Assessment of Power Generation Using Biogas from Landfills in an Equatorial Tropical Context

Abstract

:1. Introduction

1.1. Importance and Justification

1.2. Biogas from Waste

1.2.1. Biogas from Sewage Sludge

1.2.2. Biodegradable Fraction of Organic Urban Waste

1.2.3. Biogas from Controlled Landfills

2. Materials and Methods

- Location: The Ceibales landfill is in El Oro Province, 18 km from Machala city, and 23 km from the Santa Rosa community; in both cases, the entrance is via E25 (Balosa-Machala). Its exact geographical location is latitude –3.3200 and longitude –79.9491.

- Climate: The climatic characteristics of Machala were based on data from web pages, such as the world climate sites (www.worldclimate.com), because the National Institute of Meteorology and Hydrology (INAMHI) weather station only provided outdated data. These data are required for estimating the parameters of the mathematical models.

- Characteristics of municipal solid waste (MSW): The landfill began operation on September 18, 2010. On average, it receives 322.32 tonnes of MSW daily and 9933.32 tonnes monthly. In 2018, a total of 115,702 tonnes were deposited. The Ceibales landfill is scheduled to be closed in 2030 [31]. Table 2 lists the waste received per year, starting with the inauguration of the Ceibales landfill. In Machala city, no recycling activities occur in the homes or areas where waste is generated, and there are no waste separation policies at the landfill [31].

- Waste composition: There is no specific information regarding the composition of the waste sent to the landfill, and it varies over time. Since the city of Machala is the capital of the Oro province, referential data on the waste recorded for the province are used. This estimate is valid because the capital is the most representative city of the province of Oro. Table 3 summarizes the composition of the waste that arrives at the final disposal site [31].

