, 1970; pp. 641–672. [Google Scholar]

- Tait, R.A.; Taplin, D.M.R. Interaction effects during the growth of holes in a superplastically deforming medium. Scr. Met. 1979, 13, 77–82. [Google Scholar] [CrossRef]

- LeRoy, G.; Embury, J.D.; Edward, G.; Ashby, M.F. A model of ductile fracture based on the nucleation and growth of voids. Acta Met. 1981, 29, 1509–1522. [Google Scholar] [CrossRef]

- Gallican, V.; Hurre, J. Anisotropic coalescence criterion for nanoporous materials. J. Mech. Phys. Solids 2017, 108, 30–48. [Google Scholar] [CrossRef] [Green Version]

- Yerra, S.K.; Tekoglu, C.; Scheyvaerts, F.; Delannay, L.; Van Houtte, P.; Pardoen, T. Void growth and coalescence in single crystals. Int. J. Solids Struct. 2010, 47, 1016–1029. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, A.; Needleman, A. Void growth versus void collapse in a creeping single crystal. J. Mech. Phys. Solids 2013, 61, 1169–1184. [Google Scholar] [CrossRef]

- Brocks, W.; Sun, D.Z.; Hönig, A. Verification of the transferability of micromechanical parameters by cell model calculations with visco-plastic materials. Int. J. Plast. 1995, 11, 971–989. [Google Scholar] [CrossRef]

- Shakoor, M.; Bernacki, M.; Bouchard, P.O. Ductile fracture of a metal matrix composite studied using 3D numerical modeling of void nucleation and coalescence. Eng. Fract. Mech. 2018, 189, 110–132. [Google Scholar] [CrossRef]

- Barnby, J.T.; Shi, Y.W.; Nadkarmi, A.S. On the void growth in C-Mn structural steel during plastic deformation. Int. J. Fract. 1984, 25, 273–283. [Google Scholar] [CrossRef]

- Moxnes, J.F.; Frøyland, Ø. Mathematical relations related to the Lode parameter for studies of ductility. Adv. Stud. Ther. Phys. 2016, 10, 113–124. [Google Scholar] [CrossRef]

- Lin, Y.C.; Zhu, X.H.; Dong, W.Y.; Yang, H.; Xiao, Y.W.; Kotkunde, N. Effects of deformation parameters and stress triaxiality on the fracture behaviors and microstructural evolution of an Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2020, 832, 154988. [Google Scholar] [CrossRef]

- Morgeneyer, T.F.; Besson, J. Flat to slant ductile fracture transition: Tomography examination and simulations using shear-controlled void nucleation. Scr. Mater. 2011, 65, 1002–1005. [Google Scholar] [CrossRef]

- Wen, D.X.; Yue, T.Y.; Xiong, Y.B.; Wang, K.; Wang, J.K.; Zheng, Z.Z.; Li, J.J. High-temperature tensile characteristics and constitutive models of ultrahigh strength steel. Mat. Sci. Eng. A 2021, 803, 140491. [Google Scholar] [CrossRef]

- Wen, D.X.; Gao, C.X.; Zheng, Z.Z.; Wang, K.; Xiong, Y.B.; Wang, J.K.; Li, J.J. Hot tensile behavior of a low-alloyed ultrahigh strength steel: Fracture mechanism and physically based constitutive model. J. Mater. Res. Technol. 2021, 13, 1684–1697. [Google Scholar] [CrossRef]

- Zhou, W.; Chen, W.; Yuan, J. Evaluation of void nucleation, growth and coalescence parameters for HCP-Zr at extreme strain rates. AIP Adv. 2021, 11, 015343. [Google Scholar] [CrossRef]

- Mallick, D.D.; Parker, J.; Wilkerson, J.W.; Ramesh, K.T. Estimating void nucleation statistics in laser-driven spall. J. Dyn. Behav. Mater. 2020, 6, 268–277. [Google Scholar] [CrossRef]

- Ma, X.; Liu, J.; Wang, J.; Pan, H. Modeling of dynamic growth of a micro-scaled void based on strain gradient elasto-plasticity. J. Ther. Appl. Mech. 2020, 58, 927–941. [Google Scholar] [CrossRef]

| Particle | Matrix | Critical Stress [MPa] | Ref. |

|---|---|---|---|

| Particle fracture | |||

| Elongated MnS | A508 steel | 1100 | [17] |

| Cuboidal TiN | 4330 steel | 2300 | [34] |

| TiN | Inconel 718 | 1280–1540 | [37] |

| 4% spherical ZrO2-SiO2 | Al2124 (T6) | 700 | [35] |

| 20% spherical ZrO2-SiO2 | Al2124 (T4) | 700 | [35] |

| Particle separation | |||

| MnS | A508 steel | 800 | [17] |

| Si | Al (cast) | 550 | [38] |

| 4% spherical ZrO2-SiO2 | Al2124 (T6) | 1060 | [35] |

| 4% spherical ZrO2-SiO2 | Pure Al | 250 | [35] |

| 20% spherical ZrO2-SiO2 | Pure Al | 320 | [35] |

| Rounded Fe3C | Spheroidized 1045 steel | 1650 | [20] |

| Cu-Cr particles | Cu alloy | 1000 | [20] |

| TiC | Maraging steel | 1820 | [20] |

| C nodules | Cast iron | 80 | [39] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wciślik, W.; Pała, R. Some Microstructural Aspects of Ductile Fracture of Metals. Materials 2021, 14, 4321. https://doi.org/10.3390/ma14154321

Wciślik W, Pała R. Some Microstructural Aspects of Ductile Fracture of Metals. Materials. 2021; 14(15):4321. https://doi.org/10.3390/ma14154321

Chicago/Turabian StyleWciślik, Wiktor, and Robert Pała. 2021. "Some Microstructural Aspects of Ductile Fracture of Metals" Materials 14, no. 15: 4321. https://doi.org/10.3390/ma14154321

APA StyleWciślik, W., & Pała, R. (2021). Some Microstructural Aspects of Ductile Fracture of Metals. Materials, 14(15), 4321. https://doi.org/10.3390/ma14154321