A Review of Research on the Effect of Temperature on the Properties of Polyurethane Foams

Abstract

:1. Introduction

2. Influence of Temperature on Polyurethane Foam Properties during the Molding Stage

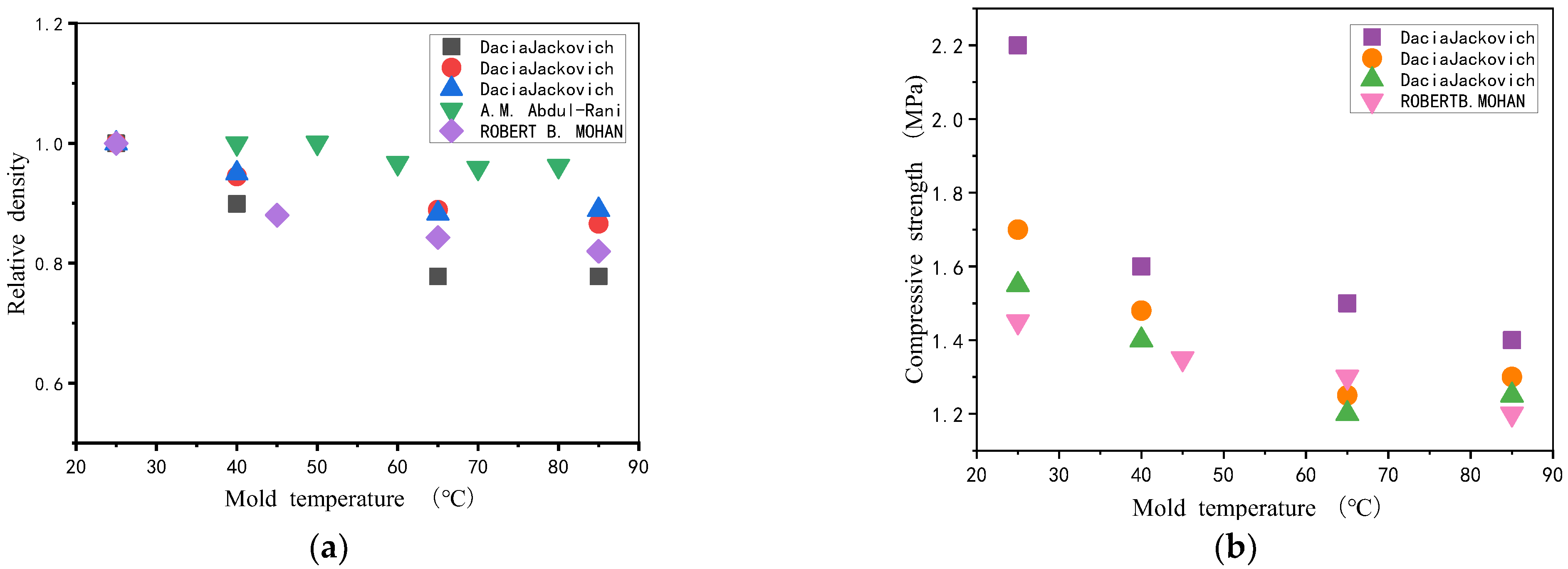

2.1. Effect of Mold Temperature on Polyurethane Foams

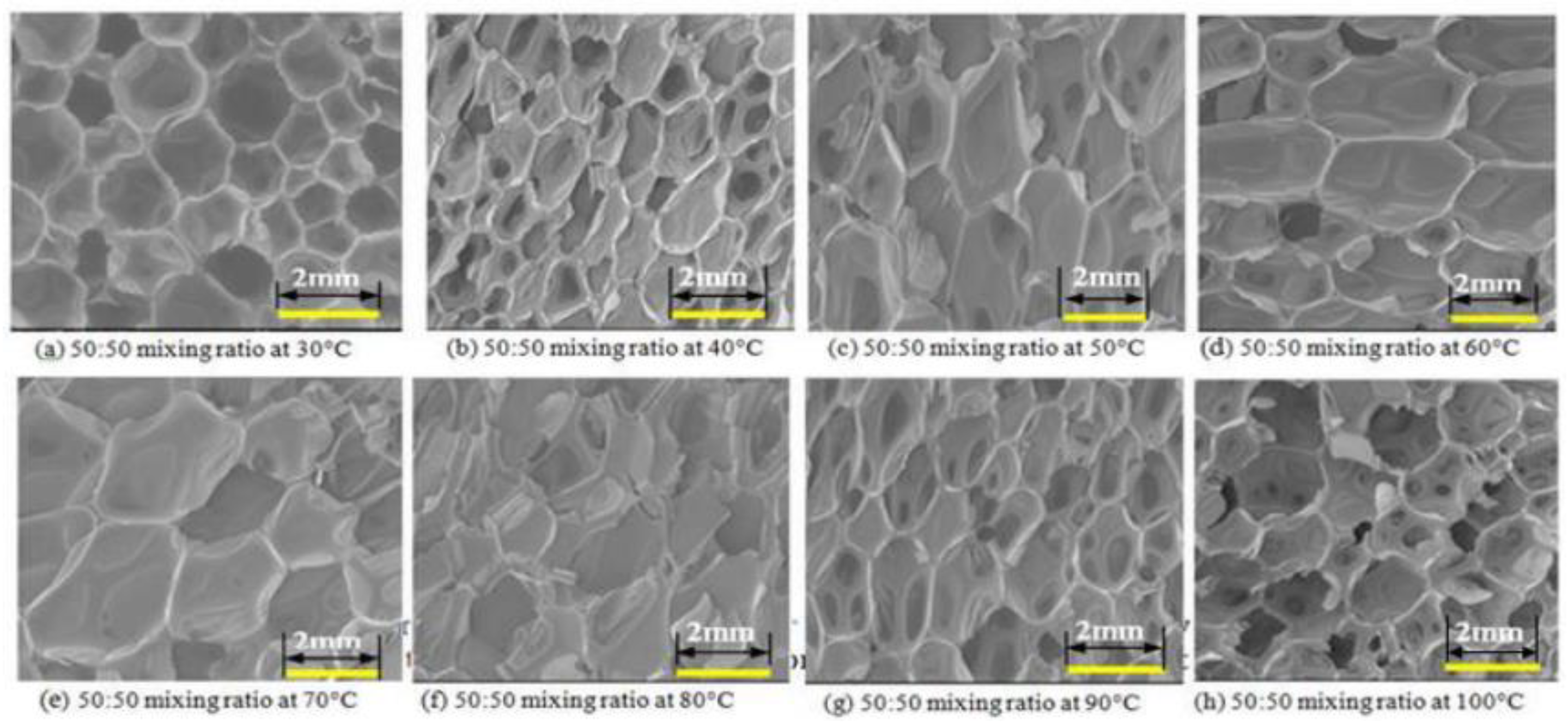

2.1.1. Influence on Cell Structure

2.1.2. Effect on Mechanical Strength

2.2. The Effect of Ambient Temperature on Polyurethane Foams

2.3. Influence of Initial Mixture Temperature on Polyurethane Foams

3. Influence of Temperature on Polyurethane Foam Properties during Service Phase

3.1. Influence of Ambient Temperature on Tensile and Compressive Strength

