Microstructure and Microhardness Evolution of Mg–8Al–1Zn Magnesium Alloy Processed by Differential Speed Rolling at Elevated Temperatures

Abstract

:1. Introduction

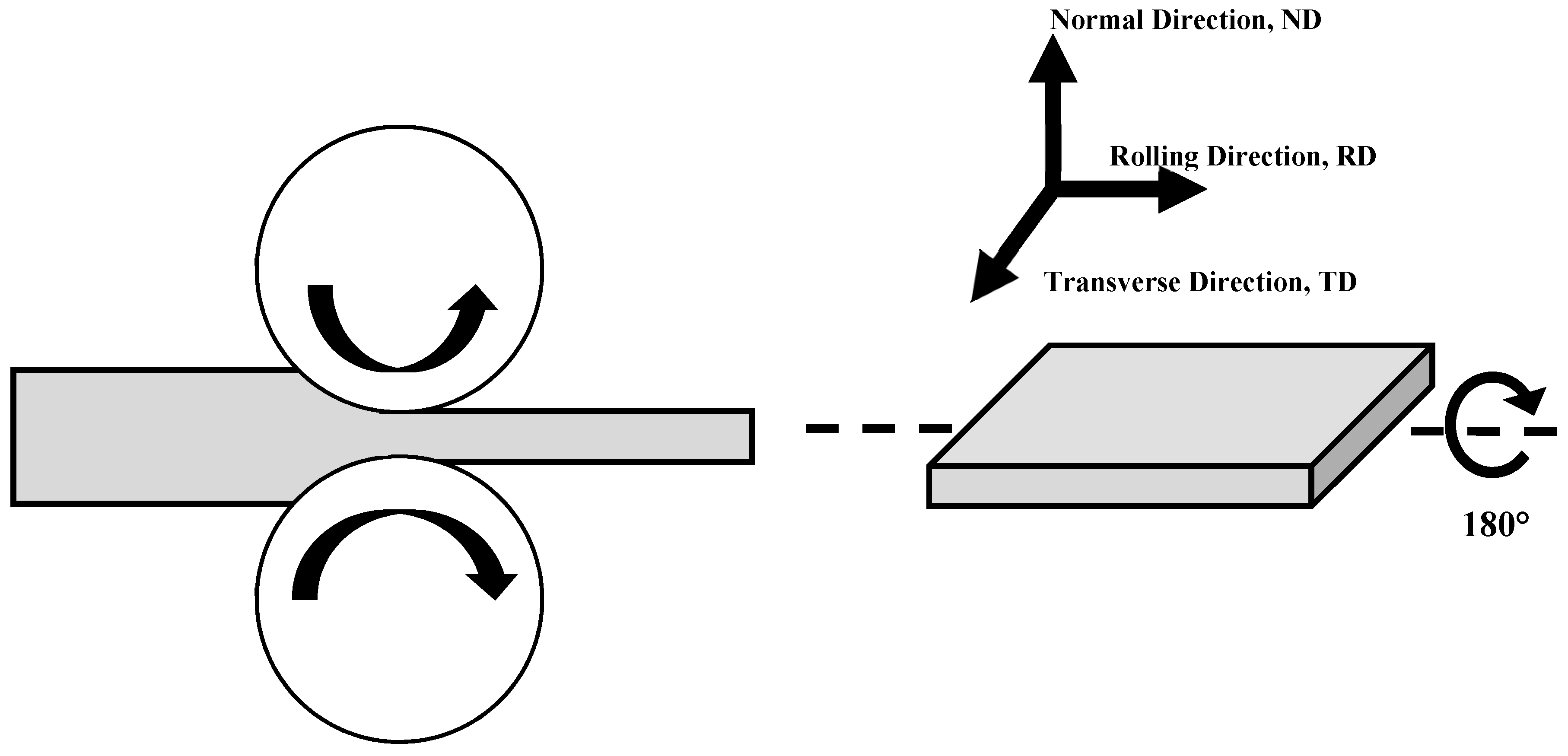

2. Experimental Material and Procedure

3. Results and Discussion

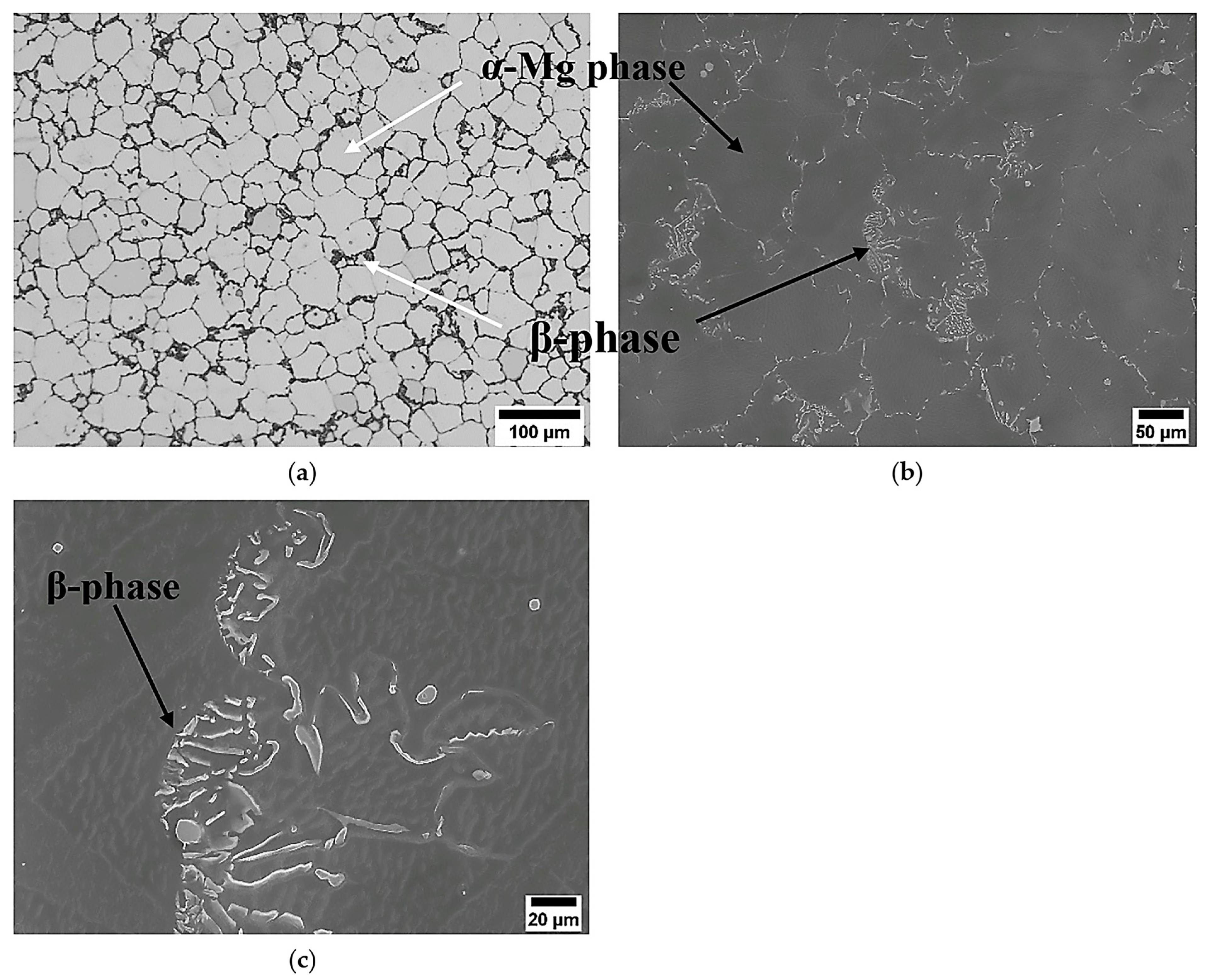

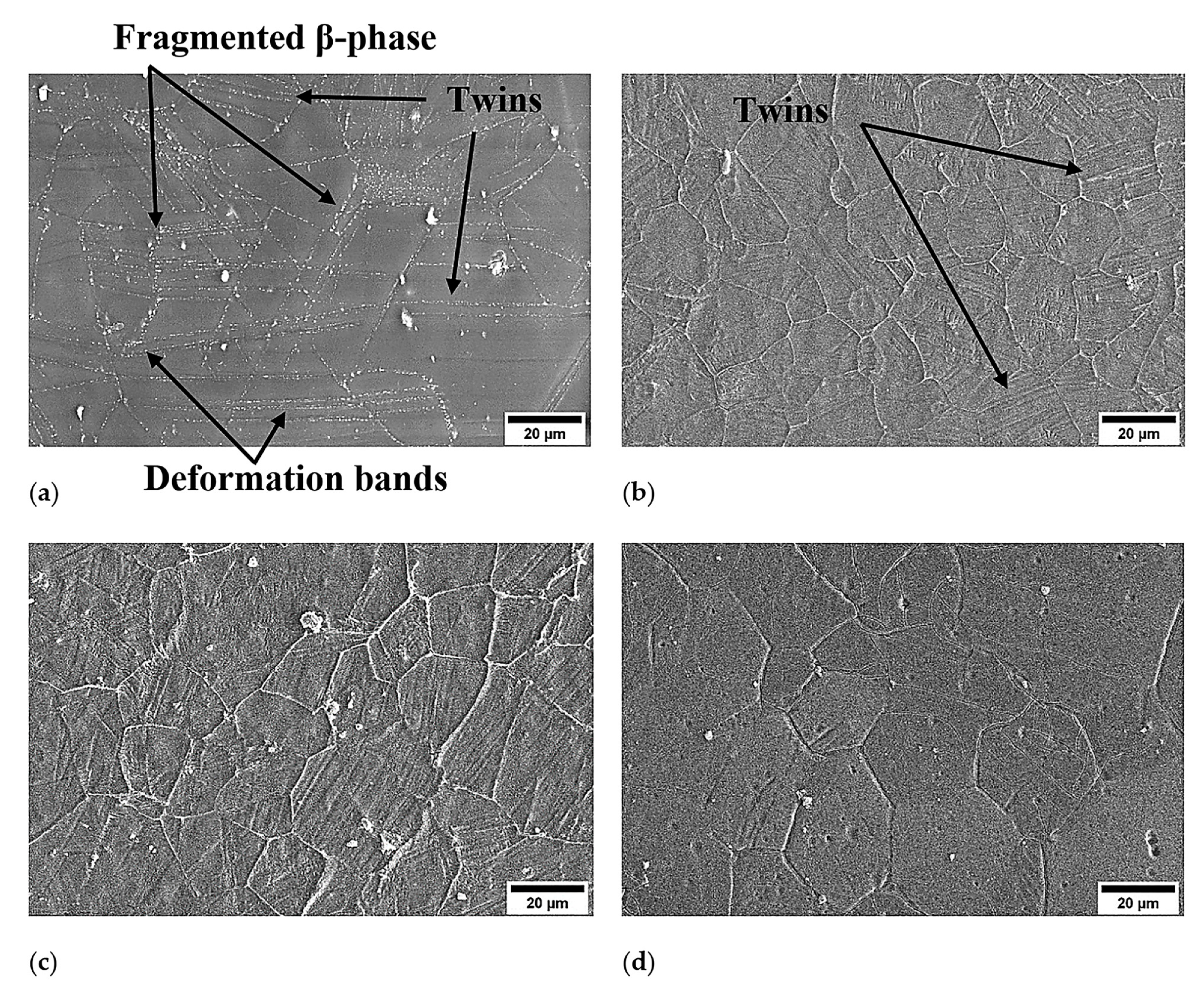

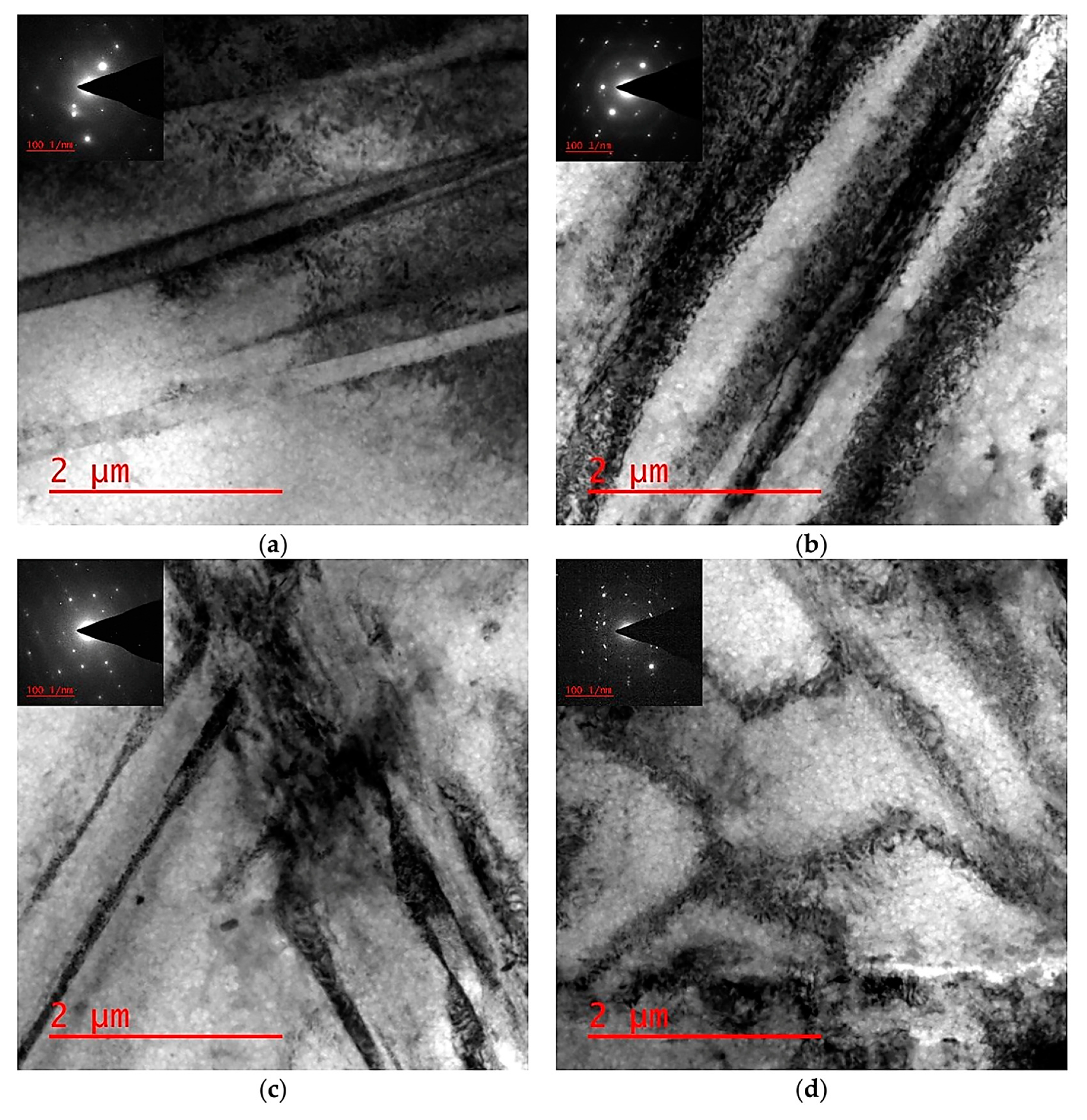

