Role of Chemically Functionalization of Bamboo Fibers on Polyethylene-Based Composite Performance: A Solution for Recycling

Abstract

:1. Introduction

2. Materials and Methods

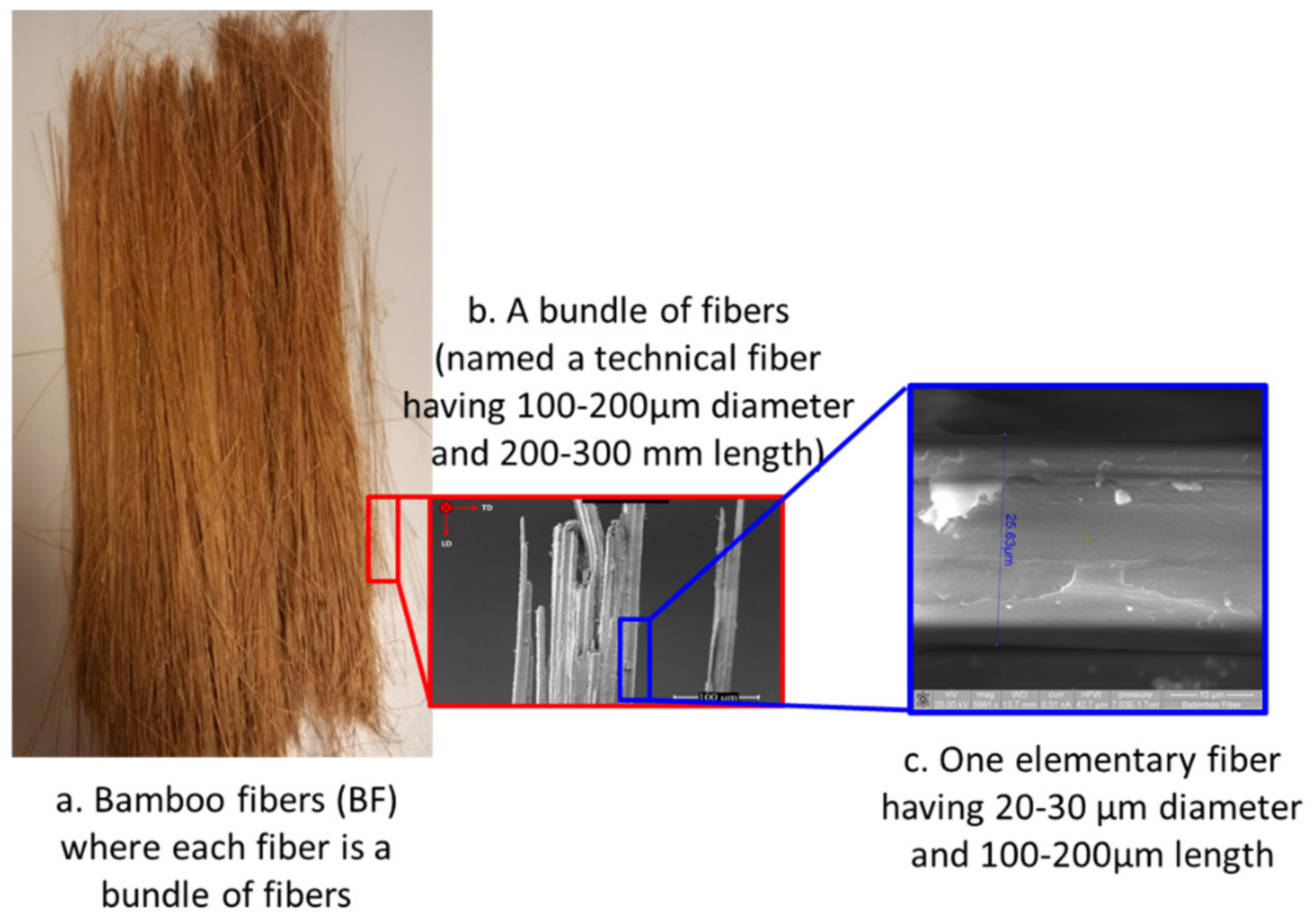

2.1. Bamboo Fibers Extraction

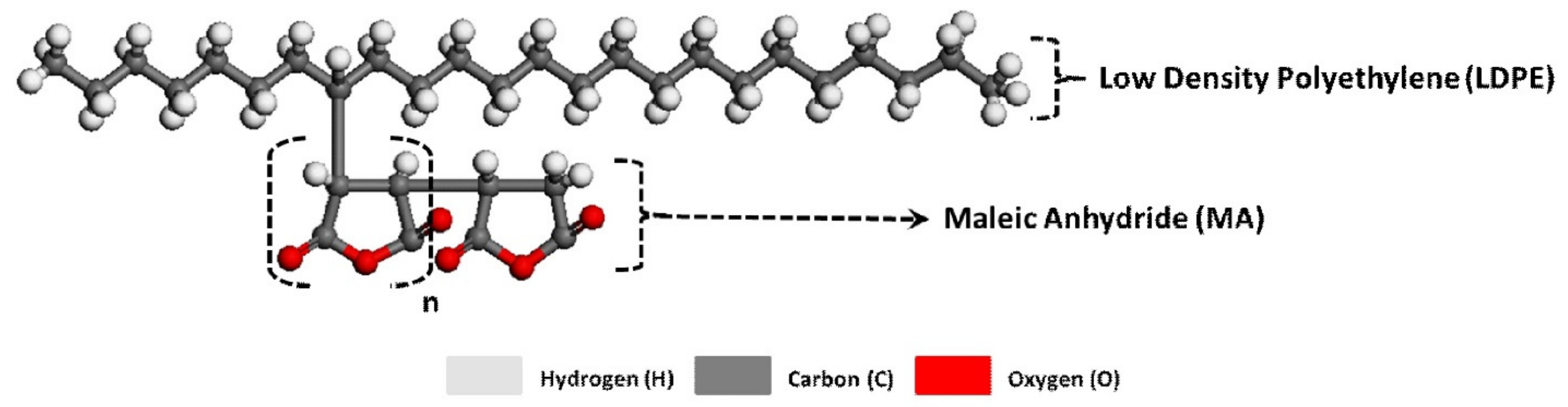

2.2. Chemically-Induced Surface Modification of the Fibers

2.3. Bamboo Fiber Reinforced Composite Sheet Fabrication

- 1.

- LDPE-BFsAL: LDPE reinforced with extracted BFs subjected to alkaline treatment;

- 2.

- LDPE-BFsTMOS: LDPE reinforced with alkaline-treated BFs immersed in a TMOS coupling agent;

- 3.

- LDPE-BFsMA: LDPE with added MA compatibilizer reinforced with BFsTMOS.