3.2. Influence of Ambient Temperature on Impact Strength

3.3. Influence of Ambient Temperature on Fracture Properties

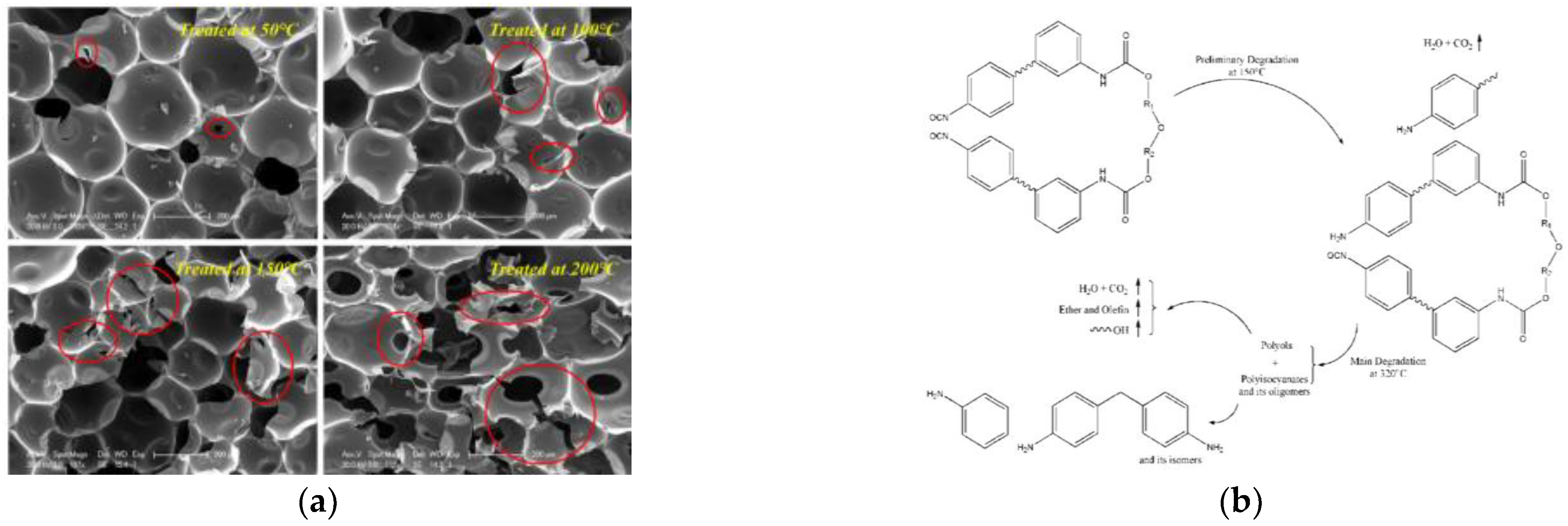

3.4. Effect of High-Temperature Heat Treatment on Polyurethane Foam Properties

3.5. Properties of Polyurethane at Low Temperature

4. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sikder, A.; Pearce, A.K.; Parkinson, S.J.; Napier, R.; O′Reilly, R.K. Recent Trends in Advanced Polymer Materials in Agriculture Related Applications. ACS Appl. Polym. Mater. 2021, 3, 1203–1217. [Google Scholar] [CrossRef]

- Chauhan, V.; Karki, T.; Varis, J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. 2022, 35, 1169–1209. [Google Scholar] [CrossRef]