2.1. Estimation of MSW for Future Years

2.2. Models to Estimate the Biogas Generation Potential

2.2.1. LandGem Model

2.2.2. The LandGem

2.2.3. IPCC Model

2.2.4. Ecuadorian Model

3. Power Potential Estimation from LFG

3.1. Available Energy Generated from LFG

3.2. Power of the Generating Element

3.3. Economic Viability

3.3.1. Determination of the Investment, Operation, and Maintenance Costs

3.3.2. Levelized Cost of Energy

3.3.3. Net Present Value (NPV) of the Levelized Cost of Energy

3.3.4. Internal Rate of Return

3.3.5. Payback Period (PBP)

4. Results and Discussion

4.1. Usable Biogas in the Ceibales Landfill

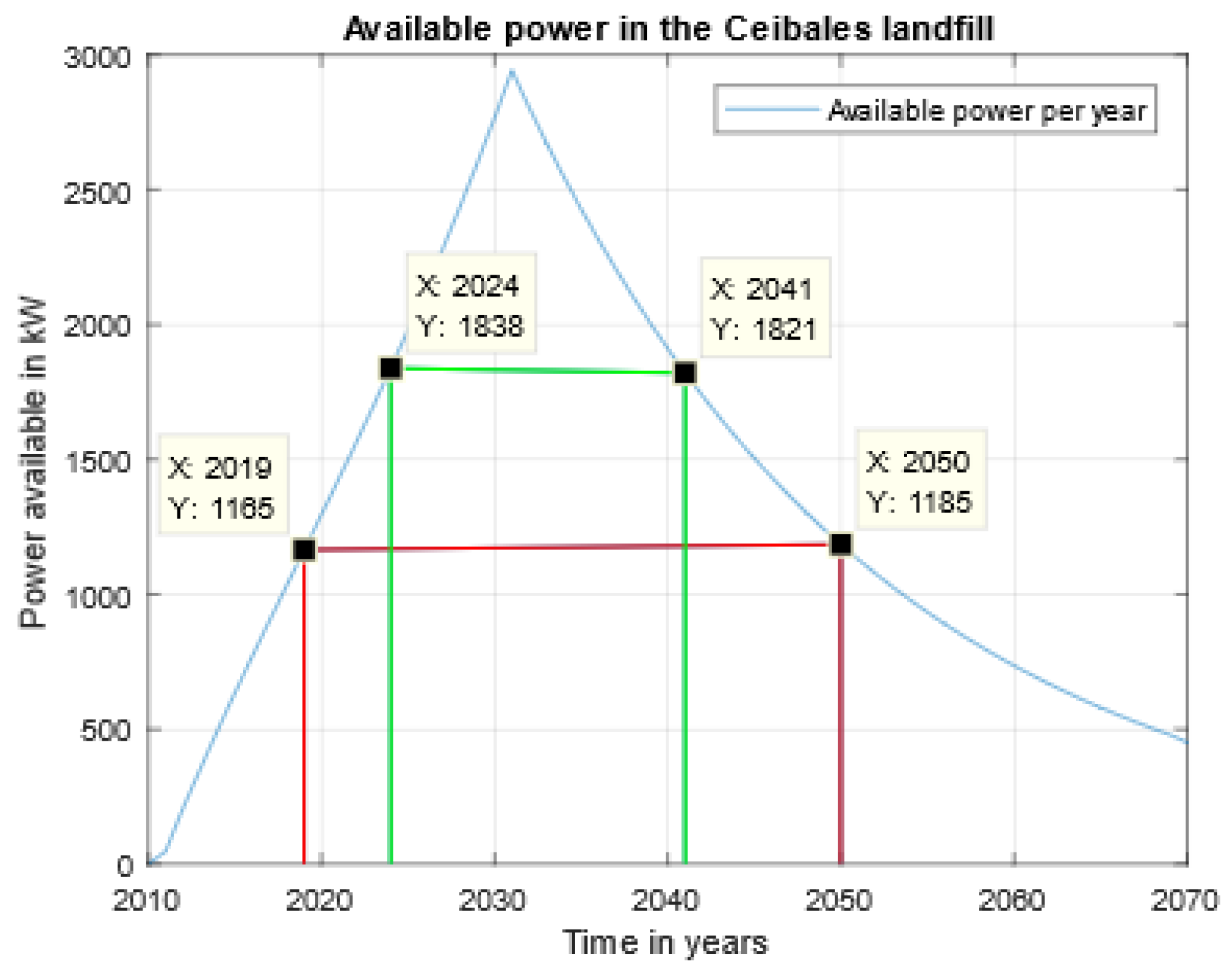

4.2. Available Power in the Ceibales Landfill

4.3. Local Implications

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Molina, J.; Serrano, X. Diseño y análisis técnico Económico para proyectos de centrales minihidráulicas. In IEEE Ecuador Magazine; IEEE Ecuador: Manta, Ecuador, 2016; pp. 7–12. [Google Scholar]

- REN21. Renewables 2016 Global Status Report; Renewable Energy Policy Network for the 21st Century: París, France, 2016. [Google Scholar]

- Chen, Y. Impacto Socio Económico del Proyecto Hidroeléctrico Coca Codo Sinclair, Construido Por la Empresa China Sinohydro; Para la Economía Ecuatoriana, Pontificia Universidad Católica del Ecuador: Quito, Ecuador, 2015. [Google Scholar]

- ARCONEL. Estadisticas Anual y Multianual del Sector Eléctrico Ecuatoriano; ARCONEL: Quito, Ecuador, 2018.

