An Attempt to Evaluate the Green Construction of Large-Scale Hydropower Projects: Taking Wudongde Hydropower Station on the Jinsha River, China as an Example

Abstract

:1. Introduction

2. Materials and Methods

2.1. Framework for Green Construction Assessment

2.1.1. Environmental Protection

2.1.2. Resource Saving

2.1.3. Comprehensive Management

2.2. Standards for Evaluation Indicators

2.2.1. Classification Standard for Quantitative Indicators

2.2.2. Classification Standard for Qualitative Indicators

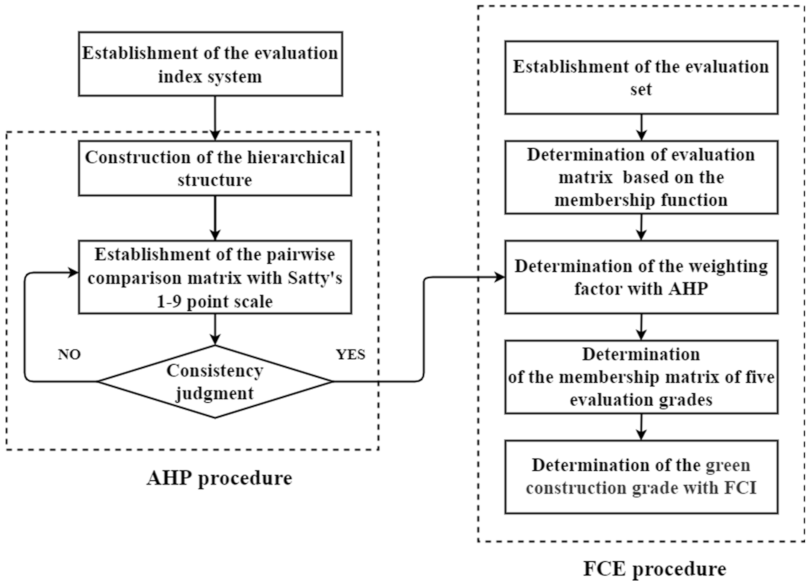

2.3. AHP-FCE Method

- Step 1. Construct a fuzzy membership matrix of evaluation indicators.

- Step 2. Weight of each indicator was calculated using the AHP method

3. Results and Discussions

3.1. Case Analysis

3.2. Evaluation Values of Indicators for Green Construction

3.3. Comprehensive Evaluation of Green Construction

3.3.1. Determination of Indicator Weight

3.3.2. Comprehensive Evaluation

3.4. Analysis of Evaluation Results

3.4.1. Evaluation Results

3.4.2. Application of Evaluation Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, B.; Wang, H.; Zheng, W. Who will take on green product development in supply chains? Manufacturer or retailer. J. Clean. Prod. 2021, 314, 128000. [Google Scholar] [CrossRef]

- Brammer, S.; Walker, H.L. Sustainable procurement in the public sector: An international comparative study. Int. J. Oper. Prod. Man. 2011, 31, 452–476. [Google Scholar] [CrossRef]

- Hsu, C.W.; Hu, A.H. Green supply chain management in the electronic industry. Int. J. Environ. Sci. Technol. 2008, 5, 205–216. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Tian, Y.; Sarkis, J. Diffusion of selected green supply chain management practices: An assessment of Chinese enterprises. Prod. Plan Control. Manag. Oper. 2012, 23, 837–850. [Google Scholar] [CrossRef]

- Grosvold, J.; Hoejmose, S.; Roehrich, J. Squaring the circle: Management, measurement and performance of sustainability in supply chains. Supply Chain. Manag. 2014, 19, 292–305. [Google Scholar] [CrossRef]

- Amann, M.; Roehrich, J.; Eßig, M.; Harland, C. Driving sustainable supply chain management in the public sector: The importance of public procurement in the EU. Supply Chain. Manag. 2014, 19, 351–366. [Google Scholar] [CrossRef] [Green Version]

- Hoejmose, S.U.; Roehrich, J.K.; Grosvold, J. Is doing more, doing better? The relationship between responsible supply chain management and corporate reputation. Ind. Market Manag. 2014, 43, 77–90. [Google Scholar] [CrossRef]