- Liu, G.F.; Sun, X.D.; Li, X.D.; Wang, Z.X. The Bioanalytical and Biomedical Applications of Polymer Modified Substrates. Polyurethane Foam. 2022, 14, 826. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Li, J.Z.; Yuan, Y.H.; Gao, C.; Cui, Y.G.; Li, S.C.; Liu, X.; Wang, H.Y.; Peng, C.; Wu, Z.J. A Review of the Polymer for Cryogenic Application: Methods, Mechanisms and Perspectives. Polyurethane Foam. 2021, 13, 320. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, N.; Kausar, A.; Muhammad, B. Advances in Shape Memory Polyurethanes and Composites: A Review. Polym.-Plast. Technol. Eng. 2015, 54, 1410–1423. [Google Scholar] [CrossRef]

- Kausar, A. Review on Technological Significance of Photoactive, Electroactive, pH-sensitive, Water-active, and Thermoresponsive Polyurethane Materials. Polym.-Plast. Technol. Eng. 2017, 56, 606–616. [Google Scholar] [CrossRef]

- Li, X.R.; Li, J.; Wang, J.Y.; Yuan, J.; Jiang, F.; Yu, X.Y.; Xiao, F.P. Recent applications and developments of Polyurethane materials in pavement engineering. Constr. Build. Mater. 2021, 304, 124639. [Google Scholar] [CrossRef]

- Jin, F.L.; Zhao, M.; Park, M.; Park, S.J. Recent Trends of Foaming in Polymer Processing: A Review. Polyurethane Foam. 2019, 11, 953. [Google Scholar] [CrossRef] [Green Version]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [Green Version]

- John, J.; Bhattacharya, M.; Turner, R.B. Characterization of polyurethane foams from soybean oil. J. Appl. Polym. Sci. 2002, 86, 3097–3107. [Google Scholar] [CrossRef]

- Kausar, A. Polyurethane Composite Foams in High-Performance Applications: A Review. Polym.-Plast. Technol. Eng. 2018, 57, 346–369. [Google Scholar] [CrossRef]

- Wang, Y.; Han, M.; Li, B.; Wan, Y. Stability evaluation of earth-rock dam reinforcement with new permeable polymer based on reliability method. Constr. Build. Mater. 2022, 320, 126294. [Google Scholar] [CrossRef]

- Wang, F.; Li, J.; Shi, M.; Guo, C. New seepage-proof and reinforcing technologies for dikes and dams and their applications. J. Hydro. Eng. 2016, 35, 1–11. [Google Scholar]

- Su, Z.P.; Liang, Y.H. Application of PU grouting in settlements of structures induced by excavation. Chin. J. Geotech. Eng.-ASCE 2017, 39, 103–106. [Google Scholar] [CrossRef]

- Cui, C.; Lu, Q.; Guo, C.C.; Wang, F.M. Analysis of the Coupling Effect of Thermal and Traffic Loads on Cement Concrete Pavement with Voids Repaired with Polymer Grout. Adv. Mater. Sci. Eng. 2022, 2022, 1–17. [Google Scholar] [CrossRef]

- Fang, H.Y.; Li, B.; Wang, F.M.; Wang, Y.K.; Cui, C. The mechanical behaviour of drainage pipeline under traffic load before and after polymer grouting trenchless repairing. Tunn. Undergr. Space Technol. 2018, 74, 185–194. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, C.; Zhou, K. Experimental Study on Polyurethane Grouting Material for Safety Protection in Coal Mining. J. Saf. Environ. 2021, 28, 65–74. [Google Scholar]

- Lam, C.; Jefferis, S.A. Performance of Bored Piles Constructed Using Polymer Fluids: Lessons from European Experience. J. Perform. Constr. Facil. 2016, 30, 04015024. [Google Scholar] [CrossRef] [Green Version]

- Hao, M.M.; Wang, F.M.; Li, X.L.; Zhang, B.; Zhong, Y.H. Numerical and Experimental Studies of Diffusion Law of Grouting with Expansible Polymer. J. Mater. Civ. Eng. 2018, 30, 04017290. [Google Scholar] [CrossRef]

- Guo, C.C.; Sun, B.; Hu, D.P.; Wang, F.M.; Shi, M.S.; Li, X.L. A Field Experimental Study on the Diffusion Behavior of Expanding Polymer Grouting Material in Soil. Soil Mech. Found. Eng. 2019, 56, 171–177. [Google Scholar] [CrossRef]

- Wang, F.; Fan, Y.; Guo, C. Practice of non-water-reacting polymer grouting treatment to seepage. J. Hydro. Eng. 2018, 37, 1–11. [Google Scholar]

- Fang, H.Y.; Su, Y.J.; Du, X.M.; Wang, F.M.; Li, B. Experimental and Numerical Investigation on Repairing Effect of Polymer Grouting for Settlement of High-Speed Railway Unballasted Track. Appl. Sci. 2019, 9, 4496. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Wang, F.M.; Fang, H.Y.; Yang, K.J.; Zhang, X.J.; Ji, Y.T. Experimental and numerical study on polymer grouting pretreatment technology in void and corroded concrete pipes. Tunn. Undergr. Space Technol. 2021, 113, 103842. [Google Scholar] [CrossRef]

