Integrated Benefits of Sustainable Utilization of Construction and Demolition Waste in a Pressure-State-Response Framework

Abstract

:1. Introduction

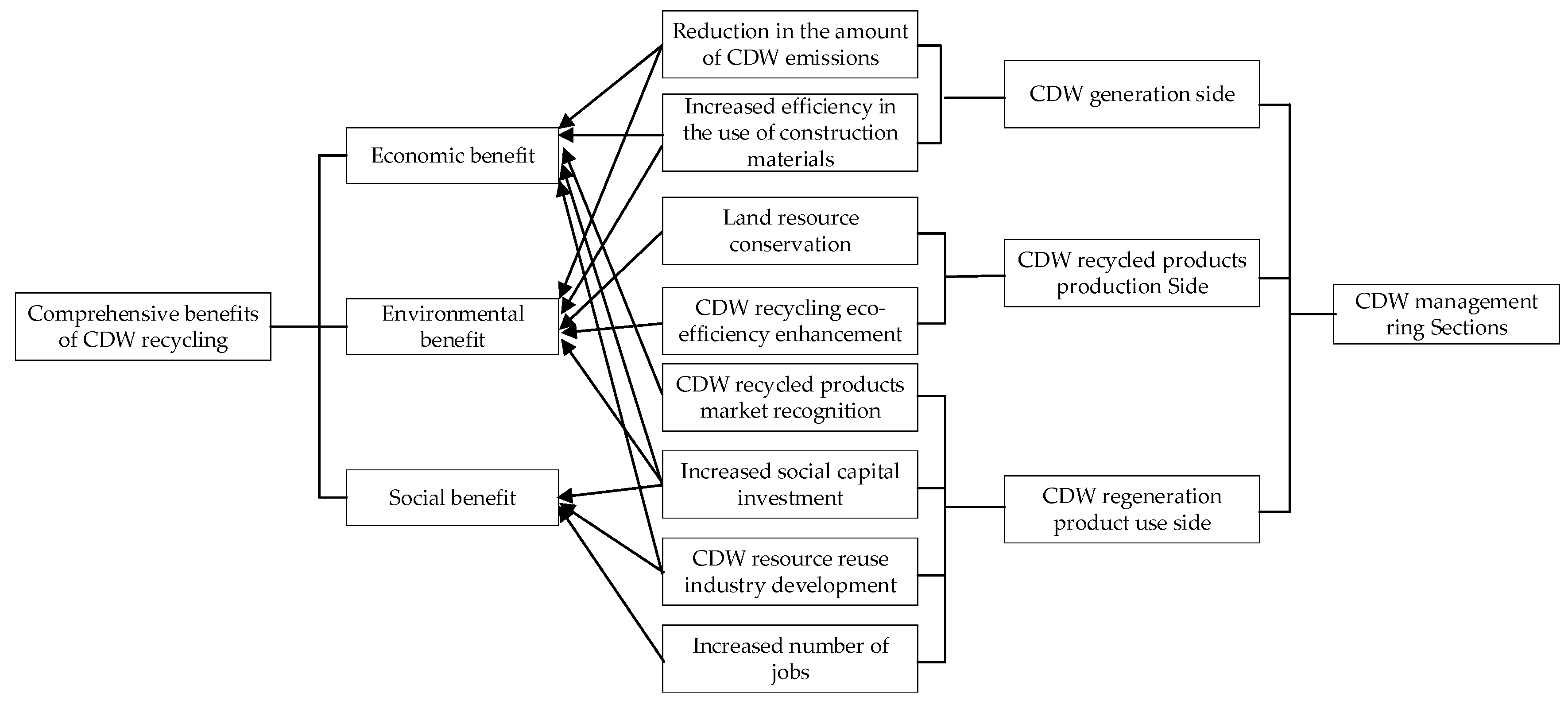

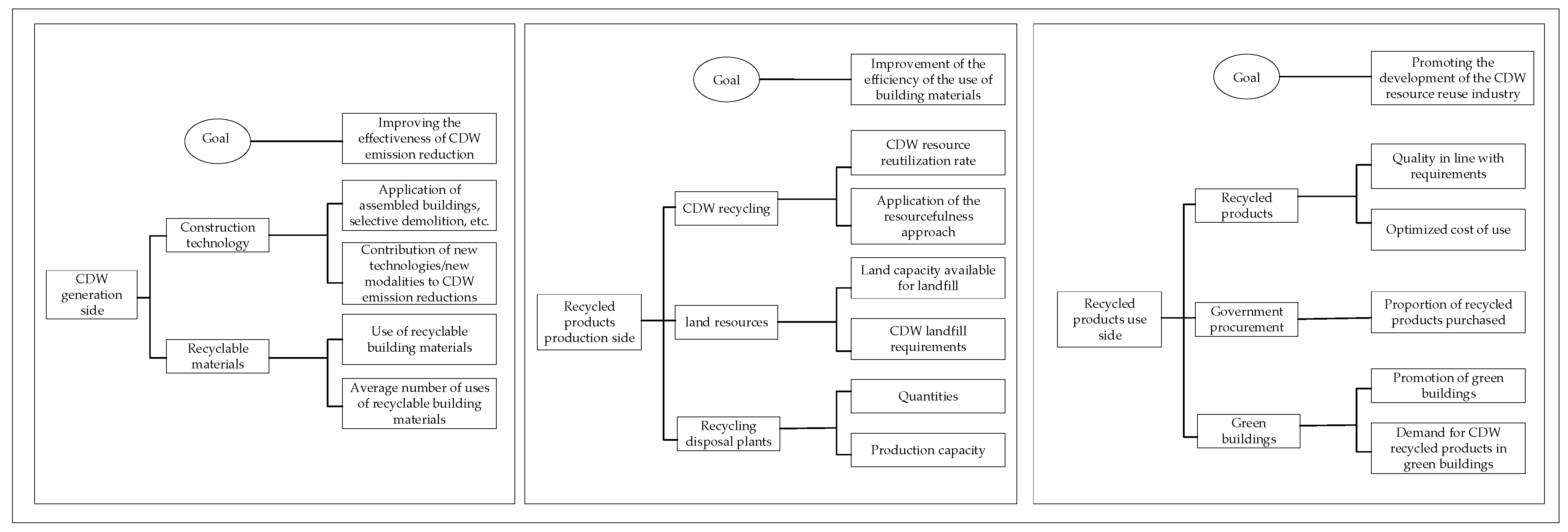

2. PSR Framework System

3. DPSIR-Based Methodology for Comprehensive Benefit Assessment of CDW Recycling

3.1. Target Layer

3.2. Pressure Layer

3.3. State Layer

