Use of Biomass Bottom Ash as an Alternative Solution to Natural Aggregates in Concrete Applications: A Review

Abstract

:1. Introduction

2. Origin and Properties of Biomass Ash (BA)

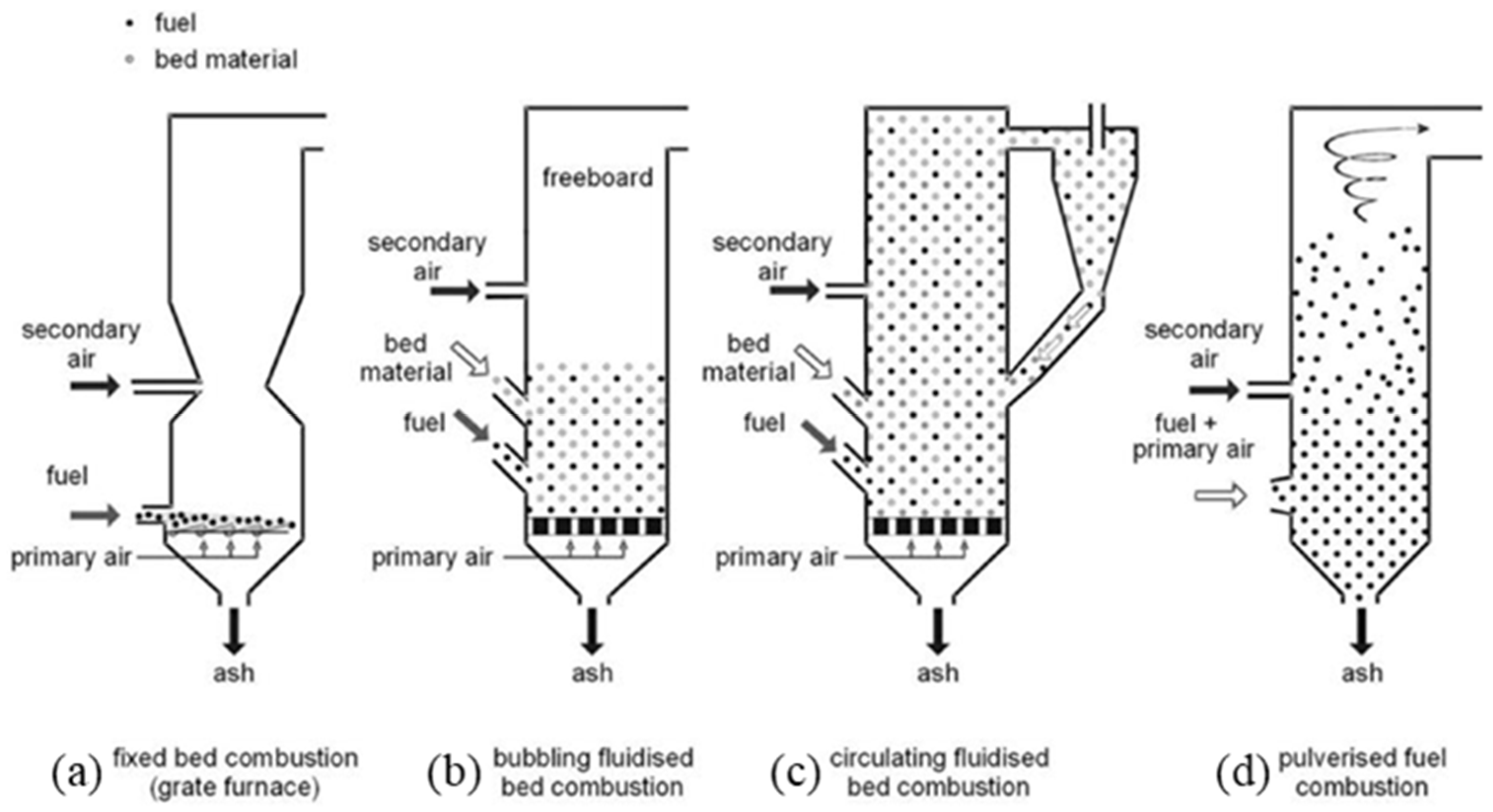

2.1. Origin and Production of Biomass Ash

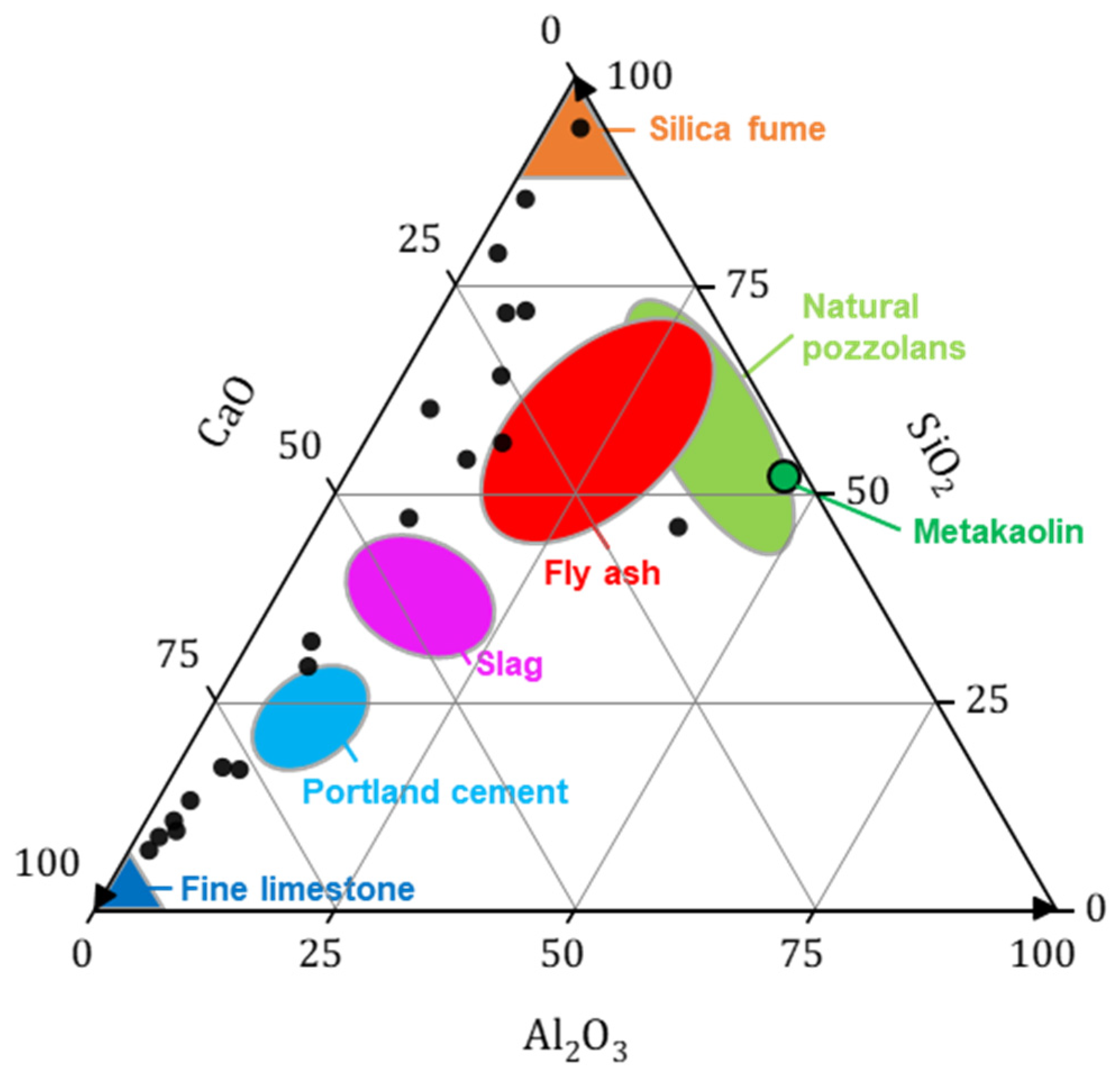

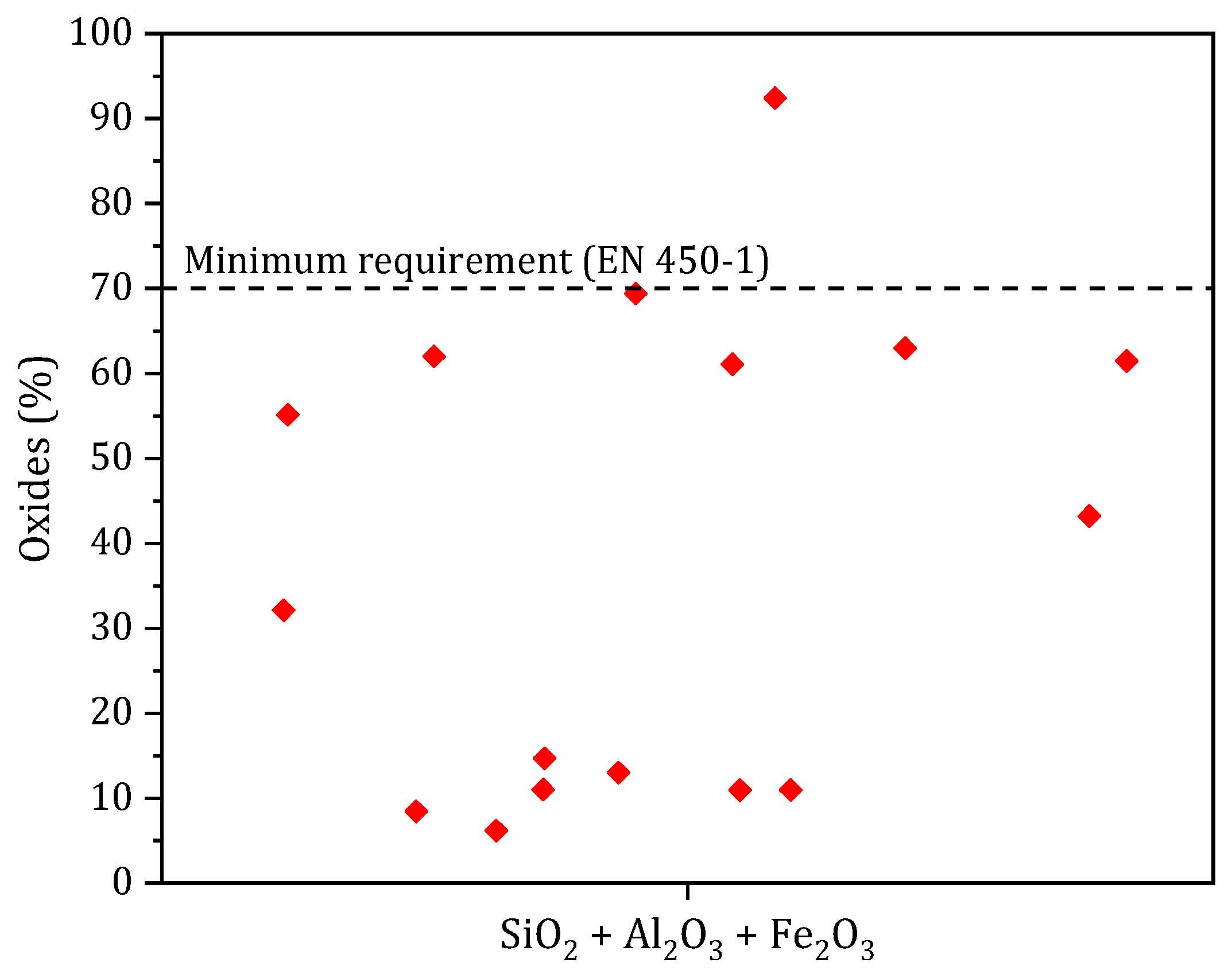