- Li, X.; Hao, M.; Zhong, Y.; Zhang, B.; Wang, F.; Wang, L. Experimental study on the diffusion characteristics of polyurethane grout in a fracture. Constr. Build. Mater. 2021, 273, 121711. [Google Scholar] [CrossRef]

- Li, M.; Du, M.; Wang, F.; Xue, B.; Zhang, C.; Fang, H. Study on the mechanical properties of polyurethane (PU) grouting material of different geometric sizes under uniaxial compression. Constr. Build. Mater. 2020, 259, 119797. [Google Scholar] [CrossRef]

- Liu, K.; Liang, W.; Ren, F.; Ren, J.; Wang, F.; Ding, H. The study on compressive mechanical properties of rigid polyurethane grout materials with different densities. Constr. Build. Mater. 2019, 206, 270–278. [Google Scholar] [CrossRef]

- Santiago-Calvo, M.; Blasco, V.; Ruiz, C.; París, R.; Villafañe, F.; Rodríguez-Pérez, M.Á. Synthesis, characterization and physical properties of rigid polyurethane foams prepared with poly(propylene oxide) polyols containing graphene oxide. Eur. Polym. J. 2017, 97, 230–240. [Google Scholar] [CrossRef]

- Lu, Z. Investigation into the tensile constitutive relation and failure mechanism of pur foamed plastics. J. Aeronaut. 2002, 23, 151–154. [Google Scholar]

- Lu, Z.X.; Xie, R.Z.; Tian, C.J.; Liu, X.P.; Li, H.X. Investigation into Shear Mechanical Properties of PUR Foamed Plastics. J. B. Univ. Aeronaut. Astronaut. 1999, 25, 561–564. [Google Scholar] [CrossRef]

- Marsavina, L.; Linul, E.; Voiconi, T.; Sadowski, T. A comparison between dynamic and static fracture toughness of polyurethane foams. Polym. Test. 2013, 32, 673–680. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, S.; Zhang, Y.; Yang, M.; Wang, L.; Li, Z. Experimental study on permeability characteristicsof clay-gravel mixtures under freezing-thawing actions in core wall of earth-rock dams. J. Hydraul. Eng. 2021, 52, 603–611. [Google Scholar]

- Wang, H.X.; Zhang, X.H.; Duan, Y.G. Effects of drilling area temperature on drilling of carbon fiber reinforced polymer composites due to temperature-dependent properties. Int. J. Adv. Manuf. Technol. 2018, 96, 2943–2951. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Wang, C.; Zhang, C.; Fang, H.; Deng, Y. Quantitative analysis of the representative volume element of polymer grouting materials based on geometric homogenization. Constr. Build. Mater. 2021, 300, 124223. [Google Scholar] [CrossRef]

- Bureau, M.N.; Gendron, R. Mechanical-morphology relationship of PS foams. J. Cell. Plast. 2003, 39, 353–367. [Google Scholar] [CrossRef]

- Hawkins, M.C.; O′Toole, B.; Jackovich, D. Cell morphology and mechanical properties of rigid polyurethane foam. J. Cell. Plast. 2005, 41, 267–285. [Google Scholar] [CrossRef]

- Andersons, J.; Modniks, J.; Kirpluks, M.; Cabulis, U. The effect of cell shape anisotropy on fracture toughness of low-density brittle foams. Eng. Fract. Mech. 2022, 269, 108565. [Google Scholar] [CrossRef]

- Ridha, M.; Shim, V. Microstructure and Tensile Mechanical Properties of Anisotropic Rigid Polyurethane Foam. Exp. Mech. 2008, 48, 763–776. [Google Scholar] [CrossRef]

- Şerban, D.A.; Linul, E.; Voiconi, T.; Marşavina, L.; Modler, N. Numerical evaluation of two-dimensional micromechanical structures of anisotropic cellular materials: Case study for polyurethane rigid foams. Iran. Polym. J. 2015, 24, 515–529. [Google Scholar] [CrossRef]

- Şerban, D.A.; Linul, E.; Sărăndan, S.; Marşavina, L. Development of Parametric Kelvin Structures will Closed Cells. Solid State Phenom. 2016, 254, 49–54. [Google Scholar] [CrossRef]

- Zhang, C.; Tong, X.; Deng, C.; Wen, H.; Huang, D.; Guo, Q.; Liu, X. The foaming dynamic characteristics of polyurethane foam. J. Cell. Plast. 2020, 56, 279–295. [Google Scholar] [CrossRef]

- Mohan, R.B.; O′Toole, B.J.; Malpica, J.; Hatchett, D.W.; Kodippili, G.; Kinyanjui, J.M. Effects of Processing Temperature on ReCrete Polyurethane Foam. J. Cell. Plast. 2008, 44, 327–345. [Google Scholar] [CrossRef]

- Abdul-Rani, A.M.; Hopkinson, N.; Dickens, P.M. Analysing the effect of mold temperature on foam density and foam surface texture. Cell. Polym. 2004, 23, 387–402. [Google Scholar] [CrossRef]

- Gupta, V.K.; Khakhar, D.V. Formation of integral skin polyurethane foams. Polym. Eng. Sci. 1999, 39, 164–176. [Google Scholar] [CrossRef]

- Jackovich, D.; O′Toole, B.; Hawkins, M.C.; Sapochak, L. Temperature and mold size effects on physical and mechanical properties of a polyurethane foam. J. Cell. Plast. 2005, 41, 153–168. [Google Scholar] [CrossRef]

