Wood Flour Modified by Poly(furfuryl alcohol) as a Filler in Rigid Polyurethane Foams: Effect on Water Uptake

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fillers Preparation and Furfurylation

2.2. Preparation of the RPUFs

2.3. Characterization of the RPUFs

2.4. Statistical Analyses

3. Results and Discussion

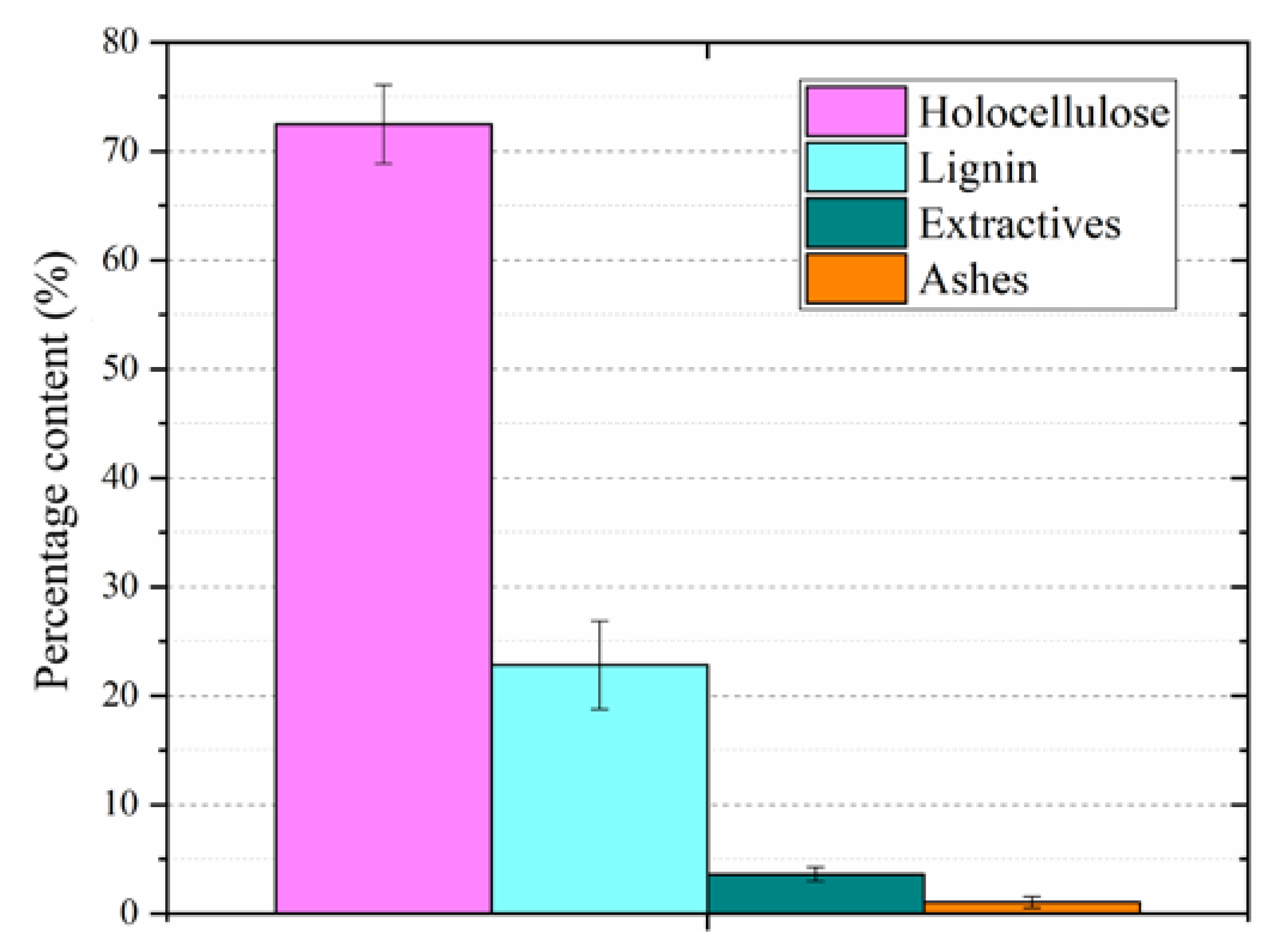

3.1. Filler’s Properties

3.2. Foam Morphology and Density

3.3. Compressive Properties

3.4. Thermal Stability

3.5. Water Uptake

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kan, Y.; Zhai, S.; Chen, B.; Pan, M.; Fan, X.; Leng, W. Effect of Brown-Rotted Spruce as Lignin-Enriched Filler on the Properties of Reinforced Polyurethane Foam. J. Polym. Environ. 2022, 30, 2355–2365. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of Walnut Shells and Silanized Walnut Shells on the Mechanical and Thermal Properties of Rigid Polyurethane Foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Wood, J.; Luo, S.; Gao, L.; Guo, W. Effect of Incorporation of Lignin as Bio - Polyol on the Performance of Rigid Lightweight Wood—Polyurethane Composite Foams. J. Wood Sci. 2020. [Google Scholar] [CrossRef] [Green Version]

- Uram, K.; Prociak, A.; Vevere, L.; Pomilovskis, R.; Cabulis, U.; Kirpluks, M. Natural Oil-Based Rigid Polyurethane Foam Thermal Insulation Applicable at Cryogenic Temperatures. Polymers 2021, 13, 4276. [Google Scholar] [CrossRef]

- Zhou, X.; Sain, M.M.; Oksman, K. Semi-Rigid Biopolyurethane Foams Based on Palm-Oil Polyol and Reinforced with Cellulose Nanocrystals. Compos. Part A Appl. Sci. Manuf. 2016, 83, 56–62. [Google Scholar] [CrossRef] [Green Version]

- Heinen, M.; Gerbase, A.E.; Petzhold, C.L. Vegetable Oil-Based Rigid Polyurethanes and Phosphorylated Flame-Retardants Derived from Epoxydized Soybean Oil. Polym. Degrad. Stab. 2014, 108, 76–86. [Google Scholar] [CrossRef]

