Enhanced Light Extraction Efficiency by Self-Masking Technology with Carbonized Photoresist for Light-Emitting Diodes

Abstract

:1. Introduction

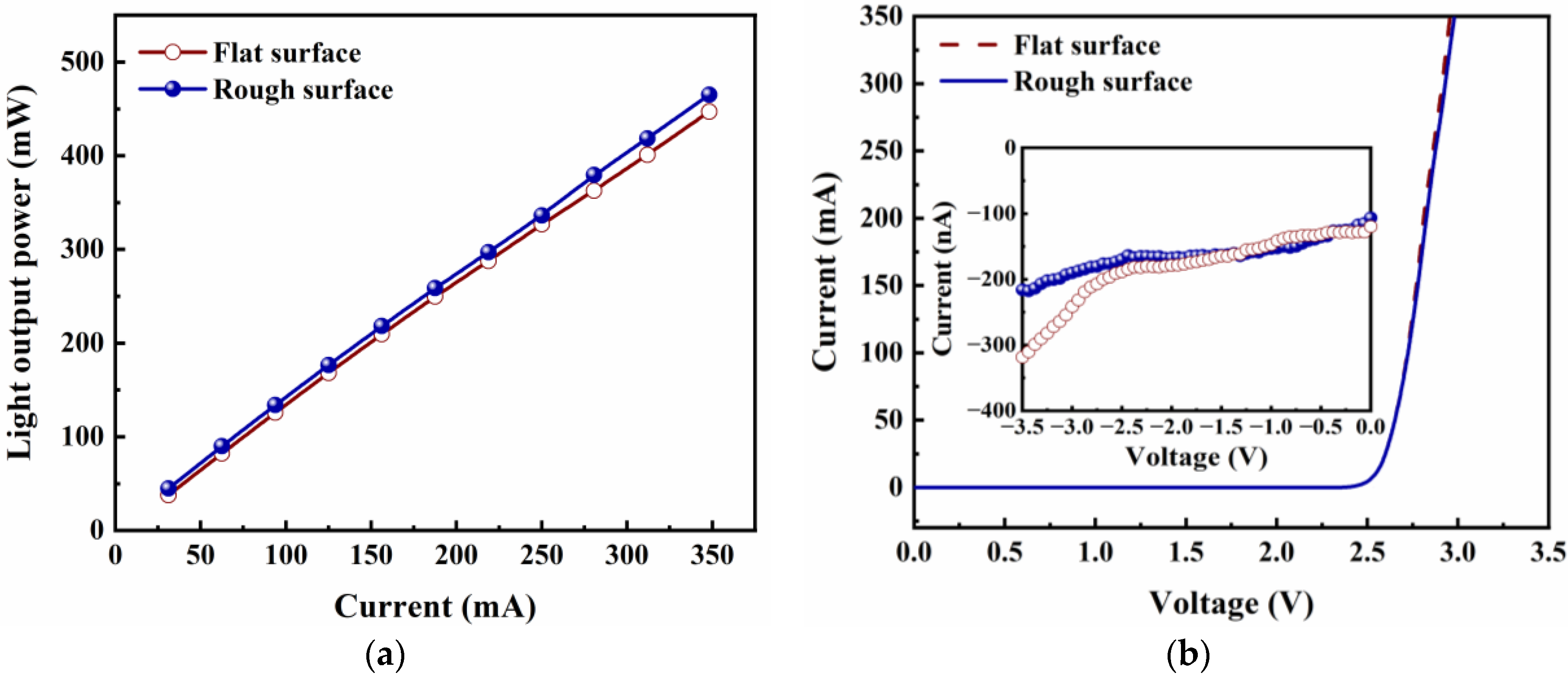

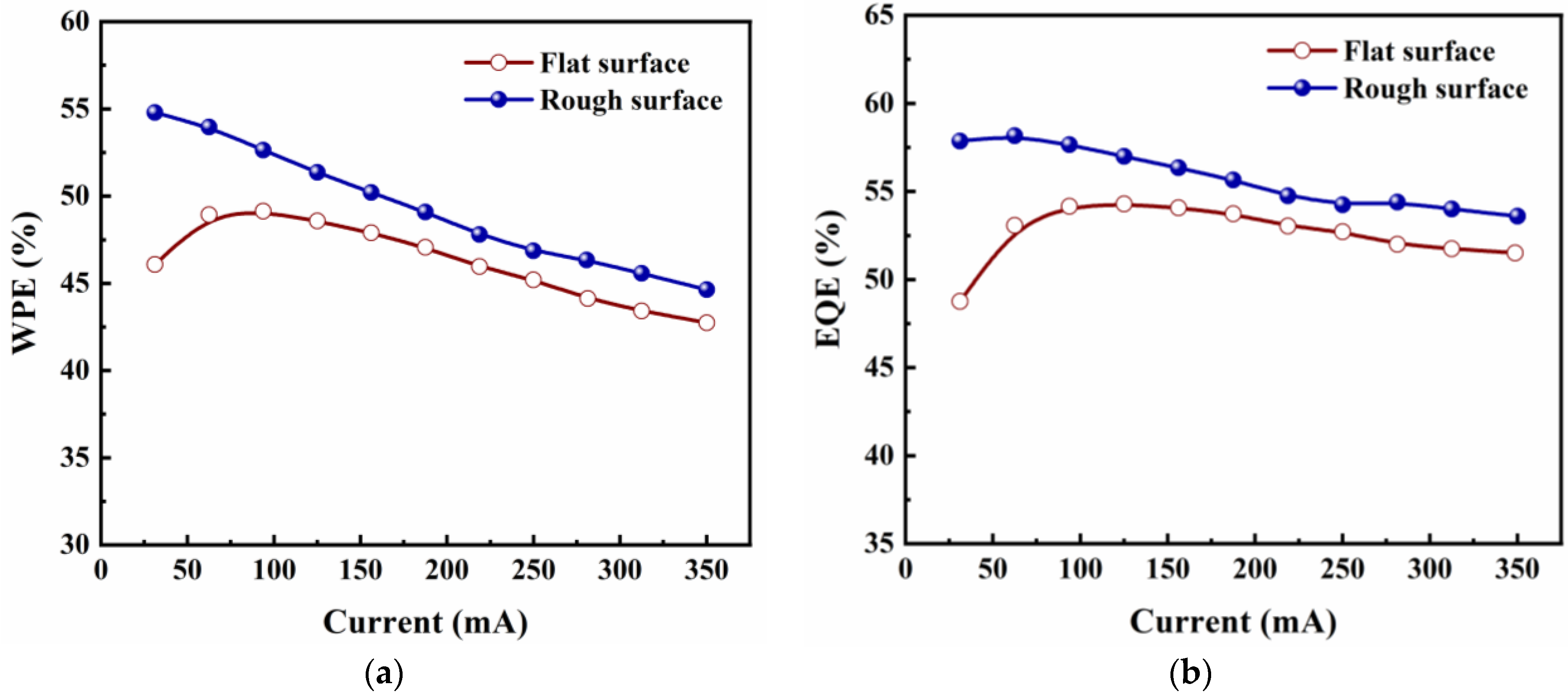

2. Fabrication

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, G.; Wang, W.; Yang, W.; Lin, Y.; Wang, H.; Lin, Z.; Zhou, S. GaN-based light-emitting diodes on various substrates: A critical review. Rep. Prog. Phys. 2016, 79, 056501. [Google Scholar] [CrossRef]

- Askari, M.; Park, J.H. Pre-compensation of an image blur in holographic projection display using light emitting diode light source. Opt. Express 2020, 28, 146–159. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Chen, Q.; Dai, J.; Wang, A.; Liang, R.; Zhang, Y.; Shan, M.; Wu, F.; Zhang, W.; Chen, C.; et al. Enhanced light extraction efficiency via double nano-pattern arrays for high-efficiency deep UV LEDs. Opt. Laser Technol. 2021, 143, 107360. [Google Scholar] [CrossRef]