- Harbron, D.R.; Page, C.J.; Scarrow, R.K. Methods of Minimising Density Gradients in Rigid Polyurethane Foams. J. Cell. Plast. 2001, 37, 43–57. [Google Scholar] [CrossRef]

- Han, H.; Nam, H.N.; Eun, Y.; Lee, S.Y.; Nam, J.; Ryu, J.H.; Lee, S.Y.; Kim, J. Numerical analysis on foam reaction injection molding of polyurethane, part B: Parametric study and real application. J. Kor. Cryst. Growth Cryst. Technol. 2016, 26, 258–262. [Google Scholar] [CrossRef] [Green Version]

- Xiang, N.; Zhang, X.W.; Zheng, M.Y.; Xu, R.J.; Yan, Y. Investigation of tensile behavior and molecular structure of the thermoplastic polyurethane sheets injection molded at different mold temperatures. J. Appl. Polym. Sci. 2021, 138, 50959. [Google Scholar] [CrossRef]

- Wang, J.; Ji, S.Y.; Xing, J. Effect of process conditions on the structure and properties of rigid polyurethane foam cells. Polyurethane Ind. 2009, 24, 32–35. [Google Scholar] [CrossRef]

- Shi, B.S.; Li, B.; Nan, Q.Z.; Qin, X.M. Effect of processing parameters on cell morphology of polycarbonate foam. Plast. Rubber Compos. 2011, 40, 457–464. [Google Scholar] [CrossRef]

- Wang, S. Study on the Control of Polyurethane Foam Pore Structure. Master’s Thesis, National University of Defense Technology, Changsha, China, 2002. [Google Scholar]

- Kim, H.; Woong, Y.J. A Study on Foaming Characteristics of Polyurethane Depending On Environmental Temperature and Blowing Agent Content. Trans. Mater. Process. 2009, 18, 256–261. [Google Scholar]

- Ochsner, A.; Murch, G. Cellular and Porous Materials: Thermal Properties Simulation and Prediction; Wiley-VCH: Weinheim, Germany, 2008. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Gordon, M.J.; Tekeei, A.; Hsieh, F.H.; Suppes, G.J. Modeling reaction kinetics of rigid polyurethane foaming process. J. Appl. Polym. Sci. 2013, 130, 1131–1138. [Google Scholar] [CrossRef]

- Wang, H.Z. Effect of the Material Temperature on the Foaming Time of Rigid Polyurethane Systems. Polyurethane Ind. 2016, 31, 42–45. [Google Scholar] [CrossRef]

- Oppon, C.; Hackney, P.M.; Shyha, I.; Birkett, M. Effect of Varying Mixing Ratios and Pre-Heat Temperature on the Mechanical Properties of Polyurethane (PU) Foam. Procedia Eng. 2015, 132, 701–708. [Google Scholar] [CrossRef] [Green Version]

- özdemir, I.B.; Akar, F. Effects of composition and temperature of initial mixture on the formation and properties of polyurethane foam. Adv. Polym. Technol. 2018, 37, 2520–2527. [Google Scholar] [CrossRef]

- Ferkl, P.; Krskova, I.; Kosek, J. Evolution of mass distribution in walls of rigid polyurethane foams. Chem. Eng. Sci. 2018, 176, 50–58. [Google Scholar] [CrossRef]

- Rao, R.R.; Mondy, L.A.; Long, K.N.; Celina, M.C.; Wyatt, N.; Roberts, C.C.; Soehnel, M.M.; Brunini, V.E. The kinetics of polyurethane structural foam formation: Foaming and polymerization. AIChE J. 2017, 63, 2945–2957. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Park, S.; Bang, C.; Lee, J. Application of Gurson Model for Evaluation of Density-Dependent Mechanical Behavior of Polyurethane Foam: Comparative Study on Explicit and Implicit Method. Macromol. Mater. Eng. 2016, 301, 694–706. [Google Scholar] [CrossRef]

- Peyrton, J.; Avérous, L. Structure-properties relationships of cellular materials from biobased polyurethanepolyurethane foams foams. Mater. Sci. Eng. R 2021, 145, 100608. [Google Scholar] [CrossRef]

- Kabakci, E.; Sayer, G.; Suvaci, E.; Uysal, O.; Güler, I.; Kaya, M. Processing-structure-property relationship in rigid polyurethane foams. J. Appl. Polym. Sci. 2017, 134, 44870. [Google Scholar] [CrossRef]

- Rabbi, M.F.; Boudreau, R.L.; Chittoori, B.; Sotirin, M.; Mishra, D. Polyurethane Grout Injection as Remedial Measure to Reduce Differential Heave in Pavement Sections Constructed over Expansive Soils. J. Transp. Eng. 2020, 146, 04020068. [Google Scholar] [CrossRef]

- Saleh, S.; Yunus, N.; Ahmad, K.; Ali, N. Improving the strength of weak soil using polyurethane grouts: A review. Constr. Build. Mater. 2019, 202, 738–752. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Singha, N.K.; Manjunath, B.S.; Naik, Y.P. Effect of foam density on the properties of water blown rigid polyurethane foam. J. Appl. Polym. Sci. 2008, 108, 1810–1817. [Google Scholar] [CrossRef]