- De Luca Bossa, F.; Santillo, C.; Verdolotti, L.; Campaner, P.; Minigher, A.; Boggioni, L.; Losio, S.; Coccia, F.; Iannace, S.; Lama, G.C. Greener Nanocomposite Polyurethane Foam Based on Sustainable Polyol and Natural Fillers: Investigation of Chemico-Physical and Mechanical Properties. Materials 2020, 13, 211. [Google Scholar] [CrossRef]

- Augaitis, N.; Vaitkus, S.; Członka, S.; Kairytė, A. Research of Wood Waste as a Potential Filler for Loose-Fill Building Insulation: Appropriate Selection and Incorporation into Polyurethane Biocomposite Foams. Materials (Basel). 2020, 13, 1–21. [Google Scholar] [CrossRef]

- Chanlert, P.; Ruamcharoen, P. Sound Absorption Properties of Rigid Polyurethane Foam Composites with Rubber-Wood Sawdust as a Natural Filler. J. Phys. Conf. Ser. 2021, 1719. [Google Scholar] [CrossRef]

- Li, Y.; Ragauskas, A.J. Kraft Lignin-Based Rigid Polyurethane Foam. J. Wood Chem. Technol. 2012, 32, 210–224. [Google Scholar] [CrossRef]

- de Avila Delucis, R.; Magalhães, W.L.E.; Petzhold, C.L.; Amico, S.C. Forest-Based Resources as Fillers in Biobased Polyurethane Foams. J. Appl. Polym. Sci. 2018, 135, 1–7. [Google Scholar] [CrossRef]

- Delucis, R. de A.; Magalhães, W.L.E.; Petzhold, C.L.; Amico, S.C. Thermal and Combustion Features of Rigid Polyurethane Biofoams Filled with Four Forest-Based Wastes. Polym. Compos. 2018, 39, E1770–E1777. [Google Scholar] [CrossRef]

- de Avila Delucis, R.; Fischer Kerche, E.; Gatto, D.A.; Magalhães Esteves, W.L.; Petzhold, C.L.; Campos Amico, S. Surface Response and Photodegradation Performance of Bio-Based Polyurethane-Forest Derivatives Foam Composites. Polym. Test. 2019, 80, 106102. [Google Scholar] [CrossRef]

- Silva, B.B.R.; Santana, R.M.C.; Forte, M.M.C. A Solventless Castor Oil-Based PU Adhesive for Wood and Foam Substrates. Int. J. Adhes. Adhes. 2010, 30, 559–565. [Google Scholar] [CrossRef]