2.4. Methods for Experimental Testing

2.4.1. Three-Point Bending Testing

2.4.2. Dynamic Mechanical Analysis

3. Results and Interpretations

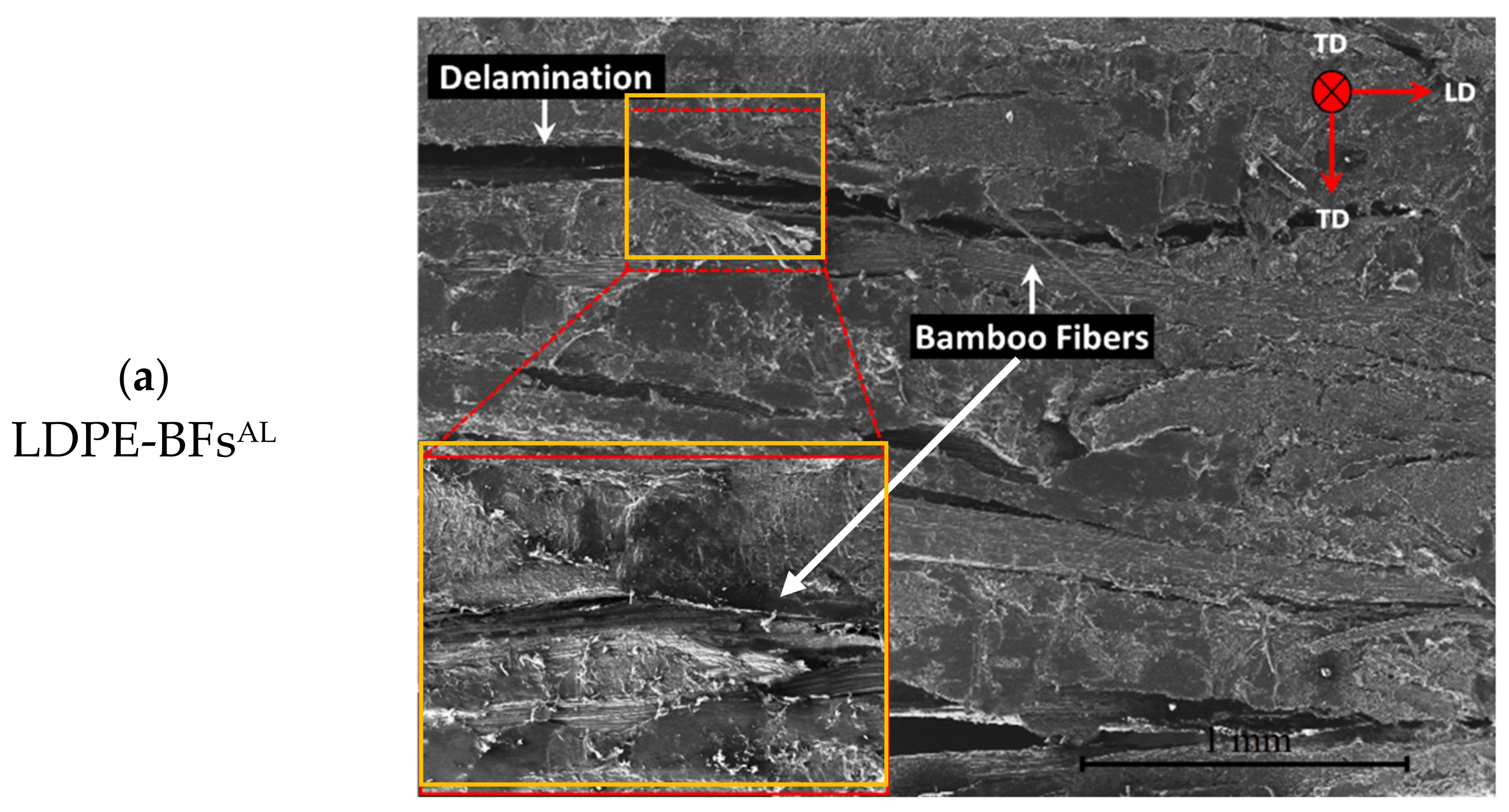

3.1. Microstructure of the LDPE-BFsAL Composite Sheet

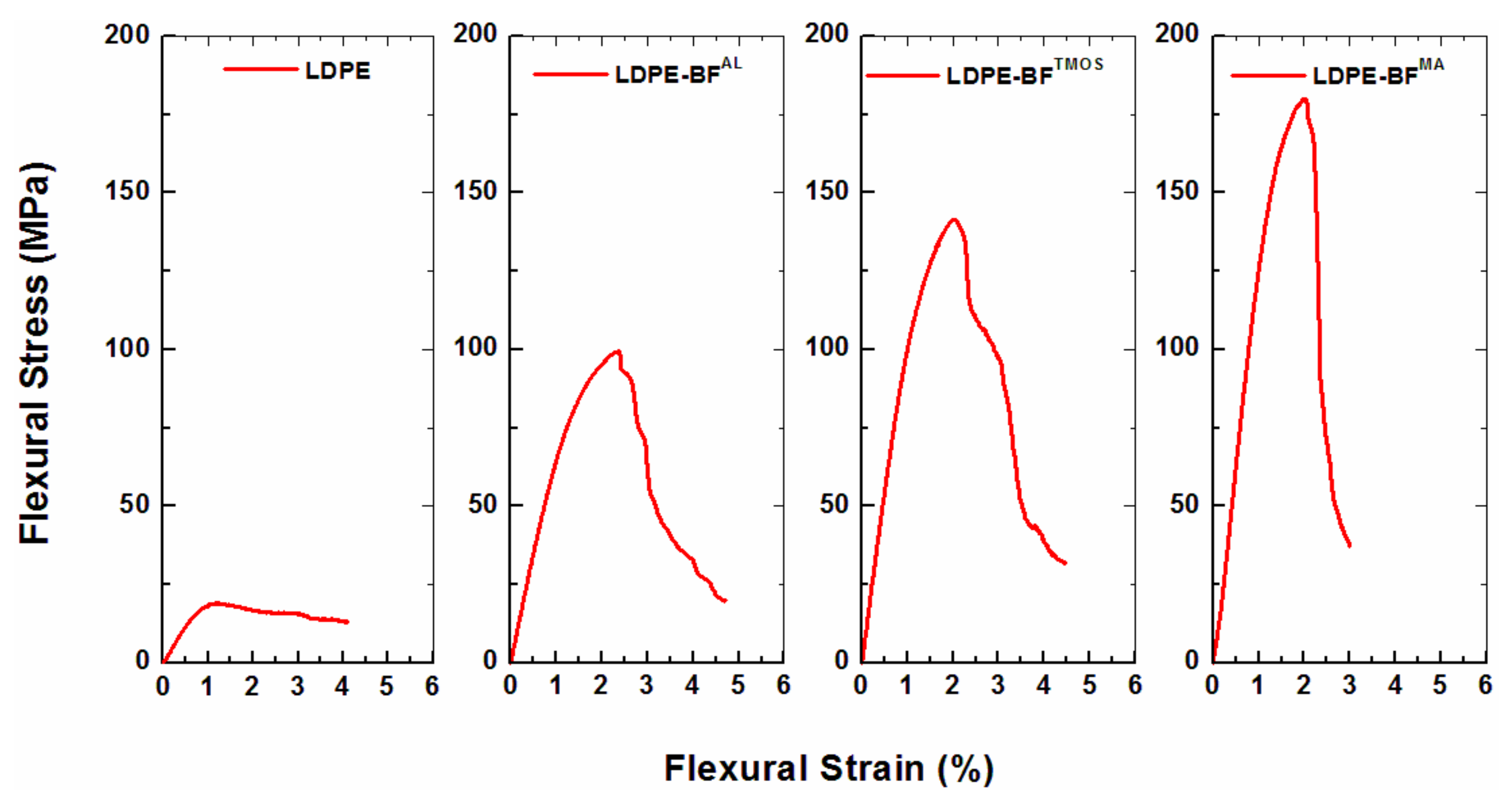

