3.2. Definitions of the Coordinate Systems

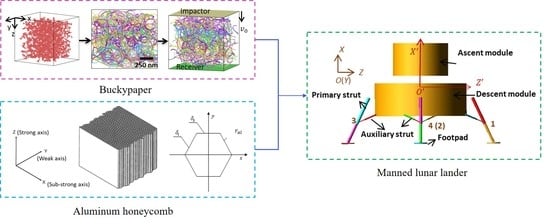

As shown in

Figure 4, two different right-handed Cartesian systems are employed to establish the soft landing dynamic model. They are inertial coordinate system and body coordinate system, which are defined as follows.

(1) In inertial coordinate system OXYZ, the origin O is located in initial barycenter of the main body and fixed to the lunar surface, X axis is direct to the opposite of lunar gravity. Z axis is perpendicular to X axis and direct to downhill. Y axis is determined by the rule of right-handed Cartesian system.

(2) In body coordinate system , the origin is located in barycenter of the main body. axis is perpendicular to the interface of the lunar lander and carrier rocket and point up. axis is perpendicular to axis and direct to Leg 1. axis is determined by the rule of right-handed Cartesian system.

Other landing legs are numbered in turn in counterclockwise direction from top view. The auxiliary struts are numbered in form of “

-

”. Here, “

” is the number of the corresponding landing leg. “

” equals “1” for the left auxiliary strut and “2” for the right one from outside view.

3.3. Determination of Key Geometric Parameters

There are two important geometric parameters of landing legs. As shown in

Figure 5, One is the initial height from the body’s bottom to the local lunar surface, expressed by

. The other is the distance between the line connecting the centers of two adjacent footpads and the central axis of the body, expressed by

. Since the surface of the moon is strewn with large and small rocks and other bumps, the bottom of the body is necessary to keep a safe distance from the lunar surface during the whole landing process, avoiding contacting the bumps. That means

should not be too small. However,

should not be too large. Otherwise, the initial distance between the barycenter and the lunar surface, expressed by

, could be too large, reducing landing stability. Landing stability is related to the “stability polygon” which is defined as a regular polygon whose vertexes are the centers of four footpads. It can be roughly believed that during the landing process, if the projection of the barycenter of the lander along the direction of gravity is located inside the stability polygon, the landing process is stable, that is, the lander will not tip over. As can be seen from

Figure 5, increasing

can increase the area of the stability polygon, so as to improve the landing stability of the lander. However, the increase of

also means the increase of the length of both primary and auxiliary struts, thus increasing the mass of the landing legs. Therefore,

and

affect the landing stability and the mass of the landing legs simultaneously. On the premise of ensuring landing stability, in order to reduce the mass of the lander,

and

should be as small as possible.

The minimum value of

can be estimated by the following formula:

where,

is the displacement of the primary strut in the vertical direction,

is the safe distance between the bottom of the lander and the lunar surface after landing, and

is the subsidence displacement of the barycenter of the lander relative to the lunar surface during landing.

In order to ensure that the lander does not tip over during landing, the following condition must be met:

where,

is the kinetic energy of the lander at the moment of tipping over, which can be approximate to that at the moment of touchdown;

refers to the increase of potential energy of the lander with the barycenter of the lander moving from the initial location at touchdown moment to the vertical plane containing centers of any two adjacent footpads;

and

can be calculated, respectively, by the following formulas:

where

is the mass of the main body, set as

;

and

are the vertical velocity and horizontal velocity of the lander at the initial moment of touchdown respectively;

is the gravitational acceleration on the lunar surface; and

refers to the increase height of the barycenter of the lander corresponding to

.

Assuming that the main primary strut has no buffering stroke,

can be estimated as follows:

According to Formulas (3)–(6), we can get:

Actually, during the process of rolling over, a buffering stroke is produced to absorb partial impact energy, and thus the kinetic energy of the lander is reduced. Therefore, this estimate is conservative.

The impact energy needed to be absorbed can be decomposed into a vertical part

and a horizontal part

. They can be obtained, respectively, by:

Since extreme landing and landing surface conditions must be taken into consideration during the design of landing mechanisms, the buffer capacity of each primary strut can be assumed as follows:

where

is a constant considering landing uncertainties, and its value is generally less than 0.7. Meanwhile, it is assumed that each auxiliary strut is able to absorb impact energy in horizontal direction. Hence, the buffer capacity of each auxiliary strut can be obtained:

Moreover, it is necessary to consider the limitation of the maximum response acceleration of the lander while landing. Thus, we have

where

is the maximum allowable response acceleration, and

is the buffering force.

According to Formulas (12) and (14), the minimum buffering stroke of the primary strut can be estimated:

where

is the number of landing mechanisms and obviously equals 4 here.

Above all, considering the size, strength and soft landing requirements synthetically, the materials and related parameters of landing mechanisms are as follows. All of the outer and inner cylinders of struts are made of aluminum alloy (7055) with elastic modulus of

, poisson’s ratio of 0.3, density of

, and yield limit of

. The geometric parameters are illustrated in

Table 2.