- Ponce-Jara, M.A.; Castro, M.; Pelaez-Samaniego, M.; Espinoza-Abad, J.L.; Ruiz, E. Electricity sector in Ecuador: An overview of the 2007–2017 decade. Energy Policy 2018, 113, 513–522. [Google Scholar] [CrossRef]

- Peláez Samaniego, M.R.; García Pérez, M.A.; Barriga, A.; Martí Herrero, J.; Montero Izquierdo, A.; Meyer, F.D.; García Núñez, J. Estado de uso de la biomasa para la producción de bioenergía, biocumbustibles y bioproductos en Ecuador. In Energías Renovables en el Ecuador. Situación Actual, Tendencias y Perspectivas; Peláez Samaniego, M., Espinoza Abad, J.L., Eds.; Universidad de Cuenca. Gráficas Hernández: Cuenca, Ecuador, 2015; pp. 29–115. [Google Scholar]

- Barragán-Escandón, A.; Arias, P.; Julio, T. Promoting circular energy metabolisms through electricity generation from landfills: Case study Cuenca, Ecuador. Ingenius 2016, 2, 36–42. [Google Scholar] [CrossRef] [Green Version]

- ARCONEL. Centrales de Generación Eólica, Biomasa, Biogás y Fotovoltaica (MW); ARCONEL: Quito, Ecuador, 2018.

- Poggi, F.; Firmino, A.; Amado, M. Planning renewable energy in rural areas: Impacts on occupation and land use. Energy 2018. [Google Scholar] [CrossRef]

- Lovarelli, D.; Falcone, G.; Orsi, L.; Bacenetti, J. Agricultural small anaerobic digestion plants: Combining economic and environmental assessment. Biomass Bioenergy 2019, 128, 105302. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, M.P. GHG emission and carbon sequestration potential from MSW of Indian metro cities. Urban Clim. 2014, 8, 30–41. [Google Scholar] [CrossRef]

- Ogunjuyigbe, A.S.O.; Ayodele, T.R.; Alao, M.A. Electricity generation from municipal solid waste in some selected cities of Nigeria: An assessment of feasibility, potential and technologies. Renew. Sustain. Energy Rev. 2017, 80, 149–162. [Google Scholar] [CrossRef]

- Aguilar-Virgen, Q.; Taboada-González, P.; Ojeda-Benítez, S. Analysis of the feasibility of the recovery of landfill gas: A case study of Mexico. J. Clean. Prod. 2014, 79, 53–60. [Google Scholar] [CrossRef]

- IDAE. Plan de Energías Renovables 2011 2020; IDAE: Madrid, Spain, 2011. [Google Scholar]

- Pandis Iveroth, S.; Johansson, S.; Brandt, N.; Iveroth, S.P.; Johansson, S.; Brandt, N. The potential of the infrastructural system of Hammarby Sjöstad in Stockholm, Sweden. Energy Policy 2013, 59, 716–726. [Google Scholar] [CrossRef]

- Shen, Y.; Linville, J.L.; Urgun-Demirtas, M.; Mintz, M.M.; Snyder, S.W. An overview of biogas production and utilization at full-scale wastewater treatment plants (WWTPs) in the United States: Challenges and opportunities towards energy-neutral WWTPs. Renew. Sustain. Energy Rev. 2015, 50, 346–362. [Google Scholar] [CrossRef] [Green Version]

- Nadaletti, W.C.C.; Cremonez, P.A.A.; de Souza, S.N.; Bariccatti, R.A.A.; Belli Filho, P.; Secco, D. Potential use of landfill biogas in urban bus fleet in the Brazilian states: A review. Renew. Sustain. Energy Rev. 2015, 41, 277–283. [Google Scholar] [CrossRef]

- De Souza, S.N.; Horttanainen, M.; Antonelli, J.; Klaus, O.; Lindino, C.A.; Nogueira, C.E. Technical potential of electricity production from municipal solid waste disposed in the biggest cities in Brazil: Landfill gas, biogas and thermal treatment. Waste Manag. Res. 2014, 32, 1015–1023. [Google Scholar] [CrossRef] [PubMed]

- Raud, M.; Mitt, M.; Oja, T.; Olt, J.; Orupõld, K.; Kikas, T. The utilisation potential of urban greening waste: Tartu case study. Urban For. Urban Green. 2017, 21, 96–101. [Google Scholar] [CrossRef]