- Possart, W.; Zimmer, B. Water in Polyurethane Networks: Physical and Chemical. Contin. Mech. Thermodyn. 2022. [Google Scholar] [CrossRef]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. Cure and Performance of Castor Oil Polyurethane Adhesive. Int. J. Adhes. Adhes. 2019, 95, 102413. [Google Scholar] [CrossRef]

- Kılınç, K.; Kanbur, Y.; Tayfun, Ü. Mechanical, Thermo-Mechanical and Water Uptake Performance of Wood Flour Filled Polyurethane Elastomer Eco-Composites: Influence of Surface Treatment of Wood Flour. Holzforschung 2019, 73, 401–407. [Google Scholar] [CrossRef]

- Ju, Z.; He, Q.; Zhan, T.; Zhang, H.; Sun, L.; Hong, L.; Shi, X.; Lu, X. Steam Exploded Peanut Shell Fiber as the Filler in the Rigid Polyurethane Foams. J. Renew. Mater. 2019, 7, 1077–1091. [Google Scholar] [CrossRef] [Green Version]

- Bradai, H.; Koubaa, A.; Bouafif, H.; Langlois, A.; Samet, B. Synthesis and Characterization of Wood Rigid Polyurethane Composites. Materials (Basel). 2022, 15, 4316. [Google Scholar] [CrossRef]

- Cai, C.M.; Zhang, T.; Wyman, C.E. Integrated Furfural Production as a Renewable Fuel and Chemical Platform from Lignocellulosic Biomass. J. Chem. Technol. Biotechnol. 2013, 89, 2–10. [Google Scholar] [CrossRef]

- Pogaku, R. Horizons in Bioprocess Engineering; 2019; ISBN 9783030290696. [Google Scholar]

- Clauser, N.M.; Felissia, F.E.; Area, M.C.; Vallejos, M.E. A Framework for the Design and Analysis of Integrated Multi-Product Biorefineries from Agricultural and Forestry Wastes. Renew. Sustain. Energy Rev. 2021, 139, 110687. [Google Scholar] [CrossRef]

- TAPPI T 204 cm-97 Solvent Extractives of Wood and Pulp T 204 Cm-97. TAPPI TEST METHODS. Technol. Assoc. Pulp an Pap. Ind. Atlanta, GA. Tappi Press. 2012, pp. 1–12. Available online: https://www.coursehero.com/file/100233522/TAPPI-METHOD-EXTRACTION-T204-cm-97PDF/.

- Tappi Lignin in Wood and Pulp. In TAPPI TEST METHODS. Technol. Assoc. Pulp an Pap. Ind.; Tappi Press: Atlanta, GA, USA, 2011; pp. 1–7.

- Acosta, A.P.; Barbosa, K.T.; Amico, S.C.; Missio, A.L.; de Avila Delucis, R.; Gatto, D.A. Improvement in Mechanical, Physical and Biological Properties of Eucalyptus and Pine Woods by Raw Pine Resin in Situ Polymerization. Ind. Crops Prod. 2021, 166, 113495. [Google Scholar] [CrossRef]

- Ribeiro, L.S.; Órfão, J.J.d.M.; Pereira, M.F.R. Direct Catalytic Conversion of Agro-Forestry Biomass Wastes into Ethylene Glycol over CNT Supported Ru and W Catalysts. Ind. Crops Prod. 2021, 166, 113461. [Google Scholar] [CrossRef]

- Acosta, A.P.; Beltrame, R.; Missio, A.L.; Amico, S.; de Avila Delucis, R.; Gatto, D.A. Furfurylation as a Post-Treatment for Thermally-Treated Wood. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Zuluaga, R.; Putaux, J.L.; Cruz, J.; Vélez, J.; Mondragon, I.; Gañán, P. Cellulose Microfibrils from Banana Rachis: Effect of Alkaline Treatments on Structural and Morphological Features. Carbohydr. Polym. 2009, 76, 51–59. [Google Scholar] [CrossRef]

- Valentino, H.A.S.; de Tarso Laia dos Reis e Silva Pupio, P.; Gandini, A.; Lacerda, T.M. Furfuryl Alcohol/tung Oil Matrix-Based Composites Reinforced with Bacterial Cellulose Fibres. Cellulose 2021, 28, 7109–7121. [Google Scholar] [CrossRef]