2.1.1. Chemical Composition

- CaO (43.03%) > SiO2 (22.22%) > K2O (10.75%) > MgO (6.07%) for wood-based biomass;

- SiO2 (47.02%) > K2O (24.55%) > CaO (12.61%) > MgO (5.44%) for biomass from herbaceous straw and agriculture;

- K2O (28.25%) > SiO2 (24.47%) > CaO (16.58%) > P2O5 (7.27%) for biomass from grass and agricultural residues;

- SiO2 (35.73%) > CaO (18.30%) > Al2O3 (15.41%) > P2O5 (3.64%) for contaminated biomass.

2.1.2. Heavy Metals

2.1.3. Mineralogical Composition

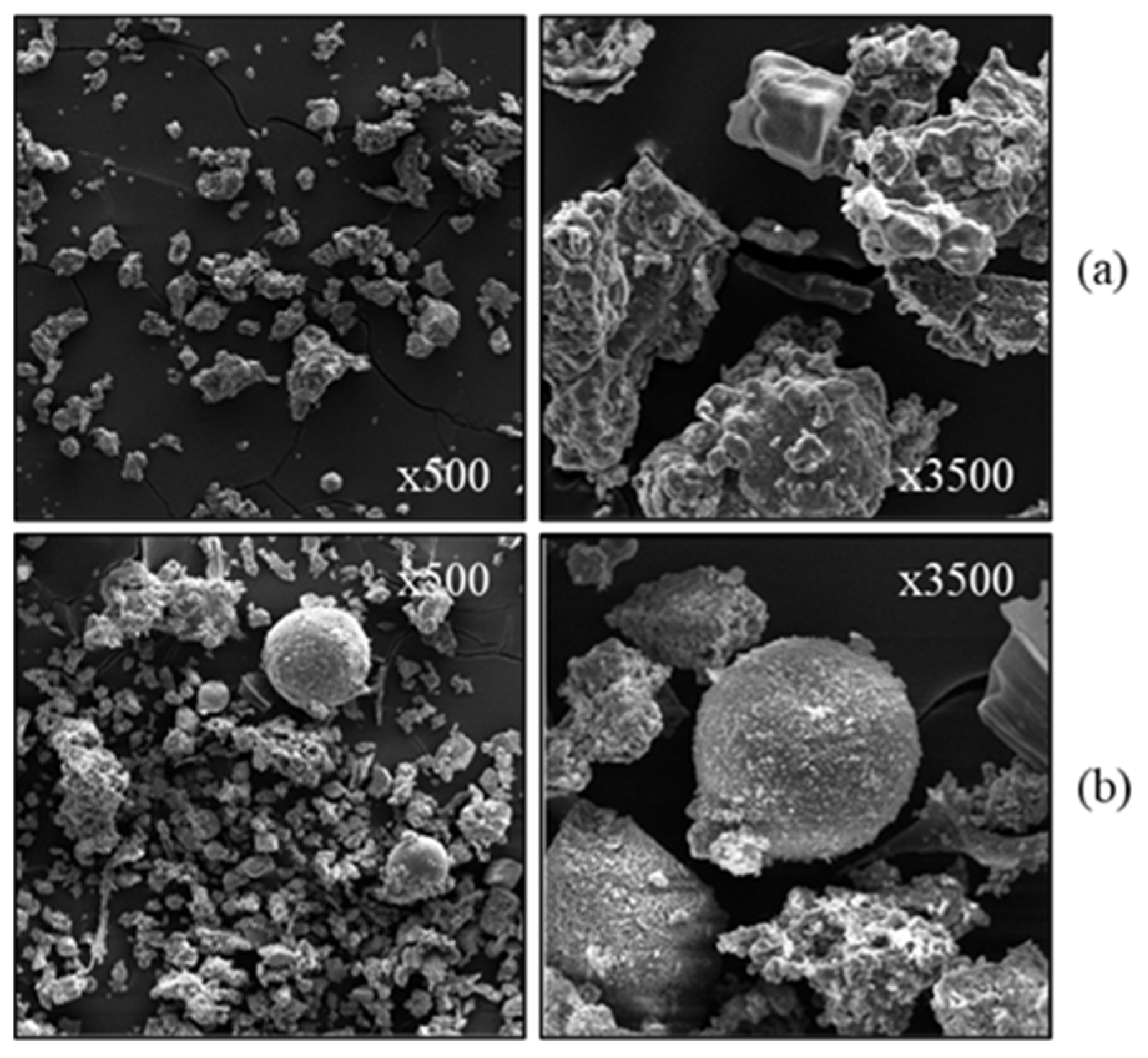

2.1.4. Morphology

2.1.5. Density and Water Absorption

| Type of Biomass | Combustion Technology | Density (g/cm3) | Water Absorption (%) | LOI (%) | Source |