- Zubizarreta, J.; Rodrigues, M.; Gómez, A.; Zubizarreta, J.; Rodrigues, M.; Dopazo, C.; Fueyo, N. Potential and cost of electricity generation from human and animal waste in Spain. Renew. Energy 2010, 35, 498–505. [Google Scholar] [CrossRef]

- Berktay, A.; Nas, B. Biogas production and utilization potential of wastewater treatment sludge. Energy Sour. Part A Recovery Util. Environ. Eff. 2008, 30, 179–188. [Google Scholar] [CrossRef]

- Salomon, K.R.; Silva Lora, E.E. Estimate of the electric energy generating potential for different sources of biogas in Brazil. Biomass Bioenergy 2009, 33, 1101–1107. [Google Scholar] [CrossRef]

- Bidart, C.; Fröhling, M.; Schultmann, F. Electricity and substitute natural gas generation from the conversion of wastewater treatment plant sludge. Appl. Energy 2014, 113, 404–413. [Google Scholar] [CrossRef]

- Raheem, A.; Yusri, M.; Shakoor, R. Bioenergy from anaerobic digestion in Pakistan: Potential, development and prospects. Renew. Sustain. Energy Rev. 2016, 59, 264–275. [Google Scholar] [CrossRef]

- Van Meerbeek, K.; Ottoy, S.; De Meyer, A.; Van Schaeybroeck, T.; Van Orshoven, J.; Muys, B.; Hermy, M. The bioenergy potential of conservation areas and roadsides for biogas in an urbanized region. Appl. Energy 2015, 154, 742–751. [Google Scholar] [CrossRef]

- Arodudu, O.; Ibrahim, E.; Voinov, A.; van Duren, I. Exploring bioenergy potentials of built-up areas based on NEG-EROEI indicators. Ecol. Indic. 2014, 47, 67–79. [Google Scholar] [CrossRef] [Green Version]

- Xydis, G.; Nanaki, E.; Koroneos, C. Exergy analysis of biogas production from a municipal solid waste landfill. Sustain. Energy Technol. Assess. 2013, 4, 20–28. [Google Scholar] [CrossRef]

- Eriksson, O. Environmental technology assessment of natural gas compared to biogas. In Natural Gas; Potocnik, P., Ed.; Intech: Rijeka, Croatia, 2010; pp. 127–146. ISBN 9789537619343. [Google Scholar]

- Scarlat, N.; Motola, V.; Dallemand, J.F.; Monforti-Ferrario, F.; Mofor, L. Evaluation of energy potential of Municipal Solid Waste from African urban areas. Renew. Sustain. Energy Rev. 2015, 50, 1269–1286. [Google Scholar] [CrossRef]

- Mambeli Barros, R.; Tiago Filho, G.L.; da Silva, T.R. The electric energy potential of landfill biogas in Brazil. Energy Policy 2014, 65, 150–164. [Google Scholar] [CrossRef]

- Vaca, O. Datos Característicos del Relleno Sanitario Los Ceibales; Empresa Municipal de Aseo de Machala, EMAM-EP: Machala, Ecuador, 2019. [Google Scholar]

- Alexander, A.; Burklin, C.; Singleton, A. Landfill Gas Emissions Model (LandGEM) Version 3.02 User’s Guide; United States Environmental Protection Agency: Washington DC, USA, 2005; p. 56.

- García Escamilla, P. Efficiency and reliability of theoretical models of biogas for landfills. LA GRANJA. Rev. Cienc. Vida 2019, 29, 44. [Google Scholar] [CrossRef]

- Krause, M.J.; Chickering, G.W.; Townsend, T.G. Translating landfill methane generation parameters among first-order decay models. J. Air Waste Manag. Assoc. 2016, 66, 1084–1097. [Google Scholar] [CrossRef] [PubMed]

- U.S Environmental Protection Agency. Evaluación del Potencial de Biogás del Relleno El Valle; U.S. EPA: Cuenca, Ecuador, 2007.