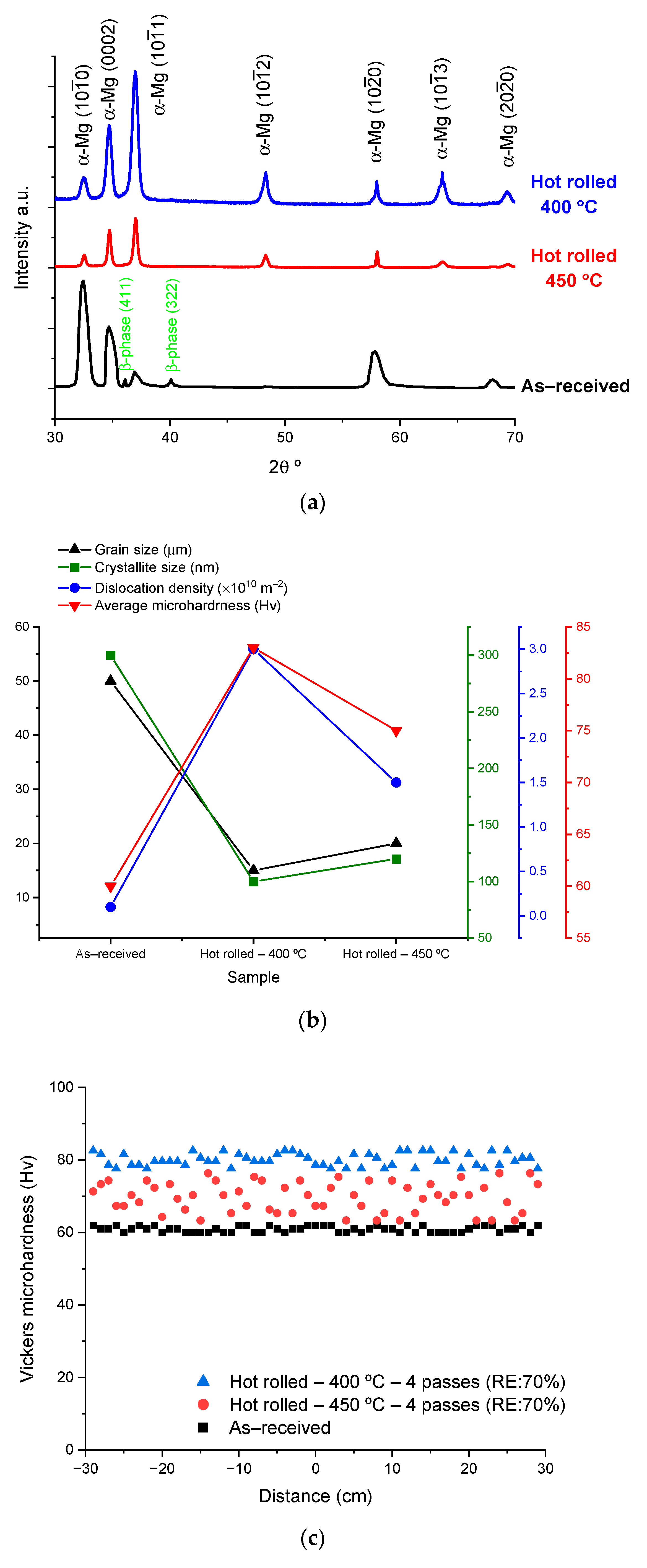

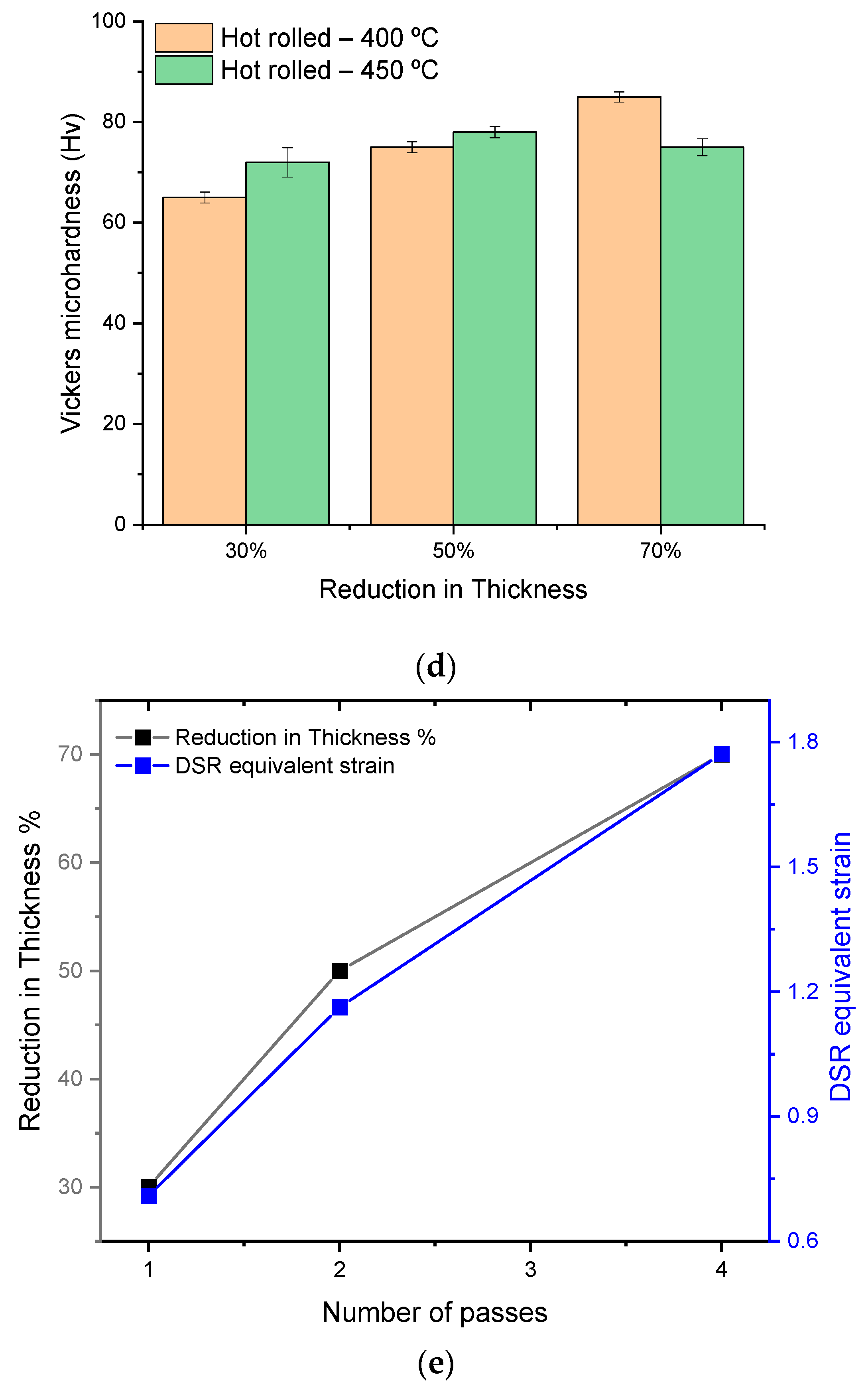

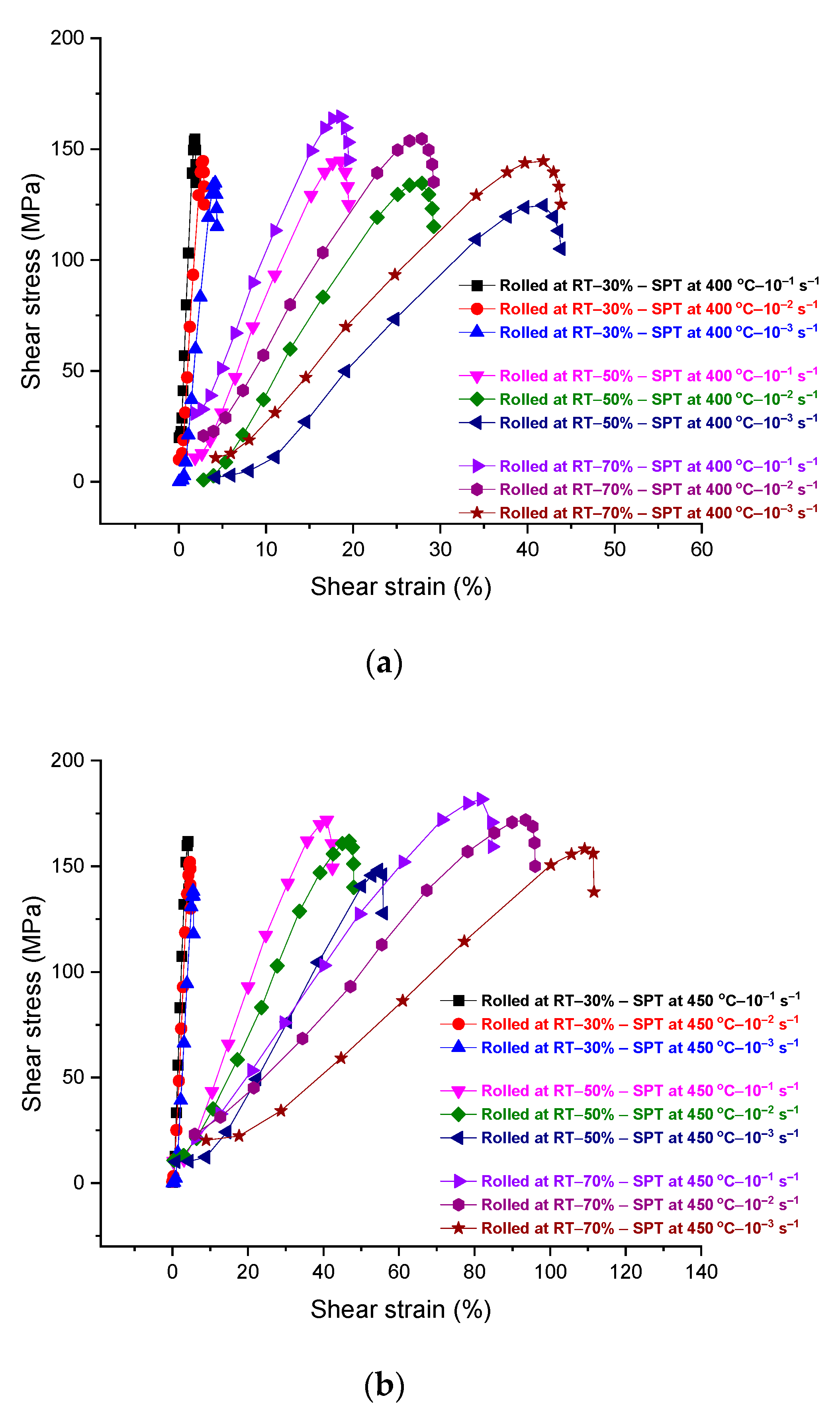

3.1. Microstructural Evolution

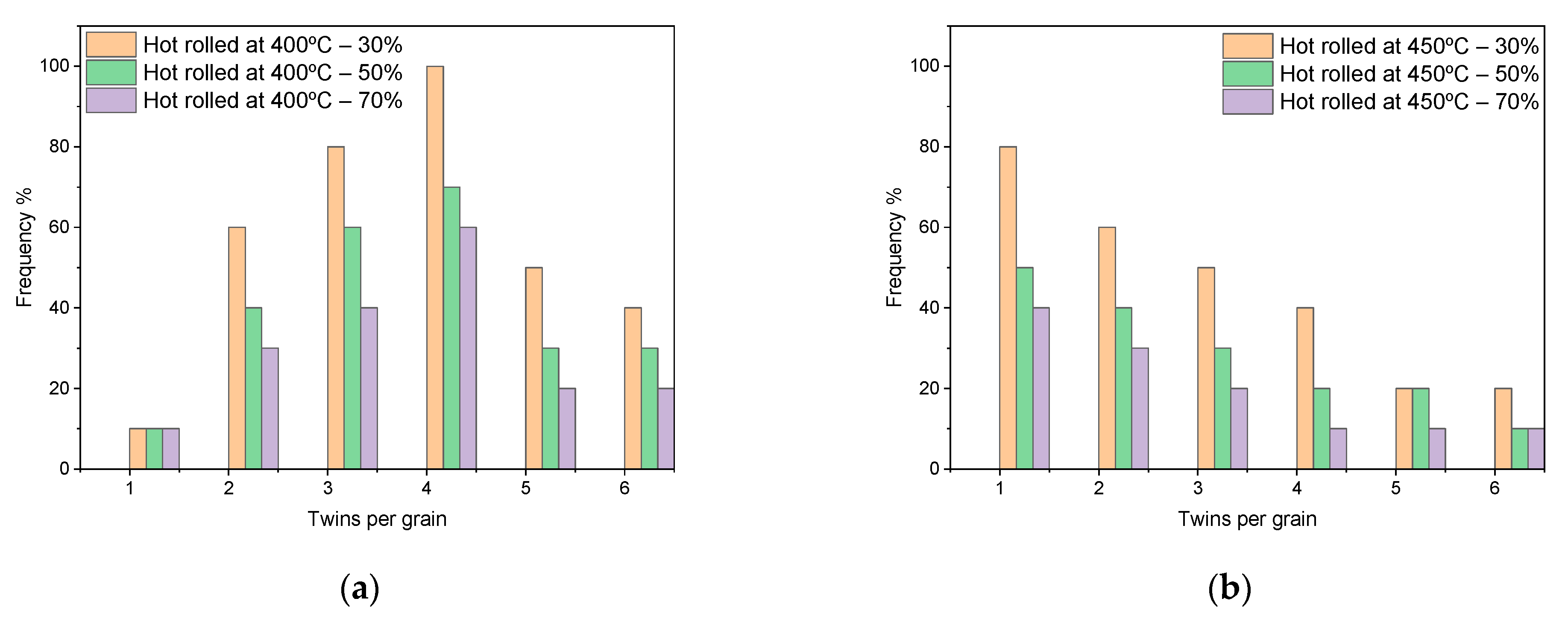

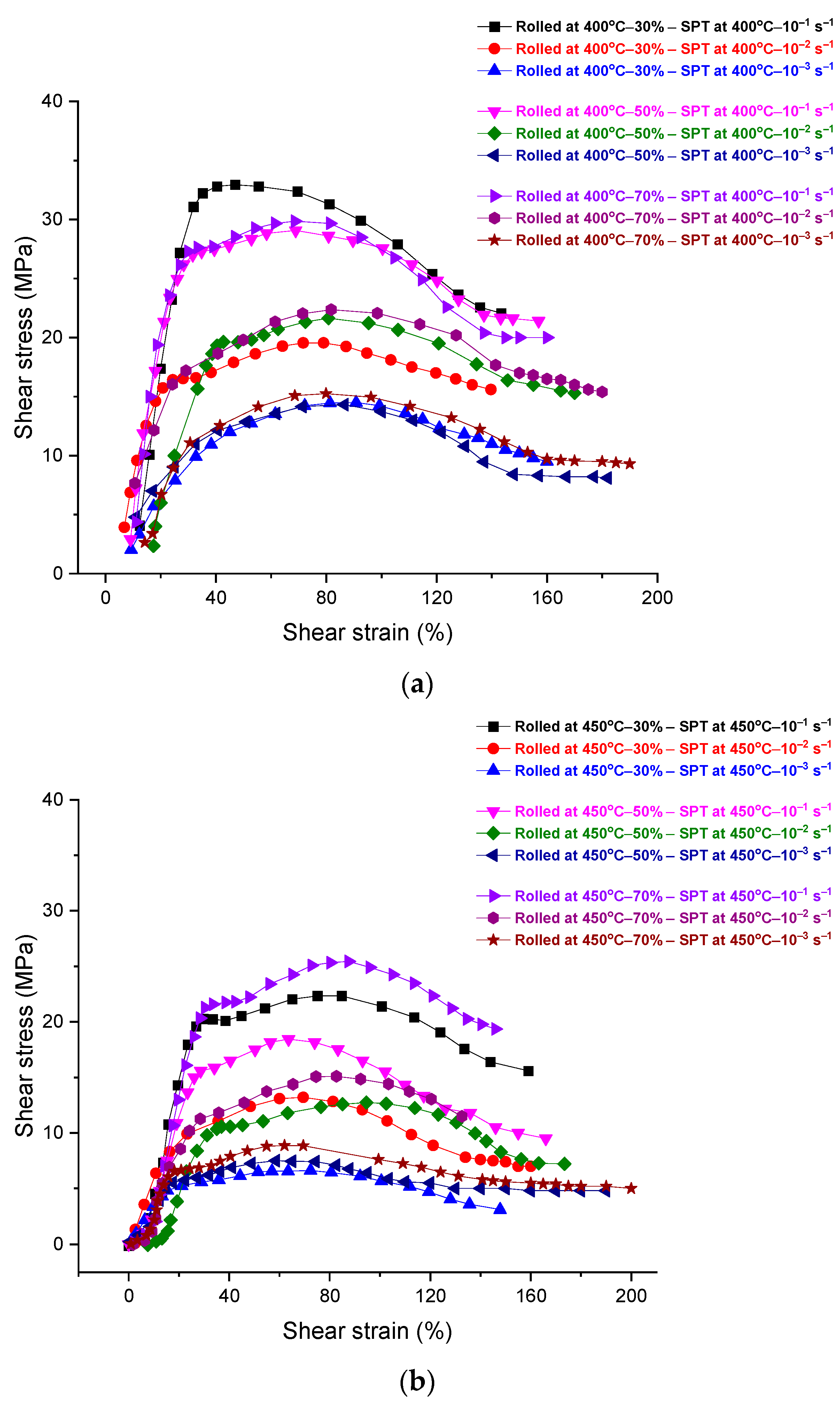

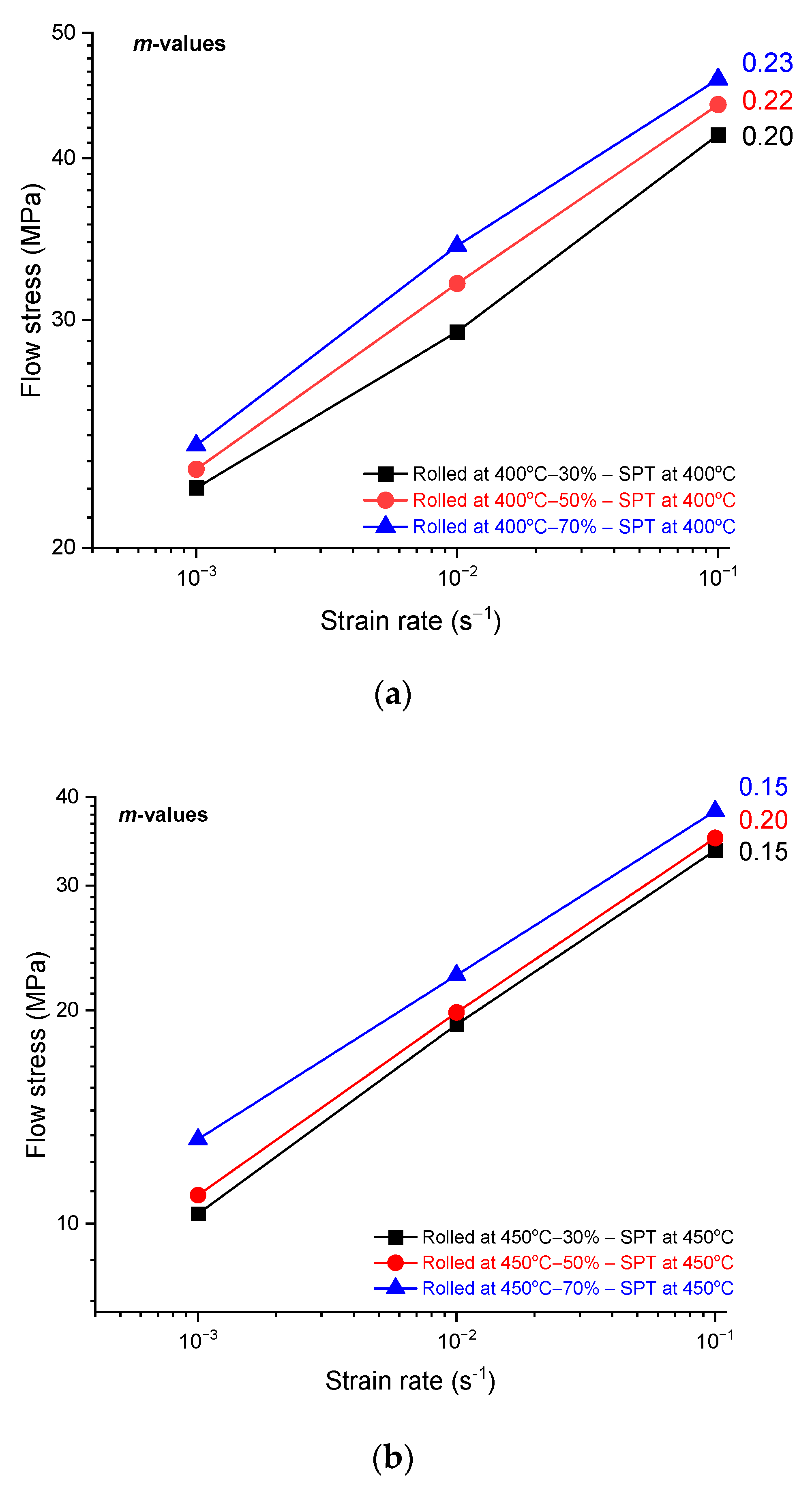

3.2. Mechanical Behaviour Evolution

4. Conclusions

- A commercial Mg–8Al–1Zn magnesium alloy was successfully processed by differential