|---|---|---|---|---|---|

| Wood | Fluidised bed | 2.28 | 2.41 | 1.84 | [25] |

| Wood | Fluidised bed | 2.65 to 2.67 | n.a. | 1.27 to 2.08 | [42] |

| Wood | Multiple | 1.75 to 2.69 | n.a. | 1.00 to 19.60 | [4] |

| Agricultural | n.a. | 2.02 | 19.90 | 3.06 | [61] |

| Agricultural | n.a. | 1.89 to 2.01 | 19.5 to 19.8 | 3.41 to 3.92 | [44] |

| Agricultural | Grid | 2.21 to 2.49 | 19.60 to 39.30 | 11.00 to 16.86 | [52] |

| Agricultural | Grid | 2.35 | n.a. | 41.49 | [43] |

| Agricultural /wood | n.a. | 2.34 to 2.41 | n.a. | n.a. | [41] |

| Agricultural /wood | Grid | 1.97 | 26.60 | 4.12 | [55] |

| Agricultural /wood | Grid | 1.82 | 31.90 | 4.85 | [62] |

| Agricultural /wood | Grid | 1.86 to 2.12 | 18.90 to 21.80 | 0.98 to 4.34 | [45] |

| Agricultural /wood | Grid | 1.73 | 19.83 | n.a. | [40] |

| Agricultural /wood | Grid | 2.34 to 2.38 | 9.80 to 10.10 | n.a. | [54] |

| Pulp and paper industry | Fluidised bed | 2.21 | 5.20 | 1.90 | [26] |

2.1.6. Granular Distribution

2.2. Improvement of Ash Properties

2.3. Interest in and Possibility of Valorisation

3. Influence of Granular Substitution of Biomass Ash on Cementitious Materials

3.1. Workability

3.2. Fresh Density

3.3. Mechanical Resistance

3.3.1. Compressive Strength

3.3.2. Elastic Modulus

3.3.3. Flexural and Tensile Strength

3.4. Durability

3.4.1. Porosity and Water Absorption

3.4.2. Ultrasonic Pulse Velocity

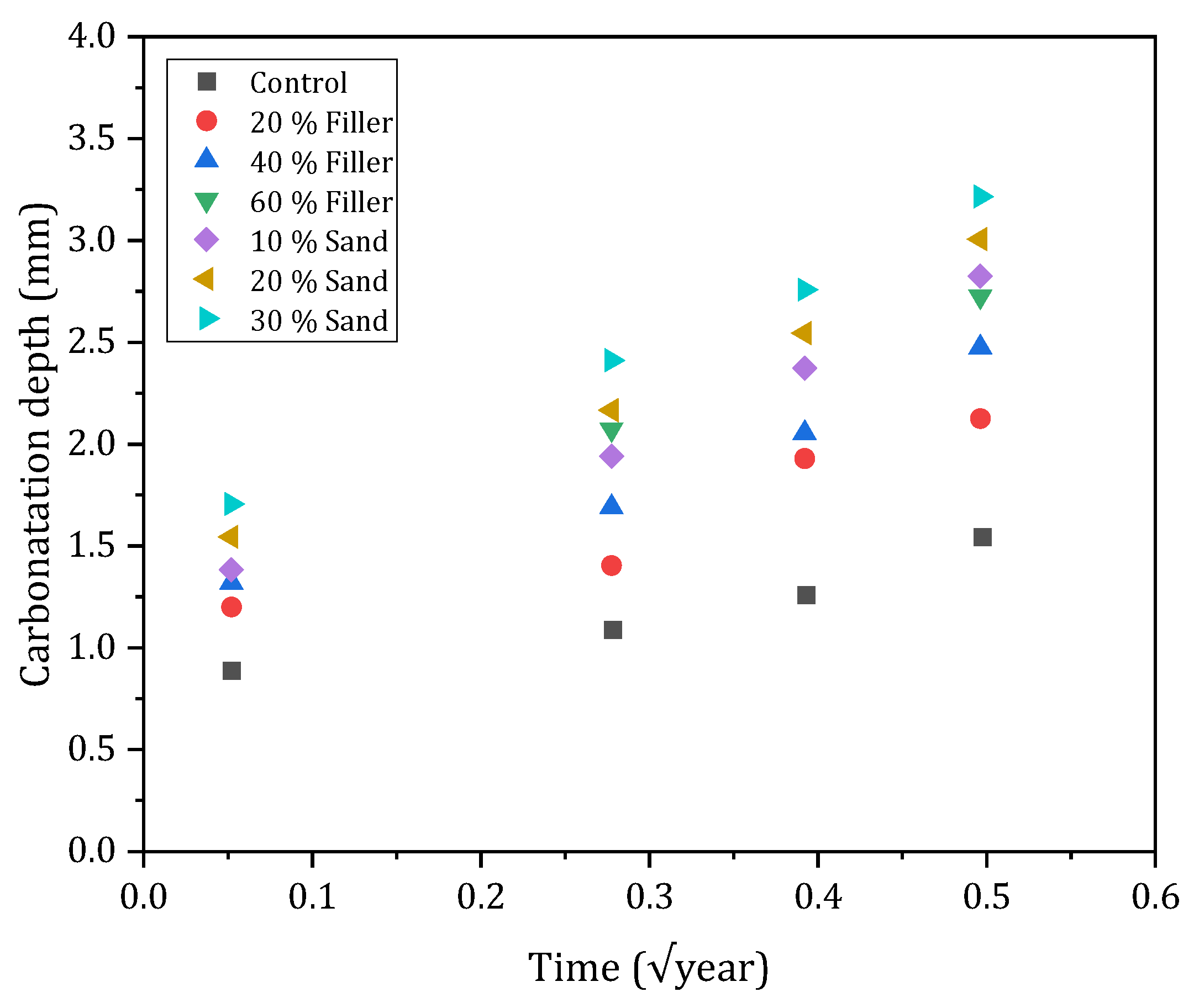

3.4.3. Depth of Carbonation

3.4.4. Penetration of Chloride Ions

3.4.5. Shrinkage

4. Conclusions

- Many studies have characterised the properties of biomass ash (fly ash and bottom ash). The high water absorption and the presence of organic matter are limiting factors for their reuse. Their amorphous nature and granulometry make them interesting for granular recovery. However, few studies have addressed the treatment of ash to improve its properties. It might be useful to specify the combustion technology, which is not always the case, as this would help to explain some of the significant variations found between studies—particularly when the biomass source is similar but the combustion technology is different.

- The density of BBA varies significantly in the literature, from 1.73 to 2.69 g/cm3, which is generally lower than that of sand. To avoid introducing errors into the studies, it is important to carry out the volume substitution of the material when replacing sand with BBA.

- Several works incorporate up to 30% ash in different types of concrete. The workability of the concrete is generally maintained through the use of a superplasticiser. The density of the concrete produced decreases with the rate of substitution due to the lower density of BBA compared to a common aggregate. A reduction in mechanical strength is also observed with the incorporation of biomass ash and may be related to the high water absorption of BBA.