- Kwartin, R. The Cost and Performance of Distributed Wind Turbines, 2010–2035: Final Report; ICF International: Fairfax, Virginia, 2010. [Google Scholar]

- U.S. Environmental Protection Agency. Evaluación del Potencial de Biogás del Relleno de Loja; U.S. EPA: Loja, Ecuador, 2007.

- U.S. Environmental Protection Agency. Landfill Methane Outreach Program. Evaluación del Potencial de Biogás del Relleno Chabay Azogues, Ecuador; U.S. EPA: Azogues, Ecuador, 2007.

- U.S Environmental Protection Agency. Estudio de Prefactibilidad del Potencial del Biogás: Relleno Las Iguanas Guayaquil, Ecuador; U.S. EPA: Guayaquil, Ecuador, 2007.

- Idehai, I.M.; Akujieze, C.N. Estimation of landfill gas and its renewable energy potential in Lagos, Nigeria. Int. J. Energy Environ. Eng. 2015, 6, 329–343. [Google Scholar] [CrossRef] [Green Version]

- Blanco, G.; Santalla, E.; Córdoba, C.; Levy, A. Generación de electricidad a partir de biogás capturado de residuos sólidos urbanos: Un análisis teórico-práctico. Banco Interam. Desarro. 2017, 52. [Google Scholar] [CrossRef] [Green Version]

- Barragán-Escandón, A.; Terrados, J.; Zalamea, E.; Arias, P. Electricity production using renewable resources in urban centres. Proc. Inst. Civ. Eng. Energy 2018, 171, 12–25. [Google Scholar] [CrossRef] [Green Version]

- De Jong, P.; Kiperstok, A.; Torres, E.A. Economic and environmental analysis of electricity generation technologies in Brazil. Renew. Sustain. Energy Rev. 2015, 52, 725–739. [Google Scholar] [CrossRef]

- IEA/NEA. Projected Costs of Generating Electricity, 2015 ed.; IEA: Paris, France, 2015. [Google Scholar]

- Energy Styrelsen. Technology Data for Energy Plants. In Generation of Electricity and District Heating, Energy Storage and Energy Carrier Generation and Conversion; Energinet: Copenhagen, Denmark, 2012. [Google Scholar]

- DWEA. Distributed Wind Vision 2015–2030; DWEA: Durango, CO, USA, 2015. [Google Scholar]

- Carrasco, A.J.; Díaz, A.F. Evaluación técnica y económica de una planta de biogás para autoabastecimiento energético. In Technical and Economic Evaluation of a Biogas Plant for Energy Self-Sufficiency; Universidad de Chile: Santiago, Chile, 2015. [Google Scholar]

| Place | Demand Coverage | Total Demand | Type of Energy | Reference |

|---|---|---|---|---|

| Cuenca (Ecuador) | 1% | Urban part of the city of Cuenca | Electricity | [7] |

| Lombardy (Italy) | 8.5% 11% | Energetic and agricultural systems | Electricity | [10] |

| Stockholm (Sweden) | 11.44% | 8300.00 kWh/per inhabitant/year | Thermal | [15] |

| Oakland (U.S.) | 120.00% | 55.00 GWh/year | Electric | [16] |

| Mexicali (Mexico) | 6.00% | Given as a lighting requirement | Electric | [13] |

| Tijuana (Mexico) | 40.00% | |||

| Brazil cities (Brazil) | 100.00% | 107000 urban buses | Fuel | [17] |

| Saint Paul Rio de Janeiro (Brazil) | 7.30% 6.73% | 8723.60 GWh/year 5481.00 GWh/year | Electric | [18] |