- Zuo, J.; Zillante, G.; Wilson, L.; Davidson, K.; Pullen, S. Sustainability policy of construction contractors: A review. Renew. Sustain. Energy Rev. 2012, 16, 3910–3916. [Google Scholar] [CrossRef]

- Zhao, D.; McCoy, A.P.; Kleiner, B.M.; Smith-Jackson, T.L. Control measures of electrical hazards: An analysis of construction industry. Saf. Sci. 2015, 77, 143–151. [Google Scholar] [CrossRef]

- Zhao, X.; Hwang, B.G.; Gao, Y. A fuzzy synthetic evaluation approach for risk assessment: A case of Singapore’s green projects. J. Clean. Prod. 2016, 115, 203–213. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Phuah, S.L. Safety in green building construction projects in Singapore: Performance, critical issues, and improvement solutions. KSCE J. Civ. Eng. 2018, 22, 447–458. [Google Scholar] [CrossRef]

- Lee, M.; Kim, T.; Jung, H.K.; Lee, U.K.; Cho, H.; Kang, K.I. Green construction hoist with customized energy regeneration system. Autom. Constr. 2014, 45, 66–71. [Google Scholar] [CrossRef]

- Badi, S.; Murtagh, N. Green supply chain management in construction: A systematic literature review and future research agenda. J. Clean. Prod. 2019, 223, 312–322. [Google Scholar] [CrossRef]

- Onubi, H.O.; Yusof, N.; Hassan, A.S. Understanding the mechanism through which adoption of green construction site practices impacts economic performance. J. Clean. Prod. 2020, 254, 120170. [Google Scholar] [CrossRef]

- Zhang, H.; He, X.J.; Yang, J.F.; Wang, T. Study of the comprehensive evaluation system of green construction of bridge. J. Wuhan Univ. Technol. (Transp. Sci. Eng.) 2015, 39, 621–624. [Google Scholar]

- Wang, B.T.; Bao, X.Y.; Li, A.C. Comprehensive evaluation of the green construction level of railway subgrade in the northwest cold arid region. J. Civ. Eng. Manag. 2019, 36, 197–202. [Google Scholar]

- Wang, Y. Research of Evaluation System of Green Construction of Decoration Engineering; Tianjin University: Tianjin, China, 2017. [Google Scholar]

- Li, Y.; Li, Y.B.; Ji, P.F.; Yang, J. The status quo analysis and policy suggestions on promoting China’s hydropower development. Renew. Sustain. Energy Rev. 2015, 51, 1071–1079. [Google Scholar] [CrossRef]

- Chu, P.H.; Liu, P.K.; Pan, H. Prospects of hydropower industry in the Yangtze River Basin: China’s green energy choice. Renew. Energy. 2019, 131, 1168–1185. [Google Scholar]

- Rosenberg, D.M.; Bodaly, R.A.; Usher, P.J. Environmental and social impacts of large scale hydroelectric development: Who is listening? Glob. Environ. Chang. 1995, 5, 127–148. [Google Scholar] [CrossRef]

- Yu, X.Z.; Xia, J.X.; Yang, J.; Ma, W. Preliminary study on the indicator system and assessment method of green hydropower. J. Hydroc. Engin. 2011, 30, 71–77. [Google Scholar]

- Zadeh, L.A. Fuzzy sets. Inf. Control. 1965, 8, 338–353. [Google Scholar] [CrossRef] [Green Version]

- Zadeh, L.A. Fuzzy sets as a basis for a theory of possibility. Fuzzy Sets Syst. 1978, 1, 3–28. [Google Scholar] [CrossRef]

- Zhang, N.; Zhou, K.; Du, X. Application of fuzzy logic and fuzzy AHP to mineral prospectivity mapping of porphyry and hydrothermal vein copper deposits in the Dananhu-Tousuquan island arc, Xinjiang, NW China. J. Afr. Earth Sci. 2017, 128, 84–96. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R.H.; Huang, P.F.; Wang, X.L.; Wang, S.H. Risk evaluation of large-scale seawater desalination projects based on an integrated fuzzy comprehensive evaluation and analytic hierarchy process method. Desalination 2020, 478, 114286. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, J. The surface rupture zone and paleoseismic evidence on the seismogenic fault of the 1976 Ms 7.8 Tangshan earthquake, China. Geomorphology 2019, 327, 297–306. [Google Scholar] [CrossRef]

- Zhang, H.; He, X.; Mitri, H. Fuzzy comprehensive evaluation of virtual reality mine safety training system. Saf. Sci. 2019, 120, 341–351. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China (MOHURD). Green Construction Guidelines; MOHURD: Beijing, China, 2007; Volume 36, pp. 1–5.