3.3.1. CDW Recycling Status

3.3.2. Impact of Construction Systems/Dismantling Technology Programs on CDW Management

3.3.3. Impact of Disposal Methods on CDW Management

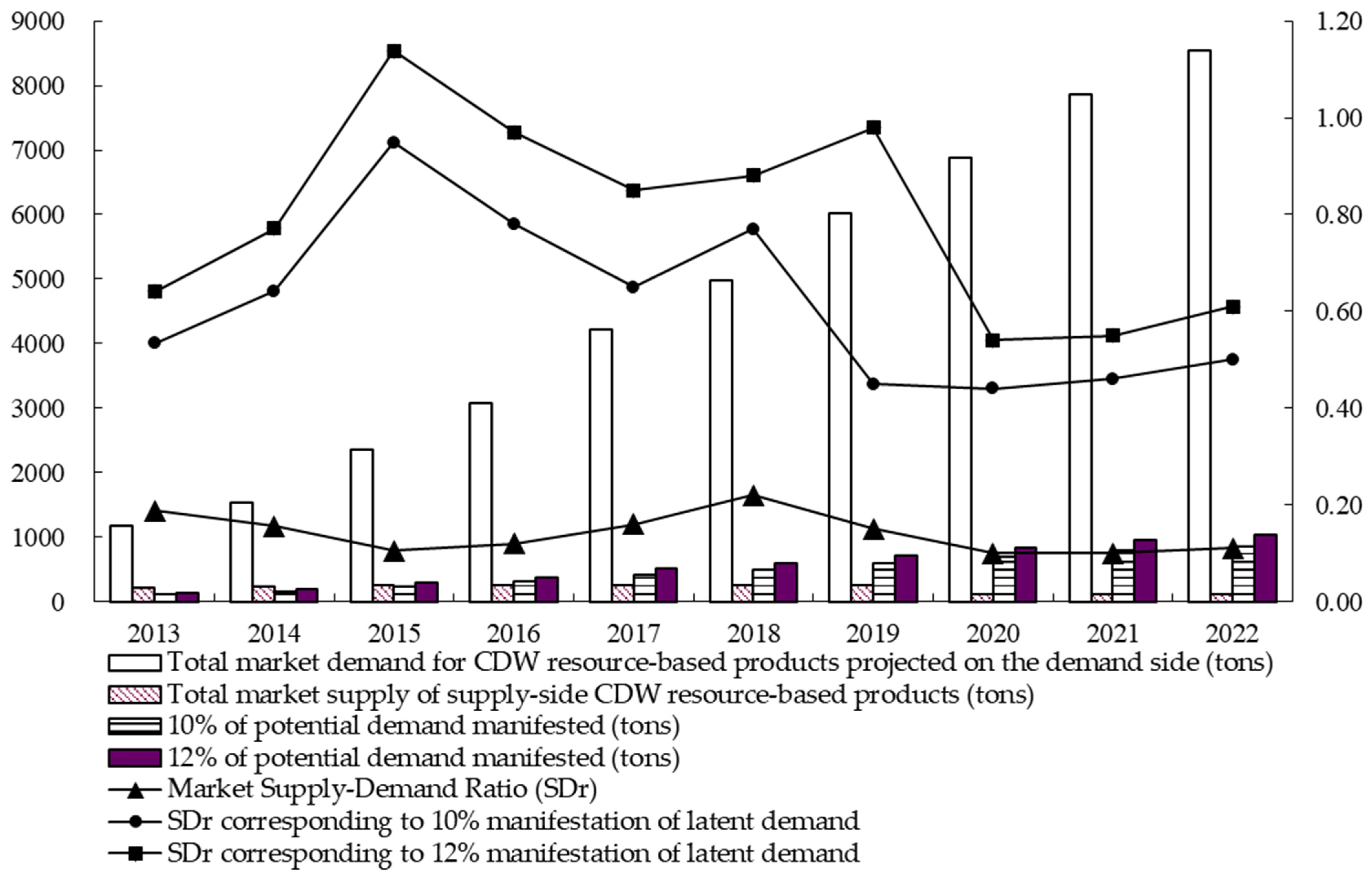

3.3.4. State of Market Demand for CDW Recycled Products

3.3.5. CDW Resourcing State of the Art

3.3.6. Cost-Effectiveness Status of Construction and Demolition Waste Disposal

3.4. Response Layer

3.4.1. Economic Benefits

- (1)

- Economic benefits of CDW recycling

- (2)

- Environmental benefits of innovation in construction systems/dismantling technology programs.

- (3)

- Economic benefits of innovation in construction and demolition waste disposal methods.

- (4)

- Economic benefits of policy optimization.

- (5)

- Economic benefits of technological innovation in sustainable utilization and recycling.