| Tartu (Estonia) | 54.50% | 0.14 t of natural gas | Fuel | [19] |

| Year | MSW [ton] | Year | MSW [ton] |

|---|---|---|---|

| 2010 | 26475.1 | 2015 | 101645.1 |

| 2011 | 91628.7 | 2016 | 105600.7 |

| 2012 | 93356.3 | 2017 | 110258.6 |

| 2013 | 95575.0 | 2018 | 115702.3 |

| 2014 | 98322.3 | 2019 | 51784.65 |

| Waste Category | Composition (%) |

|---|---|

| Food | 62 |

| Paper and paperboard | 9 |

| Humidity plastics | 3 |

| Metal | 2 |

| Glass | 3 |

| Garden waste | 12 |

| Grass trimmings, fertilizer | |

| Construction debris including rubber | |

| Wood waste |

| Years | MSW [ton] | Years | MSW [ton] |

|---|---|---|---|

| 2019 | 121459.2 | 2025 | 169543.5 |

| 2020 | 127938.5 | 2026 | 179706.2 |

| 2021 | 135031.7 | 2027 | 190482.8 |

| 2022 | 142738.8 | 2028 | 201873.3 |

| 2023 | 151059.8 | 2029 | 213877.7 |

| 2024 | 159994.7 | 2030 | 226496.0 |

| Parameters | LandGem | IPCC | Ecuadorian Model |

|---|---|---|---|

| DOCi | - | 0.1854 | - |

| DOCF | - | 0.7 | - |

| MCF | - | 1 | - |

| k * | 0.045 | 0.045 | 0.045 |

| F | - | 50% | 50% |

| L0 ** | 86.52 | - | 86.52 |

| %CH4 | 50% | - | 50% |

| Beginning of operations | 2010 | 2010 | 2010 |

| Closing year | 2030 | 2030 | 2030 |

| Technology | Flow [m3/min] | Generated Power [mw] | Electrical Efficiency [%] | Cost [usd/kw] |

|---|---|---|---|---|

| ICM | 8–30 | 0.8–3 | 32–45 | 1150–1700 |

| Turbine | > 40 | > 3 | 25–40 | 1400 |

| Micro-turbine | < 8 | 0.03–0.2 | 26–32 | 5500 |

| Variable | Value |

|---|---|

| Recovery efficiency (γ) | 71% * |

| LHV (Lower heating value) | 18 MJ/m3 ** |

| Plant availability factor (PF) | 85% |

| ICM engine efficiency (η) | 40% |

| Conversion factor of MJ to kWh (γ1) | 3.57 |

| Inga I & II | Iguanas | Ceibales | |

|---|---|---|---|

| NPV | 11,301,391.77 USD | 449,294.84 USD | 383,865.48 USD |

| IRR | 21% | 45.64% | 10% |

| PBP | 3 years, 5 months | 3 years | 9 years, 2 months |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barragán-Escandón, A.; Olmedo Ruiz, J.M.; Curillo Tigre, J.D.; Zalamea-León, E.F. Assessment of Power Generation Using Biogas from Landfills in an Equatorial Tropical Context. Sustainability 2020, 12, 2669. https://doi.org/10.3390/su12072669

Barragán-Escandón A, Olmedo Ruiz JM, Curillo Tigre JD, Zalamea-León EF. Assessment of Power Generation Using Biogas from Landfills in an Equatorial Tropical Context. Sustainability. 2020; 12(7):2669. https://doi.org/10.3390/su12072669

Chicago/Turabian StyleBarragán-Escandón, Antonio, Jonathan Miguel Olmedo Ruiz, Jonnathan David Curillo Tigre, and Esteban F. Zalamea-León. 2020. "Assessment of Power Generation Using Biogas from Landfills in an Equatorial Tropical Context" Sustainability 12, no. 7: 2669. https://doi.org/10.3390/su12072669

APA StyleBarragán-Escandón, A., Olmedo Ruiz, J. M., Curillo Tigre, J. D., & Zalamea-León, E. F. (2020). Assessment of Power Generation Using Biogas from Landfills in an Equatorial Tropical Context. Sustainability, 12(7), 2669. https://doi.org/10.3390/su12072669