3.4. Buffering Forces

The buffering force can be expressed as a function of relative stroke between the outer and inner cylinders. The buffering force of the primary strut is obtained by:

The buffering force of the auxiliary strut is obtained by:

where

denotes the number of landing legs, values 1 and 2 of j, respectively, represent the left auxiliary strut and right auxiliary struts from the outside view,

and

are the buffering forces of the main and auxiliary struts, respectively, and

is the dynamic load coefficient which takes into account the effect of impact velocity. As is known, the initial impact velocity has little effect on the buckypaper’s buffering force as a function of stroke, and thus

can be taken as 1.

and

represent the buffering stroke of the primary and auxiliary struts, respectively.

and

are the buffering velocity of the primary and auxiliary struts respectively, and they are defined to be positive for compression and negative for tension.

,

and

are permanent deformation of the buffer component within the primary strut, the compression buffer component within the auxiliary strut, and the tension buffer component within the auxiliary strut, respectively.

is the compression force as a function of compression displacement of the buffer component within the primary strut.

and

are the forces as a function of compression displacement of the buffer component for compression and tension buffer, respectively.

and

are the sliding friction between the inner and outer cylinders of the primary and auxiliary struts, respectively.

Since the compression strain rate has no obvious effect on the stress-strain relationship within the range of landing velocity (0–4 m/s), the buffering force as a function of the buffering stroke for a buckypaper-buffer component can be easily obtained based on the compression stress-strain relationship and the physical dimension. The area surrounded by the buffering force-stroke curve is just the energy absorption by the buffer component. Buffer components should meet the limitation of the physical dimensions within the struts and the energy absorption requirements. Meanwhile, buffering force is expected to be as small as possible. By comparing the buckypapers with five densities, the densities

ρbpp = 52.81 kg/m

3 and

ρbpf = 91.01 kg/m

3 have been selected for buffering materials of the primary struts and auxiliary struts, respectively. The physical dimensions of the buffer components are described in

Table 3. Neglecting the rebound of the buckypaper, the buffering force as a function of the buffering stroke can be obtained based on the compression stress-strain relationship, shown in

Figure 6. The mass of buckypaper components within one single landing mechanism can be acquired by:

where

and

are the initial diameter and length of the buckypaper component within the primary strut, respectively; and

,

, and

are the initial outer diameter, inner diameter, and length of the buckypaper components for both tension and compression buffer. Finally,

is equal to

.

As is well known, aluminum honeycomb is the most commonly used energy absorption materials for landing mechanisms of a lunar lander. For the purpose of better understanding the buffering properties of buckypaper, aluminum honeycomb is also selected as an alternative buffering material for the lunar lander. The diagram of aluminum honeycomb and the definition of coordinate system are described in

Figure 7. Aluminum honeycomb (abbreviated AH in

Table 4) is an anisotropic material with parameters illustrated in

Table 4, where

,

and

are elasticity modulus in the corresponding directions,

,

, and

are shear modulus in the corresponding directions, and

is the density. According to the mechanical properties of aluminum honeycomb material, the energy absorption process can be divided into three stages: elastic stage, plastic stage, and elastic stage of matrix material. The elastic stage of aluminum honeycomb material corresponds to the initial compression progress. Upon the compression load, elastic buckling occurs. Before the compression force reaches the peak, both the honeycomb and its matrix material have no plastic deformation. In the plastic stage, the aluminum honeycomb collapses under pressure and the plastic buckling deformation appears, resulting in a long platform of load. When the aluminum honeycomb is completely collapsed and compacted, it enters the elastic stage of the matrix material, causing the corresponding load rising sharply. Energy dissipation mainly depends on the plastic stage and can be obtained by the integral of compression load against compression stroke. The peak load during the elastic phase can be eliminated by applying a preload to the aluminum honeycomb. As is shown in

Table 3, the aluminum honeycomb components have the same physical dimensions with the buckypaper ones, yet different available strokes. It is noted that the primary strut has two aluminum honeycomb components with different strengths. The relationship between the buffering force and the buffering stroke of the aluminum honeycomb components can be approximated as depicted in

Figure 8.

3.5. Forces upon the Main Body

According to Newton’s second law, the translational equation of the main body of the lander is:

where

,

, and

are, respectively, the components of the displacement of the barycenter of the body in the inertial coordinate system, and

,

, and

are, respectively, the components of the resultant force acting on the body induced by the landing mechanisms in the inertial coordinate system.

In the body coordinate system, the rotational Euler equation of the lander is:

where

,

and

are, respectively, the rotational inertias of the body about the

axis,

axis, and

axes;

,

and

are, respectively, the corresponding components of angular velocity vector about each axis; and

,

and

are, respectively, the corresponding components of the moment applied by the landing mechanisms to the body.

The force applied on the body by the landing mechanisms can be expressed in the inertial coordinate system by:

where

, denoting the sequence number of the landing mechanisms;

,

and

are, respectively, the components of the force

induced by the primary strut about each axis in the inertial coordinate system; similarly,

,

and

are respectively the components of the force

induced by the auxiliary strut with the number of

−

;

,

and

are, respectively, the components of the force

induced by the auxiliary strut with the number of

−

.

The corresponding momentum can be expressed in the body coordinate system by:

where i still denotes the sequence number of the landing mechanisms;

,

, and

are, respectively, the components of

about each axis of the body coordinate system;

,

,

,

,

and

are, respectively, the components of

and

about each axis of the body coordinate system.

,

and

are the coordinates of the connection point between the primary strut and the body of the lander in the body coordinate system;

,

and

are the coordinates of the connection point between the auxiliary strut with the number of

−

and the main body in the body coordinate system; and

,

and

are the coordinates of the connection point between the auxiliary strut with the number of

−

and the main body in the body coordinate system.