speed rolling at elevated temperatures of 400 and 450 °C without any significant grain growth at these rolling temperatures for a reduction percentage of 30% and 70%.

- Considerable twinning was observed in DSRolled alloy with no grain growth nor dynamic recrystallization indicating that twin deformation is the dominant deformation mechanism in addition to slip mechanism.

- The DSRolled alloy showed significant elongation in terms of shear displacements at testing temperatures of 400 and 450 °C.

- The existence of twins and the distribution of fine particles of β-phase (Mg17Al12) played important roles in the behavior of DSRolled alloy under the hot shear deformation. These two factors inhibit the significant grain growth, improve the strain hardening and improve the alloy flow under the hot deformation conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Samman, T.; Gottstein, G. Room temperature formability of a magnesium AZ31 alloy: Examining the role of texture on the deformation mechanisms. Mater. Sci. Eng. A 2008, 488, 406–414. [Google Scholar] [CrossRef]

- Kainer, K.U. Magnesium–Alloys and Technology; WILEY-VCH Verlag GmbH & Co. KG aA: Weinheim, Germany, 2003; ISBN 352730570X. [Google Scholar]

- Xu, S.W.; Zheng, M.Y.; Kamado, S.; Wu, K.; Wang, G.J.; Lv, X.Y. Dynamic microstructural changes during hot extrusion and mechanical properties of a Mg–5.0 Zn–0.9 Y–0.16 Zr (wt.%) alloy. Mater. Sci. Eng. A 2011, 528, 4055–4067. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Valiev, R. Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 2004, 3, 511–516. [Google Scholar] [CrossRef] [PubMed]

