Enhanced Sensitivity of a Resistive Pressure Sensor Based on a PEDOT:PSS Thin Film on PDMS with a Random-Height Micropyramid Structure

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Reagents

2.2. Silicon Mold Fabrication

2.3. PEDOT:PSS Composite

2.4. Pressure Sensor Fabrication

2.5. Characterization and Measurements

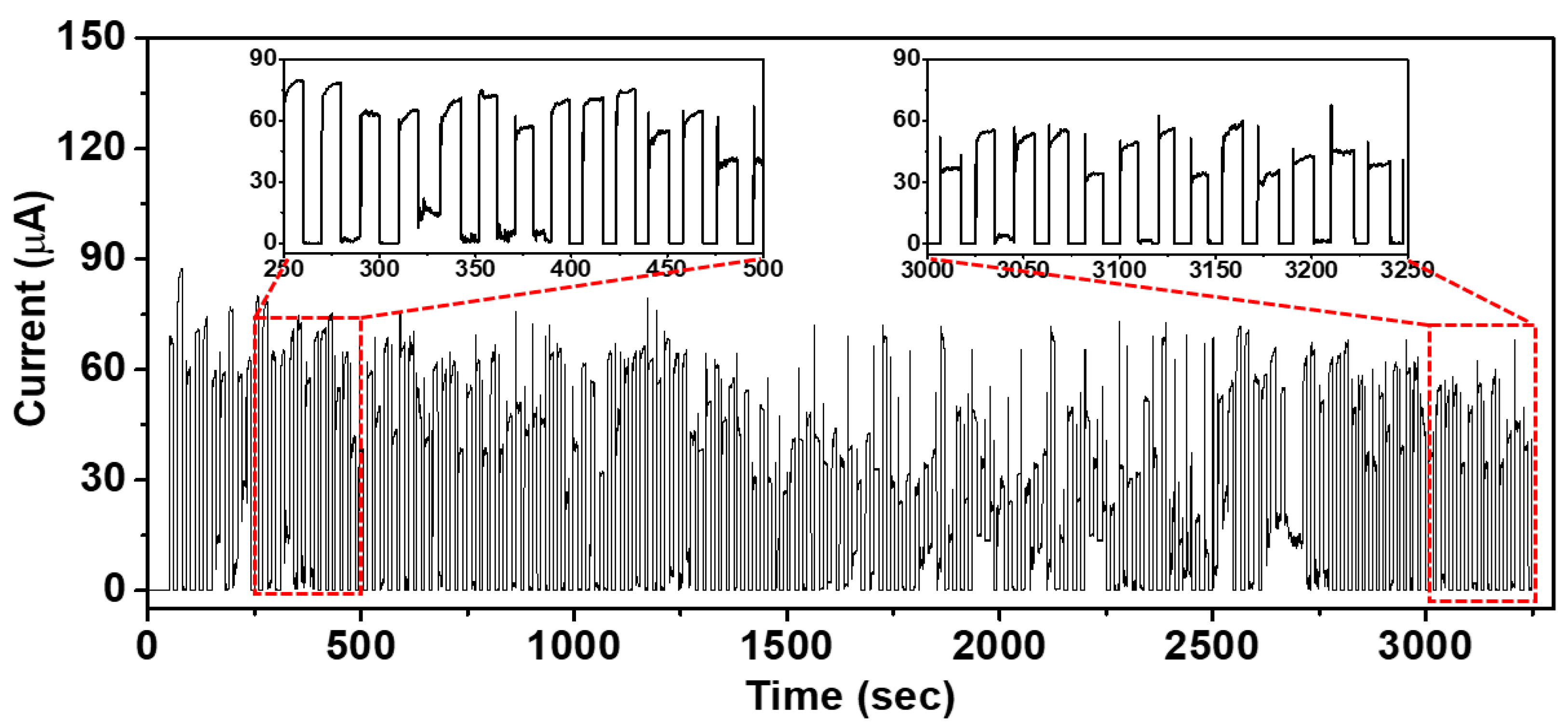

3. Results and Discussion

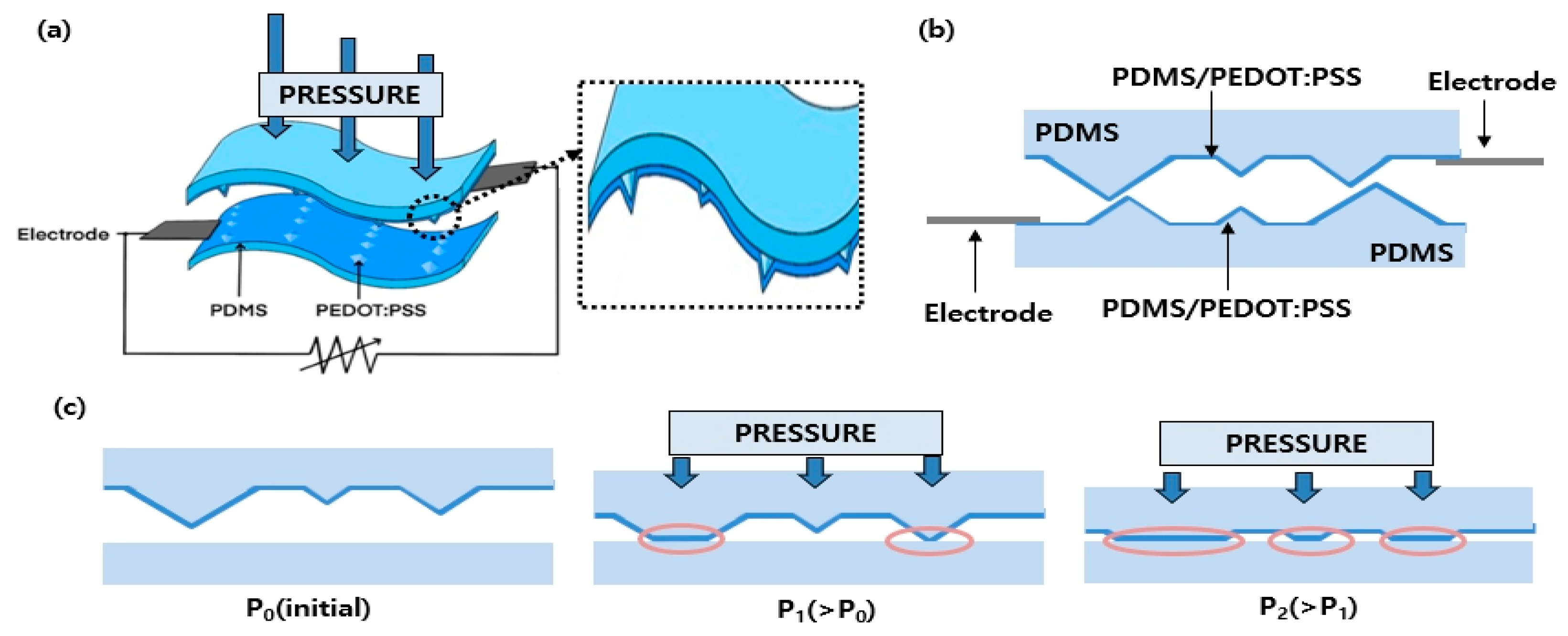

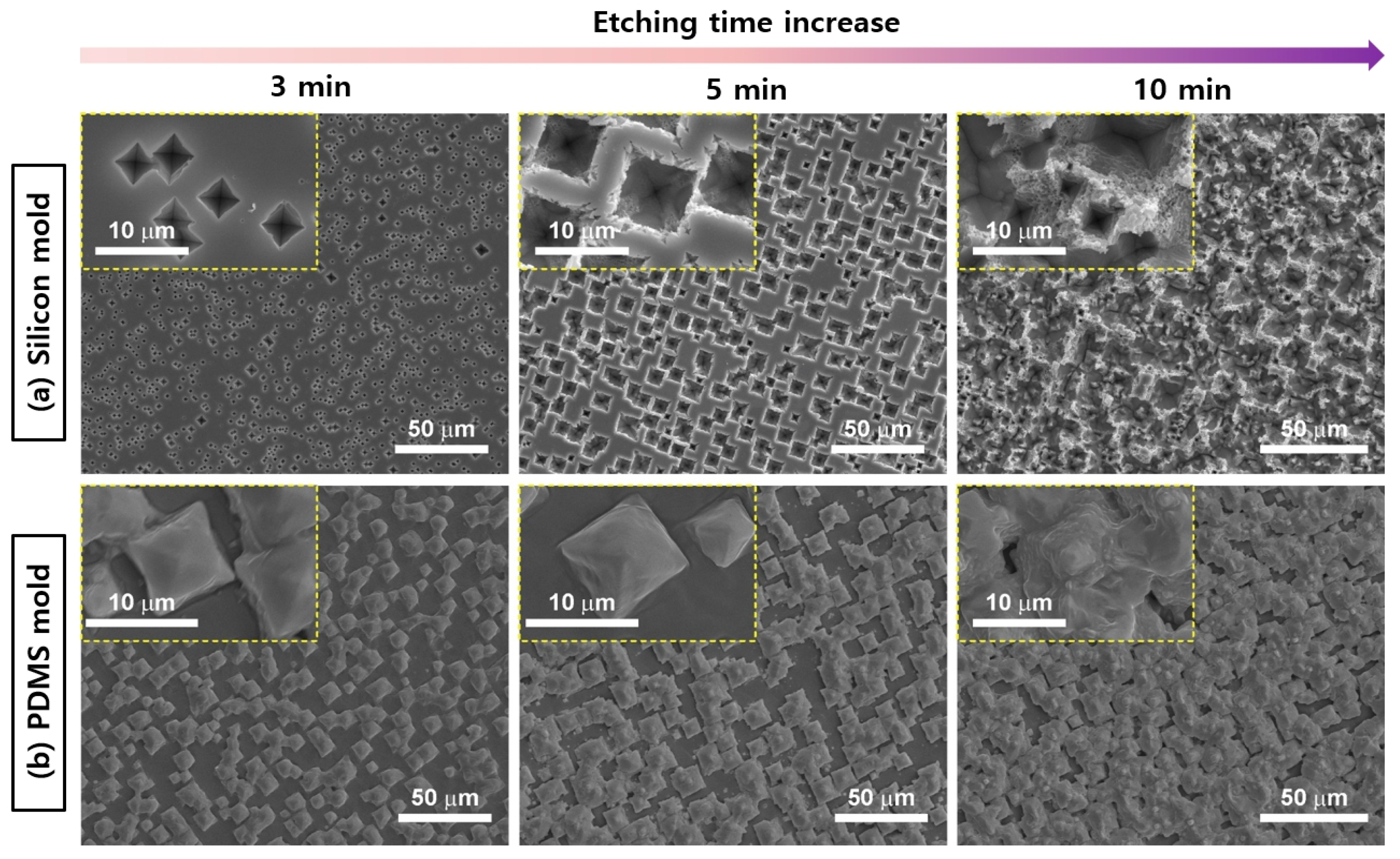

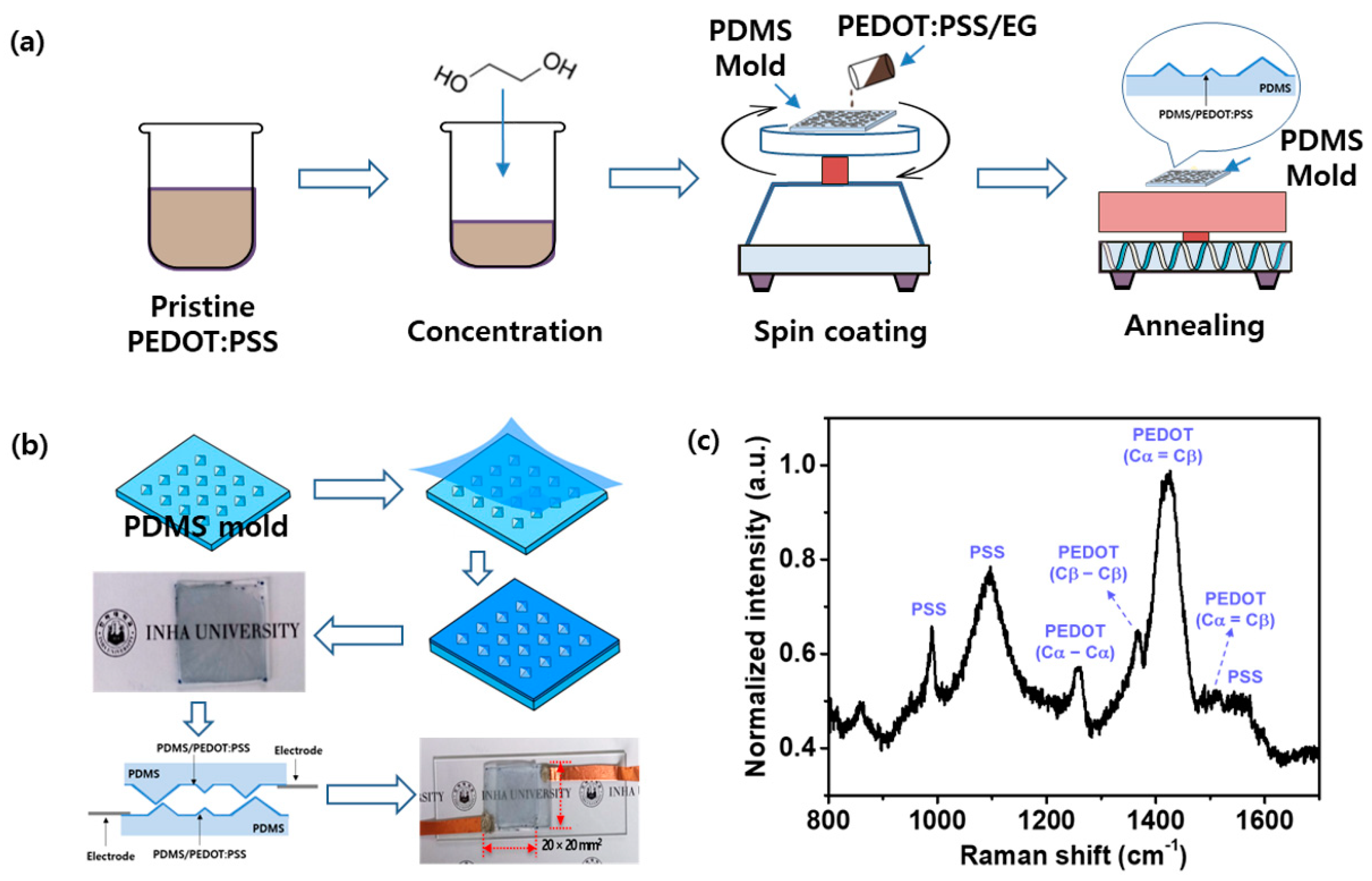

3.1. Preparation and Characterization

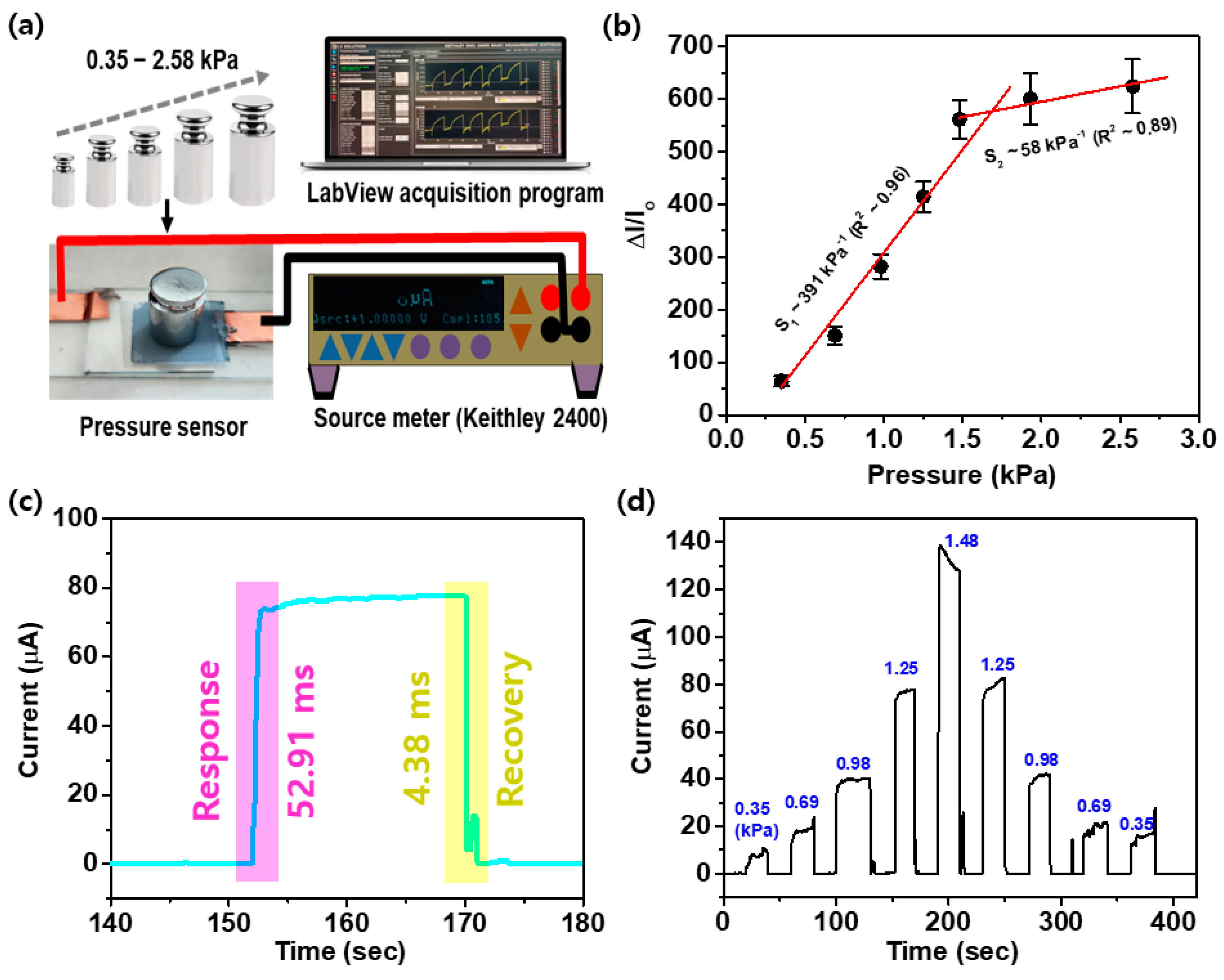

3.2. Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Chen, E.; Weng, X.; He, Z.; Chang, G.; Pan, X.; Liu, J.; Huang, K.; Huang, K.; Lei, M. Conductive polyvinyl alcohol/silver nanoparticles hydrogel sensor with large draw ratio, high sensitivity and high stability for human behavior monitoring. Eng. Sci. 2022, 18, 113–120. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Mammock, M.L.; Chortos, A.; Tee, B.C.-K.; Tok, J.B.-H.; Bao, Z. 25th anniversary article: The evolution of electronic skin (E-Skin): A brief history, design considerations, and recent progress. Adv. Mater. 2013, 25, 5997–6038. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Shih, B.; Laschi, C.; Tolley, M.T. Soft robot perception using embedded soft sensors and recurrent neural networks. Science Robotics 2019, 4, eaav1488. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, J.; Tolle, C.R.; Zhu, Z. Flexible and compressible PEDOT: PSS@ melamine conductive sponge prepared via one-step dip coating as piezoresistive pressure sensor for human motion detection. ACS Appl. Mater. Interfaces 2018, 10, 16077–16086. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Li, G.; Qin, Q.; Mi, L.; Li, G.; Zheng, G.; Liu, C.; Li, Q.; Liu, X. Electrospun PVDF/PAN membrane for pressure sensor and sodium-ion battery separator. Adv. Compos. Hybrid Mater. 2021, 4, 1215–1225. [Google Scholar] [CrossRef]

- Dos Santos, A.; Pinela, N.; Alves, P.; Santos, R.; Farinha, R.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. E-skin bimodal sensors for robotics and prosthesis using PDMS molds engraved by laser. Sensors 2019, 19, 899. [Google Scholar] [CrossRef]

- Zang, Y.; Zhang, F.; Di, C.A.; Zhu, D. Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horiz. 2015, 2, 140–156. [Google Scholar] [CrossRef]

- Chen, Z.; Yu, J.; Zhang, X.; Zeng, H.; Li, Y.; Wu, J.; Tao, K. A button switch inspired duplex hydrogel sensor based on both triboelectric and piezoresistive effects for detecting dynamic and static pressure. Nanotechnol. Precis. Eng. (NPE) 2022, 5, 023002. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Wang, Y.; Xia, K.; Yin, Z.; Wang, H.; Zhang, M.; Liang, X.; Lu, H.; Zhu, M.; et al. Physical sensors for skin-inspired electronics. InfoMat 2020, 2, 184–211. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, S.; Wang, C.; Zhou, Q.; Zhang, H.; Pan, G.B. Highly sensitive capacitive flexible pressure sensor based on a high-permittivity MXene nanocomposite and 3D network electrode for wearable electronics. ACS Sens. 2021, 6, 2630–2641. [Google Scholar] [CrossRef] [PubMed]

- Mo, L.; Meng, X.; Zhao, J.; Pan, Y.; Sun, Z.; Guo, Z.; Wang, W.; Peng, Z.; Shang, C.; Han, S.; et al. Full printed flexible pressure sensor based on microcapsule controllable structure and composite dielectrics. Flex. Print. Electron. 2021, 6, 014001. [Google Scholar] [CrossRef]

- Ji, Z.; Zhang, M. Highly sensitive and stretchable piezoelectric strain sensor enabled wearable devices for real-time monitoring of respiratory and heartbeat simultaneously. Nanotechnol. Precis. Eng. (NPE) 2022, 5, 013002. [Google Scholar] [CrossRef]

- Xie, W.; Yao, F.; Gu, H.; Du, A.; Lei, Q.; Naik, N.; Guo, Z. Magnetoresistive and piezoresistive polyaniline nanoarrays in-situ polymerized surrounding magnetic graphene aerogel. Adv. Compos. Hybrid Mater. 2022, 5, 1003–1016. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, X.; Yang, H.; Qin, H.; Wang, W. Structural engineering in piezoresistive micropressure sensors: A focused review. Micromachines 2023, 14, 1507. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.; Lu, Y.; Wang, J.; Chen, D.; Chen, J. A piezoresistive pressure sensor with optimized positions and thickness of piezoresistors. Micromachines 2021, 12, 1095. [Google Scholar] [CrossRef]