- The durability properties of concrete incorporating biomass ash are poorly studied in the literature, except for the open porosity properties, which show a decrease with an increasing BBA substitution rate. Indicators of carbonation resistance and chloride ion penetration have been characterised in the literature, but there are few results available to confirm a trend for these ashes.

- The compatibility of biomass ash with steel for reinforced concrete is not studied in the literature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Parliament and Council of the European Union. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Re-Newable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32009L0028 (accessed on 15 October 2022).

- European Parliament and Council of the European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/eli/dir/2018/2001/oj (accessed on 19 October 2022).

- Zhai, J.; Burke, I.T.; Stewart, D.I. Beneficial Management of Biomass Combustion Ashes. Renew. Sustain. Energy Rev. 2021, 151, 111555. [Google Scholar] [CrossRef]

- Carević, I.; Serdar, M.; Štirmer, N.; Ukrainczyk, N. Preliminary Screening of Wood Biomass Ashes for Partial Resources Replacements in Cementitious Materials. J. Clean. Prod. 2019, 229, 1045–1064. [Google Scholar] [CrossRef]

- Pitman, R.M. Wood Ash Use in Forestry—A Review of the Environmental Impacts. For. Int. J. For. Res. 2006, 79, 563–588. [Google Scholar] [CrossRef]

- Bendixen, M.; Best, J.; Hackney, C.; Iversen, L.L. Time Is Running out for Sand. Nature 2019, 571, 29–31. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources; United Nations Environment Programme: Nairobi, Kenya, 2019. [Google Scholar]

- Sverdrup, H.U.; Koca, D.; Schlyter, P. A Simple System Dynamics Model for the Global Production Rate of Sand, Gravel, Crushed Rock and Stone, Market Prices and Long-Term Supply Embedded into the WORLD6 Model. Biophys. Econ. Sustain. 2017, 2, 8. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Bani-Hani, K.A.; Malkawi, D.A.H.; Albatayneh, O. Suitability of Sustainable Sand for Concrete Manufacturing—A Complete Review of Recycled and Desert Sand Substitution. Results Eng. 2024, 23, 102478. [Google Scholar] [CrossRef]

- Zhong, X.; Deetman, S.; Tukker, A.; Behrens, P. Increasing Material Efficiencies of Buildings to Address the Global Sand Crisis. Nat. Sustain. 2022, 5, 389–392. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Sand, Rarer than One Thinks; United Nations Environment Programme: Nairobi, Kenya, 2014. [Google Scholar]

- Eurostat (European Commission). Key Figures on Europe: 2022 Edition; Publications Office of the European Union: Luxembourg, 2021; ISBN 978-92-76-51643-9. [Google Scholar]

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. AFNOR: Paris, France, 2012.

- EN 450-1; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. AFNOR: Paris, France, 2012.