- Ye, H. Research on Green Construction Evaluation System Suitable for China; Chongqing University: Chongqing, China, 2012. [Google Scholar]

- Luo, X.; Yang, L.; Yu, X.Z.; Zhang, N.N. Study on environmental management maturity of oil and gas exploration and development project. Nat. Gas Techno. Econ. 2019, 13, 74–79. [Google Scholar]

- Li, Y.; Mu, X.D.; Song, W.; Shi, H.W. Analytic Hierarchy Process Method Based on the Cask Theory. Appl. Mechan. Mater. 2015, 713, 1610–1614. [Google Scholar] [CrossRef]

- Bai, L.; Wang, H.; Huang, N.; Du, Q.; Huang, Y. An Environmental Management Maturity Model of Construction Programs Using the AHP-Entropy Approach. Int. J. Environ. Res. Public Health 2018, 15, 1317. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Qin, H.; Xia, W.; Gan, Q.; Li, L.; Su, J.; Yu, X. Resource slack, environmental management maturity and enterprise environmental protection investment: An enterprise life cycle adjustment perspective. J. Clean Prod. 2021, 309, 127339. [Google Scholar] [CrossRef]

- Saaty, T.L. A scaling method for priorities in hierarchical structures. J. Math. Psychol. 1977, 15, 234–281. [Google Scholar] [CrossRef]

- Tan, R.R.; Aviso, K.B.; Huelgas, A.P.; Promentilla, M.A.B. Fuzzy AHP approach to selection problems in process engineering involving quantitative and qualitative aspects. Process Saf. Environ. Protect. 2014, 92, 467–475. [Google Scholar] [CrossRef]

- Kheybari, S.; Rezaie, F.M.; Ali Naji, S.; Najafi, F. Evaluation of energy production technologies from biomass using analytical hierarchy process: The case of Iran. J. Clean Prod. 2019, 232, 257–265. [Google Scholar] [CrossRef]

| Classification Layer | Indicator Layer | Evaluation Method and Standard | Better | Good | Medium | Poor | Worse |

|---|---|---|---|---|---|---|---|

| Water environment D1 | Treatment of production wastewater D11 | Integrated Wastewater Discharge Standard or recycling without discharging | Meeting | / | / | / | Exceeding |

| Treatment of domestic sewage D12 | Meeting | / | / | / | Exceeding | ||

| Groundwater environment D2 | Control of groundwater level D21 | No impact of cavern excavation on groundwater or surface water | Yes | / | / | / | No |

| Control of groundwater quality D22 | Quality Standard for Groundwater | Meeting | / | / | / | Exceeding | |

| Atmospheric environment D3 | Control of ambient air in sensitive areas outside the boundary of the construction site D31 | Ambient Air Quality Standards | Meeting | / | / | / | Exceeding |

| Control of ambient air in the construction site D32 | Meeting | / | / | / | Exceeding | ||

| Acoustic environment D4 | Control of noise from sensitive areas outside the boundary of the construction site D41 | Environmental Quality Standard for Noise | Meeting | / | / | / | Exceeding |

| Control of noise from the construction site D42 | Emission Standard of Environment Noise for Boundary of Construction Site | Meeting | / | / | / | Exceeding | |

| Control of noise from construction roads D43 | Meeting | / | / | / | Exceeding | ||

| Control of blasting noise D44 | The blasting time in summer and winter shall be strictly within the specified time (blasting at night is strictly prohibited) | Yes | / | / | / | No | |

| Solid waste D5 | Collection and disposal of hazardous waste D53 | Standardized Management indicator System of Hazardous Waste (No. 99 of the General Office of the Ministry of Environmental Protection in 2015) | 55 | 50~55 | 43~50 | 33~43 | <32 |