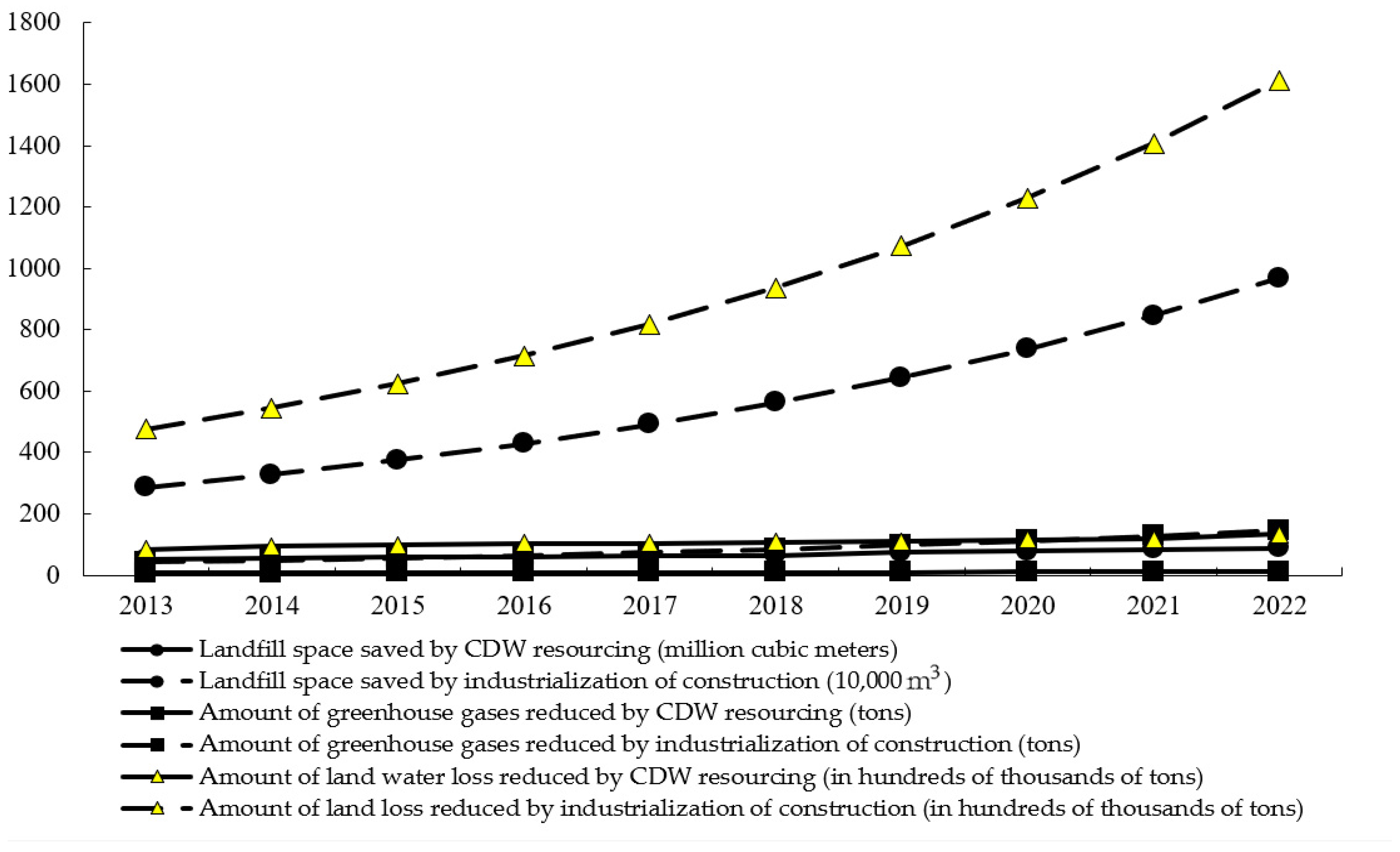

3.4.2. Environmental Benefits

- (1)

- Environmental benefits of CDW recycling

- (2)

- Environmental benefits of innovations in construction systems/dismantling technology programs

- (3)

- Environmental benefits of innovations in construction and demolition waste disposal

- (4)

- Environmental benefits of policy optimization

- (5)

- Environmental benefits of technological innovation in sustainable recycling

3.4.3. Social Benefits

4. Example Measurements and Analysis

4.1. Measurement Data Conditions

4.2. Analysis of Calculation Results

4.3. Discussion of Calculation Results

- (1)

- Changes in the construction system

- (2)

- Supply Side: CDW Resourcing Technology Innovation

- (3)

- Demand Side: Potential Demand Manifestation

5. Conclusions

5.1. Discussion and Conclusions

5.2. Prospects and Shortcomings

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ISWA. 2015 ISWA Annual Report. 2015. Available online: https://www.iswa.org/annual-reports (accessed on 28 July 2023).