- Muthusamy, K.; Rasid, M.H.; Jokhio, G.A.; Mokhtar Albshir Budiea, A.; Hussin, M.W.; Mirza, J. Coal Bottom Ash as Sand Replacement in Concrete: A Review. Constr. Build. Mater. 2020, 236, 117507. [Google Scholar] [CrossRef]

- Singh, N.; Shehnazdeep; Bhardwaj, A. Reviewing the Role of Coal Bottom Ash as an Alternative of Cement. Constr. Build. Mater. 2020, 233, 117276. [Google Scholar] [CrossRef]

- Cabrera, M.; Díaz-López, J.L.; Agrela, F.; Rosales, J. Eco-Efficient Cement-Based Materials Using Biomass Bottom Ash: A Review. Appl. Sci. 2020, 10, 8026. [Google Scholar] [CrossRef]

- Katare, V.D.; Madurwar, M.V. Experimental Characterization of Sugarcane Biomass Ash—A Review. Constr. Build. Mater. 2017, 152, 1–15. [Google Scholar] [CrossRef]

- Koppejan, J.; Van Loo, S. The Handbook of Biomass Combustion and Co-Firing; Routledge: London, UK, 2007; ISBN 978-1-84977-304-1. [Google Scholar]

- Mandø, M. Direct Combustion of Biomass. In Biomass Combustion Science, Technology and Engineering; Elsevier: Amsterdam, The Netherlands, 2013; pp. 61–83. ISBN 978-0-85709-131-4. [Google Scholar]

- Anicic, B.; Lin, W.; Dam-Johansen, K.; Wu, H. Agglomeration Mechanism in Biomass Fluidized Bed Combustion—Reaction between Potassium Carbonate and Silica Sand. Fuel Process. Technol. 2018, 173, 182–190. [Google Scholar] [CrossRef]

- Gatternig, B.; Karl, J. Investigations on the Mechanisms of Ash-Induced Agglomeration in Fluidized-Bed Combustion of Biomass. Energy Fuels 2015, 29, 931–941. [Google Scholar] [CrossRef]

- Morris, J.; Daood, S.; Chilton, S.; Nimmo, W. Mechanisms and Mitigation of Agglomeration during Fluidized Bed Combustion of Biomass: A Review. Fuel 2018, 230, 452–473. [Google Scholar] [CrossRef]

- Visser, H. The Influence of Fuel Composition on Agglomeration Behaviour in Fluidised Bed Combustion. Available online: https://publications.tno.nl/publication/34628434/5f7Iz3/c04054.pdf (accessed on 25 May 2022).

- Schlupp, F.; Page, J.; Djelal, C.; Libessart, L. Influence of Recycled Sand from Biomass Combustion on the Mechanical, Hydration and Porous Properties of Mortar Mixtures. Constr. Build. Mater. 2023, 404, 133193. [Google Scholar] [CrossRef]

- Lessard, J.-M.; Omran, A.; Tagnit-Hamou, A.; Gagne, R. Feasibility of Using Biomass Fly and Bottom Ashes in Dry-Cast Concrete Production. Constr. Build. Mater. 2017, 132, 565–577. [Google Scholar] [CrossRef]

- Li, L.; Yu, C.; Bai, J.; Wang, Q.; Luo, Z. Heavy Metal Characterization of Circulating Fluidized Bed Derived Biomass Ash. J. Hazard. Mater. 2012, 233–234, 41–47. [Google Scholar] [CrossRef]

- Hussin, M.W.; Muthusamy, K.; Zakaria, F. Effect of Mixing Constituent toward Engineering Properties of POFA Cement-Based Aerated Concrete. J. Mater. Civ. Eng. 2010, 22, 287–295. [Google Scholar] [CrossRef]

- Jamil, M.; Kaish, A.B.M.A.; Raman, S.N.; Zain, M.F.M. Pozzolanic Contribution of Rice Husk Ash in Cementitious System. Constr. Build. Mater. 2013, 47, 588–593. [Google Scholar] [CrossRef]

- Awang, H.B.; Al-Mulali, M.Z. The Inclusion of Palm Oil Ash Biomass Waste in Concrete: A Literature Review. In Palm Oil; Waisundara, V., Ed.; InTech: Houston, TX, USA, 2018; ISBN 978-1-78923-426-8. [Google Scholar]

- Sales, A.; Lima, S.A. Use of Brazilian Sugarcane Bagasse Ash in Concrete as Sand Replacement. Waste Manag. 2010, 30, 1114–1122. [Google Scholar] [CrossRef]

- Omran, A.; Soliman, N.; Xie, A.; Davidenko, T.; Tagnit-Hamou, A. Field Trials with Concrete Incorporating Biomass-Fly Ash. Constr. Build. Mater. 2018, 186, 660–669. [Google Scholar] [CrossRef]

- Rajamma, R. Biomass Fly Ash Incorporation in Cement Based Materials. Ph.D. Thesis, University of Aveiro, Portugal, Portugal, 2011. [Google Scholar]

- Rajamma, R.; Senff, L.; Ribeiro, M.J.; Labrincha, J.A.; Ball, R.J.; Allen, G.C.; Ferreira, V.M. Biomass Fly Ash Effect on Fresh and Hardened State Properties of Cement Based Materials. Compos. Part B Eng. 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Cuenca, J.; Rodríguez, J.; Martín-Morales, M.; Sánchez-Roldán, Z.; Zamorano, M. Effects of Olive Residue Biomass Fly Ash as Filler in Self-Compacting Concrete. Constr. Build. Mater. 2013, 40, 702–709. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Composition and Application of Biomass Ash. Part 1. Phase–Mineral and Chemical Composition and Classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Magdziarz, A.; Dalai, A.K.; Koziński, J.A. Chemical Composition, Character and Reactivity of Renewable Fuel Ashes. Fuel 2016, 176, 135–145. [Google Scholar] [CrossRef]