| Water and soil conservation D8 | Controlled ratio of soil erosion D81 | Control Standards for Soil and Water Loss on Development and Construction Projects | ≥0.7 | / | / | / | <0.7 |

| Slag retention rate D82 | ≥95% | / | / | / | <95% | ||

| Recovery rate of forest and grass vegetation D83 | ≥80% | 80~60% | 60~0% | 40~20% | <20% | ||

| Material utilization E1 | Rate of using local materials E12 | Proportion of building materials that are produced within 500 km of the construction site in the total consumption of building materials (%) | ≥70% | 70~50% | 50~40% | 40~20% | <20% |

| Utilization of water resources E2 | Control of production water consumption E21 | Ratio of water consumption indicator per unit gross domestic product (GDP) to national average | ≤60% | 60~80% | 80~120% | 120~150% | ≥150% |

| Saving rate of water resources E22 | Ratio of amount of recycled wastewater to water consumption | ≥90% | 90~70% | 70~50% | 50~30% | <30% | |

| Energy utilization E3 | Energy utilization rate E31 | Ratio of the comprehensive energy consumption indicator of the project to the comprehensive energy consumption indicator of GDP formulated by the central or local governments | ≤60% | 60~80% | 80~120% | 120~150% | ≥150% |

| Utilization of land resources E4 | Economical and intensive utilization of land E41 | Ratio of GDP per unit construction land to national average | ≤60% | 60~80% | 80~120% | 120~150% | ≥150% |

| Topsoil collection E42 | Ratio of collected topsoil to that required in the Report for Soil and Water Conservation Plan | ≥90% | 90~70% | 70~50% | 50~30% | <30% | |

| Implementation management F2 | Rectification rate of environmental problems F22 | Rectification and solving rate of problems found on site | 100% | 100~90% | 90~70% | 70~50% | <30% |

| Environmental risk prevention and emergency management F24 | Whether the environmental emergency plan has been filed and drilled on site? | Yes | / | / | / | No | |

| Health management of personnel F3 | Sanitation and epidemic prevention F31 | Whether there are infectious diseases and endemic diseases induced by environmental changes caused by the project and whether there are cross-infections or epidemic infectious diseases due to poor living and sanitary conditions? | No | / | / | / | Yes |

| Drinking water quality F32 | Standards for Drinking Water Quality | Yes | / | / | / | No | |

| Safety and occupational health F33 | Standardization of Safety Production of Power Engineering Construction Projects and Rating Standard (No. 247 document of South China Energy Regulatory Bureau of National Energy Administration of the People’s Republic of China in 2012) | ≥90 | 90~80 | 80~70 | 70~60 | <30 | |

| External supervision F4 | Supervision of government sectors F41 | Whether the problems found by government supervision are rectified in time as required? | Yes | / | / | / | No |

| Relationship with residents around the construction site F42 | Whether smooth communication and problem-solving channels are established, and whether complaints are handled timeously? | Yes | / | / | / | No |

| Maturity Level | Score | Grade | Main Characteristics |

|---|---|---|---|

| Disordered | 0~1 | Worse | The project is completely economic-interest-oriented, without awareness of environmental management. |

| Simple | 1~2 | Poor | With the awareness of environmental management, the impact on the ecological environment is only considered in theoretical analysis while being applied less in implementation and evaluation. |

| Standard | 2~3 | Medium | The influence on the ecological environment is assessed and appropriate countermeasures are taken according to standards during the construction of the project. Moreover, the environmental benefits of the project are well considered. |

| Improved | 3~4 | Good | The ecological environment factors are profoundly analyzed qualitatively and quantitatively, and corresponding measures are taken in each stage of implementation. |

| Lean | 4~5 | Better | Environmental management means is constantly improved and optimized, and the goal of ecological and environmental protection is achieved at an appropriate cost to the economic benefits. |