- DEFRA. UK Statistics on Waste. Available online: https://www.gov.uk/government/statistics/uk-waste-data/uk-statistics-on-waste (accessed on 28 July 2023).

- Deloitte. Study on Resource Efficient Use of Mixed Wastes Improving Management of Construction and Demolition Waste—Final Report. 2017. Available online: https://ec.europa.eu/environment/pdf/waste/studies/CDW_Final_Report.pdf (accessed on 29 July 2023).

- EPA. Advancing Sustainable Materials Management: 2017 Fact Sheet. 2017. Available online: https://www.epa.gov/sites/default/files/2019-11/documents/2017_facts_and_figures_fact_sheet_final.pdf (accessed on 29 July 2023).

- Chang, Y.; Li, X.; Masanet, E.; Zhang, L.; Huang, Z.; Ries, R. Unlocking the green opportunity for prefabricated buildings and construction in China. Resour. Conserv. Recycl. 2018, 139, 259–261. [Google Scholar] [CrossRef]

- IEA; UNEP. 2019 Global Status Report for Buildings and Construction: Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector; International Energy Agency: Hamburg, Germany, 2019. Available online: https://www.unep.org/resources/publication/2019-global-status-report-buildings-and-construction-sector (accessed on 29 July 2023).

- WRAP. Achieving Good Practice Waste Minimisation and Management Guidance for Construction Clients, Design Teams and Contractors. Available online: https://www.eauc.org.uk/file_uploads/wrap2.pdf (accessed on 29 July 2023).

- Hao, J.; Yuan, H.; Liu, J.; Chin, C.S.; Lu, W. A model for assessing the economic performance of construction waste reduction. J. Clean. Prod. 2019, 232, 427–440. [Google Scholar] [CrossRef]

- Alhawamdeh, M.; Ferriz-Papi, J.A.; Lee, A. Examining the Drivers to Support Improved Construction and Demolition Waste Management for a Circular Economy: A Comprehensive Review Using a Systematic Approach. Sustainability 2024, 16, 6014. [Google Scholar] [CrossRef]

- World Bank. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. 2018. Available online: https://openknowledge.worldbank.org/bitstream/handle/10986/30317/9781464813290.pdf?sequence=12&isAllowed=y (accessed on 17 August 2024).

- Shi, S.Y.; Hu, M.M.; Zhang, J.S. A pressure-state-response model for comprehensive benefit evaluation of construction waste recycling. Eng. Res.-Eng. Interdiscip. Perspect. 2017, 9, 616–627. [Google Scholar] [CrossRef]

- He, Y.; Kasina, M. The Sequential Extraction of Municipal Solid Waste Incineration Bottom Ash: Heavy Metals Mobility and Sustainable Application of Ashes. Sustainability 2023, 15, 14638. [Google Scholar] [CrossRef]

- Wang, L.; Lv, Y.; Huang, S.; Liu, Y.; Li, X. The Evolution of Research on C&D Waste and Sustainable Development of Resources: A Bibliometric Study. Sustainability 2023, 15, 9141. [Google Scholar] [CrossRef]

- Duan, H.; Miller, T.R.; Liu, G.; Tam, V.W.Y. Construction debris becomes growing concern of growing cities. Waste Manag. 2019, 83, 1–5. [Google Scholar] [CrossRef]

- Ju, H.; Yerzhanov, M.; Serik, A.; Lee, D.; Kim, J. Statistical and Reliability Study on Shear Strength of Recycled Coarse Aggregate Reinforced Concrete Beams. Materials 2021, 14, 3321. [Google Scholar] [CrossRef]

- Joseph, H.S.; Pachiappan, T.; Avudaiappan, S.; Maureira-Carsalade, N.; Roco-Videla, Á.; Guindos, P.; Parra, P.F. A Comprehensive Review on Recycling of Construction Demolition Waste in Concrete. Sustainability 2023, 15, 4932. [Google Scholar] [CrossRef]

- Jian, S.M.; Wu, B. Compressive behavior of compound concrete containing demolished concrete lumps and recycled aggregate concrete. Constr. Build. Mater. 2020, 272, 121624. [Google Scholar] [CrossRef]