- Tarelho, L.A.C.; Teixeira, E.R.; Silva, D.F.R.; Modolo, R.C.E.; Labrincha, J.A.; Rocha, F. Characteristics of Distinct Ash Flows in a Biomass Thermal Power Plant with Bubbling Fluidised Bed Combustor. Energy 2015, 90, 387–402. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Cabrera, M.; Martinez-Echevarria, M.J.; López-Alonso, M.; Agrela, F.; Rosales, J. Self-Compacting Recycled Concrete Using Biomass Bottom Ash. Materials 2021, 14, 6084. [Google Scholar] [CrossRef]

- Grau, F.; Choo, H.; Hu, J.W.; Jung, J. Engineering Behavior and Characteristics of Wood Ash and Sugarcane Bagasse Ash. Materials 2015, 8, 6962–6977. [Google Scholar] [CrossRef]

- Modolo, R.C.E.; Ferreira, V.M.; Tarelho, L.A.; Labrincha, J.A.; Senff, L.; Silva, L. Mortar Formulations with Bottom Ash from Biomass Combustion. Constr. Build. Mater. 2013, 45, 275–281. [Google Scholar] [CrossRef]

- Sklivaniti, V.; Tsakiridis, P.E.; Katsiotis, N.S.; Velissariou, D.; Pistofidis, N.; Papageorgiou, D.; Beazi, M. Valorisation of Woody Biomass Bottom Ash in Portland Cement: A Characterization and Hydration Study. J. Environ. Chem. Eng. 2017, 5, 205–213. [Google Scholar] [CrossRef]

- Rosales, M.; Agrela, F.; Sánchez de Rojas, M.I.; Cabrera, M.; Rosales, J. Optimisation of Hybrid Eco-Efficient Mortars with Aggregates from Construction and Demolition Waste and Olive Biomass Ash. Constr. Build. Mater. 2023, 400, 132634. [Google Scholar] [CrossRef]

- Rosales; Cabrera, M.; Beltrán, M.G.; López, M.; Agrela, F. Effects of Treatments on Biomass Bottom Ash Applied to the Manufacture of Cement Mortars. J. Clean. Prod. 2017, 154, 424–435. [Google Scholar] [CrossRef]

- Rissanen, J.; Ohenoja, K.; Kinnunen, P.; Romagnoli, M.; Illikainen, M. Milling of Peat-Wood Fly Ash: Effect on Water Demand of Mortar and Rheology of Cement Paste. Constr. Build. Mater. 2018, 180, 143–153. [Google Scholar] [CrossRef]

- Schlupp, F.; Page, J.; Djelal, C.; Libessart, L. Use of Biomass Bottom Ash as Granular Substitute in Mortar. J. Build. Eng. 2023, 75, 106927. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary Cementitious Materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Thy, P.; Jenkins, B.M.; Grundvig, S.; Shiraki, R.; Lesher, C.E. High Temperature Elemental Losses and Mineralogical Changes in Common Biomass Ashes. Fuel 2006, 85, 783–795. [Google Scholar] [CrossRef]

- Ukrainczyk, N.; Vrbos, N.; Koenders, E.A.B. Reuse of Woody Biomass Ash Waste in Cementitious Materials. Chem. Biochem. Eng. Q. 2016, 30, 137–148. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Camões, A.; Branco, F.G. Valorisation of Wood Fly Ash on Concrete. Resour. Conserv. Recycl. 2019, 145, 292–310. [Google Scholar] [CrossRef]

- Hinojosa, M.J.R.; Galvín, A.P.; Agrela, F.; Perianes, M.; Barbudo, A. Potential Use of Biomass Bottom Ash as Alternative Construction Material: Conflictive Chemical Parameters According to Technical Regulations. Fuel 2014, 128, 248–259. [Google Scholar] [CrossRef]

- Sow, M.; Hot, J.; Tribout, C.; Cyr, M. Characterization of Spreader Stoker Coal Fly Ashes (SSCFA) for Their Use in Cement-Based Applications. Fuel 2015, 162, 224–233. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.M.; Cabrera, M.; López-Alonso, M.; Martínez-Echevarría, M.J.; Agrela, F.; Rosales, J. Design of Lightweight Concrete with Olive Biomass Bottom Ash for Use in Buildings. J. Build. Eng. 2023, 69, 106289. [Google Scholar] [CrossRef]

- Rosales, J.; Beltrán, M.G.; Cabrera, M.; Velasco, A.; Agrela, F. Feasible Use of Biomass Bottom Ash as Addition in the Manufacture of Lightweight Recycled Concrete. Waste Biomass Valorization 2016, 7, 953–963. [Google Scholar] [CrossRef]

- Carević, I.; Štirmer, N.; Trkmić, M.; Kostanić Jurić, K. Leaching Characteristics of Wood Biomass Fly Ash Cement Composites. Appl. Sci. 2020, 10, 8704. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Dijkstra, J.J.; Comans, R.N.J. Assessment of Biomass Ash Applications in Soil and Cement Mortars. Chemosphere 2019, 223, 425–437. [Google Scholar] [CrossRef]

- Jura, J.; Ulewicz, M. Assessment of the Possibility of Using Fly Ash from Biomass Combustion for Concrete. Materials 2021, 14, 6708. [Google Scholar] [CrossRef]