- Horak, Z.; Dvorak, K.; Zarybnicka, L.; Vojackova, H.; Dvorakova, J.; Vilimek, M. Experimental Measurements of Mechanical Properties of PUR Foam Used for Testing Medical Devices and Instruments Depending on Temperature, Density and Strain Rate. Materials 2020, 13, 4560. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.L.; Zhou, X.Y.; Wen, M.P.; Tang, W.; Pang, H.Y. Study on the effect of multi-stress accelerated aging on compressive mechanical properties of rigid polyurethane foam. New Chem. Mater. 2012, 40, 56–58. [Google Scholar] [CrossRef]

- Hu, Z.H. Experimental Study on Mechanical Properties of High Polymer Grouting Materials in Seasonal Freeze Zone. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2019. [Google Scholar]

- Song, B.; Lu, W.; Syn, C.; Chen, W. The effects of strain rate, density, and temperature on the mechanical properties of polymethylene diisocyanate (PMDI)-based rigid polyurethane foams during compression. J. Mater. Sci. 2009, 44, 351–357. [Google Scholar] [CrossRef]

- Shi, M.S.; Wang, F.M.; Luo, J. Compressive Strength of Polymer Grouting Material at Different Temperatures. J. Wuhan Univ. Technol. 2010, 25, 962–965. [Google Scholar] [CrossRef]

- Cao, Z.M.; Wang, L.; Liu, W.Q. Energy-absorption properties of foam-filledcomposite tubes at elevated temperatures. J. Nanjing Univ. Technol. 2017, 39, 120–125. [Google Scholar]

- Jia, Z.A.; Li, T.T.; Chiang, F.P.; Wang, L.F. An experimental investigation of the temperature effect on the mechanics of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2018, 154, 53–63. [Google Scholar] [CrossRef]

- Lee, J.H.; Ryu, D.M.; Lee, C.S. Constitutive-damage modeling and computational implementation for simulation of elasto-viscoplastic-damage behavior of polymeric foams over a wide range of strain rates and temperatures. Int. J. Plast. 2020, 130, 102712. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Chen, S. Study on dynamic viscoelastic properties and constitutive model of non-water reacted polyurethane grouting materials. Measurement 2021, 176, 109115. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Huang, C.; Chen, S. Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA. Rev. Adv. Mater. Sci. 2022, 61, 238–249. [Google Scholar] [CrossRef]

- Kopal, I.; Harnicarova, M.; Valicek, J.; Kusnerova, M. Modeling the Temperature Dependence of Dynamic Mechanical Properties and Visco-Elastic Behavior of Thermoplastic Polyurethane Using Artificial Neural Network. Polyurethane Foam. 2017, 9, 519. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barua, B.; Saha, M.C. Incorporating Density and Temperature in the Stretched Exponential Model for Predicting Stress Relaxation Behavior of Polymer Foams. J. Eng. Mater. Technol. 2016, 138, 011001. [Google Scholar] [CrossRef]

- Constantinescu, D.M.; Apostol, D.A. Performance and Efficiency of Polyurethane Foams under the Influence of Temperature and Strain Rate Variation. J. Mater. Eng. Perform. 2020, 29, 3016–3029. [Google Scholar] [CrossRef]

- Richeton, J.; Schlatter, G.; Vecchio, K.S.; Remond, Y.; Ahzi, S. A unified model for stiffness modulus of amorphous polyurethane foams across transition temperatures and strain rates. Polymer 2005, 46, 8194–8201. [Google Scholar] [CrossRef]

- Neilsen, M.K.; Lu, W.Y.; Scherzinger, W.M.; Hinnerichs, T.D.; Lo, C.S. Unified Creep Plasticity Damage (UCPD) Model for Rigid Polyurethane Foams. In Mechanics of Composite and Multifunctional Materials Vol 7; Ralph, C., Silberstein, M., Thakre, P.R., Singh, R., Eds.; Annual Conference and Exposition of Society-for-Experimental-Mechanics on Experimental and Applied Mechanics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 89–97. [Google Scholar]

- Zhang, L.H.; Yao, X.H.; Zang, S.G.; Gu, Y.B. Temperature- and strain rate-dependent constitutive modeling of the large deformation behavior of a transparent polyurethane interlayer. Polym. Eng. Sci. 2015, 55, 1864–1872. [Google Scholar] [CrossRef]

- Linul, E.; Marsavina, L.; Voiconi, T.; Sadowski, T. Study of factors influencing the mechanical properties of polyurethane foams under dynamic compression. J. Physics. Conf. Ser. 2013, 451, 12002–12006. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.; Shin, J.K.; Goh, T.S.; Kim, H.; Lee, J.S.; Lee, C. Modeling of elasto-viscoplastic behavior for polyurethane foam under various strain rates and temperatures. Compos. Struct. 2017, 180, 686–695. [Google Scholar] [CrossRef]

- Marsavina, L.; Constantinescu, D. Failure and Damage in Cellular Materials; Springer: Berlin/Heidelberg, Germany, 2015; pp. 119–190. [Google Scholar]

- Kabir, M.E.; Saha, M.C.; Jeelani, S. Tensile and fracture behavior of polymer foams. Mat. Sci. Eng. A-Struct. 2006, 429, 225–235. [Google Scholar] [CrossRef]

- Saha, M.; Kabir, M.; Jeelani, S. Effect of Nanoparticles on Mode-I Fracture Toughness of Polyurethane Foams. Polym. Compos. 2009, 30, 1058–1064. [Google Scholar] [CrossRef]