- Shim, J.-I.; Shin, D.-S. Measuring the internal quantum efficiency of light-emitting diodes: Towards accurate and reliable room-temperature characterization. Nanophotonics 2018, 7, 1601–1615. [Google Scholar] [CrossRef]

- Yang, Y.; Ren, Y.; Chen, Y.; Liu, M.; Chen, W.; Han, X.; Lin, X.; Liao, Q.; Zang, W.; Luo, H.; et al. Light output enhancement of GaN-based light-emitting diodes by maskless surface roughening. Microelectron. Eng. 2015, 139, 39–42. [Google Scholar] [CrossRef]

- Hsu, Y.-T.; Yu, C.-C.; Huang, K.-F.; Lan, W.-H.; Huang, J.-E.; Lin, J.-C.; Lin, W.-J. Improved Output Power of Nitride-Based Light-Emitting Diodes With Convex-Patterned Sapphire Substrates. IEEE Photonics Technol. Lett. 2012, 24, 1686–1688. [Google Scholar] [CrossRef]

- Chang, S.J.; Lin, Y.C.; Su, Y.K.; Chang, C.S.; Wen, T.C.; Shei, S.C.; Ke, J.C.; Kuo, C.W.; Chen, S.C.; Liu, C.H. Nitride-based LEDs fabricated on patterned sapphire substrates. Solid-State Electron. 2003, 47, 1539–1542. [Google Scholar] [CrossRef]

- Damilano, B.; Brochen, S.; Brault, J.; Hossain, T.; Réveret, F.; Frayssinet, E.; Chenot, S.; Courville, A.; Cordier, Y.; Semond, F. Growth of nitride-based light emitting diodes with a high-reflectivity distributed Bragg reflector on mesa-patterned silicon substrate. Phys. Status Solidi A 2015, 212, 2297–2301. [Google Scholar] [CrossRef]

- Sheu, J.K.; Hung, I.H.; Lai, W.C.; Shei, S.C.; Lee, M.L. Enhancement in output power of blue gallium nitride-based light-emitting diodes with omnidirectional metal reflector under electrode pads. Appl. Phys. Lett. 2008, 93, 103507. [Google Scholar] [CrossRef]

- Lee, T.-X.; Gao, K.-F.; Chien, W.-T.; Sun, C.-C. Light extraction analysis of GaN-based light-emitting diodes with surface texture and/or patterned substrate. Opt. Express 2007, 15, 6670–6676. [Google Scholar] [CrossRef]

- Zhu, P.; Zhu, H.; Thapa, S.; Adhikari, G.C. Design rules for white light emitters with high light extraction efficiency. Opt. Express 2019, 27, A1297–A1307. [Google Scholar] [CrossRef]

- Wagner, A.; Ratzker, B.; Kalabukhov, S.; Frage, N. Enhanced external luminescence quantum efficiency of ceramic phosphors by surface roughening. J. Lumin. 2019, 213, 454–458. [Google Scholar] [CrossRef]

- Fujii, T.; Gao, Y.; Sharma, R.; Hu, E.L.; DenBaars, S.P.; Nakamura, S. Increase in the extraction efficiency of GaN-based light-emitting diodes via surface roughening. Appl. Phys. Lett. 2004, 84, 855–857. [Google Scholar] [CrossRef]

- Saifaddin, B.K.; Iza, M.; Foronda, H.; Almogbel, A.; Zollner, C.J.; Wu, F.; Alyamani, A.; Albadri, A.; Nakamura, S.; DenBaars, S.P.; et al. Impact of roughening density on the light extraction efficiency of thin-film flip-chip ultraviolet LEDs grown on SiC. Opt. Express 2019, 27, A1074–A1083. [Google Scholar] [CrossRef]