- Ahmed, H.; Tiznobaik, M.; Huda, S.B.; Islam, M.S.; Alam, M.S. Recycled aggregate concrete from large-scale production to sustainable field application. Constr. Build. Mater. 2020, 262, 119979. [Google Scholar] [CrossRef]

- Field, B.C.; Field, M.K. Environmental Economics: An Introduction, 7th ed.; McGraw-Hill: New York, NY, USA, 2017. [Google Scholar]

- Liu, H.; Guo, L.H. Empirical analysis of construction waste minimization management and effect at construction sites. J. Saf. Environ. 2021, 21, 1733–1742. [Google Scholar] [CrossRef]

- Ferriz-Papi, J.A.; Wang, Y.; Arevalillo Roman, A.; Valentin, J. New Technologies for New Materials and Products from Construction and Demolition Waste. Adv. Sci. Technol. 2023, 6959, 65–71. [Google Scholar] [CrossRef]

- Prakhash, N.; Bhuvaneshwari, M. Influence of Polyethylenimine (PEI) in enhancement of microstructure and surface morphology of recycled construction and demolition waste aggregate in concrete by carbonation. Constr. Build. Mater. 2023, 405, 133342. [Google Scholar] [CrossRef]

- Mário, R.; Graça, M. Influence of construction company size on the determining factors for construction and demolition waste management. Waste Manag. 2021, 136, 295–302. [Google Scholar] [CrossRef]

- Papamichael, I.; Voukkali, I.; Loizia, P.; Zorpas, A.A. Construction and demolition waste framework of circular economy: A mini review. Waste Manag. Res. 2023, 41, 1728–1740. [Google Scholar] [CrossRef]

- Ho, Y.S.; Su, Y.; Si, H.; Chen, J. Managerial Areas of Construction and Demolition Waste: A Scientometric Review. Int. J. Environ. Res. Public Health 2019, 16, 1837. [Google Scholar] [CrossRef]

- Lu, K.A. Status Quo and Comprehensive Utilization of Refuse Produced0 from Construction and Removal of Buildings in China. Constr. Technol. 1994, 28, 44–45. [Google Scholar] [CrossRef]

- Wang, Y.X.; Xue, L.L.; Gou, W.J. Research on key obstacles to resource utilization of construction waste at construction sites. Arid Zone Resour. Environ. 2023, 37, 113–119. [Google Scholar] [CrossRef]

- Hu, M.M.; Yang, M.W. Analysis of China’s construction waste resourcing policy based on policy tools. Constr. Econ. 2019, 40, 22–26. [Google Scholar] [CrossRef]

- Ding, Z.K.; Wang, X.R.; Wen, X.P. Research on carbon reduction benefit of building demolition waste management based on hybrid simulation test. J. Saf. Environ. 2024, 24, 2444–2453. [Google Scholar] [CrossRef]

- Lederer, J.; Gassner, A.; Kleemann, F.; Fellner, J. Potentials for a circular economy of mineral construction materials and demolition waste in urban areas: A case study from Vienna. Resour. Conserv. Recycl. 2020, 161, 104942. [Google Scholar] [CrossRef]

- Pimentel, M.; Arantes, A.; Cruz, C.O. Barriers to the Adoption of Reverse Logistics in the Construction Industry: A Combined ISM and MICMAC Approach. Sustainability 2022, 14, 15786. [Google Scholar] [CrossRef]

- Yang, L.; Jia, H.; Wu, A.; Jiao, H.; Chen, X.; Kou, Y.; Dong, M. Particle Aggregation and Breakage Kinetics in Cemented Paste Backfill. Int. J. Miner. Metall. Mater. 2023, 220, 172–186. [Google Scholar] [CrossRef]

- Yang, L.; Gao, Y.; Chen, H.; Jiao, H.; Dong, M.; Bier, T.A.; Kim, M. Three-dimensional concrete printing technology from a rheology perspective: A review. Adv. Cem. Res. 2024, 126, 72–86. [Google Scholar] [CrossRef]