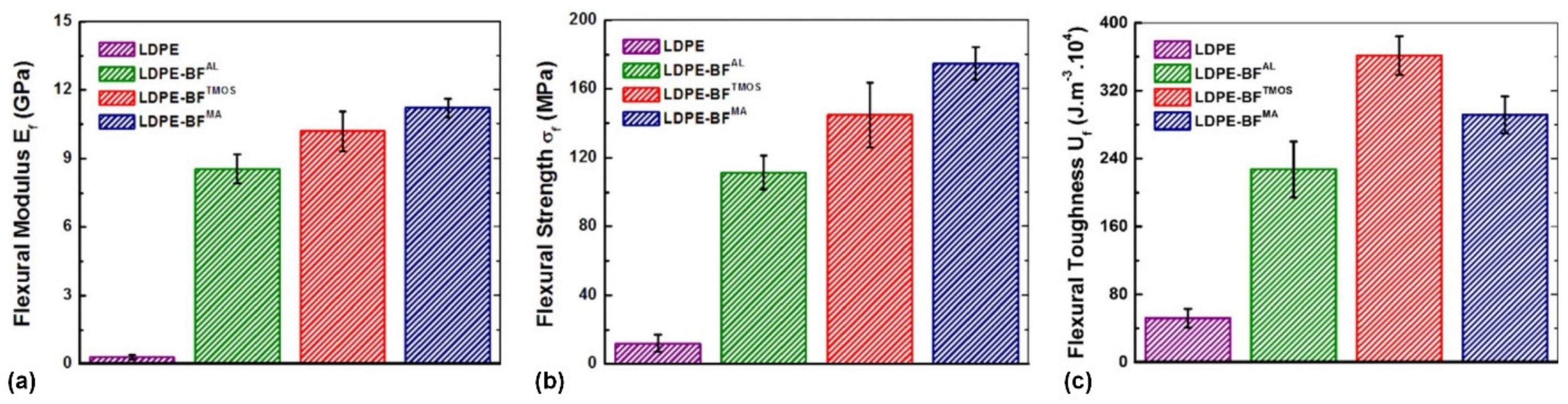

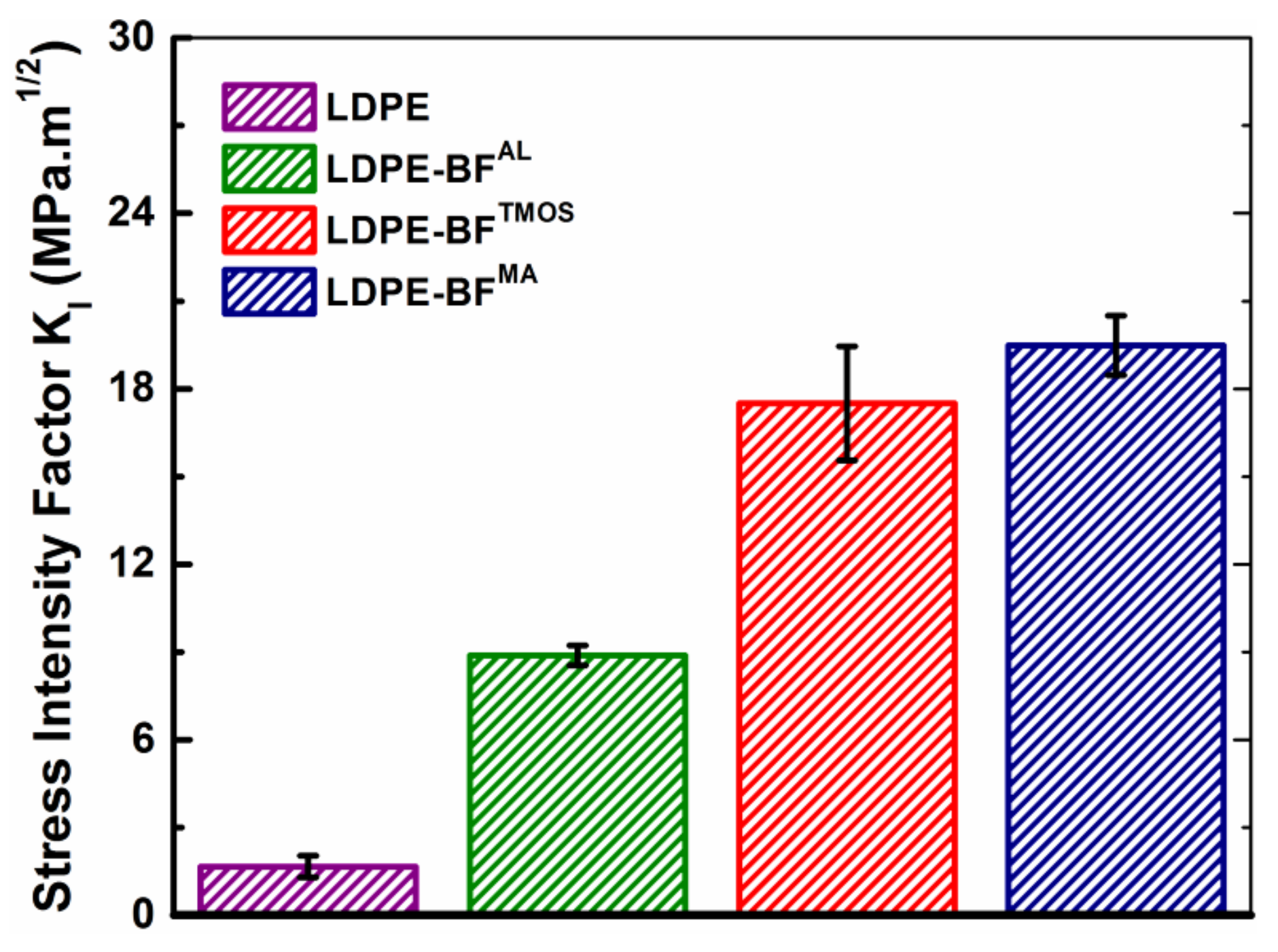

3.2. Influence of Chemically Functionalization on Mechanical Properties

3.2.1. Evaluation of the Bonding Strength

3.2.2. Evaluation of the Toughness

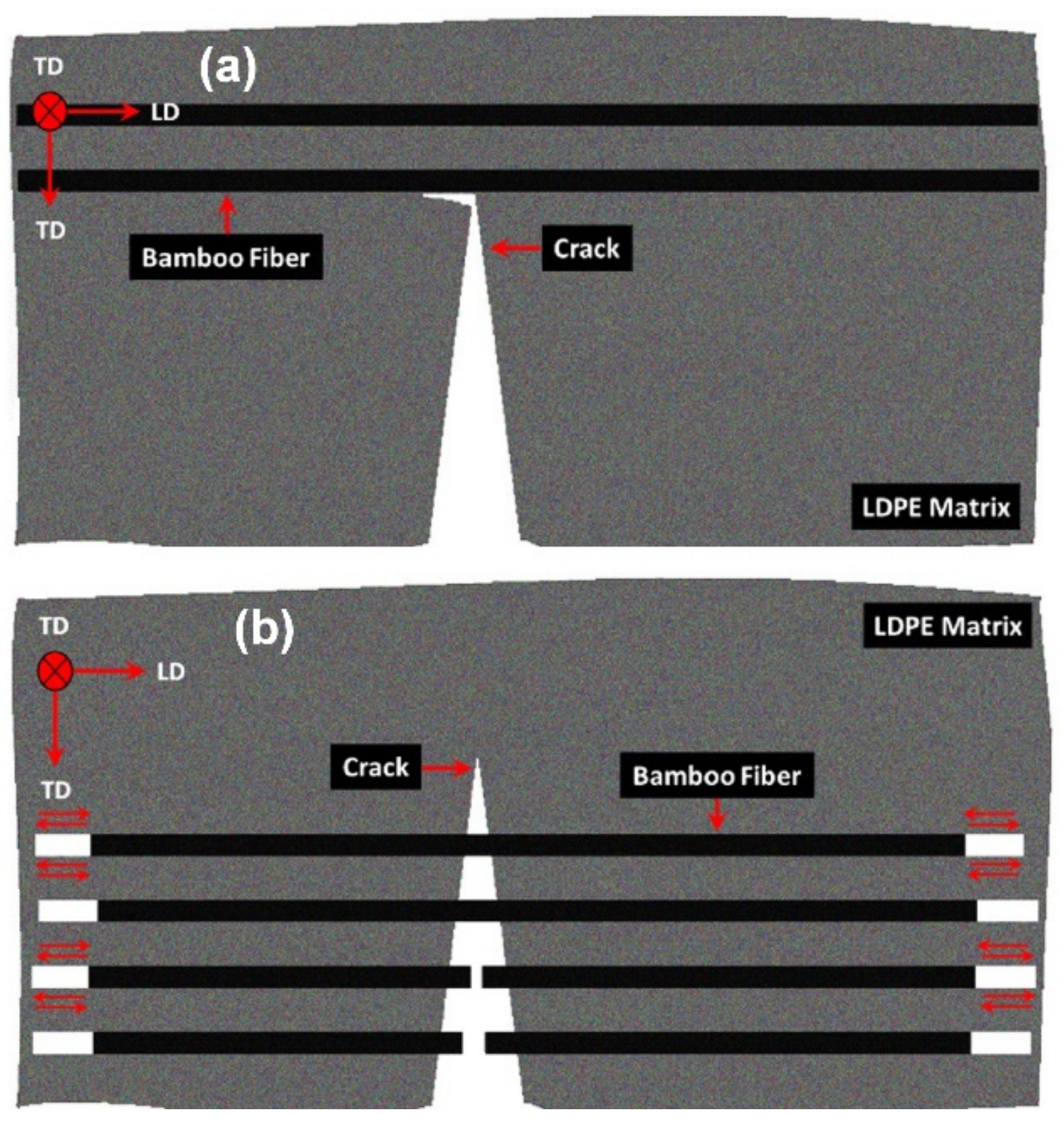