- Alias, E.A.; Samsudin, M.E.A.; Ibrahim, N.; Mughal, A.J.; Denbaars, S.P.; Speck, J.S.; Nakamura, S.; Zainal, N. Highly efficient InGaN-based LED with pre-roughening backside of GaN substrate. J. Opt. Soc. Am. B 2020, 37, 1614–1619. [Google Scholar] [CrossRef]

- Huang, H.; Hu, J.; Wang, H. GaN-based light-emitting diodes with hybrid micro/nano-textured indium-tin-oxide layer. J. Semicond. 2014, 35, 084006. [Google Scholar] [CrossRef]

- Seok-In, N.; Ga-Young, H.; Dae-Seob, H.; Seok-Soon, K.; Ja-Yeon, K.; Jae-Hong, L.; Dong-Joon, K.; Kyeong-Ik, M.; Seong-Ju, P. Selective wet etching of p-GaN for efficient GaN-based light-emitting diodes. IEEE Photonics Technol. Lett. 2006, 18, 1512–1514. [Google Scholar] [CrossRef]

- Wang, P.; Gan, Z.; Liu, S. Improved light extraction of GaN-based light-emitting diodes with surface-patterned ITO. Opt. Laser Technol. 2009, 41, 823–826. [Google Scholar] [CrossRef]

- Zuo, P.; Zhao, B.; Yan, S.; Yue, G.; Yang, H.; Li, Y.; Wu, H.; Jiang, Y.; Jia, H.; Zhou, J.; et al. Improved optical and electrical performances of GaN-based light emitting diodes with nano truncated cone SiO2 passivation layer. Opt. Quantum Electron. 2016, 48, 288. [Google Scholar] [CrossRef]

- Hsu, C.L.; Kumar, A.; Kashyap, K.; Hou, M.T.K.; Yeh, J.L.A. Street nanotexturing of n-GaN for enhancing light extraction in GaN LEDs. Micro Nano Lett. 2017, 12, 450–452. [Google Scholar] [CrossRef]

- Chen, K.-Y.; Tien, C.-H.; Hsu, C.-P.; Pai, C.-Y.; Horng, R.-H. Fabrication and Improved Performance of GaN LEDs With Finger-Type Structure. IEEE Trans. Electron Devices 2014, 61, 4128–4131. [Google Scholar] [CrossRef]

- Karpov, S. ABC-model for interpretation of internal quantum efficiency and its droop in III-nitride LEDs: A review. Opt. Quantum Electron. 2014, 47, 1293–1303. [Google Scholar] [CrossRef]

| Ion Beam Energy/eV | Ion Beam Flow/mA | Neutralizing Current/mA | Time/min |

|---|---|---|---|

| 350 | 100 | 120 | 10 |

| RF/W | CHF3/sccm | SF6/sccm | Ar/sccm | O2/sccm | Time/min |

|---|---|---|---|---|---|

| 100 | 13 | 10 | 10 | 10 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, S.; Wang, B.; Chen, B.; Guo, H.; Yue, R.; Cai, Y. Enhanced Light Extraction Efficiency by Self-Masking Technology with Carbonized Photoresist for Light-Emitting Diodes. Micromachines 2023, 14, 534. https://doi.org/10.3390/mi14030534

Zhang X, Li S, Wang B, Chen B, Guo H, Yue R, Cai Y. Enhanced Light Extraction Efficiency by Self-Masking Technology with Carbonized Photoresist for Light-Emitting Diodes. Micromachines. 2023; 14(3):534. https://doi.org/10.3390/mi14030534

Chicago/Turabian StyleZhang, Xiu, Shuqi Li, Baoxing Wang, Baojin Chen, Haojie Guo, Rui Yue, and Yong Cai. 2023. "Enhanced Light Extraction Efficiency by Self-Masking Technology with Carbonized Photoresist for Light-Emitting Diodes" Micromachines 14, no. 3: 534. https://doi.org/10.3390/mi14030534