- Yao, H.; Yu, Z.; Huang, F.; Pan, T.; Tang, C.; Zhang, H. A flexible piezoresistive pressure sensor comprising a microstructure printed with poly (3, 4-ethylenedioxythiophene): Poly (styrenesulfonate) copolymers@ graphene hybrid ink. J. Mater. Chem. C 2023, 11, 13324–13334. [Google Scholar] [CrossRef]

- Wei, H.; Li, X.; Yao, F.; Feng, X.; Zhu, X. Flexible piezoresistive pressure sensor based on a graphene-carbon nanotube-polydimethylsiloxane composite. Nanotechnol. Precis. Eng. 2024, 7, 3. [Google Scholar] [CrossRef]

- Wang, P.; Yu, W.; Li, G.; Meng, C.; Guo, S. Printable, flexible, breathable and sweatproof bifunctional sensors based on an all-nanofiber platform for fully decoupled pressure–temperature sensing application. Chem. Eng. J. 2023, 4, 139174. [Google Scholar] [CrossRef]

- Yang, W.; Xie, M.; Zhang, X.; Sun, X.; Zhou, C.; Chang, Y.; Zhang, H.; Duan, X. Multifunctional soft robotic finger based on a nanoscale flexible temperature–pressure tactile sensor for material recognition. ACS Appl. Mater. Interfaces 2021, 13, 55756–55765. [Google Scholar] [CrossRef]

- Duan, Y.; He, S.; Wu, J.; Su, B.; Wang, Y. Recent progress in flexible pressure sensor arrays. Nanomaterials 2022, 12, 2495. [Google Scholar] [CrossRef] [PubMed]

- Pyo, S.; Lee, J.; Bae, K.; Sim, S.; Kim, J. Recent progress in flexible tactile sensors for human-interactive systems: From sensors to advanced applications. Adv. Mater. 2021, 33, 2005902. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, R.; Hao, X.; Liu, G. Design of flexible pressure sensor based on conical microstructure PDMS-bilayer graphene. Sensors 2021, 21, 289. [Google Scholar] [CrossRef] [PubMed]

- Deng, C.; Zhao, S.; Su, E.; Li, Y.; Wu, F. Trilayer MXene fabric for integrated ultrasensitive pressure sensor and wearable heater. Adv. Mater. Technol. 2021, 6, 2100574. [Google Scholar] [CrossRef]

- Kim, J.; Park, D.; Moon, S.; Park, C.; Thiyagarajan, K.; Choi, S.; Hwang, H.; Jeong, U. Omnidirectional tactile profiling using a deformable pressure sensor array based on localized piezoresistivity. Adv. Mater. Technol. 2022, 7, 2100688. [Google Scholar] [CrossRef]

- Hung, L.S.; Chen, C.H. Materials science and engineering: R: Reports. Mater. Sci. Eng. 2002, 39, 143–222. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, L.; Li, Z.; Wang, F.; Chen, X.; Liu, J.; Song, C.; Yao, J. Facile fabrication of highly sensitive and durable cotton fabric-based pressure sensors for motion and pulse monitoring. J. Mater. Chem. C 2021, 9, 12605–12614. [Google Scholar] [CrossRef]

- Pan, H.; Lee, T.-W. Recent progress in development of wearable pressure sensors derived from biological materials. Adv. Healthc. Mater. 2021, 10, 2100460. [Google Scholar] [CrossRef]

- Huang, L.; Zeng, R.; Tang, D.; Cao, X. Bioinspired and multiscale hierarchical design of a pressure sensor with high sensitivity and wide linearity range for high-throughput biodetection. Nano Energy 2022, 99, 107376. [Google Scholar] [CrossRef]

- Yang, Y.; Deng, H.; Fu, Q. Recent progress on PEDOT: PSS based polymer blends and composites for flexible electronics and thermoelectric devices. Mater. Chem. Front. 2020, 4, 3130–3152. [Google Scholar] [CrossRef]

- Fan, X.; Nie, W.; Tsai, H.; Wang, N.; Huang, H.; Cheng, Y.; Wen, R.; Ma, L.; Yan, F.; Xia, Y. PEDOT: PSS for flexible and stretchable electronics: Modifications, strategies, and applications. Adv. Sci. 2019, 6, 1900813. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Duan, T.; Zhang, F.; Tian, X.; Li, H.; Feng, M.; Wang, R.; Jiang, B.; Zhang, K. Flexible electrode materials for emerging electronics: Materials, fabrication and applications. J. Mater. Chem. A 2024, 2024. 12, 20606–20637. [Google Scholar] [CrossRef]