- Loorent, Z.; Ko, Y.G. Effect of differential speed rolling strain on microstructure and mechanical properties of nanostructured 5052 Al alloy. J. Alloys Compd. 2014, 586, S205–S209. [Google Scholar] [CrossRef]

- Loorentz; Ko, Y.G. Microstructure evolution and mechanical properties of severely deformed Al alloy processed by differential speed rolling. J. Alloys Compd. 2012, 536, S122–S125. [Google Scholar] [CrossRef]

- Ko, Y.G.; Hamad, K. Development of ultrafine grain if steel via differential speed rolling technique. Metals 2021, 11, 1925. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Z.; Yarmolenko, S.; Kecskes, L.J.; Sankar, J. Evolution of microstructure and mechanical properties of mg-6al alloy processed by differential speed rolling upon post-annealing treatment. Metals 2021, 11, 926. [Google Scholar] [CrossRef]

- Ko, Y.G.; Widiantara, I.P.; Hamad, K. On the Considerability of DSR (Differential Speed Rolling) as a Severe Plastic Deformation Method. Adv. Eng. Mater. 2017, 19, 1600722. [Google Scholar] [CrossRef]

- Hamad, K.; Ko, Y.G. Continuous Differential Speed Rolling for Grain Refinement of Metals: Processing, Microstructure, and Properties. Crit. Rev. Solid State Mater. Sci. 2019, 44, 470–525. [Google Scholar] [CrossRef]

- Hamad, K.; Chung, B.K.; Ko, Y.G. Microstructure and mechanical properties of severely deformed Mg-3%Al-1%Zn alloy via isothermal differential speed rolling at 453 K. J. Alloys Compd. 2015, 615, S590–S594. [Google Scholar] [CrossRef]

- Zhao, F.; Suo, T.; Chen, B.; Li, Y.L. Strength–ductility combination of fine-grained magnesium alloy with high deformation twin density. J. Alloys Compd. 2019, 798, 350–359. [Google Scholar] [CrossRef]

- Hamad, K.; Ko, Y.G. A cross-shear deformation for optimizing the strength and ductility of AZ31 magnesium alloys. Sci. Rep. 2016, 6, 29954. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.K.; Lee, D.N. Texture control and grain refinement of AA1050 Al alloy sheets by asymmetric rolling. Int. J. Mech. Sci. 2008, 50, 869–887. [Google Scholar] [CrossRef]

- Polkowski, W.; Jóźwik, P.; Polański, M.; Bojar, Z. Microstructure and texture evolution of copper processed by differential speed rolling with various speed asymmetry coefficient. Mater. Sci. Eng. A 2013, 564, 289–297. [Google Scholar] [CrossRef]

- Ko, Y.G.; Hamad, K. Structural features and mechanical properties of AZ31 Mg alloy warm-deformed by differential speed rolling. J. Alloys Compd. 2018, 744, 96–103. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, W.J. Microstructural instability and strength of an AZ31 Mg alloy after severe plastic deformation. Mater. Sci. Eng. A 2004, 385, 300–308. [Google Scholar] [CrossRef]

- del Valle, J.A.; Pérez-Prado, M.T.; Ruano, O.A. Texture evolution during large-strain hot rolling of the Mg AZ61 alloy. Mater. Sci. Eng. A 2003, 355, 68–78. [Google Scholar] [CrossRef]

- Al-Zubaydi, A.; Figueiredo, R.B.; Huang, Y.; Langdon, T.G. Structural and hardness inhomogeneities in Mg-Al-Zn alloys processed by high-pressure torsion. J. Mater. Sci. 2013, 48, 4661–4670. [Google Scholar] [CrossRef]

- Al-Zubaydi, A.S.J.; Zhilyaev, A.P.; Wang, S.C.; Kucita, P.; Reed, P.A.S. Evolution of microstructure in AZ91 alloy processed by high-pressure torsion. J. Mater. Sci. 2016, 51, 3380–3389. [Google Scholar] [CrossRef]

- Huang, X.; Suzuki, K.; Saito, N. Microstructure and mechanical properties of AZ80 magnesium alloy sheet processed by differential speed rolling. Mater. Sci. Eng. A 2009, 508, 226–233. [Google Scholar] [CrossRef]

- Esfandyarpour, M.J.; Alizadeh, R.; Mahmudi, R. Applicability of shear punch testing to the evaluation of hot tensile deformation parameters and constitutive analyses. J. Mater. Res. Technol. 2019, 8, 996–1002. [Google Scholar] [CrossRef]

- Yakubtsov, I.A.; Diak, B.J.; Sager, C.A.; Bhattacharya, B.; MacDonald, W.D.; Niewczas, M. Effects of heat treatment on microstructure and tensile deformation of Mg AZ80 alloy at room temperature. Mater. Sci. Eng. A 2008, 496, 247–255. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kim, W.J. Microstructure and superplasticity of the as-cast Mg–9Al–1Zn magnesium alloy after high-ratio differential speed rolling. Mater. Sci. Eng. A 2016, 677, 332–339. [Google Scholar] [CrossRef]

- Liu, S.; Guo, H. Influence of Heat Treatment on Microstructure and Mechanical Properties of AZ61 Magnesium Alloy Prepared by Selective Laser Melting (SLM). Materials 2022, 15, 7067. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Li, S.; Yan, F.; Zhang, Z.; Wu, Y. Microstructure evolution and mechanical properties of AZ80 Mg alloy during annular channel angular extrusion process and heat treatment. Materials 2019, 12, 4223. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.Y.; Wang, C.; Ning, H.; Wang, T.; Zhang, C.C.; Yang, Z.Z.; Wang, H.Y. Relieving segregation in twin-roll cast Mg–8Al–2Sn–1Zn alloys via controlled rolling. J. Magnes. Alloy. 2021, 9, 254–265. [Google Scholar] [CrossRef]

- Zhang, K.; Zheng, J.H.; Huang, Y.; Pruncu, C.; Jiang, J. Evolution of twinning and shear bands in magnesium alloys during rolling at room and cryogenic temperature. Mater. Des. 2020, 193, 108793. [Google Scholar] [CrossRef]

- Chang, L.L.; Kang, S.B.; Cho, J.H. Influence of strain path on the microstructure evolution and mechanical properties in AM31 magnesium alloy sheets processed by differential speed rolling. Mater. Des. 2013, 44, 144–148. [Google Scholar] [CrossRef]