- Qu, M.; Tian, Y.; Liu, B.; Xu, D. Ecological Risk Assessment and Impact Factor Analysis of Ecological Spatial Patterns in Coastal Counties: Taking Dalian Pulandian District as an Example. Sustainability 2023, 15, 11805. [Google Scholar] [CrossRef]

- Rapport, D.; Friend, A. Towards a Comprehensive Framework for Environmental Statistics: A Stress-Response Approach; Statistics Canada Catalogue: Ottawa, ON, Canada, 1979. [Google Scholar]

- OECD. Core Set of Indicators for Environmental Performance Reviews: A Synthesis Report by the Group on the State of the Environment; Environment Monographs, Organisation for Economic Co-operation and Development: Paris, France, 1993; Volume 83. [Google Scholar]

- Shooshtarian, S.; Caldera, S.; Maqsood, T.; Ryley, T. Evaluating the COVID-19 impacts on the construction and demolition waste management and resource recovery industry: Experience from the Australian built environment sector. Clean Techn Env. Policy 2022, 24, 3199–3212. [Google Scholar] [CrossRef]

- Quéheille, E.; Ventura, A.; Saiyouri, N.; Taillandier, F. A Life Cycle Assessment model of End-of-life scenarios for building deconstruction and waste management. J. Clean. Prod. 2022, 339, 130694. [Google Scholar] [CrossRef]

- Zhu, D.J. Sustainability science: An Object-Process-Subject analytical framework. China Popul.-Resour. Environ. 2016, 26, 1–9. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z.; Liu, J. Exploring spatial heterogeneity and factors influencing construction and demolition waste in China. Env. Sci. Pollut. Res. 2022, 29, 53269–53292. [Google Scholar] [CrossRef]

- Li, Q.H.; Wang, D.D.; Zeng, D.L. Difficulties and countermeasures faced in the development of new construction industrialization. Constr. Econ. 2022, 43, 11–17. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.M.; Zeng, S.X.; Ng, W.C. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Hong, P.Y.; Wen, B.D.; Xiao, Z.M.; Jing, L.; Ling, Y.L. Critical factors to influence the illegal dumping behavior of construction and demolition waste: An ISM-DEMATEL analysis. Dev. Built Environ. 2023, 14, 100159. [Google Scholar] [CrossRef]

- Barbudo, A.; Ayuso, J.; Lozano, A.; Cabrera, M.; López-Uceda, A. Recommendations for the management of construction and demolition waste in treatment plants. Env. Sci. Pollut. Res. 2020, 27, 125–132. [Google Scholar] [CrossRef]

- Spišáková, M.; Mandičák, T.; Mésároš, P.; Špak, M. Waste Management in a Sustainable Circular Economy as a Part of Design of Construction. Appl. Sci. 2022, 12, 4553. [Google Scholar] [CrossRef]

- Zhao, X.; Webber, R.; Kalutara, P.; Browne, W.; Pienaar, J. Construction and demolition waste management in Australia: A mini-review. Waste Manag. Res. 2022, 40, 34–46. [Google Scholar] [CrossRef] [PubMed]

- Mália, M.; De Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef]

- Zhao, W.; Leeftink, R.B.; Rotterc, V.S. Evaluation of the economic feasibility for the recycling of construction and demolition waste in China-The case of Chongqing. Resour. Conserv. Recycl. 2010, 54, 377–389. [Google Scholar] [CrossRef]

- Wang, H.Z.; Pan, X.M.; Zhang, S.B. Spatial autocorrelation, influencing factors and temporal distribution of the construction and demolition waste disposal industry. Waste Manag. 2021, 127, 158–167. [Google Scholar] [CrossRef]

- Nunes, K.R.A.; Mahler, C.F. Comparison of construction and demolition waste management between Brazil, European Union and USA. Waste Manag. Res. 2020, 38, 415–422. [Google Scholar] [CrossRef]

- C2CA. The C2CA project [EB/OL]. Available online: http://www.c2ca.eu/activities/the-c2ca-project/ (accessed on 17 August 2024).