- Tringides, C.M.; Vachicouras, N.; de Lázaro, I.; Wang, H.; Trouillet, A.; Seo, B.R.; Elosegui-Artola, A.; Fallegger, F.; Shin, Y.; Casiraghi, C.; et al. Viscoelastic surface electrode arrays to interface with viscoelastic tissues. Nat. Nanotechnol. 2021, 16, 1019–1029. [Google Scholar] [CrossRef] [PubMed]

- Díez-Pascual, A.M.; Rahdar, A. Graphene-based polymer composites for flexible electronic applications. Micromachines 2022, 13, 1123. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-J.; Ni, W.-S.; Lee, J.-Y. Effect of incorporation of ethylene glycol into PEDOT: PSS on electron phonon coupling and conductivity. J. Appl. Phys. 2015, 118, 219901. [Google Scholar] [CrossRef]

- Dong, J.; Portale, G. Role of the Processing Solvent on the Electrical Conductivity of PEDOT: PSS. Adv. Mater. Interfaces 2020, 7, 2000641. [Google Scholar] [CrossRef]

- Singh, L.; Tripathy, K.; Bhattacharjee, M. Porous microstructure-assisted flexible and highly sensitive polymer piezoresistive pressure sensor. Adv. Eng. Mater. 2022, 24, 2200500. [Google Scholar] [CrossRef]

- Tang, R.; Lu, F.; Liu, L.; Yan, Y.; Du, Q.; Zhang, B.; Zhou, T.; Fu, H. Flexible pressure sensors with microstructures. Nano Sel. 2021, 2, 1874–1901. [Google Scholar] [CrossRef]

- Pang, Y.; Zhang, K.; Yang, Z.; Jiang, S.; Ju, Z.; Li, Y.; Wang, X.; Wang, D.; Jian, M.; Zhang, Y.; et al. Epidermis microstructure inspired graphene pressure sensor with random distributed spinosum for high sensitivity and large linearity. ACS Nano 2018, 12, 2346–2354. [Google Scholar] [CrossRef]

- Tu, S.; Xi, Y.; Cui, X.; Xu, Z.; Liu, Z.; Zhu, Y. Skin-inspired interlocked microstructures with soft-hard synergistic effect for high-sensitivity and wide-linear-range pressure sensing. Chem. Eng. J. 2024, 496, 154083. [Google Scholar] [CrossRef]

- Zhao, Y.; Shen, T.; Zhang, M.; Yin, R.; Zheng, Y.; Liu, H.; Sun, H.; Liu, C.; Shen, C. Advancing the pressure sensing performance of conductive CNT/PDMS composite film by constructing a hierarchical-structured surface. Nano Mater. Sci. 2022, 5, 343–350. [Google Scholar] [CrossRef]

- Jung, Y.; Choi, J.; Lee, W.; Ko, J.S.; Park, I.; Cho, H. Irregular microdome structure-based sensitive pressure sensor using internal popping of microspheres. Adv. Funct. Mater. 2022, 32, 2201147. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Zeng, J.; Ren, X.; Chee, A.J.; Yiu, B.Y.; Chung, W.C.; Yang, Y.; Yu, A.C.; Roberts, R.C.; et al. High sensitivity, wearable, piezoresistive pressure sensors based on irregular microhump structures and its applications in body motion sensing. Small 2016, 12, 3827–3836. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Liu, Y.; Yang, L.; Wu, J.; Chen, Q.; Zhao, Y.; Wang, Y.; Du, X. Difference in anisotropic etching characteristics of alkaline and copper based acid solutions for single-crystalline Si. Sci. Rep. 2018, 8, 3408. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Yuan, G.; Wang, Q.; Liu, W.; Zhang, S.; Liu, Z.; Wang, J.; Li, J. Morphology control of c-Si via facile copper-assisted chemical etching: Managements on etch end-points. Appl. Surf. Sci. 2019, 489, 776–785. [Google Scholar] [CrossRef]

- Huang, H.; Zhong, J.; Ye, Y.; Wu, R.; Luo, B.; Ning, H.; Qiu, T.; Luo, D.; Yao, R.; Peng, J. Research progresses in microstructure designs of flexible pressure sensors. Polymers 2022, 14, 3670. [Google Scholar] [CrossRef]