- Kim, W.J.; Hwang, B.G.; Lee, M.J.; Park, Y.B. Effect of speed-ratio on microstructure, and mechanical properties of Mg-3Al-1Zn alloy, in differential speed rolling. J. Alloys Compd. 2011, 509, 8510–8517. [Google Scholar] [CrossRef]

- Jia, W.P.; Hu, X.D.; Zhao, H.Y.; Ju, D.Y.; Chen, D.L. Texture evolution of AZ31 magnesium alloy sheets during warm rolling. J. Alloys Compd. 2015, 645, 70–77. [Google Scholar] [CrossRef]

- Barnett, M.R.; Nave, M.D.; Bettles, C.J. Deformation microstructures and textures of some cold rolled Mg alloys. Mater. Sci. Eng. A 2004, 386, 205–211. [Google Scholar] [CrossRef]

- Wang, M.; Xu, X.Y.; Wang, H.Y.; He, L.H.; Huang, M.X. Evolution of dislocation and twin densities in a Mg alloy at quasi-static and high strain rates. Acta Mater. 2020, 201, 102–113. [Google Scholar] [CrossRef]

- Ghandehari Ferdowsi, M.R.; Mazinani, M.; Ebrahimi, G.R. Effects of hot rolling and inter-stage annealing on the microstructure and texture evolution in a partially homogenized AZ91 magnesium alloy. Mater. Sci. Eng. A 2014, 606, 214–227. [Google Scholar] [CrossRef]

- Liu, X.; Wan, Q.; Yang, H.; Zhu, B.; Wu, Y.; Liu, W.; Tang, C. The Effect of Twins on Mechanical Properties and Microstructural Evolution in AZ31 Magnesium Alloy during High Speed Impact Loading. J. Mater. Eng. Perform. 2022, 31, 3208–3217. [Google Scholar] [CrossRef]

- Liu, D.; Bian, M.Z.; Zhu, S.M.; Chen, W.Z.; Liu, Z.Y.; Wang, E.D.; Nie, J.F. Microstructure and tensile properties of Mg-3Al-1Zn sheets produced by hot-roller-cold-material rolling. Mater. Sci. Eng. A 2017, 706, 304–310. [Google Scholar] [CrossRef]

- Chang, T.-C.; Wang, J.-Y.; Chia-Ming, O.; Lee, S. Grain refining of magnesium alloy AZ31 by rolling. J. Mater. Process. Technol. 2003, 140, 588–591. [Google Scholar] [CrossRef]

- Yan, H.; Xu, S.W.; Chen, R.S.; Kamado, S.; Honma, T.; Han, E.H. Twins, shear bands and recrystallization of a Mg-2.0%Zn-0.8%Gd alloy during rolling. Scr. Mater. 2011, 64, 141–144. [Google Scholar] [CrossRef]

- Changizian, P.; Zarei-Hanzaki, A.; Ghambari, M.; Imandoust, A. Flow localization during severe plastic deformation of AZ81 magnesium alloy: Micro-shear banding phenomenon. Mater. Sci. Eng. A 2013, 582, 8–14. [Google Scholar] [CrossRef]

- Fatemi, S.M.; Moradipour, Y.; Chulist, R.; Paul, H. Flow softening, twinning and dynamic evolution of second phase particles in a rolled Mg–Y-Nd-Zr alloy under shear deformation mode. J. Mater. Res. Technol. 2022, 18, 2368–2383. [Google Scholar] [CrossRef]

- Xu, S.W.; Matsumoto, N.; Kamado, S.; Honma, T.; Kojima, Y. Effect of Mg17Al12 precipitates on the microstructural changes and mechanical properties of hot compressed AZ91 magnesium alloy. Mater. Sci. Eng. A 2009, 523, 47–52. [Google Scholar] [CrossRef]

- Salevati, M.A.; Akbaripanah, F.; Mahmudi, R. Microstructure, Texture, and Mechanical Properties of AM60 Magnesium Alloy Processed by Extrusion and Multidirectional Forging. J. Mater. Eng. Perform. 2019, 28, 3021–3030. [Google Scholar] [CrossRef]

- Karimi, E.; Zarei-Hanzaki, A.; Pishbin, M.H.; Abedi, H.R.; Changizian, P. Instantaneous strain rate sensitivity of wrought AZ31 magnesium alloy. Mater. Des. 2013, 49, 173–180. [Google Scholar] [CrossRef]

- He, B.; Hu, Y.; Zhao, T.; Yao, Q.; Pan, F. Microstructure and mechanical properties of aged and hot rolled AZ80 magnesium alloy sheets. Crystals 2019, 9, 239. [Google Scholar] [CrossRef]

- Masoudpanah, S.M.; Mahmudi, R. The microstructure, tensile, and shear deformation behavior of an AZ31 magnesium alloy after extrusion and equal channel angular pressing. Mater. Des. 2010, 31, 3512–3517. [Google Scholar] [CrossRef]

- Lee, S.W.; Chen, Y.L.; Wang, H.Y.; Yang, C.F.; Yeh, J.W. On mechanical properties and superplasticity of Mg-15Al-1Zn alloys processed by reciprocating extrusion. Mater. Sci. Eng. A 2007, 464, 76–84. [Google Scholar] [CrossRef]

- Al-Zubaydi, A.S.J.; Zhilyaev, A.P.; Wang, S.C.; Reed, P.A.S. Superplastic behaviour of AZ91 magnesium alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2015, 637, 1–11. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsubaie, S.A.; Al-Zubaydi, A.S.J.; Hussein, E.A.; Alawadhi, M.Y. Microstructure and Microhardness Evolution of Mg–8Al–1Zn Magnesium Alloy Processed by Differential Speed Rolling at Elevated Temperatures. Materials 2024, 17, 4072. https://doi.org/10.3390/ma17164072

Alsubaie SA, Al-Zubaydi ASJ, Hussein EA, Alawadhi MY. Microstructure and Microhardness Evolution of Mg–8Al–1Zn Magnesium Alloy Processed by Differential Speed Rolling at Elevated Temperatures. Materials. 2024; 17(16):4072. https://doi.org/10.3390/ma17164072

Chicago/Turabian StyleAlsubaie, Saad A., Ahmed S. J. Al-Zubaydi, Emad A. Hussein, and Meshal Y. Alawadhi. 2024. "Microstructure and Microhardness Evolution of Mg–8Al–1Zn Magnesium Alloy Processed by Differential Speed Rolling at Elevated Temperatures" Materials 17, no. 16: 4072. https://doi.org/10.3390/ma17164072