- Bayram, B.; Greiff, K. Correction to: Life cycle assessment on construction and demolition waste recycling: A systematic review analyzing three important quality aspects. Int. J. Life Cycle Assess. 2023, 28, 1072. [Google Scholar] [CrossRef]

- Raskovic, M.; Ragossnig, A.M.; Kondracki, K.; Ragossnig-Angst, M. Clean construction and demolition waste material cycles through optimised pre-demolition waste audit documentation: A review on building material assessment tools. Waste Manag. Res. 2020, 38, 923–941. [Google Scholar] [CrossRef] [PubMed]

| Year | CDW Reductions Due to Innovations in Construction Systems/Dismantling Techniques (tons) | Market Supply–Demand Ratio (SDr) | Resourcing Technology Innovation Advances Changes in Resourcing Rates | CDW Management Benefit–Cost Ratio (B/C) | CDW Recycling Status | |

| Construction System | Dismantling Techniques | |||||

| 2013 | 2974.98 | 172.18 | 0.19 | 0.64 | 0.32 | 0.13 |

| 2014 | 3406.93 | 98.58 | 0.16 | 0.66 | 0.33 | 0.13 |

| 2015 | 3901.61 | 40.00 | 0.11 | 0.69 | 0.35 | 0.14 |

| 2016 | 4468.09 | 67.04 | 0.15 | 0.70 | 0.35 | 0.14 |

| 2017 | 5116.84 | 61.36 | 0.12 | 0.70 | 0.37 | 0.14 |

| 2018 | 5859.78 | 57.52 | 0.11 | 0.80 | 0.37 | 0.16 |

| 2019 | 6710.59 | 49.52 | 0.17 | 0.80 | 0.37 | 0.16 |

| 2020 | 7684.94 | 59.12 | 0.19 | 0.80 | 0.38 | 0.16 |

| 2021 | 8800.75 | 44.92 | 0.21 | 0.80 | 0.39 | 0.16 |

| 2022 | 10,078.58 | 48.08 | 0.14 | 0.85 | 0.39 | 0.17 |

| Year | Economic Benefit | Social Benefit | Environmental Benefit | ||

| Savings in Natural Aggregates (tons) | Led to Employment (Persons) | Landfill Space Savings (Million Cubic Meters) | Greenhouse Gas Reduction (tons) | Reduction in Land Water Loss (tons) | |

| 2013 | 218.45 | 157 | 51.36 | 7.7896 | 856 |

| 2014 | 238.87 | 172 | 56.16 | 8.5176 | 936 |

| 2015 | 249.08 | 179 | 58.56 | 8.8816 | 976 |

| 2016 | 260.14 | 183 | 61.32 | 9.2314 | 1036 |

| 2017 | 275.32 | 187 | 63.78 | 9.5478 | 1036 |

| 2018 | 291.49 | 188 | 64.99 | 9.7156 | 1086 |

| 2019 | 310.56 | 193 | 75.74 | 10.1426 | 1102 |

| 2020 | 330.78 | 195 | 79.12 | 10.6547 | 1158 |

| 2021 | 347.65 | 197 | 84.37 | 10.9815 | 1174 |

| 2022 | 361.01 | 197 | 89.45 | 11.2147 | 1349 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Shi, S.; Zhao, F.; Hu, M.; Fu, X. Integrated Benefits of Sustainable Utilization of Construction and Demolition Waste in a Pressure-State-Response Framework. Sustainability 2024, 16, 8459. https://doi.org/10.3390/su16198459

Zhang H, Shi S, Zhao F, Hu M, Fu X. Integrated Benefits of Sustainable Utilization of Construction and Demolition Waste in a Pressure-State-Response Framework. Sustainability. 2024; 16(19):8459. https://doi.org/10.3390/su16198459

Chicago/Turabian StyleZhang, Han, Shiying Shi, Fangfang Zhao, Mingming Hu, and Xiao Fu. 2024. "Integrated Benefits of Sustainable Utilization of Construction and Demolition Waste in a Pressure-State-Response Framework" Sustainability 16, no. 19: 8459. https://doi.org/10.3390/su16198459