| xi Interval | Calculation of Membership Degrees in Different Intervals | ||||

|---|---|---|---|---|---|

| 5 | 4 | 3 | 2 | 1 | |

| xi > c5 | 1 | 0 | 0 | 0 | 0 |

| c4 < xi ≤ c5 | (xi − c4)/(c5 − c4) | (c5 − xi)/(c5 − c4) | 0 | 0 | 0 |

| c3 < xi ≤ c4 | 0 | (xi − c3)/(c4 − c3) | (c4 − xi)/(c4 − c3) | 0 | 0 |

| c2 < xi ≤ c3 | 0 | 0 | (xi − c2)/(c3 − c2) | (c3 − xi)/(c3 − c2) | 0 |

| c1 < xi ≤ c2 | 0 | 0 | 0 | (xi − c1)/(c2 − c1) | (c2 − xi)/(c2 − c1) |

| c0 < xi ≤ c1 | 0 | 0 | 0 | 0 | 1 |

| Dimension | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| RI | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

| Indicator | D11 | D12 | D21 | D22 | D31 | D32 | D41 | D42 | D43 | D44 |

|---|---|---|---|---|---|---|---|---|---|---|

| Calculation value | 4.83 | 3.71 | 5 | 5 | 5 | 3 | 3.67 | 3.67 | 5 | 5 |

| Evaluation value | 4.83 | 3.71 | 5 | 5 | 5 | 3 | 3.67 | 3.67 | 5 | 5 |

| Indicator | D51 | D52 | D53 | D61 | D62 | D71 | D81 | D82 | D83 | E11 |

| Calculation value | 2.16 | 3 | 38 | 2.5 | 3 | 3 | 0.62 | 97.16% | 87.77% | 3.16 |

| Evaluation value | 2.16 | 3 | 2.5 | 2.5 | 3 | 3 | 1 | 5 | 5 | 3.16 |

| Indicator | E12 | E21 | E22 | E31 | E41 | E42 | F11 | F12 | F21 | F22 |

| Calculation value | 0.74 | 110.08% | 24% | 0.407 | 102.82% | 88.22% | 4.33 | 4.33 | 2.66 | 71.43% |

| Evaluation value | 5 | 2.75 | 1 | 5 | 2.43 | 4.911 | 4.33 | 4.33 | 2.66 | 2.072 |

| Indicator | F23 | F24 | F31 | F32 | F33 | F41 | F42 | |||

| Calculation value | 2.33 | 5 | 5 | 5 | 96.6 | 5 | 5 | |||

| Evaluation value | 2.33 | 5 | 5 | 5 | 5 | 5 | 5 |

| Rule Layer | Weight | Classification Layer | Weight | Indicator Layer | Weight | Final Weight | Ranking |