- Kim, H.K.; Jeon, J.H.; Lee, H.K. Flow, Water Absorption, and Mechanical Characteristics of Normal- and High-Strength Mortar Incorporating Fine Bottom Ash Aggregates. Constr. Build. Mater. 2012, 26, 249–256. [Google Scholar] [CrossRef]

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of Coal Bottom Ash and Fly Ash in Concrete as Replacement for Sand and Cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Beltrán, M.G.; Agrela, F.; Barbudo, A.; Ayuso, J.; Ramírez, A. Mechanical and Durability Properties of Concretes Manufactured with Biomass Bottom Ash and Recycled Coarse Aggregates. Constr. Build. Mater. 2014, 72, 231–238. [Google Scholar] [CrossRef]

- Cabrera, M.; Agrela, F.; Ayuso, J.; Galvin, A.P.; Rosales, J. Feasible Use of Biomass Bottom Ash in the Manufacture of Cement Treated Recycled Materials. Mater. Struct. 2016, 49, 3227–3238. [Google Scholar] [CrossRef]

- Beltrán, M.G.; Barbudo, A.; Agrela, F.; Jiménez, J.R.; de Brito, J. Mechanical Performance of Bedding Mortars Made with Olive Biomass Bottom Ash. Constr. Build. Mater. 2016, 112, 699–707. [Google Scholar] [CrossRef]

- Cabrera, M.; Galvin, A.P.; Agrela, F.; Carvajal, M.D.; Ayuso, J. Characterisation and Technical Feasibility of Using Biomass Bottom Ash for Civil Infrastructures. Constr. Build. Mater. 2014, 58, 234–244. [Google Scholar] [CrossRef]

- EN 12620; Aggregates for Concrete. AFNOR: Paris, France, 2008.

- Agrela, F.; Beltran, M.G.; Cabrera, M.; López, M.; Rosales, J.; Ayuso, J. Properties of Recycled Concrete Manufacturing with All-in Recycled Aggregates and Processed Biomass Bottom Ash. Waste Biomass Valorization 2017, 9, 1247–1259. [Google Scholar] [CrossRef]

- da Costa, T.P.; Quinteiro, P.; Tarelho, L.A.C.; Arroja, L.; Dias, A.C. Environmental Assessment of Valorisation Alternatives for Woody Biomass Ash in Construction Materials. Resour. Conserv. Recycl. 2019, 148, 67–79. [Google Scholar] [CrossRef]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of Woody Biomass Fly Ash in Cement-Based Materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- Modolo, R.C.E.; Silva, T.; Senff, L.; Tarelho, L.A.C.; Labrincha, J.A.; Ferreira, V.M.; Silva, L. Bottom Ash from Biomass Combustion in BFB and Its Use in Adhesive-Mortars. Fuel Process. Technol. 2015, 129, 192–202. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N. Use of Increasing Amounts of Bagasse Ash Waste to Produce Self-Compacting Concrete by Adding Limestone Powder Waste. J. Clean. Prod. 2013, 57, 308–319. [Google Scholar] [CrossRef]

- Hamza Hasnain, M.; Javed, U.; Ali, A.; Saeed Zafar, M. Eco-Friendly Utilization of Rice Husk Ash and Bagasse Ash Blend as Partial Sand Replacement in Self-Compacting Concrete. Constr. Build. Mater. 2021, 273, 121753. [Google Scholar] [CrossRef]

- Barbosa, R.; Lapa, N.; Dias, D.; Mendes, B. Concretes Containing Biomass Ashes: Mechanical, Chemical, and Ecotoxic Performances. Constr. Build. Mater. 2013, 48, 457–463. [Google Scholar] [CrossRef]

- EN 12390-13; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. AFNOR: Paris, France, 2021.

- Obernberger, I. Nutzung Fester Biomasse in Verbrennungsanlagen: Unter Besonderer Berücksichtigung Des Verhaltens Aschebildender Elemente. In Schriftenreihe Thermische Biomassenutzung; Dbv-Verlag: Graz, Austria, 1998; ISBN 978-3-7041-0244-7. [Google Scholar]

- EN 12504-4; Testing Concrete in Structures—Part 4: Determination of Ultrasonic Pulse Velocity. AFNOR: Paris, France, 2021.

- Al-Shwaiter, A.; Awang, H.; Khalaf, M.A. Performance of Sustainable Lightweight Foam Concrete Prepared Using Palm Oil Fuel Ash as a Sand Replacement. Constr. Build. Mater. 2022, 322, 126482. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schlupp, F.; Page, J.; Djelal, C.; Libessart, L. Use of Biomass Bottom Ash as an Alternative Solution to Natural Aggregates in Concrete Applications: A Review. Materials 2024, 17, 4504. https://doi.org/10.3390/ma17184504

Schlupp F, Page J, Djelal C, Libessart L. Use of Biomass Bottom Ash as an Alternative Solution to Natural Aggregates in Concrete Applications: A Review. Materials. 2024; 17(18):4504. https://doi.org/10.3390/ma17184504

Chicago/Turabian StyleSchlupp, Florian, Jonathan Page, Chafika Djelal, and Laurent Libessart. 2024. "Use of Biomass Bottom Ash as an Alternative Solution to Natural Aggregates in Concrete Applications: A Review" Materials 17, no. 18: 4504. https://doi.org/10.3390/ma17184504