- Pranger, L.A.; Nunnery, G.A.; Tannenbaum, R. Mechanism of the Nanoparticle-Catalyzed Polymerization of Furfuryl Alcohol and the Thermal and Mechanical Properties of the Resulting Nanocomposites. Compos. Part B Eng. 2012, 43, 1139–1146. [Google Scholar] [CrossRef]

- Kerche, E.F.; Bock, D.N.; de Avila Delucis, R.; Magalhães, W.L.E.; Amico, S.C. Micro Fibrillated Cellulose Reinforced Bio-Based Rigid High-Density Polyurethane Foams. Cellulose 2021, 28, 4313–4326. [Google Scholar] [CrossRef]

- Mosiewicki, M.A.; Dell’Arciprete, G.A.; Aranguren, M.I.; Marcovich, N.E. Polyurethane Foams Obtained from Castor Oil-Based Polyol and Filled with Wood Flour. J. Compos. Mater. 2009, 43, 3057–3072. [Google Scholar] [CrossRef]

- Gu, R.; Sain, M.M.; Konar, S.K. A Feasibility Study of Polyurethane Composite Foam with Added Hardwood Pulp. Ind. Crops Prod. 2013, 42, 273–279. [Google Scholar] [CrossRef]

- Strakowska, A.; Członka, S.; Kairyte, A. Rigid Polyurethane Foams Reinforced with Poss-Impregnated Sugar Beet Pulp Filler. Materials 2020, 13, 5493. [Google Scholar] [CrossRef] [PubMed]

- González-Díaz, E.; Alonso-López, J.M. Characterization by Thermogravimetric Analysis of the Wood Used in Canary Architectural Heritage. J. Cult. Herit. 2017, 23, 111–118. [Google Scholar] [CrossRef]

- Guigo, N.; Mija, A.; Zavaglia, R.; Vincent, L.; Sbirrazzuoli, N. New Insights on the Thermal Degradation Pathways of Neat Poly (furfuryl Alcohol) and Poly (furfuryl alcohol)/SiO2 Hybrid Materials. Polym. Degrad. Stab. 2009, 94, 908–913. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A.; Kremensas, A. Nutmeg Filler as a Natural Compound for the Production of Polyurethane Composite Foams with Antibacterial and Anti-Aging Properties. Polym. Test. 2020, 86, 106479. [Google Scholar] [CrossRef]

| Group | Filler Weight Fraction (%) | FA Weight Fraction (%) |

|---|---|---|

| PU | 0 | 0 |

| RPUFW | 2.5 | 0 |

| RPUFW10 | 2.5 | 10 |

| RPUFW15 | 2.5 | 15 |

| Group | T2% (°C) | T5% (°C) | T50% (°C) | Residue at 600 °C (%) |

|---|---|---|---|---|

| RPUF | 84.88 | 114.81 | 500.58 | 21.26 |

| RPUFW | 91.38 | 125.24 | 504.69 | 25.94 |

| RPUFW10 | 89.32 | 187.31 | 514.94 | 33.88 |

| RPUFW15 | 67.27 | 94.96 | 494.59 | 29.23 |

| W | 91.55 | 108.65 | 342.40 | 15.40 |

| W10 | 97.70 | 112.76 | 355.23 | 16.77 |

| W15 | 108.65 | 113.10 | 351.98 | 17.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acosta, A.; Aramburu, A.B.; Beltrame, R.; Gatto, D.A.; Amico, S.; Labidi, J.; Delucis, R.d.A. Wood Flour Modified by Poly(furfuryl alcohol) as a Filler in Rigid Polyurethane Foams: Effect on Water Uptake. Polymers 2022, 14, 5510. https://doi.org/10.3390/polym14245510

Acosta A, Aramburu AB, Beltrame R, Gatto DA, Amico S, Labidi J, Delucis RdA. Wood Flour Modified by Poly(furfuryl alcohol) as a Filler in Rigid Polyurethane Foams: Effect on Water Uptake. Polymers. 2022; 14(24):5510. https://doi.org/10.3390/polym14245510

Chicago/Turabian StyleAcosta, Andrey, Arthur B. Aramburu, Rafael Beltrame, Darci A. Gatto, Sandro Amico, Jalel Labidi, and Rafael de Avila Delucis. 2022. "Wood Flour Modified by Poly(furfuryl alcohol) as a Filler in Rigid Polyurethane Foams: Effect on Water Uptake" Polymers 14, no. 24: 5510. https://doi.org/10.3390/polym14245510