|---|---|---|---|---|---|---|---|

| D | 0.667 | D1 | 0.239 | D11 | 0.667 | 0.106 | 1 |

| D12 | 0.333 | 0.053 | 4 | ||||

| D2 | 0.089 | D21 | 0.750 | 0.045 | 5 | ||

| D22 | 0.250 | 0.015 | 24 | ||||

| D3 | 0.089 | D31 | 0.500 | 0.030 | 14 | ||

| D32 | 0.500 | 0.030 | 15 | ||||

| D4 | 0.089 | D41 | 0.300 | 0.018 | 20 | ||

| D42 | 0.300 | 0.018 | 21 | ||||

| D43 | 0.300 | 0.018 | 22 | ||||

| D44 | 0.100 | 0.006 | 36 | ||||

| D5 | 0.171 | D51 | 0.333 | 0.038 | 8 | ||

| D52 | 0.333 | 0.038 | 9 | ||||

| D53 | 0.333 | 0.038 | 10 | ||||

| D6 | 0.042 | D61 | 0.800 | 0.022 | 19 | ||

| D62 | 0.200 | 0.006 | 37 | ||||

| D7 | 0.042 | D71 | 1.000 | 0.028 | 16 | ||

| D8 | 0.239 | D81 | 0.444 | 0.071 | 2 | ||

| D82 | 0.111 | 0.018 | 23 | ||||

| D83 | 0.444 | 0.071 | 3 | ||||

| E | 0.167 | E1 | 0.250 | E11 | 0.800 | 0.033 | 11 |

| E12 | 0.200 | 0.008 | 34 | ||||

| E2 | 0.250 | E21 | 0.750 | 0.031 | 12 | ||

| E22 | 0.250 | 0.010 | 25 | ||||

| E3 | 0.250 | E31 | 1.000 | 0.042 | 7 | ||

| E4 | 0.250 | E41 | 0.750 | 0.031 | 13 | ||

| E42 | 0.250 | 0.010 | 26 | ||||

| F | 0.167 | F1 | 0.190 | F11 | 0.750 | 0.024 | 18 |

| F12 | 0.250 | 0.008 | 35 | ||||

| F2 | 0.420 | F21 | 0.625 | 0.044 | 6 | ||

| F22 | 0.125 | 0.009 | 31 | ||||

| F23 | 0.125 | 0.009 | 32 | ||||

| F24 | 0.125 | 0.009 | 33 | ||||

| F3 | 0.269 | F31 | 0.200 | 0.009 | 29 | ||

| F32 | 0.200 | 0.009 | 30 | ||||

| F33 | 0.600 | 0.027 | 17 | ||||

| F4 | 0.210 | F41 | 0.500 | 0.010 | 27 | ||

| F42 | 0.500 | 0.010 | 28 |

| Classification Layer Indicator | Evaluation Value | 5 | 4 | 3 | 2 | 1 |

|---|---|---|---|---|---|---|

| Water environment D1 | 4.457 | 0.457 | 0.543 | 0 | 0 | 0 |

| Groundwater environment D2 | 5.000 | 1 | 0 | 0 | 0 | 0 |

| Atmospheric environment D3 | 4.000 | 0 | 1 | 0 | 0 | 0 |

| Acoustic environment D4 | 4.202 | 0.202 | 0.798 | 0 | 0 | 0 |

| Solid waste D5 | 2.551 | 0 | 0 | 0.551 | 0.449 | 0 |

| Protection of terrestrial ecosystem D6 | 2.600 | 0 | 0 | 0.600 | 0.400 | 0 |

| Protection of aquatic ecosystem D7 | 3.000 | 0 | 0 | 1.000 | 0 | 0 |

| Water and soil conservation D8 | 3.219 | 0 | 0.219 | 0.781 | 0 | 0 |

| Material utilization E1 | 3.528 | 0 | 0.528 | 0.472 | 0 | 0 |

| Utilization of water resources E2 | 2.313 | 0 | 0 | 0.313 | 0.687 | 0 |

| Energy utilization E3 | 5.000 | 1 | 0 | 0 | 0 | 0 |

| Utilization of land resources E4 | 3.050 | 0 | 0.050 | 0.950 | 0 | 0 |

| Organizational management F1 | 4.330 | 0.330 | 0.670 | 0 | 0 | 0 |

| Implementation management F2 | 2.838 | 0 | 0 | 0.838 | 0.162 | 0 |

| Health management of personnel F3 | 5.000 | 1 | 0 | 0 | 0 | 0 |

| External supervision F4 | 5.000 | 1 | 0 | 0 | 0 | 0 |

| Rule Layer Indicator | Evaluation Value | 5 | 4 | 3 | 2 | 1 |

|---|---|---|---|---|---|---|

| Environmental protection D | 3.681 | 0 | 0.681 | 0.319 | 0 | 0 |

| Resource saving E | 3.473 | 0 | 0.473 | 0.527 | 0 | 0 |

| Comprehensive management F | 3.965 | 0 | 0.965 | 0.035 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Zhang, Y.; Zhao, L.; Zhan, C.; Liang, C. An Attempt to Evaluate the Green Construction of Large-Scale Hydropower Projects: Taking Wudongde Hydropower Station on the Jinsha River, China as an Example. Sustainability 2022, 14, 194. https://doi.org/10.3390/su14010194

Liu L, Zhang Y, Zhao L, Zhan C, Liang C. An Attempt to Evaluate the Green Construction of Large-Scale Hydropower Projects: Taking Wudongde Hydropower Station on the Jinsha River, China as an Example. Sustainability. 2022; 14(1):194. https://doi.org/10.3390/su14010194

Chicago/Turabian StyleLiu, Liwen, Yaling Zhang, Lu Zhao, Cun Zhan, and Chuan Liang. 2022. "An Attempt to Evaluate the Green Construction of Large-Scale Hydropower Projects: Taking Wudongde Hydropower Station on the Jinsha River, China as an Example" Sustainability 14, no. 1: 194. https://doi.org/10.3390/su14010194