- Pugna, A.; Negrea, R.; Linul, E.; Marsavina, L. Is Fracture Toughness of PUR Foams a Material Property? A Statistical Approach. Materials 2020, 13, 4868. [Google Scholar] [CrossRef] [PubMed]

- Linul, E.; Marşavina, L.; Vălean, C.; Bănică, R. Static and dynamic mode I fracture toughness of rigid PUR foams under room and cryogenic temperatures. Eng. Fract. Mech. 2020, 225, 106274. [Google Scholar] [CrossRef]

- Park, S.; Lee, C.; Choi, S.; Kim, J.; Bang, C.; Lee, J. Polymeric foams for cryogenic temperature application: Temperature range for non-recovery and brittle-fracture of microstructure. Compos. Struct. 2016, 136, 258–269. [Google Scholar] [CrossRef]

- Jia, Z.M.; Yuan, G.Q.; Hui, D.; Feng, X.P.; Zou, Y. Effect of high loading rate and low temperature on mode I fracture toughness of ductile polyurethane adhesive. J. Adhes. Sci. Technol. 2019, 33, 79–92. [Google Scholar] [CrossRef]

- Yang, R.; Wang, B.; Li, M.; Zhang, X.; Li, J. Preparation, characterization and thermal degradation behavior of rigid polyurethane foam using a malic acid based polyols. Ind. Crop. Prod. 2019, 136, 121–128. [Google Scholar] [CrossRef]

- He, Y.; Wu, J.; Qiu, D.; Yu, Z. Experimental and numerical analyses of thermal failure of rigid polyurethane foam. Mater. Chem. Phys. 2019, 233, 378–389. [Google Scholar] [CrossRef]

- Li, J.; Chen, S.; Zhang, J.; Wang, J. Dynamic Viscoelastic Property of Non-water Reacted Polymer Materials Based on Dynamic Thermomechanical Analysis. J. Build. Mater. 2020, 23, 1398–1409. [Google Scholar] [CrossRef]

- Tian, Q.; Krakovsky, I.; Yan, G.Y.; Bai, L.F.; Liu, J.H.; Sun, G.A.; Rosta, L.; Chen, B.; Almasy, L. Microstructure Changes in Polyester Polyurethane upon Thermal and Humid Aging. Polyurethane Foam. 2016, 8, 197. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.C.; He, Y.N.; Yu, Z.Q. Failure mechanism of rigid polyurethane foam under high temperature vibration condition by experimental and finite element method. J. Appl. Polym. Sci. 2020, 137, 48343. [Google Scholar] [CrossRef]

- Yoshitake, N.; Furukawa, M. Thermal-Degradation Mechanism of Alpha, Gamma-Diphenyl Alkyl Allophanate as A Model Polyurethane by Pyrolysis High-Resolution Gas Chromatography/Ft-Ir. J. Anal. Appl. Pyrolysis 1995, 33, 269–281. [Google Scholar] [CrossRef]

- Wang, S.P.; Chen, H.X.; Zhang, L.H. Thermal Decomposition Kinetics of Rigid Polyurethane Foam and Ignition Risk by a Hot Particle. J. Appl. Polym. Sci. 2014, 131, 39359. [Google Scholar] [CrossRef]

- He, J.; Jiang, L.; Sun, J.; Lo, S. Thermal degradation study of pure rigid polyurethane in oxidative and non-oxidative atmospheres. J. Anal. Appl. Pyrolysis 2016, 120, 269–283. [Google Scholar] [CrossRef]

- Li, S.F.; Zhi, J.; Yuan, K.J.; Yu, S.Q.; Chow, W.K. Studies on the thermal behavior of polyurethanes. Polym.-Plast. Technol. Eng. 2006, 45, 95–108. [Google Scholar] [CrossRef]

- Jiao, L.; Xiao, H.; Wang, Q.; Sun, J. Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS. Polym. Degrad. Stab. 2013, 98, 2687–2696. [Google Scholar] [CrossRef]

- He, Y.N.; Qiu, D.C.; Yu, Z.Q. Multiscale investigation on molecular structure and mechanical properties of thermal-treated rigid polyurethane foam under high temperature. J. Appl. Polym. Sci. 2021, 138, 51302. [Google Scholar] [CrossRef]

- Lee, Y.; Baek, K.H.; Choe, K.; Han, C. Development of mass production type rigid polyurethane foam for LNG carrier using ozone depletion free blowing agent. Cryogenics 2016, 80, 44–51. [Google Scholar] [CrossRef]

- Cabulis, U.; Yakushin, V.; Fischer, W.P.P.; Rundans, M.; Sevastyanova, I.; Deme, L. Rigid Polyurethane Foams as External Tank Cryogenic Insulation for Space Launchers. IOP Conf. Series Mater. Sci. Eng. 2019, 500, 012009. [Google Scholar] [CrossRef]

- Denay, A.; Castagnet, S.; Roy, A.; Alise, G.; Thenard, N. Compression behavior of glass-fiber-reinforced and pure polyurethane foams at negative temperatures down to cryogenic ones. J. Cell. Plast. 2013, 49, 209–222. [Google Scholar] [CrossRef]