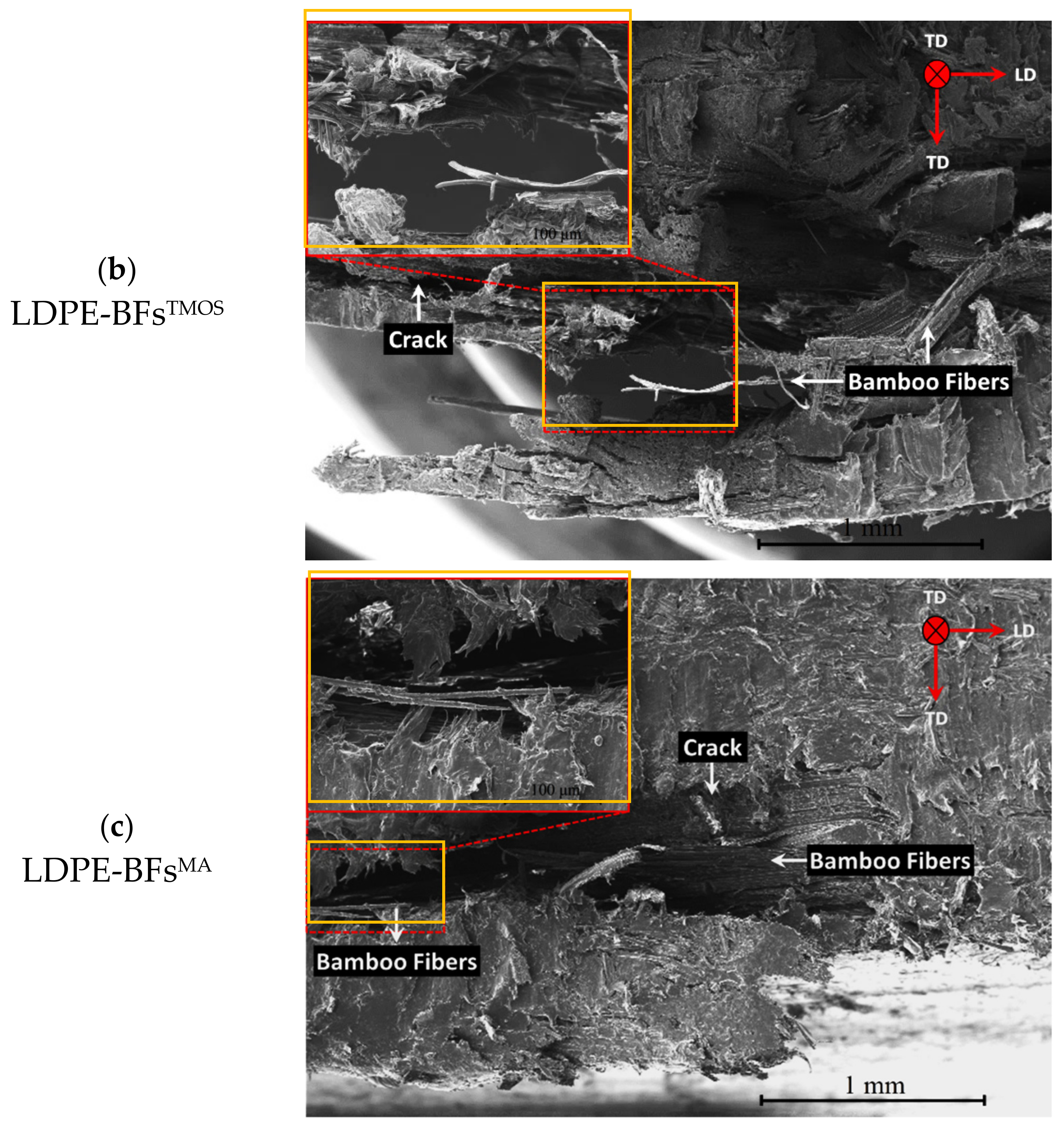

3.2.3. Toughening Mechanism

3.2.4. Evaluation of the Failure Mode

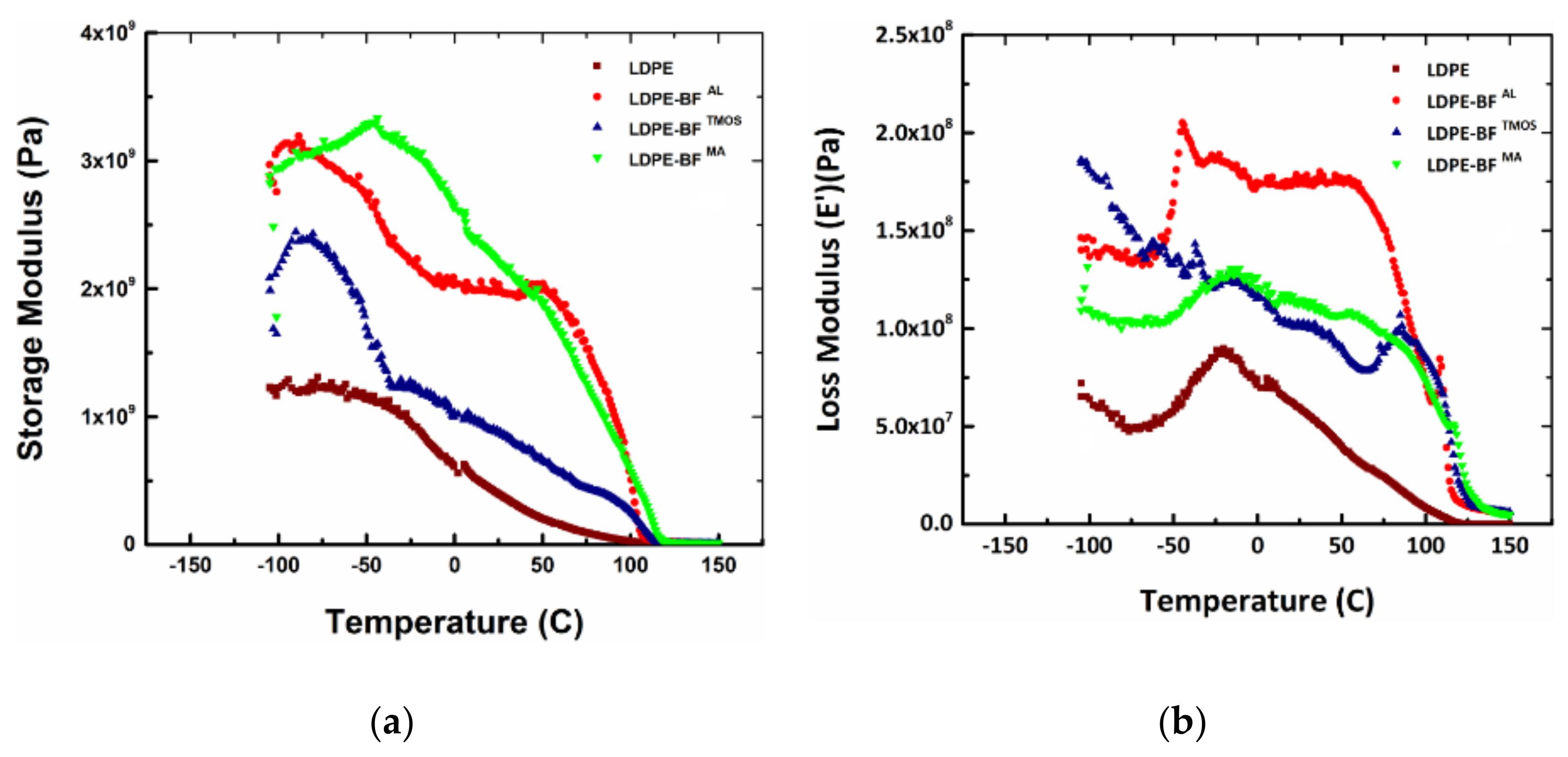

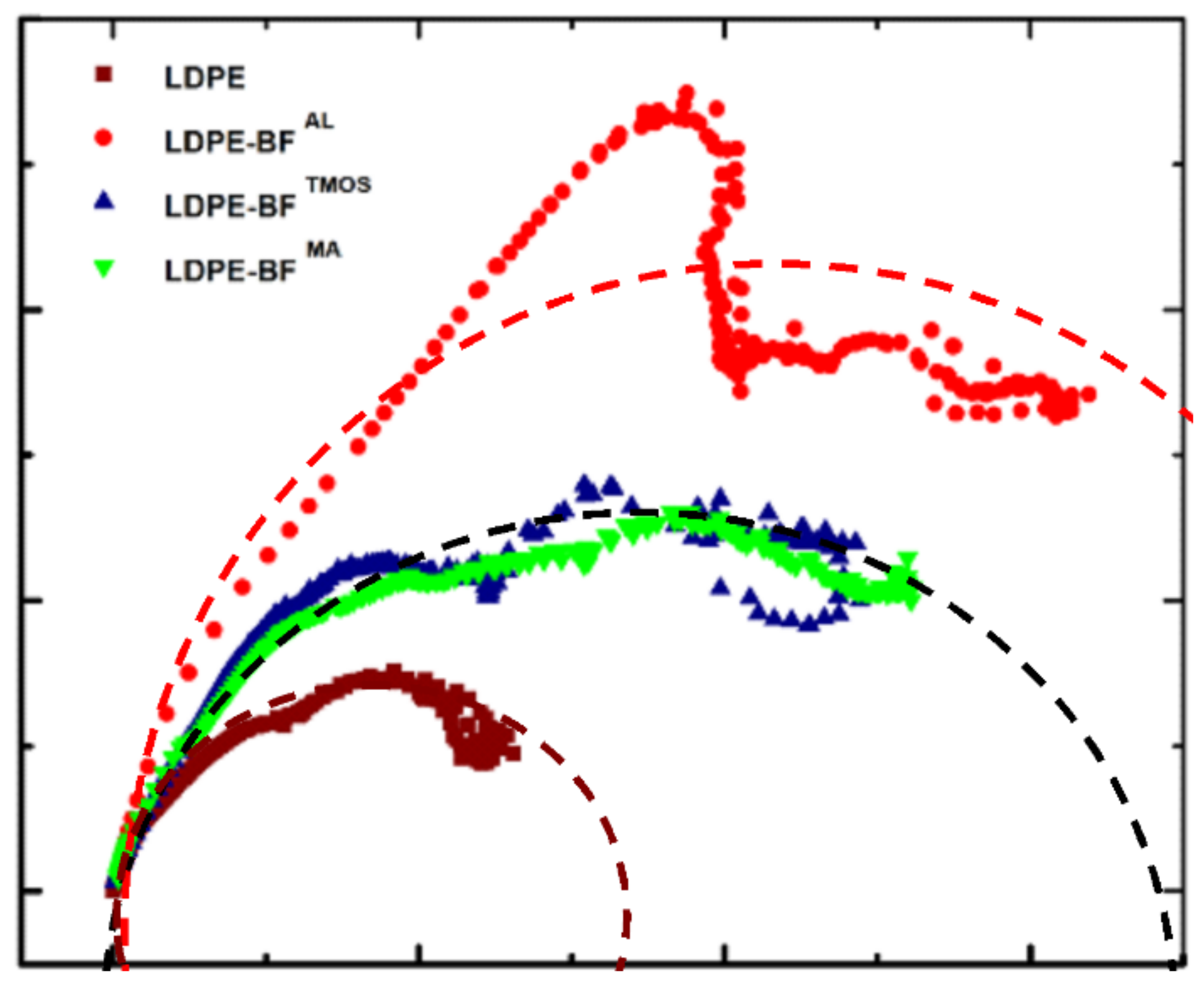

3.3. Influence on the Viscous Behavior

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos. Part B 2020, 200, 108254. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef] [Green Version]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. J. Thermoplast. Compos. Mater. 2019, 34, 238–284. [Google Scholar] [CrossRef]

- Lou, Z.; Yuan, T.; Wang, Q.; Wu, X.; Hu, S.; Hao, X.; Liu, X.; Li, Y. Fabrication of Crack-Free Flattened Bamboo and Its Macro-/Micro-Morphological and Mechanical Properties. J. Renew. Mater. 2021, 9, 959–977. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, Q.; Sun, W.; Zhao, Y.; Wang, X.; Liu, X.; Li, Y. Bamboo flattening technique: A literature and patent review. Eur. J. Wood Wood Prod. 2021, 1–14. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.; Anderson, D.P.; Chang, P.R.; Hua, Y. Bamboo fiber and its reinforced composites: Structure and properties. Cellulose 2012, 19, 1449–1480. [Google Scholar] [CrossRef]