- Gao, Y.; Xiao, T.; Li, Q.; Chen, Y.; Qiu, X.; Liu, J.; Bian, Y.; Xuan, F. Flexible microstructured pressure sensors: Design, fabrication and applications. Nanotechnology 2022, 33, 322002. [Google Scholar] [CrossRef]

- Yan, J.; Ma, Y.; Li, X.; Zhang, C.; Cao, M.; Chen, W.; Luo, S.; Zhu, M.; Gao, Y. Flexible and high-sensitivity piezoresistive sensor based on MXene composite with wrinkle structure. Ceram. Int. 2020, 46, 23592–23598. [Google Scholar] [CrossRef]

- Shi, L.; Li, Z.; Chen, M.; Qin, Y.; Jiang, Y.; Wu, L. Quantum effect-based flexible and transparent pressure sensors with ultrahigh sensitivity and sensing density. Nat. Commun. 2020, 11, 3529. [Google Scholar] [CrossRef]

- Chen, W.; Yan, X. Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: A review. J. Mater. Sci. Technol. 2020, 43, 175–188. [Google Scholar] [CrossRef]

- Li, W.-D.; Pu, J.H.; Zhao, X.; Jia, J.; Ke, K.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Yang, W. Scalable fabrication of flexible piezoresistive pressure sensors based on occluded micro-structures for subtle pressure and force waveform detection. J. Mater. Chem. C 2020, 8, 16774–16783. [Google Scholar] [CrossRef]

- Dai, S.-W.; Gu, Y.-L.; Zhao, L.; Zhang, W.; Gao, C.-H.; Wu, Y.-X.; Shen, S.-C.; Zhang, C.; Kong, T.-T.; Li, Y.-T.; et al. Bam-boo-Inspired Mechanically Flexible and Electrically Conductive Polydimethylsiloxane Foam Materials with Designed Hierar-chical Pore Structures for Ultra-Sensitive and Reliable Piezoresistive Pressure Sensor. Compos. Part B. Eng. 2021, 225, 109243. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, L.; Li, H.; Lai, X.; Zeng, X. Skin-Inspired Flexible and High-Performance MXene@polydimethylsiloxane Pie-zoresistive Pressure Sensor for Human Motion Detection. J. Colloid Interface Sci. 2022, 617, 478–488. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Choi, S.; Lee, B.; Seo, J.; Lee, S.; Yoon, J.; Hong, Y. Nonpatterned Soft Piezoresistive Films with Filamentous Conduction Paths for Mimicking Multiple-Resolution Receptors of Human Skin. ACS Appl. Mater. Interfaces 2022, 14, 55088–55097. [Google Scholar] [CrossRef] [PubMed]

| Materials | Sensitivity | Pressure Range | Response Time | Reference |

|---|---|---|---|---|

| MXene | 148.26 kPa−1 | 0~16 kPa | 120 ms | [48] |

| Urchin-like hollow carbon spheres | 260.3 kPa−1 | 1~10,000 Pa | 30/60 ms | [49] |

| CNT/PDMS | 15.1 kPa−1 | - | 4 ms | [50] |

| Carbon nanostructure on patterned PDMS | 1.214 kPa−1 | 0~100 Pa | 266/766 ms | [51] |

| Carbon nanofibers/PDMS | 0.60 kPa−1 | 0~1 kPa | 30/25 ms | [52] |

| MXene on patterned PDMS | 2.6 kPa−1 | 0~30 kPa | 40/40 ms | [53] |

| Aligned Ni/PDMS | 0.72 kPa−1 at 357 kPa | 373 kPa | ~12/~20 ms | [54] |

| PDMS/PEDOT:PSS | 391 kPa−1 | 0.3~1.48 kPa | 52.91 ms | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Kim, D.Y. Enhanced Sensitivity of a Resistive Pressure Sensor Based on a PEDOT:PSS Thin Film on PDMS with a Random-Height Micropyramid Structure. Micromachines 2024, 15, 1110. https://doi.org/10.3390/mi15091110

Kim S, Kim DY. Enhanced Sensitivity of a Resistive Pressure Sensor Based on a PEDOT:PSS Thin Film on PDMS with a Random-Height Micropyramid Structure. Micromachines. 2024; 15(9):1110. https://doi.org/10.3390/mi15091110

Chicago/Turabian StyleKim, Sungyong, and Dae Yu Kim. 2024. "Enhanced Sensitivity of a Resistive Pressure Sensor Based on a PEDOT:PSS Thin Film on PDMS with a Random-Height Micropyramid Structure" Micromachines 15, no. 9: 1110. https://doi.org/10.3390/mi15091110