- Cabulis, U.; Yakushin, V.; Fischer, W.P.P. Preparation of rigid polyurethane foams as inner wetted thermal insulation. AIP Conf. Proc. 2019, 2139, 130001. [Google Scholar] [CrossRef]

- Stirna, U.; Beverte, I.; Yakushin, V.; Cabulis, U. Mechanical properties of rigid polyurethane foams at room and cryogenic temperatures. J. Cell. Plast. 2011, 47, 337–355. [Google Scholar] [CrossRef]

- Yakushin, V.A.; Stirna, U.K.; Zhmud′, N.P. Effect of the chemical structure of the polymer matrix on the properties of foam polyurethanes at low temperatures. Mech. Compos. Mater. 1999, 35, 351–356. [Google Scholar] [CrossRef]

- Uram, K.; Prociak, A.; Vevere, L.; Pomilovskis, R.; Cabulis, U.; Kirpluks, M. Natural Oil-Based Rigid Polyurethane Foam Thermal Insulation Applicable at Cryogenic Temperatures. Polymers 2021, 13, 4276. [Google Scholar] [CrossRef]

- Sture, B.; Vevere, L.; Kirpluks, M.; Godina, D.; Fridrihsone, A.; Cabulis, U. Polyurethane Foam Composites Reinforced 740 with Renewable Fillers for Cryogenic Insulation. Polymers 2021, 13, 4089. [Google Scholar] [CrossRef] [PubMed]

- Hwang, B.; Kim, S.; Kim, J.; Kim, J.; Lee, J. Dynamic compressive behavior of rigid polyurethane foam with various densities under different temperatures. Int. J. Mech. Sci. 2020, 180, 105657. [Google Scholar] [CrossRef]

- Lee, D.; Kim, M.; Walsh, J.; Jang, H.; Kim, H.; Oh, E.; Nam, J.; Kim, M.; Suhr, J. Experimental characterization of temperature dependent dynamic properties of glass fiber reinforced polyurethane foams. Polym. Test. 2019, 74, 30–38. [Google Scholar] [CrossRef]

- Deng, L.; Yang, H.; Cheng, X.D. Study on the Properties of Artificial Accelerated wet Thermal Aging of Polyurethane Insulation Materials. J. Saf. Environ. 2014, 14, 49–53. [Google Scholar] [CrossRef]

- Holcroft, N. Temperature dependency of the long-term thermal conductivity of spray polyurethane foam. J. Build. Phys. 2021, 45, 571–603. [Google Scholar] [CrossRef]

- Wang, Z.P.; Xiang, R.; Sun, J.; Yu, A.M. Evolution of Thermal Performance of Roofing Insulation Materials under Multi-field Coupling Conditions in Cold Climate Region. J. Build. Mater. 2020, 23, 889–895. [Google Scholar] [CrossRef]

- Zhang, K.X.; Li, D.C.; Shen, X.Y.; Xue, X.W.; Gu, D.D. Experimental Study on Mechanical Properties of Polyurethane Powder Composites. Civ. Eng. J. 2021, 30, 877–888. [Google Scholar] [CrossRef]

- Ma, W.B.; Hu, C.; Guo, S.C.; Zhao, Z.G.; Huang, T.B. Flexural and Shear Bond Performance of Polyurethane-Mortar Interface under Micro- and Macroscale. J. Mater. Civ. Eng. 2019, 31, 04019105. [Google Scholar] [CrossRef]

| Refer | Method | Model |

|---|---|---|

| Jeong-Ho Lee [72] | Modification of Two Existing Material Models Originally Applied to Metals (i.e., KHL and GTNL) | Strain-Rate and Temperature-Dependent Elasto-Viscoplastic Damage Model for Polymer Foam |

| Jia Li [73], Zhang Jingwei [74] | Generalized Maxwell Model (GMM) | Viscoelastic Ontological Model for Non-Water Reactive Polyurethane Grouting Materials |

| Ivan Kopal [75] | Artificial neural network model | Temperature-dependent model of dynamic mechanical properties and viscoelastic behavior of polyurethanes over a wide temperature range |

| Bipul Barua [76] | Tensile index (SE) model | Stress relaxation model for polyurethanes considering density and temperature |

| Dan [77] | Nagy-type image-only model for reconstruction of engineering stress-strain curves | Modeling the effect of temperature and test rate on the specific strain energy absorbed by polyurethane materials |

| Richeton [78] | Combining the physical frequency/strain rate dependence of the energy storage modulus and the initial Young’s modulus to improve the Weibull statistical model | Physically based robust model for predicting stiffness moduli for various temperatures and frequency/strain rates |

| Michael K. Neilsen [79] | /- | Models describing the effects of load path, strain rate and temperature on mechanical response |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhang, C.; Deng, Y.; Zhang, P. A Review of Research on the Effect of Temperature on the Properties of Polyurethane Foams. Polymers 2022, 14, 4586. https://doi.org/10.3390/polym14214586

Wang J, Zhang C, Deng Y, Zhang P. A Review of Research on the Effect of Temperature on the Properties of Polyurethane Foams. Polymers. 2022; 14(21):4586. https://doi.org/10.3390/polym14214586

Chicago/Turabian StyleWang, Juan, Chenxiao Zhang, Yu Deng, and Peng Zhang. 2022. "A Review of Research on the Effect of Temperature on the Properties of Polyurethane Foams" Polymers 14, no. 21: 4586. https://doi.org/10.3390/polym14214586