- Sharath Shekar, H.S.; Ramachandra, M. Green Composites: A Review. Mater. Today Proc. 2018, 5, 2518–2526. [Google Scholar] [CrossRef]

- Kang, J.T.; Kim, S.H. Improvement in the mechanical properties of polylactide and bamboo fiber biocomposites by fiber surface modification. Macromol. Res. 2011, 19, 789–796. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Yu, W. A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Compos. Part B Eng. 2014, 56, 48–53. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Chi Truong, T.; Vangrimde, B.; Verpoest, I. Improving the properties of UD flax fibre reinforced composites by applying an alkaline fibre treatment. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1368–1376. [Google Scholar] [CrossRef]

- Phuong, N.T.; Sollogoub, C.; Guinault, A. Relationship between fiber chemical treatment and properties of recycled pp/bamboo fiber composites. J. Reinf. Plast. Compos. 2010, 29, 3244–3256. [Google Scholar] [CrossRef]

- Huang, J.-K.; Young, W.-B. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites. Compos. Part B 2019, 166, 272–283. [Google Scholar] [CrossRef]

- Wang, C.; Zuo, Q.; Lin, T.; Anuar, N.I.S.; Salleh, K.M.; Gan, S.; Yousfani, S.H.S.; Zuo, H.; Zakaria, S. Predicting thermal conductivity and mechanical property of bamboo fibers/polypropylene nonwovens reinforced composites based on regression analysis. Int. Commun. Heat Mass Transf. 2020, 118, 104895. [Google Scholar] [CrossRef]

- ASTM. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Habibi, M.K.; Lu, Y. Crack Propagation in Bamboo’s Hierarchical Cellular Structure. Sci. Rep. 2014, 4, 1–7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ostertag, C.P. Experimental evidence of crack tip shielding mechanisms in quasi-brittle materials. J. Mater. Sci. 1997, 32, 4011–4017. [Google Scholar] [CrossRef]

- Suresh, S.; Mortensen, A.; Suresh, S. Fundamentals of Functionally Graded Materials; Institute of Materials: London, UK, 1998. [Google Scholar]

- Hanlon, T.; Tabachnikova, E.D.; Suresh, S. Fatigue behavior of nanocrystalline metals and alloys. Int. J. Fatigue 2005, 27, 1147–1158. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue crack deflection and fracture surface contact: Micromechanical models. Metall. Trans. A 1985, 16, 249–260. [Google Scholar] [CrossRef]

- Zhang, M.; Colby, R.H.; Milner, S.T.; Chung, T.M.; Huang, T.; de Groot, W. Synthesis and Characterization of Maleic Anhydride Grafted Polypropylene with a Well-Defined Molecular Structure. Macromolecules 2013, 46, 4313–4323. [Google Scholar] [CrossRef]

- Cottrell, T.L. The Strengths of Chemical Bonds; Butterworths Scientific Publications: London, UK, 1958. [Google Scholar]

- Rolere, S.; Cartault, M.; Sainte-Beuve, J.; Bonfils, F. A rheological method exploiting Cole-Cole plot allows gel quantification in Natural Rubber. Polym. Test. 2017, 61, 378–385. [Google Scholar] [CrossRef]

- Mann, G.S.; Singh, L.P.; Kumar, P.; Singh, S. Green composites: A review of processing technologies and recent applications. J. Thermoplast. Compos. Mater. 2020, 33, 1145–1171. [Google Scholar] [CrossRef]

| Materials | Damping Coefficient | Glass Transition Temperature (Tg) (°C) |

|---|---|---|

| LDPE | 0.068 | ~−20 |

| LDPE-BFsAL | 0.052 | ~60 |

| LDPE-BFsTMOS | 0.048 | ~69 |

| LDPE-BFsMA | 0.042 | ~75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kouhi, M.; Butan, S.; Li, Y.; Shakour, E.; Banu, M. Role of Chemically Functionalization of Bamboo Fibers on Polyethylene-Based Composite Performance: A Solution for Recycling. Polymers 2021, 13, 2564. https://doi.org/10.3390/polym13152564

Kouhi M, Butan S, Li Y, Shakour E, Banu M. Role of Chemically Functionalization of Bamboo Fibers on Polyethylene-Based Composite Performance: A Solution for Recycling. Polymers. 2021; 13(15):2564. https://doi.org/10.3390/polym13152564

Chicago/Turabian StyleKouhi, Meisam, Simona Butan, Yang Li, Elias Shakour, and Mihaela Banu. 2021. "Role of Chemically Functionalization of Bamboo Fibers on Polyethylene-Based Composite Performance: A Solution for Recycling" Polymers 13, no. 15: 2564. https://doi.org/10.3390/polym13152564

APA StyleKouhi, M., Butan, S., Li, Y., Shakour, E., & Banu, M. (2021). Role of Chemically Functionalization of Bamboo Fibers on Polyethylene-Based Composite Performance: A Solution for Recycling. Polymers, 13(15), 2564. https://doi.org/10.3390/polym13152564